Supercritical fluid-type external-combustion heat engine

A technology of supercritical fluid and heat engine, which is applied in the direction of hot gas variable displacement engine devices, mechanical equipment, machines/engines, etc. It can solve the problems of inability to achieve zero leakage, small power/weight ratio, low heat conversion efficiency, etc., and achieve structural The result of simplicity, high power/weight ratio and low material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

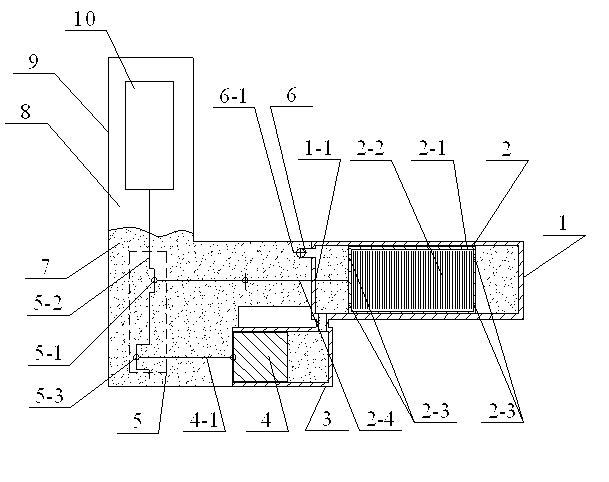

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is made up of gas guide cylinder cavity 1, gas guide piston 2, work cylinder chamber 3, work piston 4, flywheel crankshaft assembly 5, valve 6, carbon dioxide 7, gas working medium 8, airtight casing 9 , Generator 10 forms;

[0015] The inner cavity 2-1 of the gas guide piston 2 is provided with a multi-layer heat storage and gas conduction metal mesh 2-2, and each of the two ends of the gas guide piston 2 has a through hole 2-3 connected with the inner cavity 2-1. , the air guide piston 2 is arranged in the air guide cylinder chamber 1, and the connecting rod 2-4 of the air guide piston 2 passes through the sliding seal sleeve 1-1 at one end of the air guide cylinder chamber 1 and connects with the first part of the flywheel crankshaft assembly 5 The crank rod 5-1 is connected in rotation. When the crankshaft 5-2 of the flywheel crankshaft assembly 5 rotates, it drives the air...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 This embodiment will be described. The difference between this embodiment and the first embodiment is that the pressure in the airtight casing 9 is 8 MPa. Other components and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that the pressure in the airtight casing 9 is 9 MPa. Other components and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com