Electromagnetic actuation stop valve for venting pile top of nuclear power station

A technology for nuclear power plants and stop valves, which is applied in the direction of lifting valves, valve details, valve devices, etc., to achieve the effects of improving sealing, improving service life, protecting integrity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

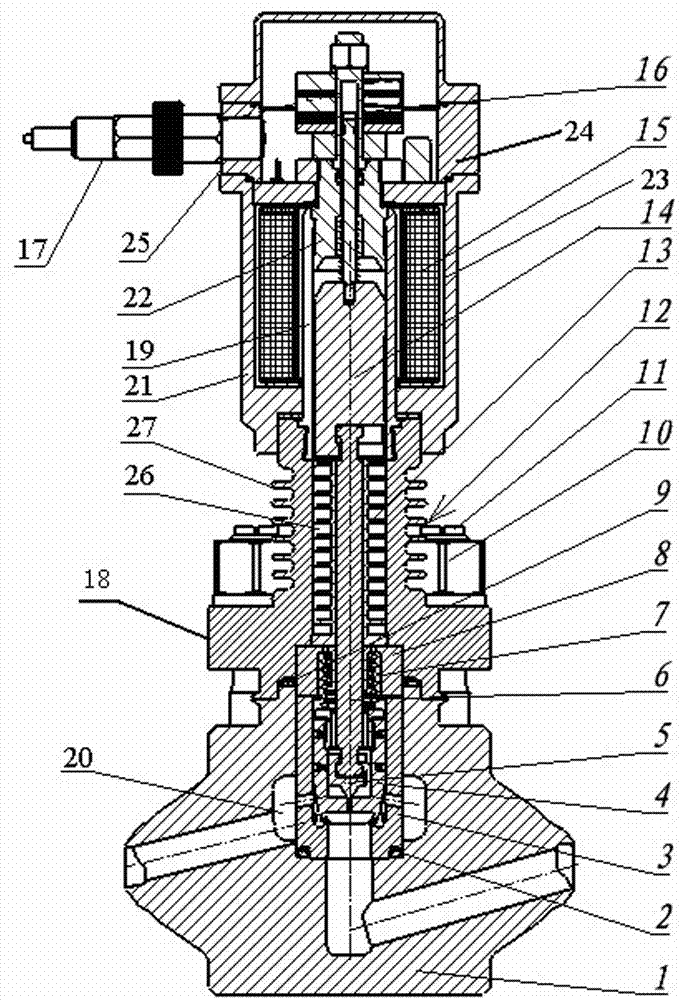

[0059] An electromagnetic shut-off valve for reactor top exhaust in a nuclear power plant, comprising a main valve body assembly, an auxiliary valve body assembly, a valve cover 24, an electromagnetic drive mechanism, and an electrical connector 17, characterized in that:

[0060] The main valve body assembly includes a valve body 1 , a sleeve 3 and a valve sleeve assembly 12 . The valve sleeve assembly comprises valve sleeve 18, non-magnetic pipe 19 and heat insulation cover 13, and after the lower end of non-magnetic pipe 19 is threadedly connected with valve sleeve 18 upper ports, it is solidified with argon arc welding. The heat insulating sleeve 13 is fixedly arranged in the valve sleeve 18 . The valve sleeve 18 sits on the upper end of the valve body 1 and is connected as a whole by the nut 10 and the pressure-bearing bolt 11 . The sleeve 3 is arranged in the valve cavity 20 of the valve body 1 .

[0061] The auxiliary valve body assembly is assembled from a valve head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com