Film with high heat conduction efficiency and antifouling capability and preparation method thereof

A technology with high heat conduction and efficiency, applied in heat exchange equipment, lighting and heating equipment, heat transfer modification, etc., can solve problems such as increasing the cost of heat exchange devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

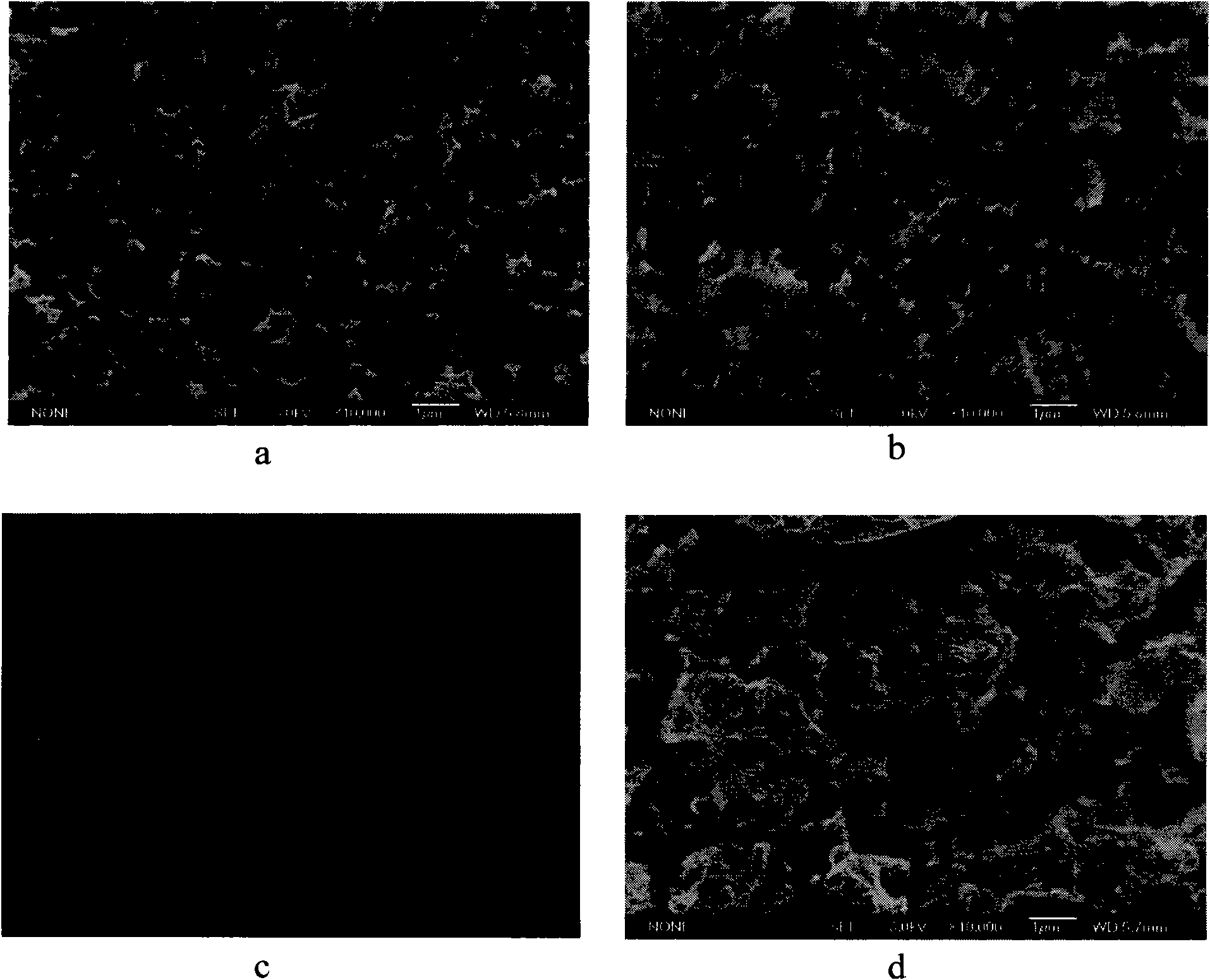

[0043] Electrochemical method: Immerse a pair of aluminum sheets (100mm×50mm×1mm) in a 0.5mol / L sulfuric acid solution in an electrolytic cell at room temperature. The two aluminum sheets are respectively used as the reaction electrode and the counter electrode. The distance is 6cm. Current density control now 10mA / cm 2 React for 3 hours. During the reaction, the temperature of the reaction solution is controlled below 40°C. The oxidized aluminum sheet was washed with deionized water to remove residual sulfuric acid, and then the aluminum sheet was placed in a muffle furnace for 20 minutes, and the temperature of the furnace was controlled at 180°C. Soak the ablated product in deionized water and ethanol for 30 minutes, and then dry it in the air, then directly prepare the hydrophilic Al surface based on the metal Al surface with rod-shaped particles with a diameter of 200nm. 2 o 3 Membrane, the film thickness is about 300nm, and the contact angle between the film and wate...

Embodiment 2

[0045] Electrochemical method: place two cleaned copper sheets in an electrolytic cell with electrolyte solution, the two copper sheets are respectively used as the counter electrode and the working electrode, and the distance between the two electrodes is 5cm. The electrolyte is an ethanol solution of 0.5 mol / L n-tetradecanoic acid. At room temperature, set the voltage of the DC power supply to 5V and react for 3 hours, and the metal surface of the working electrode will deposit Cu[CH 3 -(CH 2 ) 12 COO] 2 . will be deposited with Cu[CH 3 -(CH 2 ) 12 COO] 2 Put the Cu sheet into the muffle furnace for 10 minutes, and the temperature of the furnace is controlled at 100°C. Soak the ablated product in deionized water and ethanol for 20 minutes, and then dry it in the air, then directly prepare a hydrophilic CuO film with a rough structure based on the accumulation of square particles with a diameter of 150 nm on the surface of metallic Cu. , about 100nm behind the film, ...

Embodiment 3

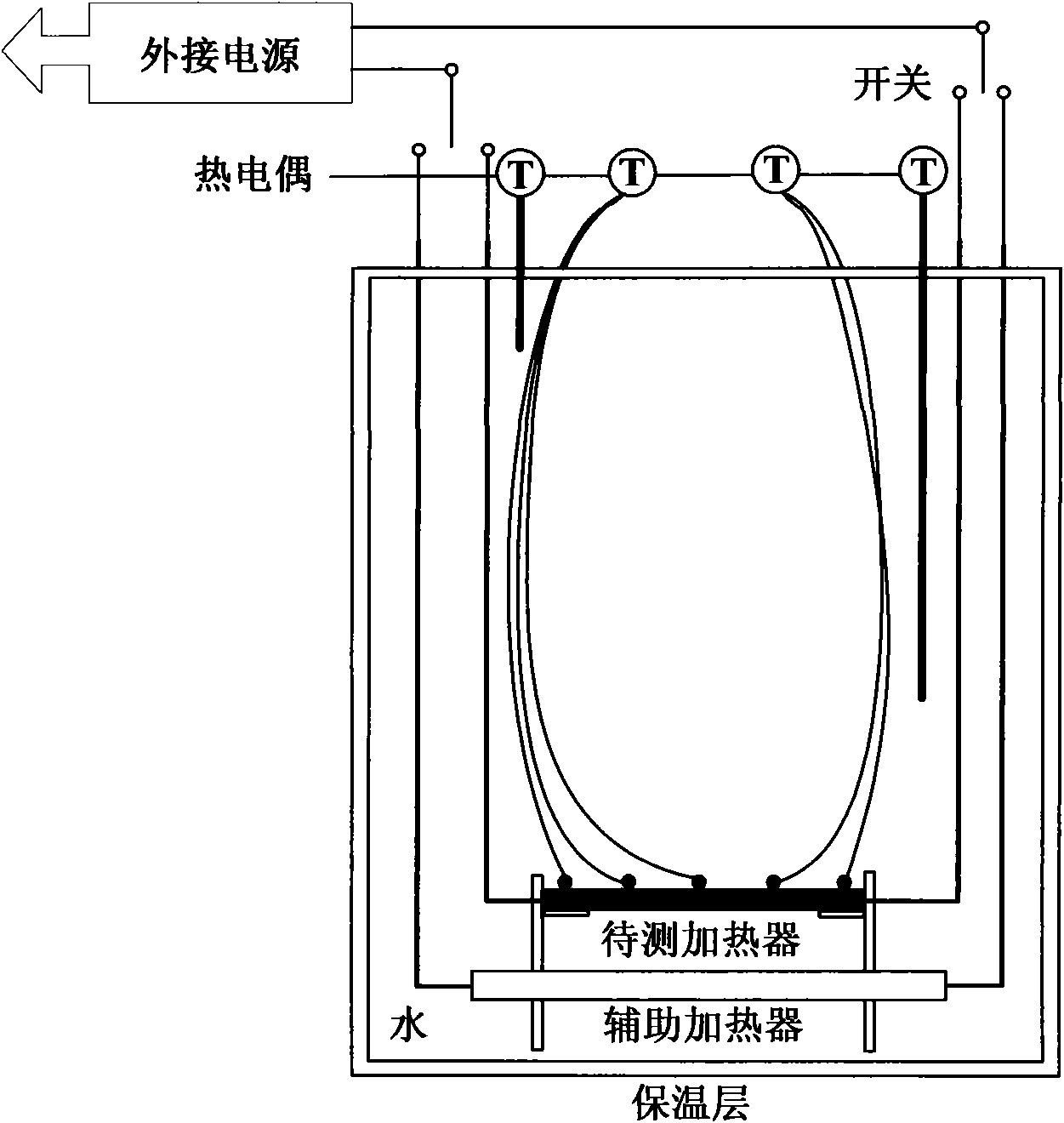

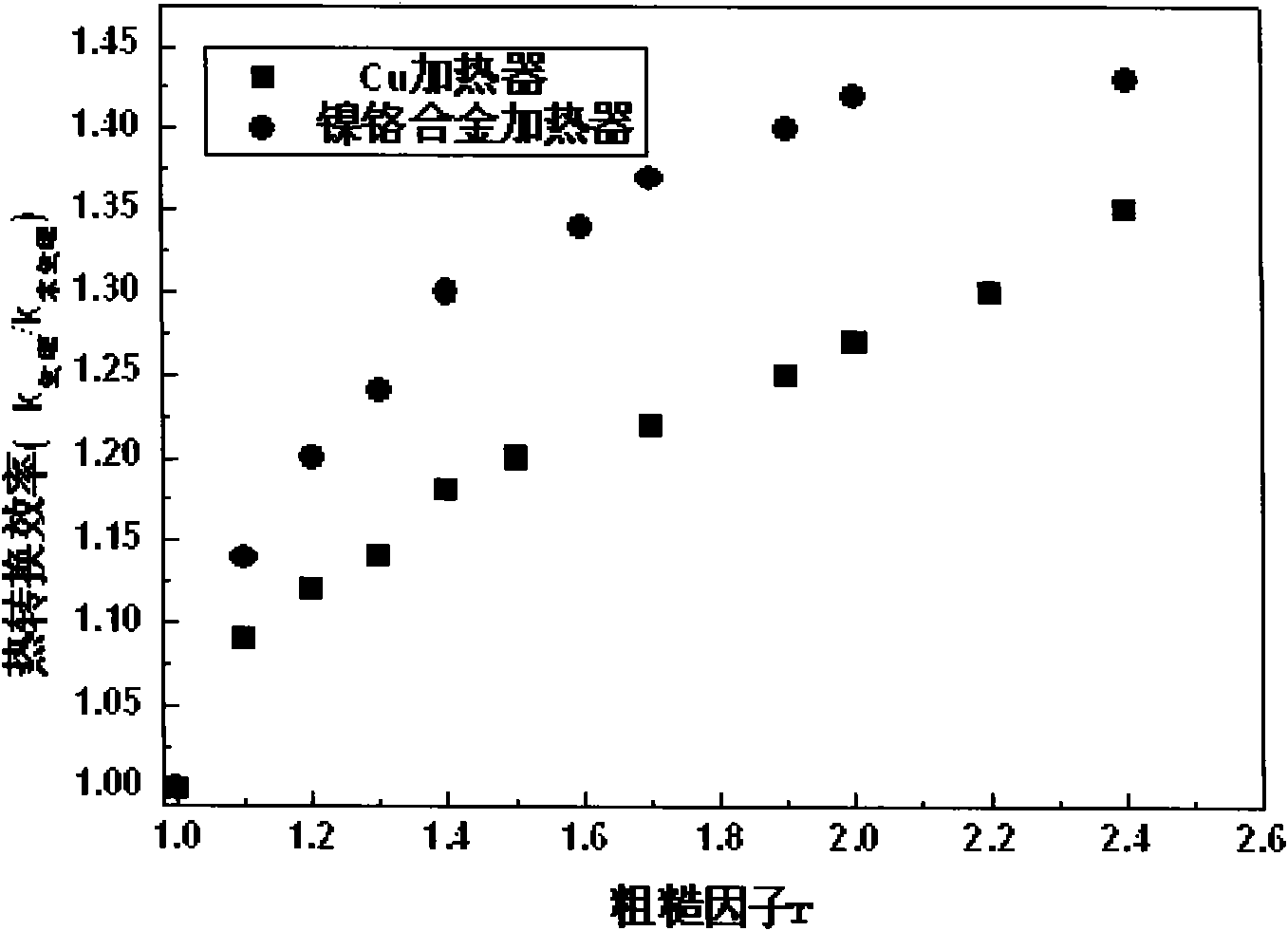

[0047] Hydrothermal reaction method: Coating an ethanol solution containing tetrabutyl titanate with a mass concentration of 5% on the surface of cleaned Cu and nickel-chromium alloy, controlling the temperature of the reaction furnace at 300 ° C, firing in the reaction furnace for 1 hour, Cu and nickel-chromium alloys covered with titania seeds were obtained. Prepare 50 mL of 0.15 mol / L titanium trichloride hydrochloric acid aqueous solution, wherein the mass concentration of hydrochloric acid is 5%. Solid NaCl was added to the solution and supersaturation was achieved. Transfer the solution to a polytetrafluoroethylene-lined stainless steel reactor (temperature probes are installed inside and outside the container to detect the temperature inside and outside the reactor; there are pressurization devices and venting pipes on the lid of the reactor) . At this time, the prepared Cu and nickel-chromium alloy covered with titanium oxide seed crystals are put into the reaction c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com