Cutting blind plate on-line pressurized plugging device and plugging method for small-pipe-diameter high-pressure pipeline

A technology for high-pressure pipelines and plugging devices, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of irregular pipe diameters, long blocking time, etc., and achieve the effect of blocking safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

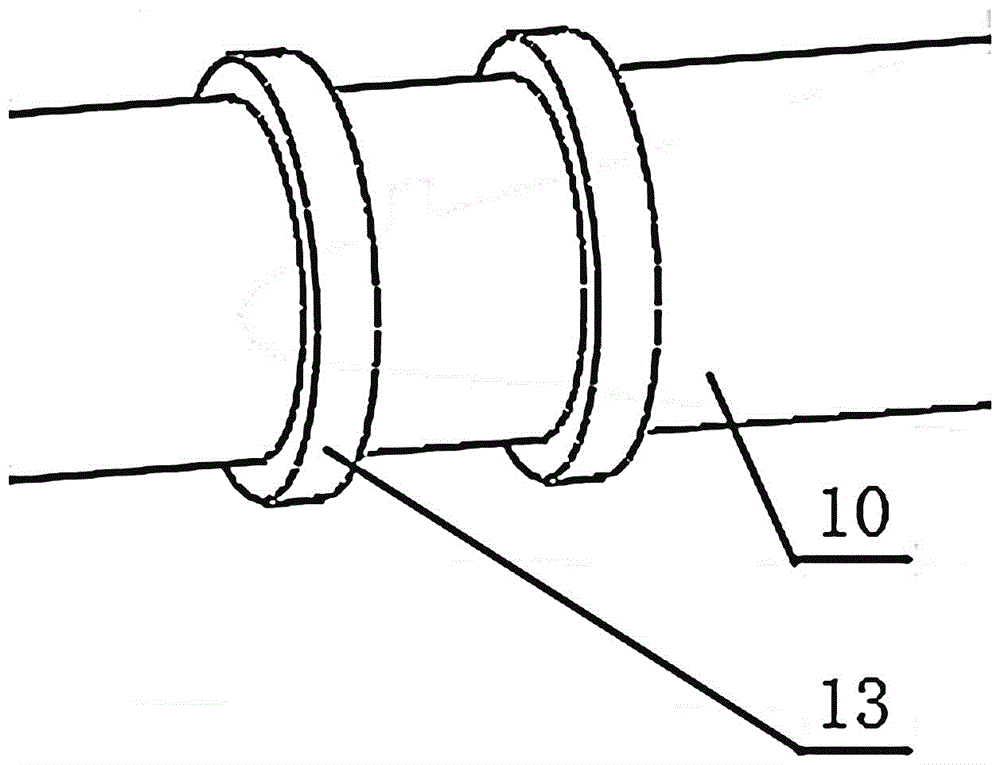

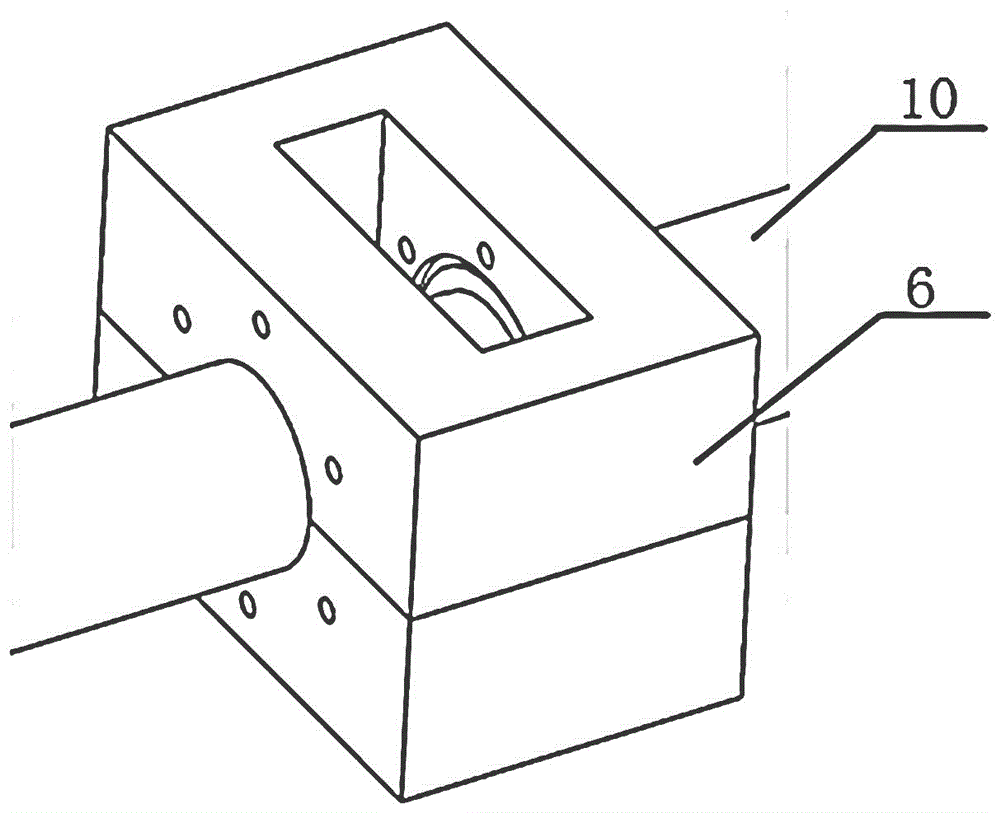

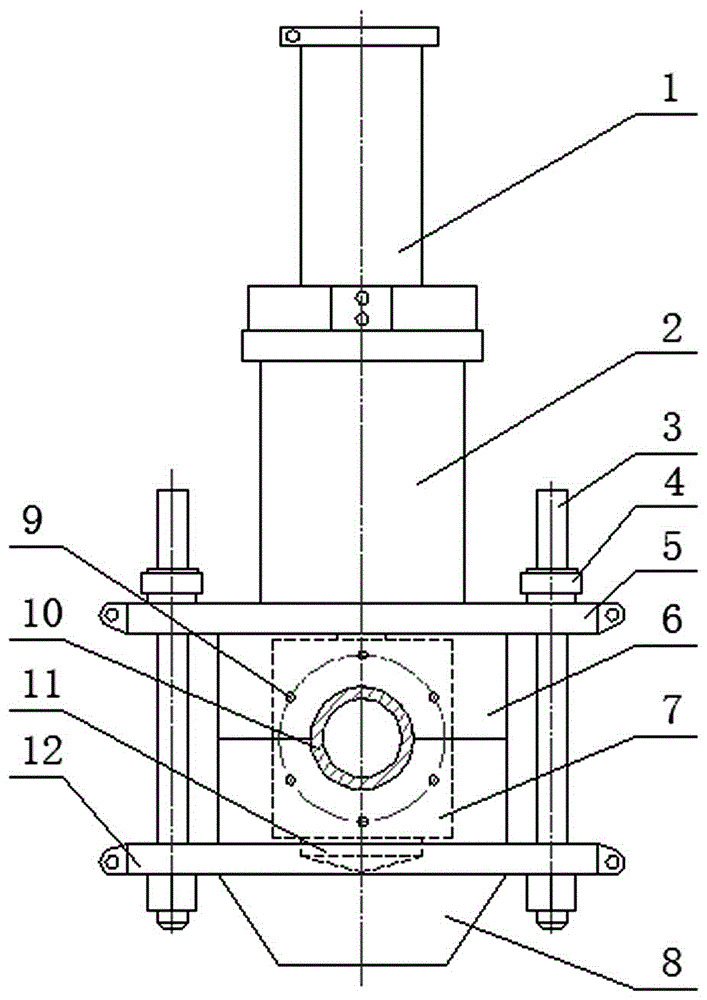

[0030] An online pressure plugging device for a small-diameter high-pressure pipeline with a shearing blind plate is shown in the figure, including a shearing and sealing hydraulic cylinder 1, a sealing header 2, a sealing blind plate 7, a triangular cutter 11, a shearing Cutting and sealing box 6, upper flange 5, lower flange 12, bottom box 8, thrust bolt 9 and grease injection bolt 14; the upper and lower ends of the shearing and sealing box 6 are provided with through holes; the shearing and sealing Thrust bolts 9 are installed on the end face of the downstream side of the box 6, and grease injection bolts 14 are installed on the end face of the upstream side of the shearing and sealing box; , the upper flange 5 is installed on the top surface of the shearing and sealing box 6, and the sealing header and the shearing and sealing hydraulic cylinder are connected into one and hoisted to the upper flange 5; the piston of the shearing and sealing hydraulic cylinder 1 The pluggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com