Material stirring device of unloading trough

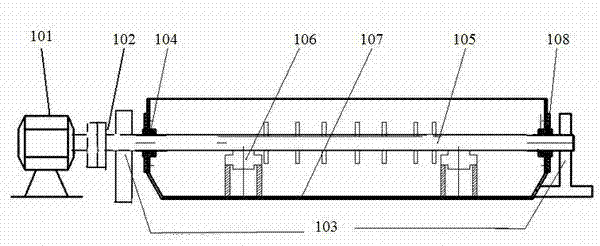

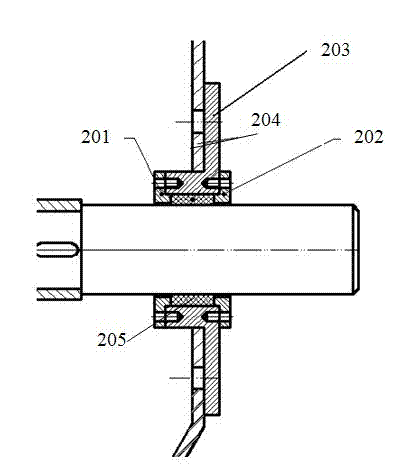

A technology of stirring spindle and storage tank, which is applied to mixers, mixer accessories, mixers and other directions with rotating stirring devices, can solve the problems of uneven force on the combined oil seal, inability to guarantee the sealing effect, and poor oil seal sealing effect, etc. To achieve the effect of reducing maintenance costs, strong scalability, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

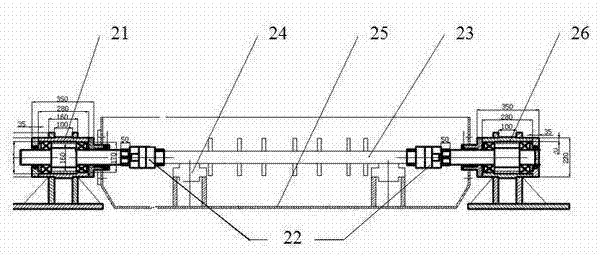

[0029] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

[0030] as attached image 3 As shown, the material stirring device of the unloading tank according to the present invention includes a front-end sealing structure 21, an Oldham coupling 22, a supporting roller 24, a material storage tank 25, a stirring spindle 23 and a rear-end sealing structure 26. The front end sealing structure 21 is installed on the front end of the material storage tank 25. One end of the front main shaft in the front end sealing structure 21 is connected to the reducer that provides power through a coupling, and the other end of the main shaft is connected to the Oldham coupling 22. The other end of the block coupling 22 is connected to one end of the stirring main shaft 23, and the other end of the stirring main shaft 23 is connected to another Oldham coupling 22, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com