Filature conveyer with positioning function

A transmission device and screw machine technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of only acting on one side or two sides of the shell, the labor intensity of the operator is high, and the production efficiency is affected. , to achieve the effect of improving lock payment efficiency, realizing positioning work, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

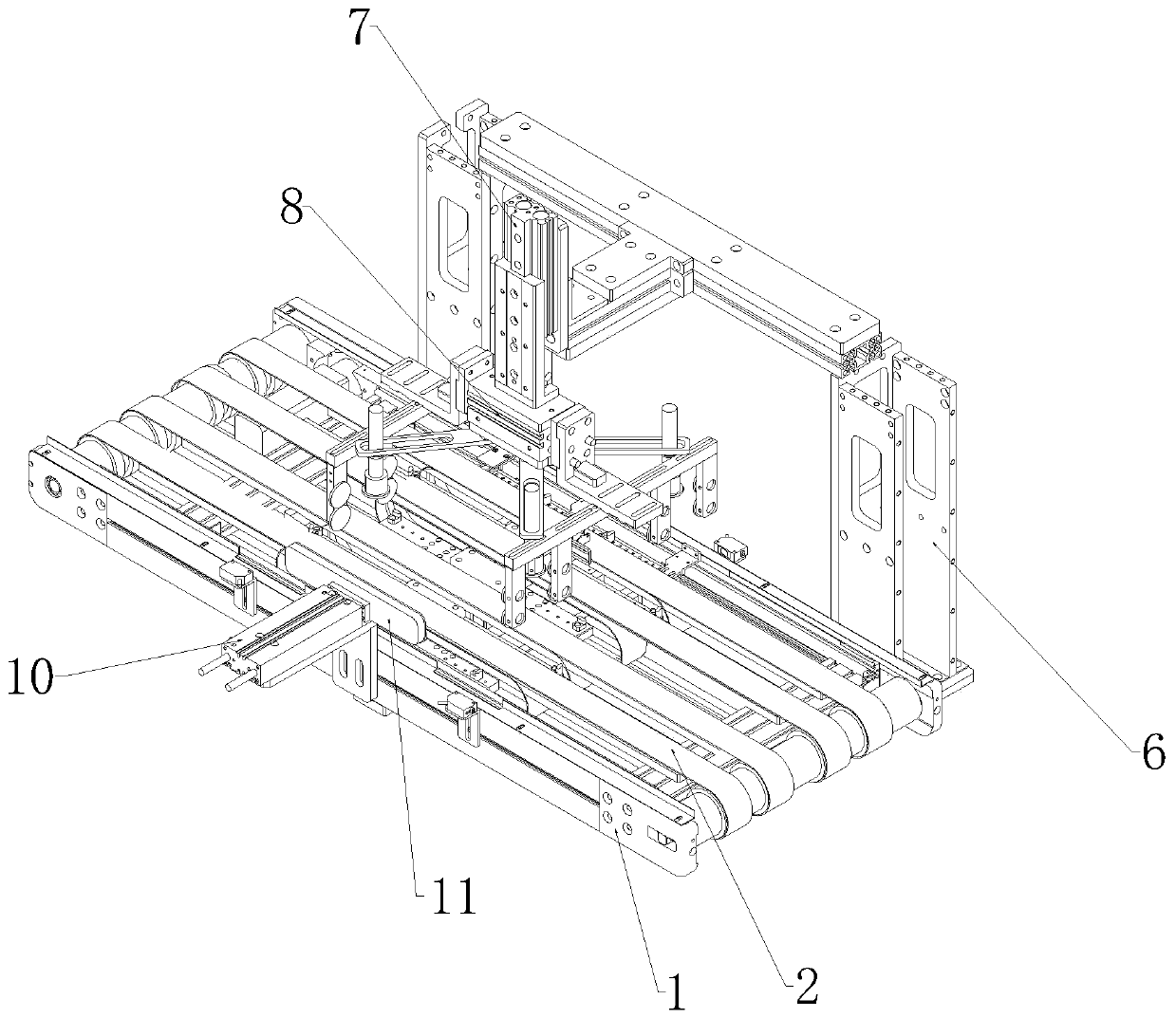

[0044] Such as Figure 1 to Figure 6 As shown, the screw machine transmission device with positioning function includes a transmission unit and a positioning unit;

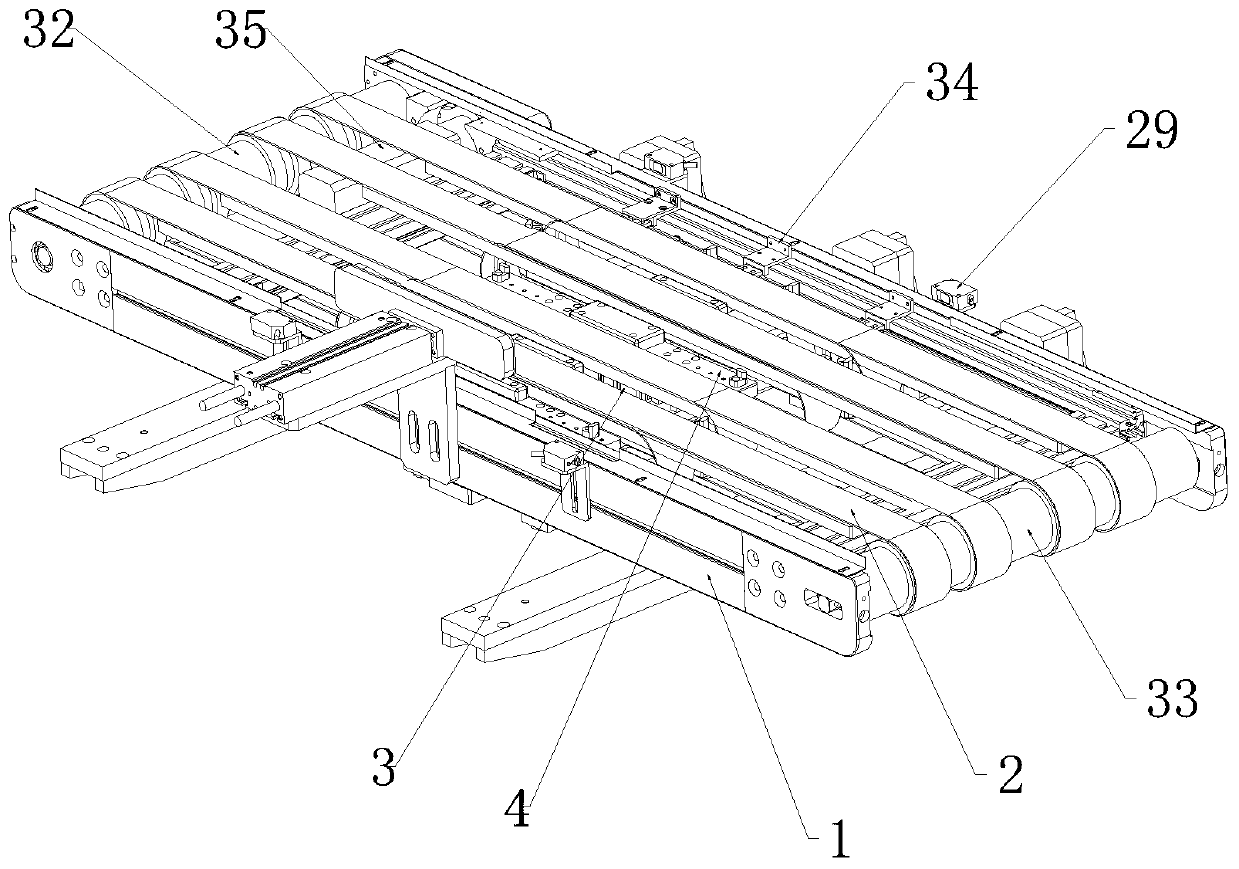

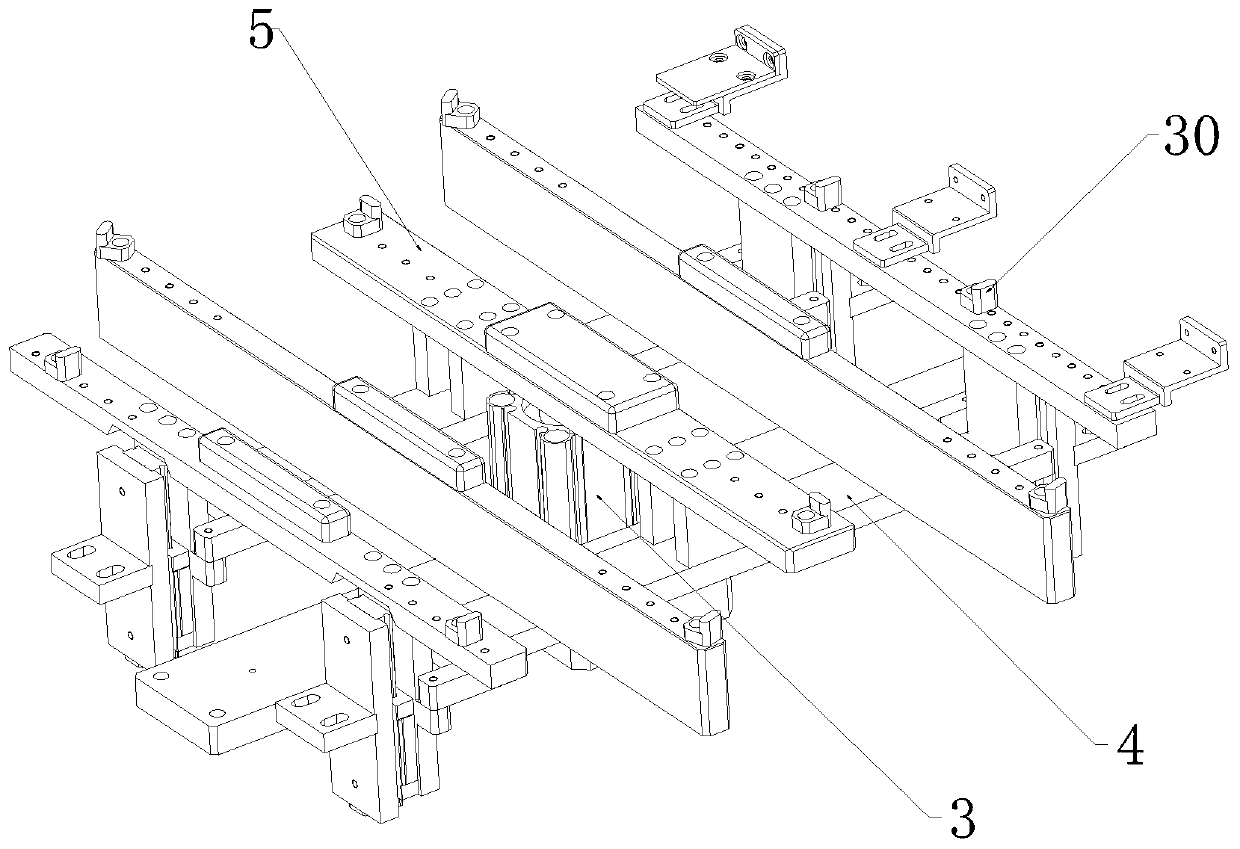

[0045] The transmission unit includes a transmission frame 1; the transmission frame 1 is provided with at least two transmission belts 2 arranged at intervals, and the transmission frame 1 is equipped with a belt drive device for driving the transmission belt 2; the transmission frame 1 is equipped with a push rod drive In the device 3, the output end of the ejector rod driving device 3 is connected with the ejector rod connecting frame 4, and the ejector rod connecting frame 4 is provided with a ejector rod 5 which is staggered with the conveyor belt 2, and the ejector rod driving device 3 acts on the ejector rod 5 so that: The ejector rod 5 can move up and down relative to the conveyor belt 2;

[0046] The positioning unit includes a clamping support base 6, on which a pressing driving device 7 is installed, a...

Embodiment 2

[0049] This embodiment makes the following further limitations on the basis of Embodiment 1: a side pressure drive device 10 is installed on the transmission frame 1, and the output end of the side pressure drive device 10 is connected with a side pressure plate 11, and the side pressure drive device 10 functions Because of the side pressure plate 11, the side pressure plate 11 can move along the direction across the transmission frame 1;

[0050] Several ejector rods 5 are arranged on the ejector rod connecting frame 4, and the ejector rod 5 which is located farthest from the side pressure driving device 10 among the several ejector rods 5 is provided with at least two spacing protrusions. plate 34.

[0051] In this embodiment, the lateral pressure drive device 10 can be a sliding table cylinder, a double-axis cylinder, or the like. If the lateral pressure driving device 10 is located on the right side of the transmission frame 1 , then the limiting convex plate 34 is locate...

Embodiment 3

[0054] This embodiment makes the following further limitations on the basis of Embodiment 1: the elastic pressing member includes a pressing supporting column 12 and a movable cylinder 13 sleeved on the pressing supporting column 12, and the bottom end of the pressing supporting column 12 Connected with a limit head 14 that prevents the movable cylinder 13 from detaching from the pressing support column 12;

[0055] An elastic supporting member 15 is sleeved on the pressing support column 12 , and the elastic supporting member 15 acts on the movable cylinder 13 , so that the movable cylinder 13 is located at a low position and abuts against the limit head 14 .

[0056] In this embodiment, the elastic supporting member 15 may be a compression spring. Movable cylinder 13 can have the movable groove that top opening small inner cavity is big, and limit head 14 is positioned at movable groove and the outer diameter of limit head 14 is greater than the top opening width of movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com