Patents

Literature

195results about How to "Achieving Zero Leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

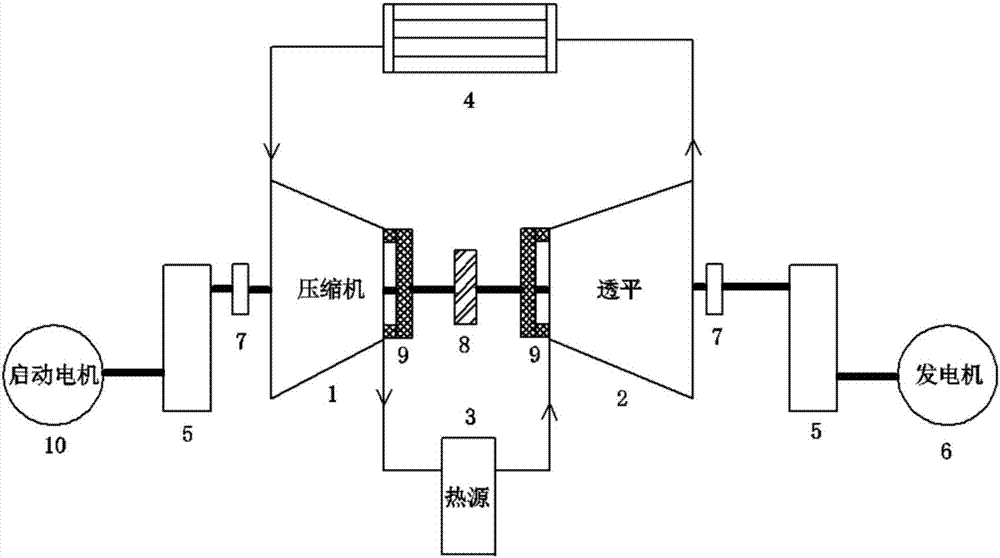

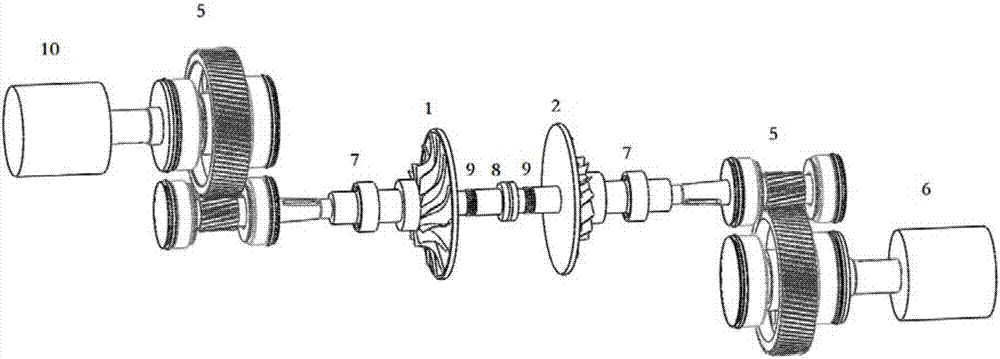

Supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure

InactiveCN107461227AViscosity of working mediumSmall working fluid viscositySteam engine plantsMotor driveElectric machine

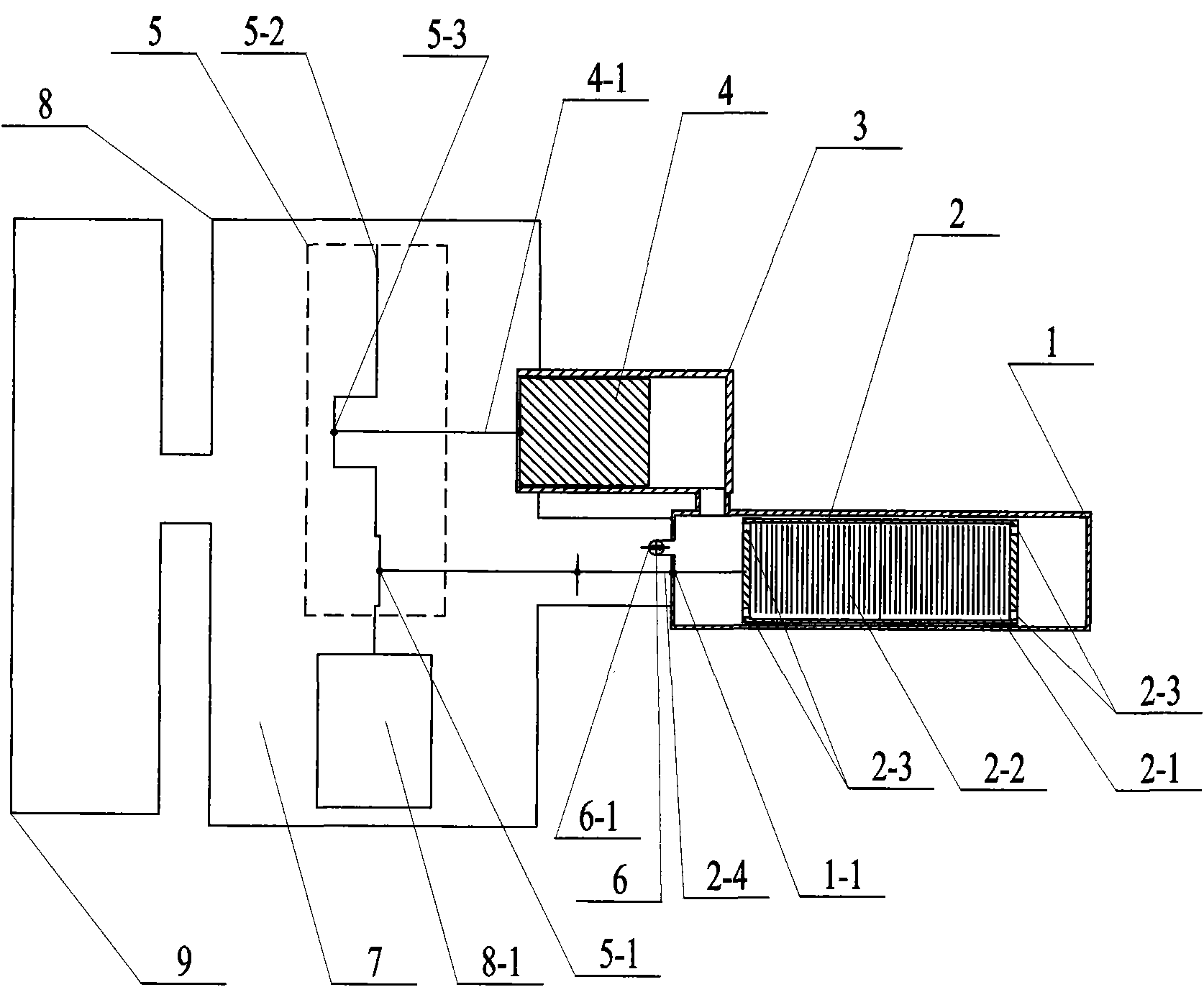

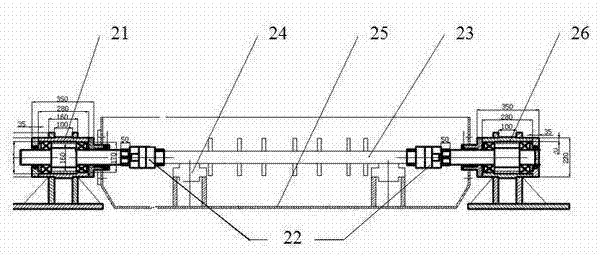

The invention discloses a supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure. A supercritical carbon dioxide working medium sequentially flows through a centrifugal compressor to improve pressure and a heat source to improve temperature, and finally after output work in a radial-inward-flow turbine, the supercritical carbon dioxide working medium enters a cooler to be cooled and circulates to enter the centrifugal compressor again. A start motor drives the coaxial structure to start working through one gearbox, the coaxial structure is formed by the radial-inward-flow turbine and the centrifugal compressor through a rotor shaft, the centrifugal compressor is driven by one part of output work of the radial-inward-flow turbine, and the other part of output work of the radial-inward-flow turbine is output into a generator through the other gearbox. Radial bearings are arranged at the shaft ends of the two sides of the coaxial structure, a thrust bearing is arranged in the middle of the coaxial structure, and the type adapting to the corresponding rotary shaft rotating speed can be selected. Furthermore, the form of supercritical carbon dioxide dry gas seals is adopted in sealing parts. The supercritical carbon dioxide centrifugal compressor and radial-inward-flow turbine coaxial structure has the prominent beneficial effects of being simple and compact in structure, high in pneumatic efficiency, low in manufacturing cost and the like and has wide market prospects.

Owner:XI AN JIAOTONG UNIV

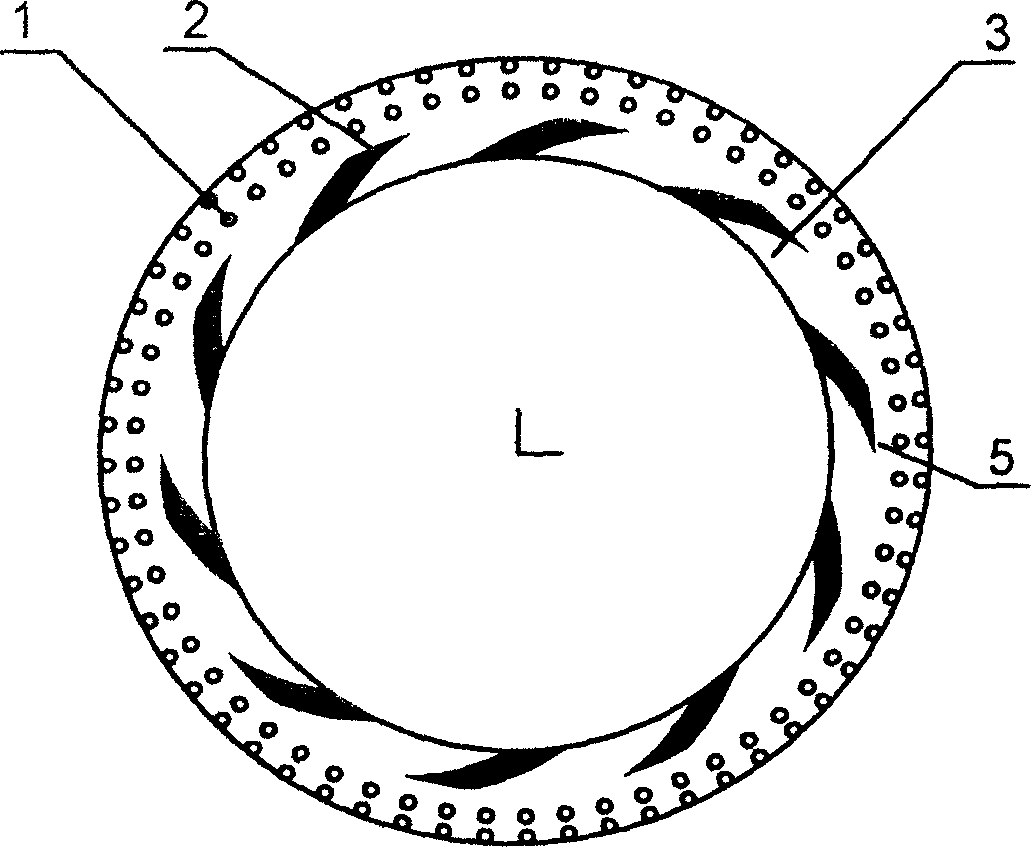

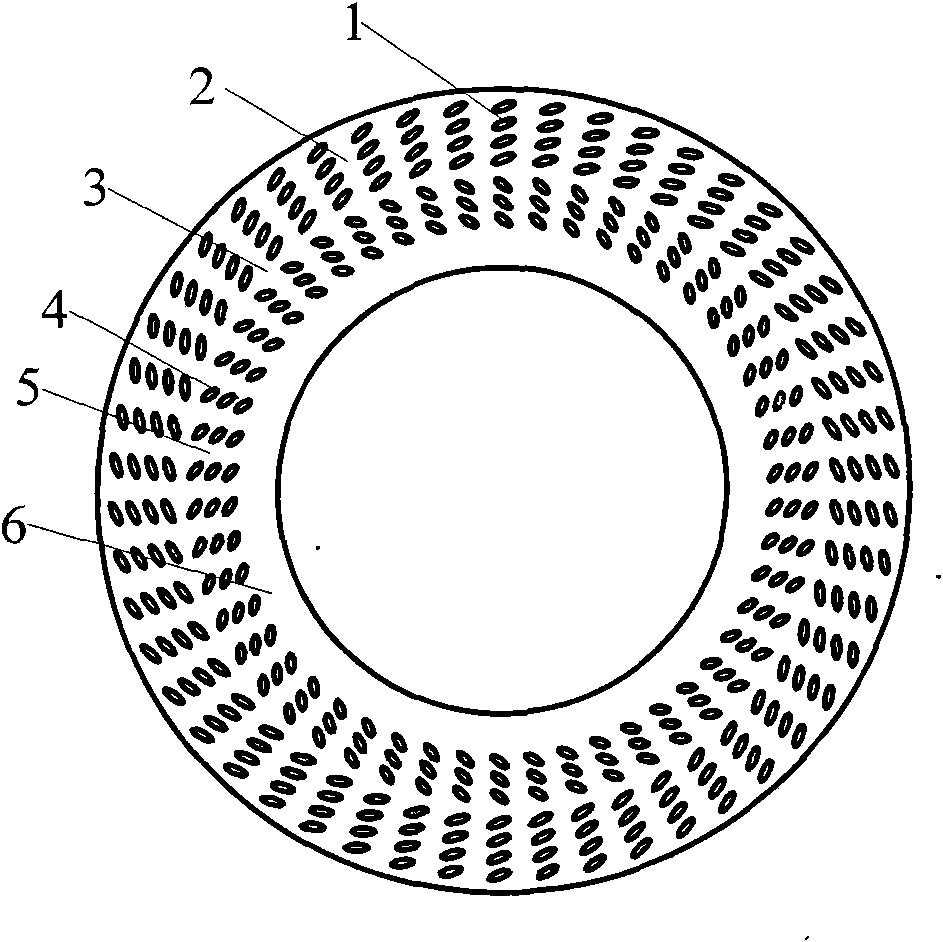

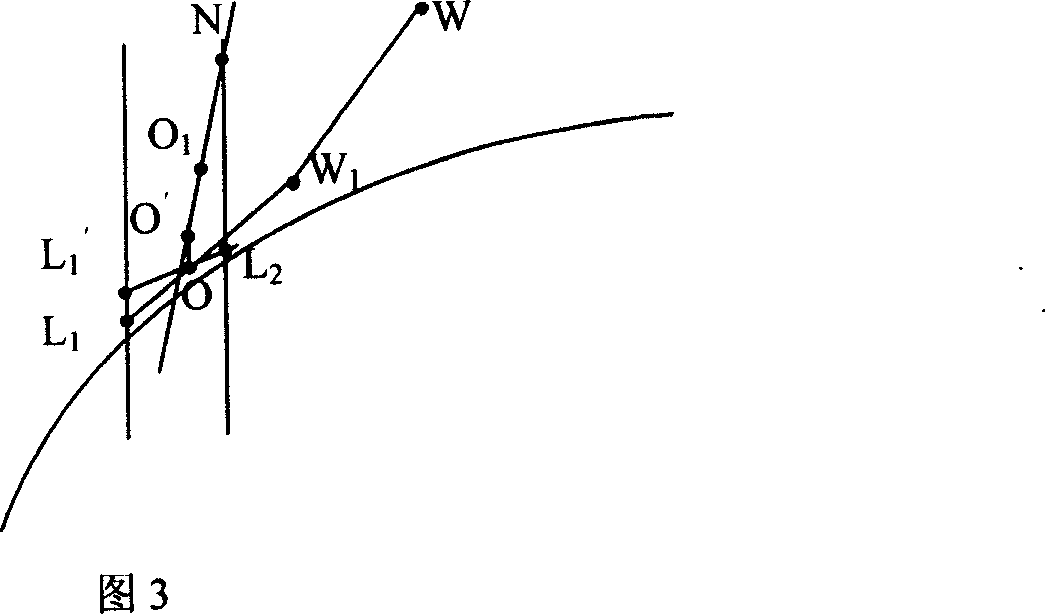

Non-contact mechanical end face sealing structure

InactiveCN1828098AImprove sealing abilityExtended service lifeEngine sealsCentre of rotationEngineering

The invention relates to a non-contact mechanical end surface sealing structure, which comprises mechanical sealed movable ring and stable ring. While the end surface of stable or movable ring has micro groove and porous zone that symmetry according to the rotational center. Wherein, said zone is at the ascending part of end surface and the micro groove is at the descending part, which has a circular sealing dam beside it. The invention can be used in variable mediums to increase the ability of solid particle, the static pressure property, fluid dynamic pressure property and the pump adsorption property, to attain better sealing effect, with long service life.

Owner:ZHEJIANG UNIV OF TECH

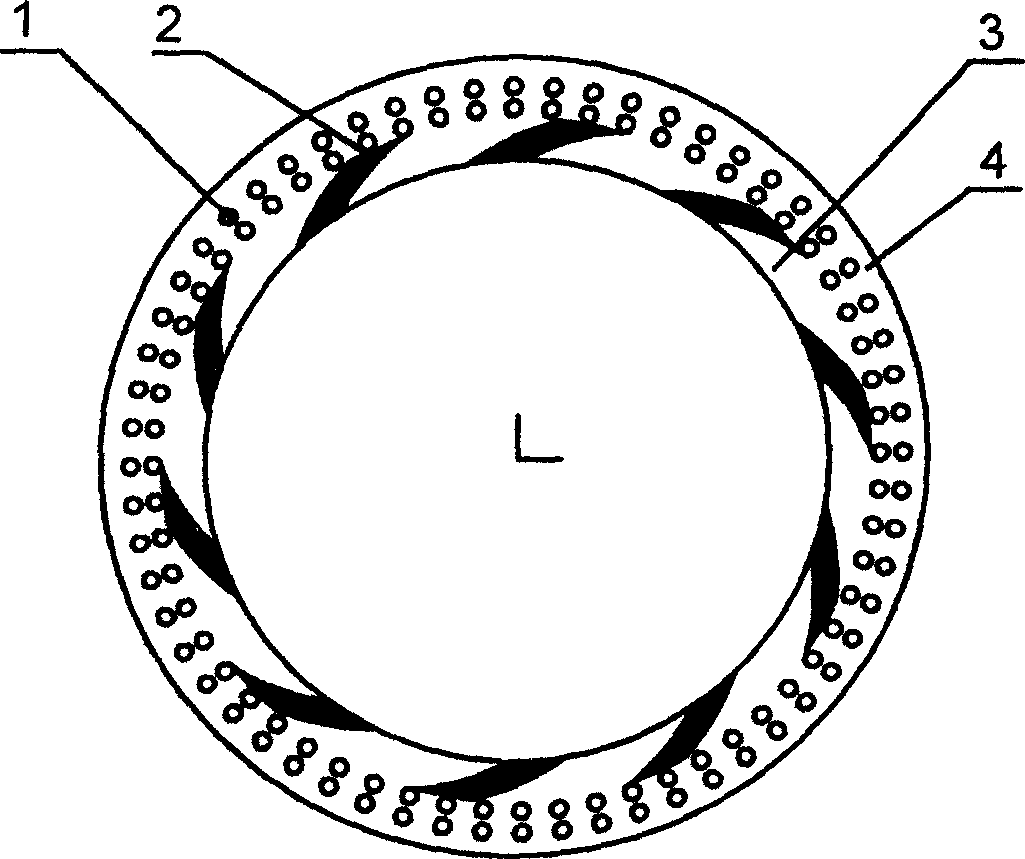

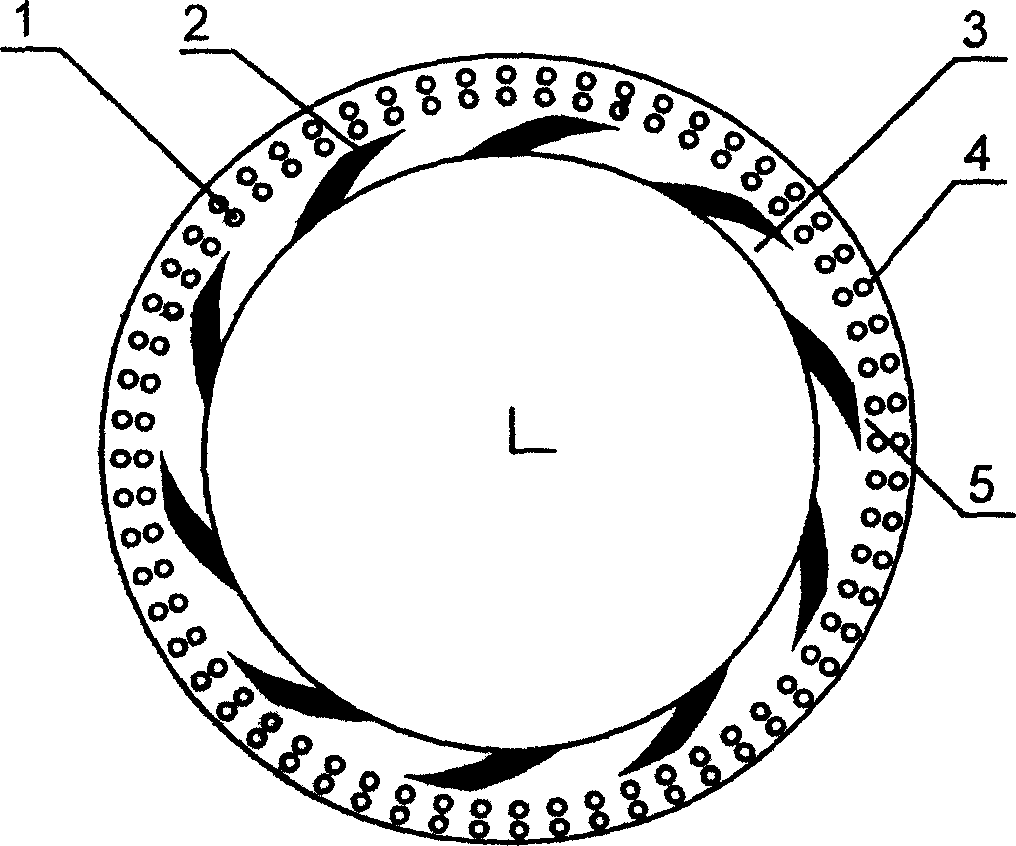

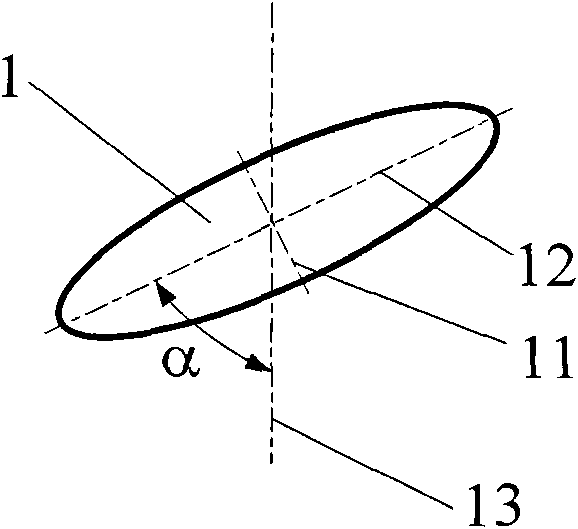

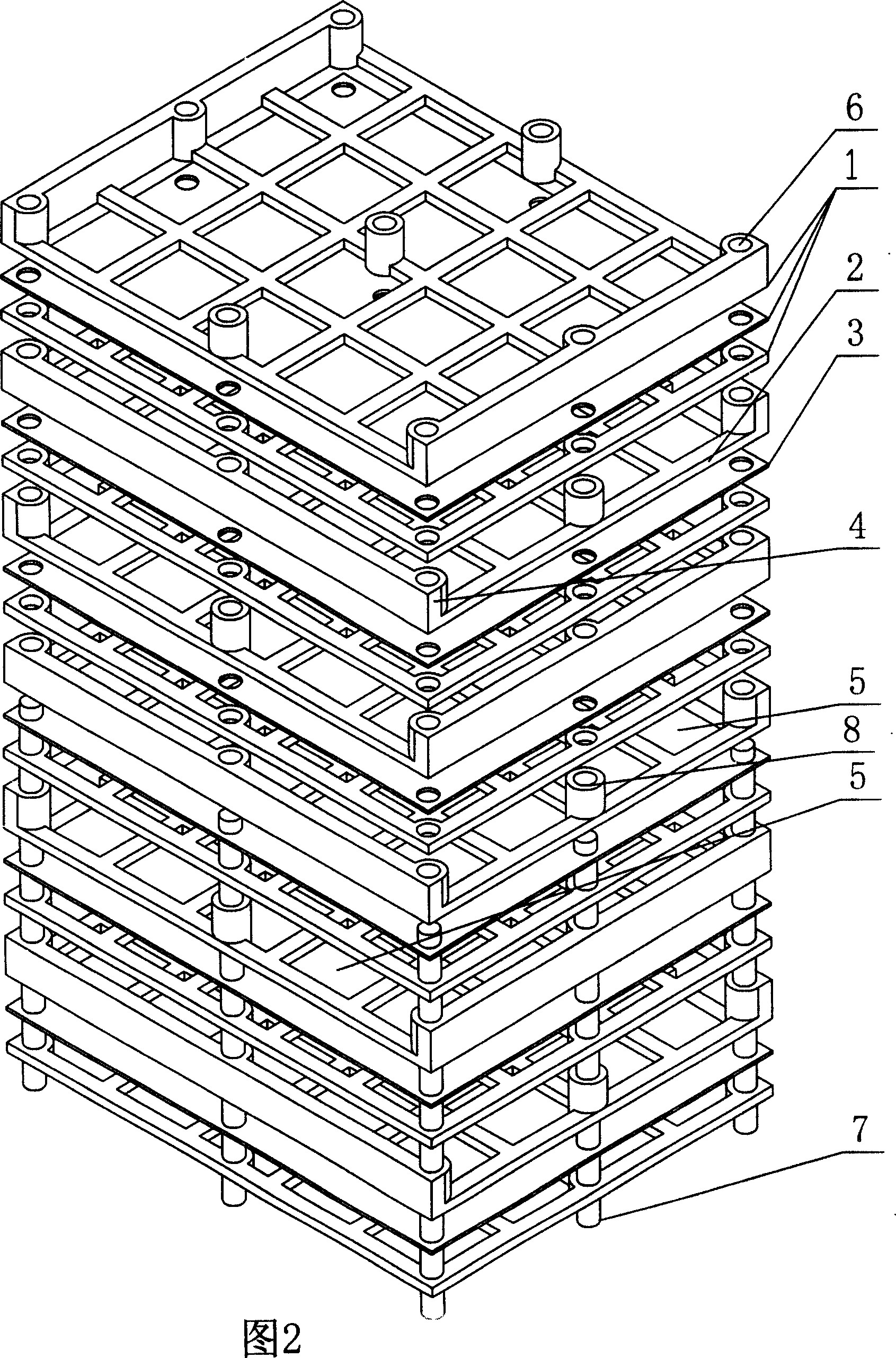

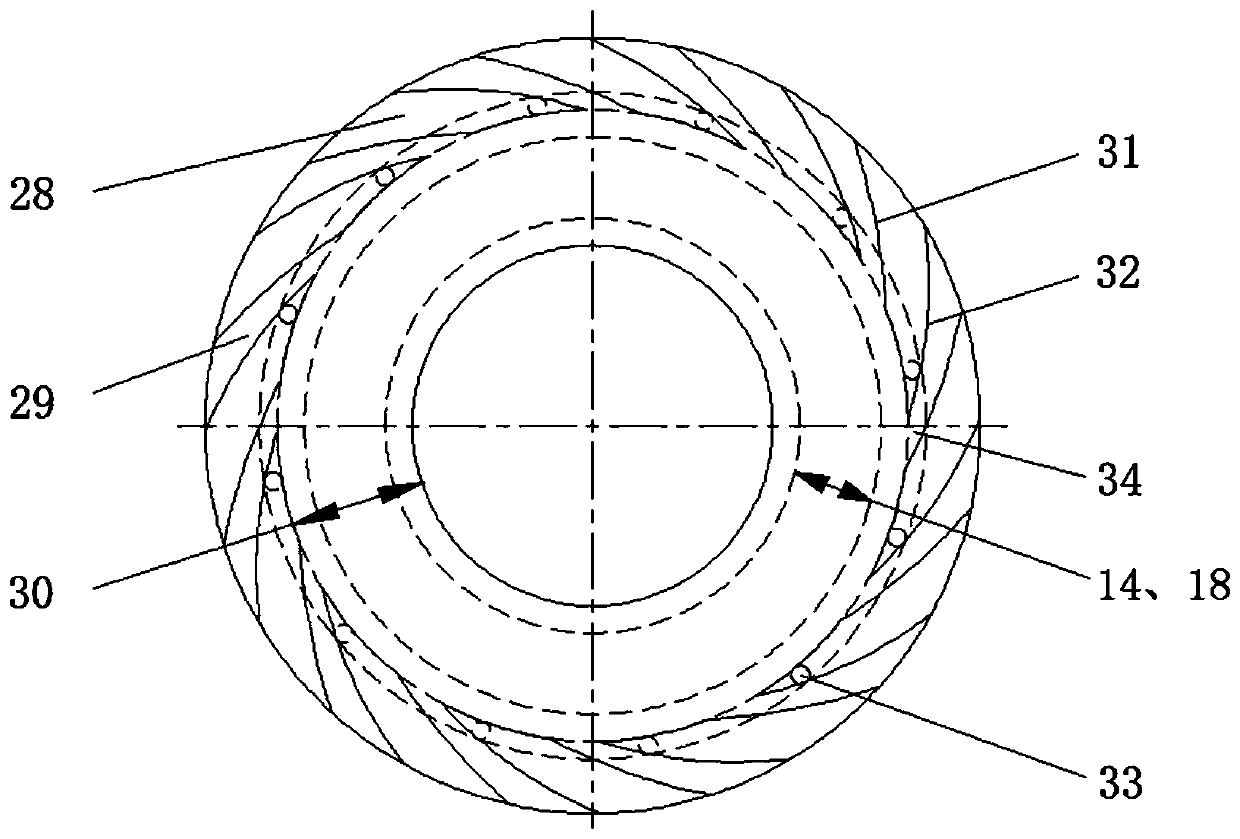

Double-row tilting directional microporous end surface no-leakage mechanical sealing structure

ActiveCN101672364AImproved hydrodynamic effect and tightnessGood start and stop effectEngine sealsDouble rowEngineering

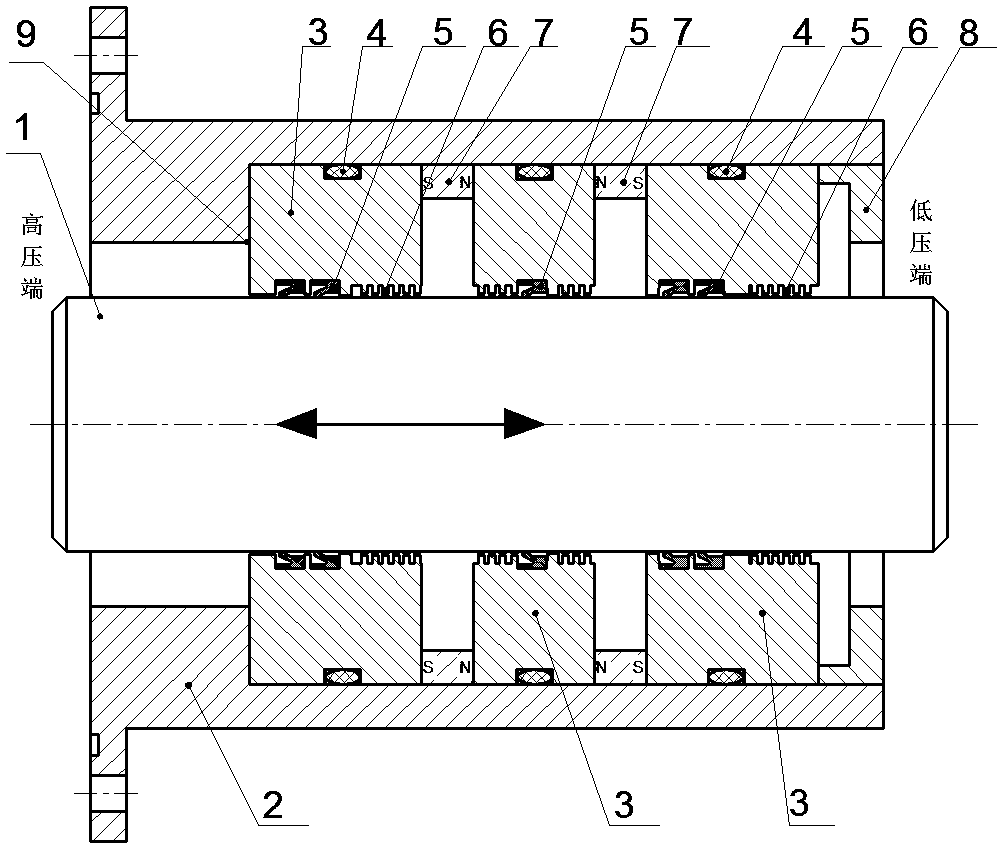

The invention relates to a double-row tilting directional microporous end surface no-leakage mechanical sealing structure, comprising a dynamic ring and a static ring which are sealed mechanically, wherein one side of the end surface of the dynamic ring or the static ring is an high-voltage side, namely an upstream part, and the other side thereof is a low-voltage side, namely an downstream part,the end surface of the dynamic ring or the static ring is provided with an outer microporous ring belt and an inner microporous ring belt; microporous long shafts of the outer microporous ring belt and the inner microporous ring belt are opposite to the direction of a tilting angle of the diameter of the sealing end surface passing through the center of the micropore; the outer microporous ring belt and the inner microporous ring belt are respectively arranged on the upstream part and the downstream part of the end surface; and a continuous ring-shaped sealing dam are respectively arranged between the outer microporous ring belt and the inner microporous ring belt and the downstream part of the inner microporous ring belt. The mechanical sealing structure has the beneficial effects of: realizing no contact, wear resistance and no leakage of sealing, prolonging the service life and improving the sealing reliability.

Owner:ZHEJIANG UNIV OF TECH

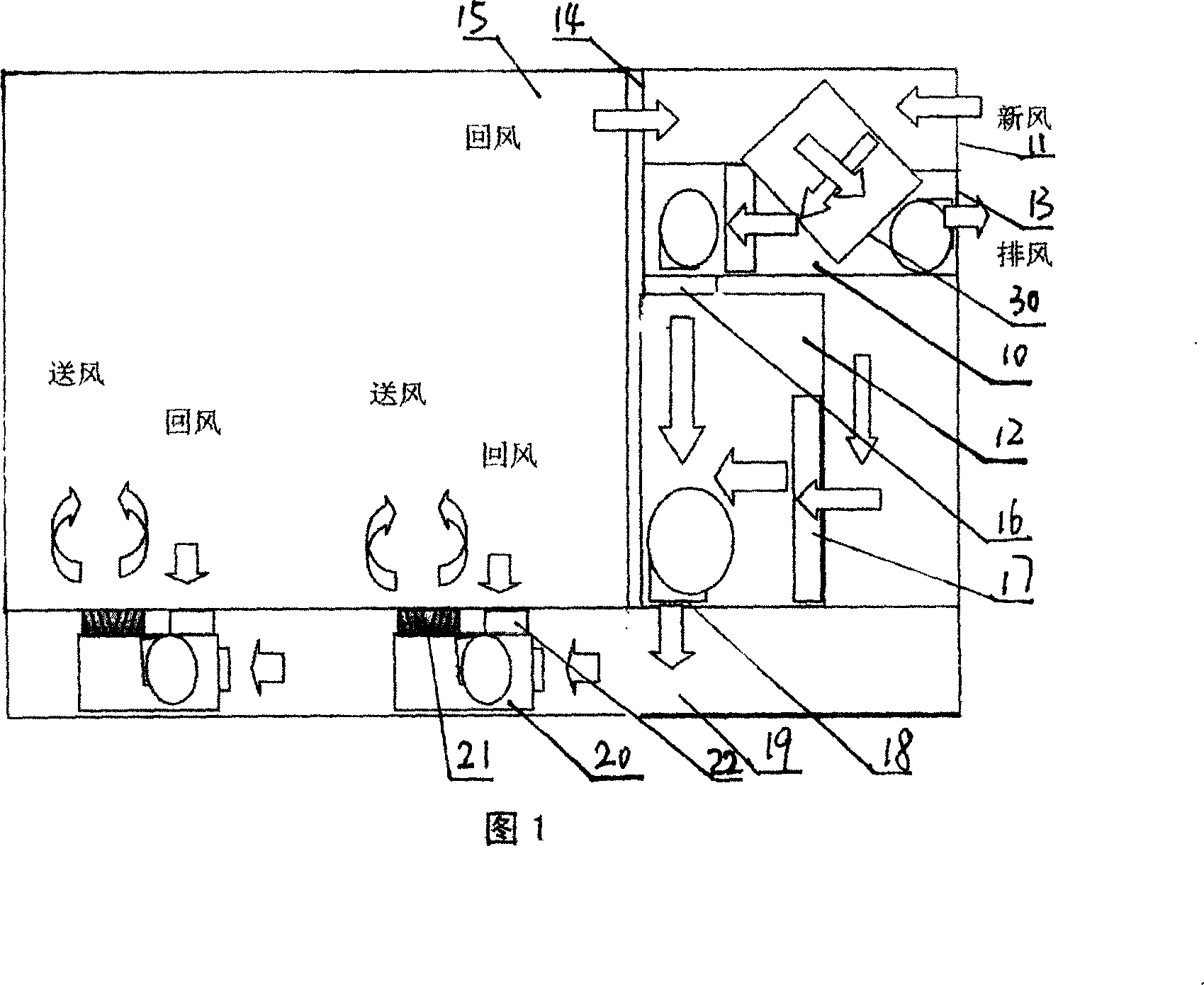

Independent fres hair floor blowing and changing air volume air conditioner system and its operation method

ActiveCN1945138AFlexible controlReduce energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusAir volumeTerminal unit

The present invention is one air conditioner system with independent fresh air unit and variable blowing rate unit. The air conditioner system includes one fresh air unit with full heat exchanger, one air conditioner unit, one variable blowing rate box or terminal unit, one cyclonic air outlet, one temperature controller and one variable blowing rate controlling system. Compared with traditional air conditioning system, the air conditioner system of the present invention has over 50 % lowered power consumption, and possesses the advantages of high efficiency, low power consumption and health.

Owner:惠盟电力科技有限公司

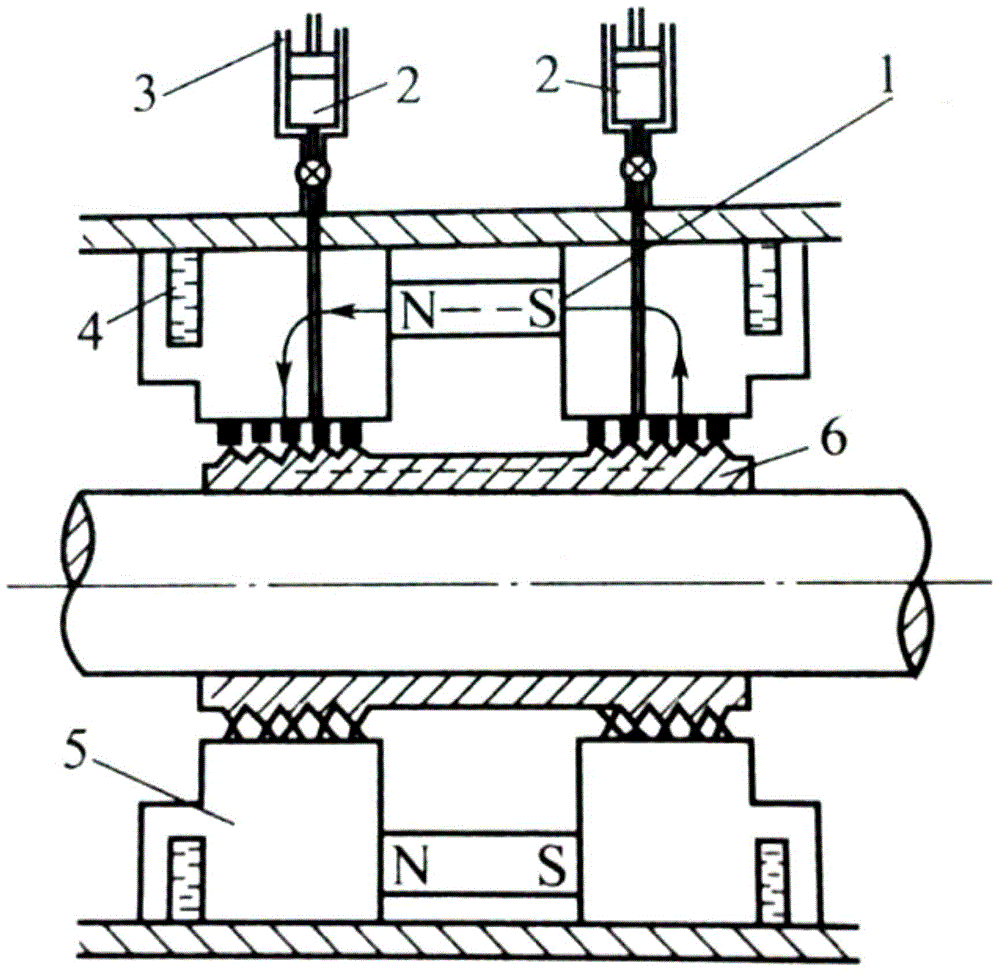

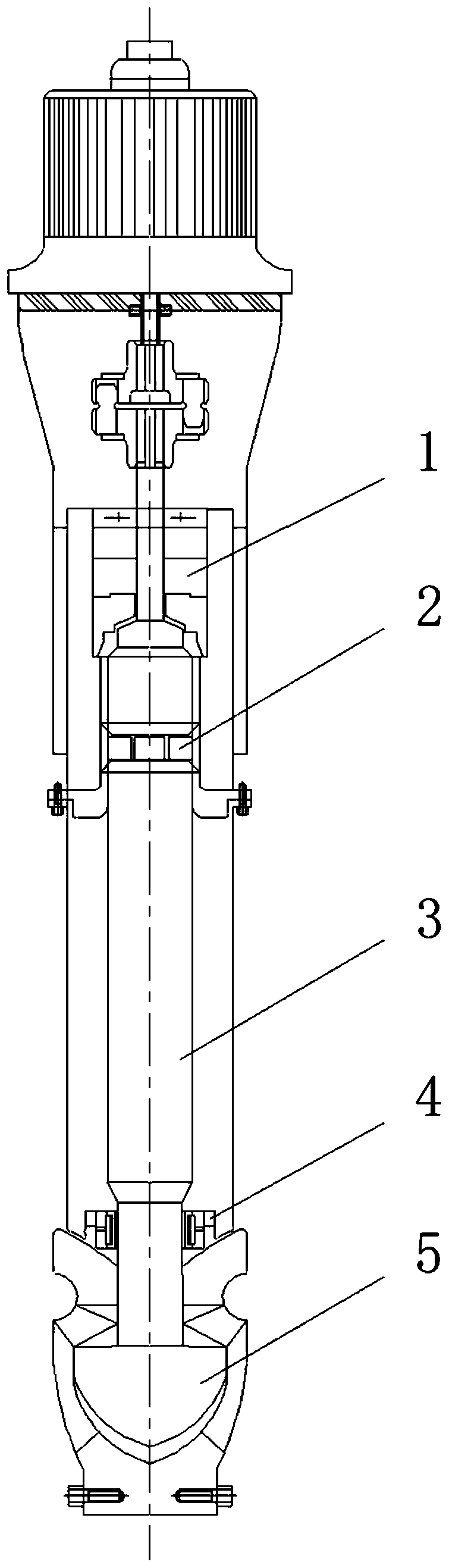

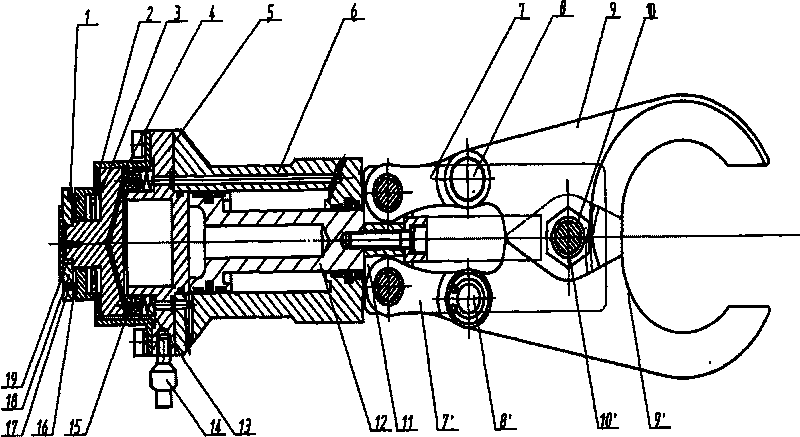

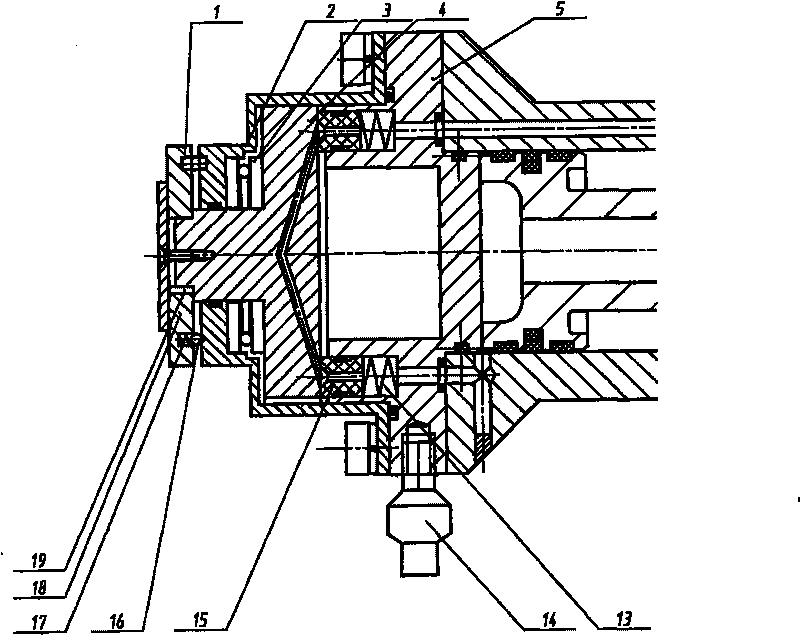

Universal random deviation rectification outside injected magnetic fluid polished rod sealing device

Provided is a universal random deviation rectification outside injected magnetic fluid polished rod sealing device applied for oil extraction in the oil field. The universal random deviation rectification outside injected magnetic fluid polished rod sealing device comprises a polished rod sealing culvert at the upper portion, wherein an upper and a lower group of permanent magnets are arranged in the culvert, an injection hole is formed in the middle portion capable of Is capable of injecting and supplying magnetic fluid into a cavity in due time to conduct a dynamic sealing to the polished rod, and a universal-joint mechanism at the lower portion is capable of rectifying deviation randomly in radial and axial three-dimensional space. A polished rod sealing culvert assembly is arranged above the random deviation rectification mechanism. The universal random deviation rectification outside injected magnetic fluid polished rod sealing device thoroughly resolves problems that production halts often occur due to applying packing polished rod sealing device in the existing oil extraction with huge energy consumption and easy damage, causing emitting, dipping and leakage of well mouth pressed oil, gas and water and accompanying serious environmental pollution, potential safety hazard and other world class problems, and can be widely applied in well mouth polished rod sealing of oil field sucker-rod pump oil extractor.

Owner:邓海波

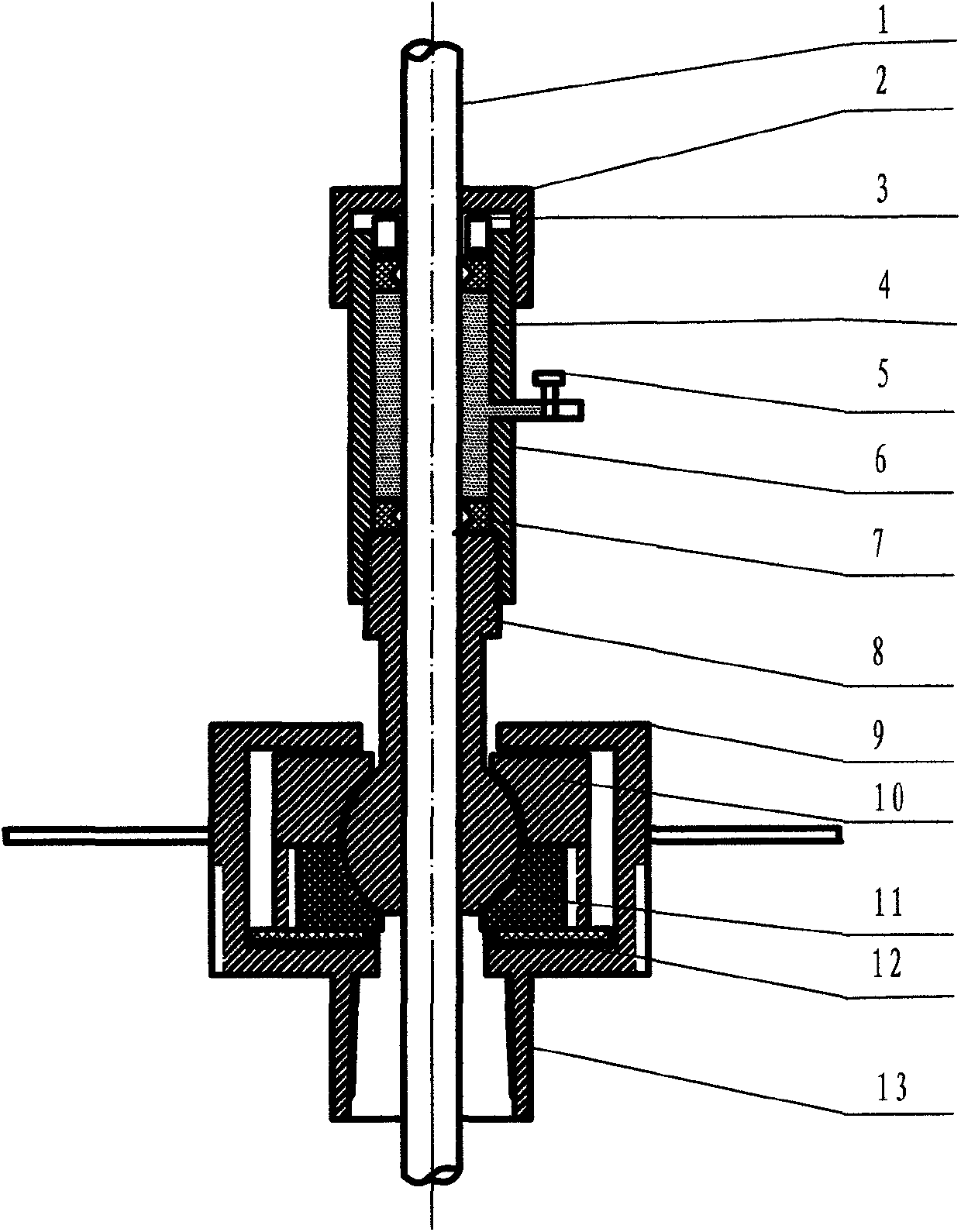

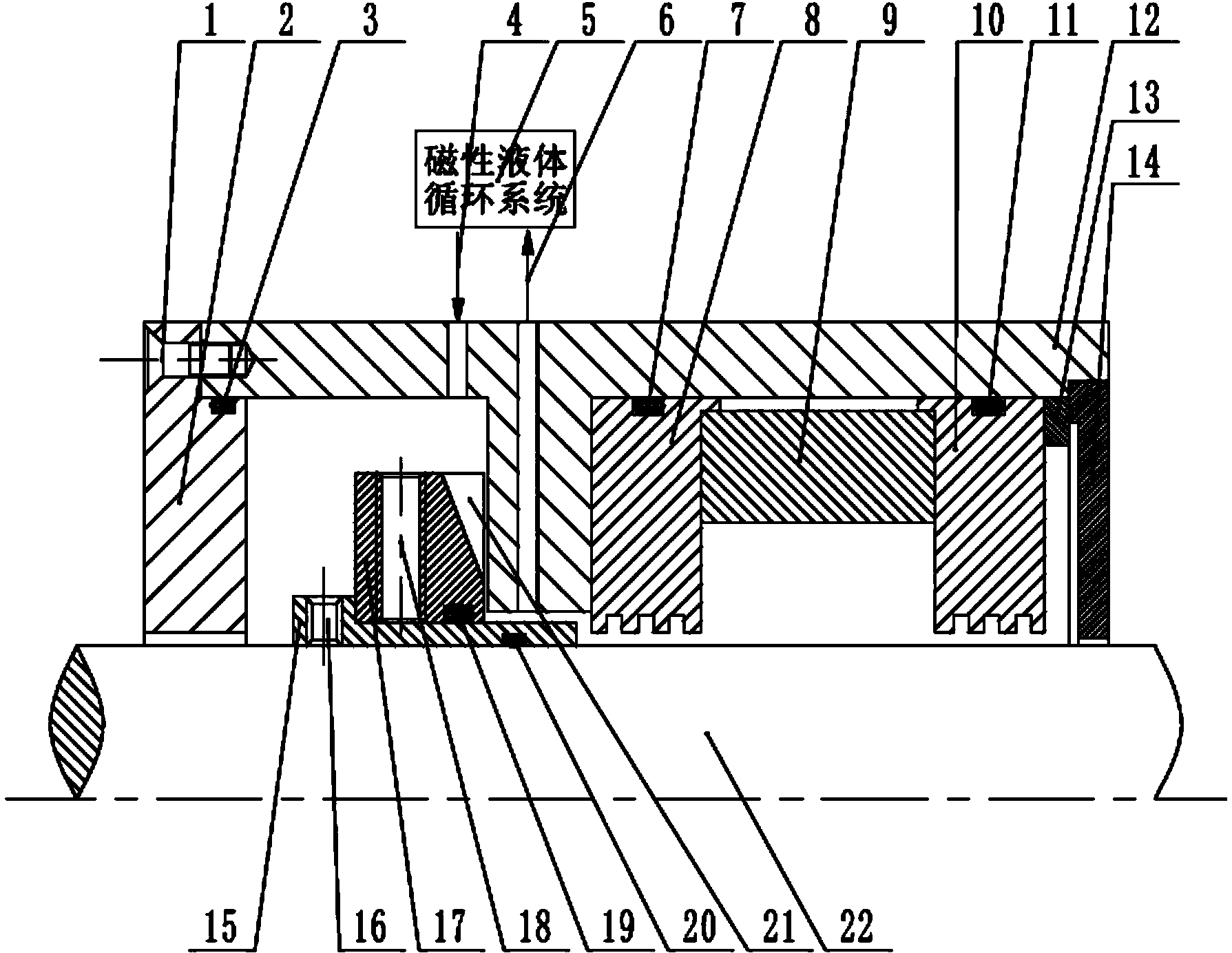

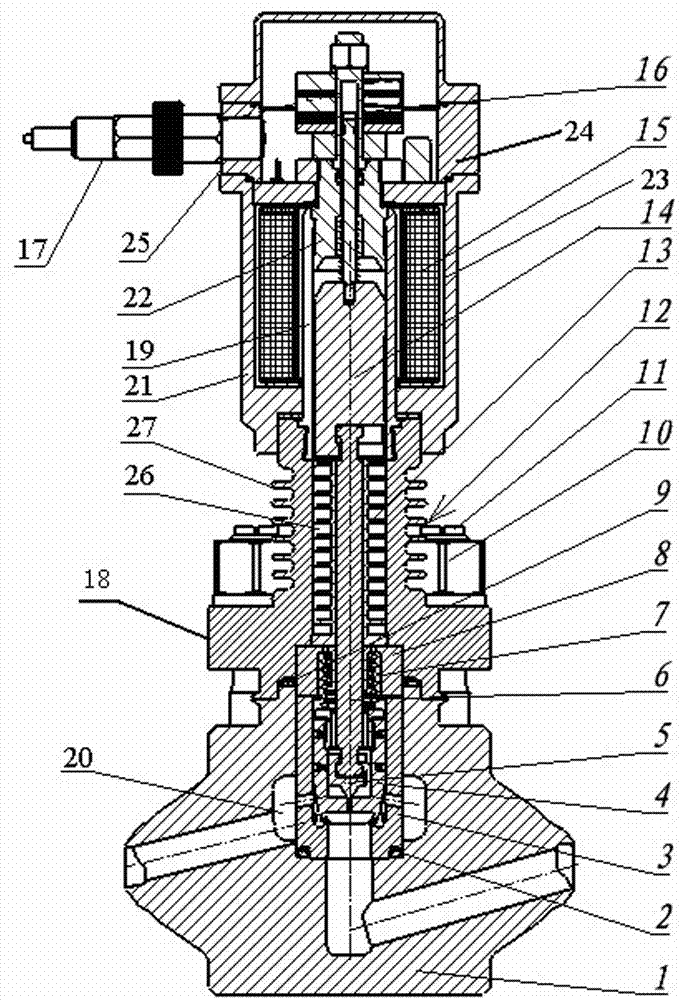

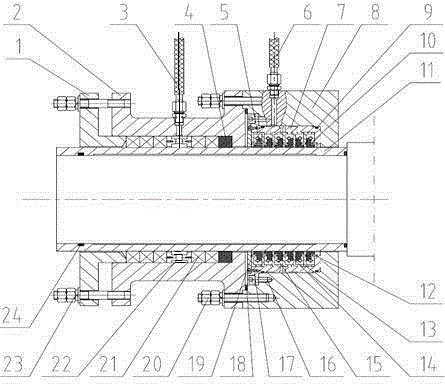

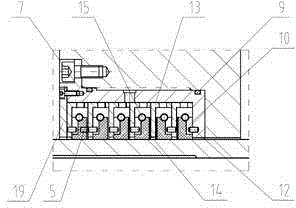

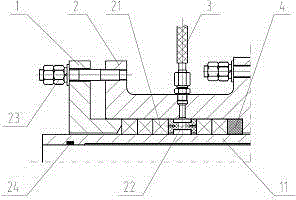

Fluid dynamic pressure type magnetic liquid seal device

The invention relates to a fluid dynamic pressure type magnetic liquid seal device and belongs to the field of mechanical engineering seal. The fluid dynamic pressure type magnetic liquid seal device comprises a screw (1), an end cover (2), a first seal ring (3), a circulation tube inlet path (4), a magnetic liquid circulation system (5), a circulation tube outlet path (6), a second seal ring (7), a left pole shoe (8), an annular permanent magnet (9), a right pole shoe (10), a third seal ring (11), a shell (12), a magnetism isolation ring (13), a threaded end cover (14), a shaft sleeve (15), a first set screw (16), a movable ring (17), a second set screw (18), a fourth seal ring (19), a fifth seal ring (20), a wedge-shaped fluid slot (21) and a shaft (22). The fluid dynamic pressure type magnetic liquid seal device has the advantages that the high pressure resistance feature of fluid dynamic pressure seal and the zero leakage feature of magnetic liquid seal are utilized, fluid dynamic pressure magnetic liquid seal zero leakage is achieved, and the application range of magnetic liquid seal is widened.

Owner:BEIJING JIAOTONG UNIV

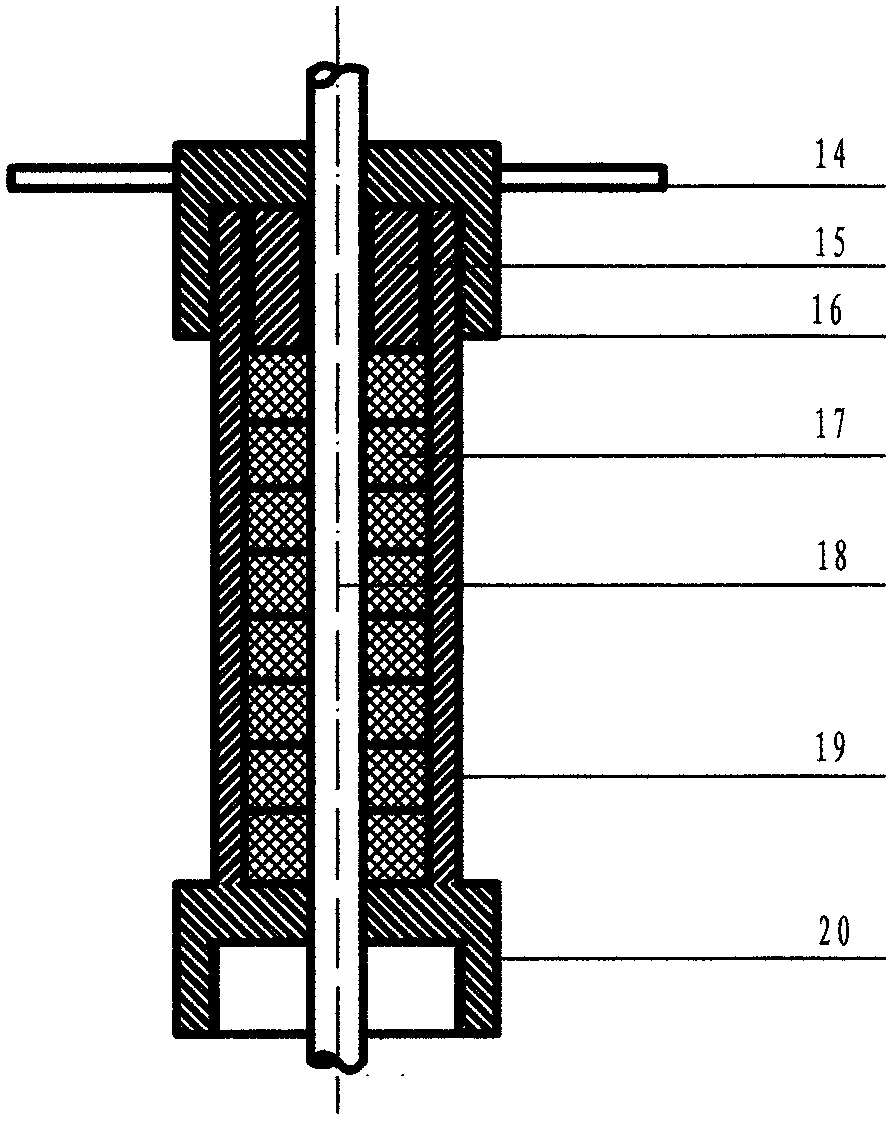

Novel magnetizing fluid seal device

InactiveCN104595495AMake up for lossSimple sealing structureEngine sealsRadioactive agentToxic material

The invention discloses a novel magnetizing fluid seal device. The novel magnetizing fluid seal device comprises permanent magnets, annular magnet poles and a magnetic conduction shaft cover, wherein the magnetic conduction shaft cover is sleeved with a main shaft, the annular magnet poles are connected with the magnetic conduction shaft cover in a sleeved mode, magnetizing fluid is filled in the clearance spaces between the annular magnet poles and the magnetic conduction shaft cover, the annular magnet poles are multiple, a permanent magnet is arranged between two adjacent annular magnet poles, an added magnetizing fluid device is arranged on each annular magnet poles in a matched mode, and each added magnetizing fluid device is provided with the corresponding magnetizing fluid inside. The novel magnetizing fluid seal device is simple in structure, and easy to manufacture. Further, no complex parts are required and the requirements for the shaft surface quality and clearance processing are not high. The novel magnetizing fluid seal device can realize zero leakage as long as under the tolerant pressure differential range due to the fact that the seal is formed by a fluid, and therefore the seal for an extremely toxic substance, a combustible substance, an explosive substance, a radioactive substance and particularly a precious substance and a substance with high purity can be realized.

Owner:常州市锐金轮机械配件有限公司

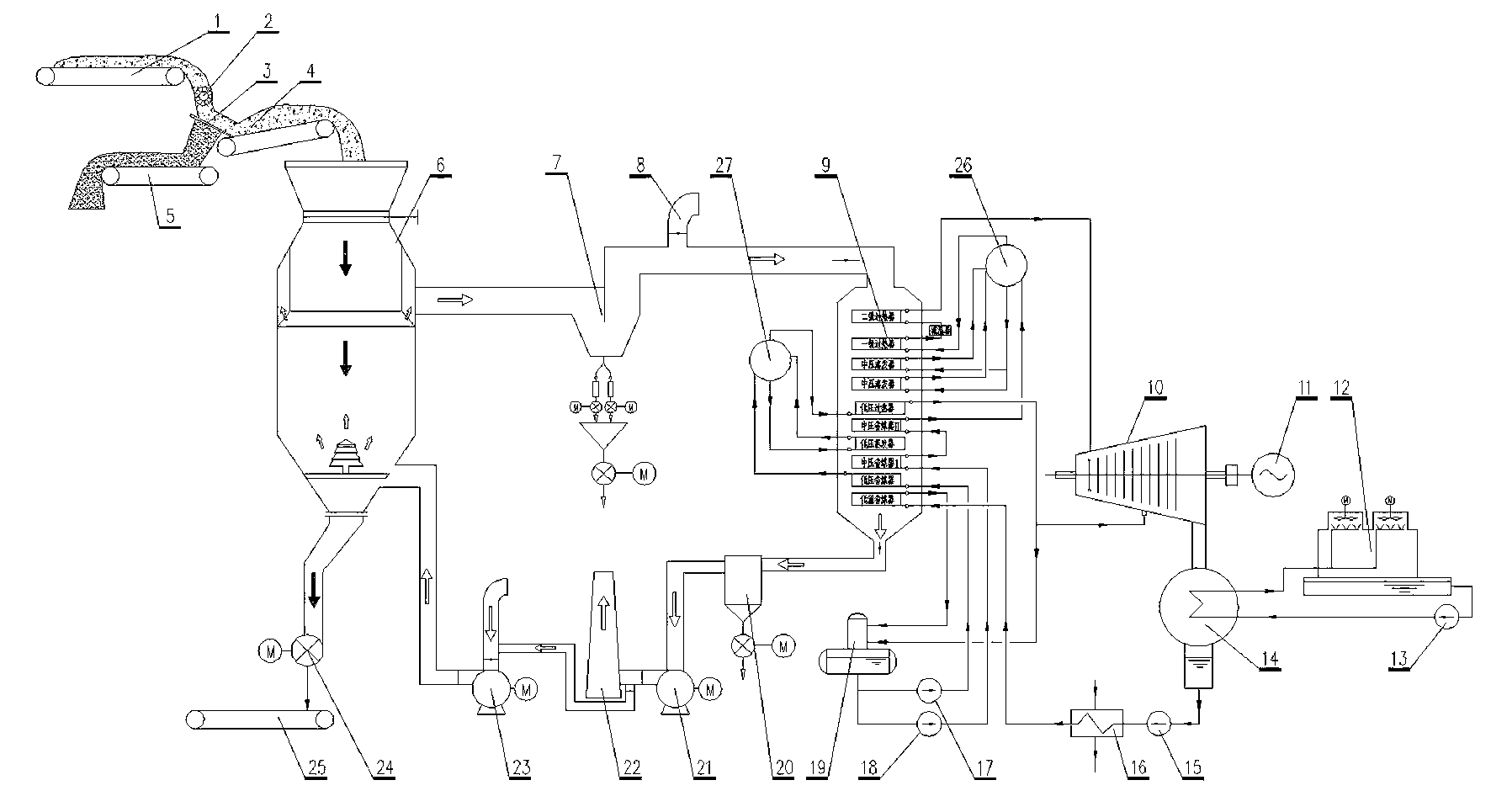

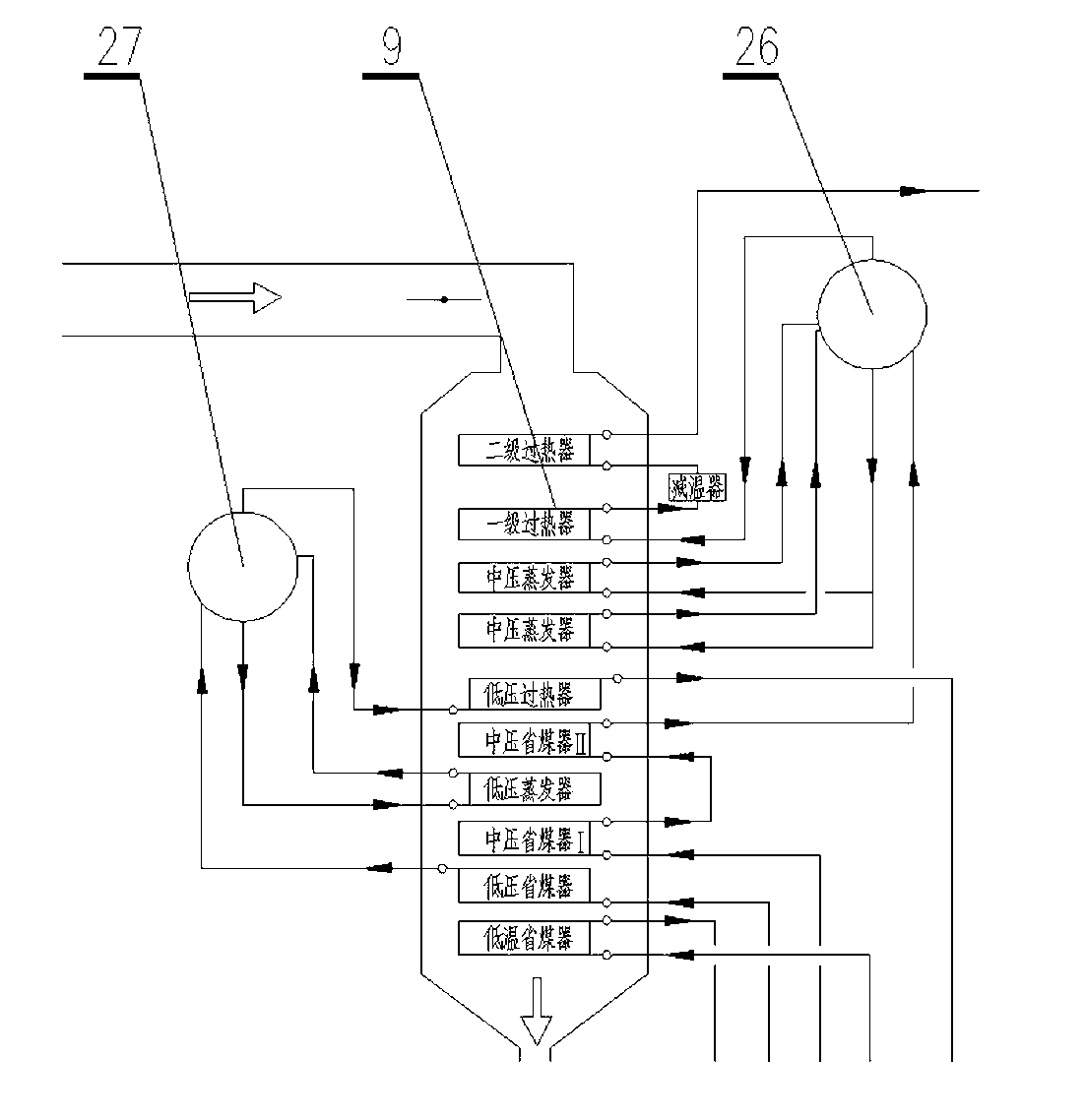

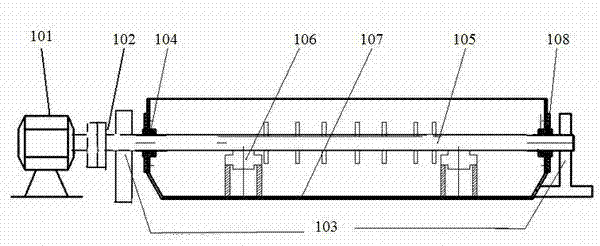

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

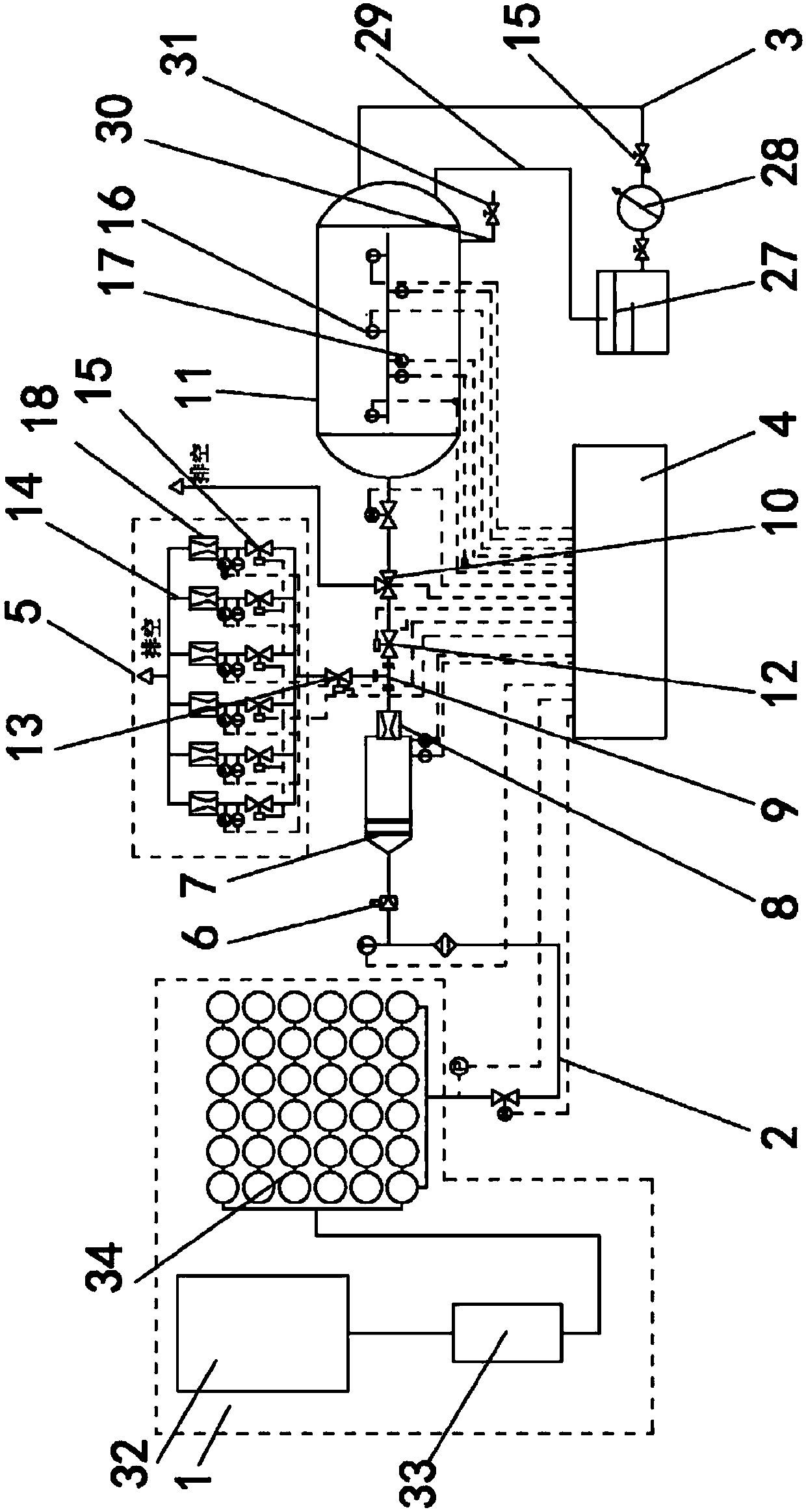

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

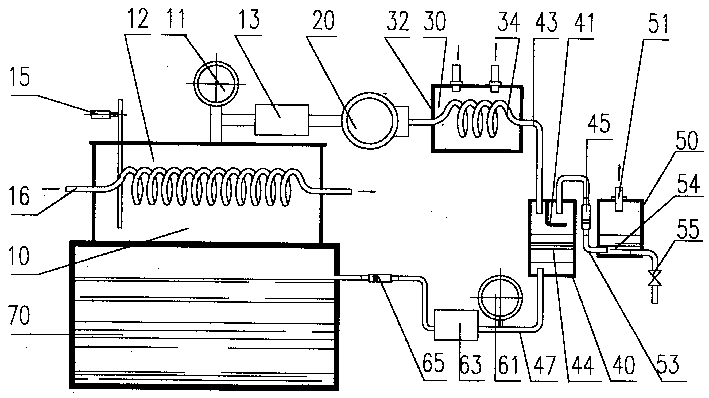

Supercritical fluid-type external-combustion heat engine

ActiveCN102797589AHigh heat conversion efficiencyAchieving Zero LeakageHot gas positive displacement engine plantsStirling engineHeat engine

The invention relates to the technical field of heat energy conversion and discloses a supercritical fluid-type external-combustion heat engine for overcoming the problems of low heat conversion efficiency and atmospheric pollution caused by incomplete combustion, and high noise in the present internal-combustion engines, the problems of low power / weight radio and incapability of zero leakage due to difficulty in sealing in the present Stirling engines. According to the invention, carbon dioxide and a gas working medium are filled in an airtight shell, the pressure in the airtight shell ranges from 7.4 MPa to 10 MPa, so that the carbon dioxide is in a supercritical carbon dioxide fluid state; and the interior of a gas guide cylinder cavity, a gas guide piston, the interior of a work-applying cylinder cavity, a work-applying piston, a flywheel crankshaft assembly and a valve are all immersed in the supercritical carbon dioxide fluid, the heat end temperature of the gas guide cylinder cavity is set to be between 60 DEG C and 130 DEG C, and the cold end temperature of the gas guide cylinder cavity is set be between 32 DEG C and 40 DEG C. By the supercritical fluid-type external-combustion heat engine disclosed by the invention, the heat energy at a temperature being higher than 50 DEG C can be directly and efficiently converted to mechanical energy and then to electrical energy, and then zero leakage can be realized. The efficiency of the heat energy-mechanical energy conversion is 20-80%.

Owner:HARBIN XIANGKAI TECH DEV

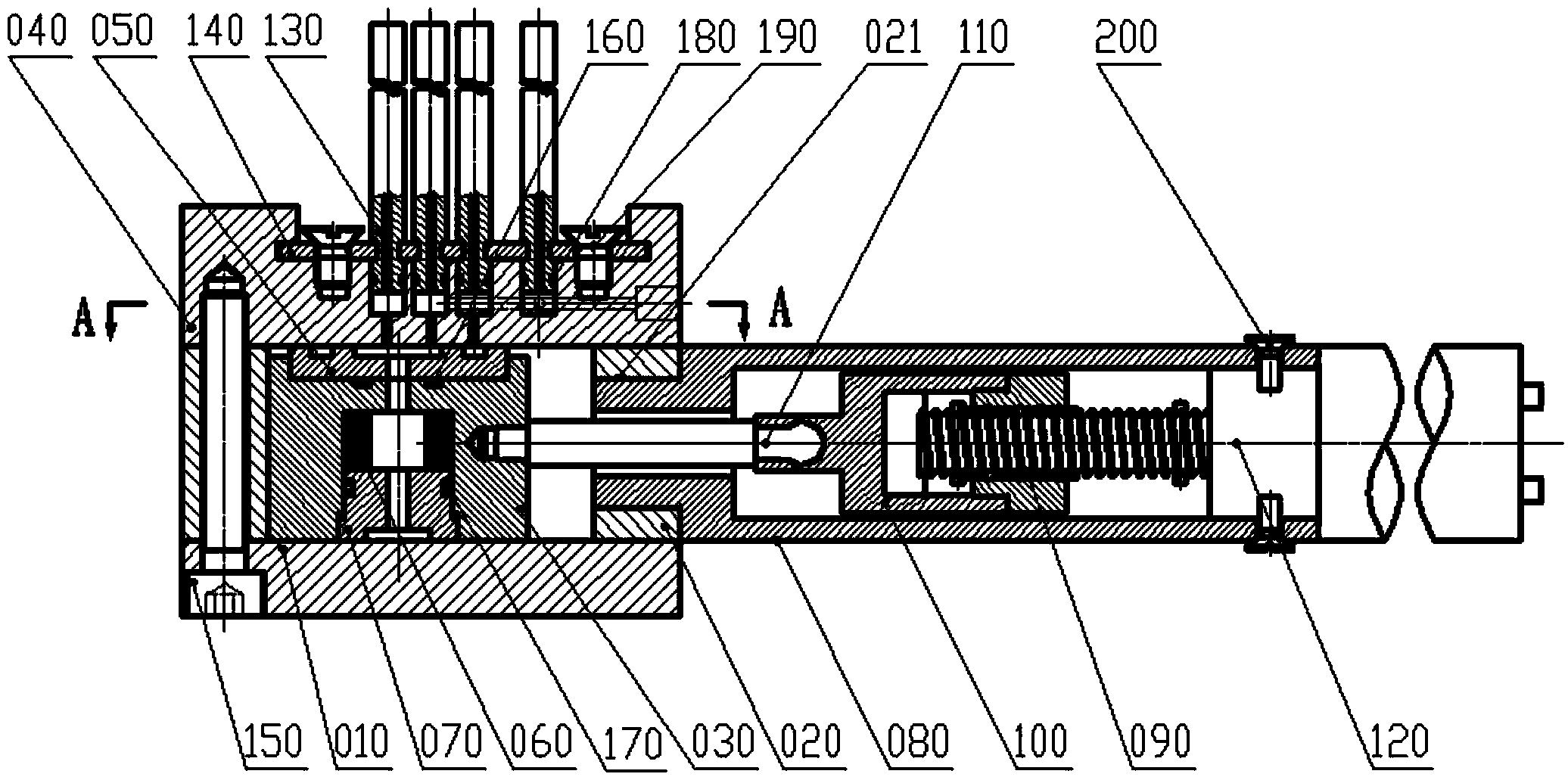

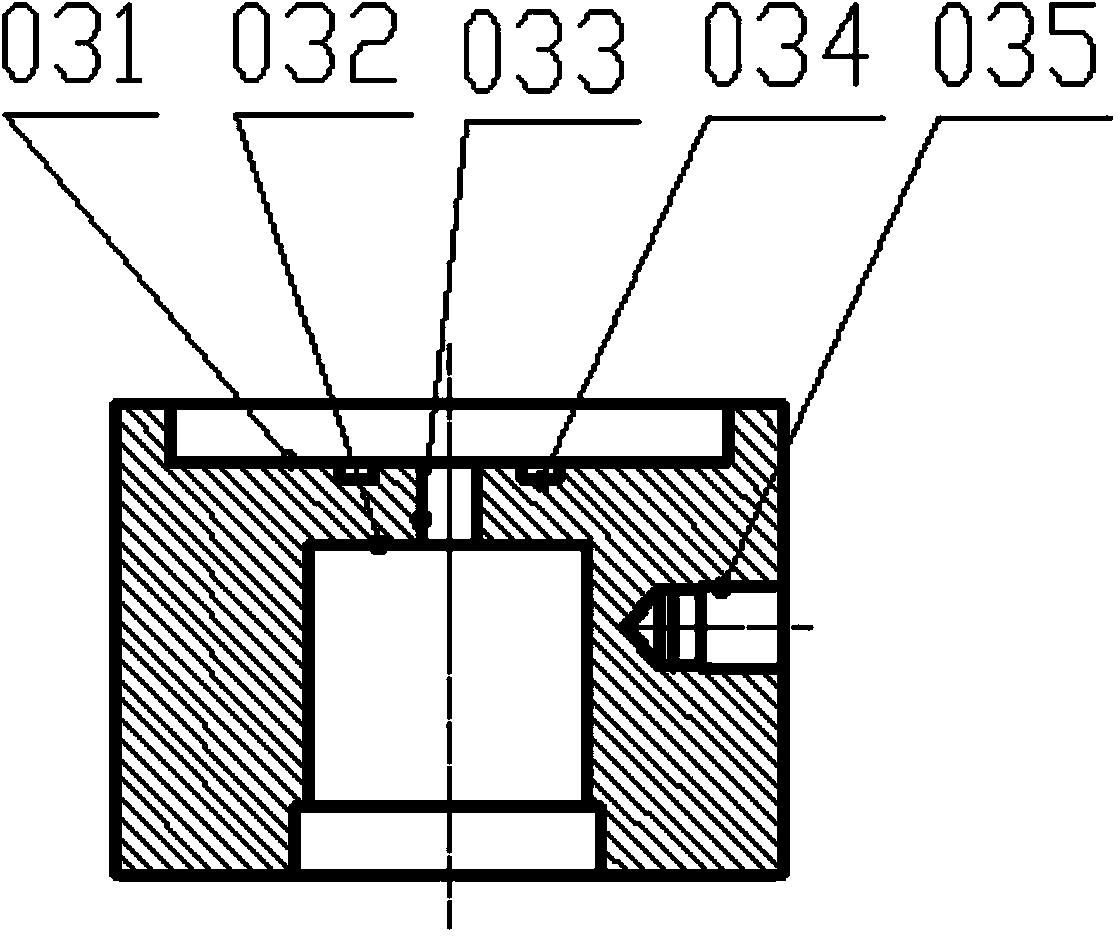

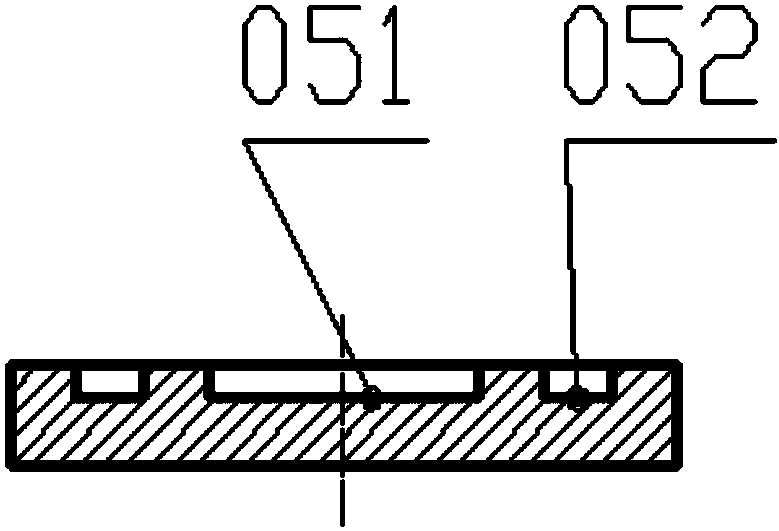

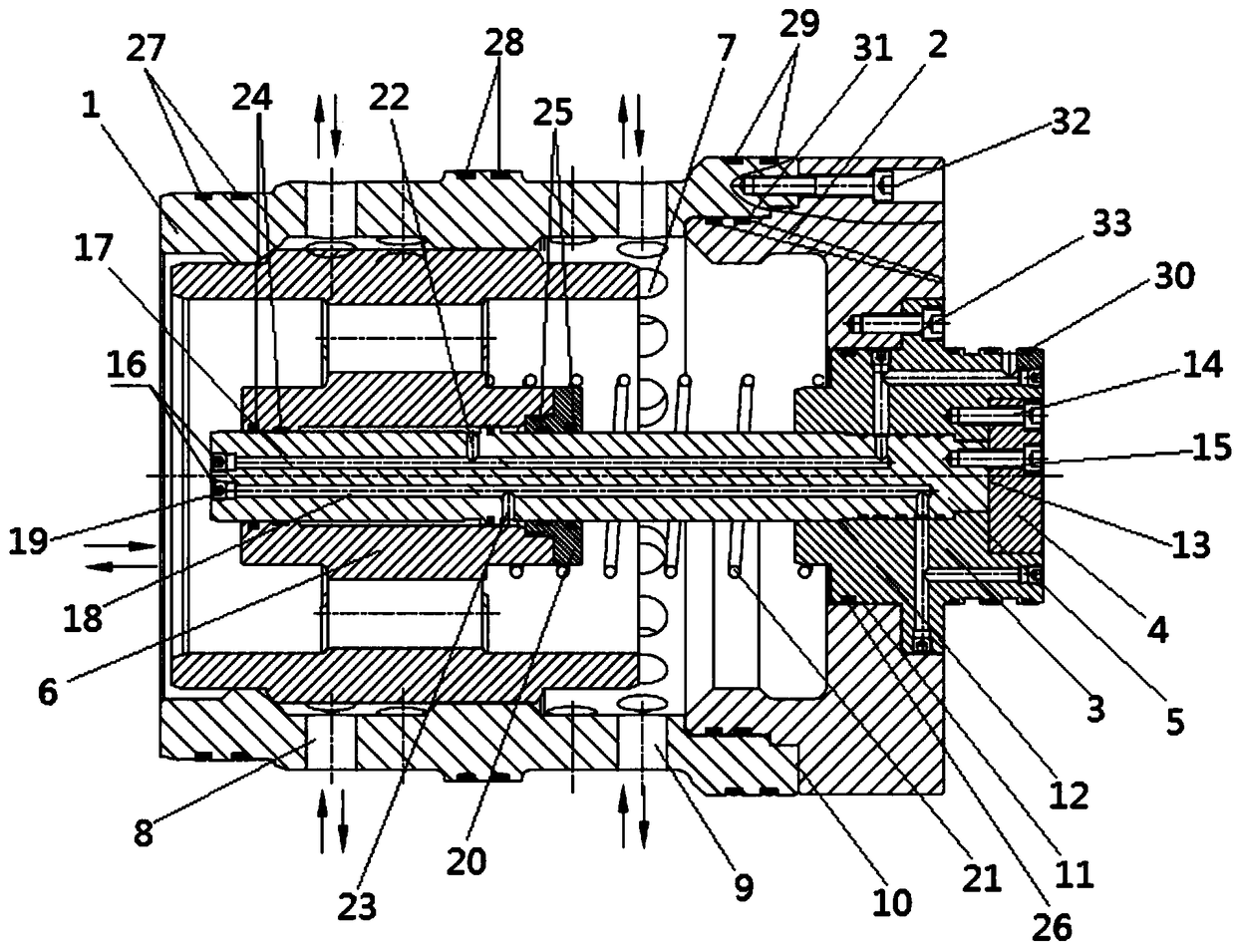

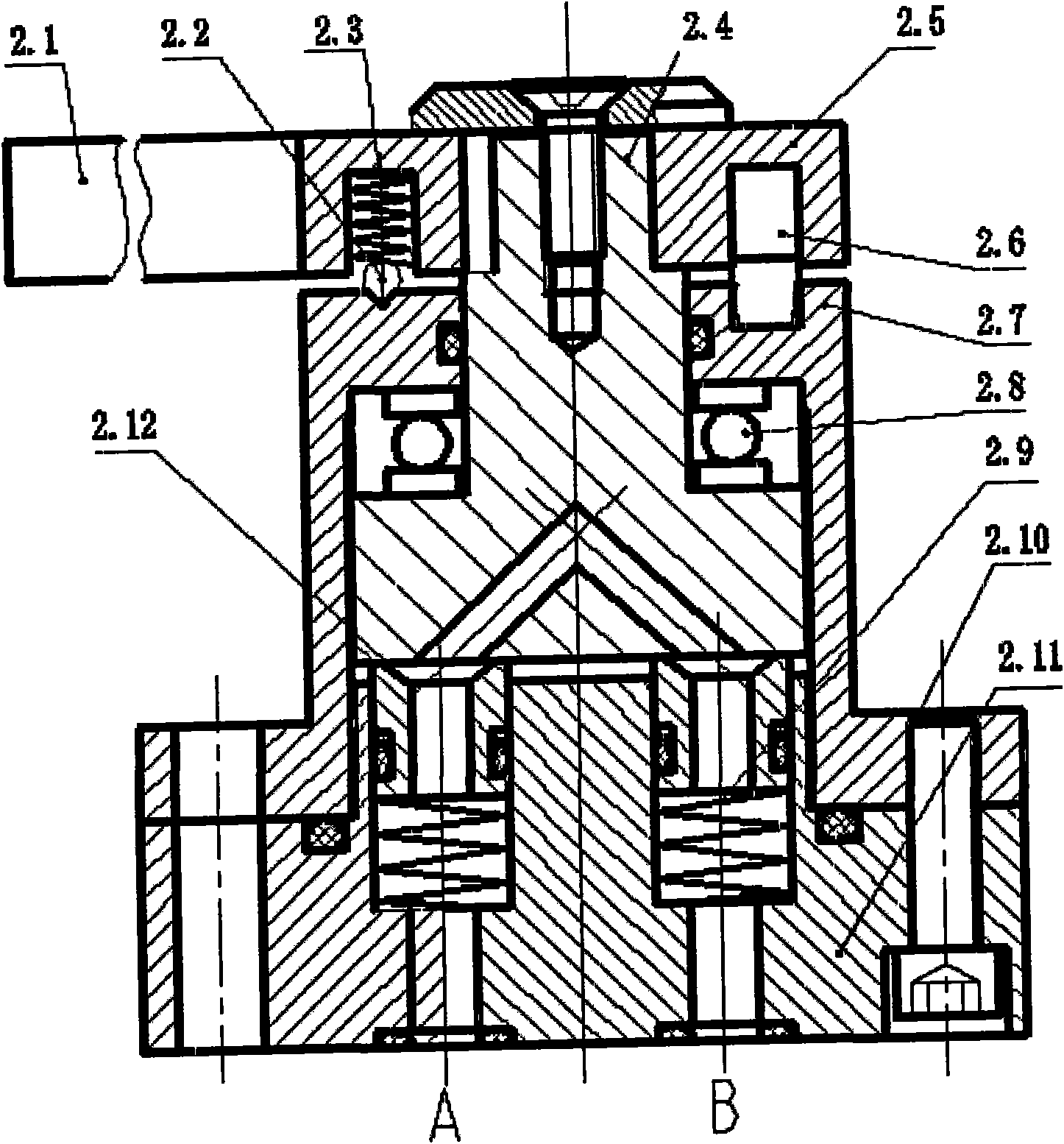

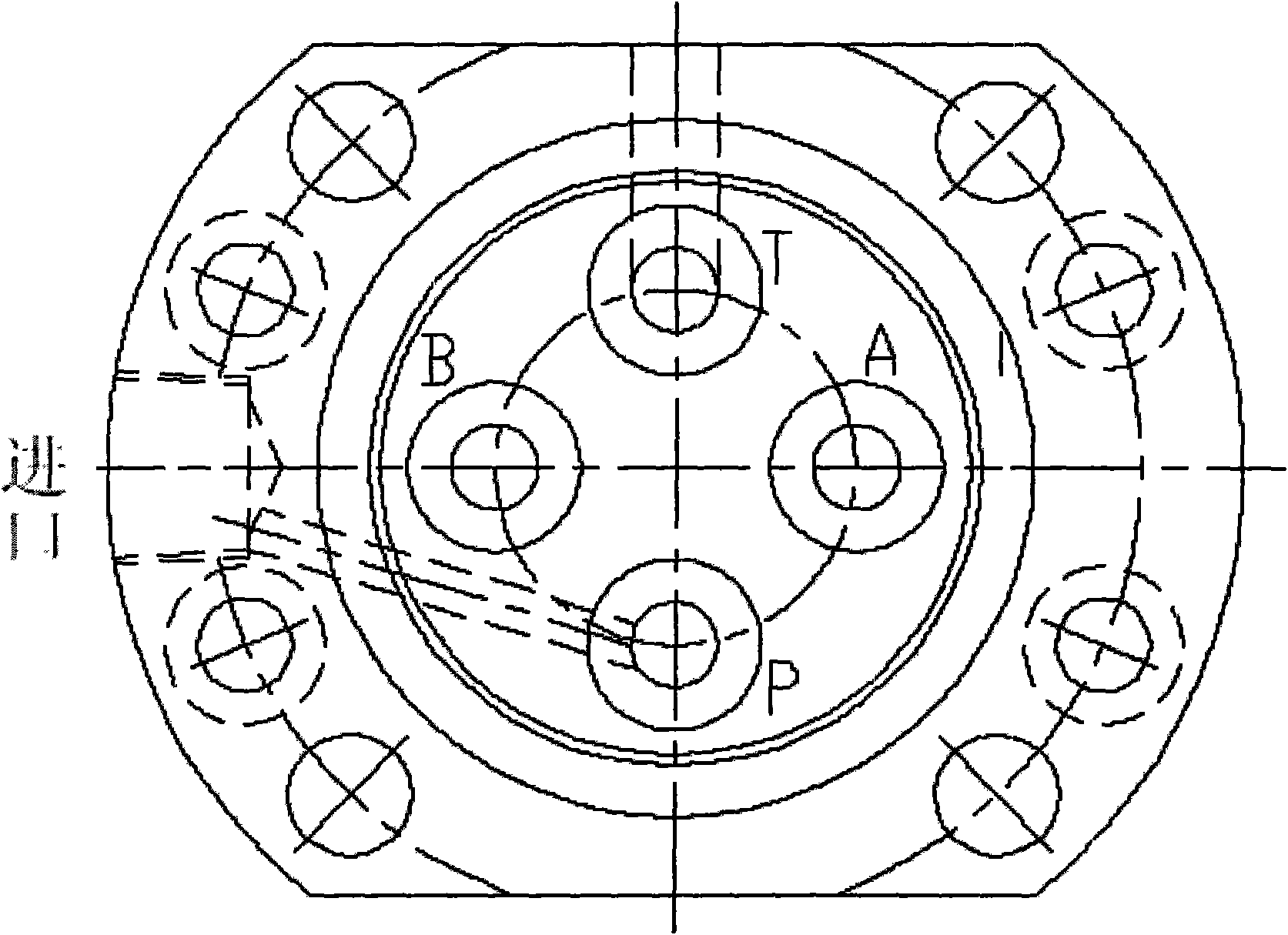

Plane sealing type reversing valve

ActiveCN104344017ACommutation is reliableAchieving Zero LeakageServomotor componentsMultiple way valvesFluid controlBall screw

The invention discloses a plane sealing type reversing valve which belongs to hydraulic control valves and is used for the fluid switching of a plurality of channels and solving the problem that the reversing valves at present are relatively large in reversing operation force, bad in anti-pollution capacity, high in processing difficulty and high in cost. The plane sealing type reversing valve comprises a lower valve seat, a support seat, a sliding block, an upper valve seat, a fixed valve element, a disc spring, a floating valve element, a sleeve, a ball screw assembly, a connection threaded sleeve, a push rod and a gear motor. According to the plane sealing type reversing valve, plane sealing is used, and the small rotary gear motor with the ball screw assembly is used for linear driving to drive the sliding block to move straightly and control the reversing of the oil path. The plane sealing type reversing valve is simple in structure, convenient in interface form and good in manufacturability, is capable of reliably realizing the sealing of the entire life cycle and ensuring the reliable reversing of the hydraulic systems, is suitable for standard and serial production and suitable for the high-temperature high-pressure severe environments and working conditions such as petroleum and natural gas extraction, and can be used for the fluid control of various hydraulic systems.

Owner:HUAZHONG UNIV OF SCI & TECH

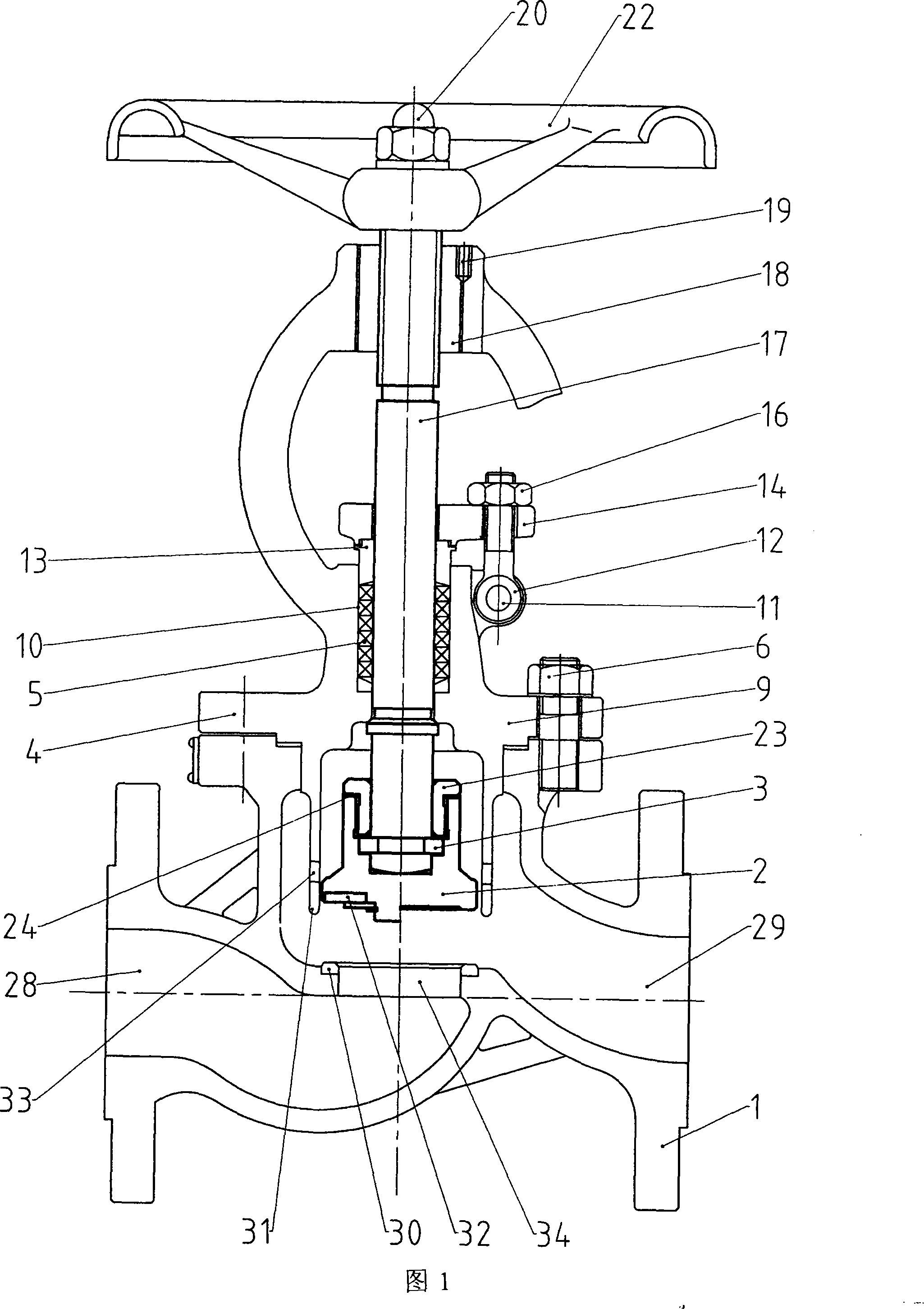

Electromagnetic actuation stop valve for venting pile top of nuclear power station

ActiveCN103759021AEasy to disassembleEasy maintenanceOperating means/releasing devices for valvesValve members for heating/coolingNuclear powerHeat sink

An electromagnetic actuation stop valve for venting a pile top of a nuclear power station comprises a main valve body assembly, an auxiliary valve body assembly, a valve cover, an electromagnetic driving mechanism, and an electric connector assembly, wherein the main valve body assembly comprises a valve body, a valve cylinder and a valve bush assembly, the valve bush assembly comprises a valve bush, a nonmagnetic pipe and an insulation cover, the lower end of the nonmagnetic pipe is in threaded connection with an upper port of the valve bush, the insulation cover is fixed in the valve bush, the valve bush is fixedly connected with the upper end of the valve body, a sleeve is disposed in the valve body, the auxiliary valve body assembly is formed by assembling a valve head, a valve rod and a piston, a guiding member is arranged between the valve bush and the valve body, a plurality of cooling fins are arranged on the outer wall of the valve bush, a plurality of maze grooves are formed in the outer wall of the insulation cover, and the electromagnetic driving mechanism comprises a movable iron core, a coil assembly, a coil outer shell, and a static iron core. The electromagnetic actuation stop valve must bear high-temperature and high-pressure pipeline ambient conditions and high-temperature, high-heat, and high-radiation environmental conditions and is small and light.

Owner:ANSHAN SOLENOID VALVE +1

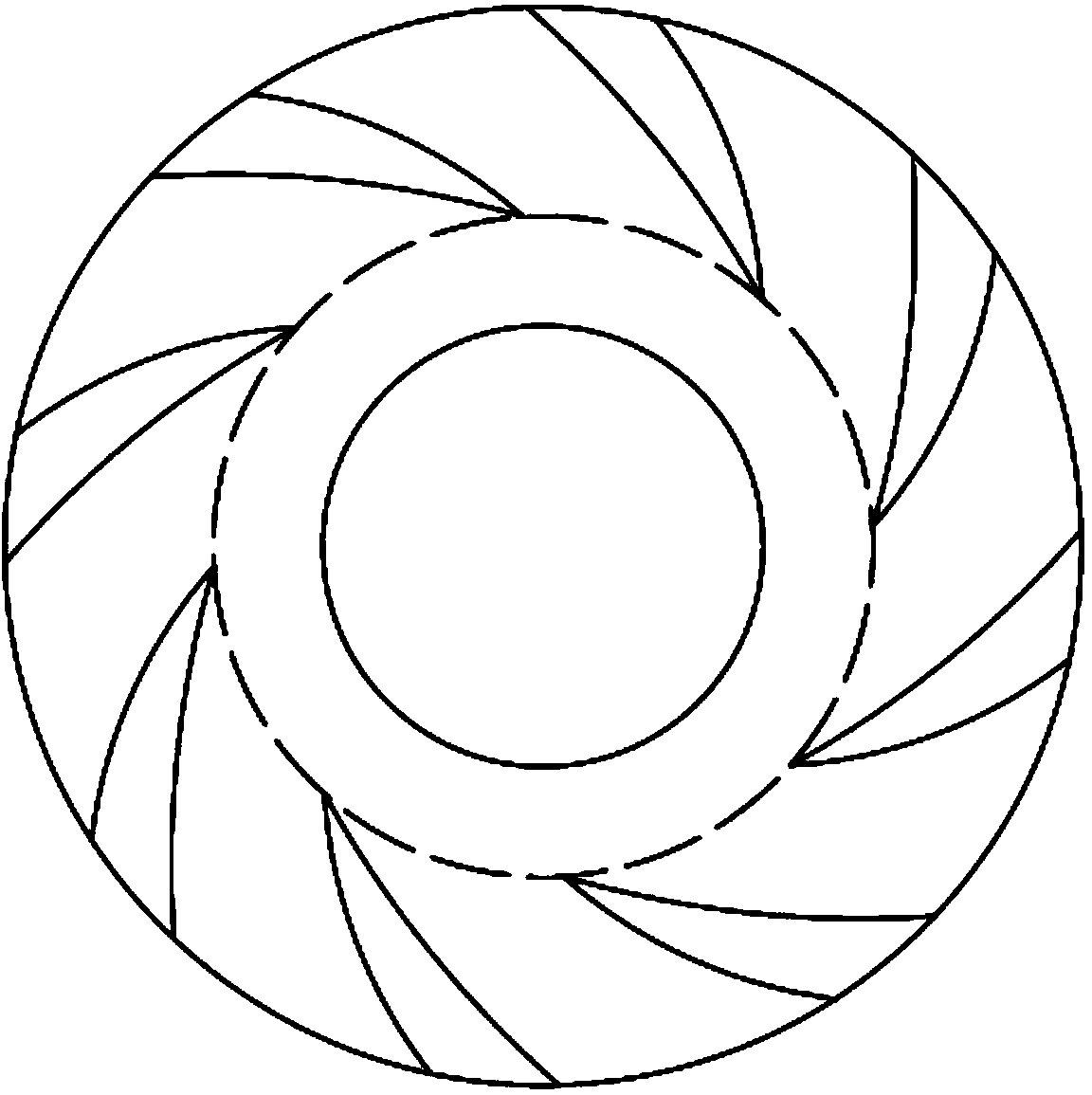

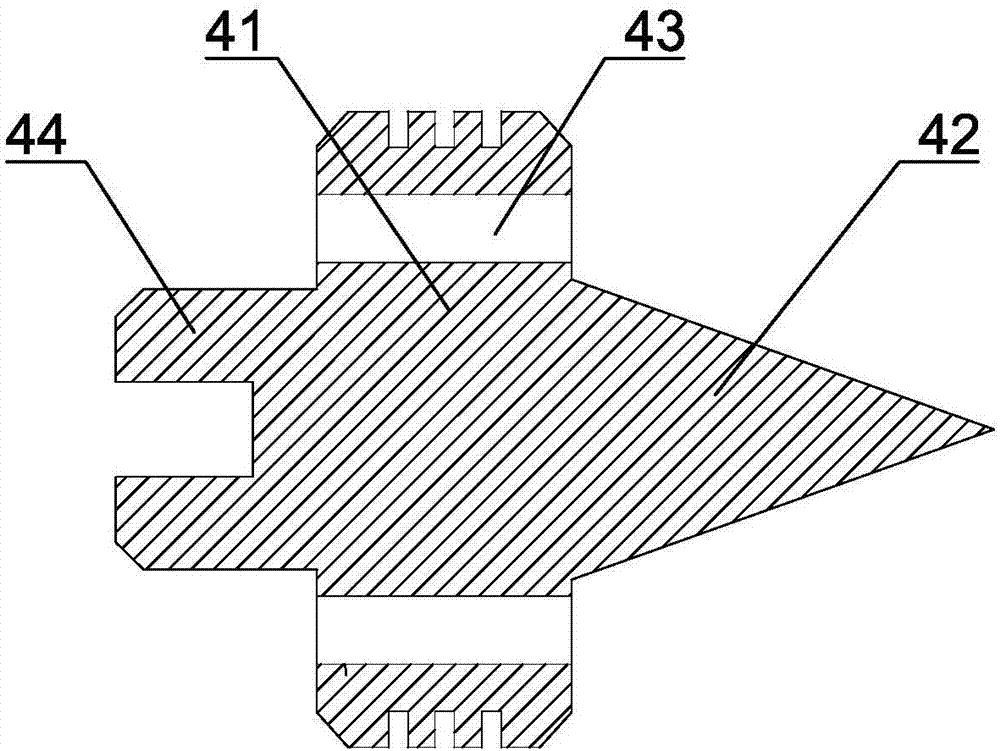

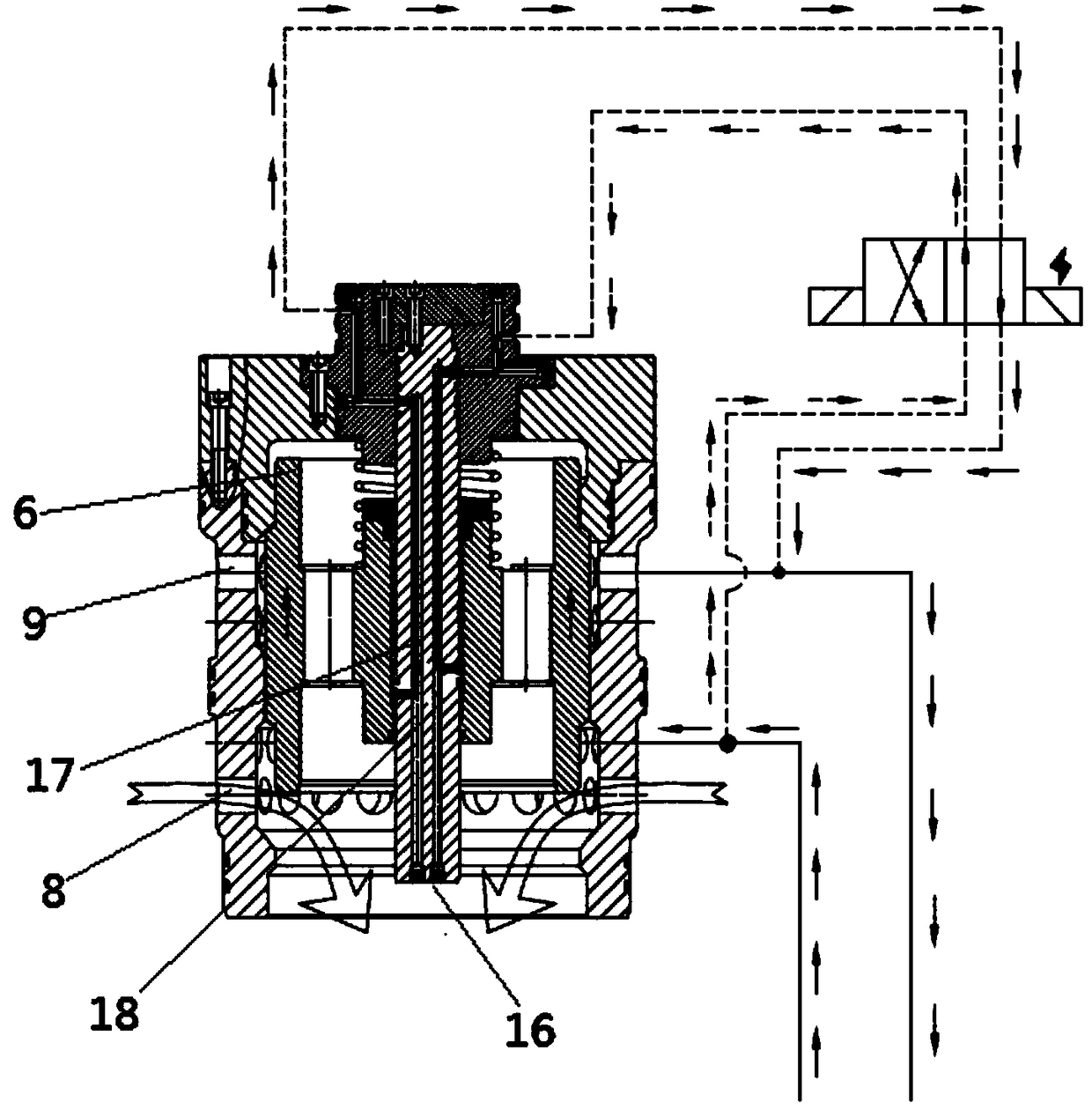

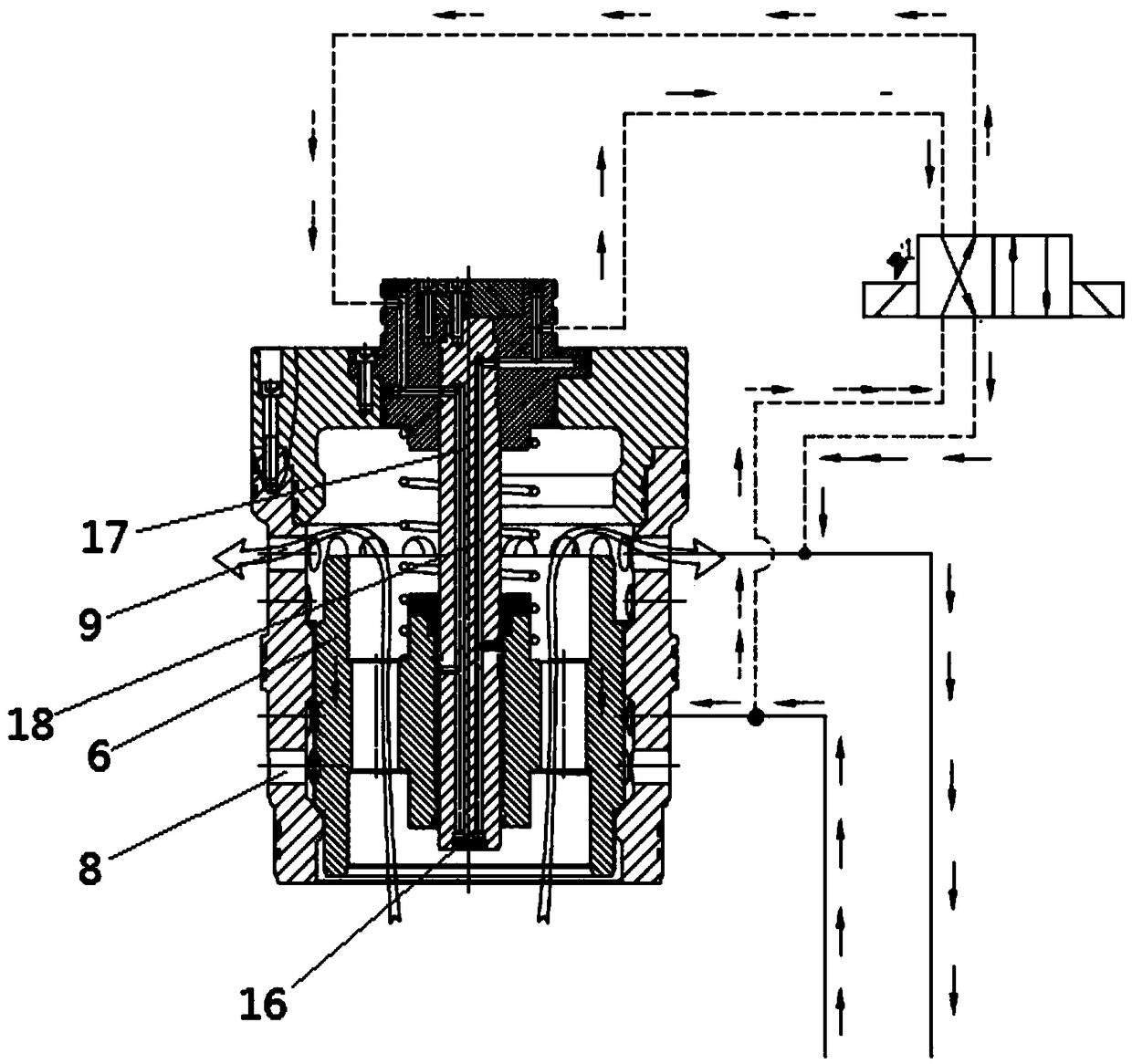

Liquid expander

ActiveCN101644170AFlexible brakingReduce energy consumptionBlade accessoriesLeakage preventionImpellerCoupling

The invention discloses a liquid expander comprising a bearing box, a rotor, a spray nozzle assembly and an expander casing. The liquid expander is characterized in that the spray nozzle assembly comprises a spray nozzle press plate, a spray nozzle cover, a spray nozzle vane, a spray nozzle turntable and a spray nozzle chassis, wherein the spray nozzle cover, the spray nozzle vane and the spray nozzle turntable are sequentially connected together in an axial direction by a cylinder pin, and the spray nozzle press plate and the spray nozzle cover are elastically connected in the axial direction; the spray nozzle turntable is connected on the external diameter of a step circle of the spray nozzle chassis in a circumferential rotation way; both axial ends of the spray nozzle chassis are respectively connected with the expander casing and the bearing box; a middle component is arranged between the bearing box and the axial direction of the spray nozzle chassis; the rotor comprises a main shaft, the front part of the main shaft is provided with an oil thrower, and the back part of the main shaft is provided with a shaft coupling; shaft necks at both sides of the main shaft are fixed inthe bearing box in a rotation way, and the front end of the main shaft passes through the spray nozzle and the middle component and is connected with an impeller;]the oil thrower is positioned at theposition of the middle component in the axial direction; and a position from the wheel back side of the impeller to the main shaft section of the oil thrower is provided with a shaft sealer in the axial direction, and the shaft sealer has a compound sealed structure.

Owner:XI AN JIAOTONG UNIV +1

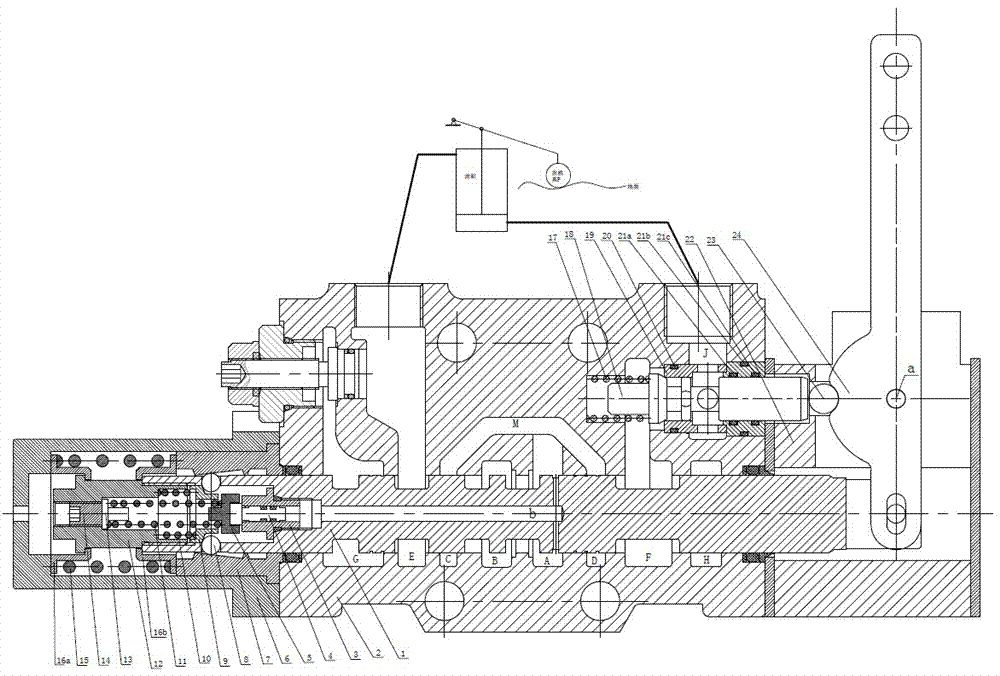

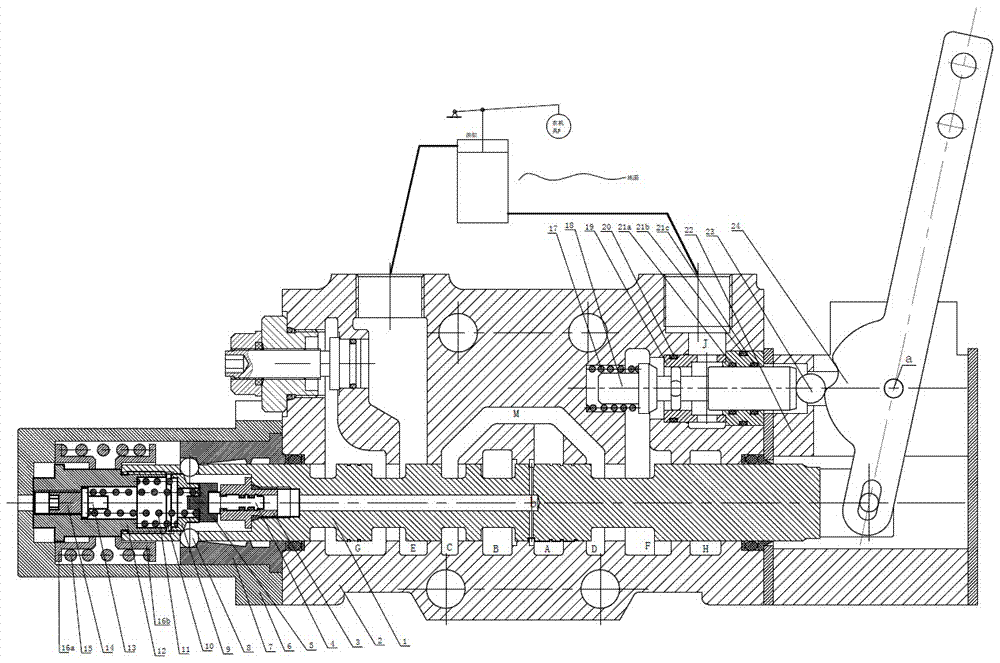

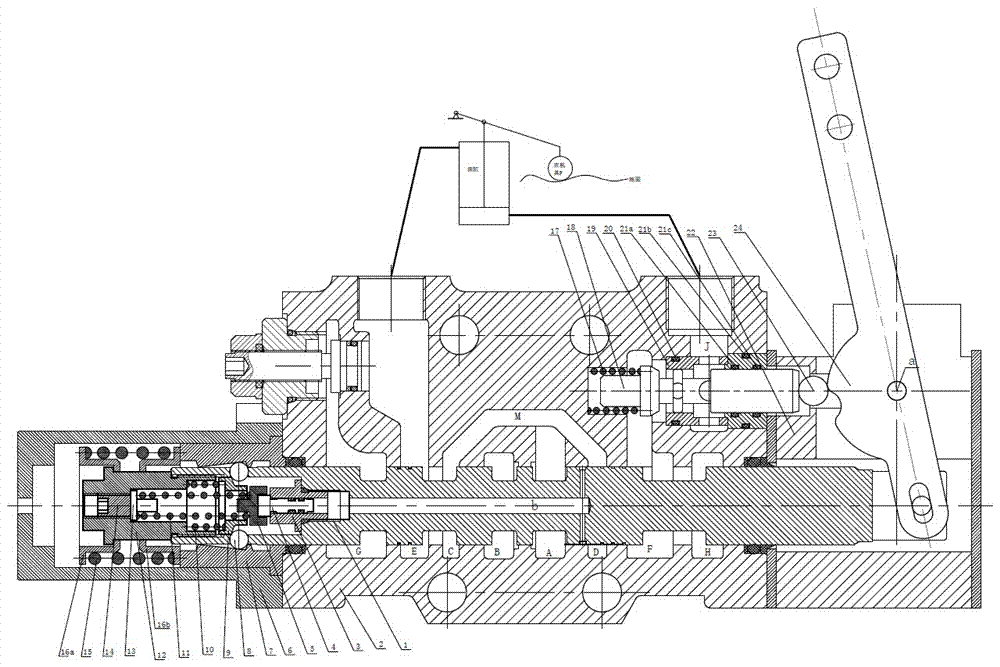

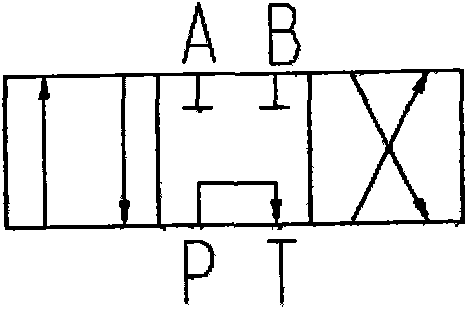

Manual pressure-maintaining and skipping floating reversing valve for tractor

The invention discloses a manual pressure-maintaining and skipping floating reversing valve for a tractor. The manual pressure-maintaining and skipping floating reversing valve for the tractor comprises a valve element (1), a valve body (2), a front end cover (6) and a rear end cover (22), wherein the valve element (1) is assembled in the valve body (2), and the front end cover (6) and the rear end cover (22) are assembled at the front end and the rear end of the valve body (2) correspondingly. The manual pressure-maintaining and skipping floating reversing valve for the tractor is characterized in that the reversing valve further comprises an oil duct switching lock arranged in the valve body, a cam handle mechanism arranged in the rear end cover, a skipping mechanism arranged in the valve element and a positioning mechanism arranged in the front end cover. The manual pressure-maintaining and skipping floating reversing valve for the tractor is compact in structure and flexible in reversing and has reliable functions, and the problem of settling, caused by internal leakage of an existing sliding reversing valve, of large agricultural implements on the rear portion of the tractor in the farming process is solved.

Owner:江苏力源液压机械有限公司

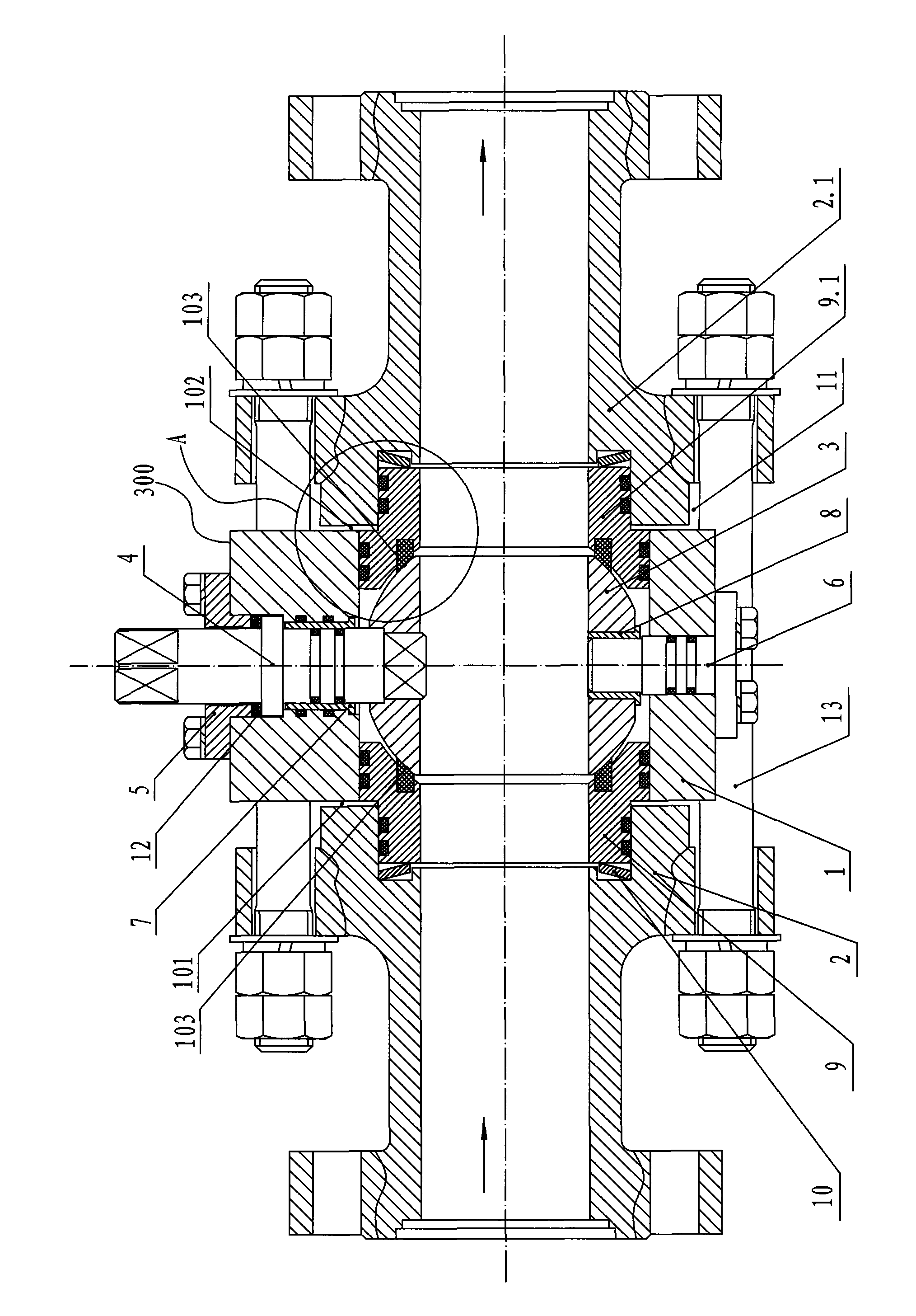

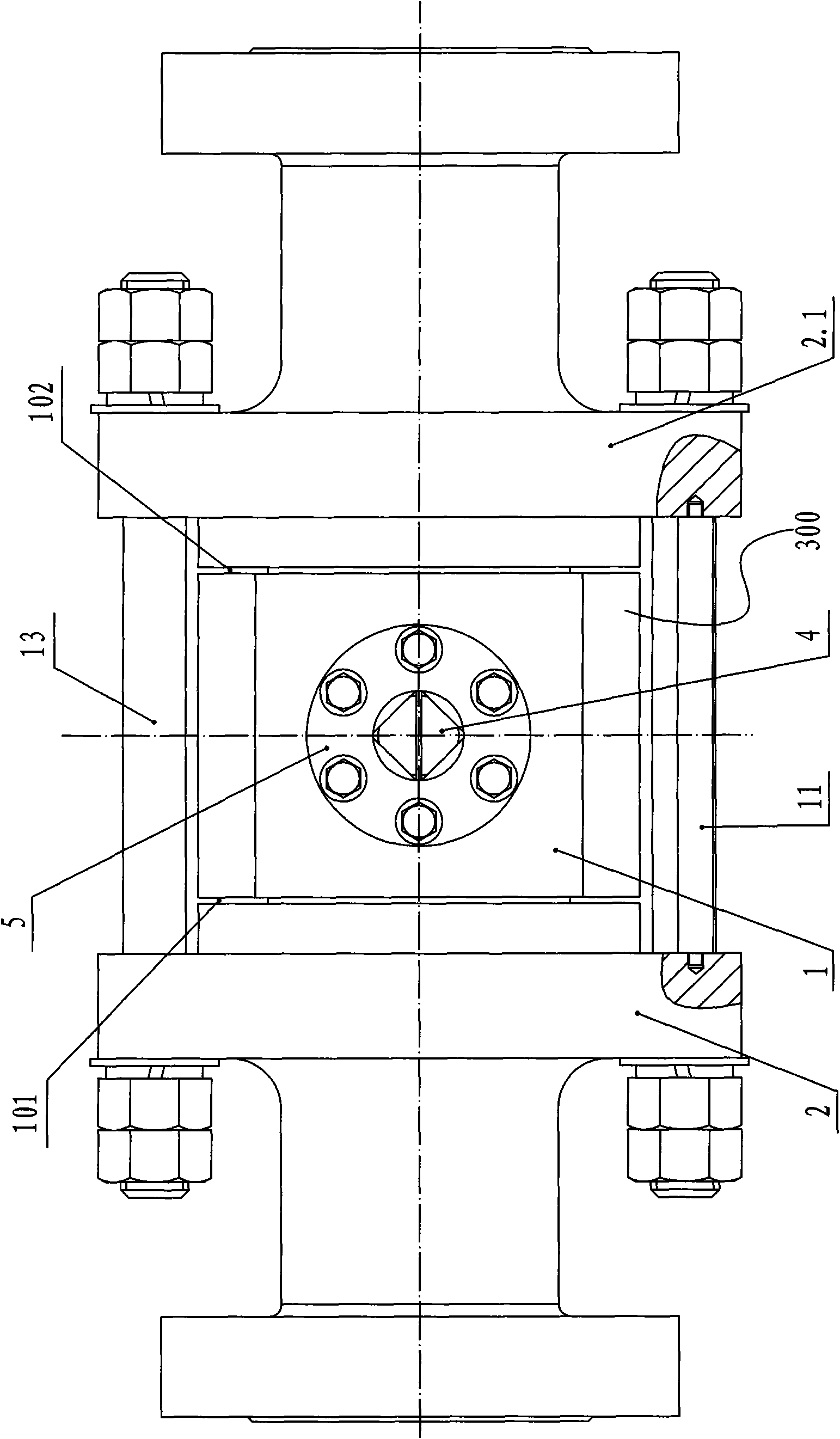

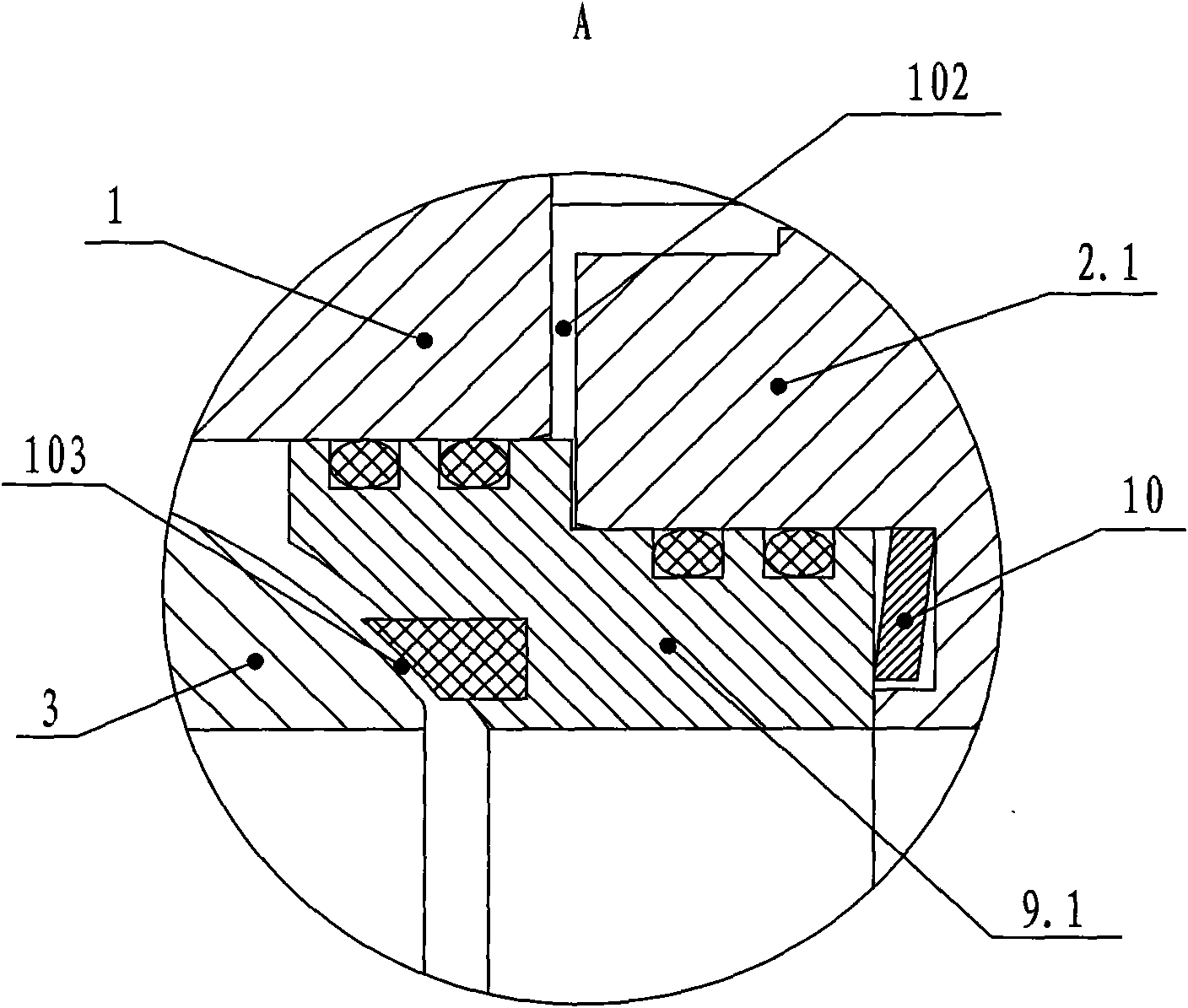

Ball valve

The invention relates to a ball valve. A main valve body assembly (300) comprises a main valve body (1), a ball body (3) which is positioned in the main valve body (1), an upper shaft (4) which is rotatably matched with the main valve body (1), a pressure cover (5) which is connected with the main valve body (1) and axially positions the upper shaft (4) and a lower shaft (6) which is connected with the main valve body (1), wherein the upper shaft (4) is fixedly connected with the upper end of the ball body (3), the lower end of the ball body (3) is rotatably connected with the lower shaft (6), the right end of a left valve seat is in slide connection with the left end of the main valve body (1), the left end of a right valve seat 9.1 is in slide connection with the right end of the main valve body (1), and the vertical distance between the right end face of a left auxiliary valve body (2) and the left end face of a right auxiliary valve body (2.1) is larger than the axial distance of the main valve body (1). Compared with the prior art, the invention has both of the advantages of a float ball valve and a fixed ball valve, and also has small operating torque, long service life and better sealing reliability.

Owner:星箭科技股份有限公司

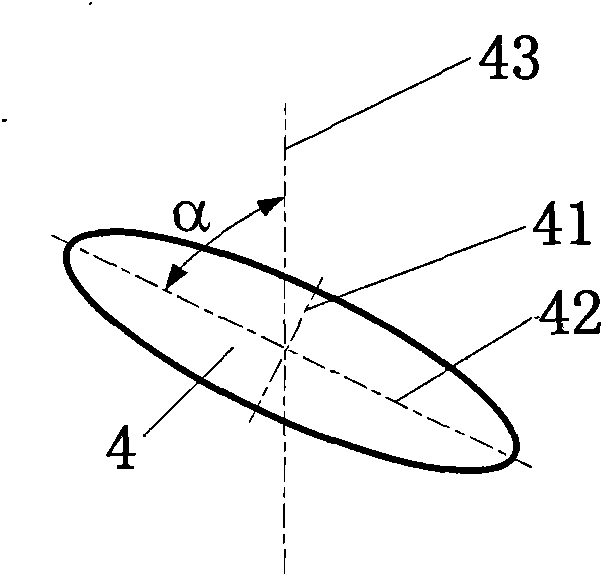

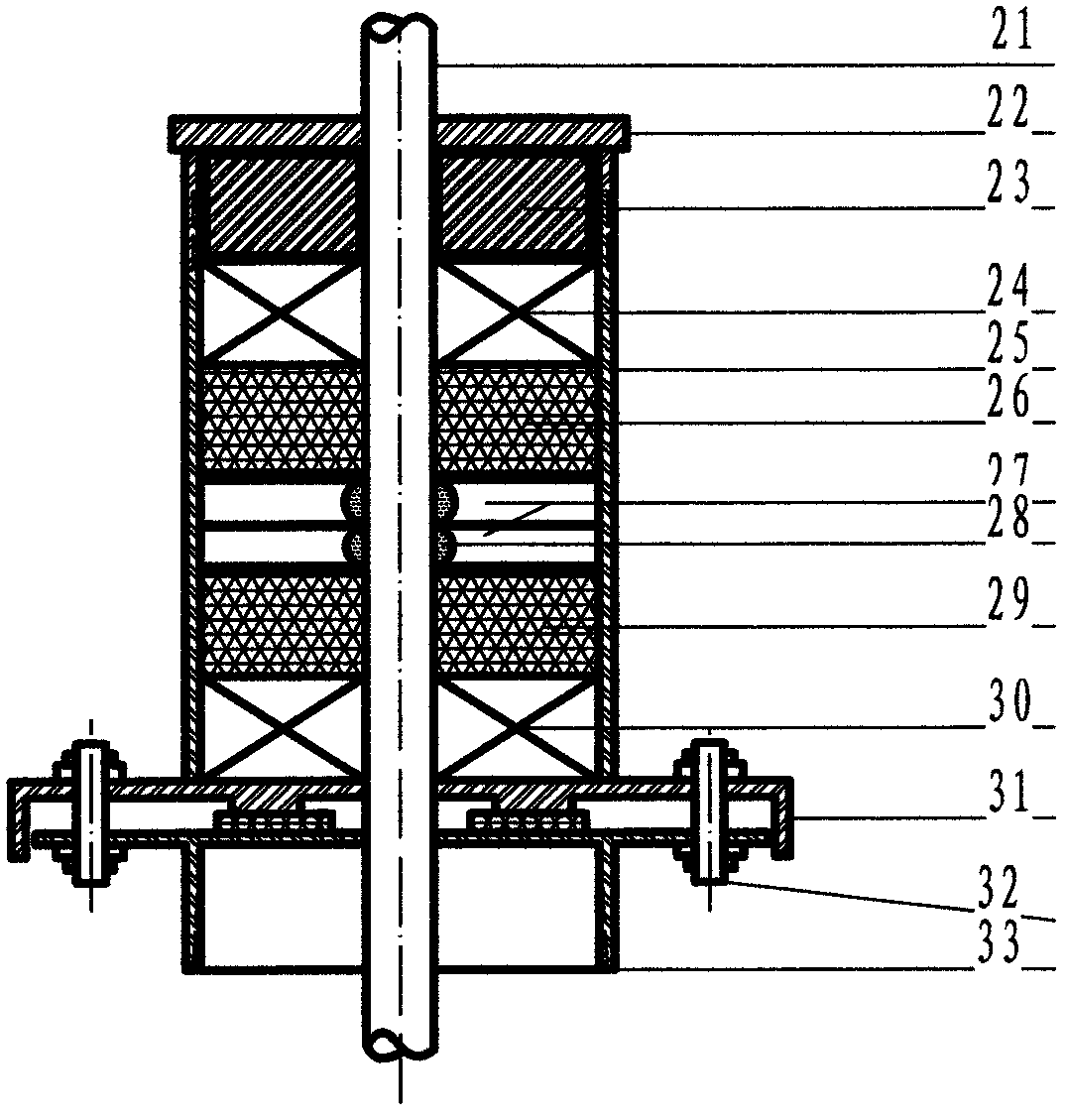

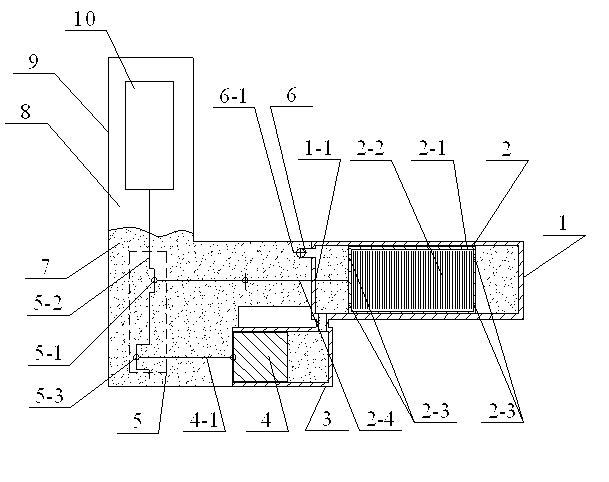

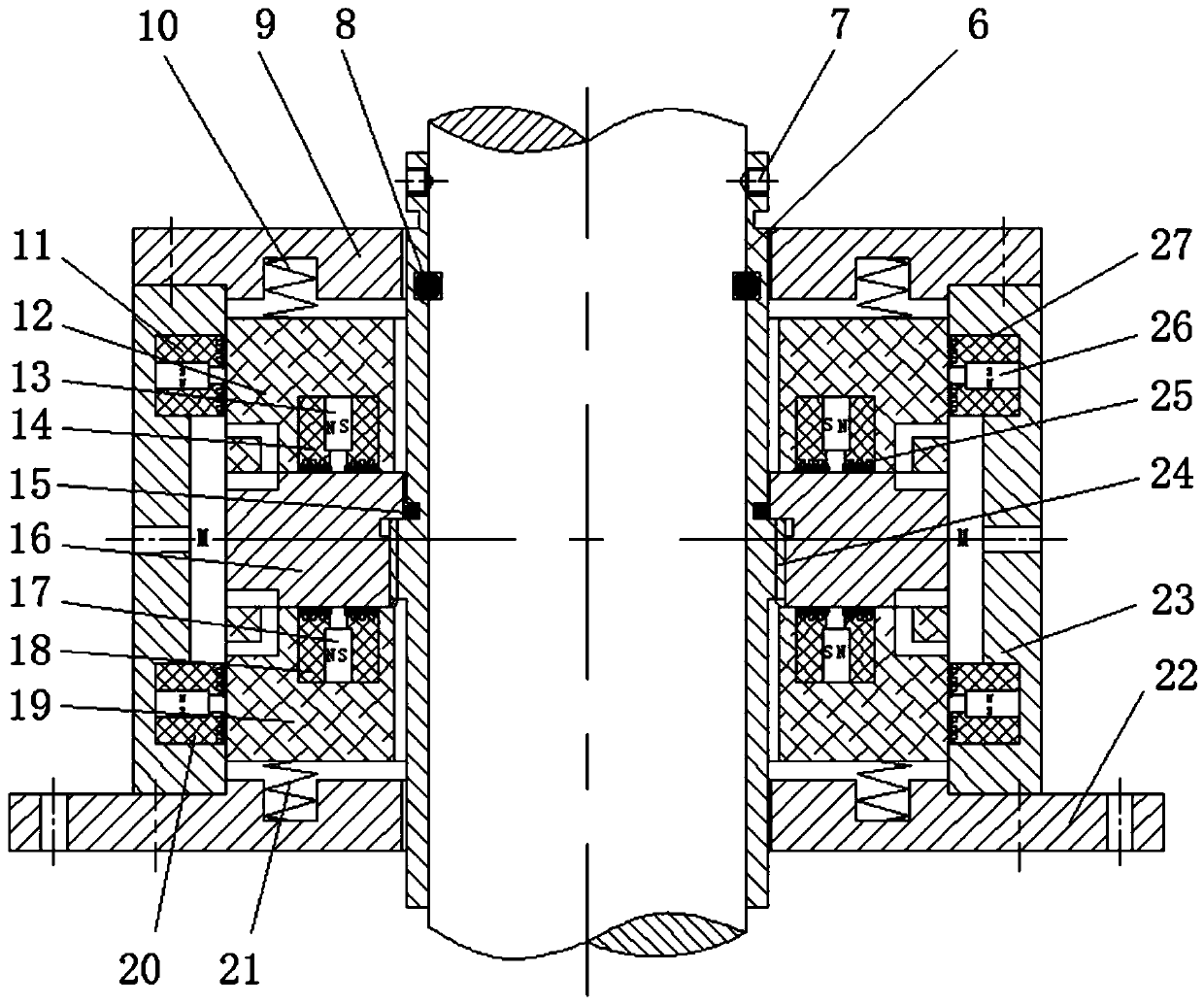

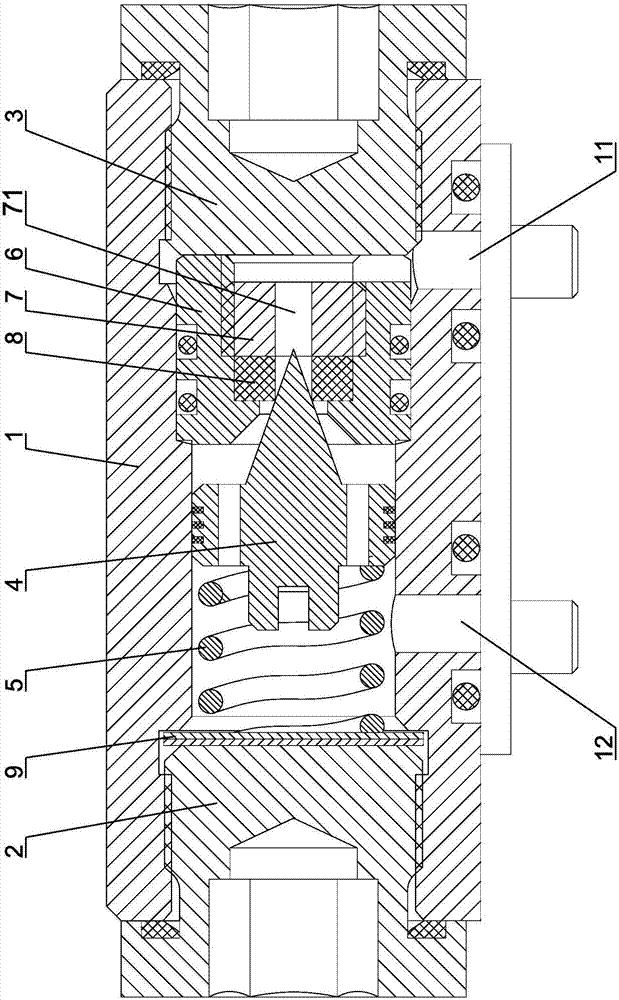

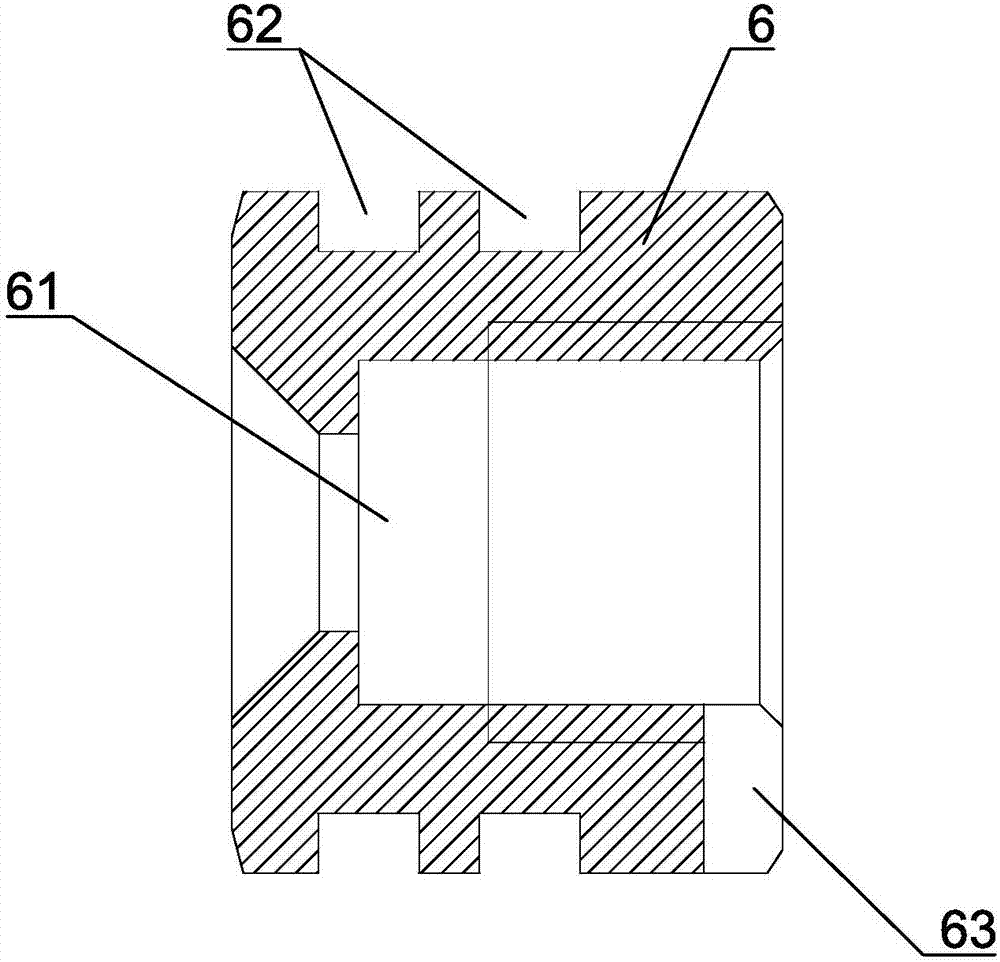

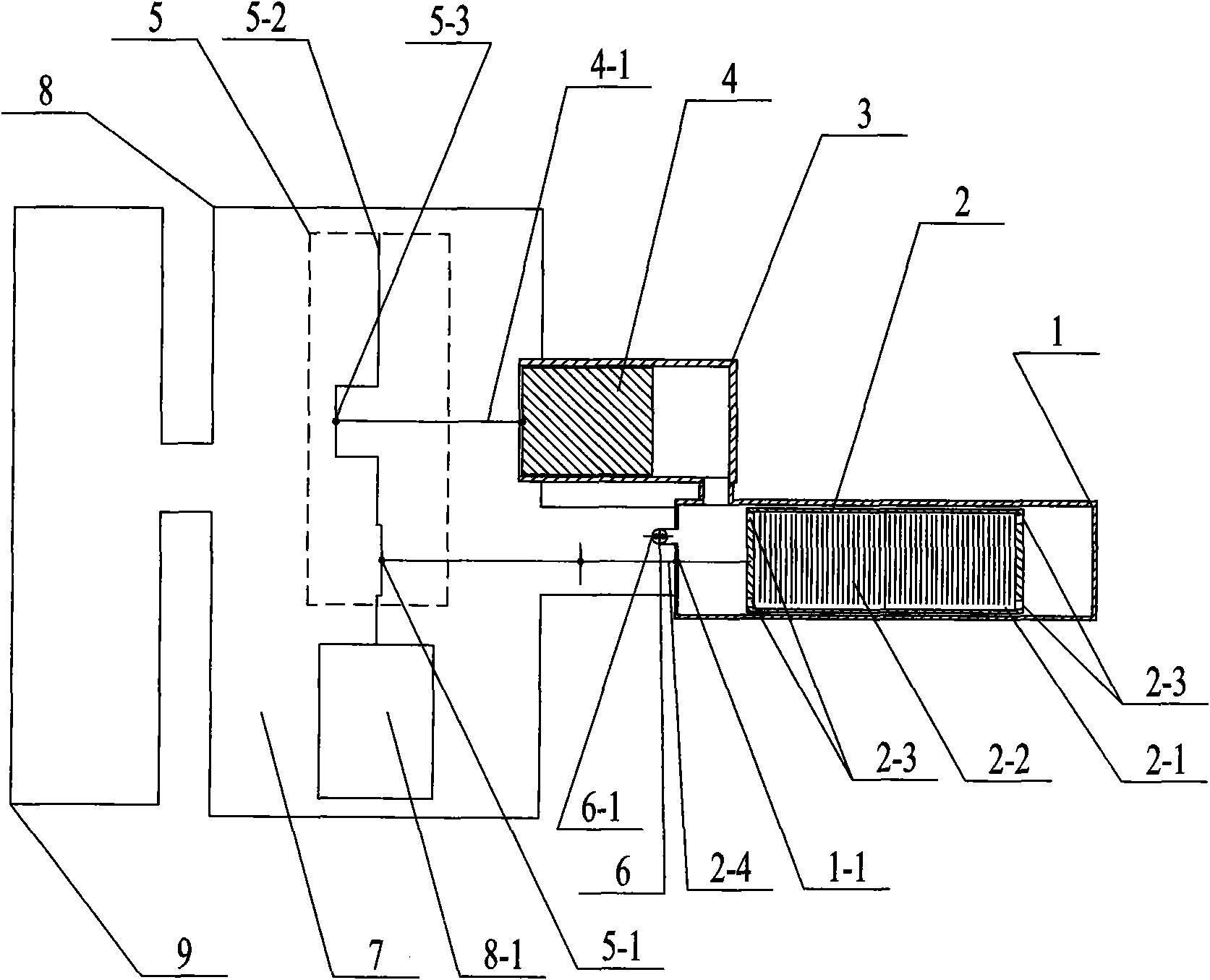

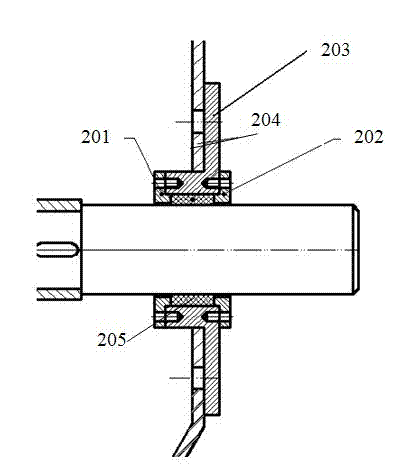

Combined non-contact double-end-face seal based on magnetic liquid sealing and fluid dynamic-pressure mechanical sealing

PendingCN110185653AAchieving Zero LeakagePrevent leakagePump componentsPumpsMagnetic tension forceMolten salt

The invention provides a combined type non-contact double-end-face seal based on magnetic liquid sealing and fluid dynamic-pressure mechanical sealing, so that the zero leakage and the long-period safe and stable operation of the molten salt pump shaft seal can be guaranteed. The combined type non-contact double-end-face seal is arranged between a shell and a rotary shaft of the rotary equipment,the combined non-contact double-end-face seal is composed of "a pumping-in type" fluid dynamic-pressure mechanical seal and a magnetic liquid seal, the upper end surface and the lower end surface of movable rings are movable ring sealing end surfaces, each movable ring sealing end surface is provided with a groove table area and a sealing dam, and the groove table area is provided with uniformly distributed spiral grooves; a current collecting ring groove is located on the outer diameter side of a sealing end surface, the drainage hole channel is used for communicating the current collecting ring groove with a blocking fluid cavity, and a magnetic generating mechanism is located at the inner diameter side part of the sealing end surface; when the movable rings rotate relative to static rings, the spiral grooves are pumped into blocking fluid, the opening force of the end face is generated, the sealing end face is separated, at the moment, the opening distance delta of the end face formed by the fluid dynamic pressure and the distance d between the pole shoe and the end face of the static rings form an operation state magnetic liquid sealing clearance d+delta.

Owner:NANJING FORESTRY UNIV

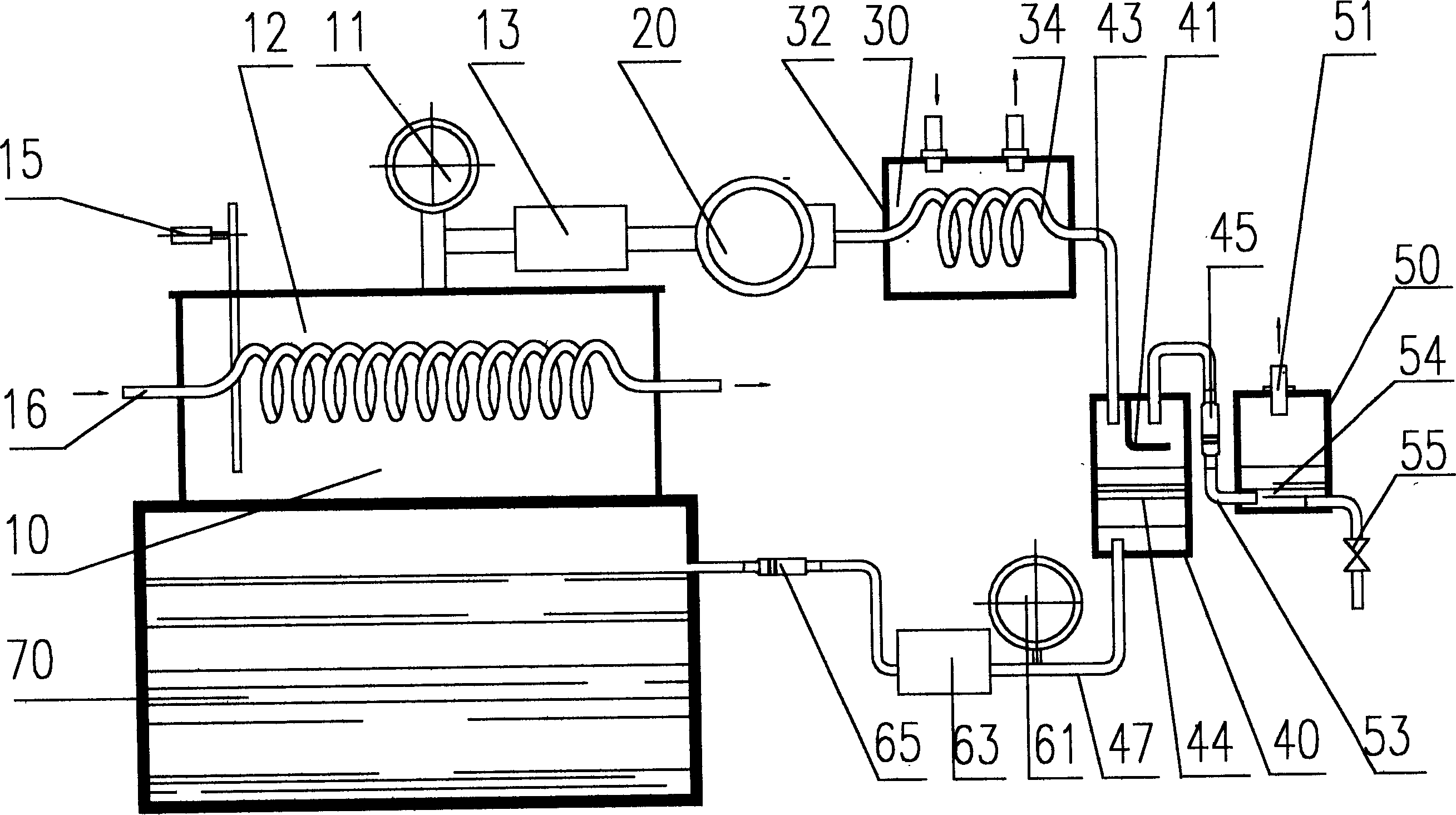

Device for recycling exhaust air and cooling fluid of condensator for evaporative cooling electric motor

InactiveCN1463068APrevent leakageAchieving Zero LeakageCooling/ventillation arrangementAir filterSolenoid valve

The invented device is installed between the main condenser and the evaporative cooling chamber for dipping stators. A pressure controller is installed at the top part of the main condenser and connected to its condensation space. The pressure controller is connected to the solenoid valve, the air pump, auxiliary condenser and the tank for separating air and liquid. The separated air through a one-way valve entering into the air filter is discharged after filtering. The liquid cooling medium (coolant) condensed in the said tank through the lower tube with installed another pressure controllerand solenoid valve runs back to the evaporative cooling chamber. When the pressure in the condensation space is higher than the set value, the air in the main condenser is discharged out. The invention makes the condenser operate at presetting pressure and recycles coolant so as to meet the requests of safe and economical running.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

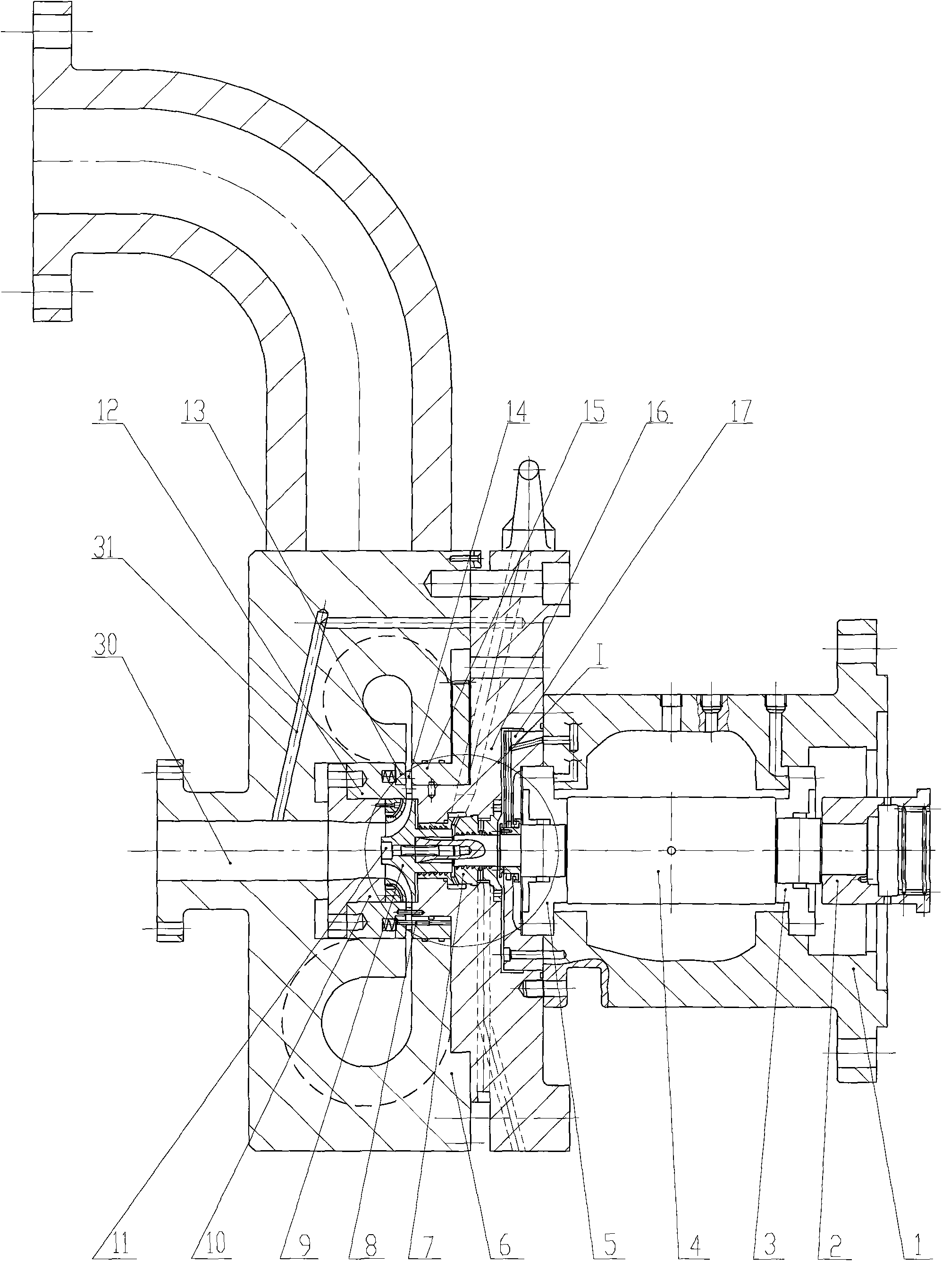

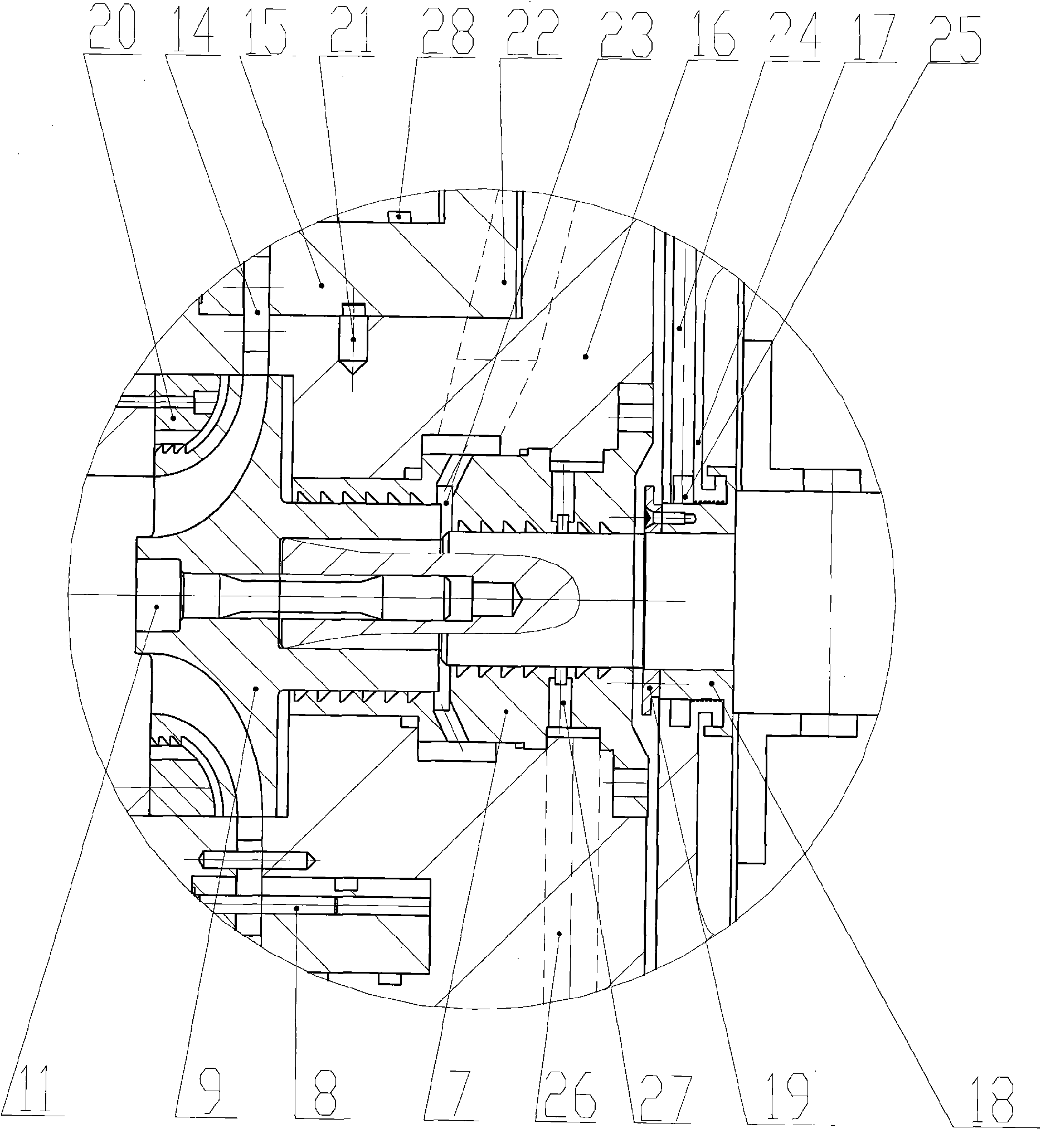

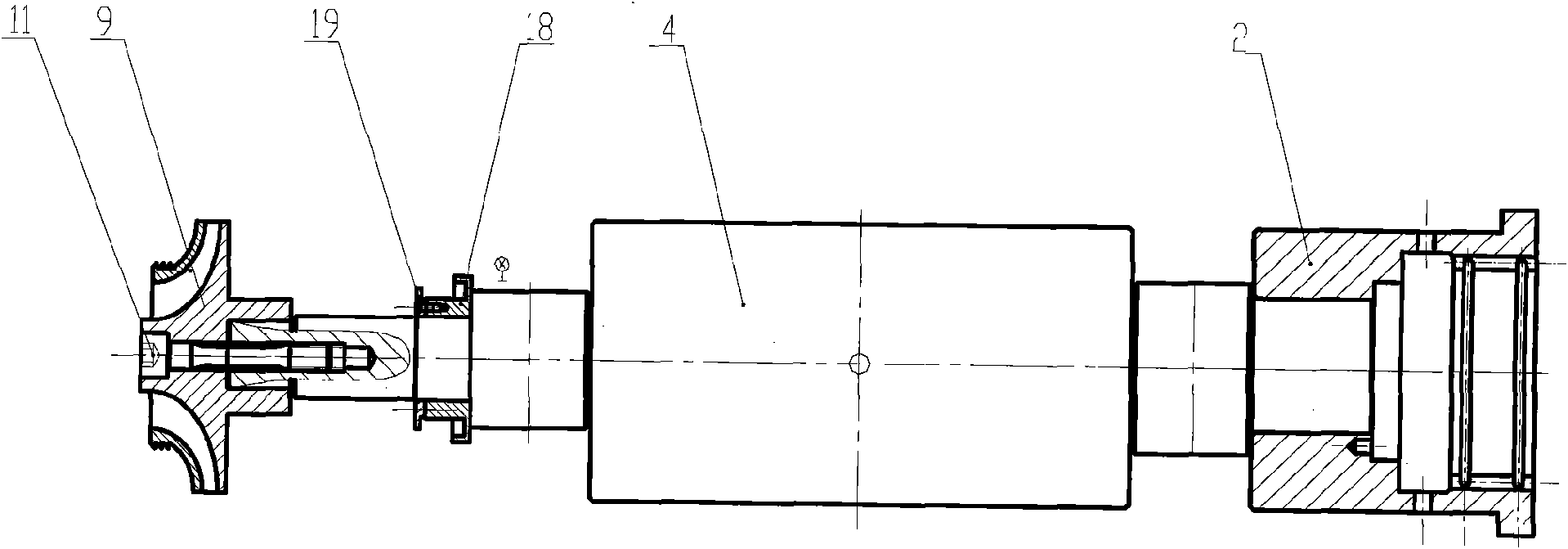

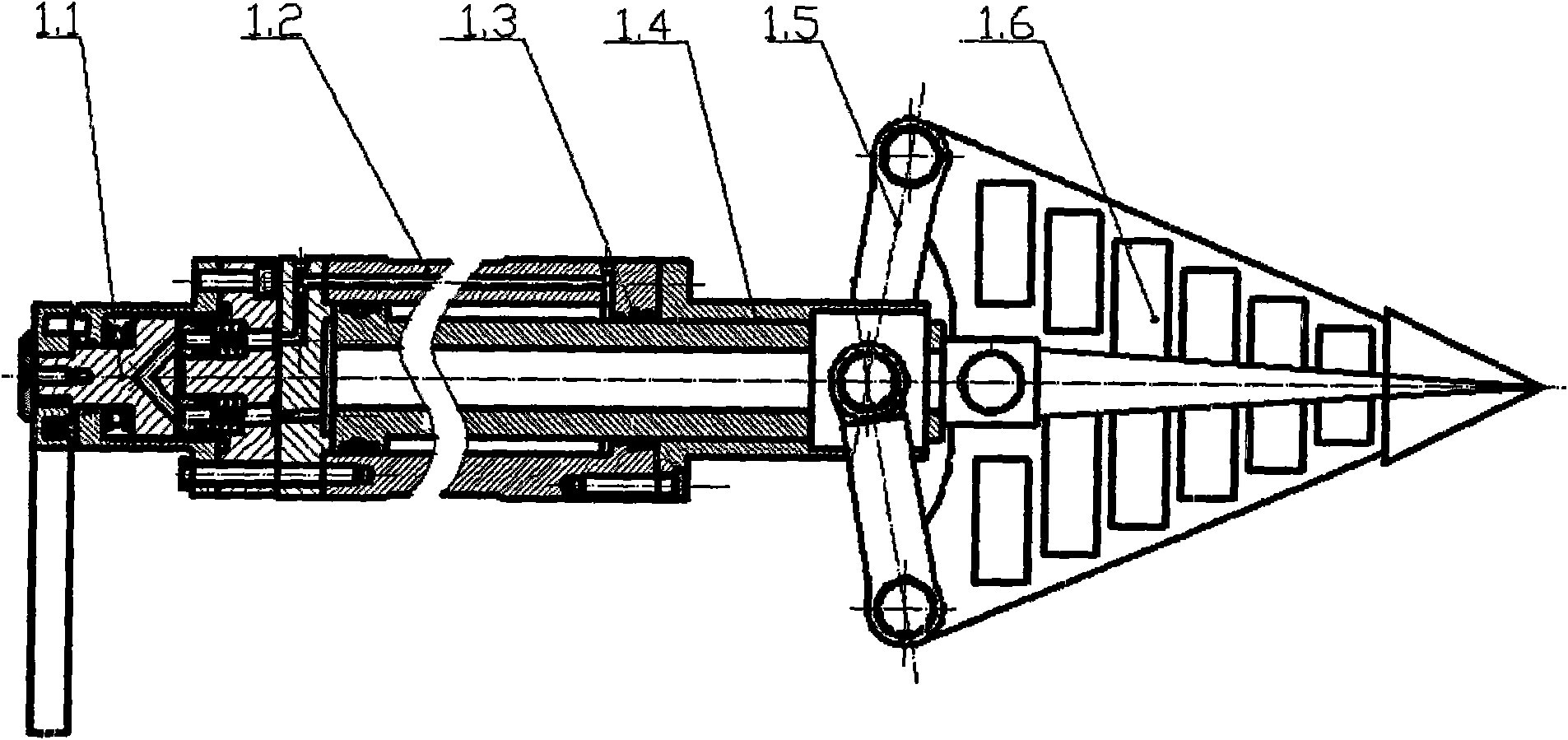

Air compressor system adopting supercritical carbon dioxide as working medium

InactiveCN106089435AReduce volumeImprove efficiencyLeakage preventionGas turbine plantsAutomotive engineeringImpeller

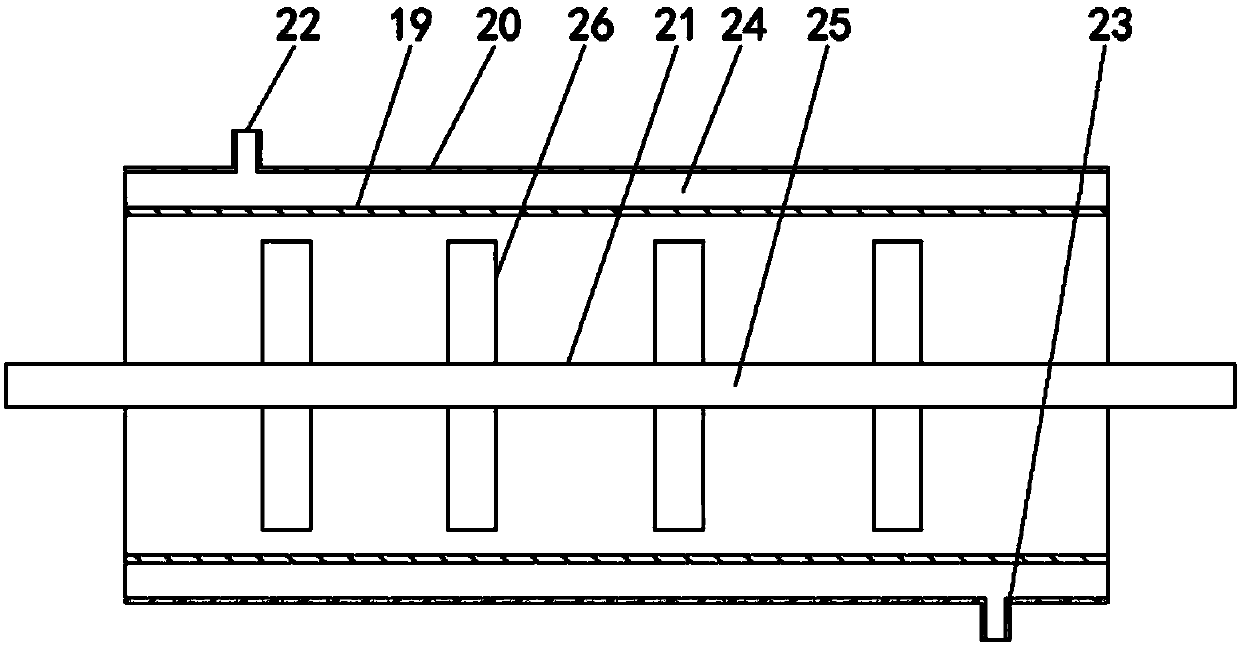

The invention discloses an air compressor system adopting supercritical carbon dioxide as a working medium. The air compressor system mainly comprises an air compressor part, a high speed starting motor part and a driving turbine part, wherein the air compressor, the high speed starting motor and the driving turbine are connected through one shaft, have the same rotation speed during operation, and are sealed inside a pressure outer shell composed of high-pressure and low-pressure boundaries; the air compressor part mainly comprises parts such as an air compressor high-pressure outer shell, an air compressor impeller and air compressor side dry gas seals; the high speed starting motor part mainly comprises parts such as an air compressor side radial bearing, a high speed motor, an axial bearing, a turbine side radial bearing, a low-pressure outer shell and a suction pump; and the driving turbine part mainly comprises parts such as a turbine high-pressure outer shell, a driving turbine impeller, tooth seals, a turbine side dry gas seal and an air injection pipe. The air compressor system provided by the invention has the characteristics that the size is small, external zero leakage is achieved, and the efficiency is high, and can be utilized as an air compressor device of a supercritical carbon dioxide power generation technology.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Hydraulic flexible cable cutting knife

InactiveCN101695839ANo pollution in the processSmall pressure lossServomotor componentsMetal working apparatusHydraulic cylinderUnderwater

The invention discloses a hydraulic flexible cable cutting knife, which comprises a control valve, a seawater or fresh water hydraulic cylinder and a shear movement mechanism which are connected in order, wherein the control valve controls the hydraulic cylinder to extend and retract; the hydraulic cylinder drives the shear movement mechanism to open and close by extending and retracting so as to realize shearing; the shear movement mechanism adopts a connecting rod-slide block mechanism; a slide block guide rail is integrated with the cylinder body into a whole, which has the characteristics of compact structure and high rigidity; a reversing valve is designed to have a three-position four-way structure; a contact mode of a valve plug and a valve seat of the reversing valve adopts a floating structure; and under the action of spring pressure, the valve plug and the valve seat always contact reliably, and a clearance after abrasion can be automatically compensated so as to greatly improve the reliability and service life of a seal. The hydraulic flexible cable cutting knife takes seawater or fresh water as a working medium, has the characteristics of high efficiency, large operational depth, convenient operation and good environmental compatability, and can be widely used for underwater and land shearing operation.

Owner:HUAZHONG UNIV OF SCI & TECH

Soft sealing safety valve

ActiveCN107228215ASimple structureImprove sealingEqualizing valvesSafety valvesBarrel ShapedEngineering

The invention relates to a soft sealing safety valve. The soft sealing safety valve comprises a barrel-shaped valve body, a left blocking cap and a right blocking cap, wherein the left blocking cap and the right blocking cap are correspondingly fixed to the left end and the right end of the valve body; the valve body is provided with a first oil port and a second oil port; a tapered valve element is arranged in the middle of an inner cavity of the valve body, a spring is arranged between the tapered valve element and the left blocking cap, and a valve base is fixed between the tapered valve element and the right blocking cap; a stepped hole is formed in the valve base, a soft sealing ring is fixed into the stepped hole through a screw plug, and the screw plug is provided with a through hole along the central axis of the screw plug; the tip of the tapered valve element stretches into an inner hole of the soft sealing ring; the first oil port communicates with the right end of the stepped hole of the valve base, and the second oil port communicates with the portion, between the tapered valve element and the left blocking cap, of the inner cavity of the valve body. The soft sealing safety valve has the advantages of being simple in structure, safe, reliable, good in sealing effect and adjustable in switch-on pressure.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

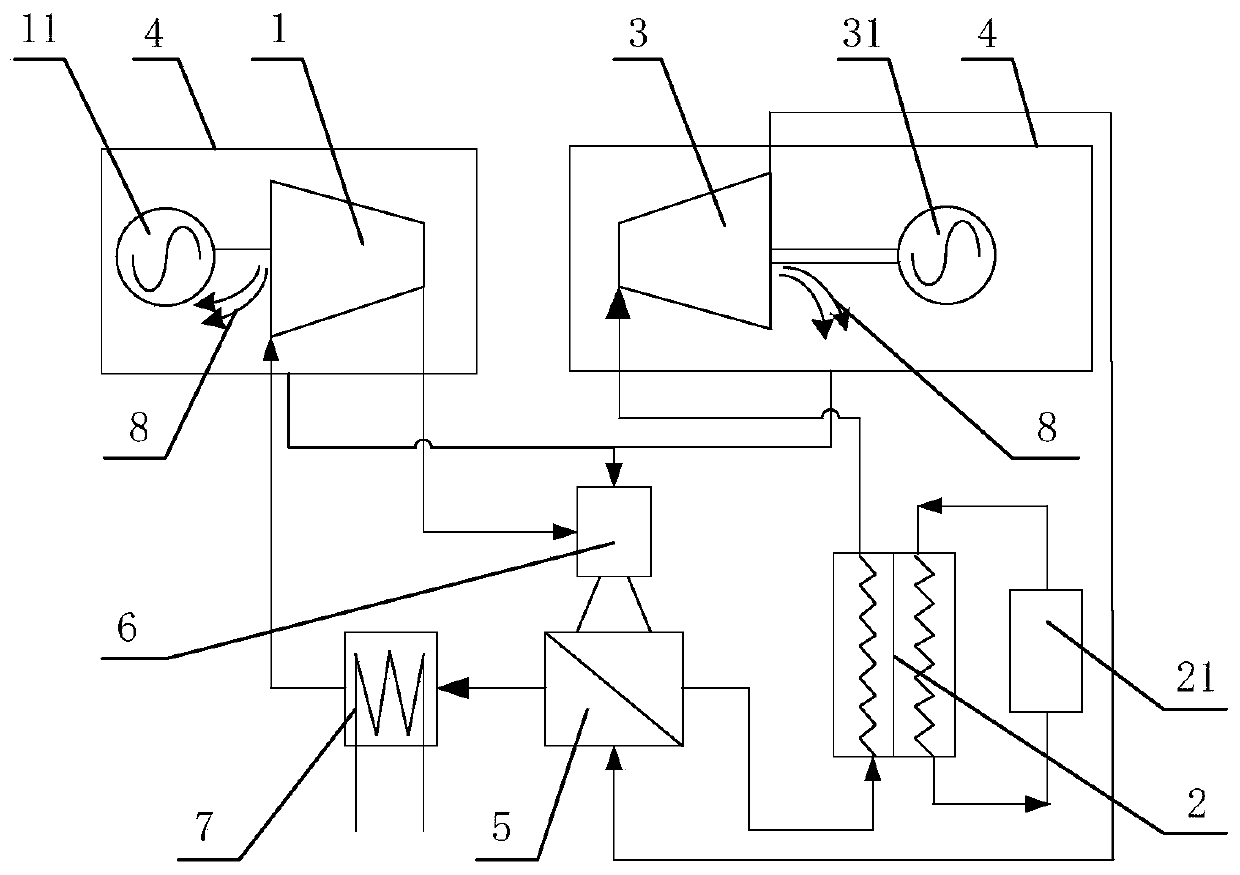

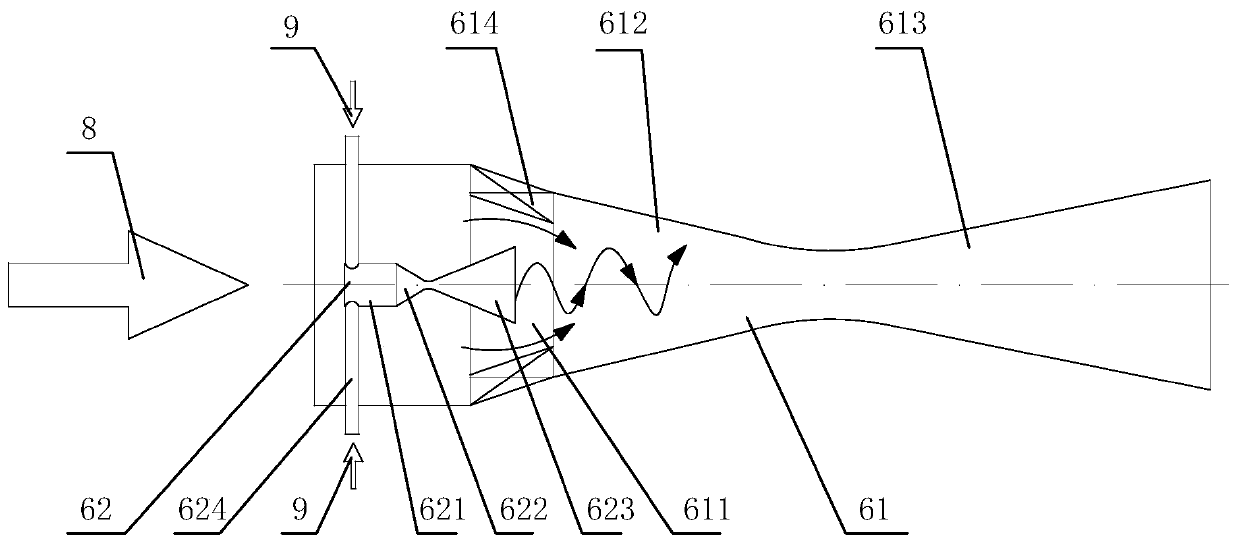

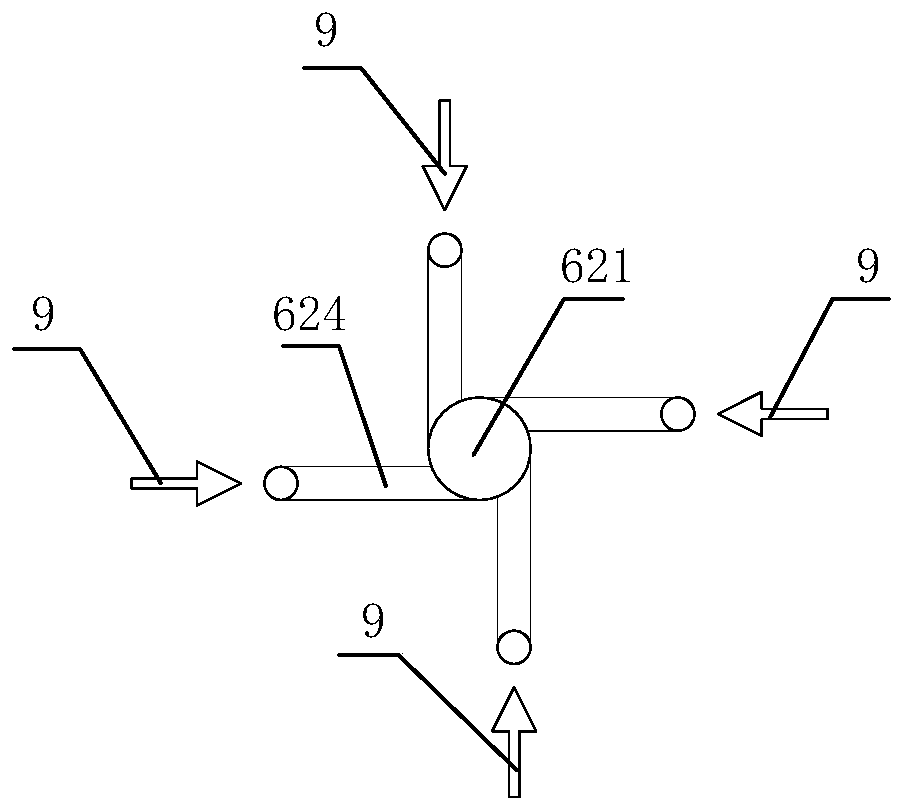

Brayton cycle power generation system and method

PendingCN110469376AGuaranteed uptimeSimplify intermittent replenishmentJet pumpsLeakage preventionBrayton cycleEngineering

The invention relates to the technical field of power generation systems, and discloses a Brayton cycle power generation system and method. The Brayton cycle power generation system comprises a compressor, a heater and a turbine, all of which are connected in sequence. The Brayton cycle power generation system further comprises a sealing shell, a heat regenerator and at least one injector. The compressor and the turbine are arranged in the sealing shell. The sealing shell is connected to an injected fluid inlet of the injector, and an outlet of the compressor is connected to an injection source fluid outlet of the injector. An outlet of the injector is connected to an inlet of the first heat exchange side of the heat regenerator, and an outlet of the first heat exchange side of the heat regenerator is connected to an inlet of the heater. An outlet of the turbine is connected to an inlet of the second heat exchange side of the heat regenerator, and an outlet of the second heat exchangeside of the heat regenerator is connected to an inlet of the compressor. According to the Brayton cycle power generation system, the sealing shell is utilized for converting dynamic sealing of a rotary machine into static sealing, meanwhile, a leaking work medium and a main work medium are mixed through the injector, and heat of the leaking work medium is fully recycled.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

High-flow dynamic output control method of cartridge valve and cartridge valve

The invention discloses a high-flow dynamic output control method of a cartridge valve. The high-flow dynamic output control method of the cartridge valve comprises the steps that a DT2 oil path of acontrol solenoid valve is through while a DT1 oil path of the control solenoid valve is stopped, hydraulic oil inside a first oil conveying channel passes through the DT2 oil path to return to an oiltank so that a guide shaft can provide power for a valve element sleeving the guide shaft, and thus the valve element is driven to move upwards; the DT1 oil path of the control solenoid valve is through while the DT2 oil path of the control solenoid valve is stopped, hydraulic oil inside a second oil conveying channel passes through the DT1 oil path to return to the oil tank so that the guide shaft can provide supporting power for the valve element, and thus the valve element is driven to move downwards; a second oil outlet communicates with a third oil outlet, and hydraulic oil inside the third oil outlet is discharged out from the second oil outlet. The invention further provides the high-flow dynamic output cartridge valve for implementation of the method. By increasing the flow of thecartridge valve and improving flow stability, the requirements of providing sufficient power and stable control for large piling machines of 1000 tons or above.

Owner:GUANGDONG LIYUAN HYDRAULIC MACHINERY

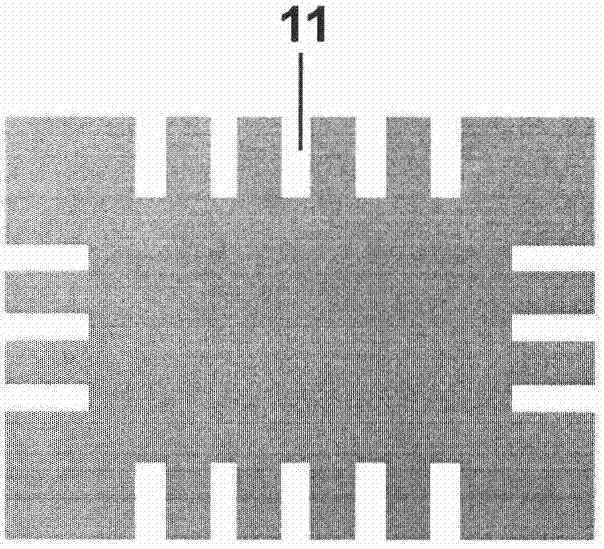

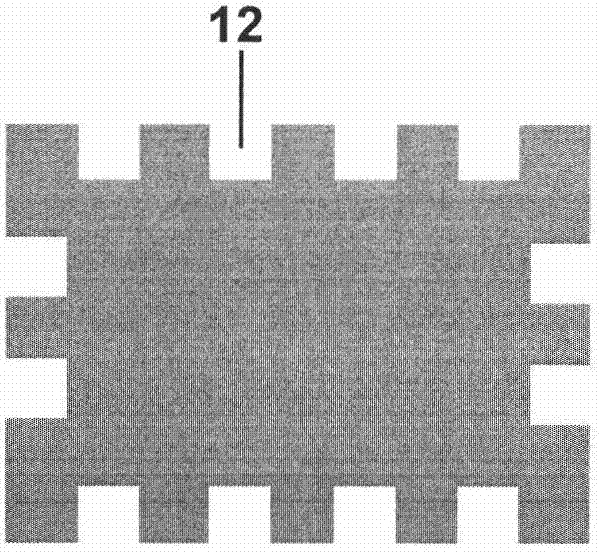

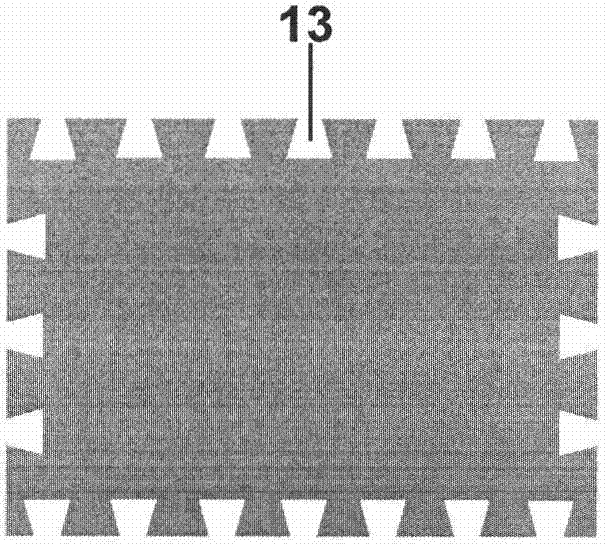

Microwave shield plate of microwave oven door

InactiveCN103175242AShieldingPrevent leakageDomestic stoves or rangesLighting and heating apparatusMicrowave ovenLaboratory facility

The invention discloses a microwave shield plate of a microwave oven door, and belongs to the technical field of microwave shield. The microwave shield plate is mainly characterized in that the periphery of the shield plate has an opening structure, each opening is an arbitrary shape, the size of each opening is that the width of the opening is greater than 0.5 mm and is less than 10 mm, optimally, the width of the opening is greater than 1 mm and is less than 4 mm, the opening depth and opening distance are determined to ensure that a bulge between any two adjacent openings is in close contact with the edge of a metal oven hole or the small plane of the edge of the metal oven hole, and the depth of the openings in the periphery of the shield plate in the metal oven hole is smaller than 25mm. The microwave shield plate with the characteristics can effectively shield microwave to prevent microwave leakage, a shield effect can achieve an ambient level, the zero leakage is realized, and the microwave shield plate has the notable advantages of simple structure and low manufacturing cost. The microwave shield plate provided by the invention is widely used by household microwave ovens and microwave instruments for laboratories and microwave shield and leakage prevention of microwave equipment for industries.

Owner:申偲伯

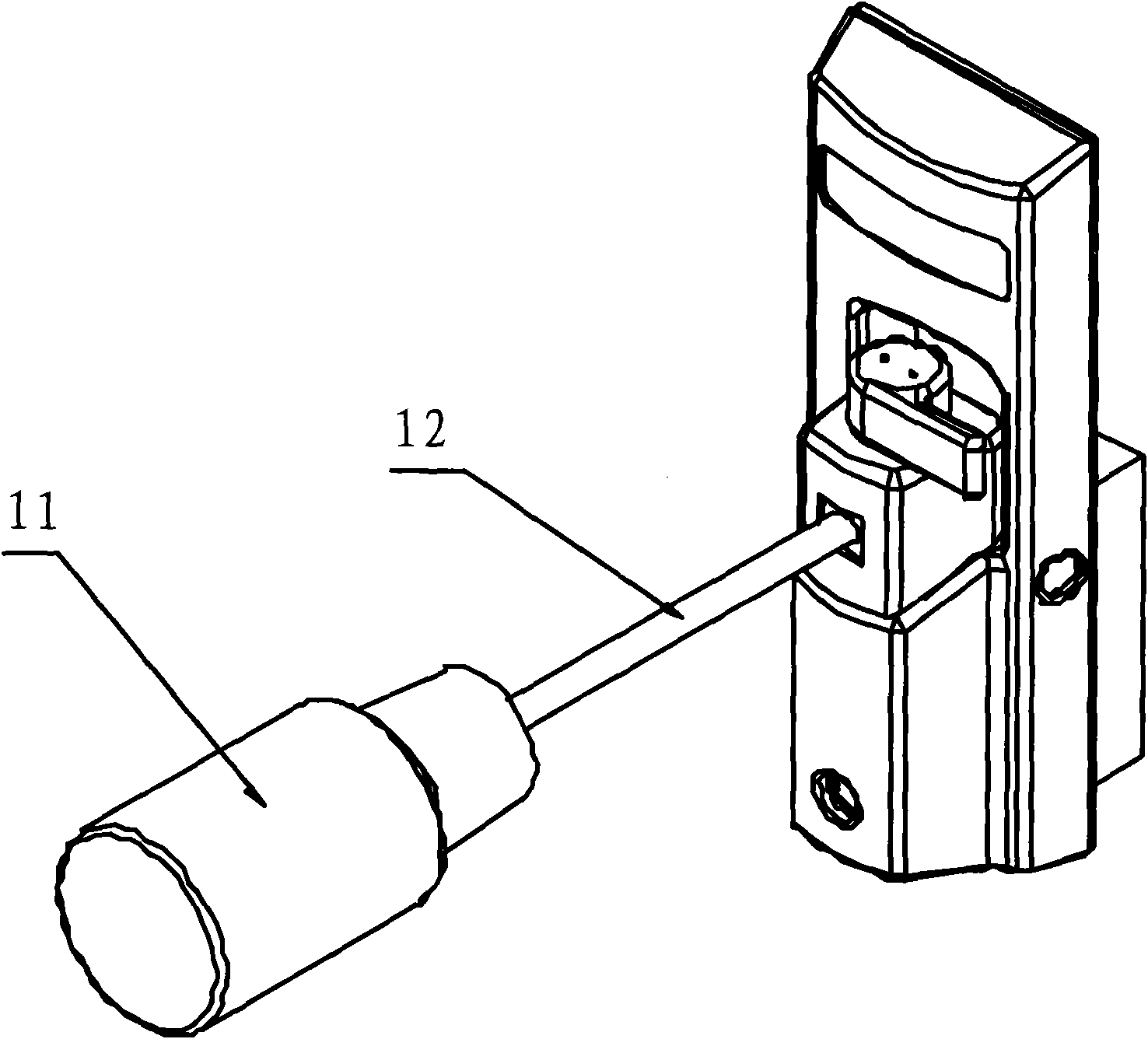

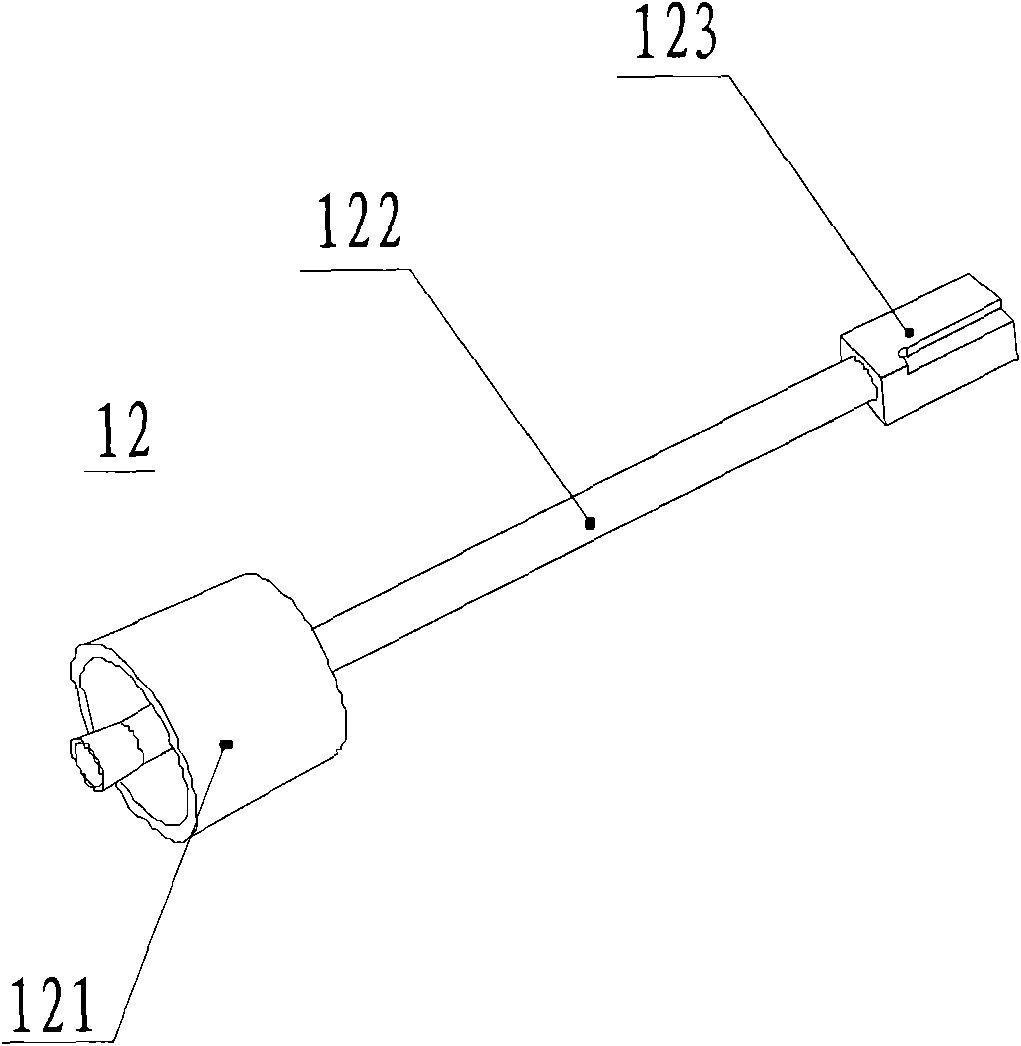

Injection device of anesthetic vaporizer

The invention discloses an injection device of an anesthetic vaporizer, which comprises an injection seat, a transition sleeve and a compressing mechanism, wherein the injection seat is used for being connected with an anesthetic vaporizer main body and is provided with a filling port; the transition sleeve is hermetically mounted on the filling port of the injection seat and is provided with a plug hole for the plugging of a plug-in adapter or an injection port sealing pin, the circumferential wall of the plug hole is previously provided with at least two pin holes, and each pin hole is matched with a positioning pin of one corresponding plug-in adapter; and the compressing mechanism is arranged above the transition sleeve and is used for compressing the plug-in adapter or the injection port sealing pin. In the injection device of an anesthetic vaporizer, the different combinations of the positions of the positioning pin and the transition sleeve can realize the composite applicationof multiple anesthetics, and the additional compressing mechanism can realize zero leakage in the injection process. Besides, based on the matching between a cam and a pin, the compressing mechanism realizes the functions of reliable compression and release prevention.

Owner:BEIJING AEONMED

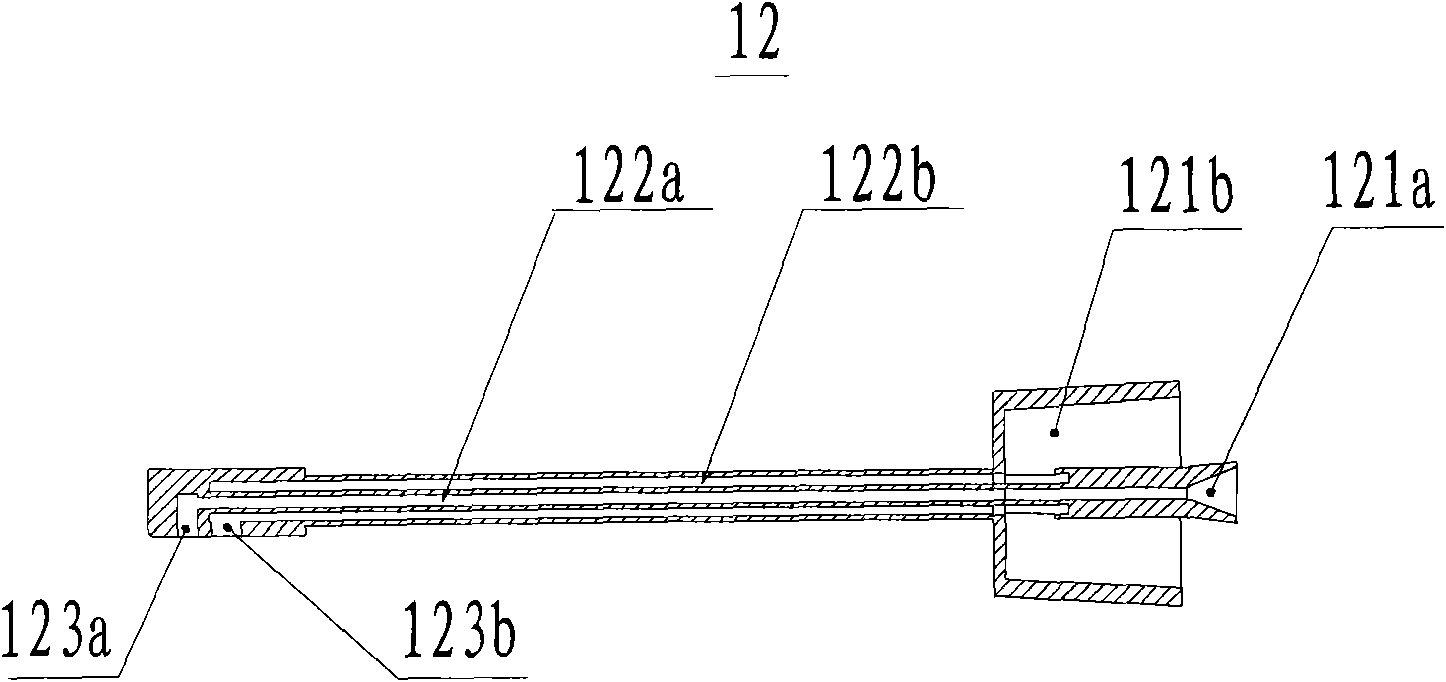

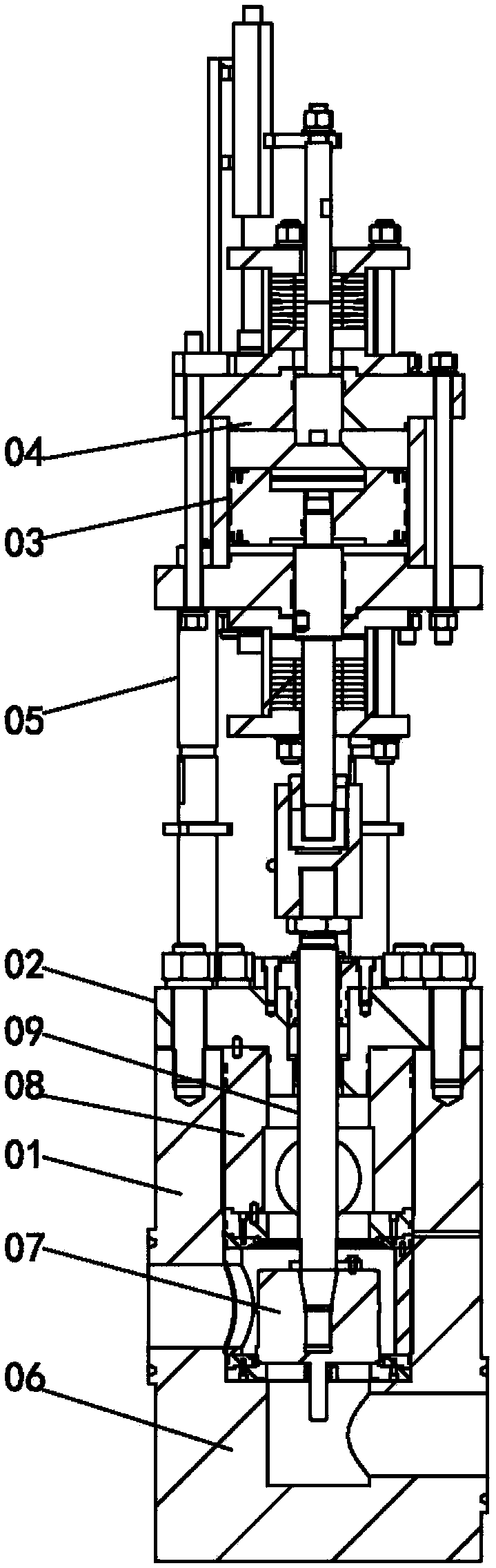

Integrated shaft end sealing device

ActiveCN103939607AOvercome limitationsSolution to short lifeEngine sealsEngineeringMechanical engineering

The invention relates to an integrated shaft end sealing device which is mainly composed of a primary floating ring sealing structure and a secondary filler sealing cabinet. The secondary filler sealing cabinet is provided with a sealing medium distributing ring. The primary floating ring sealing structure is composed of a plurality of groups of floating ring seals, wherein the several former groups of float ring seals and the several later groups of float ring seals are symmetrically arranged back to back and are respectively arranged on the two sides of an L-shaped partition ring. The secondary filler sealing cabinet provided with the sealing medium distributing ring is composed of a hard partition ring, fillers, the sealing medium distributing ring, a filler pressing cover and a filler box. The integrated shaft end sealing device is mainly used for sealing shaft ends of middle-low-pressure rotating shaft type equipment. The integrated shaft end sealing device can achieve an integrated combined sealing structure, can achieve the purpose of zero leakage of dangerous media in the rotating shaft type equipment and has the advantages of being long in service life, reliable in sealing, simple to maintain, convenient to overhaul, free of pollution and the like.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Hydraulic pressure expander

InactiveCN101670885ANo pollution in the processLow viscosityServomotor componentsUnderwater equipmentHydraulic cylinderFresh water organism

The invention discloses a hydraulic pressure expander, comprising a reversing valve, a seawater or freshwater hydraulic cylinder or an expanding mechanism which are connected in sequence, wherein thereversing valve controls the hydraulic cylinder to expand and retract; hydraulic cylinder realizes expansion and traction by telescopically driving expanding arms to expand; the reversing valve is a three-position four-way structure; the contacting form of a valve core and a valve seat of the reversing valve adopts a floating structure; under the effect of pressure of a spring, the valve core andthe valve seat are contacted reliably all the time, the gap after being worn can be compensated automatically, and the sealing reliability and service life are greatly improved. The hydraulic pressureexpander adopts seawater or freshwater as working medium, is characterized by high efficiency, large operating depth, convenient operation and good environment compatibility, not only can be used foroperation of underwater expansion, clamping and the like, but also can be used for fighting fire on land, rescuing emergency and saving lives.

Owner:HUAZHONG UNIV OF SCI & TECH

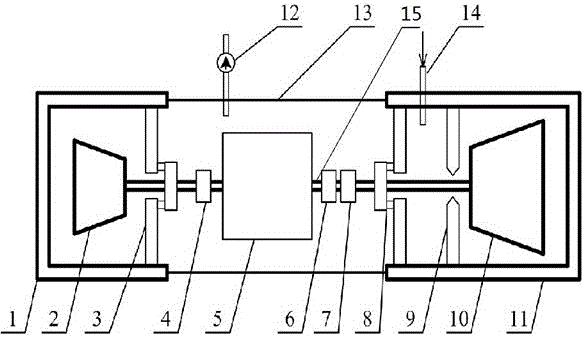

Zero leakage external firing heat engine

InactiveCN101915178AHigh power/weight ratioAchieving Zero LeakageEngine sealsStirling type enginesCombustionMechanical energy

The invention discloses a zero leakage external firing heat engine, which relates to the technical field of heat energy conversion. The zero leakage external firing heat engine aims to solve the problem of the low heat conversion efficiency and insufficient combustion of the conventional internal combustion engine, the problem that the conventional Stirling engine has a low power-to-weight ratio and zero leakage cannot be realized due to difficulties in sealing, and the like. An outward ventilation valve is connected with a closed chamber formed by communicating an air guiding cylinder chamber with the upper part of a dowork cylinder chamber; a conduction start point of the ventilation valve is that an air guiding piston moves between positions which are 20 degrees in front of and behind the top of the high temperature end of the air guiding cylinder chamber; the conduction angle of the ventilation valve 6 is between 5 and 30 degrees; and all movable sealing positions and the outward ventilation port of the ventilation valve are sealed in a closed shell. The zero leakage external firing heat engine can directly and efficiently convert combustion heat energy of fuels into mechanical energy and realize zero leakage; the internal movable sealing part technology of the engine can meet working requirements by adopting the prior art; the power-to-weight ratio is extremely high; and the convention efficiency is 20 percent to 80 percent.

Owner:雷涛

Shuttle type vibration damping break valve

InactiveCN101220867AFlexible opening and closingIncreased opening and closing sensitivity and reliabilityValve members for absorbing fluid energyLift valveRetaining ringHigh energy

The invention provides a shuttle-typed damping check valve, which solves the problem that the existing check valve has insensitive start and closeness, much noise and high energy consumption. The vertical communication section (34) of the inlet passage (28) and the outlet passage (29) of a valve body (1) are provided with valve seats (30); a guide sleeve (31) which is arranged above the valve seat is connected with the valve body (1) or a valve seat (4); the column surface of the guide sleeve is provided with a through hole (33) and the guide sleeve is movably matched with a valve flap; the valve flap (2) is hermetically matched with a valve seat (30); a valve rod (17) is connected with the valve cover (4) through a thread; the lower end surface of the valve rod (17) is an arc surface which is contacted with the bottom plane point of the internal chamber of the valve flap (2); the valve rod (17) is connected with a retaining ring (3); the lower surface of the retaining rind (3) is contacted with the step surface of the internal chamber of the valve flap (2); the upper surface of the retaining ring (3) is contacted with the lower end surface of a liner (23); the internal wall of the liner (23) is connected with the thread of the external wall of the valve rod (17); a flexible pad or a damping element (24) is arranged between the upper surfaces of the flange of the liner (23) and the valve flap (2).

Owner:WINJET HIGH TECH INVESTMENT BEIJING

Material stirring device of unloading trough

ActiveCN103041726AImprove sealingPrevent leakageRotary stirring mixersMixer accessoriesMechanical engineeringEngineering

Owner:广西蓝星大华化工有限责任公司

Magnetic fluid sealing structure for reciprocating motion

InactiveCN107893854AReduce pollutionExtended service lifeEngine sealsReciprocating motionEngineering

The invention discloses a magnetic fluid sealing structure for the reciprocating motion. The magnetic fluid sealing structure comprises a hollow shell, a reciprocating shaft arranged in an inner cavity of the shell and at least one permanent magnet. Pole shoes are arranged on the two sides of each permanent magnet. At least one groove is formed around the inner circle face of each pole shoe, and aY-shaped sealing ring is arranged in each groove. Pole teeth are arranged on the inner circle faces of the pole shoes, gaps exist between the pole teeth and the outer surface of the reciprocating shaft, and magnetic fluid is injected into the gap positions. Through combined usage of the magnetic fluid and the Y-shaped sealing rings, a sealing structure excellent in pressure resisting performanceand sealing performance is formed. Accordingly, due to the fact that the magnetic fluid seal has a dustproof function, pollution to the Y-shaped sealing rings from outside impurities is reduced, purity of sealed media is improved, the service life of the sealing ring is prolonged to the maximum degree, and the requirements for zero leakage and long service life are met.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

High pressure air large flow field correction device and method

ActiveCN107702768ACalibration is achieved accuratelyReduce mistakesTesting/calibration apparatusControl systemEngineering

Owner:XIAN AEROSPACE PROPULSION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com