Ventilation skylight

A ventilator and ventilation device technology, applied in the field of roof ventilation skylights, can solve the problems of large motor load, inflexible opening and closing, and inability to adjust the upper and lower positions of the valve plate, so as to improve work efficiency, flexible opening and closing of the valve plate, and shorten the movement the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

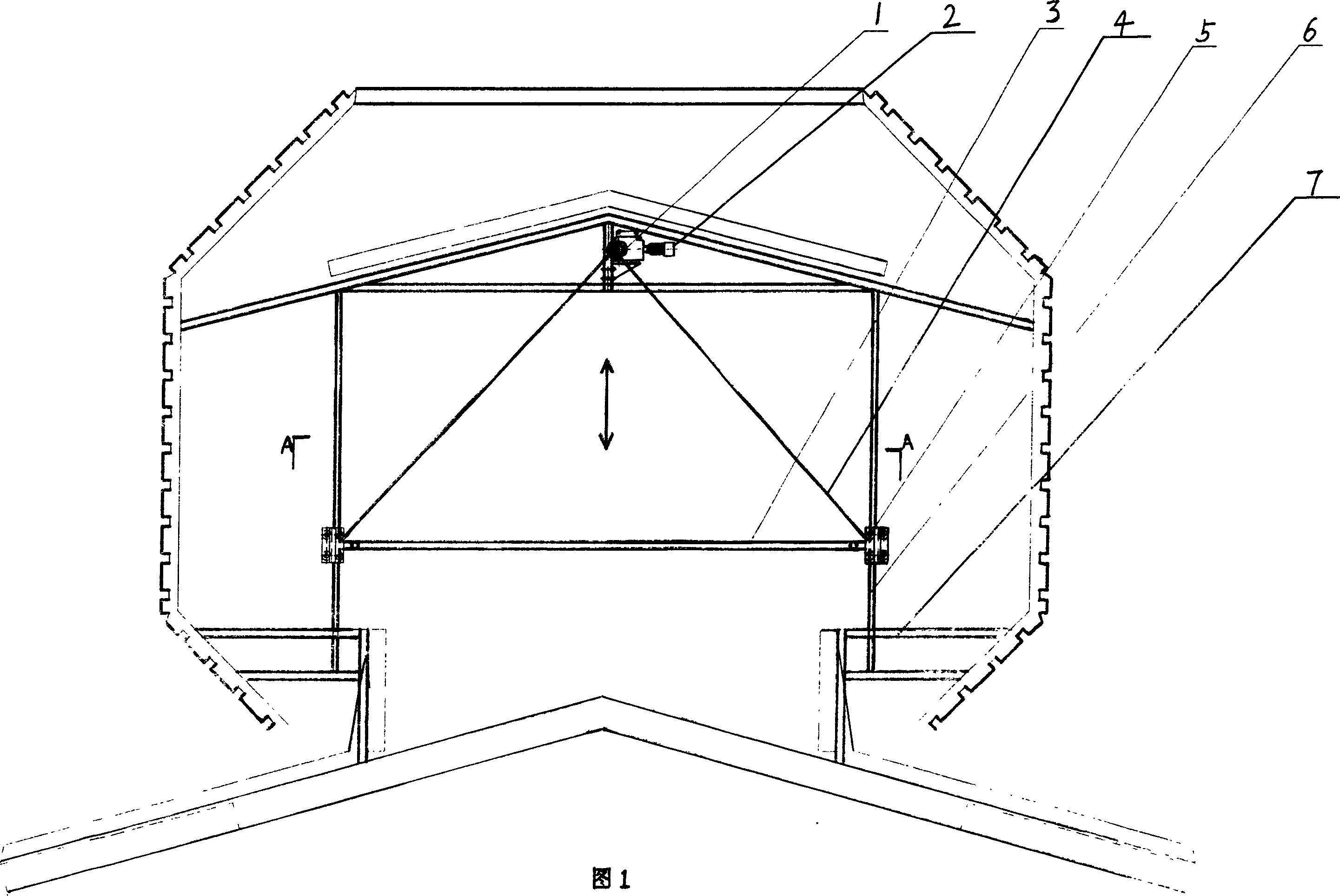

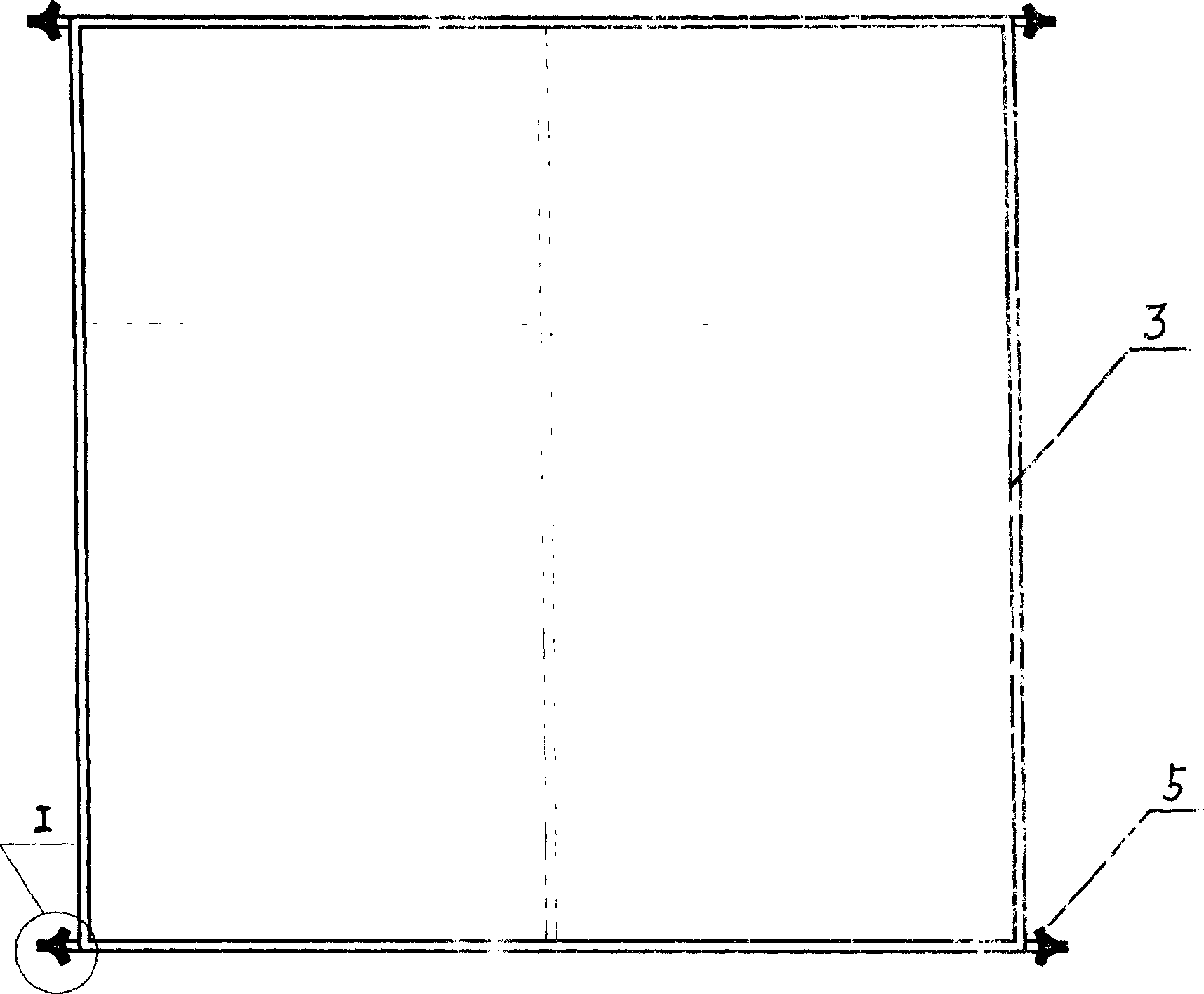

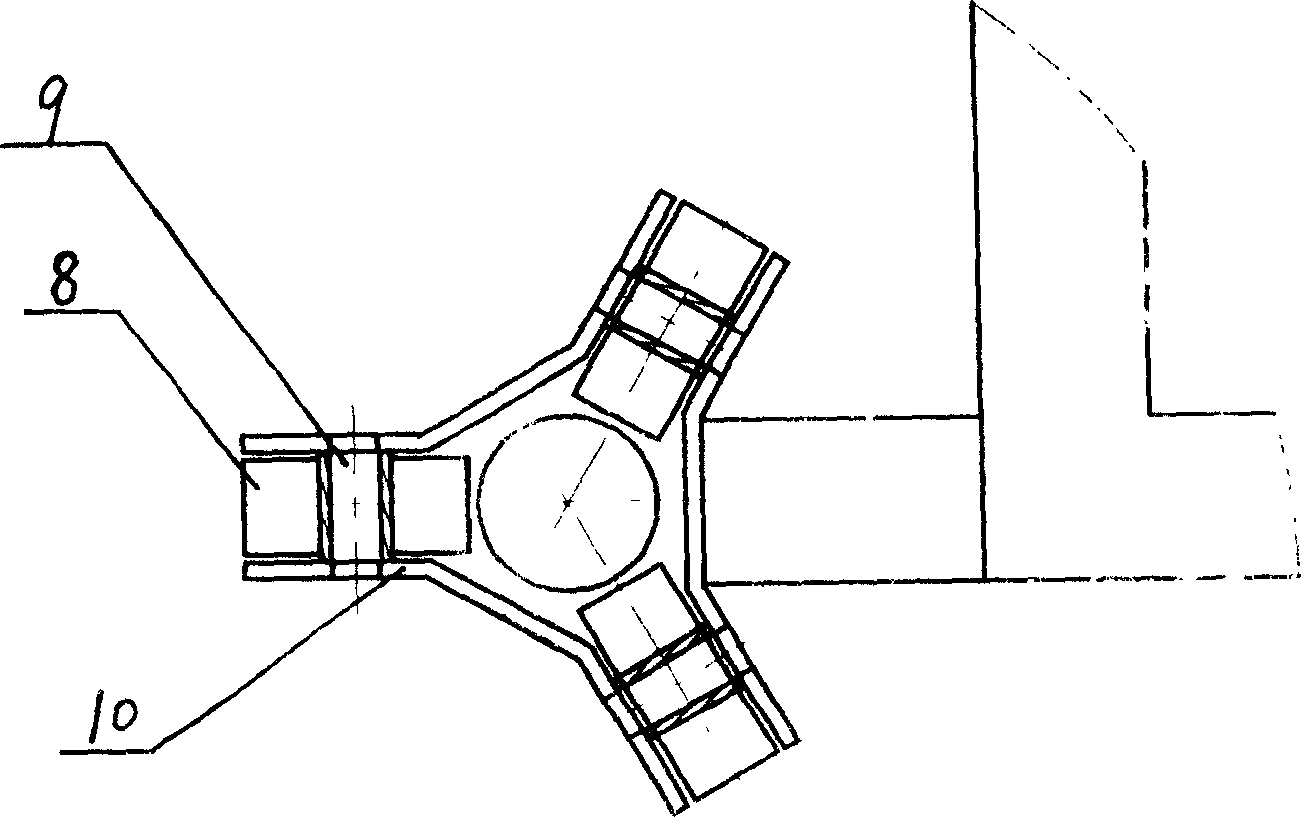

[0010] It can be seen from Figure 1 that the present invention includes a ventilator frame 7, a valve plate 3 located at the throat, and an electric opening and closing mechanism. The valve plate 3 is realized by the electric opening and closing mechanism. The electric opening and closing mechanism is composed of a motor 2 and a reducer. 1. Consists of a limit device 5 and a draw rope 4. The limit device 5 is fixedly connected to the end of the valve plate 3, and the limit device 5 is movably sleeved on the guide frame 6, so that the valve plate 3 can move up and down along the guide frame 6. , The guide frame 6 is installed and fixed on the ventilator frame 7. When the motor 2 rotates clockwise or counterclockwise, the opening and closing function of the valve plate 3 is realized through the pulling of the transmission mechanism and the pull rope 4, and the upper and lower positions of the entire valve plate of the ventilation skylight can be adjusted to improve the flow state of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com