Screw locking device for module circuit board

A circuit board and locking technology, which is applied to electrical components, electrical components, etc., can solve the problems that the manual locking accuracy cannot meet the requirements, and the manual locking efficiency cannot meet the products, so as to ensure the accuracy of locking operations and reduce labor costs. , the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

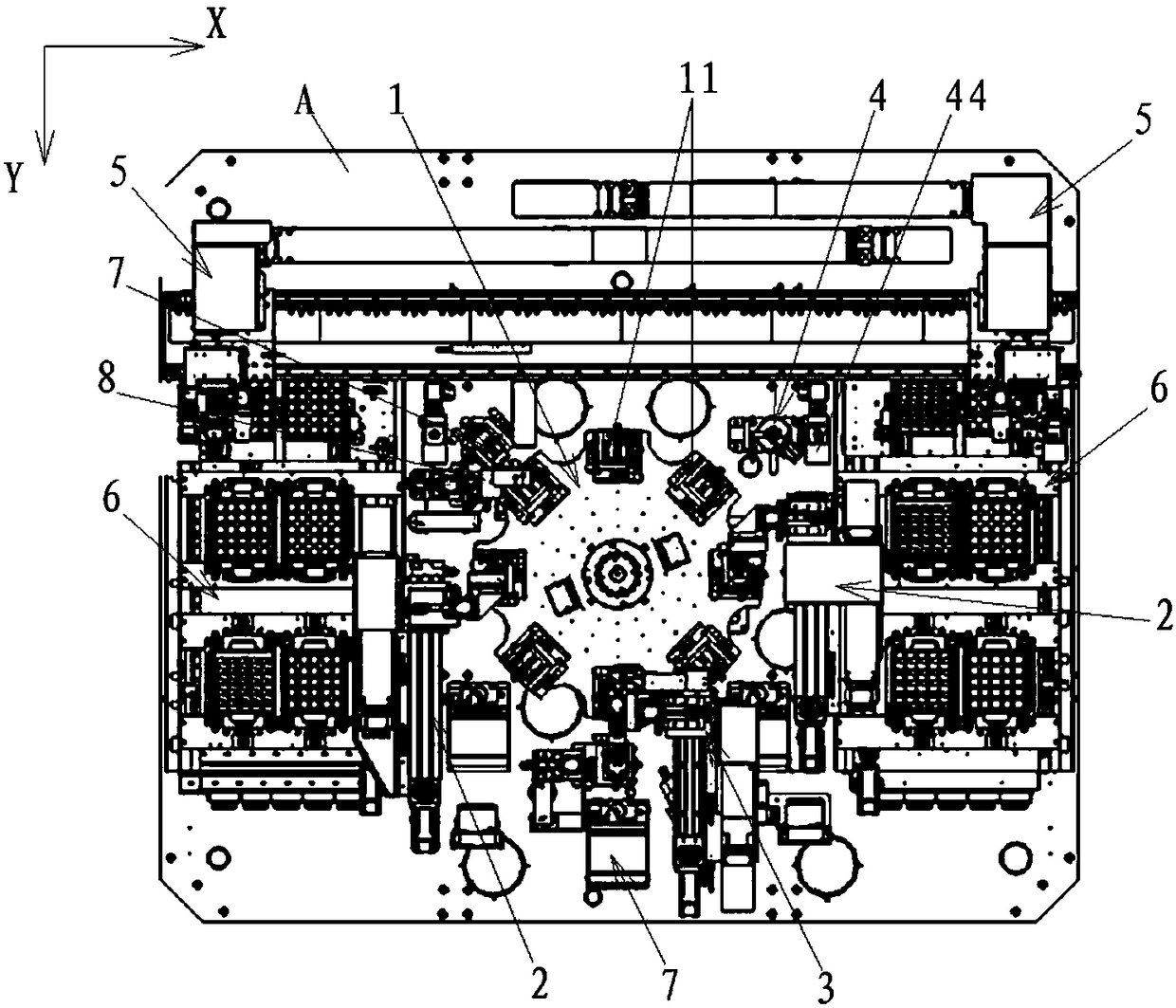

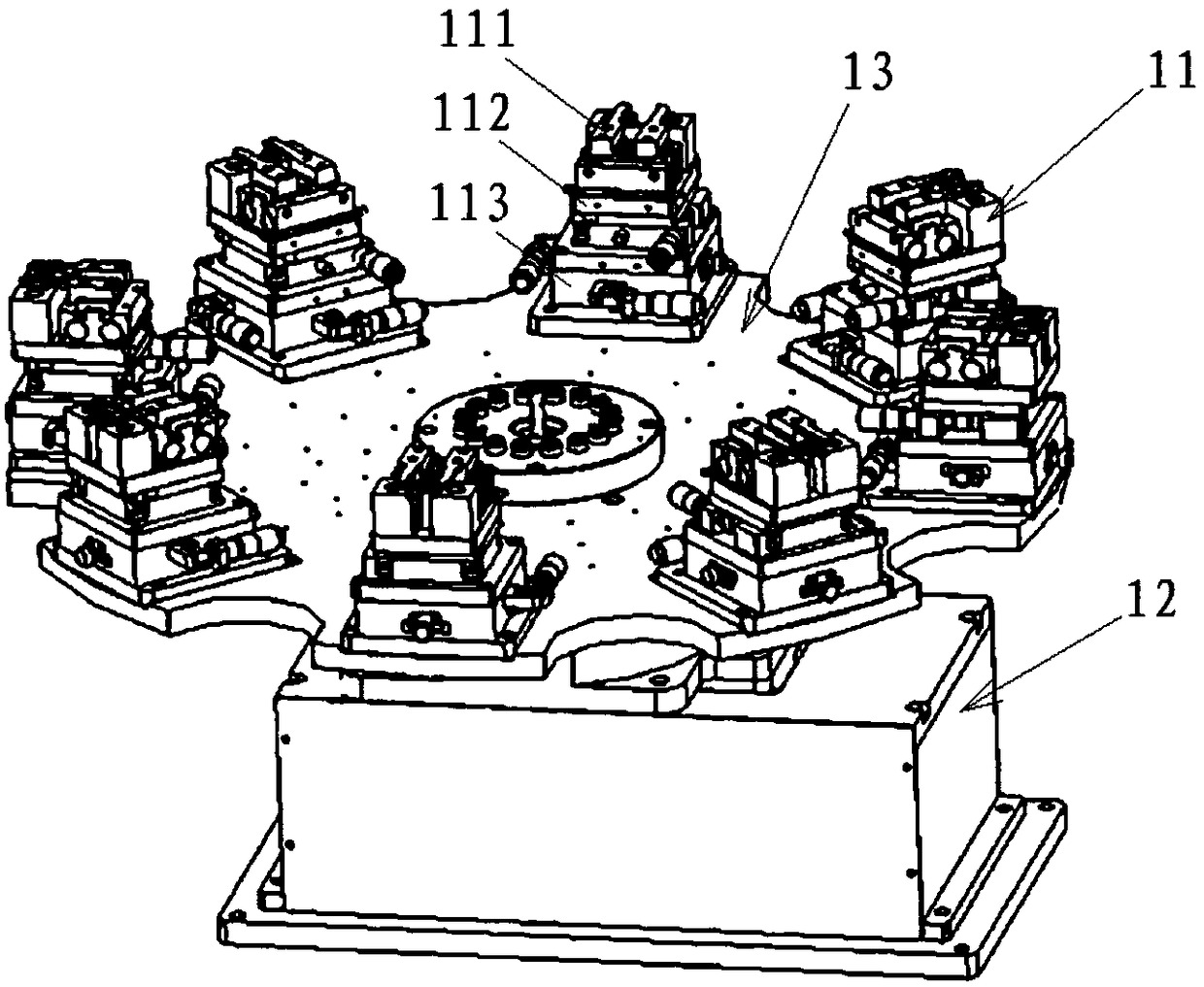

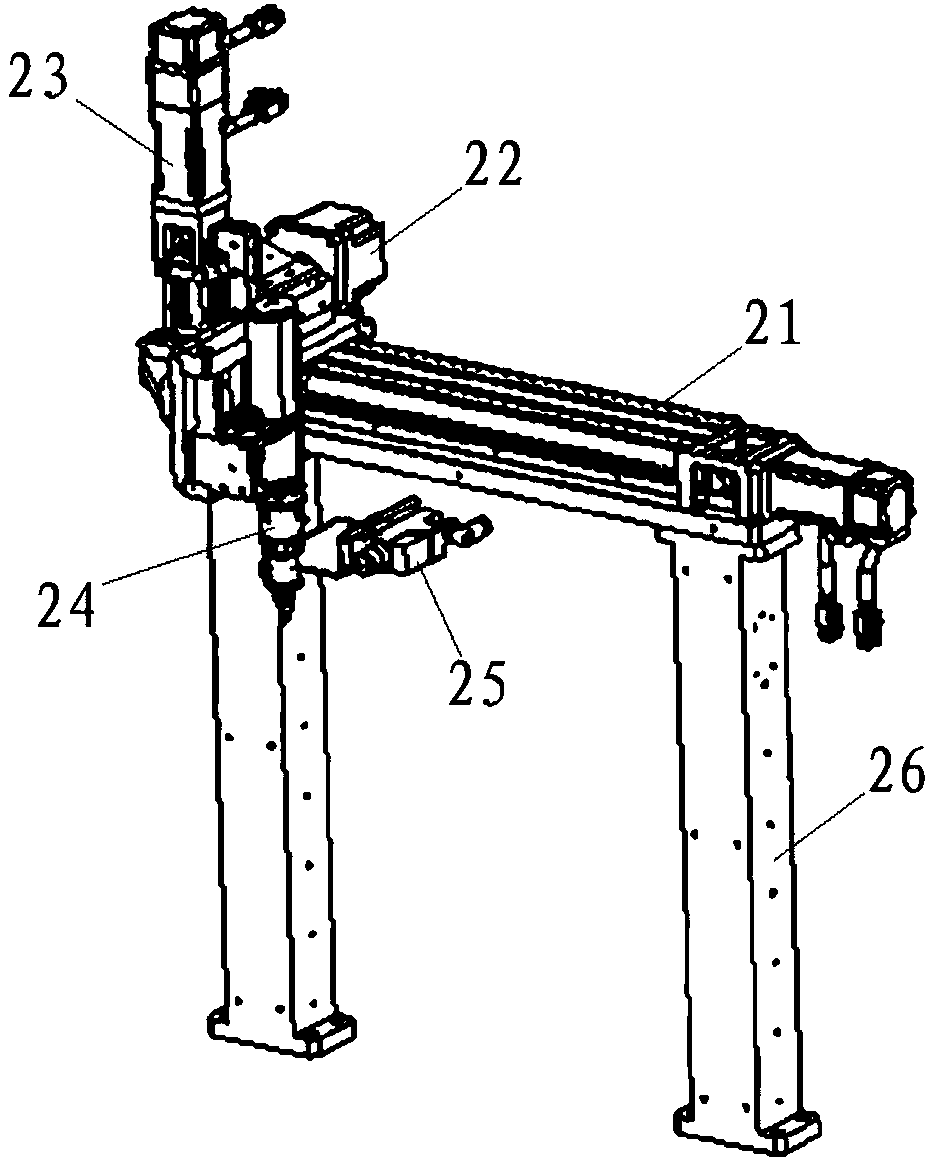

[0059] Such as figure 1 As shown, according to an embodiment of the present invention, it further includes: a locking and detecting unit 3 . In this embodiment, the transmission unit 1 , the locking unit 2 and the locking and detection unit 3 are all installed on the mounting board A. In this embodiment, along the transmission direction of the transmission unit 1, the locking unit 2 and the locking and detection unit 3 are located on one side of the transmission unit 1, and the locking unit 2 and the locking and detection unit 3 are sequentially arranged at intervals. Through the above setting, through the transmission function of the transmission unit 1, the material passes through the locking unit 2 and the locking and detection unit 3 in sequence. The material is locked through the locking unit 2, and the locking operation is carried out through the locking and detection unit 3 and the quality inspection is completed. The entire operation process is completed through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com