A lock screw fixture

A technology for locking screws and jigs, which is applied in the direction of manufacturing tools, metal processing, and metal processing equipment. It can solve the problems of easily scratching the appearance of products, difficulty in quickly locking screw holes, and screw or screw hole slipping, so as to improve the quality of screws. Lock payment efficiency, reduce defect rate, and avoid the effect of sliding teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments.

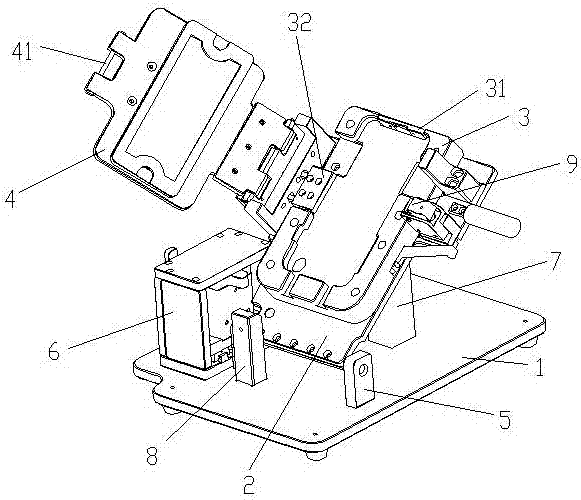

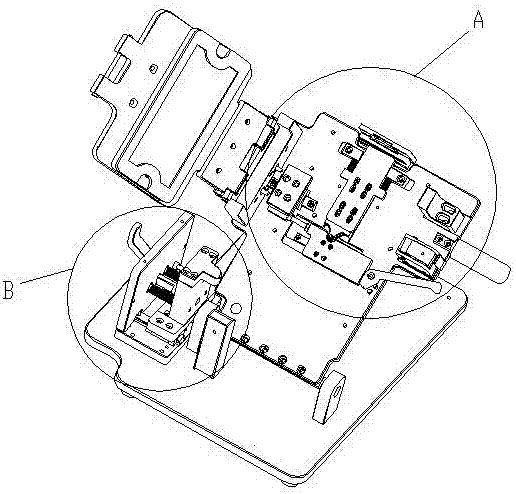

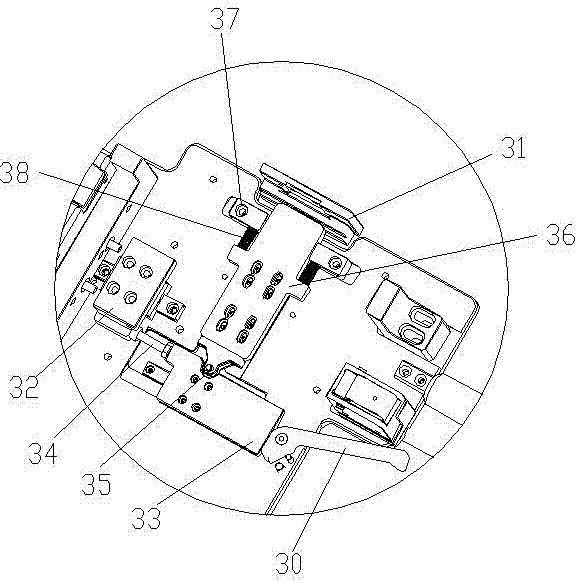

[0020] Such as Figure 1 to Figure 5 As shown, a locking screw fixture includes a base 1, on which a base 2 that can rotate relative to it is provided, on which a product fixing device 3 is arranged, and the upper end of the product fixing device 3 An upper fixing plate 31 is provided, and a screw guide sleeve 311 is arranged on the upper fixing plate 31. The base 1 is provided with a first support column 7 for supporting the base plate 2 and making it inclined and for supporting The base plate 2 is formed into a vertical second support column 8 .

[0021] When the substrate 2 is pressed against the first support column 7, the product fixing device 3 is in an inclined state, which is convenient for fixing the product therein. After the product is fixed, by rotating the substrate 2, the product fixing device 3 is driven to rotate to a vertical shape, Keep the axis of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com