Shuttle type vibration damping break valve

A shut-off valve and shuttle-type technology, applied in the field of shut-off valves, can solve problems such as inflexible opening and closing, easy leakage, and noise in the pipeline system, and achieve the effect of increasing the sensitivity and reliability of opening and closing, and flexible opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

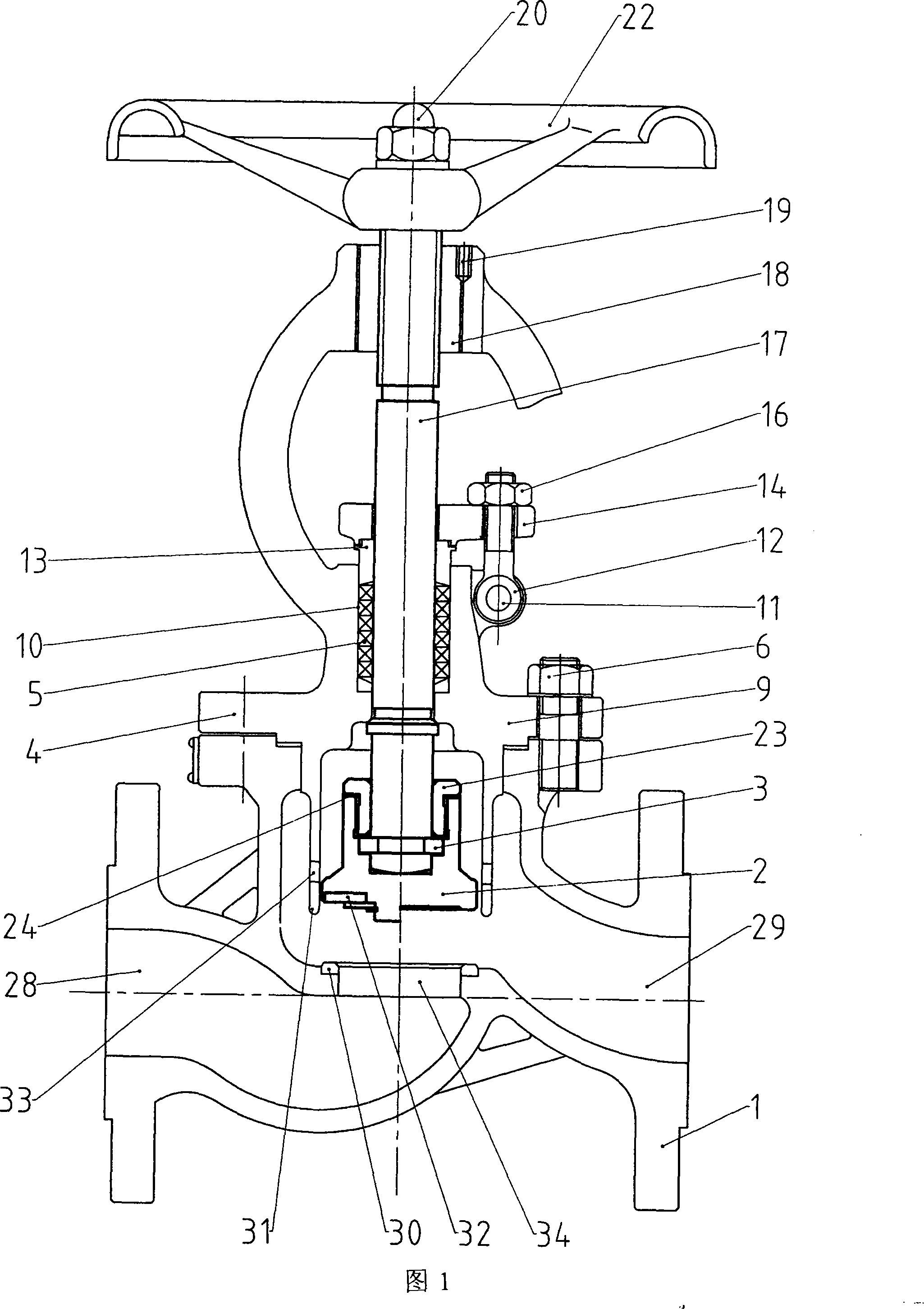

[0011] The valve body 1 of the present invention is connected with the valve cover 4 by bolts 6, and the neck 9 of the valve cover 4 has a packing groove 10 and a packing ear. Shaft 11 is connected with stud 12 on the stuffing lug, stuffing 5 and stuffing pressure ring 13 are arranged in stuffing groove 10 . A filler cover 14 is arranged on the pressure ring 13, and the filler cover 14 is fastened by a nut 16. The main support seat 18 on the bonnet top is fixed by a pin 19, and the main support seat 18 is threaded with the valve stem. There is a retaining ring 3 in the groove on the cylindrical surface of the lower end of the valve stem 17, which is connected with the bushing 23 and the inner cavity of the valve disc 2. Stem threaded connection. The buffer element 24 is located between the bush 23 and the upper end surface of the valve disc.

[0012] The present invention designs a shuttle-shaped valve clack 2 that slides with the valve stem 17, and a flexible pad or cushio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com