End effector for self-adaptive picking of watermelons

An end-effector, self-adaptive technology, applied in the field of agricultural machinery, can solve the problems of high cost and low efficiency of watermelon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

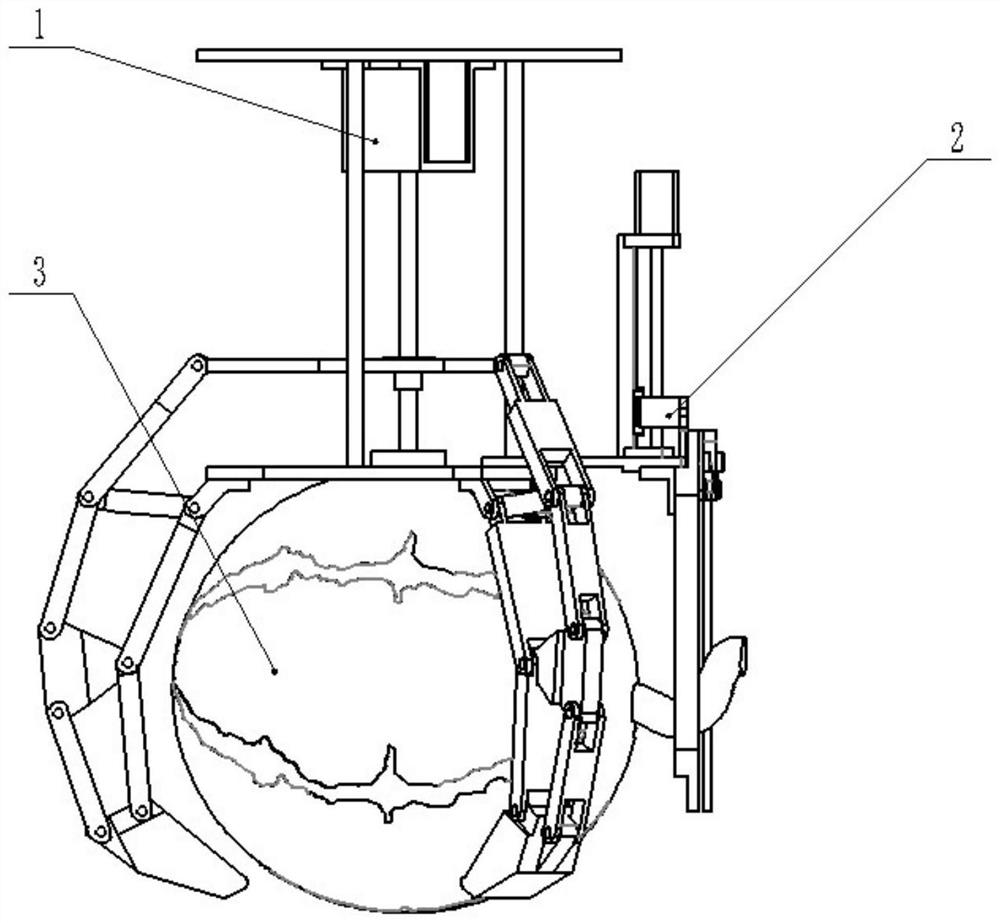

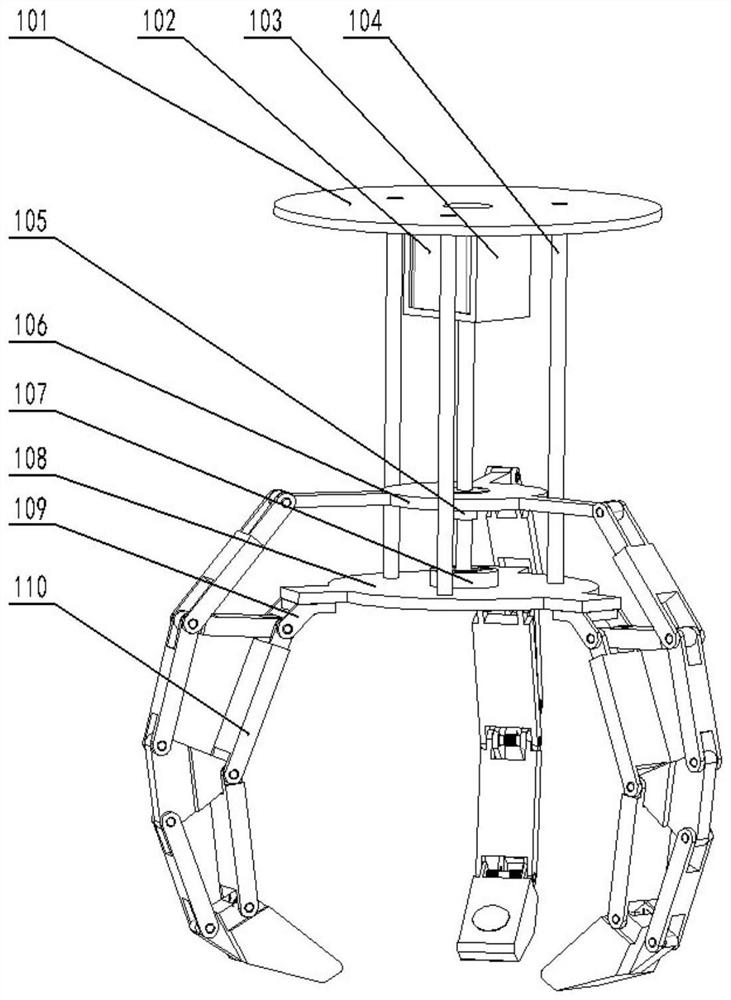

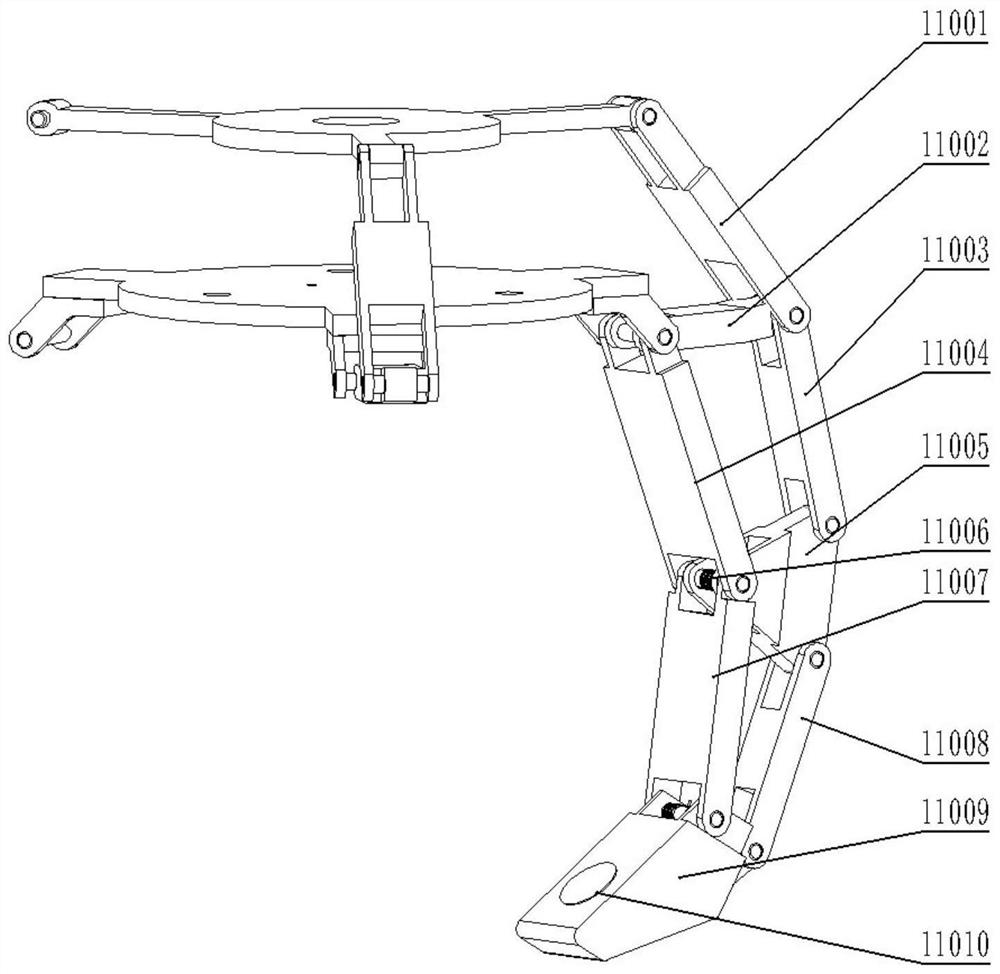

[0017] refer to Figure 1 to Figure 5 , an end effector for adaptive picking of watermelon, including a clamping mechanism for clamping watermelon and a shearing mechanism for realizing picking and shearing action, the clamping mechanism includes a fixed base 101, a screw step Into the motor 102, the motor base 103, the guide rod 104, the screw nut 105, the lifting platform 106, the bearing seat 107, the base 108, the base connecting block 109 and the underactuated manipulator finger 110, the fixed base 101 is used for the end effector and For the connection of the manipulator, the lead screw stepping motor 102 is an integrated product of the lead screw and the stepping motor. The motor base 103 fixes the lead screw stepping motor 102 on the fixed base 101 with screws. The lead screw nut 105 and the lifting platform 106 It is fixedly connected and is sleeved on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com