A composite four-axis locking screw locking device and its control method

A lock and screw technology, applied in metal processing equipment, manufacturing tools, metal processing, etc., can solve the problems of inflexible lock, low efficiency and production capacity, and achieve the effect of improving the efficiency of screw lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

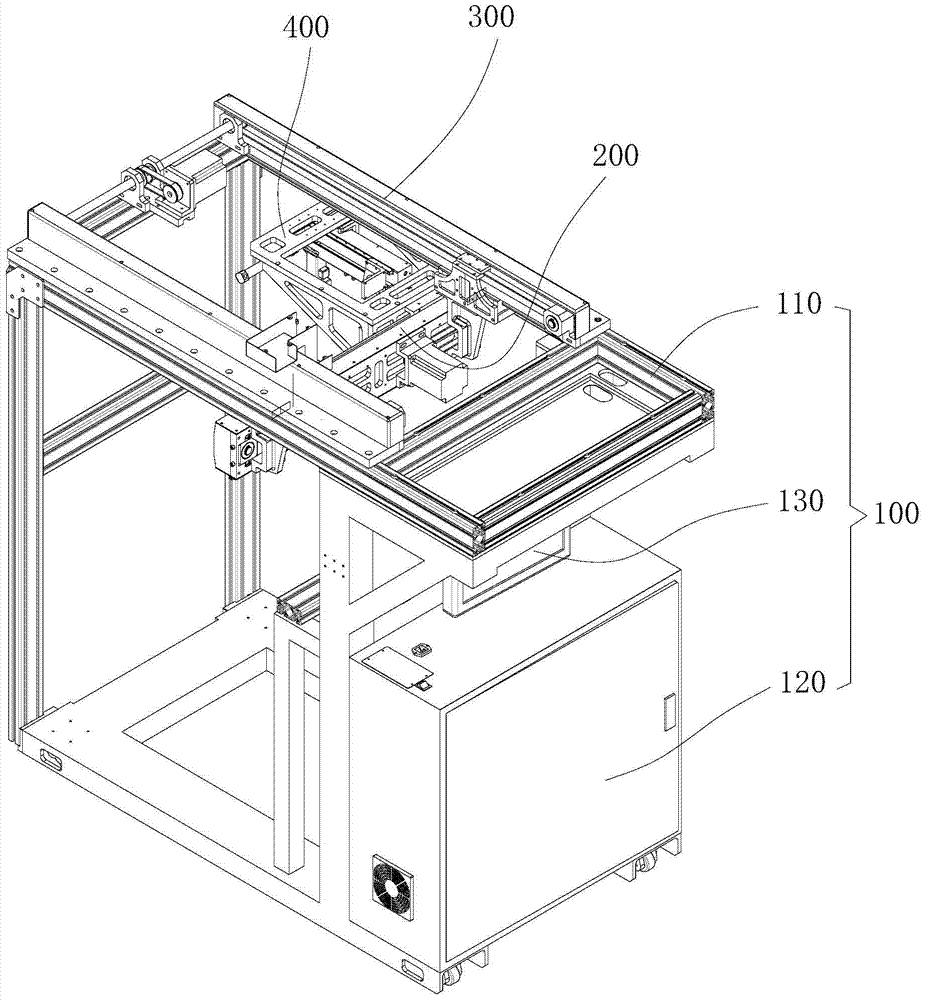

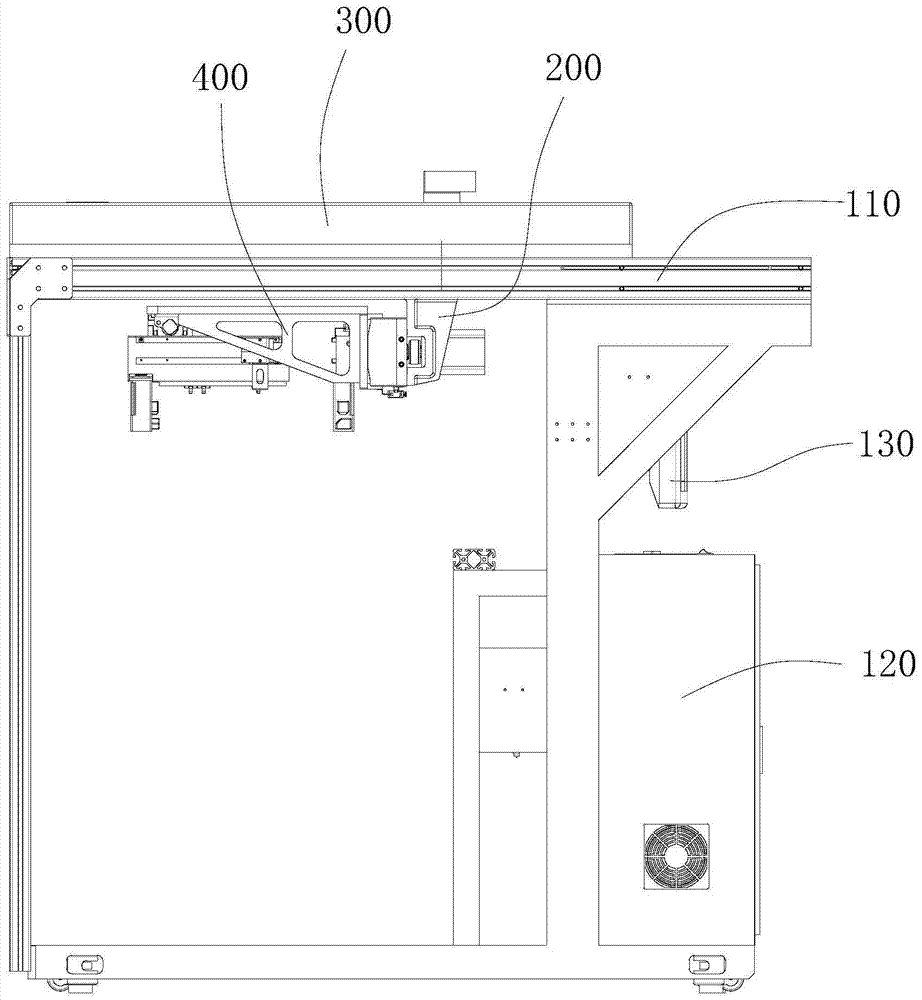

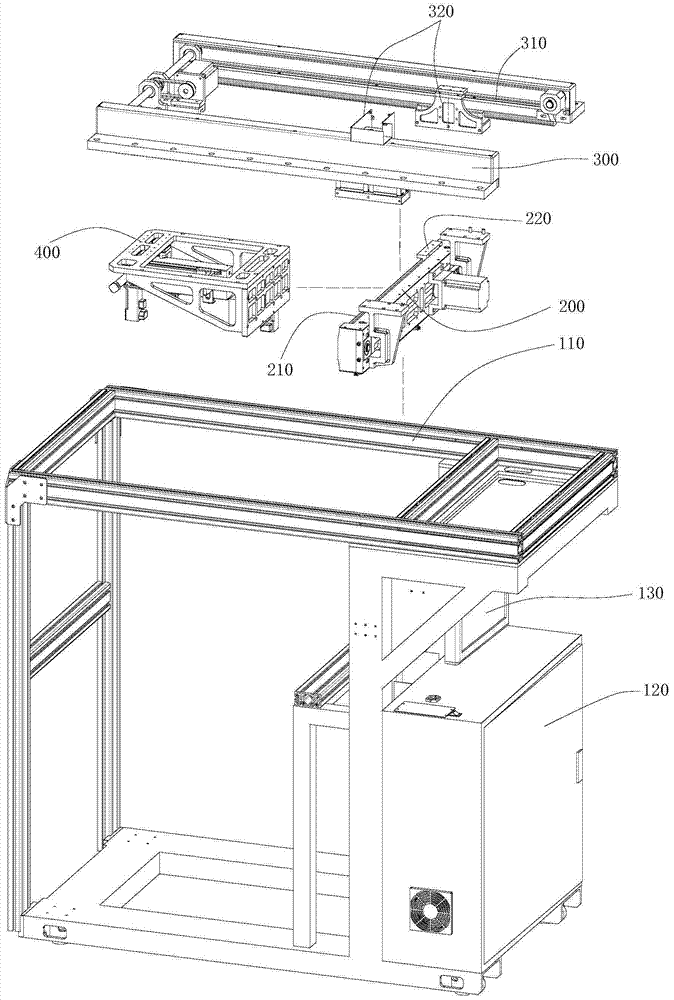

[0032] This embodiment provides a compound four-axis locking screw locking device, such as figure 1 , 2 , 3, including machine installation platform 100, X-axis device, Y-axis device 300, XY coordinate device 400, first electric screwdriver lock 510 and second electric screwdriver lock 520.

[0033] The machine installation platform 100 includes an electric control box 120 , a human-computer interaction interface 130 and an installation frame 110 . The electric control box 120 is used to provide power supply and control processing end for the X-axis device, the Y-axis device 300 and the XY coordinate device 400; Input and output operation and display platform.

[0034] The Y-axis device 300 is arranged on the top of the installation frame 110 of the machine installation platform 100 , and the Y-axis device 300 is provided with a Y-axis guide rail 310 and a Y-axis slider 320 that can move along the Y-axis guide rail 310 along the horizontal and vertical directions.

[0035] ...

Embodiment 2

[0047] This embodiment provides a control method for the composite four-axis locking screw locking device described in the above embodiments, the steps of which are as follows:

[0048] Step 1: Move the product to be locked into the composite four-axis locking screw locking device, and the specific position to be locked is the first coordinate, the second coordinate...;

[0049] Step 2: the first electric screwdriver 512 and the second electric screwdriver suck the screws respectively;

[0050] The third step: the XY coordinate device 400 walks the X coordinate on the X-axis device, and walks the Y coordinate on the Y-axis device 300 under the drive of the X-axis device. The first electric screwdriver 512 walks the X1 coordinate on the XY coordinate device 400, and the second The electric screwdriver moves the Y1 coordinate on the XY coordinate device 400, locates the first electric screwdriver 512 at the first coordinate, and positions the second electric screwdriver at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com