Patents

Literature

129results about How to "Achieve cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

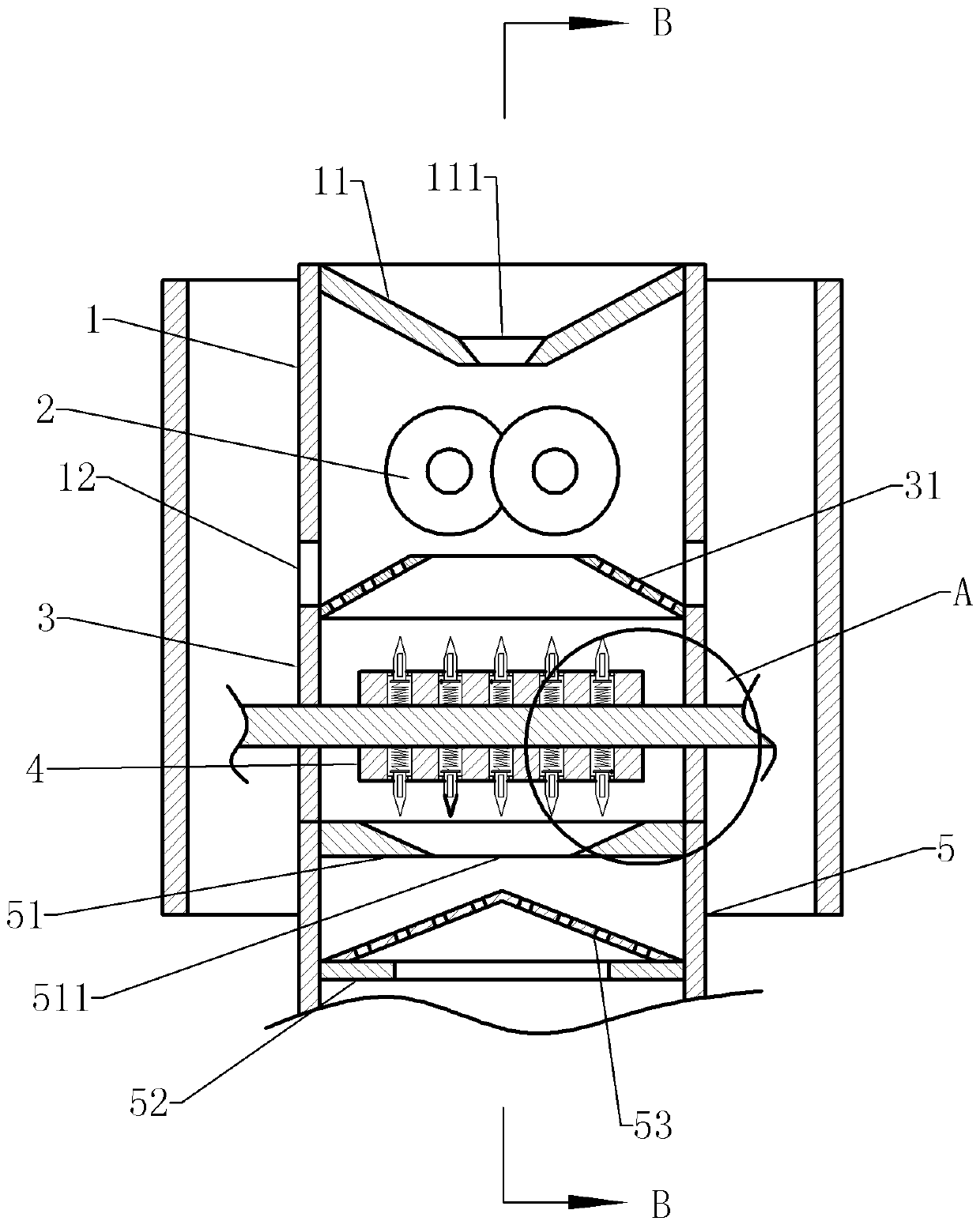

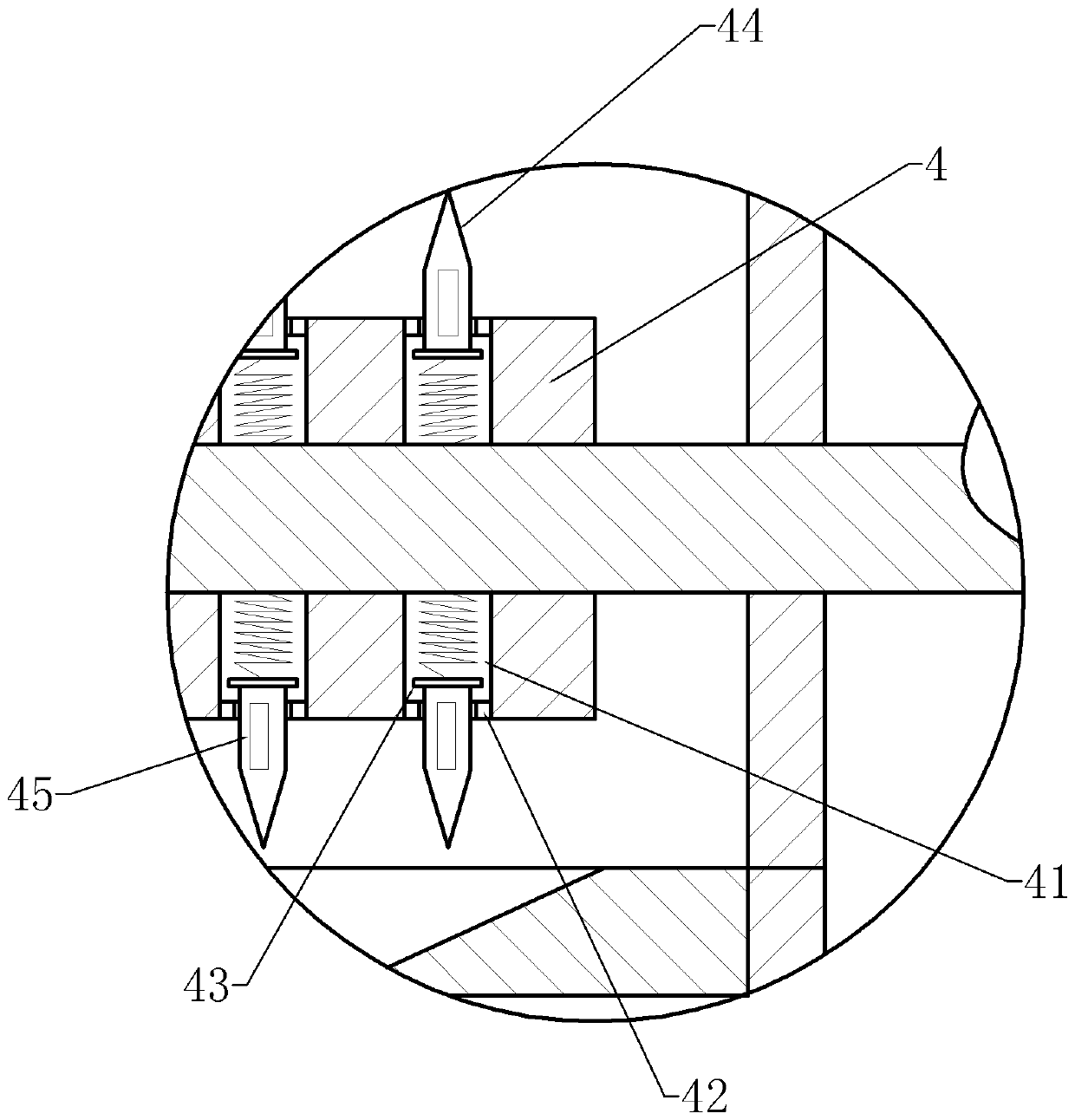

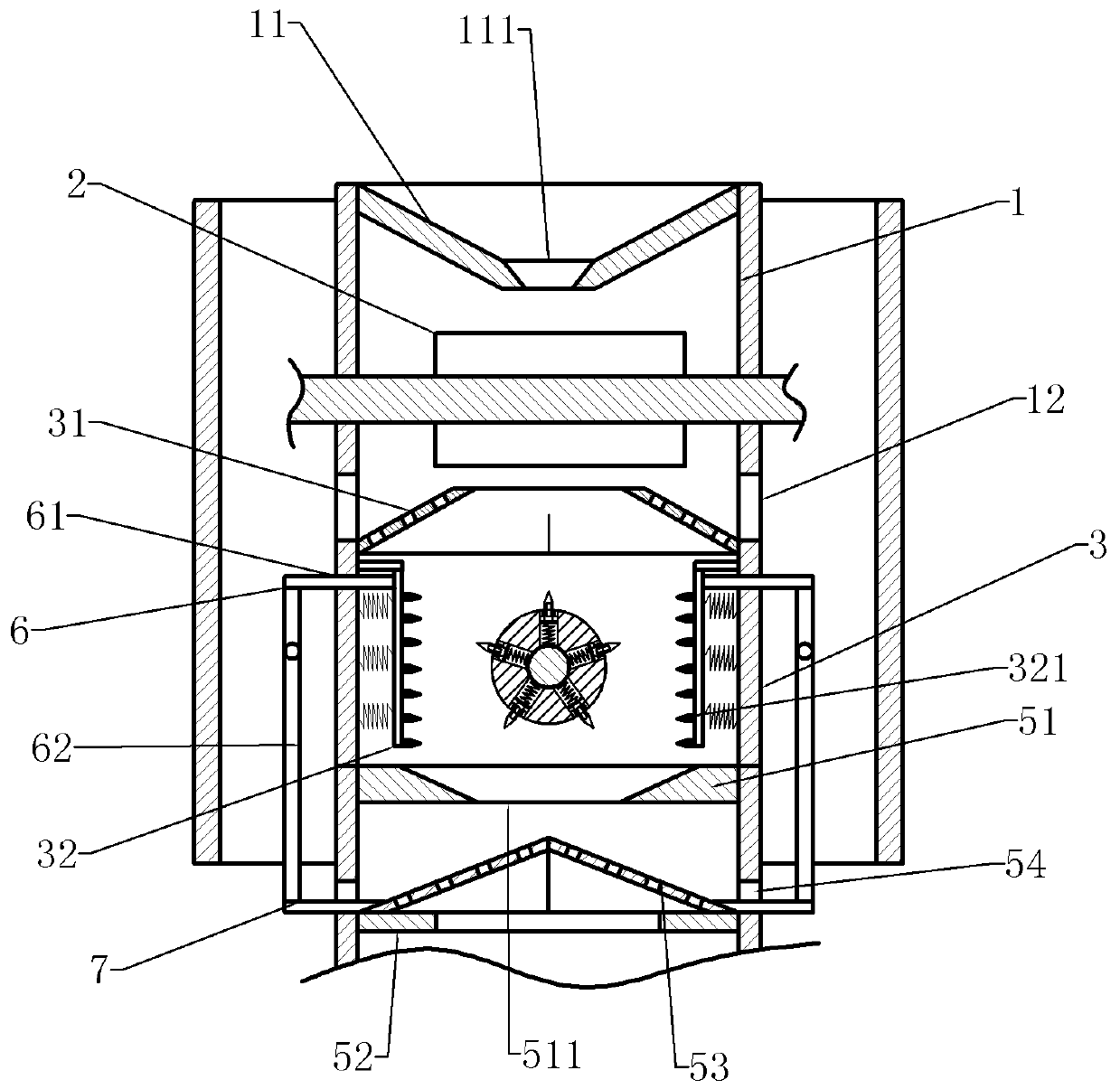

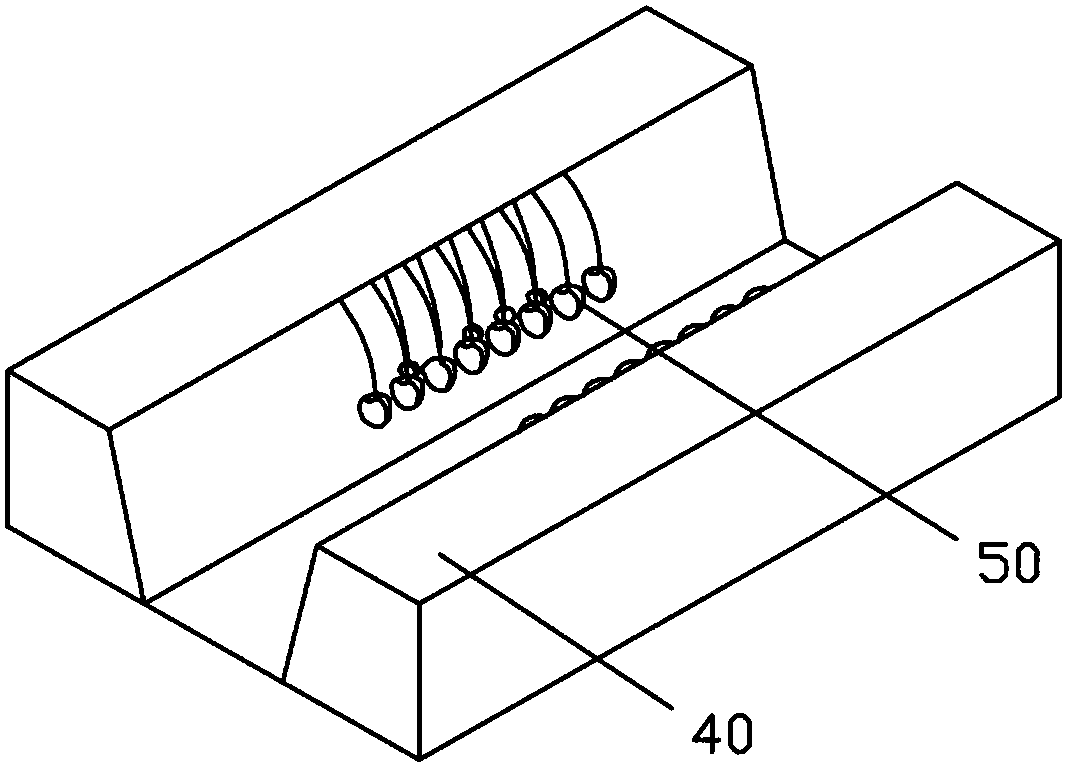

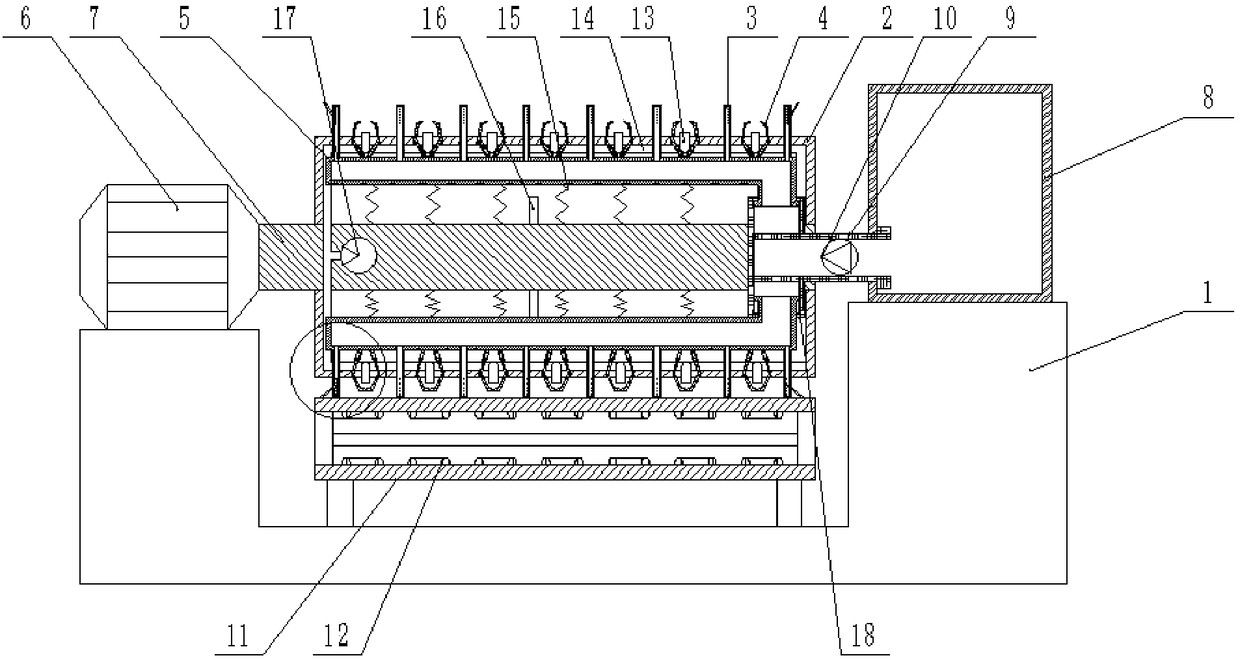

Uniform crushing device for rubber

The invention belongs to the technical field of crushing machinery, and discloses a uniform crushing device for rubber. The uniform crushing device for rubber comprises a machine body, wherein a firstcrushing bucket, a second crushing bucket and a receiving bucket are arranged in the machine body, a first rotary shaft and a second rotary shaft are rotationally connected in the first crushing bucket, and a crushing roll knife is arranged on each of the first rotary shaft and the second rotary shaft; a third rotary shaft is rotationally connected in the second crushing bucket, and vertical to the first rotary shaft; a sleeve is arranged on the third rotary shaft, a plurality of through holes are formed in the sidewall of the sleeve, and a first shearing knife and a spring are arranged in each through hole; two material-stopping plates are further arranged in the second crushing bucket, a compression spring is arranged between each of the two material-stopping plates and the second crushing bucket, and a second shearing knife is arranged on each material-stopping plate; and a strip-shaped magnet is arranged in each of the first shearing knife and the second shearing knife. The uniform crushing device for rubber solves the problems that the crushed rubber particles are non-uniform in particle size, and the rubber particles with large particle sizes need to be crushed again, so that the crushing time is long, in the prior art.

Owner:CHONGQING WEIXING RUBBER

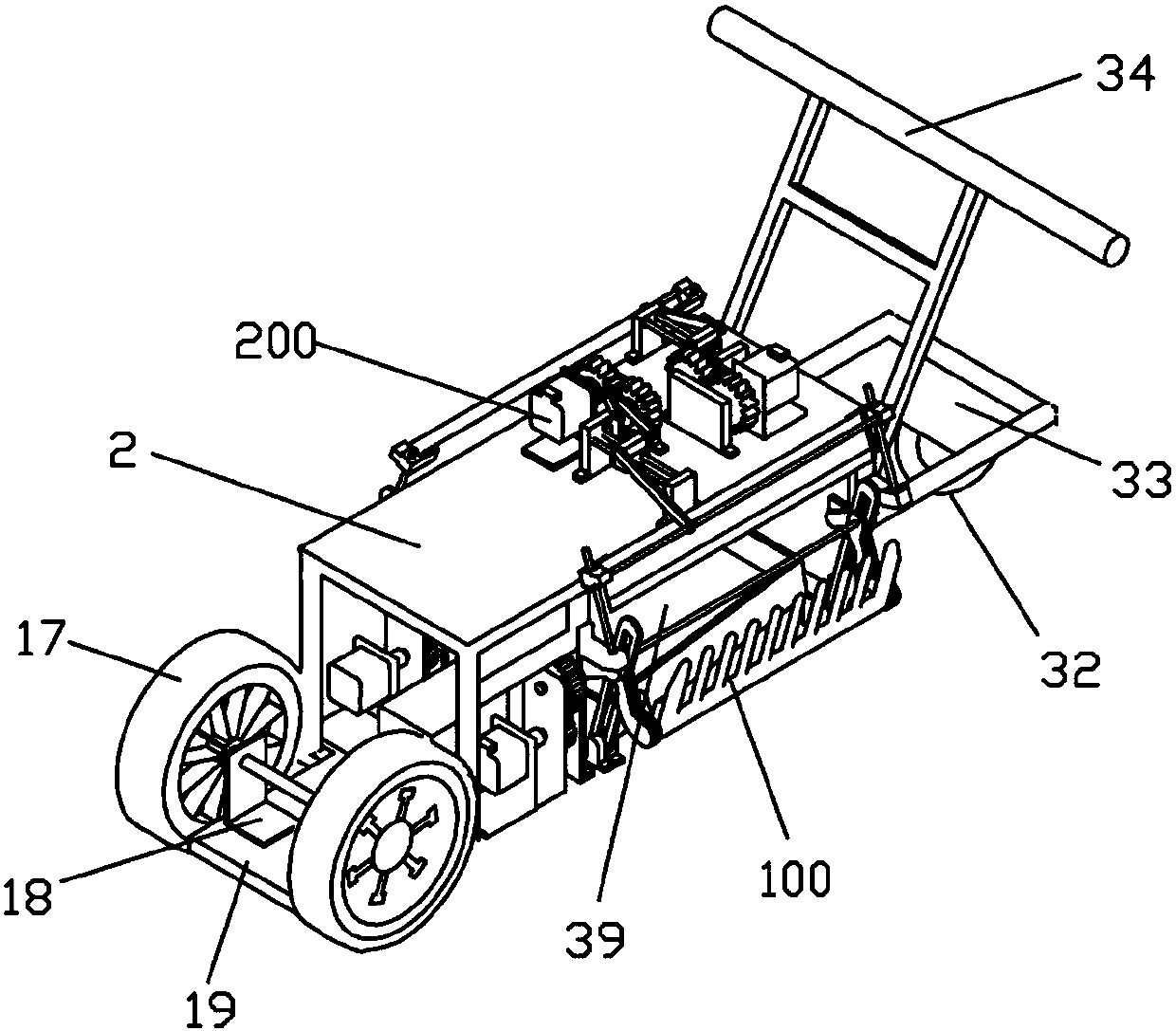

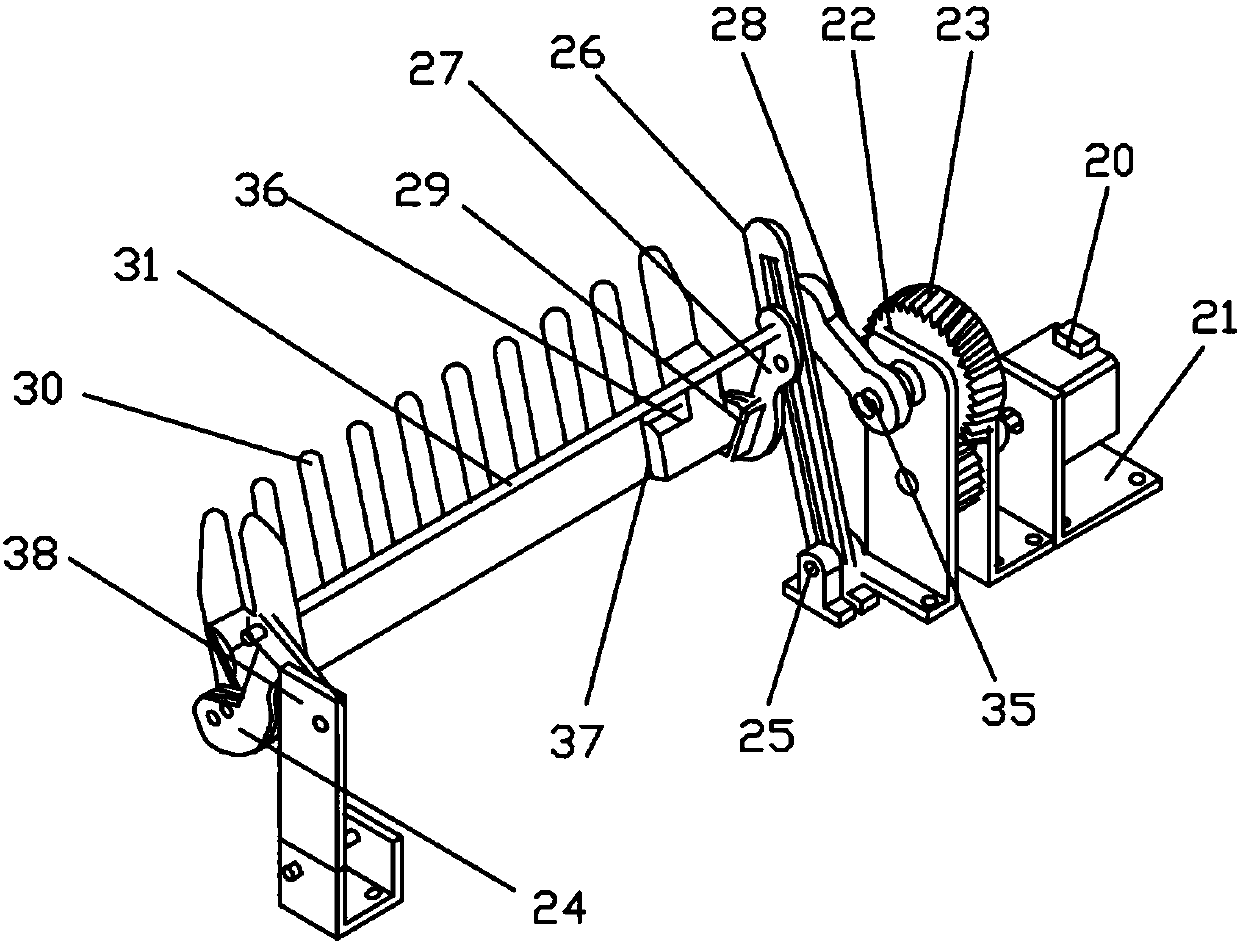

Assistant strawberry picking device

InactiveCN107889620AEasy to driveEasy steeringPicking devicesAgricultural engineeringAgricultural machinery

The invention relates to the technical field of agricultural machine application and in particular relates to an assistant strawberry picking device comprising a picking vehicle; the bottom of the picking vehicle is provided with a traveling mechanism; two sides of the picking vehicle are provided with carding mechanisms; the top of the picking vehicle is provided with a shearing mechanism; both the carding mechanisms and the shearing mechanism are driven by a stepping motor; the tail of the picking vehicle is provided with a hand push rod on which a starting / stopping switch for controlling the stepping motor is arranged; and a vehicle body of the picking vehicle is provided with a strawberry collecting box. Due to the adoption of the structural arrangement, the traveling and steering of the picking vehicle can be conveniently realized by using the traveling mechanism; strawberries can be sorted by the carding mechanisms; the strawberries can be sheared by the shearing mechanism; and the sheared strawberries are collected by the strawberry collecting box, so that the work efficiency for strawberry picking is effectively increased, and meanwhile, the picking personnel can pick a great number of strawberries on ridges without stooping.

Owner:WUHAN UNIV OF TECH

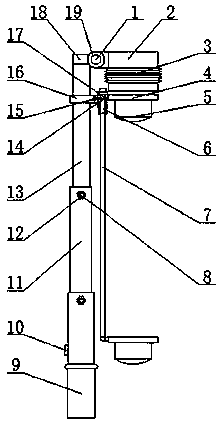

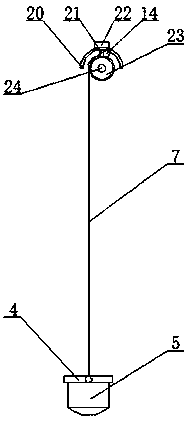

Electric fruit picker with continuous picking function

ActiveCN107624363AImprove picking efficiencyGuaranteed continuityPicking devicesEngineeringKnife blades

The invention discloses an electric fruit picker with a continuous picking function. The fruit picker comprises hollow loop bars, a picker shell, an arc-shaped baffle and knife blades. A fruit pickingring fixing bracket is arranged on the top of the picker shell, and a fruit picking ring rotating shaft is arranged at the right end of the fruit picking ring fixing bracket; a fruit picking ring ofa hollow structure is arranged on the top of the picker. The knife blades and a motor are placed in the fruit picking ring, the cutting function of the knife blades is achieved through gear transmission, manual cutting is not needed, and operation is convenient. Two fruit storing baskets are arranged under the fruit picking ring, the two fruit storing baskets alternately work on the top of the arc-shaped baffle through a steel wire rope and a standing pulley, so that fruits are transported up and down. The machine operation continuity is ensured, continuous operation can be achieved, and the picking efficiency of the picker is improved; the picker is of the structure formed in the mode that the three hollow loop bars are connected so that the length can be changed according to the needs, and the picker is convenient to use.

Owner:TAIZHOU SHUOXIANG COMMODITY CO LTD

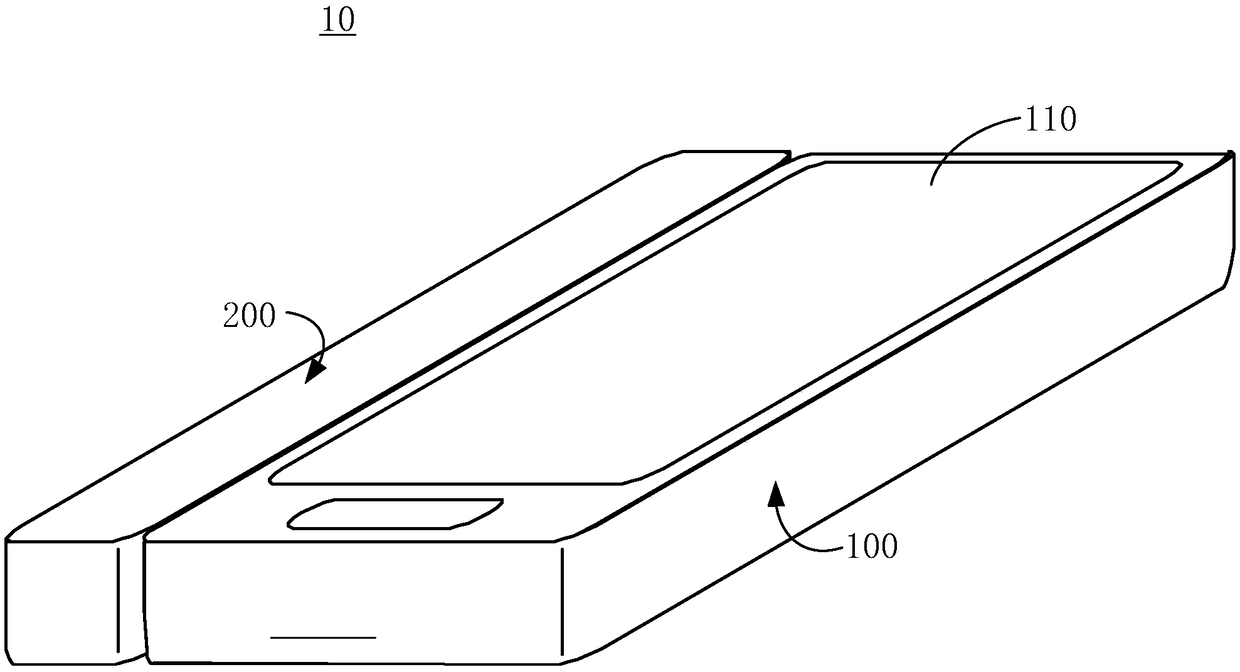

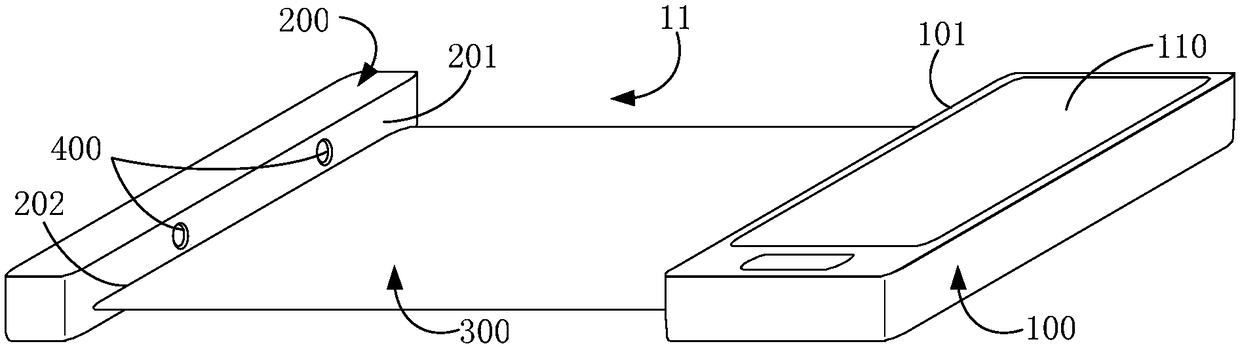

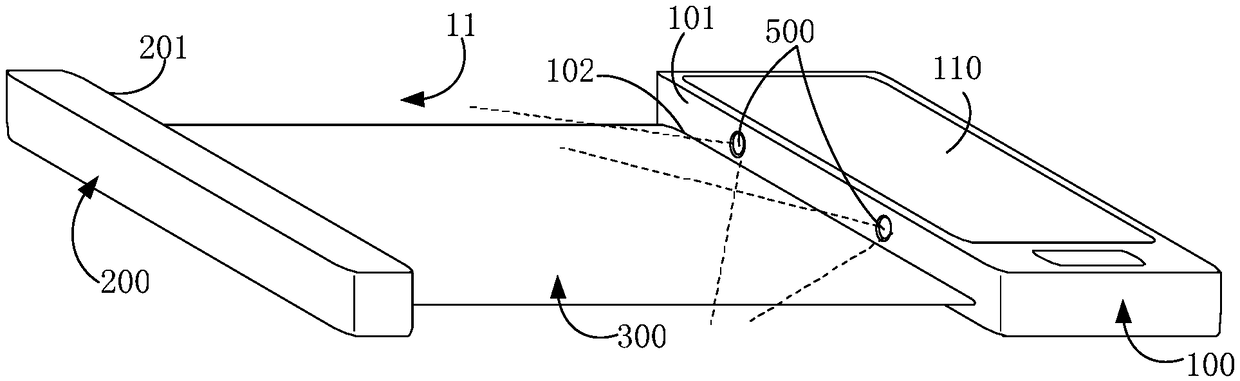

Electronic device

InactiveCN108632411AAvoid pressingAvoid shearing and other forcesInput/output for user-computer interactionGraph readingOperation modeComputer science

The invention relates to an electronic device with a combined state and an opened state. The electronic device comprises a main body; a secondary body which is set in opposite to the main body and canmove relative to the main body; a flexible screen, wherein one end of the flexible screen is set on the main body, and the other end of the flexible screen is set on the secondary body; and a gestureidentifier which is connected with the secondary body, wherein the gesture identifier is used for identifying a gesture, thereby carrying out non-touch screen operation on the flexible screen. When the electronic device is in the opened state, a gap exists between the main body and the secondary body, and the flexible screen is unfolded in the gap. When the electronic device is in the combined state, the gap between the main body and the secondary body is removed, and the flexible screen is stored in the main body or the secondary body. An icon on the flexible screen is operated through identification of the gesture identifier for the gesture. An operation mode is the non-touch screen operation. The flexible screen is effectively prevented from deformation under the touch screen effect. Adisplay effect of the electronic device is ensured. The user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

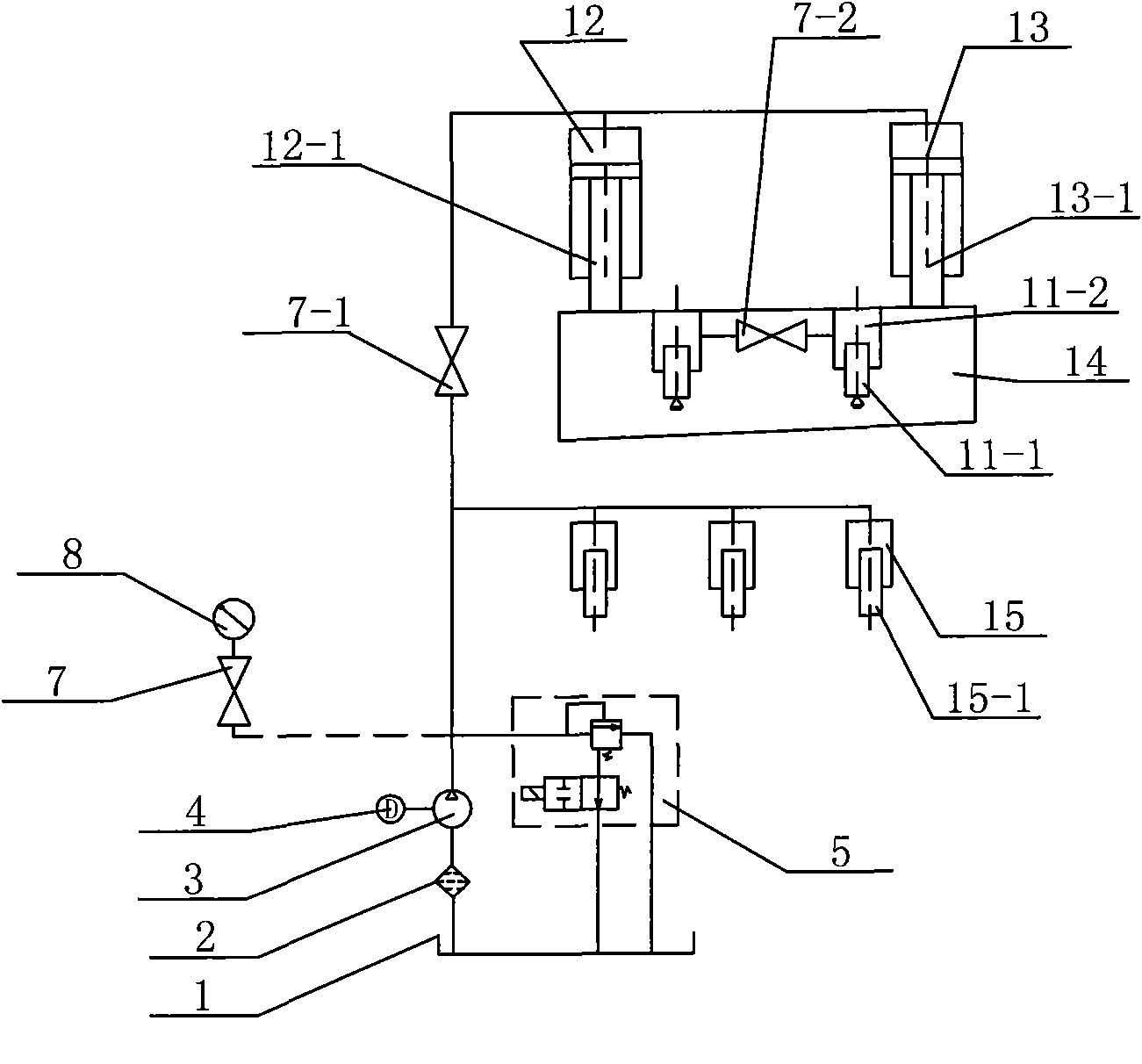

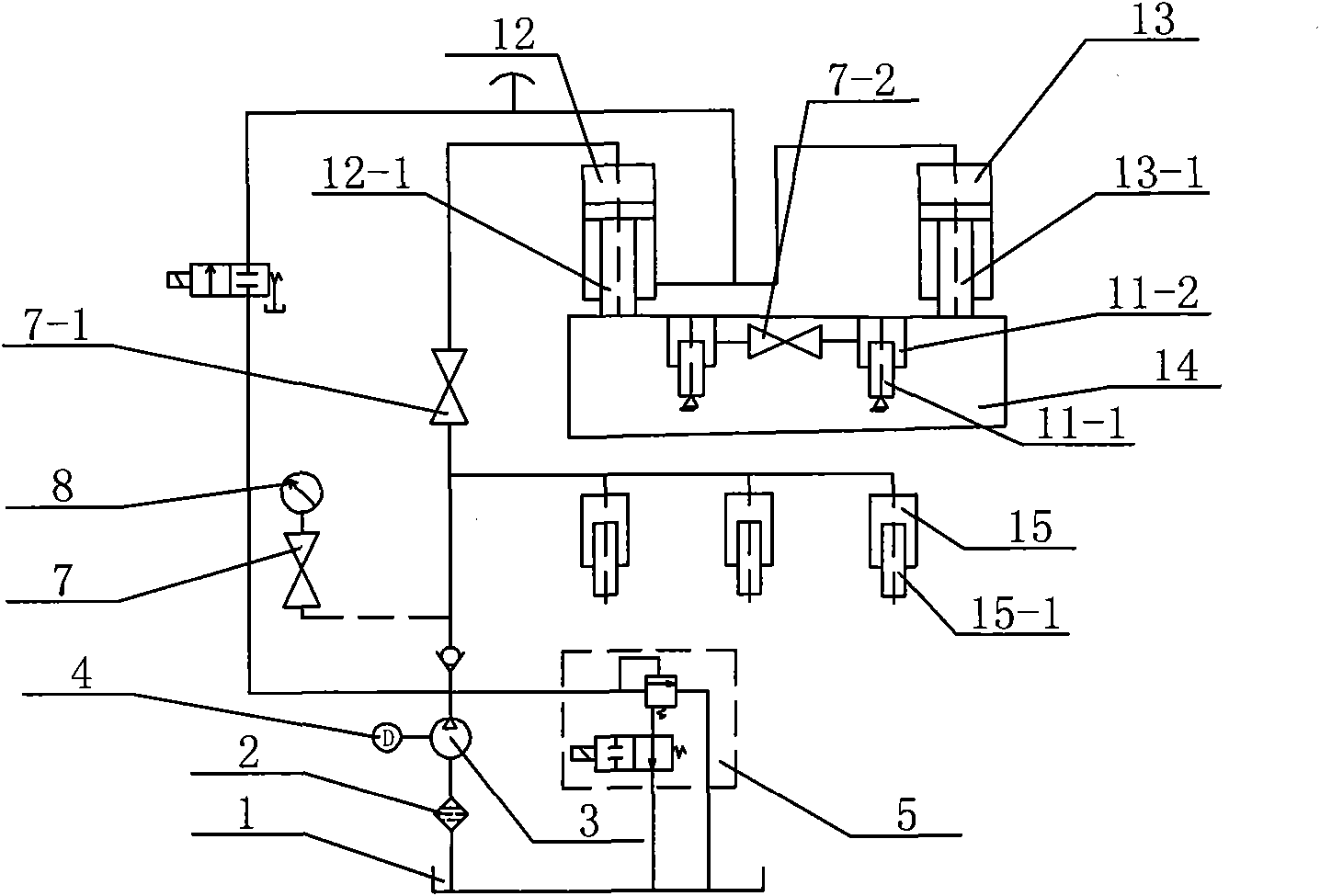

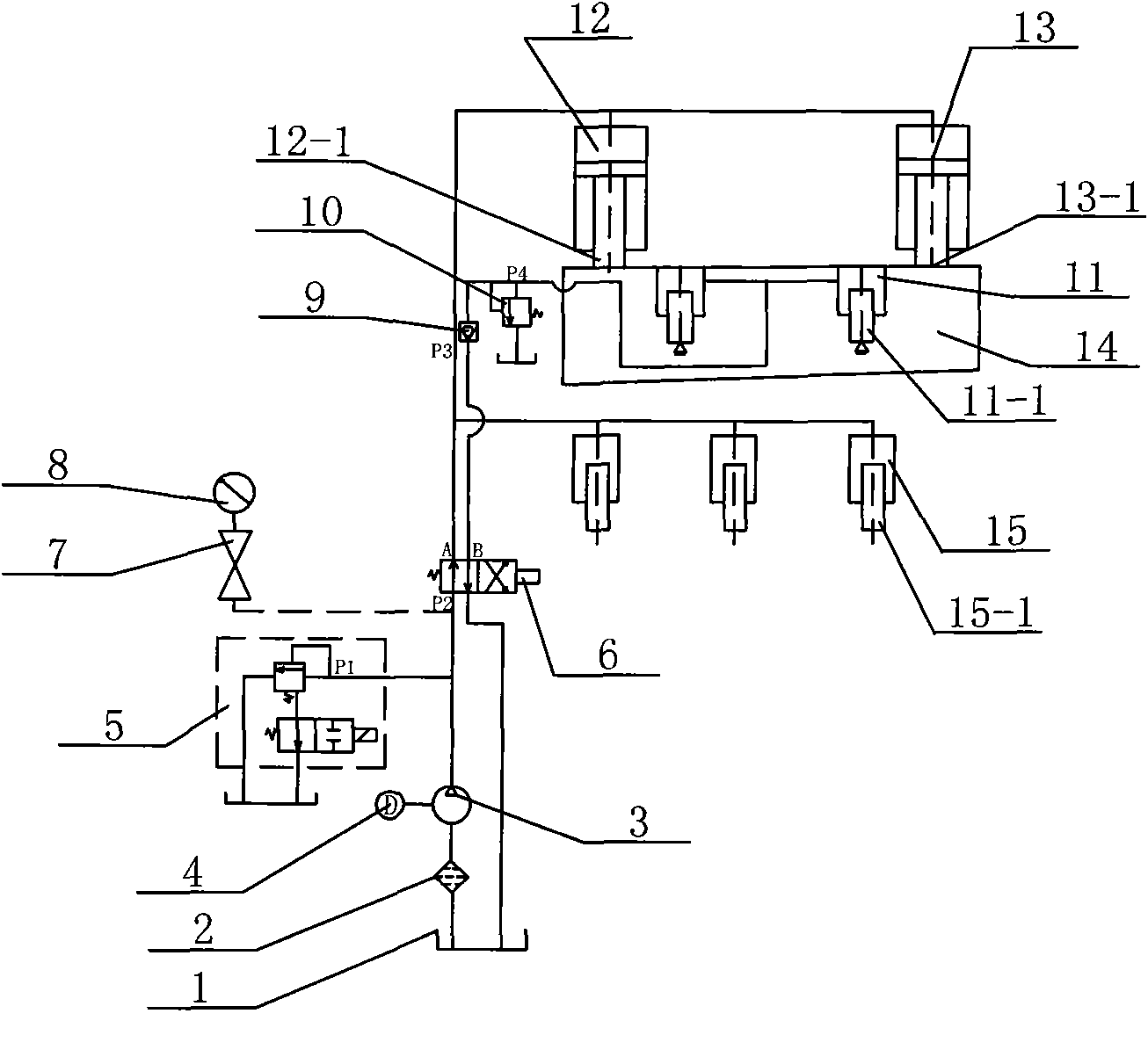

Hydraulic transmission device for plate shearing machine

The invention provides a hydraulic transmission device for a plate shearing machine, and relates to a plate shearing machine used in a forging and pressing product. In the invention, an oil outlet of a hydraulic pump (3) is connected with an oil inlet P1 of an electromagnetic relief valve (5) and an oil inlet P2 of a reversing valve (6); an oil outlet A of the reversing valve (6) is connected with a left master cylinder (12), a right master cylinder (13) and a material pressing cylinder (15); an oil outlet B of the reversing valve (6) is connected with a straight-through opening P3 of a one-way valve (9); and the other opening of the one-way valve (9) is connected with an opening P4 of a pressure regulating valve (10) and an oil inlet of a hydraulic return cylinder (11). By adopting the hydraulic transmission device, an upper knife rest can stop at any position, thus greatly facilitating adjustment on clearance uniformity degree of a knife blade, avoiding accidents and being safer and more convenient.

Owner:周建波

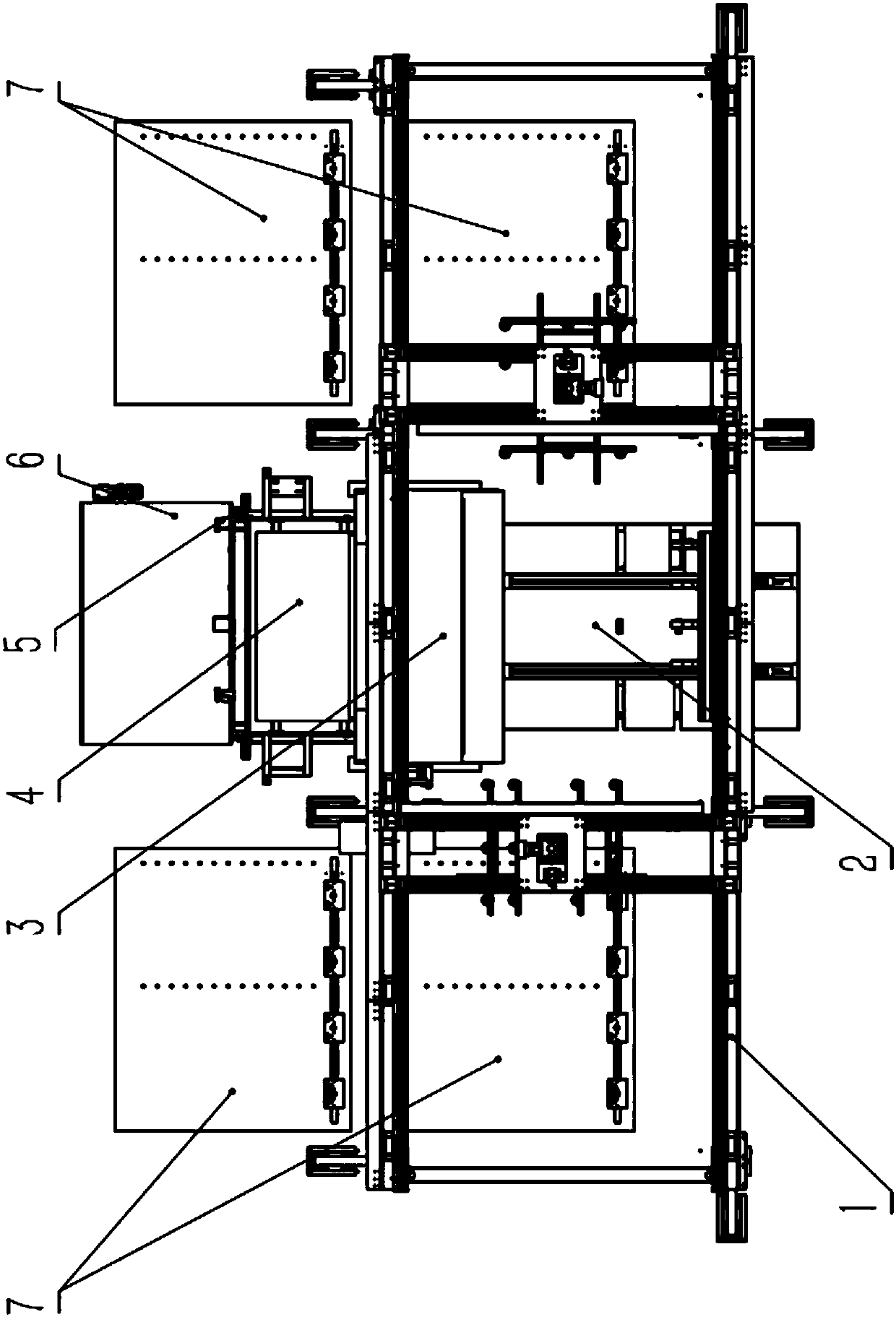

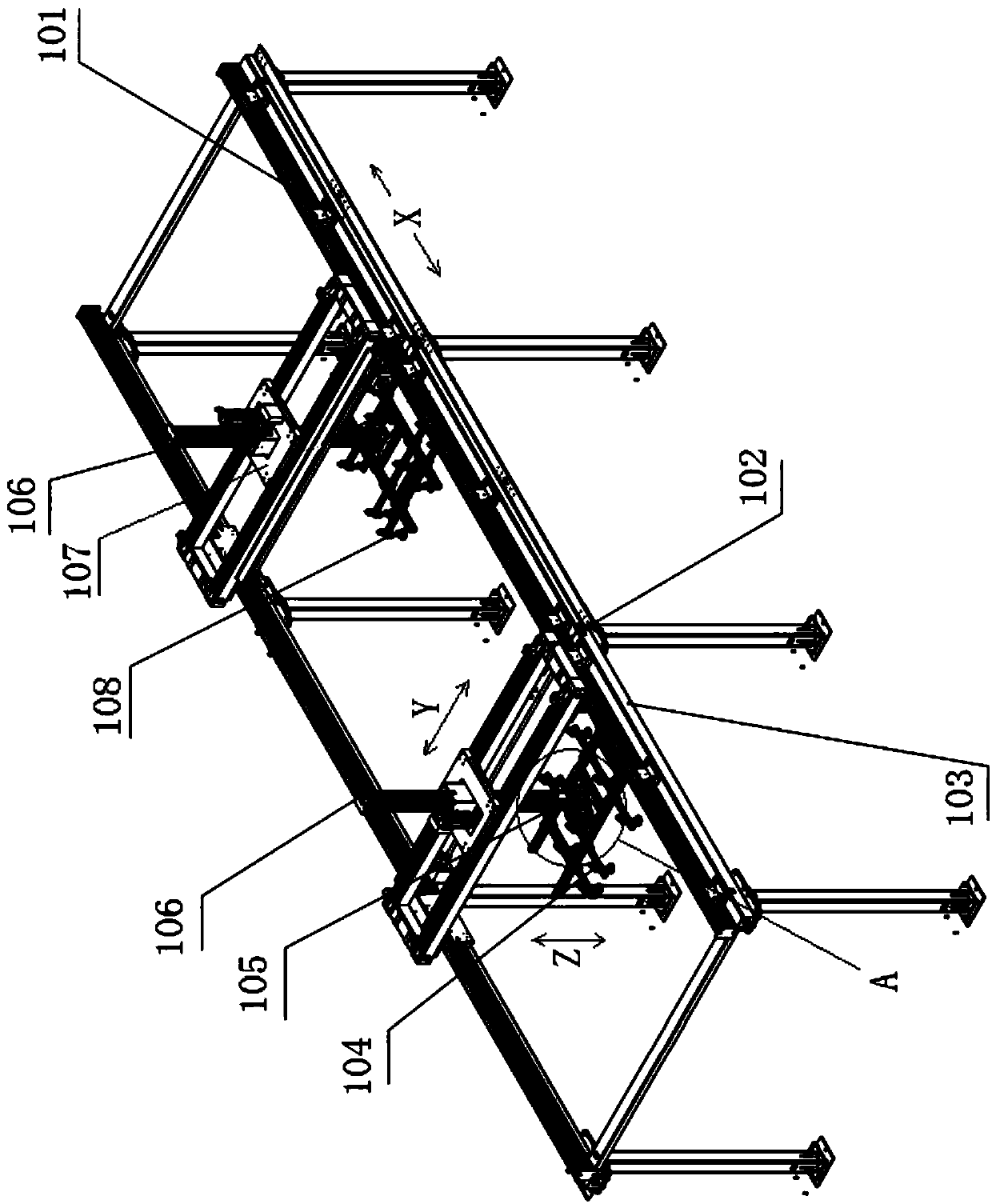

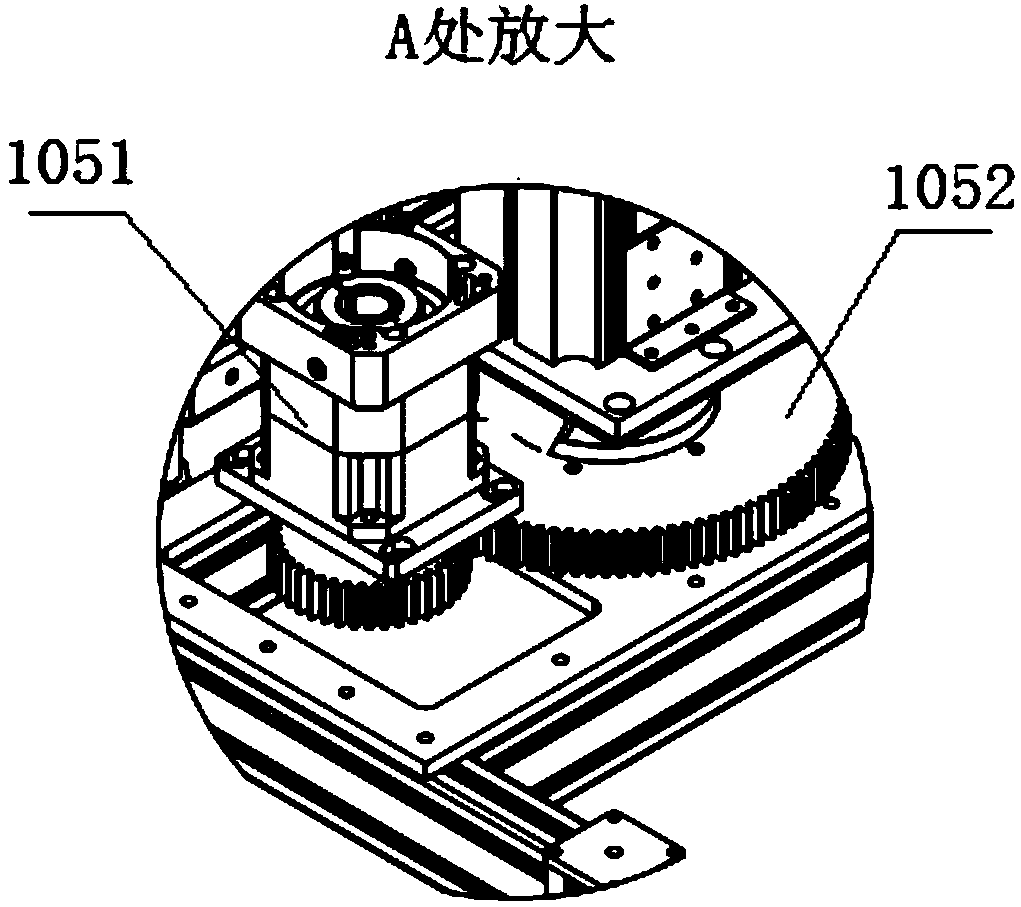

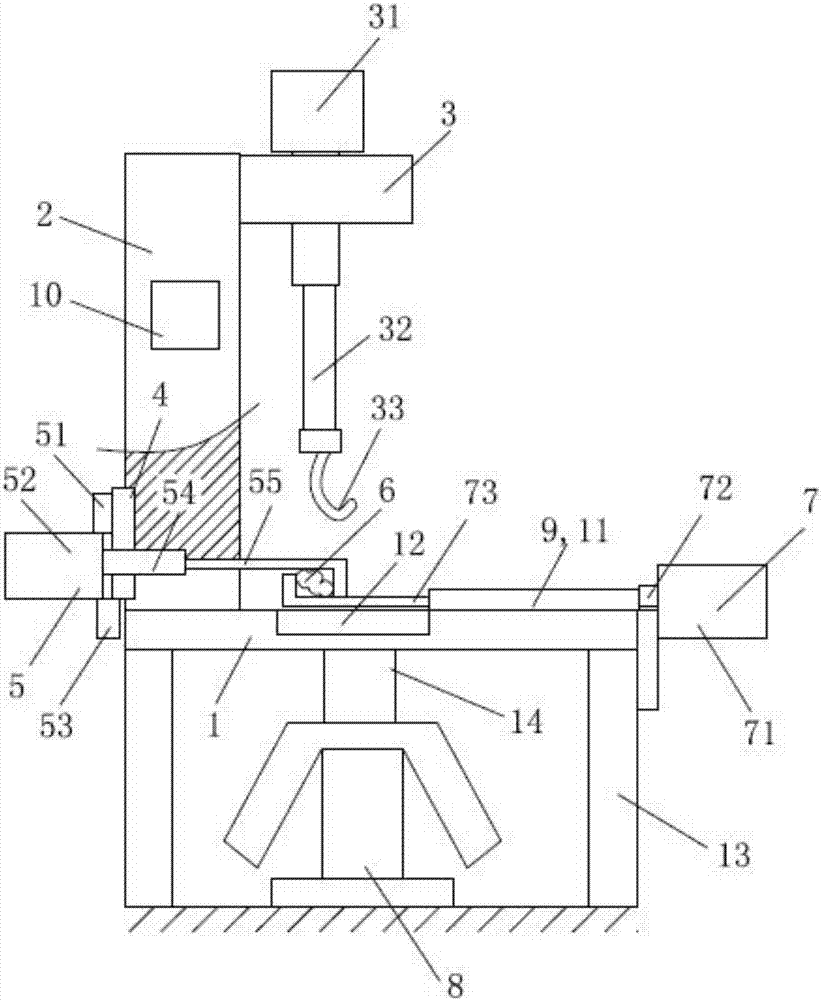

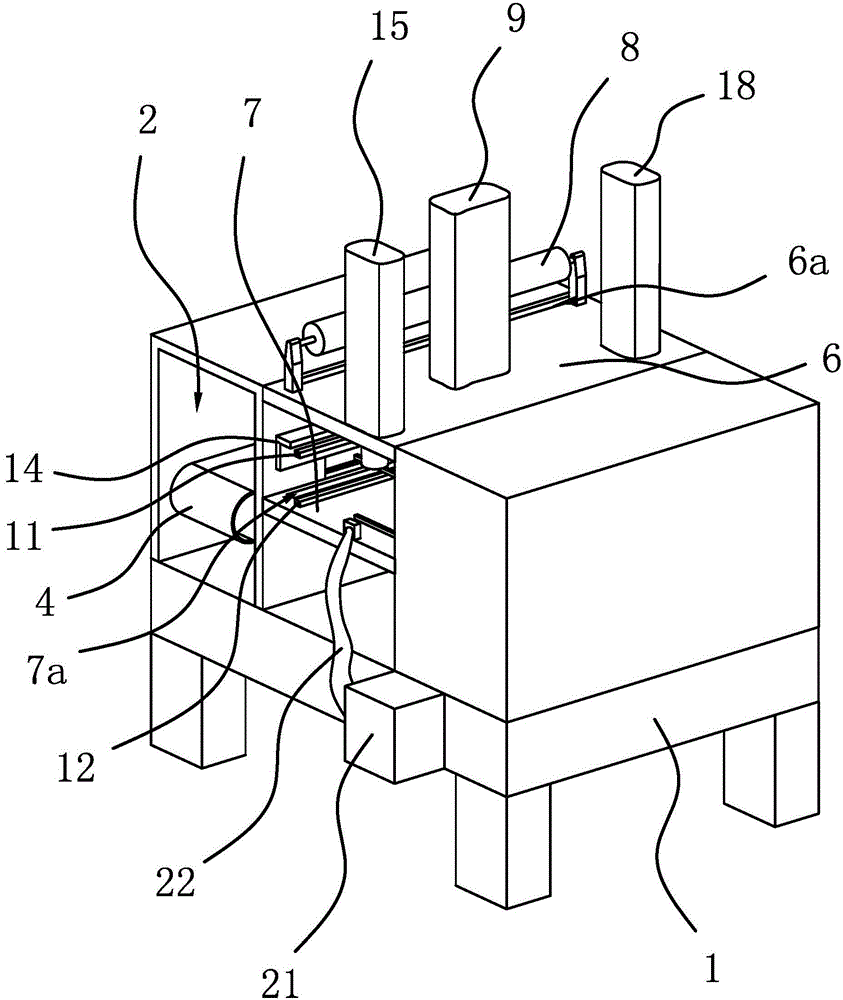

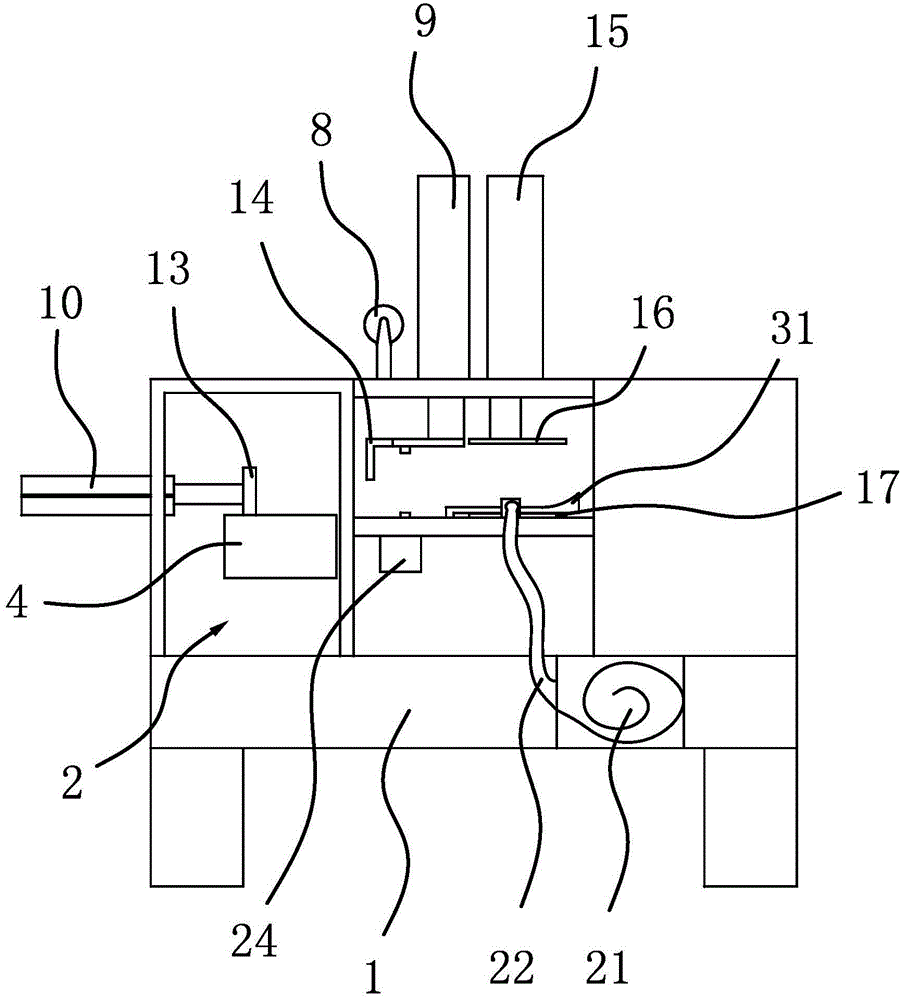

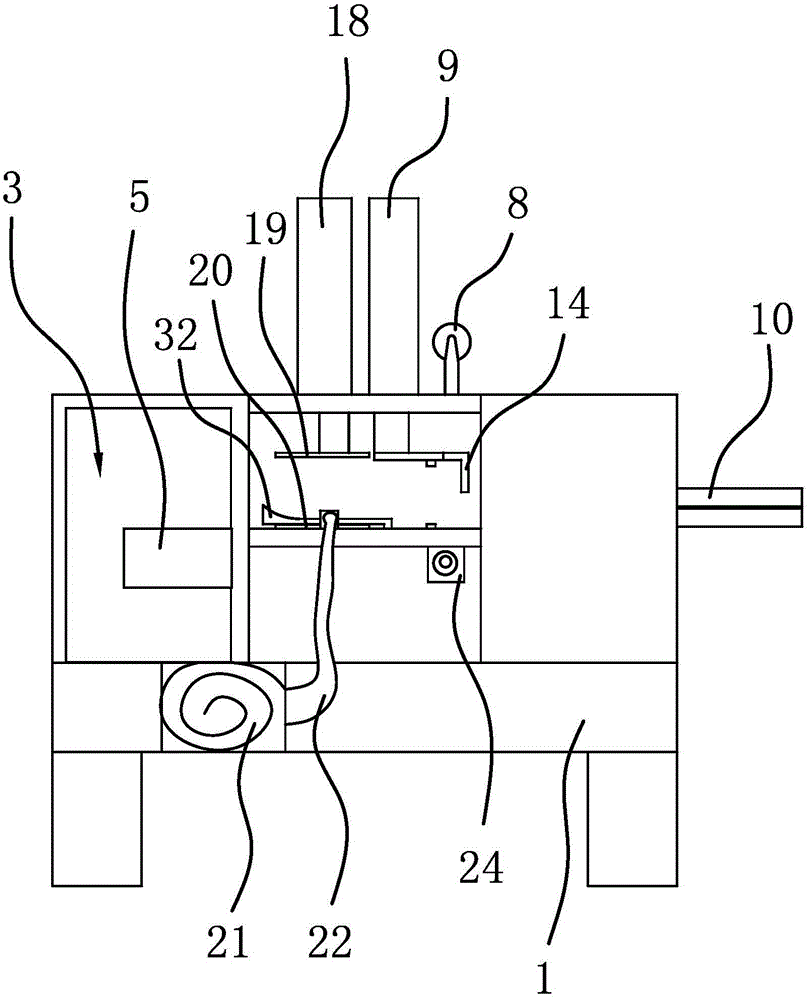

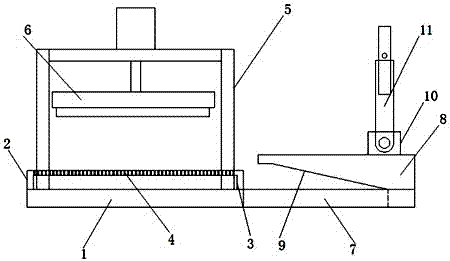

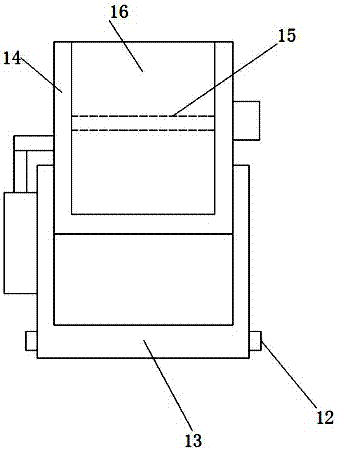

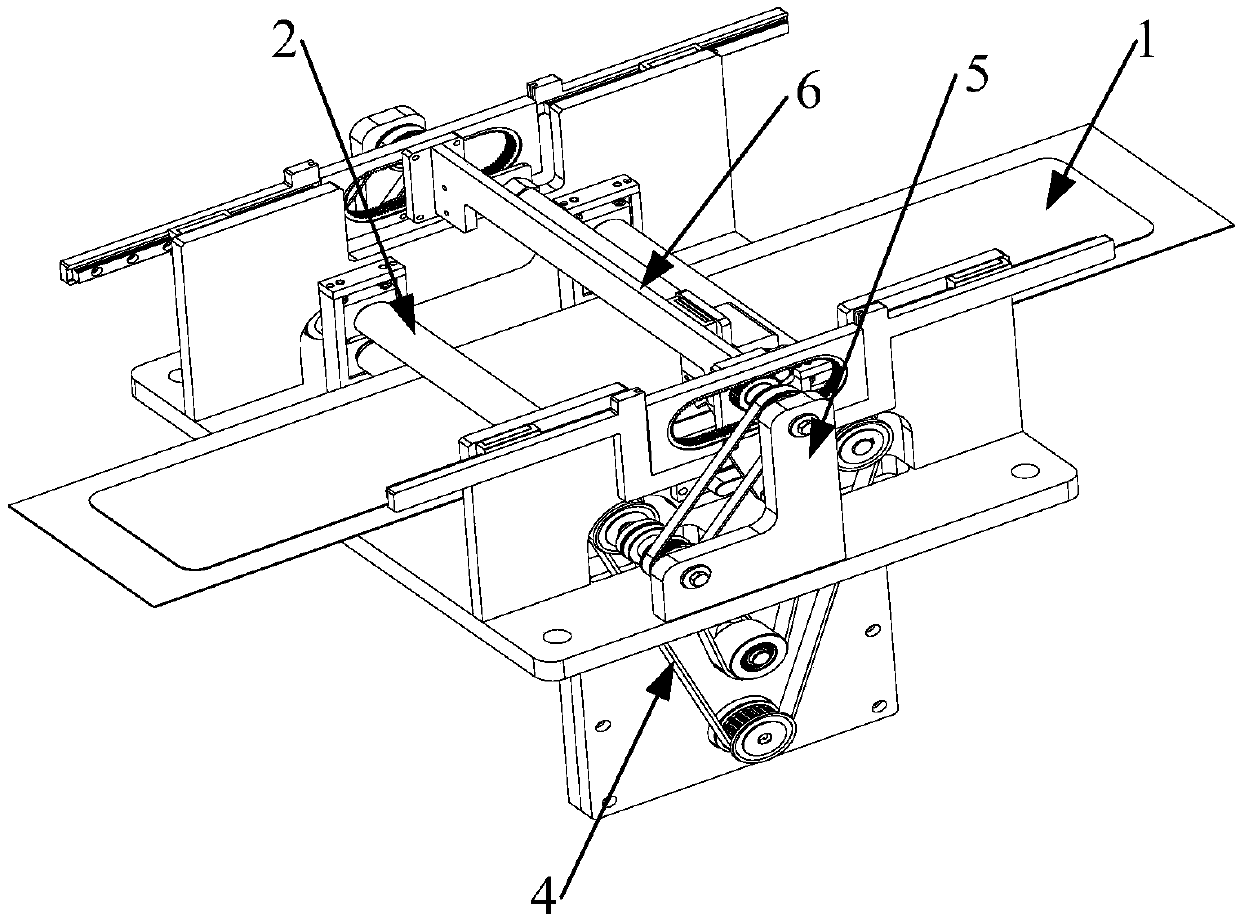

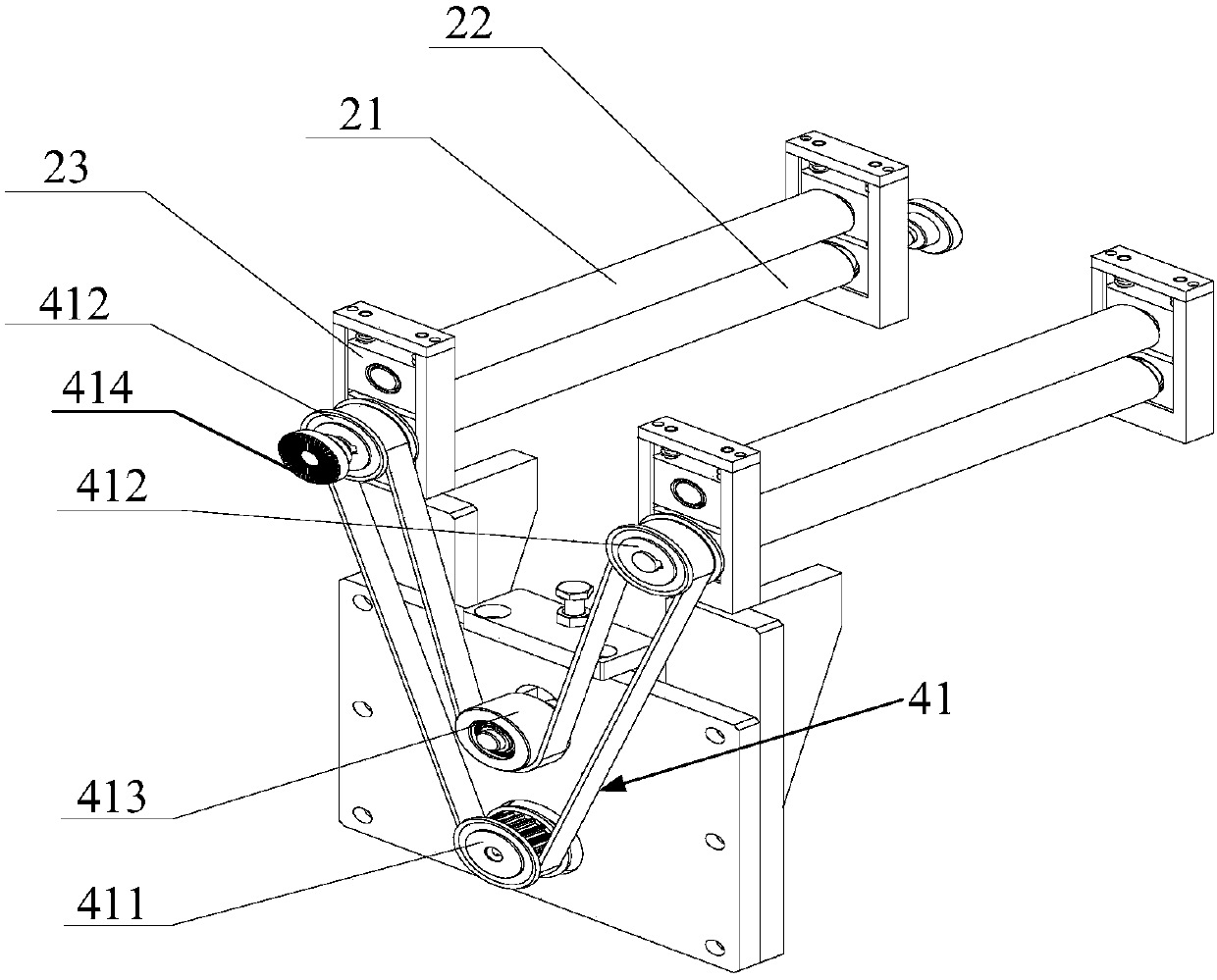

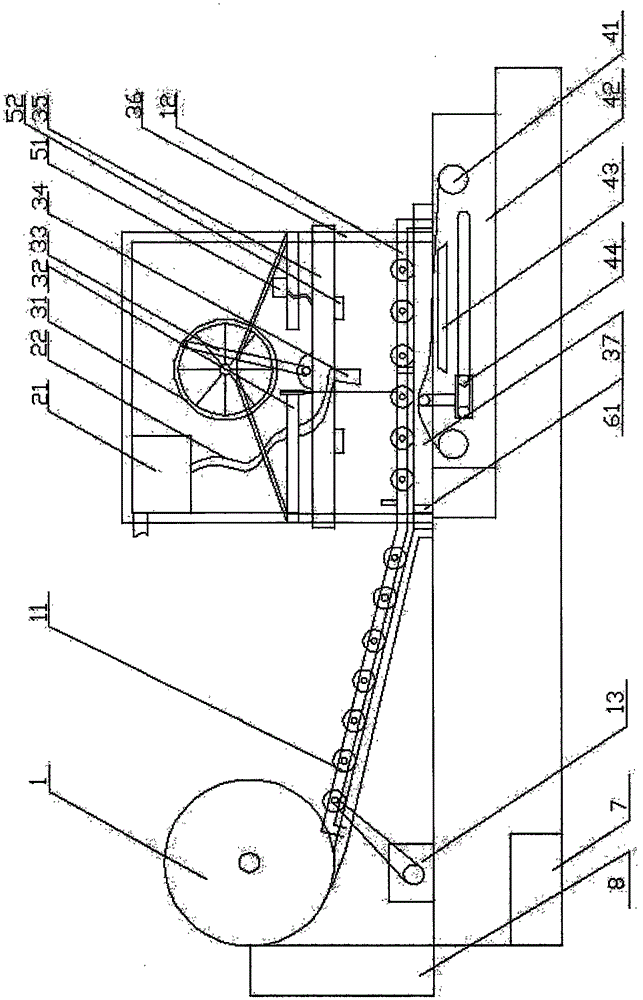

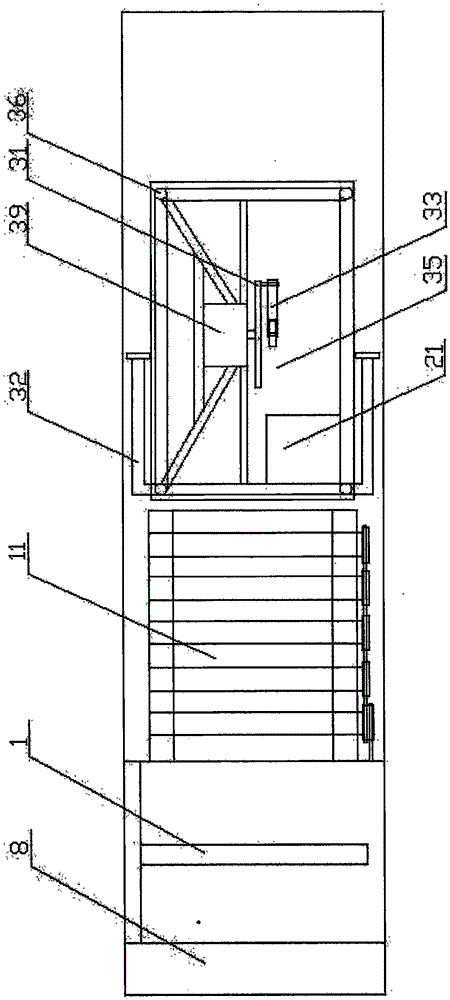

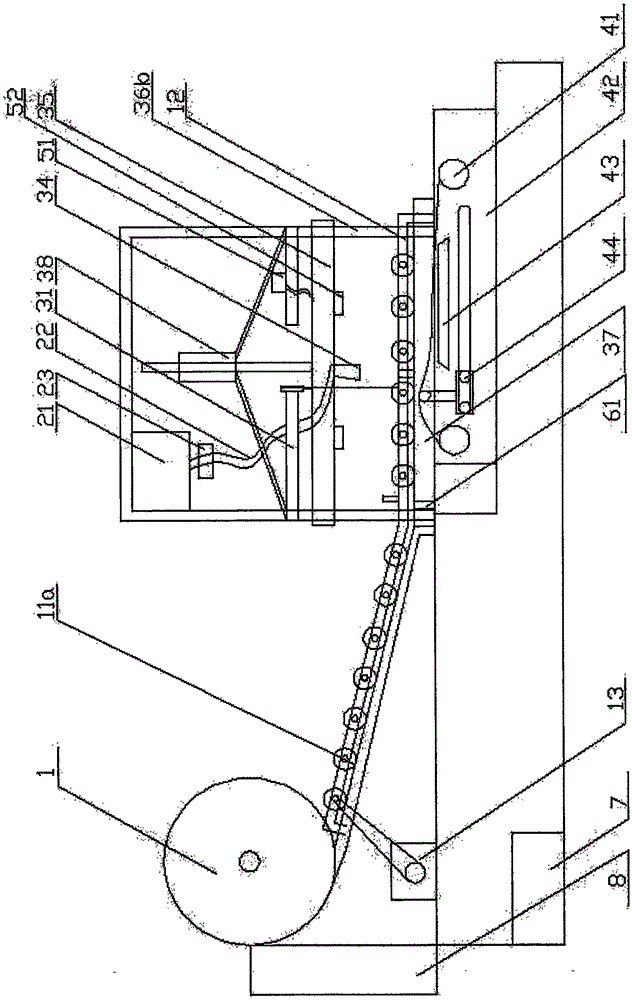

Automobile steel plate fine shearing automatic production device

ActiveCN109692992AAchieve cutGuaranteed bevel cutShearing machinesStacking articlesSheet steelDegrees of freedom

The invention relates to the field of automobile steel plate processing, and specifically relates to an automobile steel plate fine shearing automatic production device. The device includes a loadingand unloading mechanism, a feeding mechanism, a fine plate-shearing machine, a transmission mechanism, a palletizing mechanism and ground rail electric translation vehicles; the loading and unloadingmechanism includes a support rack body and two sucker driving mechanisms; one sucker driving mechanism is provided with a loading sucker assembly having X, Y and Z degrees of freedom and freedom of rotation, and the other sucker driving mechanism is provided with an unloading sucker assembly having X, Y and Z degrees of freedom; the feeding mechanism is arranged at the middle part on the lower side of the support rack body; the ground rail electric translation vehicles are respectively arranged on the two sides of the feeding mechanism; the feeding mechanism is provided with feeding clamps; aplate is driven to move to the fine plate-shearing machine along the Y direction through the clamping of the feeding clamps; and the side, away from the feeding mechanism, of the fine plate-shearing machine is successively provided with the transmission mechanism and the palletizing mechanism. Thus, various steel plate shearing modes can be realized, and the precision and production efficiency ofautomobile steel plate shearing can be enhanced.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

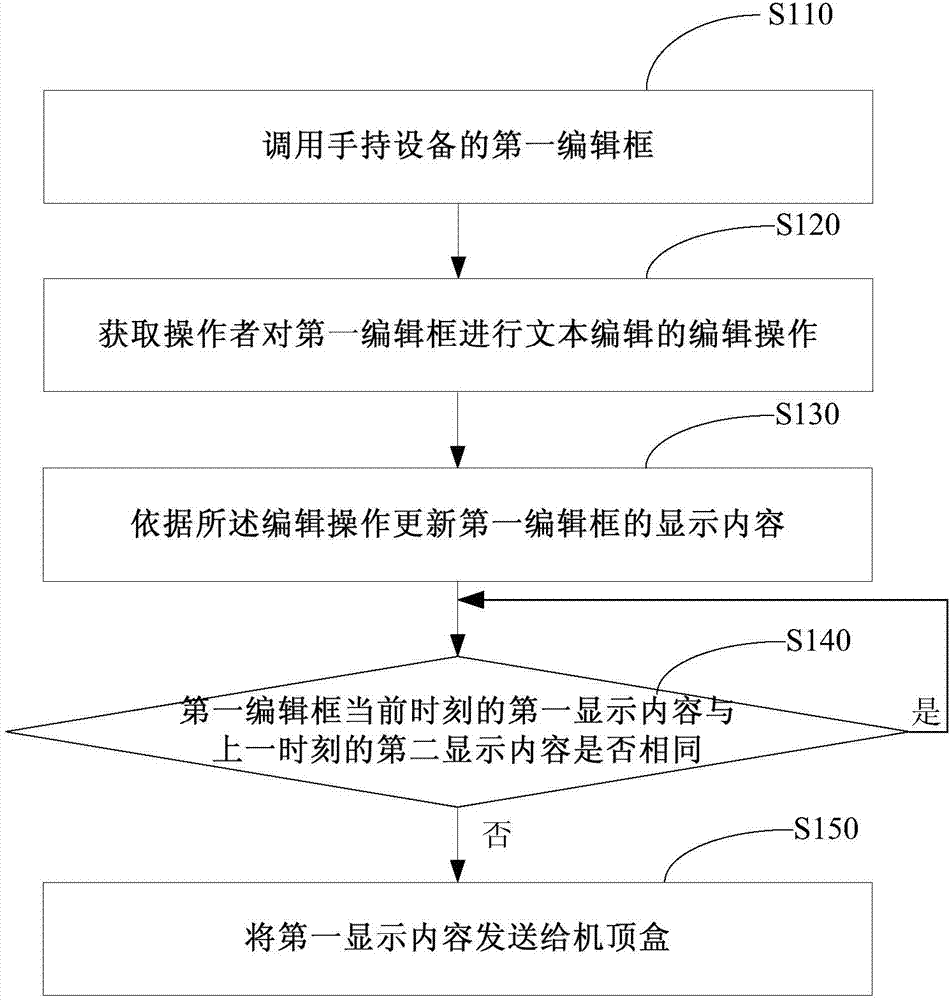

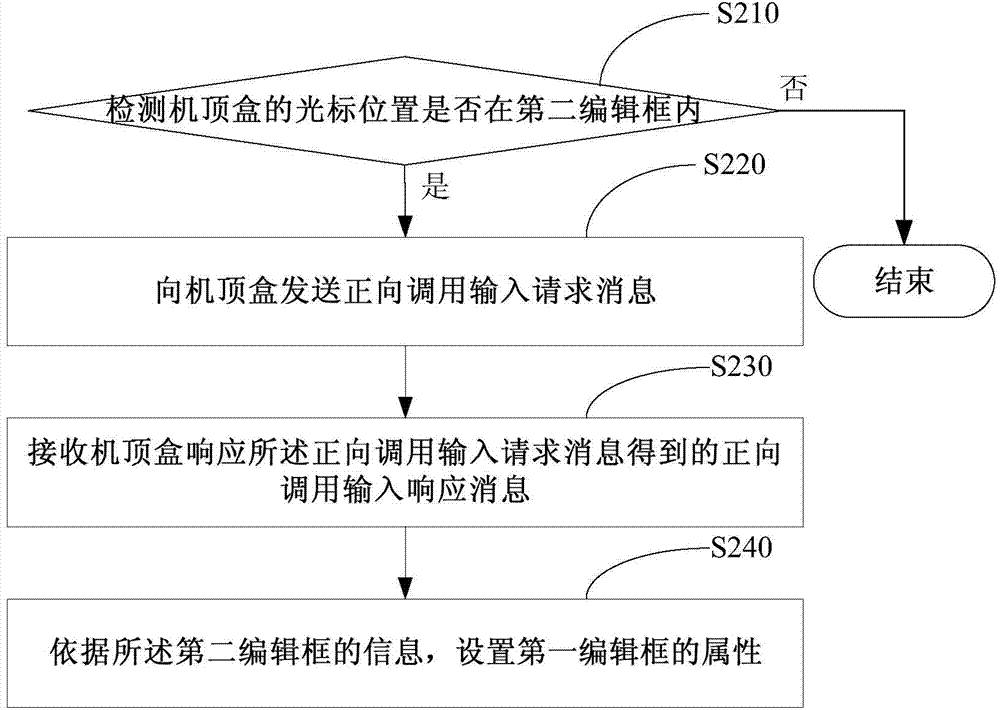

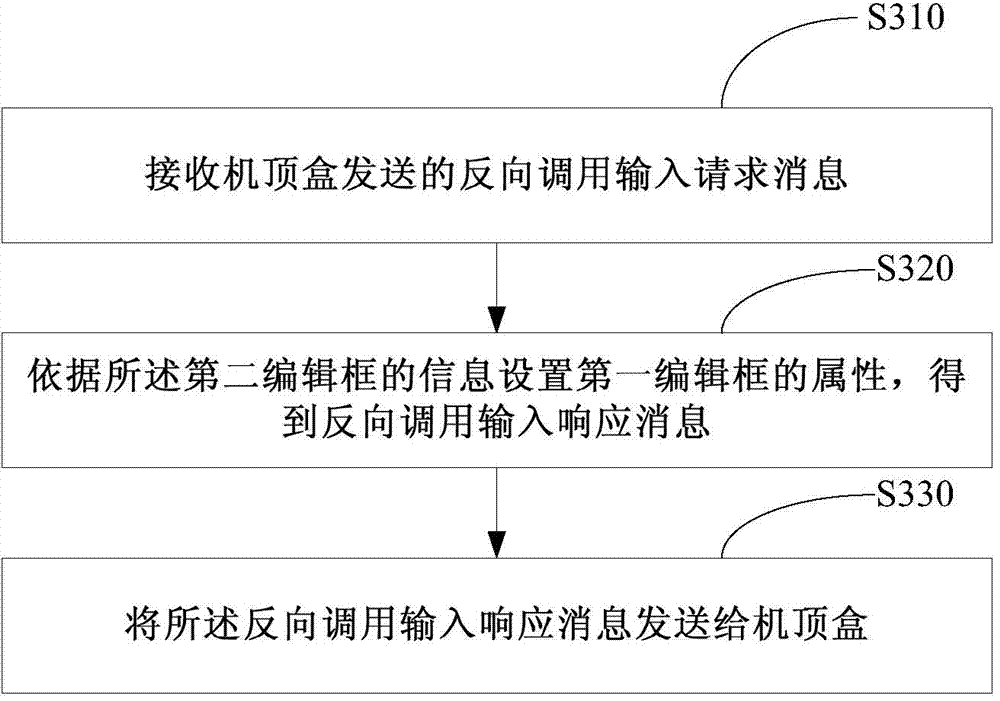

Text message input method and device

ActiveCN103593213AImprove the efficiency of entering text informationImprove efficiencyNatural language data processingProgram loading/initiatingText editingComputer graphics (images)

The embodiment of the invention discloses a text message input method and device. According to the method, firstly, a first editing frame of a handheld device is called; then, display contents of the first editing frame are updated according to editing operation of an operator on the first editing frame; finally, whether first display contents at the current moment of the first editing frame and second display contents at the last moment are the same, if not, the first display contents are sent to a set top box, and the set top box can update display contents of a second editing frame. Thus, the display contents of the second editing frame of the set top box and the display contents of the first editing frame of the handheld device can be synchronous, and then input and delete operation of a single word or a specific symbol by users utilizing built-in input methods of the handheld device can be facilitated, in addition, text editing operation like cutting and copying large block of text messages can be achieved, and the text input efficiency and speed of the set top box can be improved.

Owner:HISILICON (SHANGHAI) TECH CO LTD

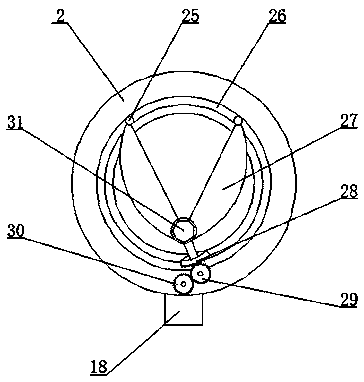

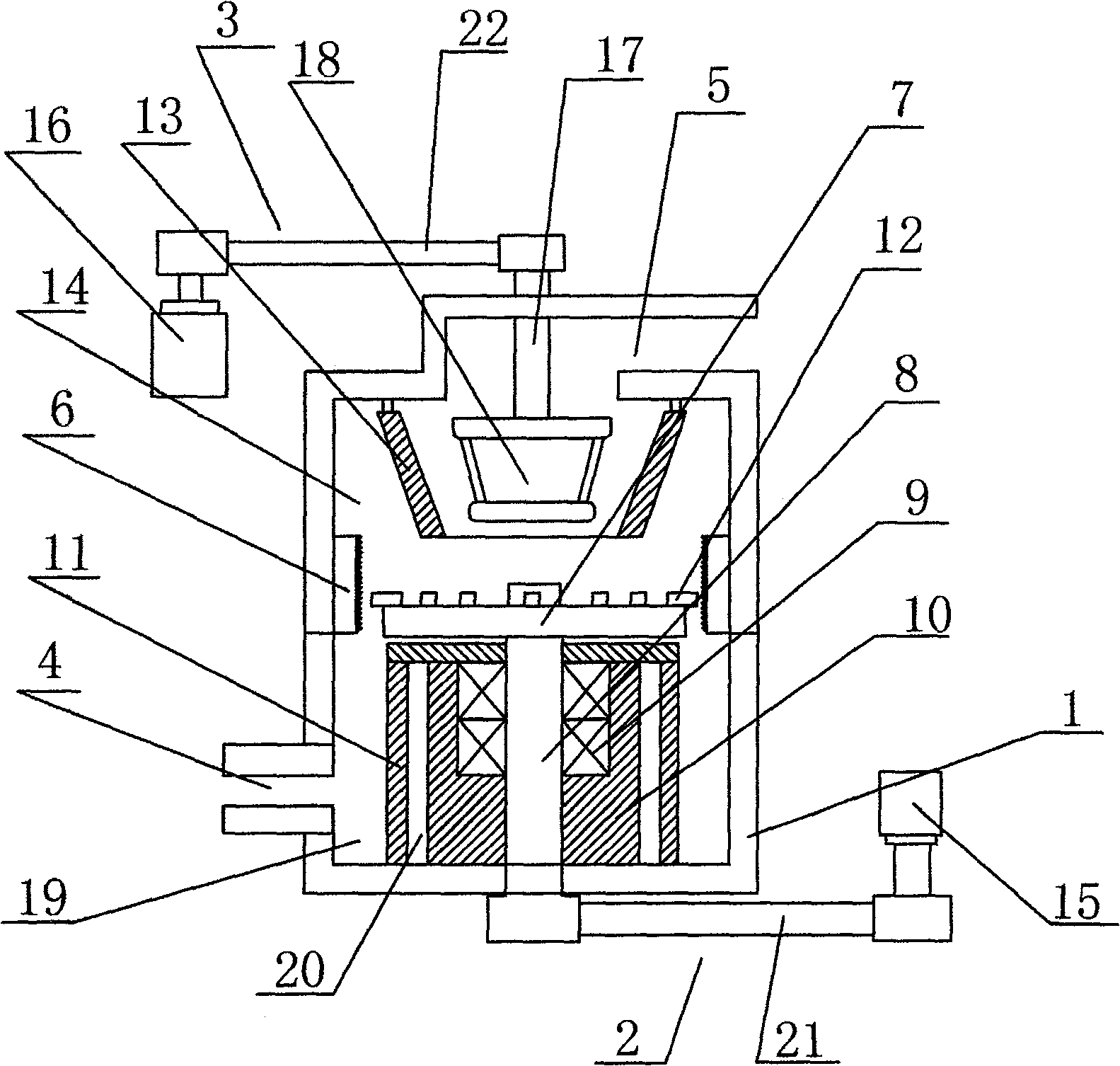

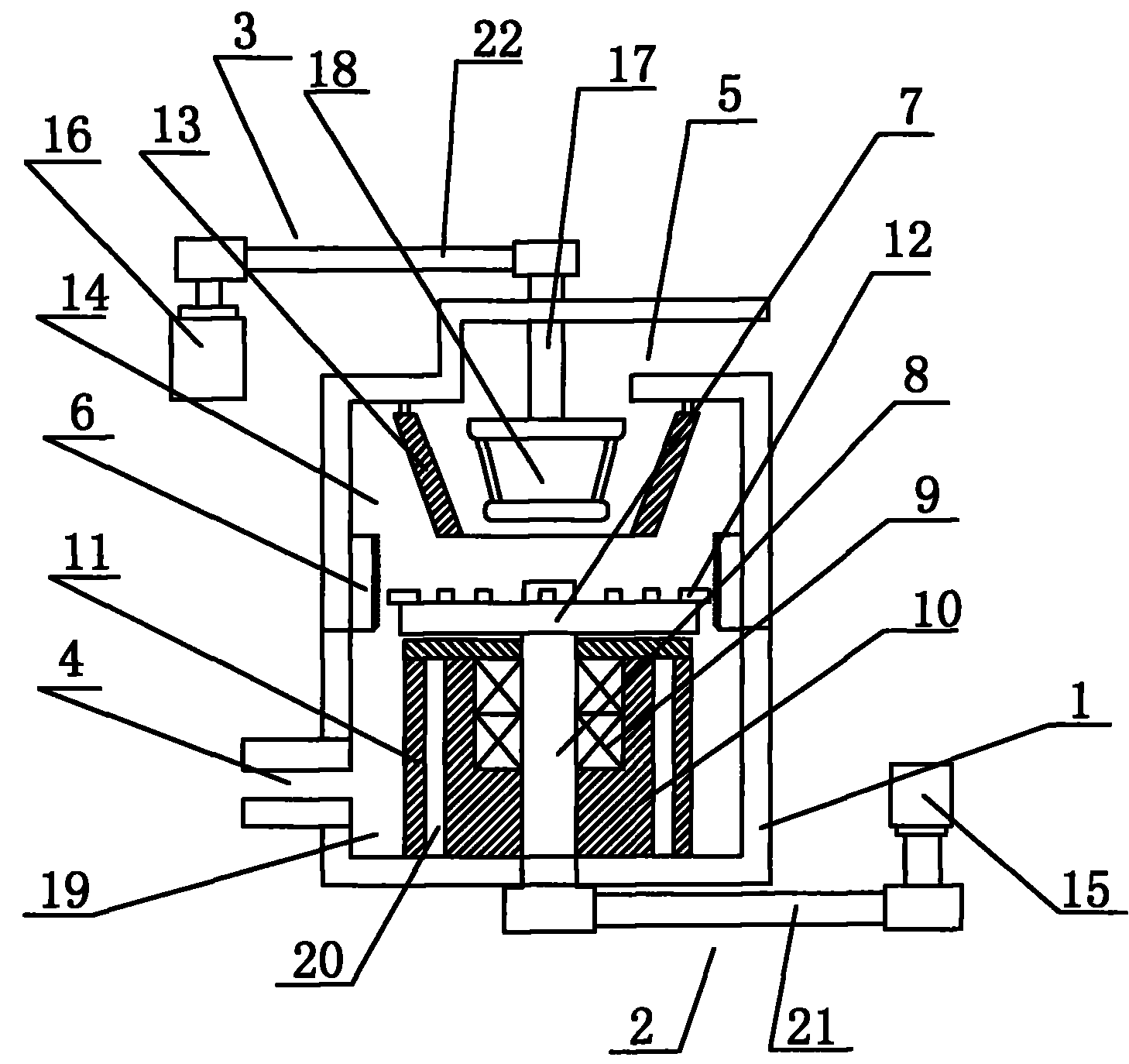

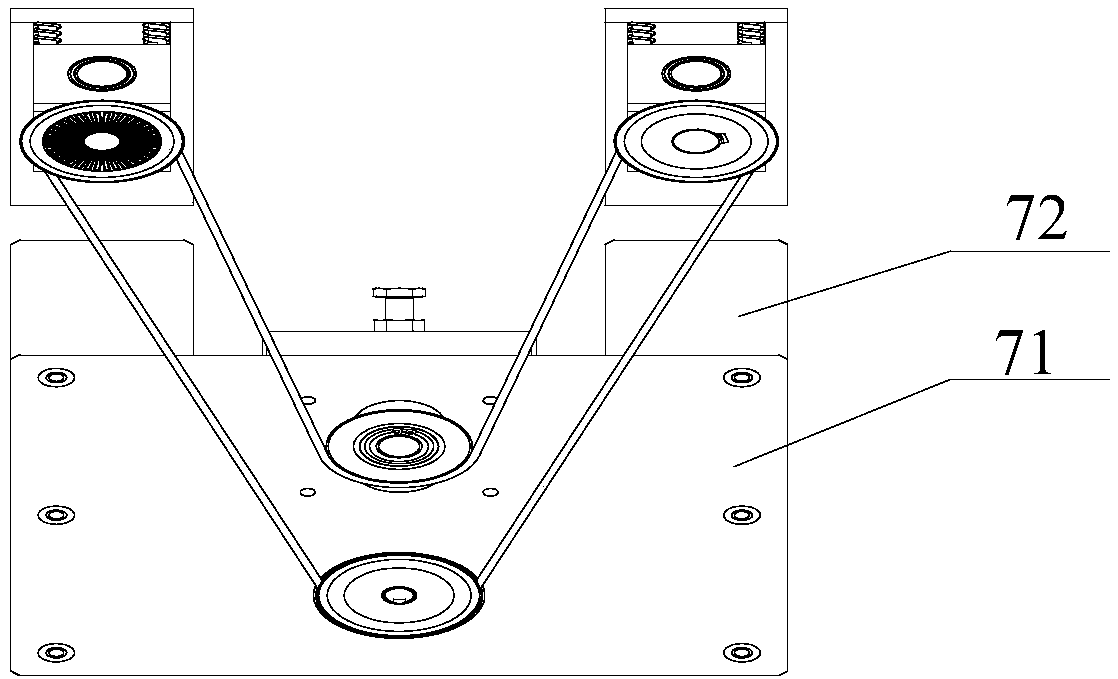

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling process and a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

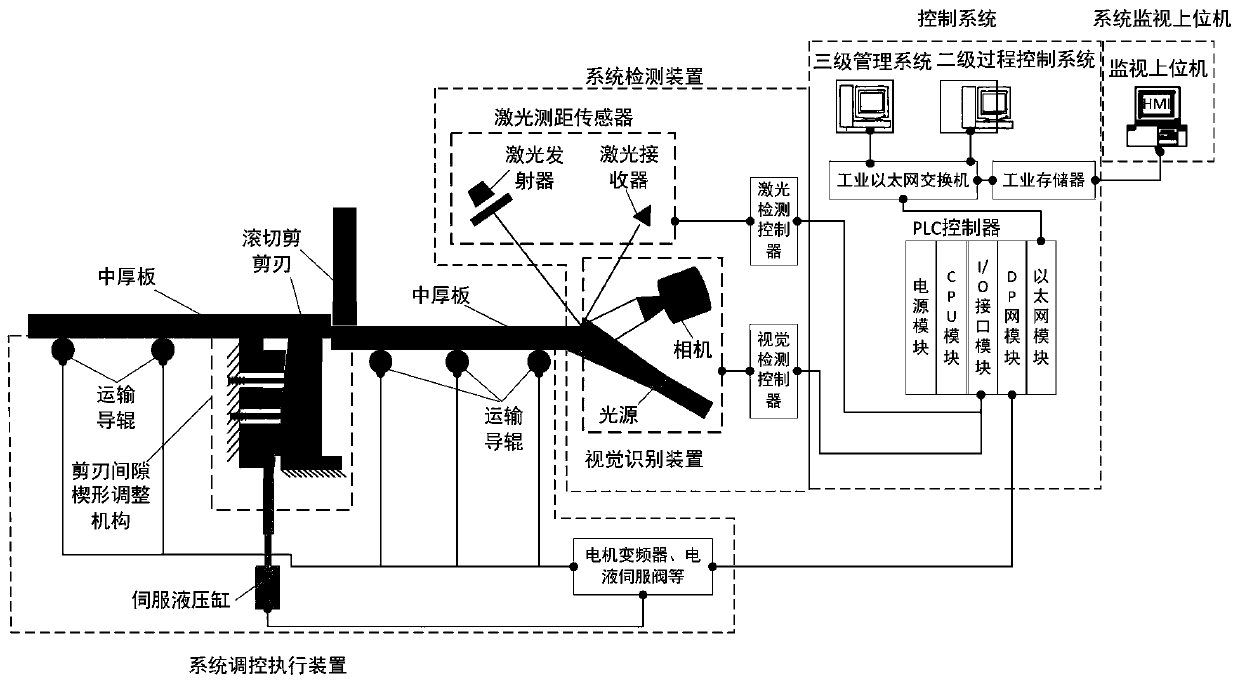

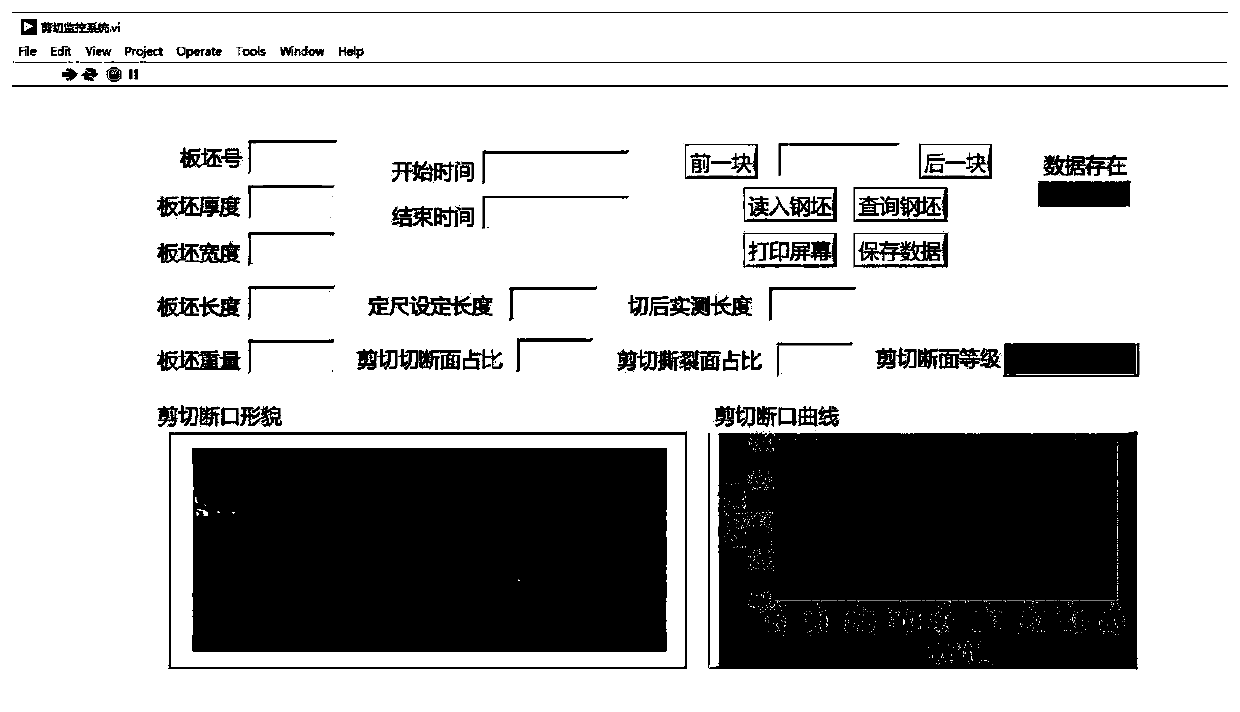

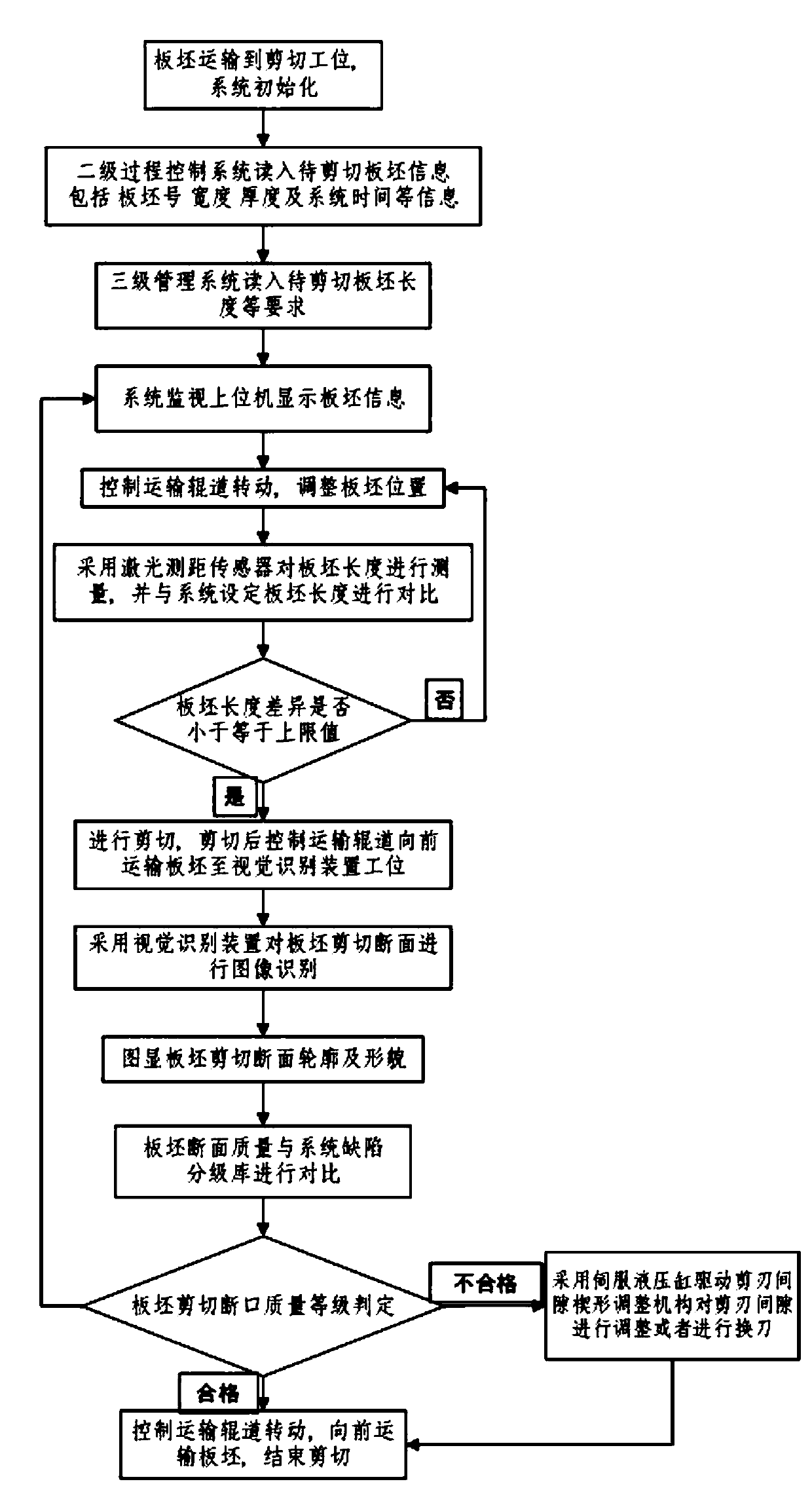

Roll-cutting shear quality monitoring system and method based on laser and visual inspection

ActiveCN111176218ARealize traceabilityRealize monitoringShearing machinesNumerical controlMetallic materialsServo

The invention belongs to the technical field of metal material machining process control systems, and particularly relates to a roll-cutting shear quality monitoring system and method based on laser and visual inspection. The invention aims to improve the intelligent control level of the roll-cutting shear and improve the shearing quality of a medium plate. The system comprises a system monitoringupper computer, a system detection device, a system regulation and control execution device and a control system, a shear blade gap wedge-shaped adjusting mechanism is driven by a servo hydraulic cylinder, a servo valve is used for regulation and control, the adjustment of the shear blade gap is achieved, the shear blade gap wedge-shaped adjusting mechanism converts longitudinal linear motion ofthe hydraulic cylinder into horizontal transverse motion of a shear blade, the rigidity of the shear blade is guaranteed through a wedge-shaped block and a pressing mechanism, and the control over theshear blade gap of the roll-cutting shear is achieved.

Owner:TAIYUAN UNIV OF TECH

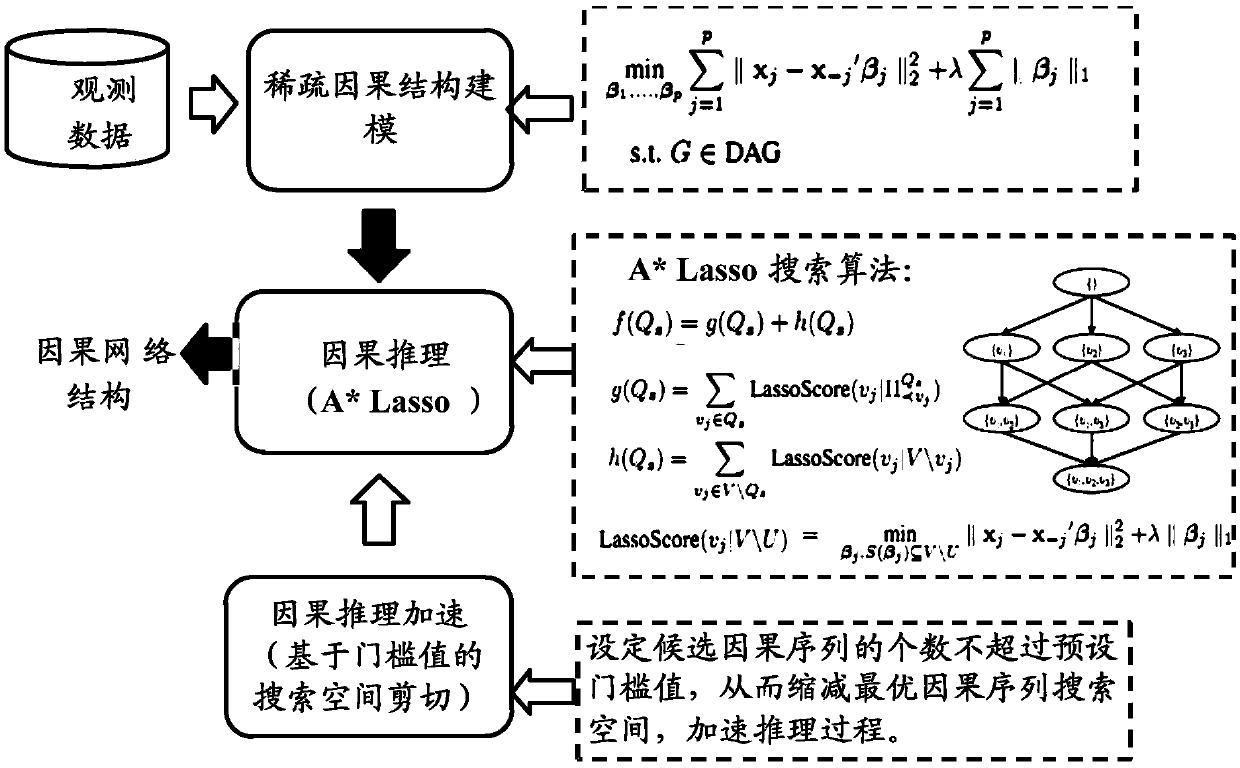

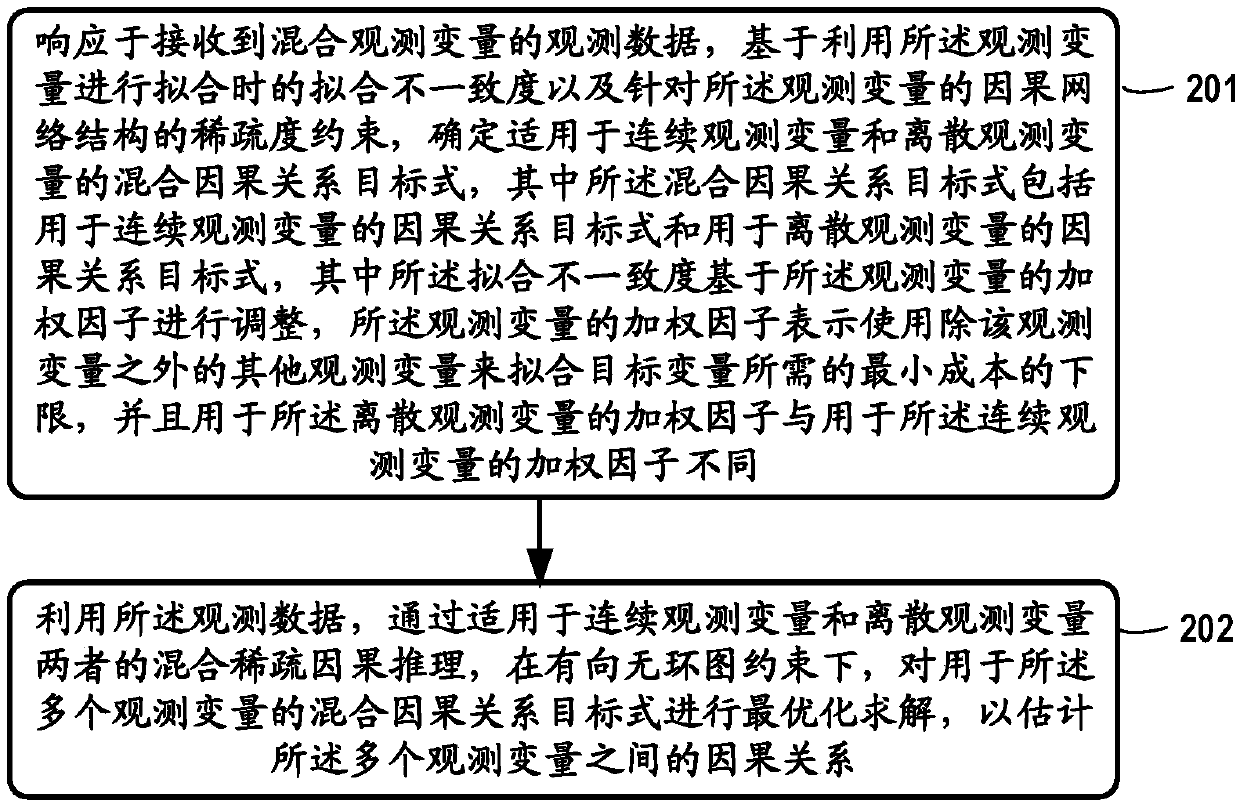

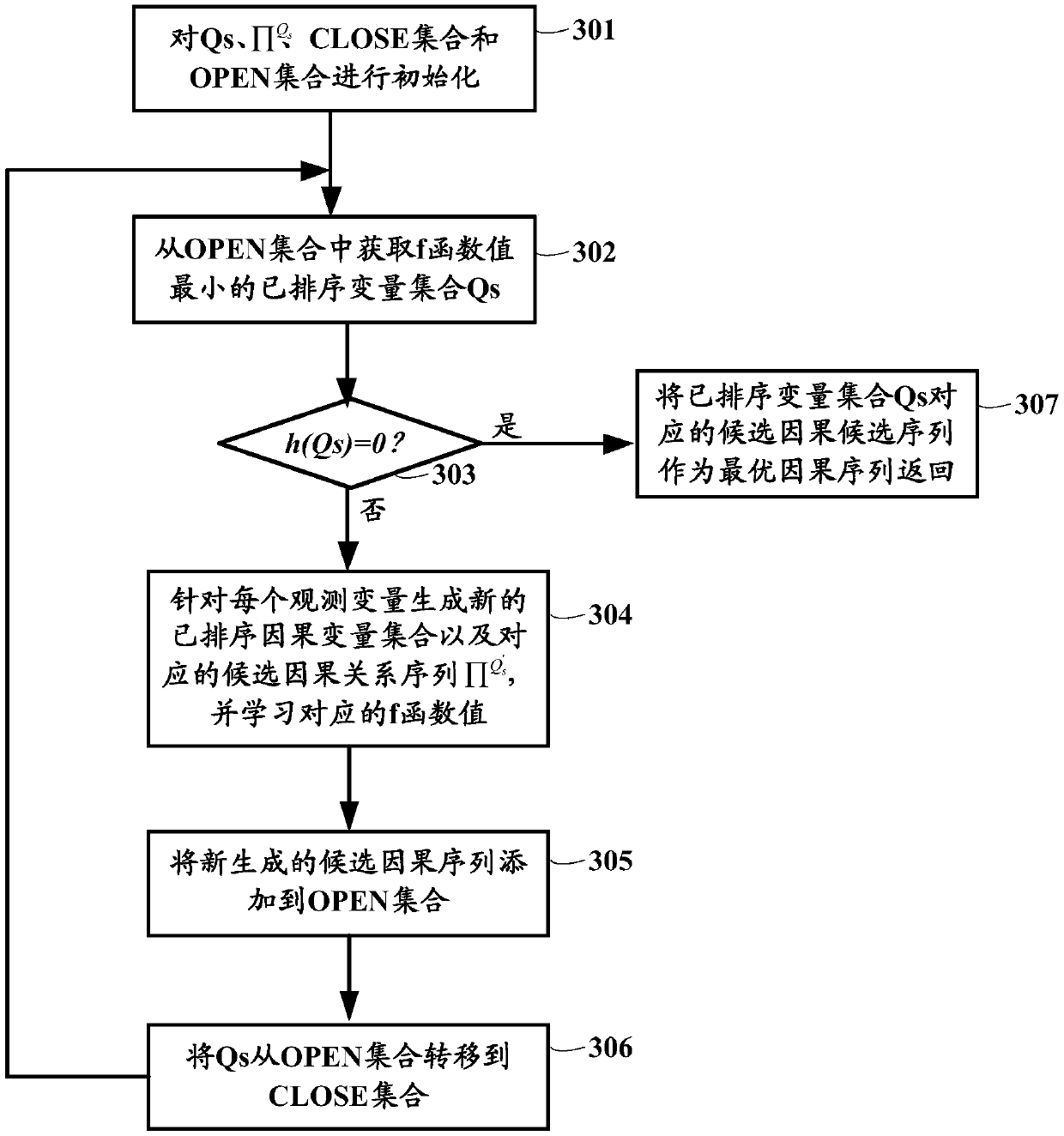

Methods, apparatus, and systems for estimating causal relationships between observed variables

PendingCN110390396AAchieve cutSpeed up the solutionMathematical modelsMachine learningTarget expressionObservation data

Methods, apparatus, and systems are disclosed for estimating causal relationships between observed variables. According to the method provided by the present disclosure, responding to the received observation data of the mixed observation variable, a mixed causal relationship target formula suitable for the continuous observation variable and the discrete observation variable is determined, whichincludes a causal relationship target formula for the continuous observation variable and a causal relationship target formula for the discrete observation variable, and the fitting inconsistency is adjusted based on a weighting factor of the observation variable. Then optimal solution is performed on the mixed causal relationship target expression by utilizing the mixed observation data and through mixed sparse causal reasoning suitable for continuous observation variables and discrete observation variables under the constraint of a directed acyclic graph so as to estimate the causal relationship among a plurality of observation variables. The embodiment of the invention is suitable for causal relationship estimation of the mixed observation variable, and the causal network structure haslow sensitivity to the observation variable estimation error, so that the accurate causal relationship can be obtained.

Owner:NEC CORP

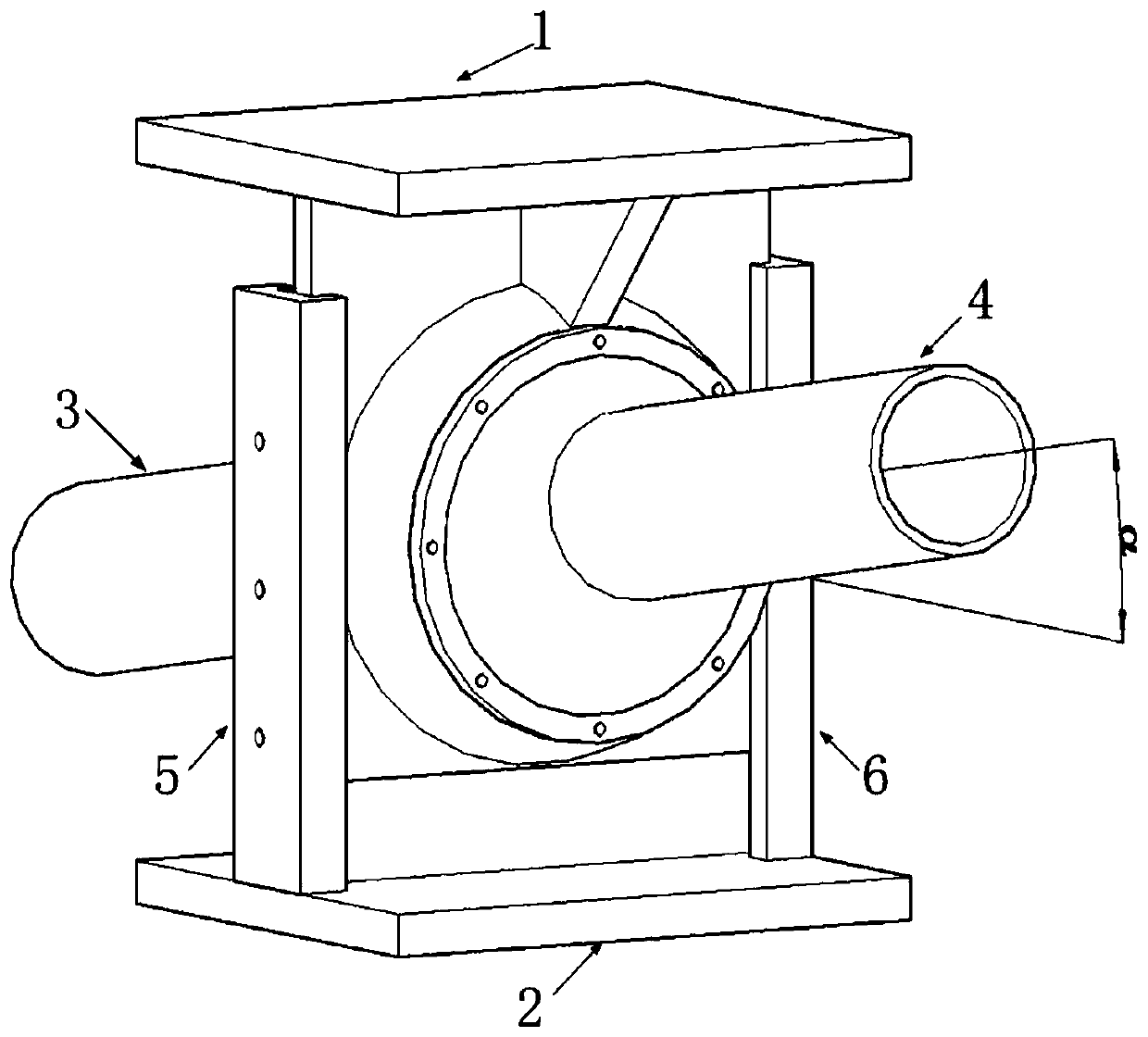

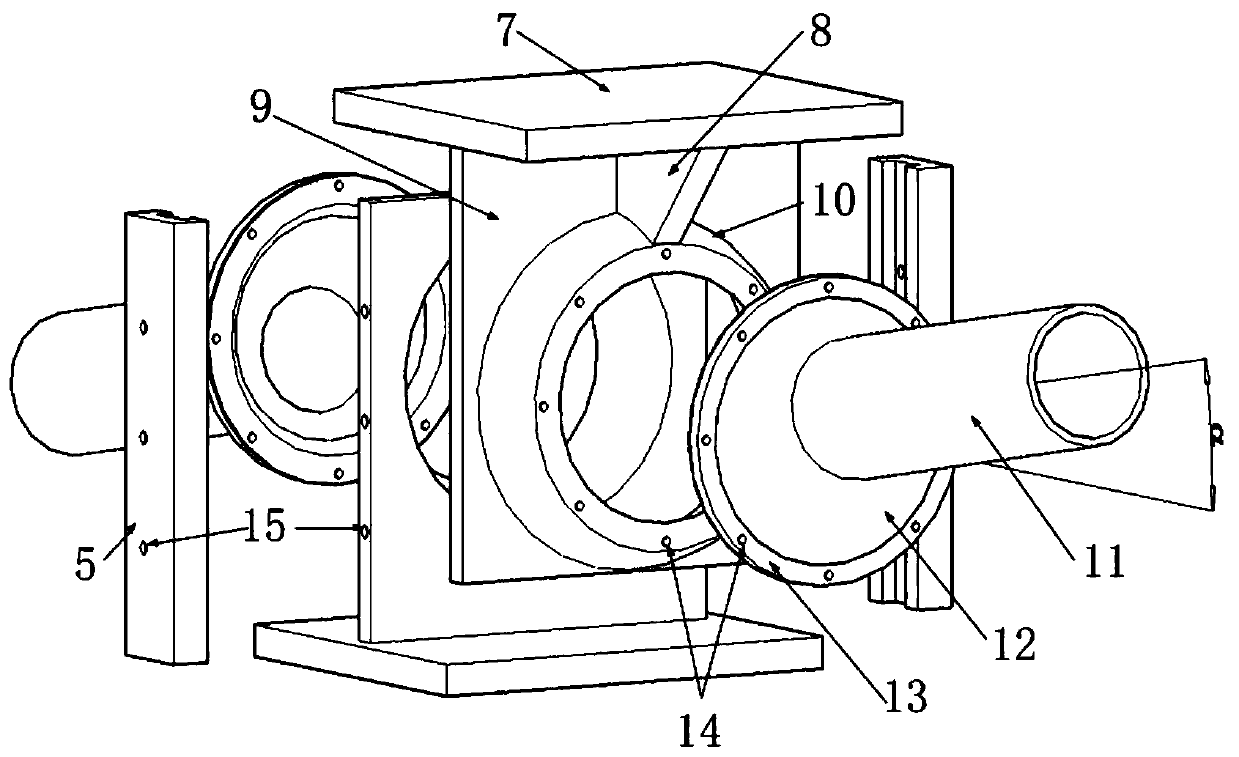

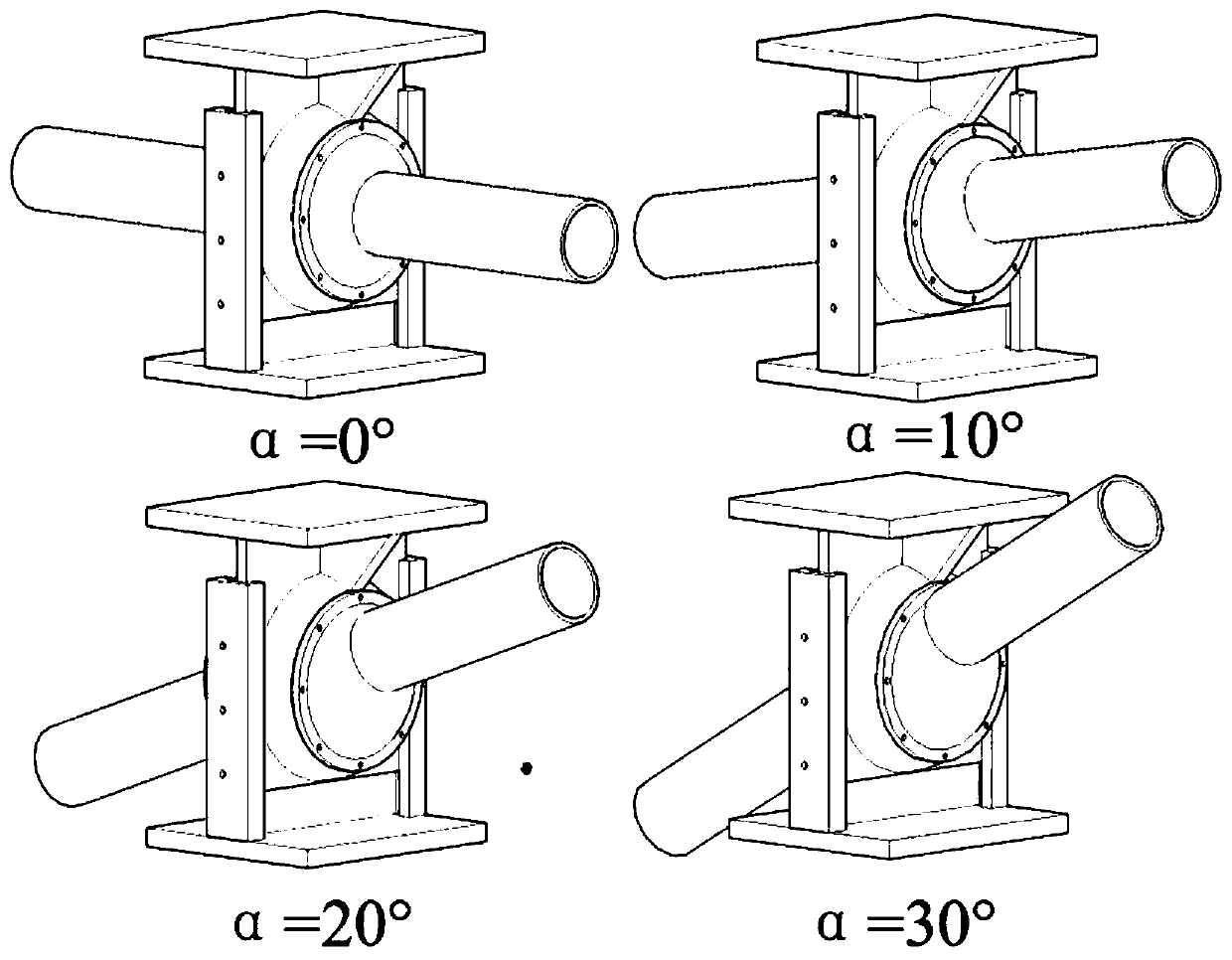

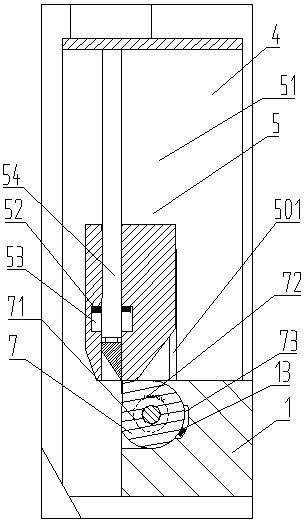

New ball-type single-shear experimental device for anchor rods and anchor cables

ActiveCN110530738AAvoid a destructive situationSimple structurePreparing sample for investigationMaterial strength using steady shearing forcesUniaxial compressionEngineering

The invention discloses a new ball-type single-shear experimental device for anchor rods and anchor cables, and the device comprises upper and lower shear devices, left and right fixed cylinders, front and rear fixed guide grooves, and samples, wherein the shear devices comprise a loading flat plate, a fixed support plate, a vertical guide rail plate and a hollow shear ball table; the fixed cylinders comprise a long hollow cylinder and a hollow ball table coupled with one side of the hollow shear ball table; the fixed guide grooves comprise a concave steel block with three bolt holes; the samples comprise a left and right symmetric long cylinder, a middle spherical protrusion, and anchor rods or anchor cables built in the centers of the long cylinder and the middle spherical protrusion. The new ball-type single-shear experimental device has a simple structure, is easy to operate and convenient to control variables by loading through a common uniaxial compression tester, can achieve theshearing at any space angle with the shearing surface, overcomes the defect that the traditional single-shear experiment for anchor rods cannot change the installation angle, and increases the sheararea at the same time, thereby not only adapting to the conditions of large shear displacement, but also considering the impact of the shear surface on shear engineering.

Owner:CENT SOUTH UNIV

Portable electric pincers

Owner:SUZHOU BAITAIKE MACHINERY

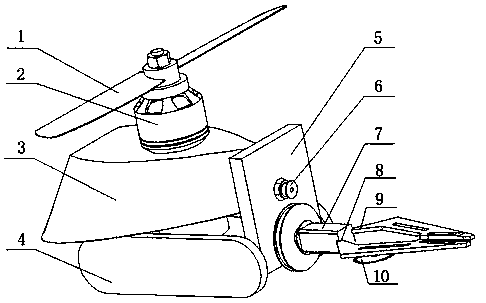

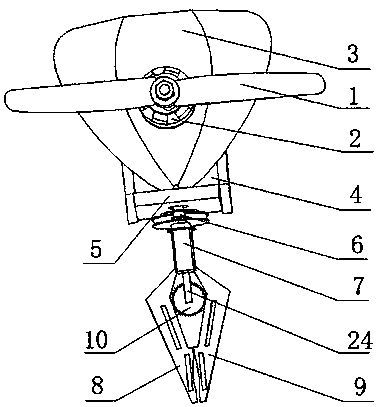

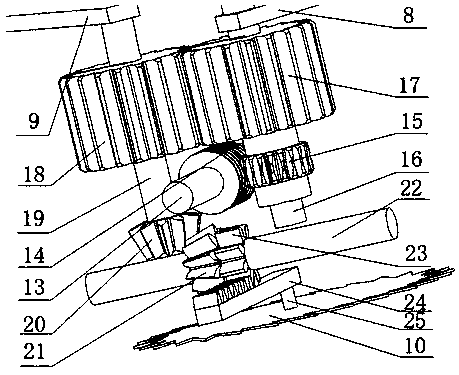

Small fruit picking unmanned aerial vehicle and operating method thereof

ActiveCN109436322AAccurate HarvestingReduce volumeAircraft componentsRemote controlled aircraftRemote controlEngineering

The invention belongs to the field of agricultural machinery and relates to a small fruit picking unmanned aerial vehicle and an operating method thereof. The small fruit picking unmanned aerial vehicle comprises an unmanned aerial vehicle system, a clamping mechanism, a cutting mechanism and a remote control system and is mainly applied to a fruit or nut picking process. The unmanned aerial vehicle is controlled to fly towards target fruits by operating personnel through a remote control, instructions transmitted by wireless signals are completed by the aid of a lithium battery serving as anenergy source, and accordingly fruit clamping and carpopodium cutting are performed to finish a harvesting process of fruits difficulty to pick in common ways. The small fruit picking unmanned aerialvehicle has advantages of small size, convenience in operation, synchronous implementation of clamping and cutting, clamping tightness adjustability, safety and reliability.

Owner:KUNMING UNIV OF SCI & TECH

Method for cutting and bending electronic elements in belt

The invention discloses a method for cutting and bending electronic elements in a belt. The method comprises the following steps of: A, loading: placing each single element in the electronic elements in a belt on cutter seats and bending seat which are arranged side by side by using a conveying mechanism; B, cutting: starting a cutter bending device in order that the cutter bending device moves downwardly to be in cooperation with the cutter seats and the bending seats, thereby cutting the single element in the electronic elements in the belt and bending the pins of the electronic element; and C collecting: collecting the bent electronic elements so as to complete a work process, and then repeating the above steps to complete next work process. The method for cutting and bending electronic elements in the belt is simple and good in using effect.

Owner:ZHONGSHAN ZHINIU ELECTRONICS

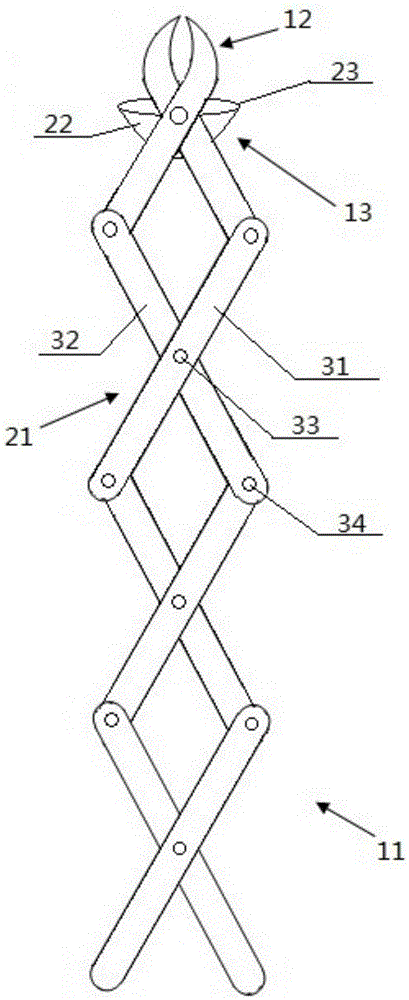

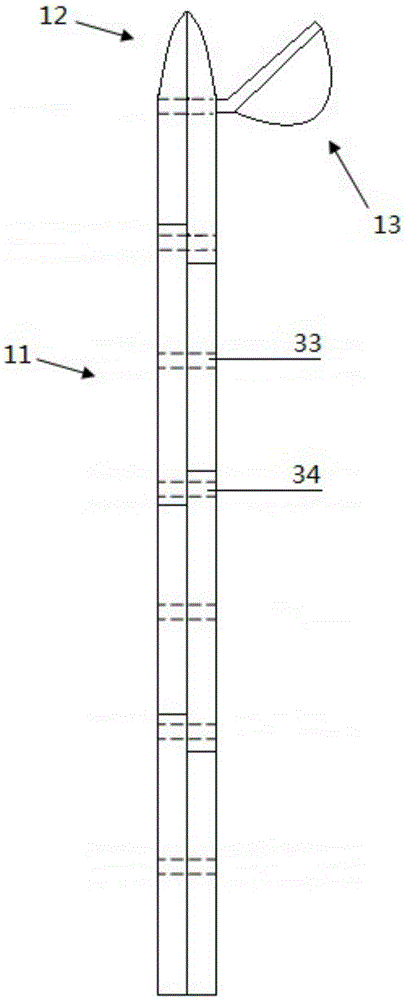

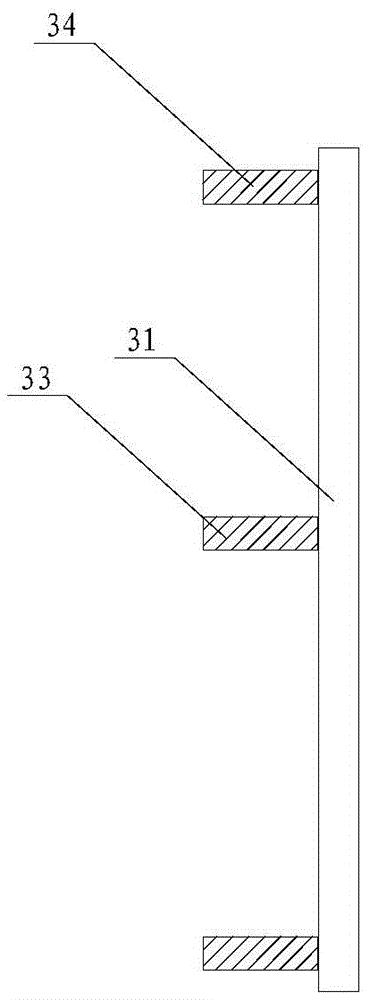

fruit picker

InactiveCN103782722BIncrease or decrease the number of sectionsAvoid falling directlyPicking devicesEngineeringShort arms

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Fabric cleaning device

ActiveCN108166189AAchieve cleaningAvoid deformationLiquid/gas/vapor removalFloats removalDrive shaftEngineering

The invention belongs to the technical field of washing and cleaning devices for fabrics, and specially discloses a fabric cleaning device. The fabric cleaning device includes a rack, and a conveyingbelt arranged on the rack; a horizontal cleaning roller is arranged above the conveying belt, and the cleaning roller is a hollow roller; the cleaning roller is fixedly connected to a drive shaft along a central axis; the drive shaft passes through the cleaning roller; one end of the drive shaft is fixedly connected to a motor; the motor is fixed on the rack; and a cleaning portion, a cutting portion for cutting hair bulbs on the surface of the knitted fabric, a hair bulb collection portion, and a supporting portion are arranged on the cleaning roller. The invention can solve the problem thathigh-speed rotation will result in deformation of the knitted fabric and the hair bulbs on the surface of the knitted fabric are difficult to remove while the knitted fabric is cleaned by using the prior art.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Cutting blind plate on-line pressurized plugging device and plugging method for small-pipe-diameter high-pressure pipeline

The invention discloses an online pressurized plugging device and a plugging method for a shearing blind plate of a small-diameter high-pressure pipeline. Blocking box, upper flange, lower flange, bottom box, thrust bolts, grease injection bolts, reinforcement rings, upper top cover, lower bottom cover, etc. The cutter is installed on the front end of the plugging blind plate, and the plugging blind plate is installed on the piston rod of the shearing plugging hydraulic cylinder. Start the hydraulic cylinder, push the plugging blind plate and the cutter to move downward in the shearing and sealing box, the cutter cuts the pipe, and the thrust bolt on the downstream side of the shearing and sealing box pushes the sealing blind to move axially and tighten Closely fit the sealing end face of the shearing and sealing box to achieve metal-to-metal sealing. The sealing grease is injected from the grease injection bolt on the upstream side of the shearing and sealing box to the sealing surface for secondary auxiliary sealing. On-line pressurized plugging of small-diameter pipelines is realized.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Device used for lithium battery electrode tab shearing

ActiveCN107717464AIncrease speedImprove accuracyOther manufacturing equipments/toolsCell component detailsElectrical batteryEngineering

The invention discloses a device used for lithium battery electrode tab shearing. The device is characterized by comprising a rack, a feeding table used for containing a lithium battery, a battery compression mechanism used for compressing a lithium battery body and an electrode tab shearing mechanism used for smoothening and shearing an electrode tab; the electrode tab shearing mechanism comprises an installing rod, an installing block and a pushing rod, a driving wheel is arranged at the bottom of the installing rod, a hook block is fixed to the installing block, and a hook table is formed on the side wall of the hook block; a set of cutters are arranged on the upper end face of the pushing rod, an installing column is fixed to the lower end of the pushing rod, a roller and a pulling rodare arranged on the installing column rotationally, a hook part is formed at the upper end of the pulling rod, the outer end of the hook part is in contact with the side wall of the hook table, a torsional spring is arranged between the pulling rod and the outer end of the installing column, and a protrusion part is formed on the outer wall of the driving wheel; and an arc-shaped installing holeis formed in the side face of the driving wheel, a pulling plate is arranged in the installing hole, and a pulling column is arranged at the outer end of the pulling plate.

Owner:东莞致宏精密模具有限公司

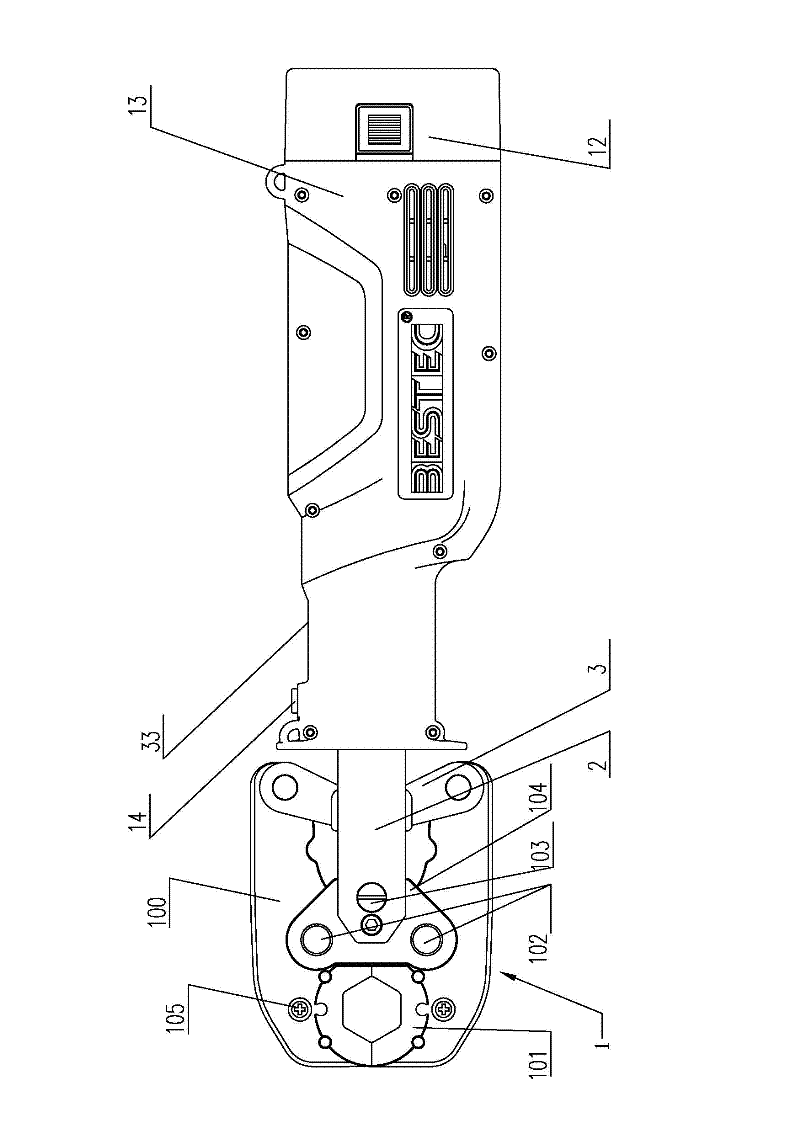

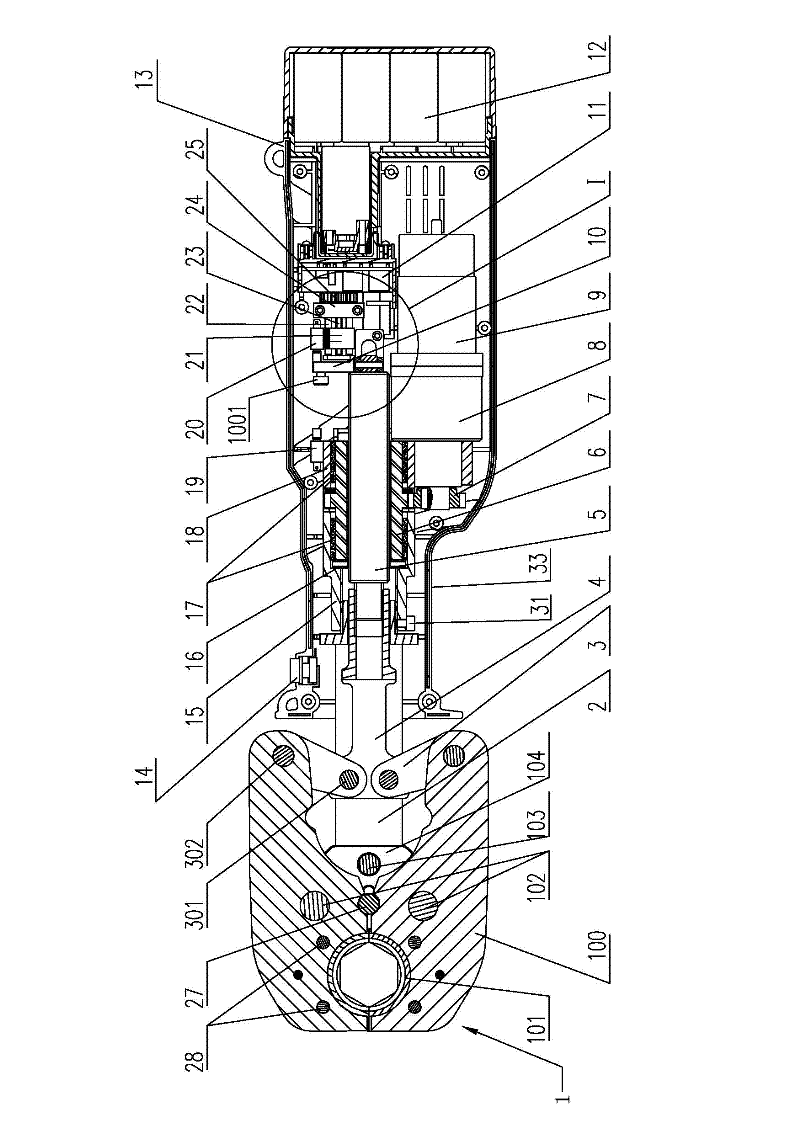

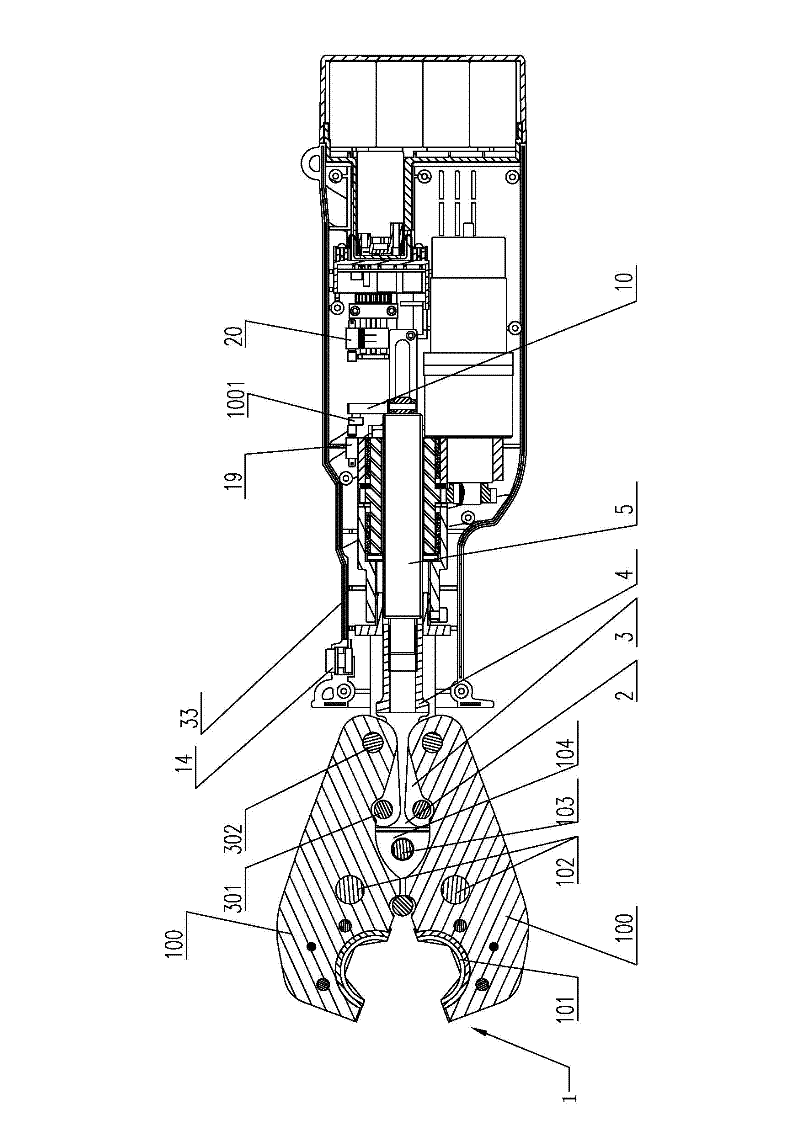

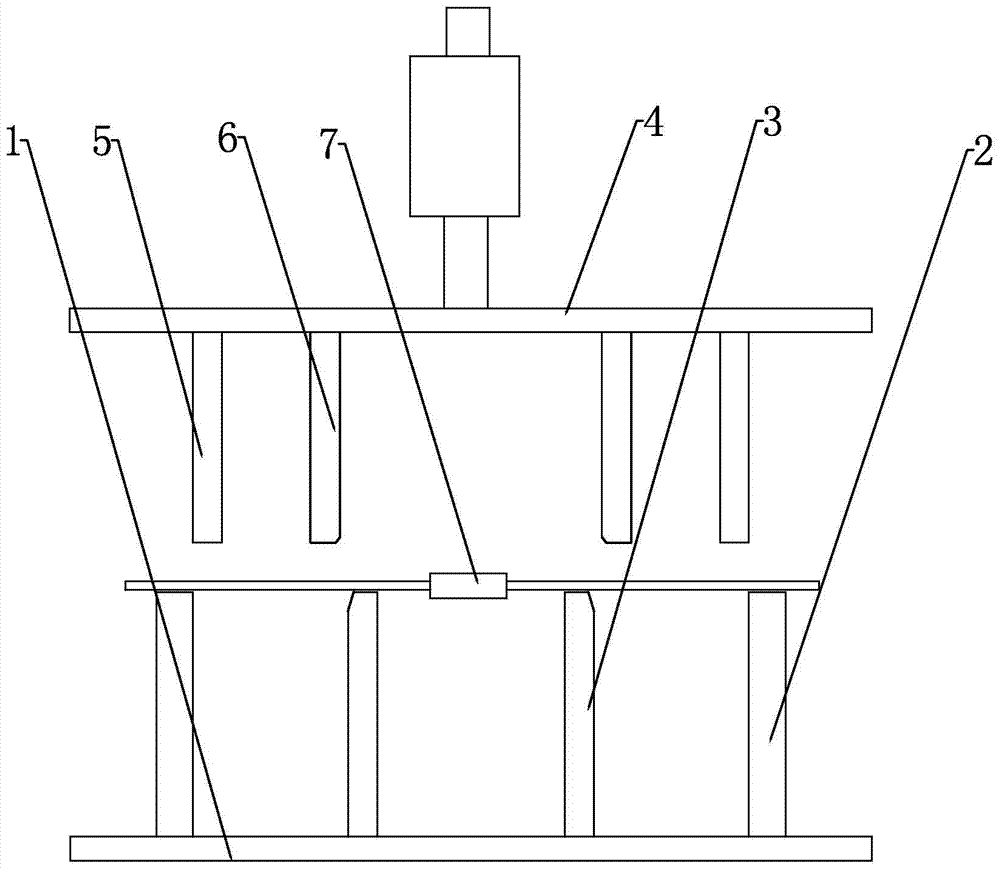

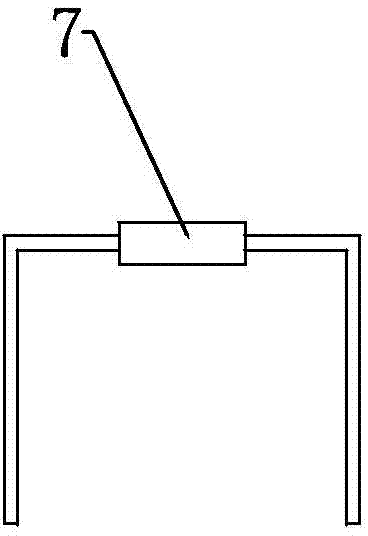

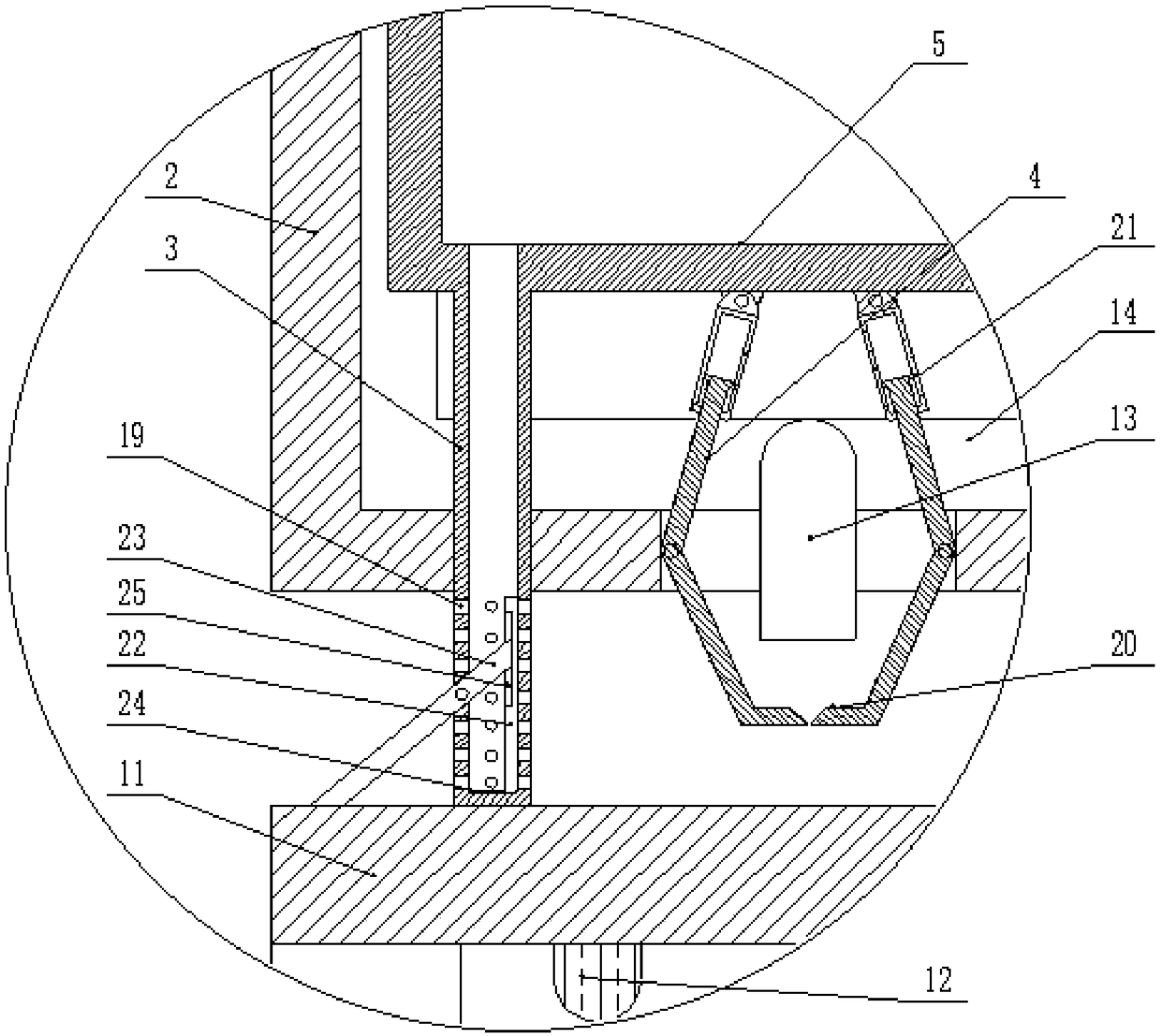

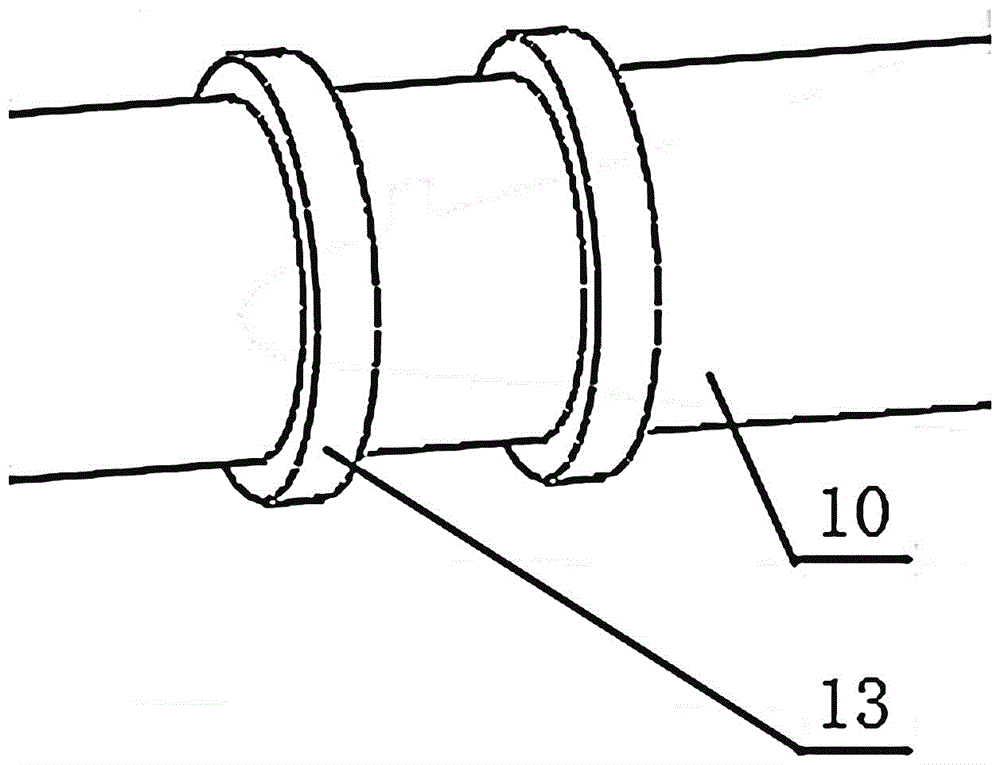

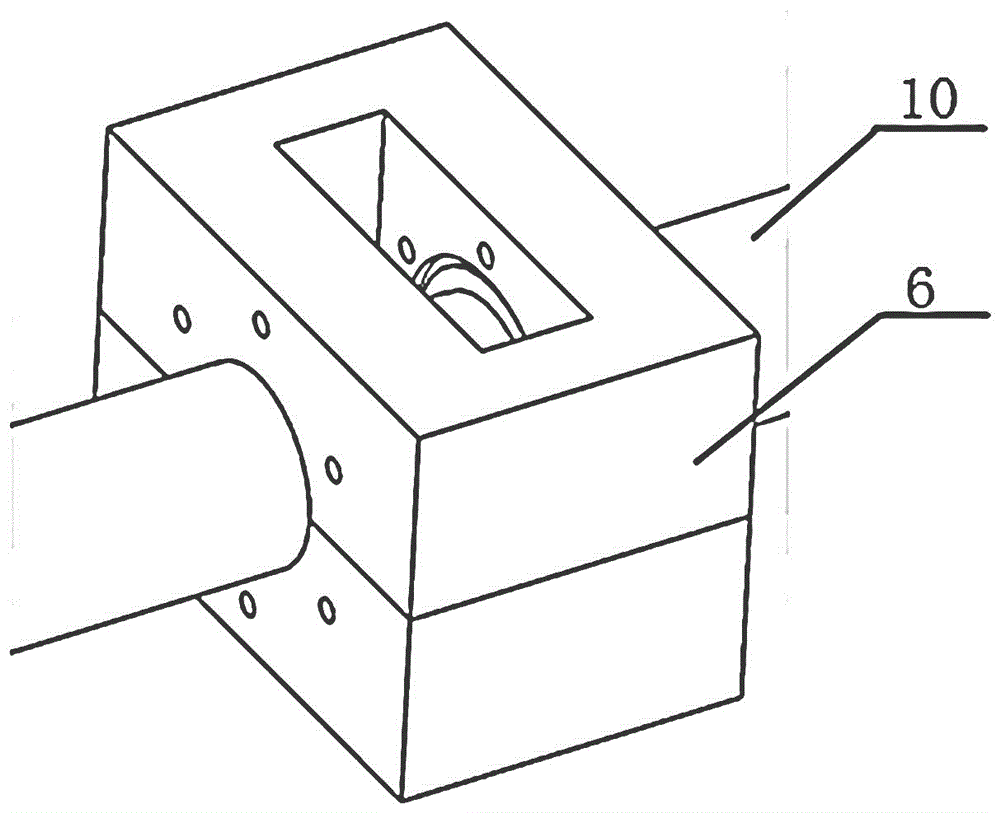

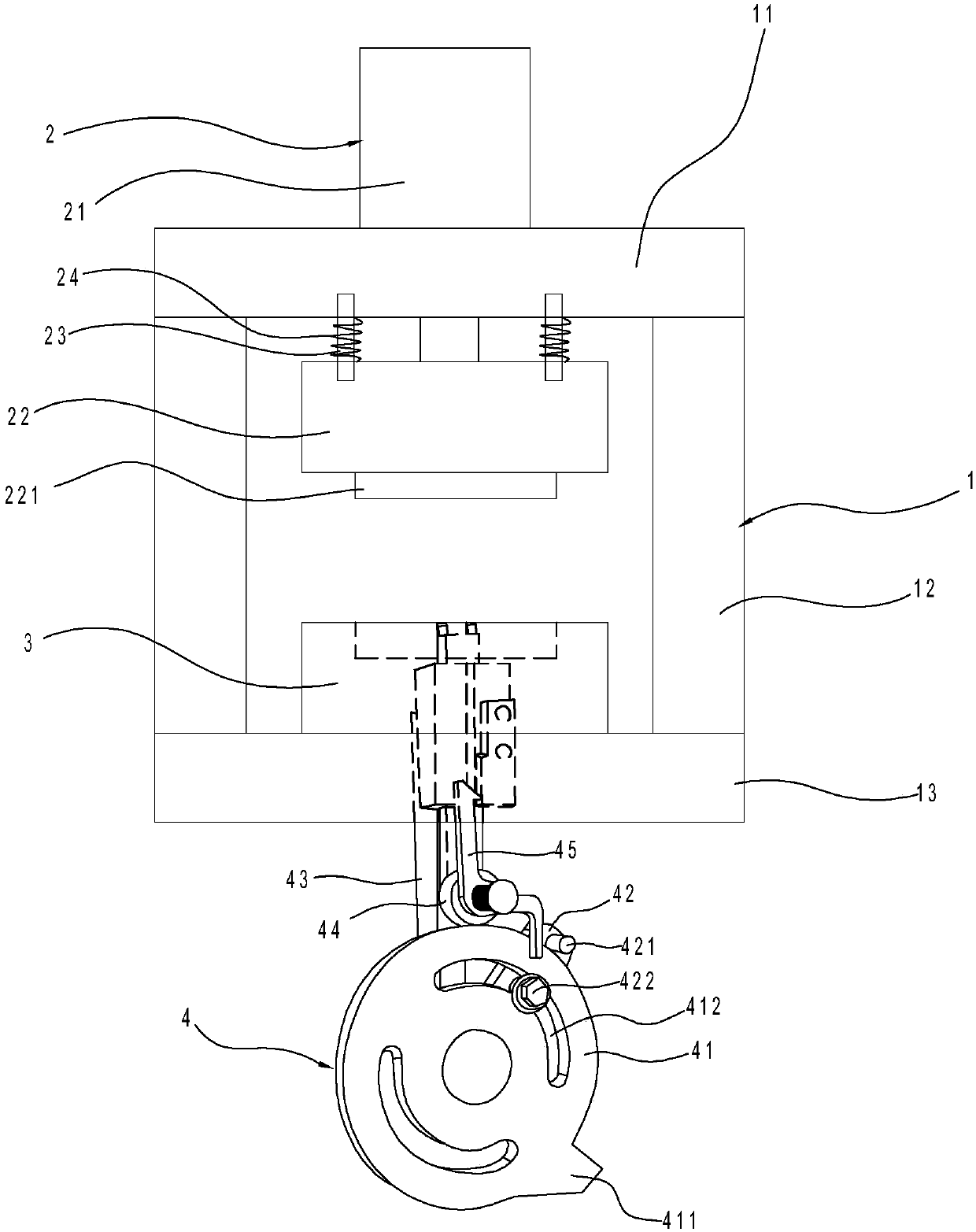

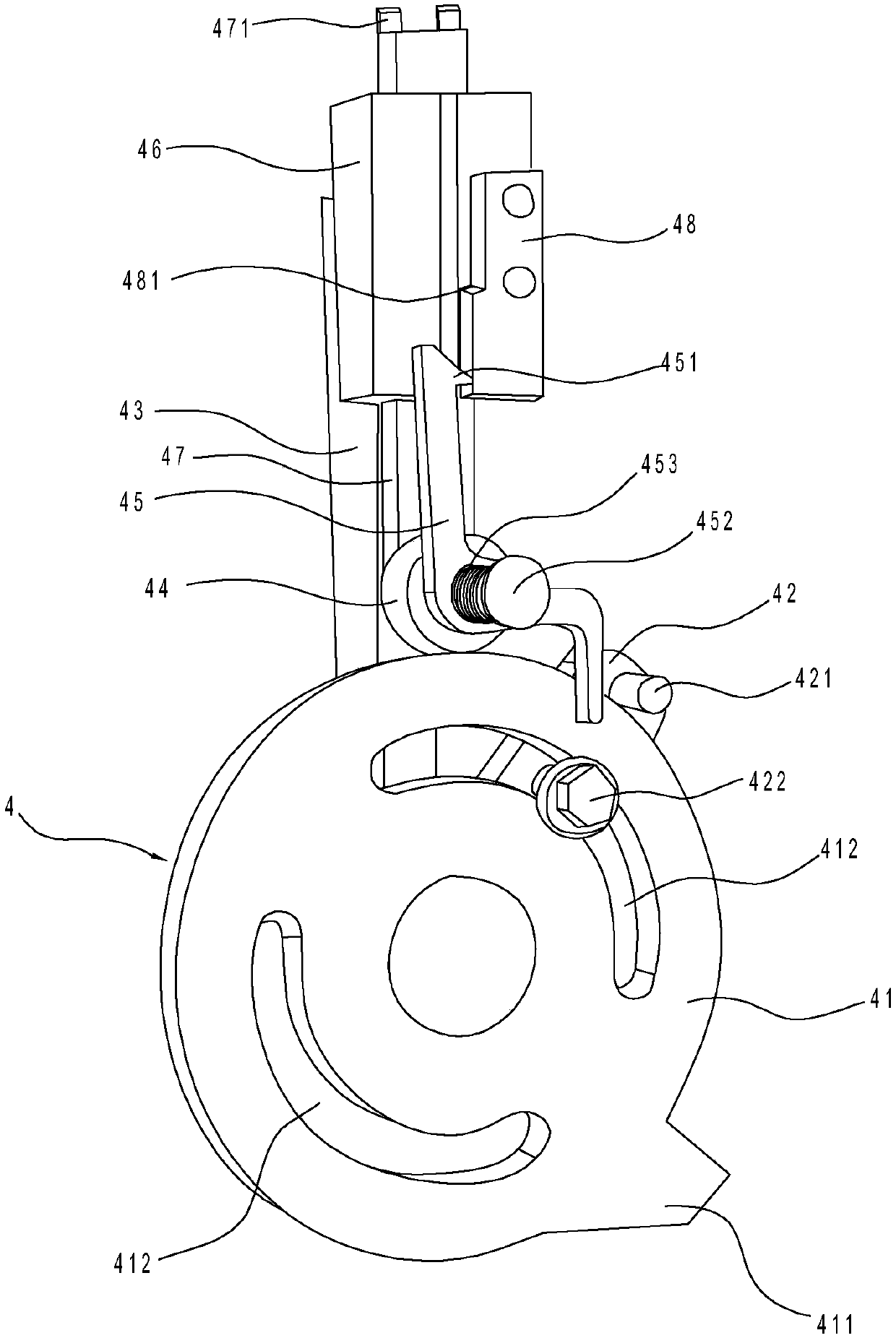

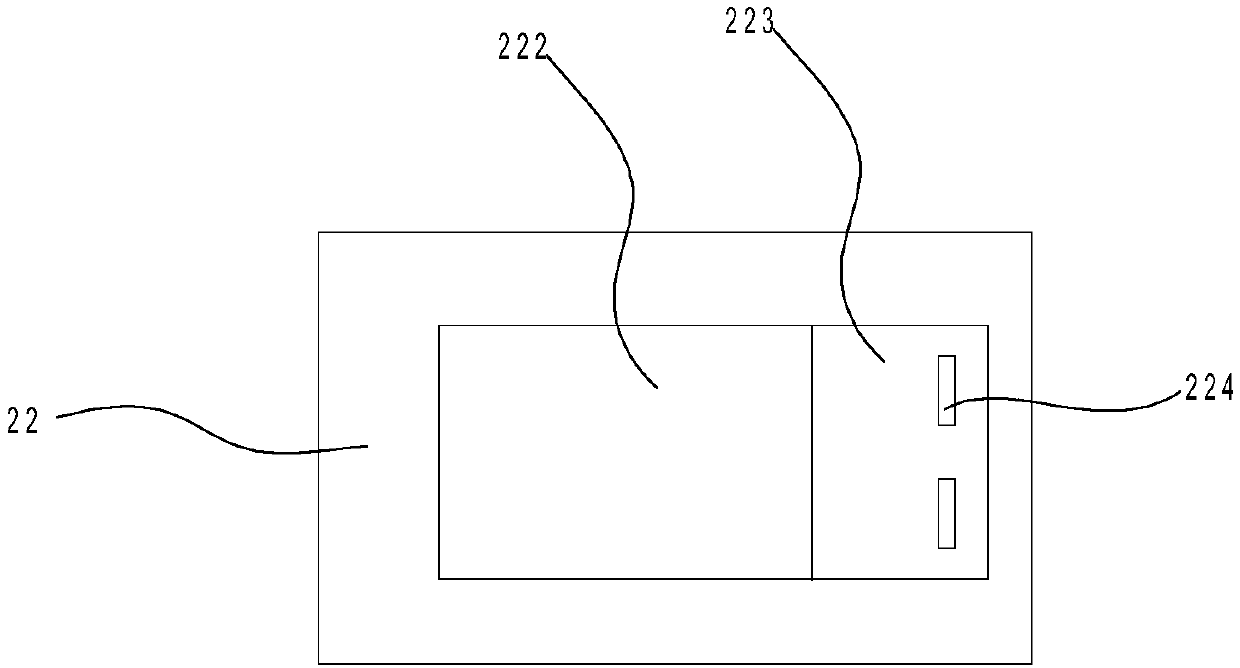

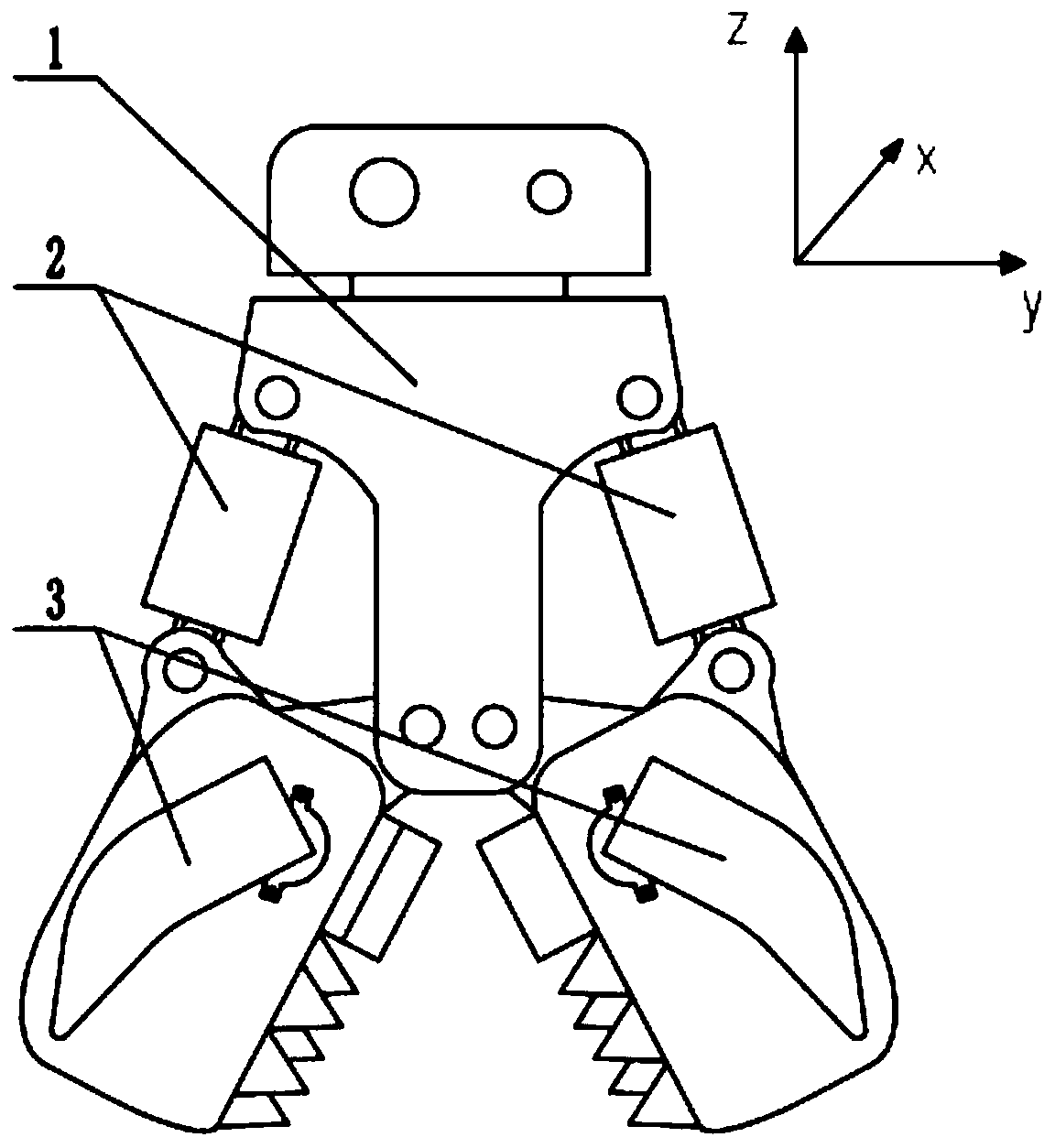

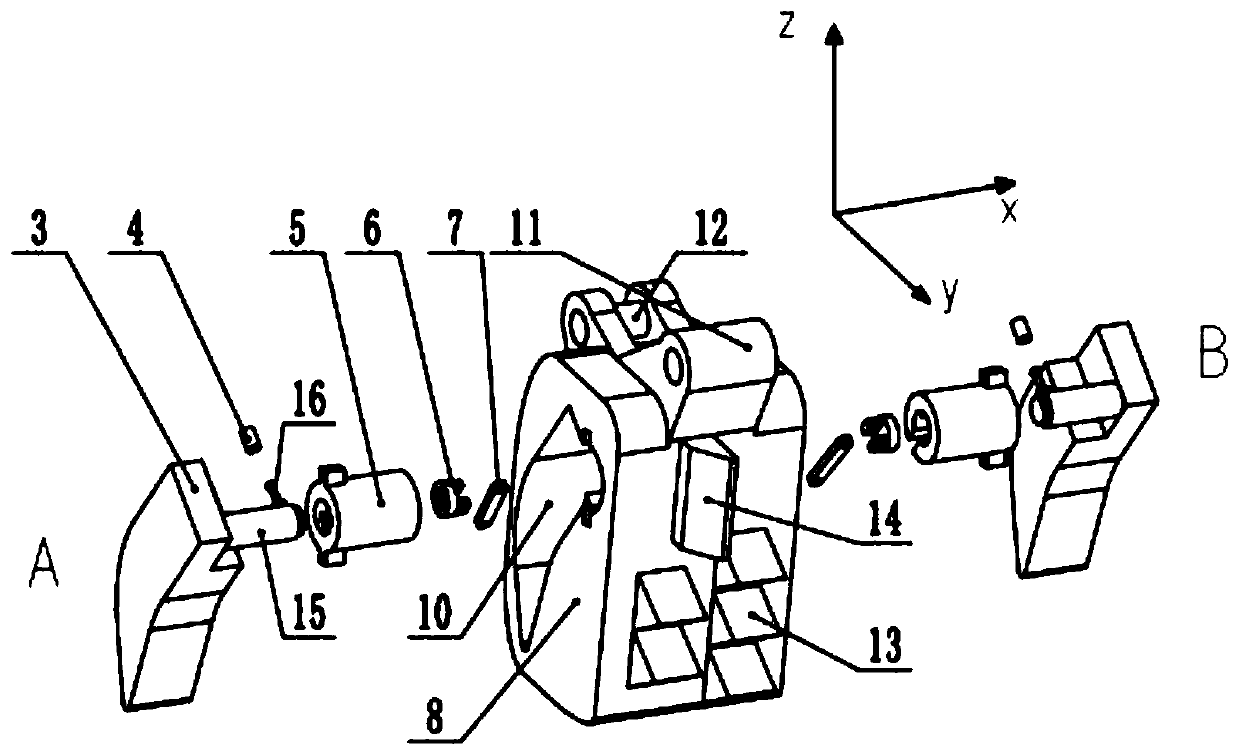

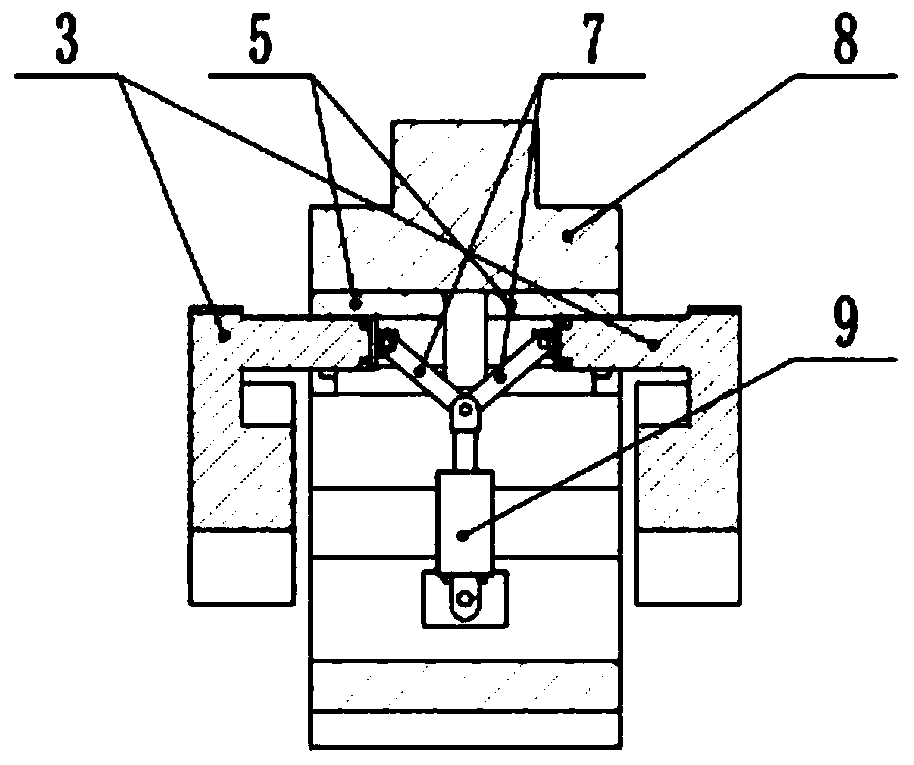

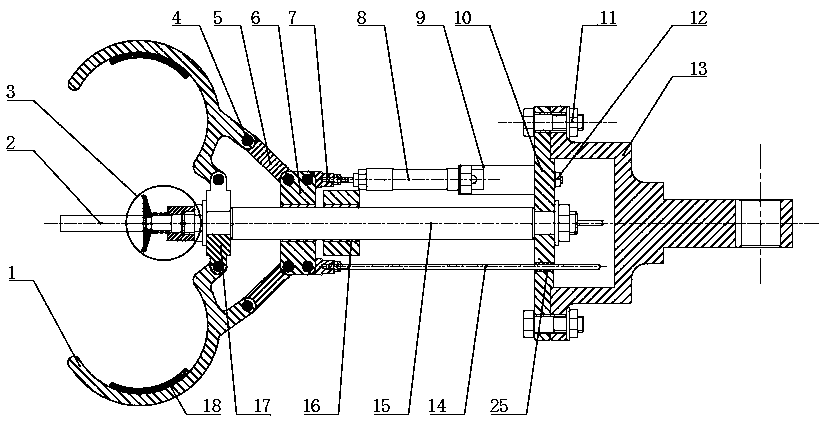

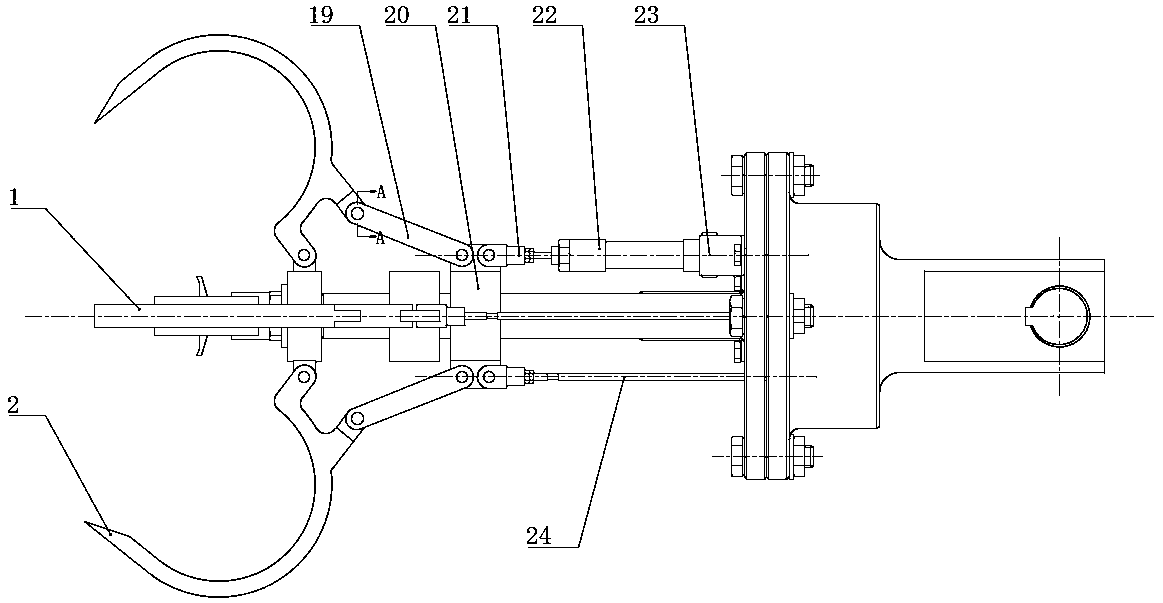

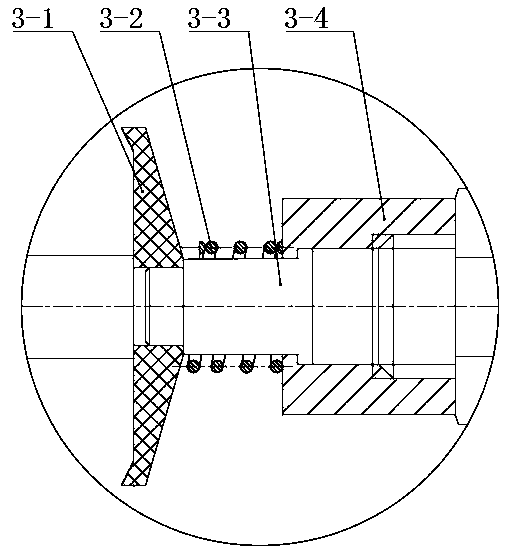

Half-hidden movable holding claw hydraulic tongs based on spatial four-bar mechanism

ActiveCN111515998ASimple structureHighly integratedGripping headsGrain treatmentsHydraulic cylinderStructural engineering

The invention discloses a pair of half-hidden movable holding claw hydraulic tongs based on a spatial four-bar mechanism, and belongs to the field of multifunctional engineering accessories. The pairof half-hidden movable holding claw hydraulic tongs based on the spatial four-bar mechanism comprises a machine frame (1), two working hydraulic cylinders (2), four holding claws (3), four locating guide sleeves (4), four cylindrical cams (5), four movement conversion sliding blocks (6), four functional connecting rods (7), two tongs shear bases (8) and two functional hydraulic cylinders (9). Thepair of half-hidden movable holding claw hydraulic tongs based on the spatial four-bar mechanism is high in integration level and simple in structure, the purpose that the breaking function, the shearing function and the holding claw function are fulfilled in the mode that only one engineering accessory is adopted is achieved, and a labor-saving structure of an existing pair of hydraulic breakingtongs is reserved; and the conversion of a tongs shear device and a holding claw device can be rapidly accomplished by the spatial four-bar mechanism, the working requirements are met in the various working states, and the movement interference does not happen.

Owner:BEIJING UNIV OF TECH

Plate shearing machine

The invention discloses a plate shearing machine. The machine comprises a supporting base and a baffle seat away from the supporting base; a baffle mechanism is arranged on the baffle seat, a discharging groove is formed between the supporting base and the baffle seat, a portal frame is arranged at one end of the supporting base, a upper tool capable of ascending and descending in a manner of being perpendicular to the surface of the supporting base is arranged in the portal frame, a lower tool is arranged below the upper tool in a matched manner, an elastic clamping plate used for pressing aboard is arranged on the side, away from the baffle seat, of the portal frame, the lower tool is rotatably arranged on the supporting base, a rotating shaft is arranged in the lower tool in a penetrating manner, rotating wheels are arranged on the two ends of the rotating shaft, transmission teeth are arranged on the rotating wheels, and racks matched with the transmission teeth of the rotating wheels are arranged on the two sides of the upper tool. The plate shearing machine effectively prevents the board from being scratched, part quality is improved, and safety property is high.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

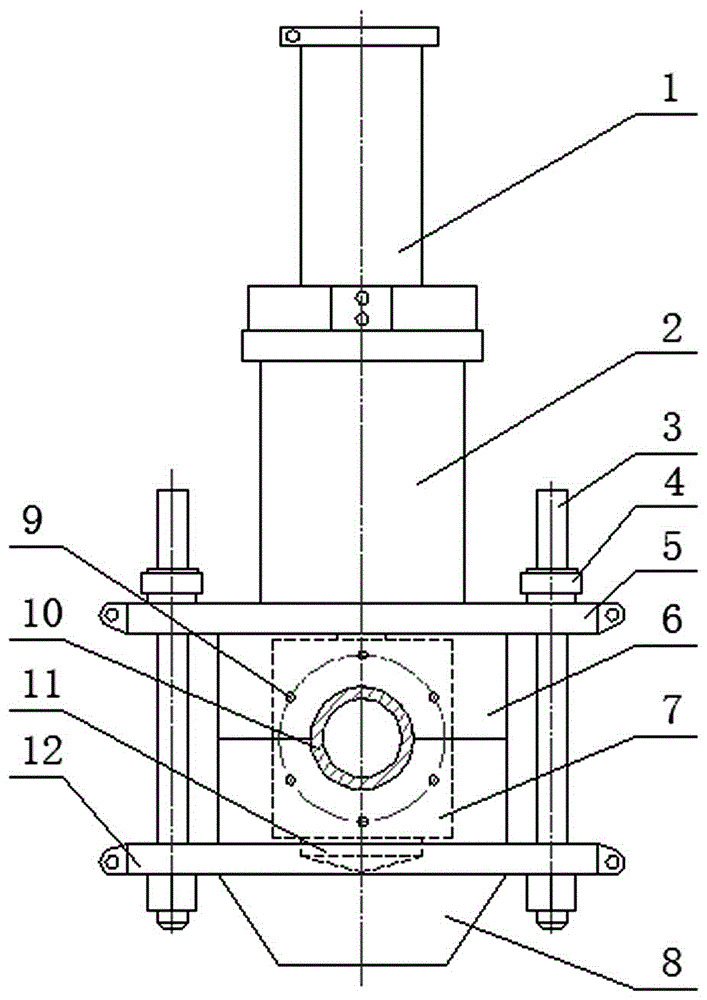

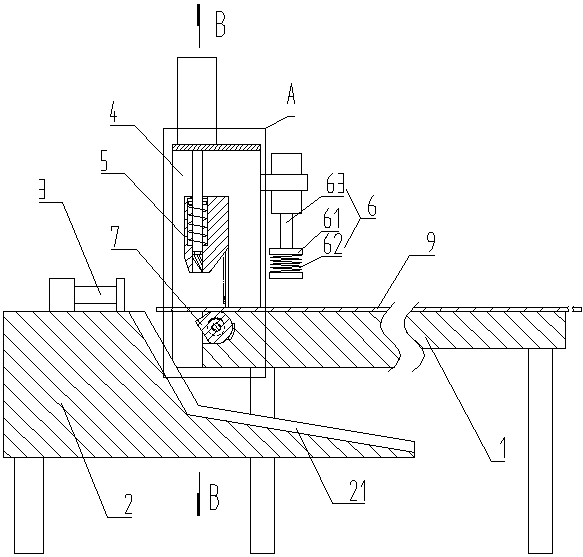

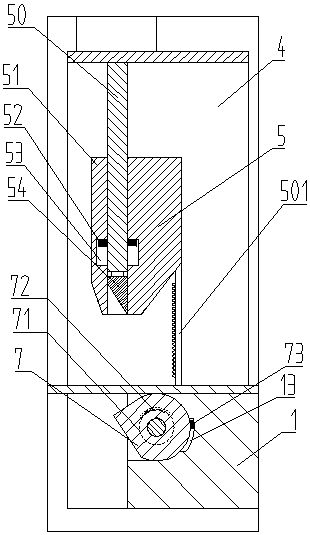

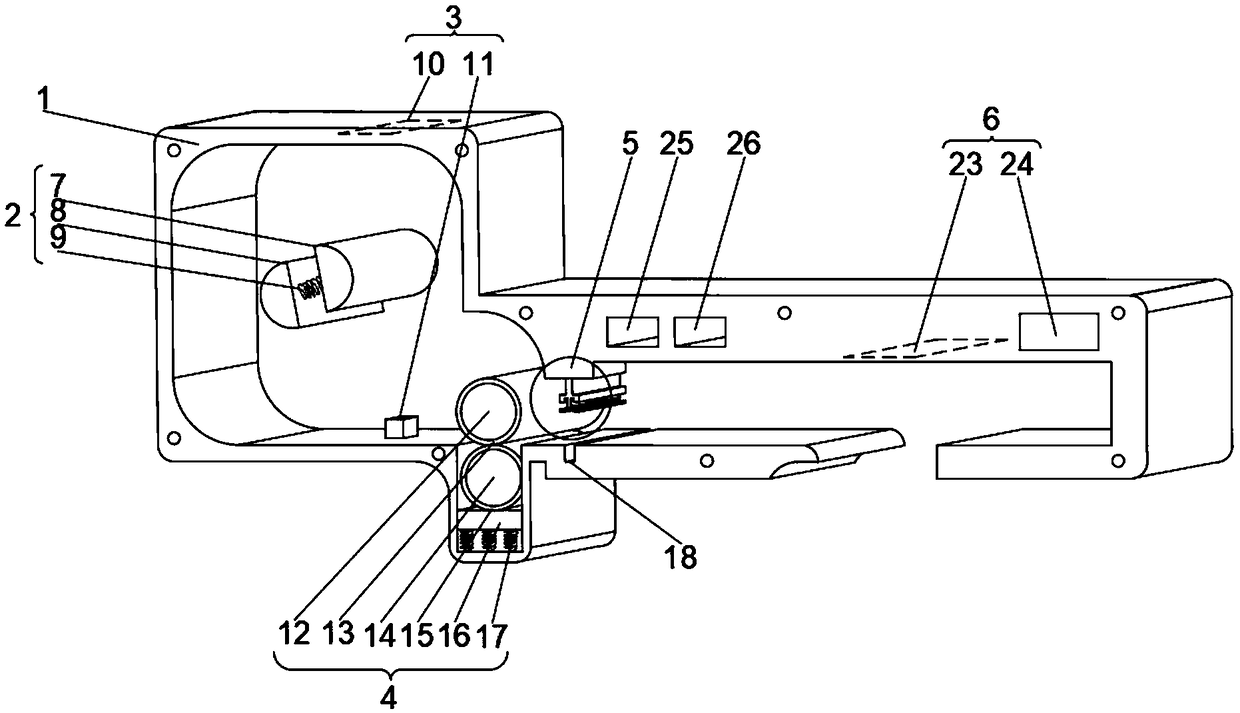

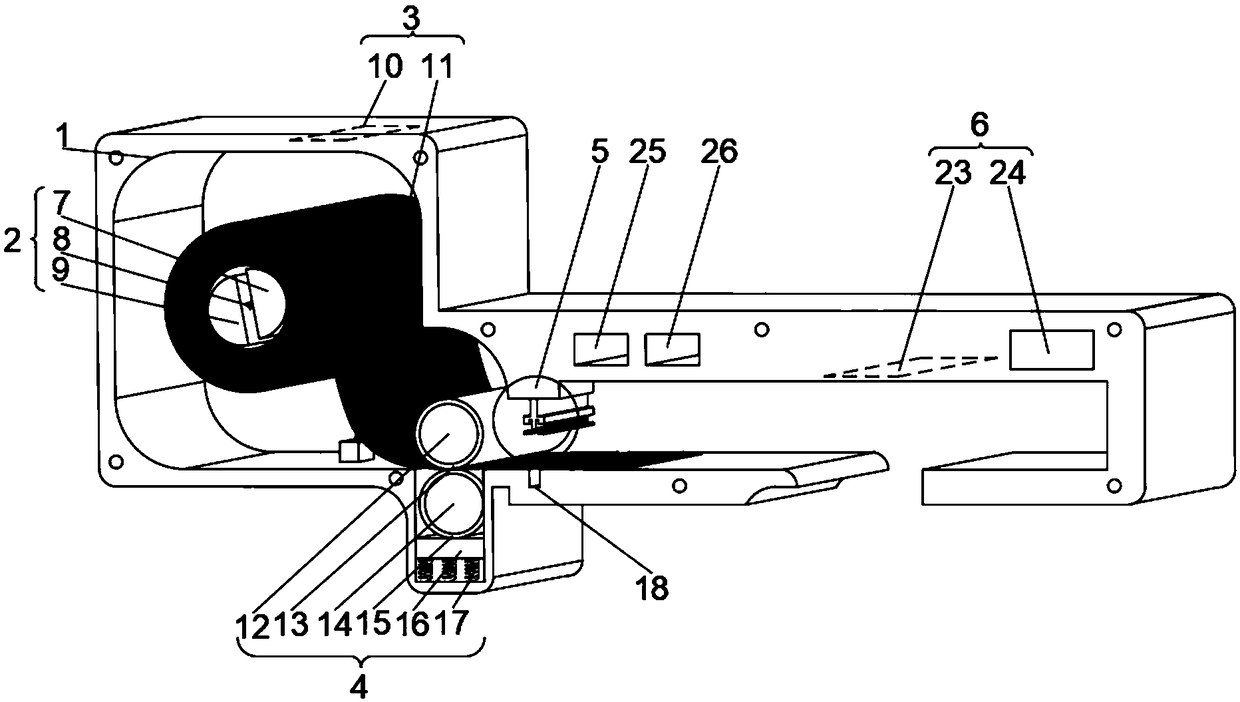

Multifunctional rock mechanical property tester

ActiveCN107121331AAchieve cutAchieve stretchClimate change adaptationStrength propertiesClassical mechanicsTester device

The invention discloses a multifunctional rock mechanical property tester. The tester comprises a base, a vertical beam and a suspension arm, wherein a conveying platform and a test rotation table are arranged on the base in the direction towards the vertical beam in sequence, the vertical beam is fixed at one end of the base, a vertical sliding rail is arranged at the center, and the suspension arm is arranged in the position, opposite to the test rotation table on the base, of the top of the vertical beam; a left cutting device is connected to the vertical sliding rail through a locking device; a right cutting device is arranged in the position, opposite to a rock specimen, of the base; the suspension arm comprises a vertical power source and an upper vertical telescopic shaft; a detachable hook is further arranged at the bottom of the upper vertical telescopic shaft, so that stretching of the rock specimen is achieved; the bottom of the test rotation table is supported by a jack structure. The rock mechanical property tester has longer service life, and can realize functions of uniaxial and biaxial compression and stretching as well as cutting.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Automatic light sensing paper extraction machine

InactiveCN108742261AWide applicabilityImprove service qualityDomestic applicationsPaper sheetLight sensing

The invention discloses an automatic light sensing paper extraction machine and belongs to the technical field of automatic machinery. The machine comprises a paper storage mechanism, a detection mechanism, a paper rolling mechanism, a shearing mechanism and a light sensing area, wherein the paper storage mechanism comprises two semi-cylindrical rollers and a first spring; the detection mechanismcomprises a first light sensing unit and a light emitter; the paper rolling mechanism comprises two cylindrical rollers, a lifting module and a second spring; and the shearing mechanism comprises a blade, a push rod, pressure plates and third springs. The machine aims at achieving automatic paper extraction; the light sensing area is shielded during the paper extraction; the paper rolling mechanism begins to operate; when required length is reached, hands are pulled out of the light sensing area; the shearing mechanism performs shearing; and the machine further can detect if rolling paper is used up to facilitate timely replacement. The device achieves the automatic paper extraction, avoids the problem of absorption of bacteria by a residual part exposed to air since the rolling paper is pulled out excessively, and has the advantages of simple structure, quickness, convenience and the like.

Owner:JIANGSU UNIV

Apple picking robot hand structure

The invention provides an apple picking robot hand structure. The structure comprises a supporting flange and a supporting rod, the supporting flange is connected with the supporting rod, the supporting rod is connected with a fixing ring, the fixing ring is provided with movable grasping fingers and cutting fingers, the grasping fingers are movably connected with a telescopic mechanism I, and thecutting fingers are movably connected with the telescopic mechanism II. The structure has the advantages that a grasping mechanism and a cutting mechanism are included, and the cutting of fruits canbe achieved while the grasping is completed; the grasping mechanism and the cutting mechanism are independent of each other, and independent air cylinders are respectively used for driving to avoid mutual influence of the grasping mechanism and the cutting mechanism, which is beneficial to the dragging of the fruits; the structure includes adaptive assemblies, and improves the adaptability of a manipulator to the size of the fruits.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

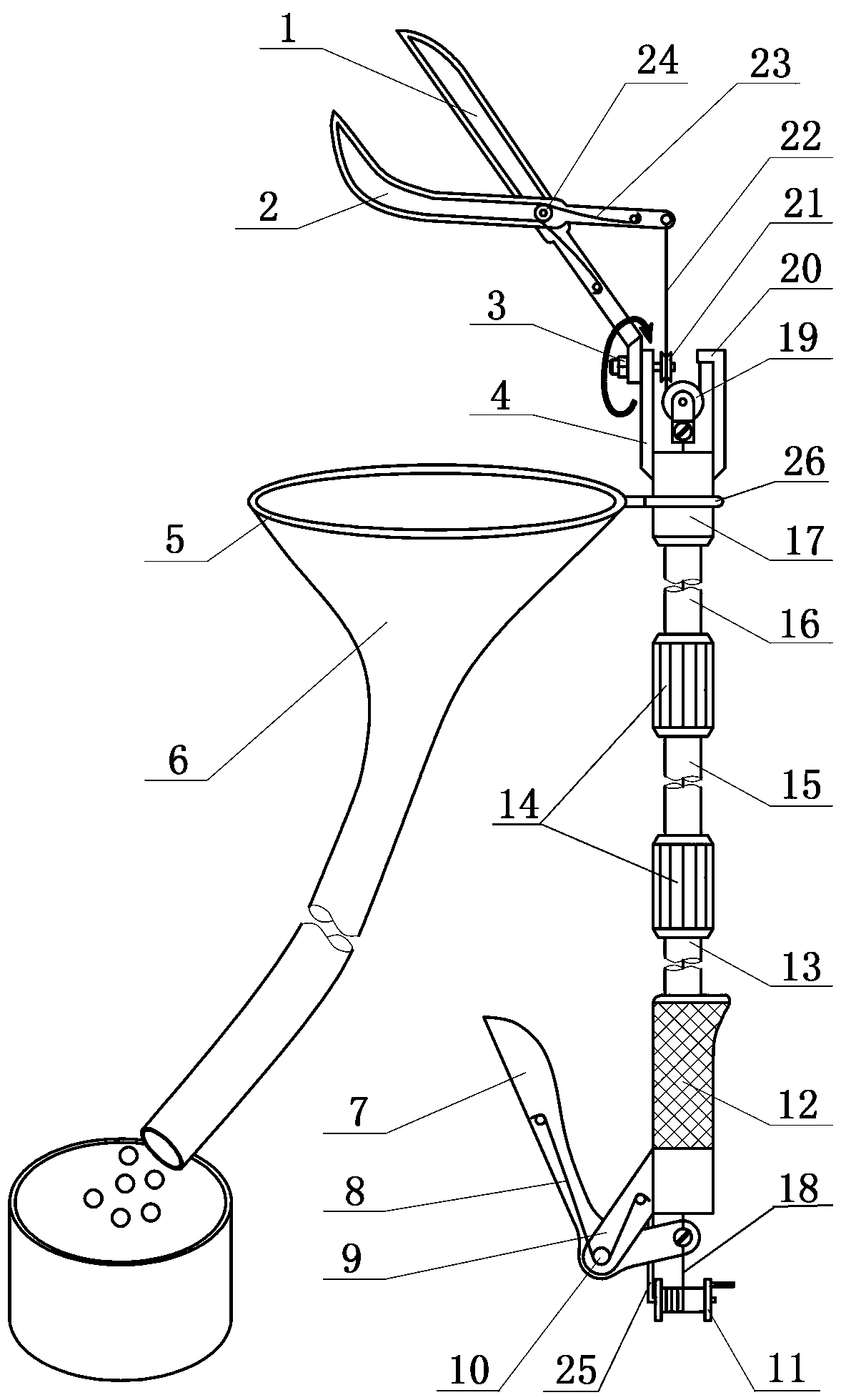

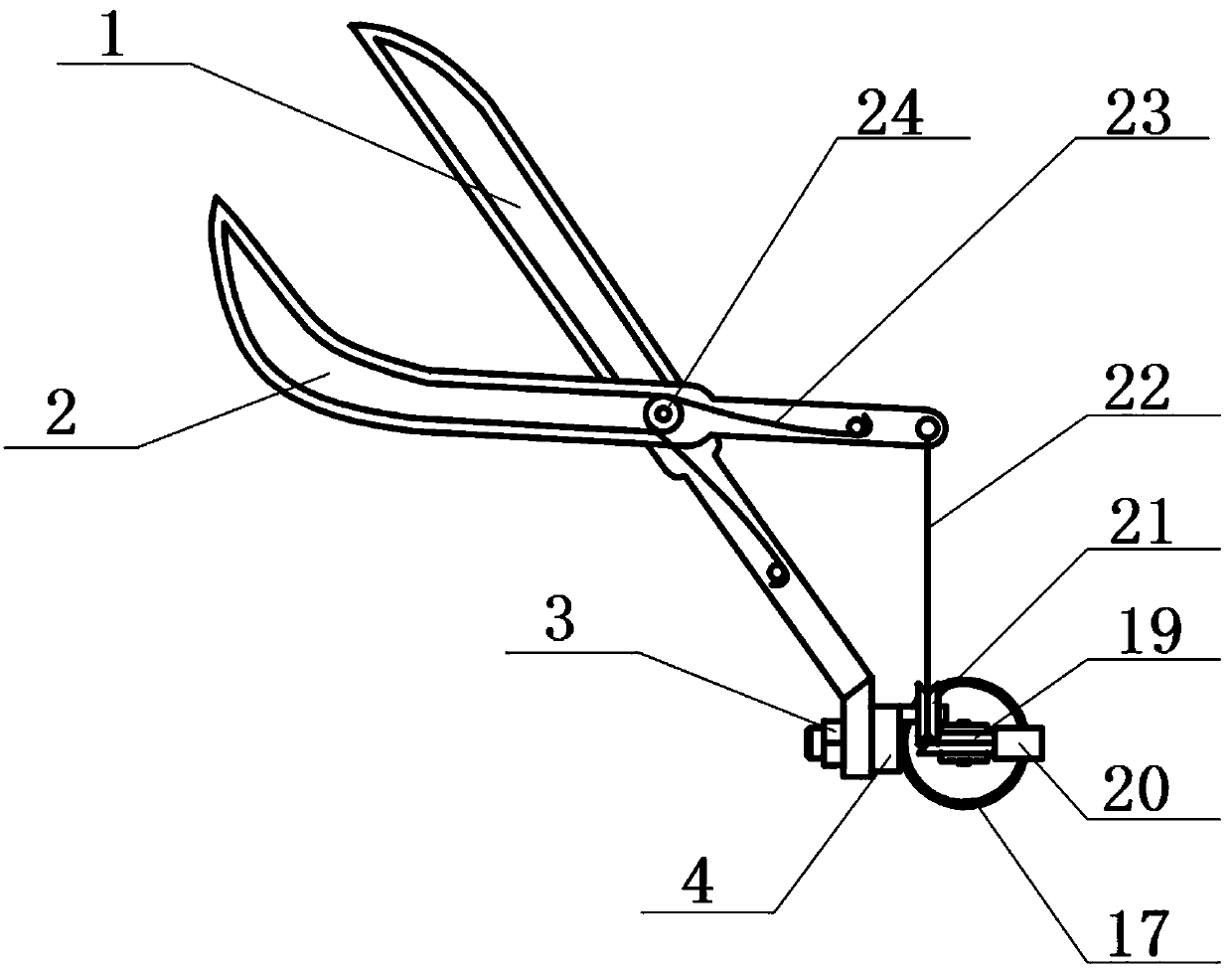

Tree seed collecting machine with adjustable shear plane and using method of tree seed collecting machine

PendingCN109804780AAdapt to the requirements of harvesting characteristicsAdapt to working height requirementsPicking devicesForest industryPull force

The invention discloses a tree seed collecting machine with adjustable shear plane and a using method of the tree seed collecting machine. The tree seed collecting machine with the adjustable shear plane comprises a cutting mechanism, a lever pulling mechanism, a rod body and a film funnel collecting machine; the cutting mechanism mainly comprises a rod head, a movable block, a first-level pullingrope, a second-level pulling rope, a main blade, a deputy blade, a pin roll II, and a direction guiding sliding wheel; the lever pulling mechanism mainly comprises a holding handle, an L-shaped trigger, and a supporting arm; the supporting arm is fixedly installed on one side of the holding handle, and a pin roll I is arranged at the front end of the supporting arm. According to the tree seed collecting machine with the adjustable shear plane and the using method of the tree seed collecting machine, a difficult problem that a special tree seed collecting tool lacks in the forestry seedling production is solved, a simple, light, convenient, safe, efficient and practical forest seed collecting machine is provided for the forestry tree seed collecting production, the labor intensity of workers is reduced, safety and the working efficiency are improved, and the forestry seedling production is better serviced.

Owner:中国林业科学研究院热带林业实验中心

Jean fabric packing machine

ActiveCN104554887ARealize edge bandingImprove edge banding efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringEdge banding

The invention provides a jean fabric packing machine, belongs to the technical field of mechanisms, and aims at solving the problem that the coiled jean fabric cannot be quickly packed in the prior art. The jean fabric packing machine comprises a rack; a feeding opening and a discharging opening are formed in the rack; a first conveyor belt is arranged between the feeding opening and the sidewall of the rack; a second conveyor belt is arranged between the discharging opening and the other sidewall of the rack. The jean fabric packing machine is characterized in that an upper mounting plate and a lower mounting plate which are arranged in parallel are fixed on the rack; a film uncoiling roller is arranged on the upper surface of the upper mounting plate; an upper through hole and a lower through hole through which a film passes are respectively formed in the upper mounting plate and the lower mounting plate; a side thermal sealing mechanism and an end thermal sealing mechanism are arranged between the upper mounting plate and the lower mounting plate; a slitting mechanism is arranged on the lower surface of the lower mounting plate; an automatic blanking mechanism is arranged on the upper surface of the lower mounting plate. The jean fabric packing machine has the advantage that the side sealing side and the end sealing side of the coiled jean fabric can be quickly packed.

Owner:HAINING DENIM WEAVING CO LTD

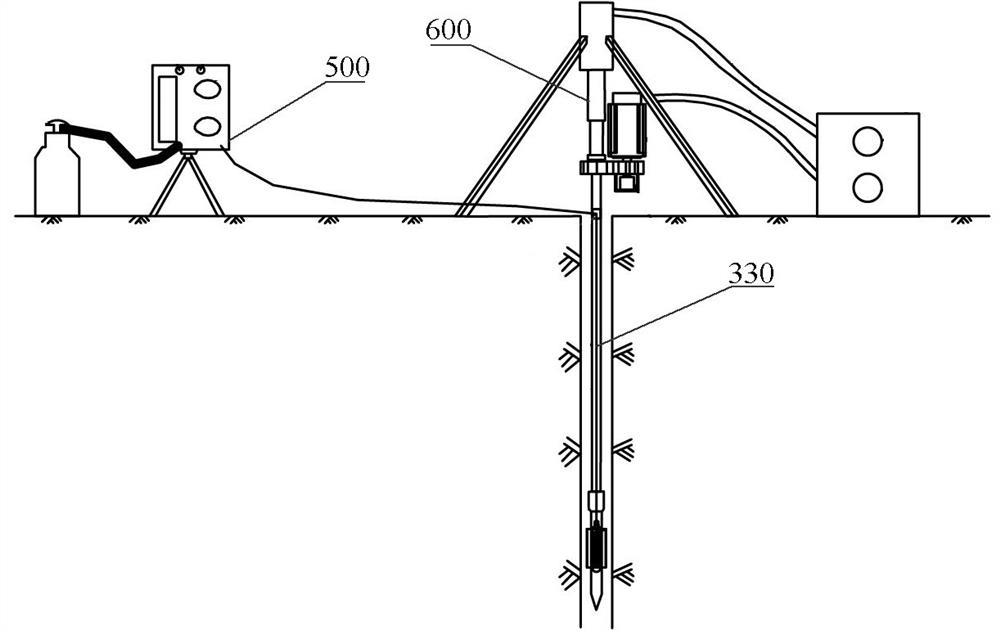

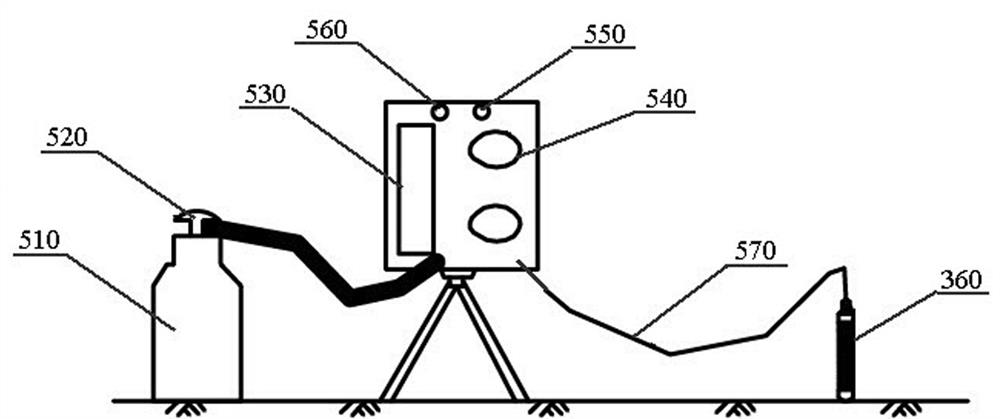

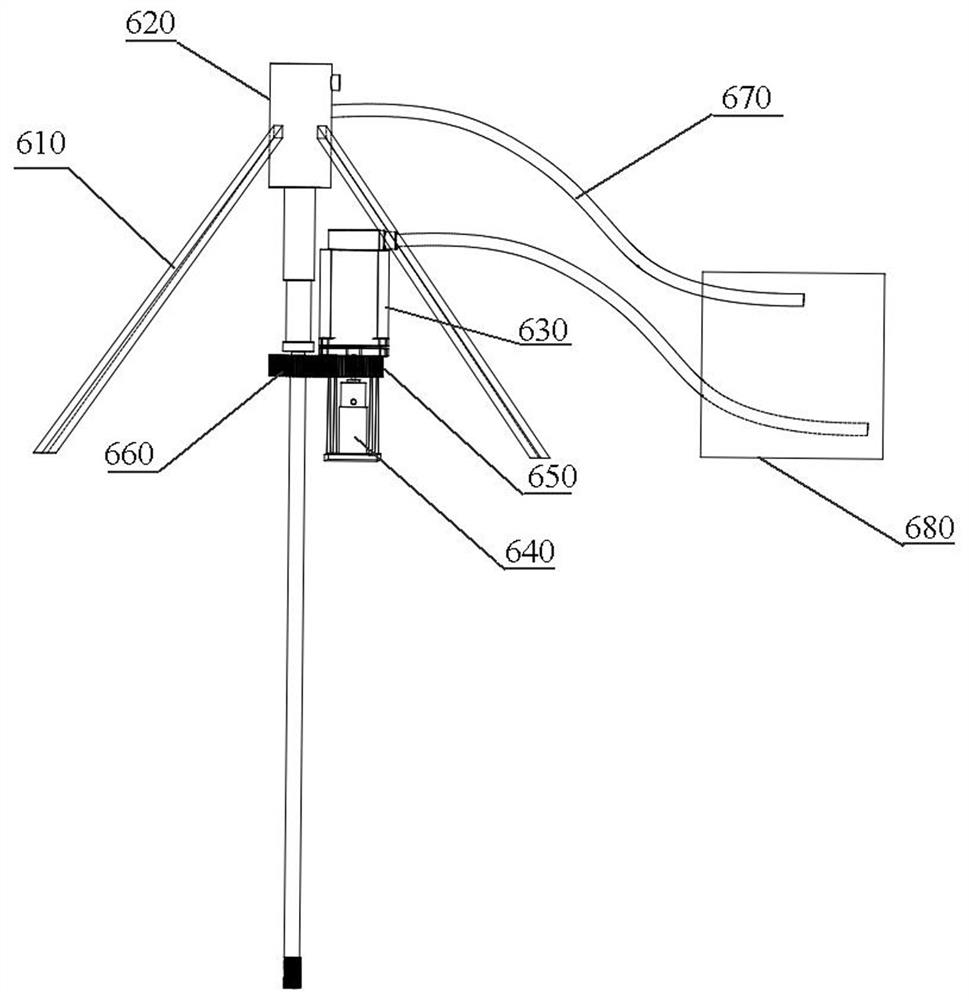

Hole wall side expansion rotary shearing device for drilling shear test and test method

ActiveCN113702211AGood mechanical performanceGood mechanical propertiesMaterial strength using steady shearing forcesDrill holeStructural engineering

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Logistics packaging box shearing device

InactiveCN107571540AAchieve cutAchieve separationPaper-makingBox making operationsMaterial resources

The invention discloses a logistics packaging box shearing device which comprises an installation bottom board. A long-bar-shaped cutting board is installed on the top of the installation bottom boardin the length direction of the installation bottom board. A long-bar-shaped cavity is formed in the cutting board in the length direction of the cutting board. Air holes communicating with the interior of the cavity are formed in the top of the cutting board in the length direction of the cutting board in an array manner. A support fixedly connected with the installation bottom board is installedon the top of the cutting board. A tool installation board parallel to the installation bottom board is installed on the side, close to the installation bottom board, of the support. Two sets of cross beams arranged in parallel are welded to the two ends of one side of the installation bottom board. A long-bar-shaped base board is welded to the position, away from the installation bottom board, of one ends of the cross beams. A guide groove obliquely arranged is formed in the lower portion of the side, close to the installation bottom board, of the base board. An installation seat is installed on the top of the base board, and the installation seat is movably connected with a clamping mechanism in a sleeved manner. The logistics packaging box shearing device is easy and fast to operate, shearing, waste separating and overturning discharging of packaging boxes are achieved, the shearing efficiency of the packaging boxes is improved, and labor force and material resources are saved.

Owner:徐慧敏

Cutting mechanism

The invention discloses a cutting mechanism. The cutting mechanism comprises a pinch roll device used for pinching a film-coated product, a drive device used for driving the pinch roll device, a transmission device connected with the drive device and carrying out power transfer, a lifting traversing device connected with the transmission device, and a cutting device connected with the lifting traversing device and used for cutting the film-coated product, wherein the transmission device is capable of driving the lifting traversing device to carry out horizontal movement and lifting movement. The forward-moving speeds of the film-coated product and the cutting device are the same, so that a film-coating machine does not need to be turned off to wait for cutting, and cutting for the film-coated product can be realized during film-coating; and therefore, the production takt is accelerated, the waiting time is reduced, the production efficiency is effectively increased, and the cutting quality for the film-coated product is improved.

Owner:LANS INTELLIGENT ROBOT CHANGSHA CO LTD

Granular material automatic packaging device

ActiveCN105231484AAccurate settingIntegrity guaranteedDevices for heating/cooling reflex pointsCigar manufactureAdhesiveEngineering

The invention discloses a granular material automatic packaging device, which comprises a packaging device, a paper conveying mechanism, a storage mechanism and a control mechanism which are arranged on a stand, wherein the control mechanism is respectively in signal connection with the packaging mechanism, the paper conveying mechanism and the storage mechanism; the conveying mechanism is arranged on the upper part of the packaging mechanism; the paper storage mechanism is arranged at the back of the packaging mechanism; and a gluing mechanism, which is used for smearing an adhesive on packaging paper which is conveyed to the packaging mechanism from the paper storage mechanism, is arranged between the paper storage mechanism and the packaging mechanism. By virtue of the structural form, the granular material automatic packaging device disclosed by the invention greatly shortens a time of coiling a single granular material and also diminishes the volume of the single granular material, and the granular material automatic packaging device is suitable for coiling granular materials differing in diameter and length and is capable of achieving disposal packaging; and the granular material automatic packaging device is simple and compact in structure, and is worthy of popularization and application.

Owner:启东宏威五金制品有限公司

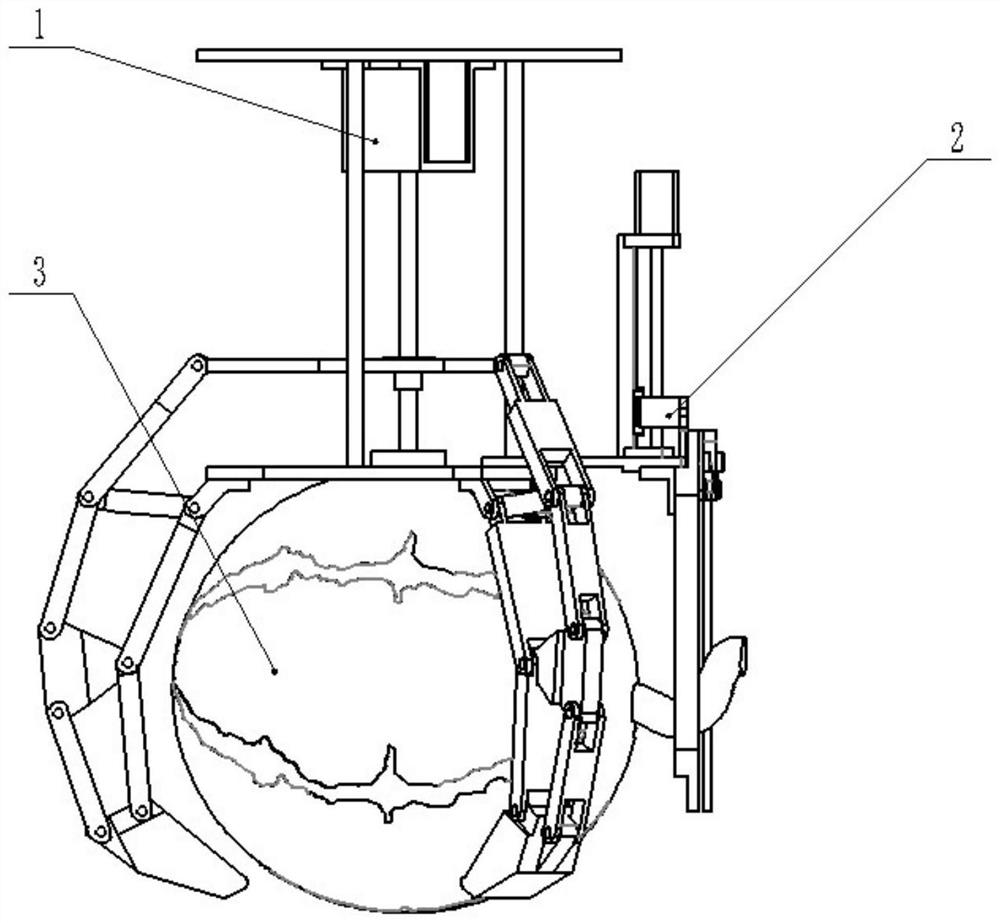

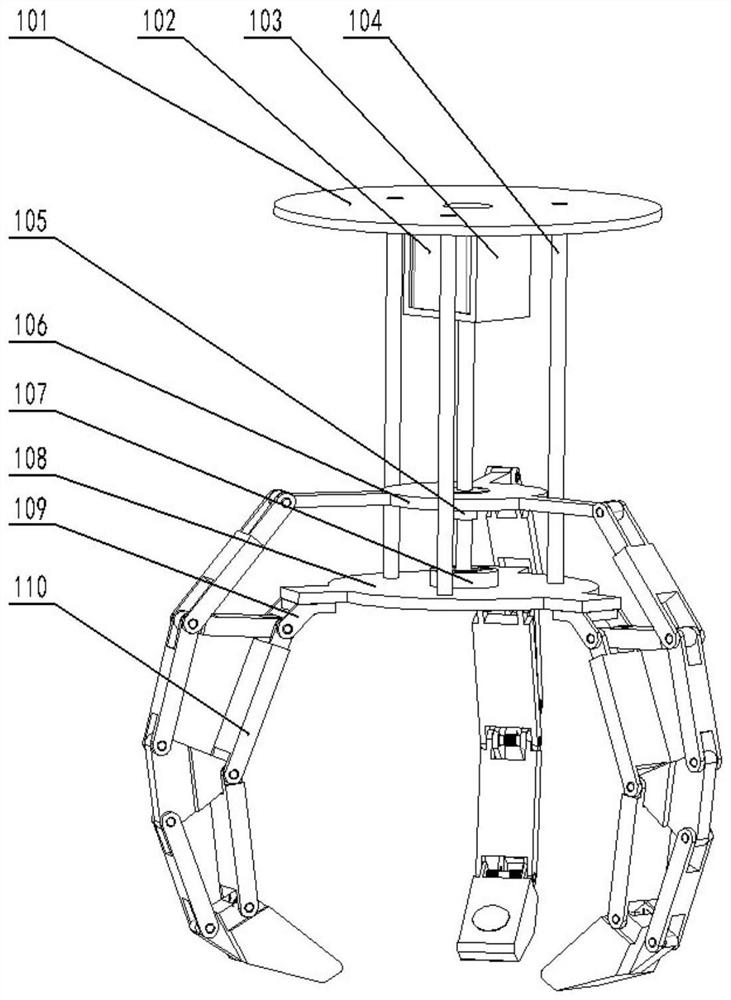

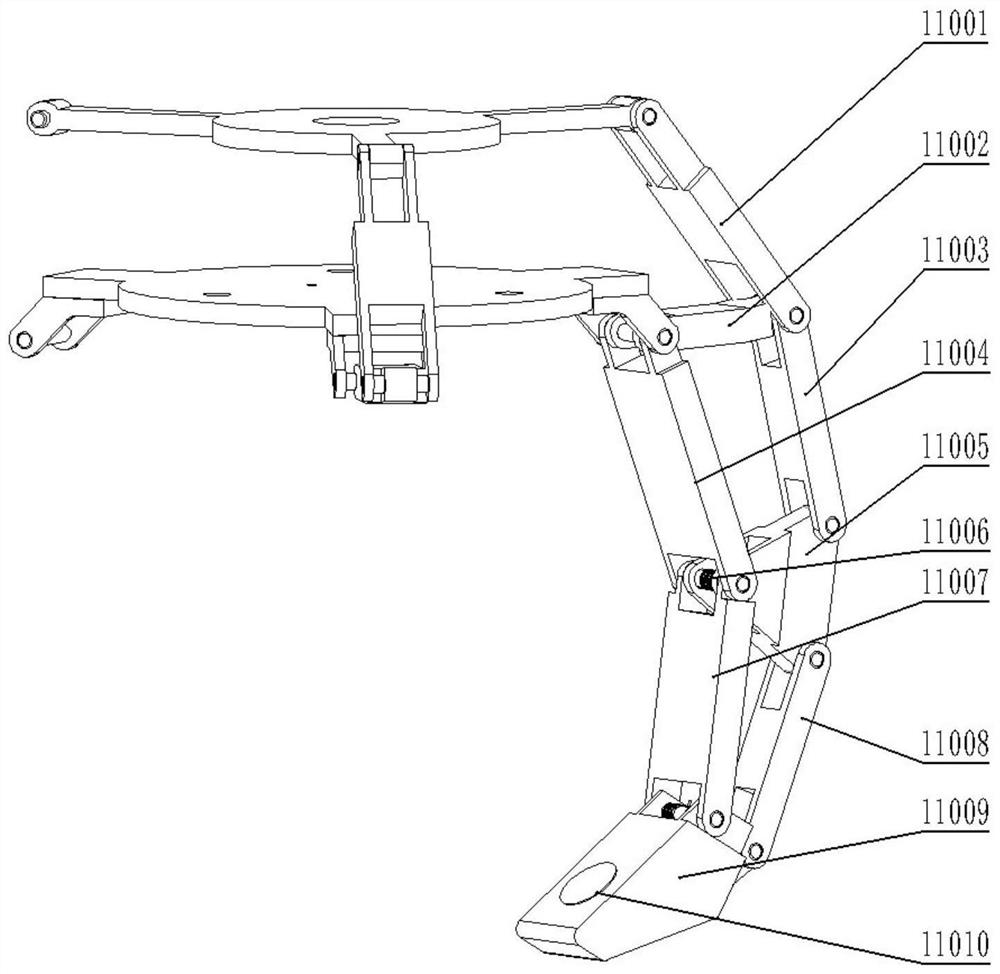

End effector for self-adaptive picking of watermelons

InactiveCN114793627AImprove automationImprove the level of intelligencePicking devicesRobot handControl engineering

An end effector for self-adaptive picking of watermelons comprises a clamping mechanism for clamping the watermelons and a shearing mechanism for achieving picking and shearing actions, in the clamping mechanism, a fixing base is used for connecting the end effector with a mechanical arm, and a lead screw stepping motor is fixedly installed on the fixing base through a motor base; the lead screw nut is connected with the lifting platform and installed on a lead screw of the lead screw stepping motor, the bearing seat is connected with the other end of the lead screw and installed on the base, the guide rod is fixedly connected with the base and the base, the base connecting block is installed on the base, and the three under-actuated mechanical fingers are evenly installed on the lifting platform and the base connecting block. And a cavity enclosed by the three under-actuated manipulators is a watermelon model for placing watermelons. According to the invention, the labor cost is reduced and the production efficiency is improved.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com