Patents

Literature

653results about How to "High heat conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

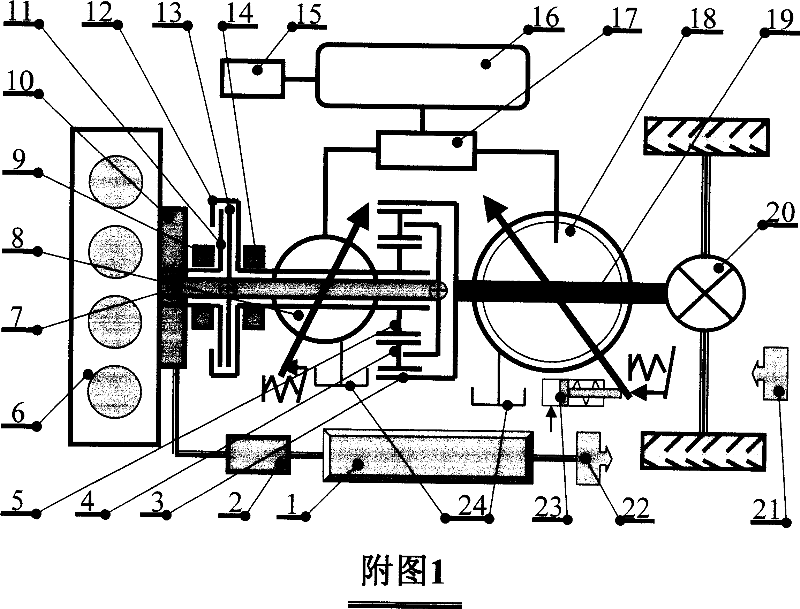

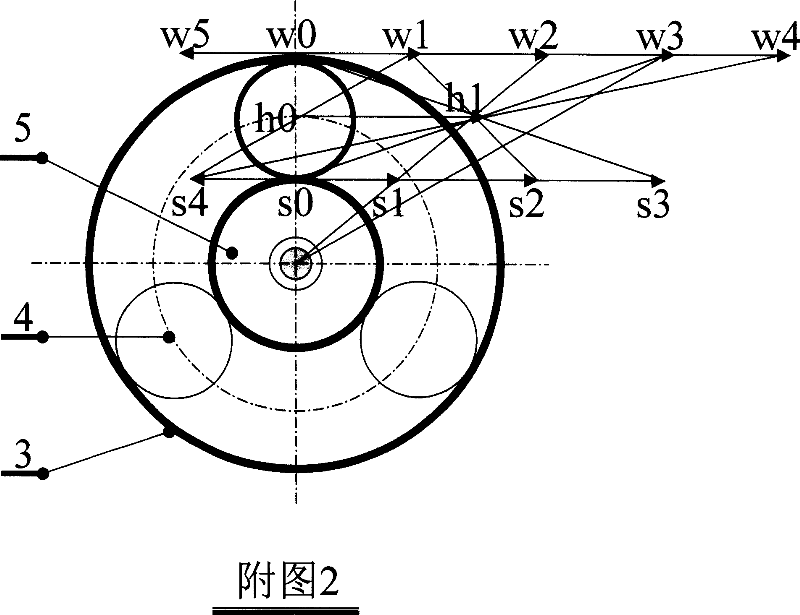

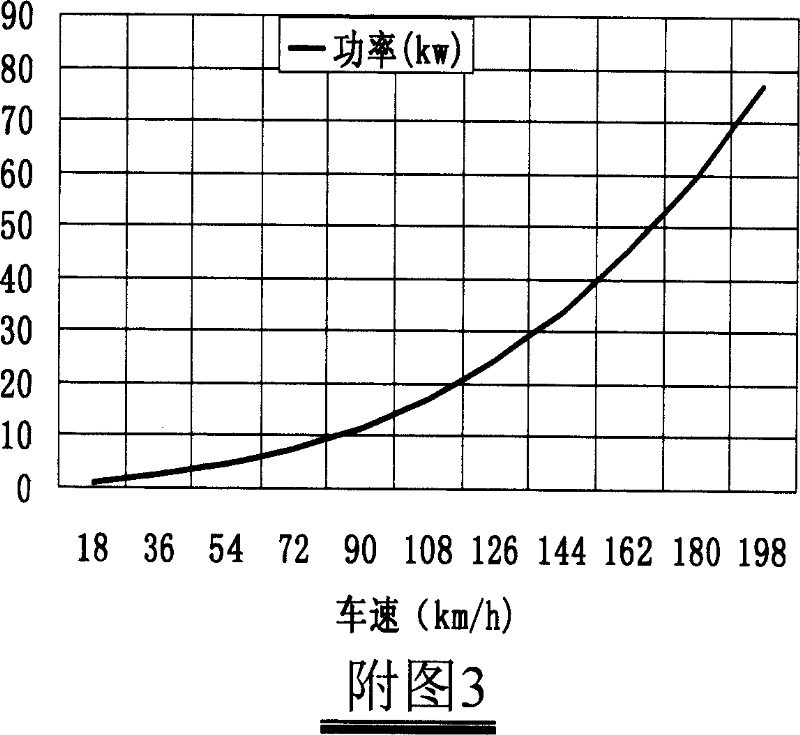

Mix-driving and energy-saving device of continuously variable motor vehicle

InactiveCN101037087AHigh heat conversion efficiencyReduce idling energy consumptionGearing controlTransmission elementsElectronic control unitVariator

The invention relates to a device for power transmission, transformation and storing for a motor vehicle, especially a high-efficiency energy-saving motor vehicle power device employing integration of mechanics, hydraulics and electronics to realize multi-power hybrid driving and stepless variable drive. The device is mostly composed of an engine, a low-power variable pump / motor, a high-power variable motor / pump, an electromotor / generator, a planet gear system, a locking device, a hydraulic energy storing device, a hydraulic controller, a converter / electronic control unit and battery unit, a hydraulic air conditioner compressor, etc. The invention has advantages of simple structure, easy manufacturing, convenient operation, low cost and small bulk. By employing special power control logics, the high-efficiency stepless transmission energy saving device provided by the invention can match the engine features rationally and optimizedly, force the engine work in the high-efficiency low-discharge area frequently, possess excellent dynamical features, realize parking stop and braking energy recovery, replace the present automobile transmission, improve the energy-saving feature of the present automobile and energy-saving driving feature of new automobile.

Owner:朱荣辉

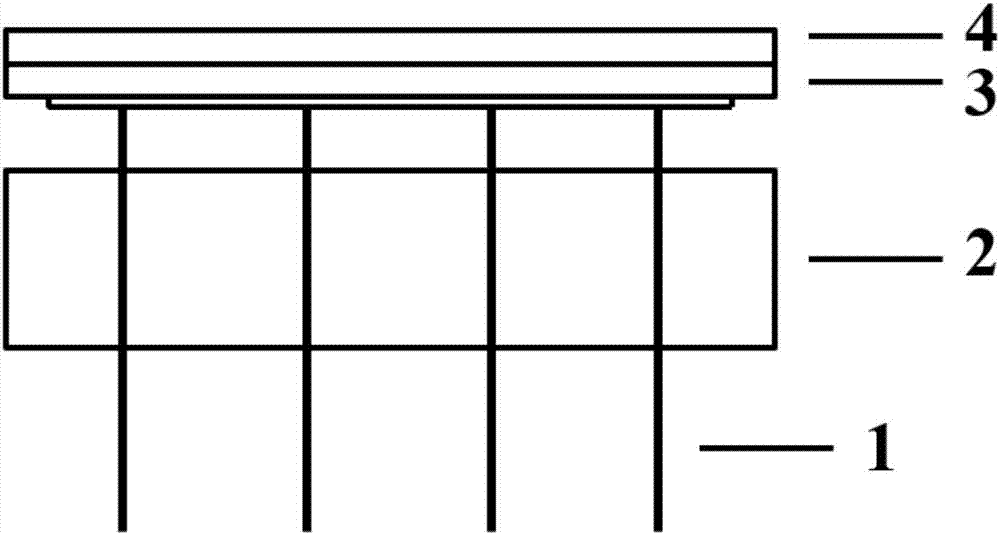

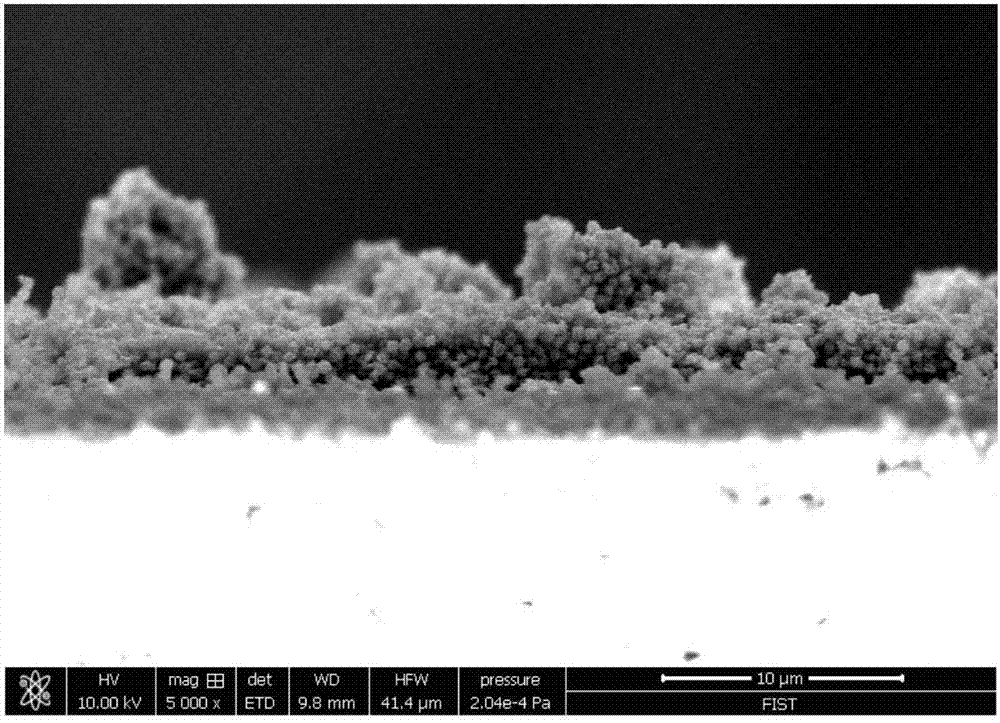

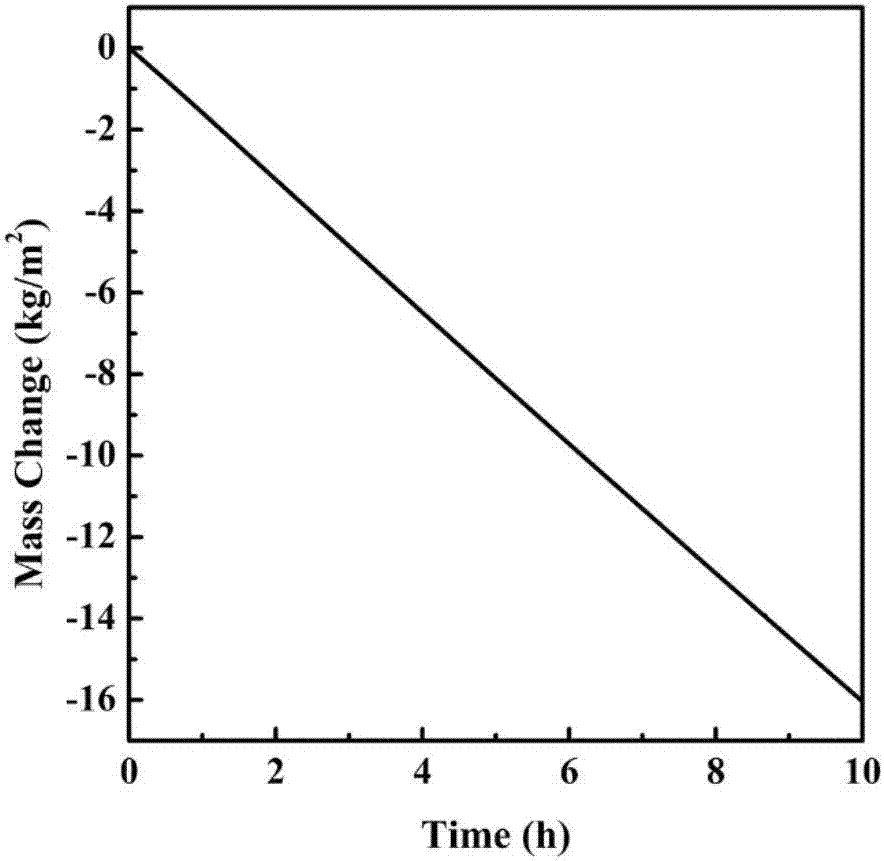

Solar water evaporation purification and decomposition device

ActiveCN107879405AAchieve fadeAchieve purificationGeneral water supply conservationSeawater treatmentWater desalinationEvaporation Purification

The invention discloses a solar water evaporation purification and decomposition device which comprises a water supply line, a float and heat insulation layer, an evaporation layer and a photothermalconversion and solute barrier layer which are connected in sequence from bottom to top. The water supply line enables water to pass through the float and heat insulation layer, and the water is pumpedinto the evaporation layer by virtue of a capillary action; solar energy absorbed by the photothermal conversion and solute barrier layer is converted into heat, and water is heated to be vaporized into water vapor from the evaporation layer; due to pore channel volatilization of the photothermal conversion and solute barrier layer, partial water vapor is decomposed to produce hydrogen and oxygen; since the photothermal conversion and solute barrier layer contains a hydrophobic part and is not infiltrated by water, the solar energy can directly heat a heat-absorbing material only, but not heat water, so that high photothermal conversion efficiency is realized; and meanwhile, the solute in the water is prevented from being separated out on the membrane, and sea water desalination, sewage purification and water decomposition can be realized. Due to the design of a hydrophilic / hydrophobic double-layer evaporation structure, the solar water evaporation purification and decomposition device with high photothermal conversion efficiency and high stability is obtained.

Owner:XI AN JIAOTONG UNIV

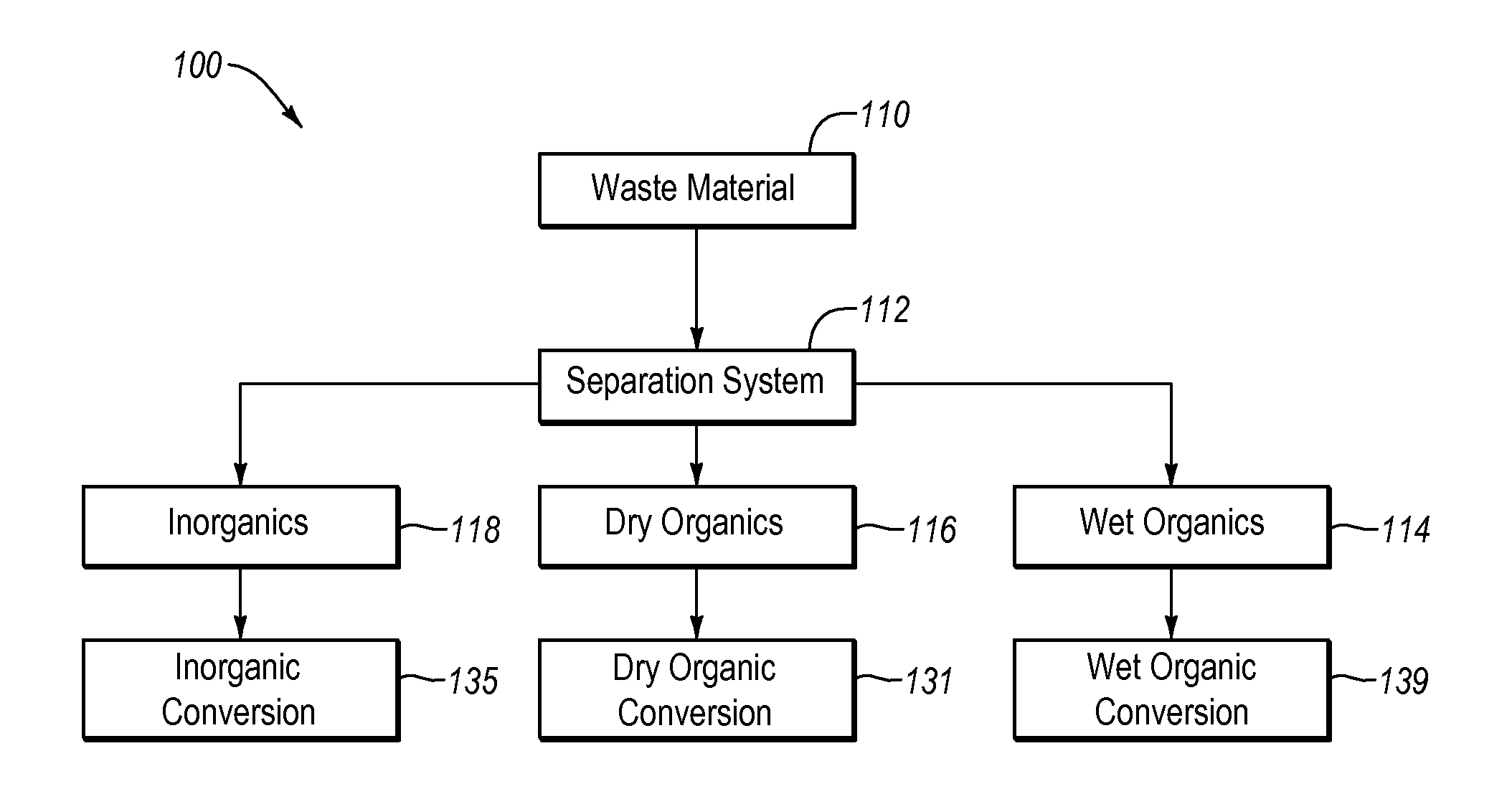

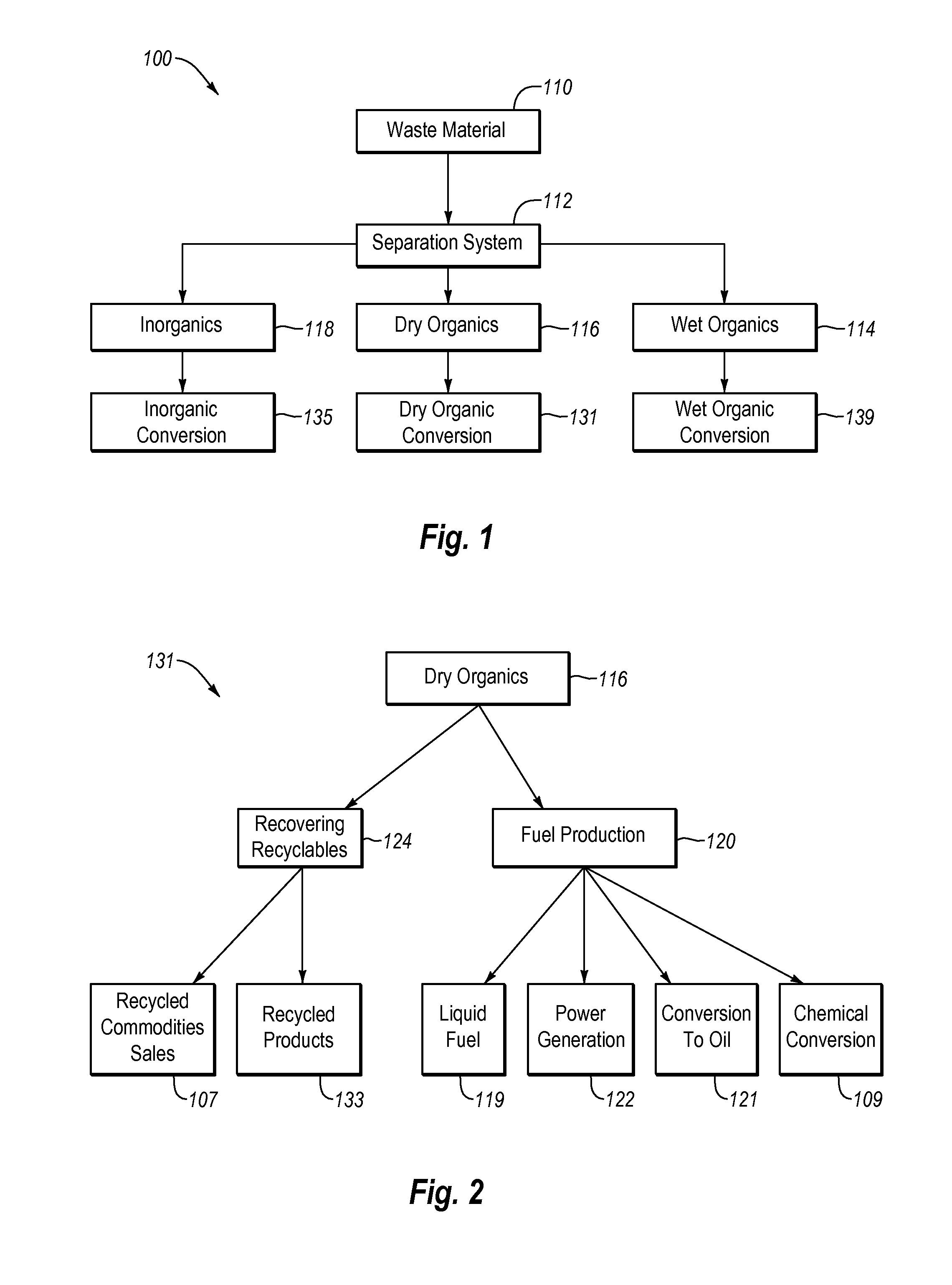

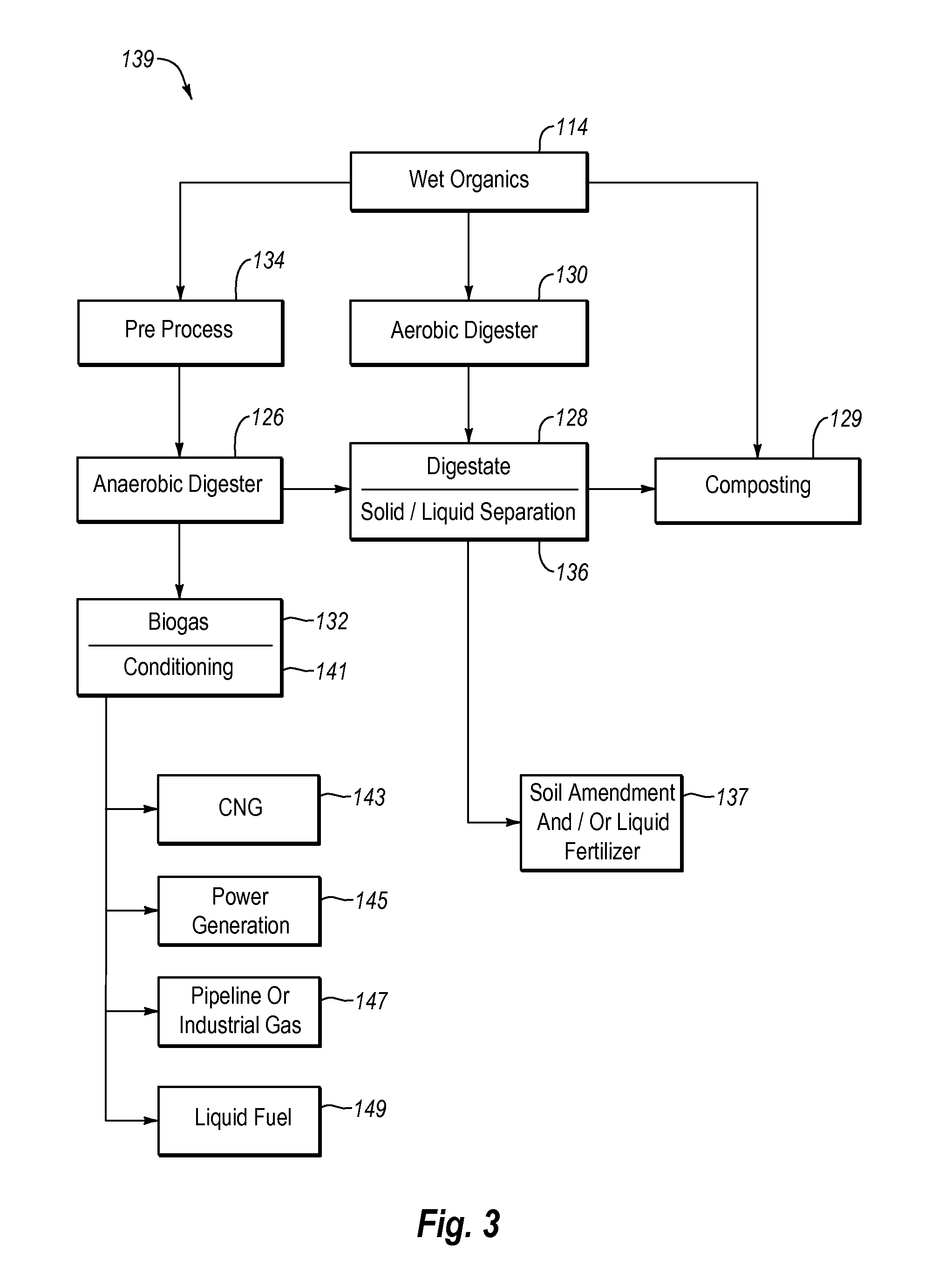

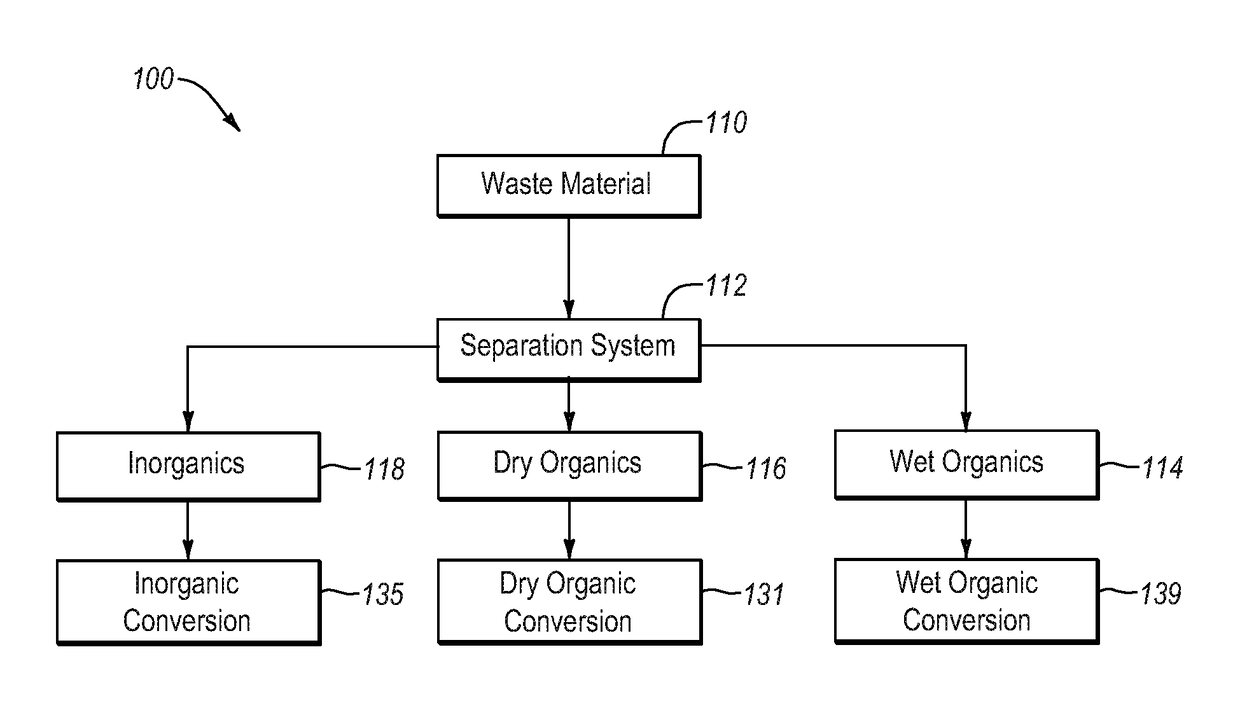

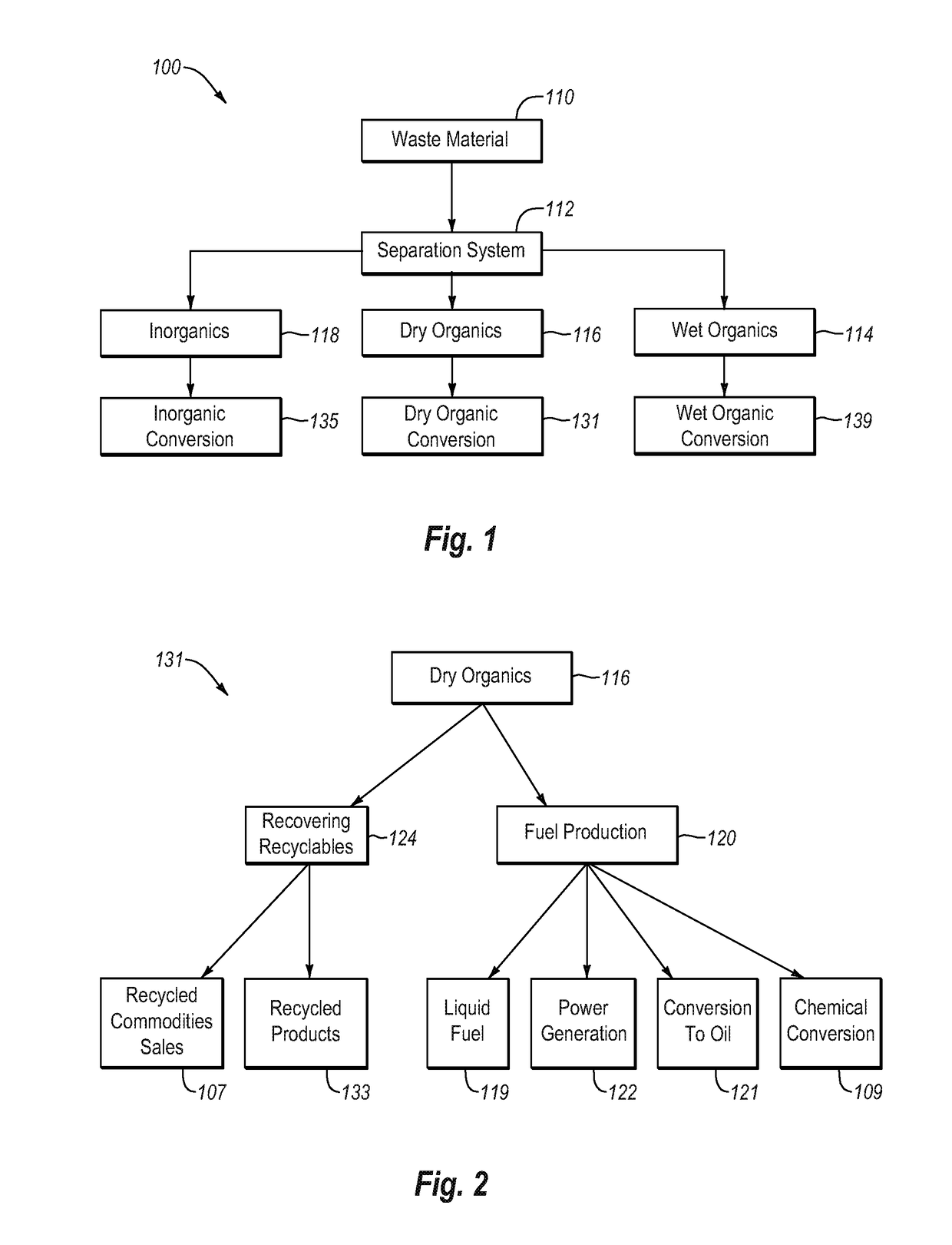

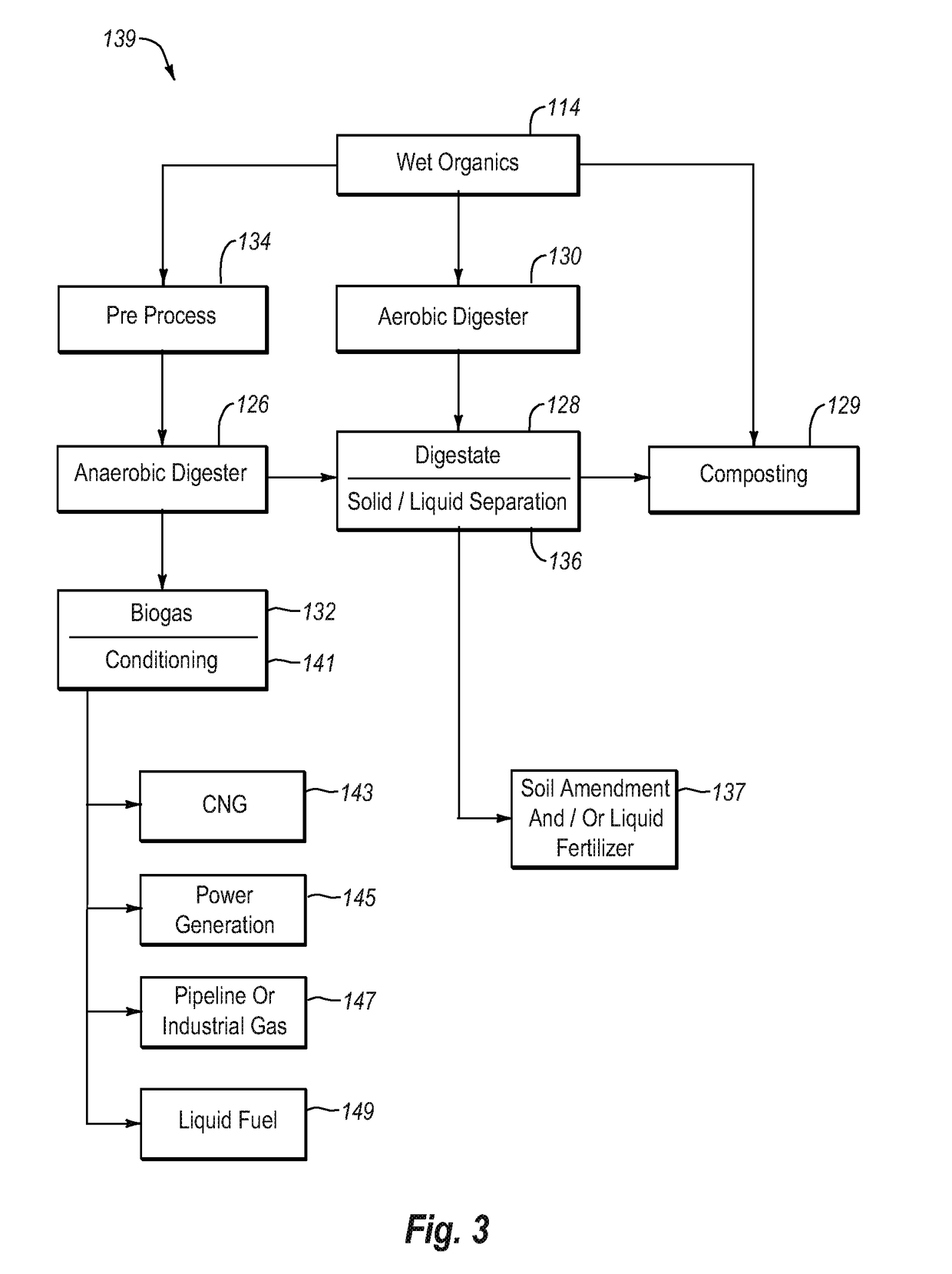

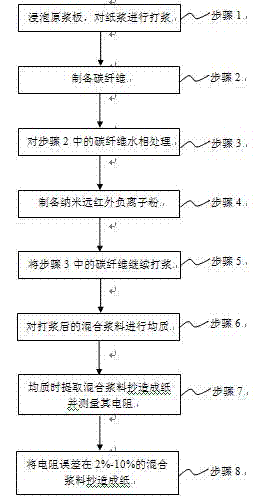

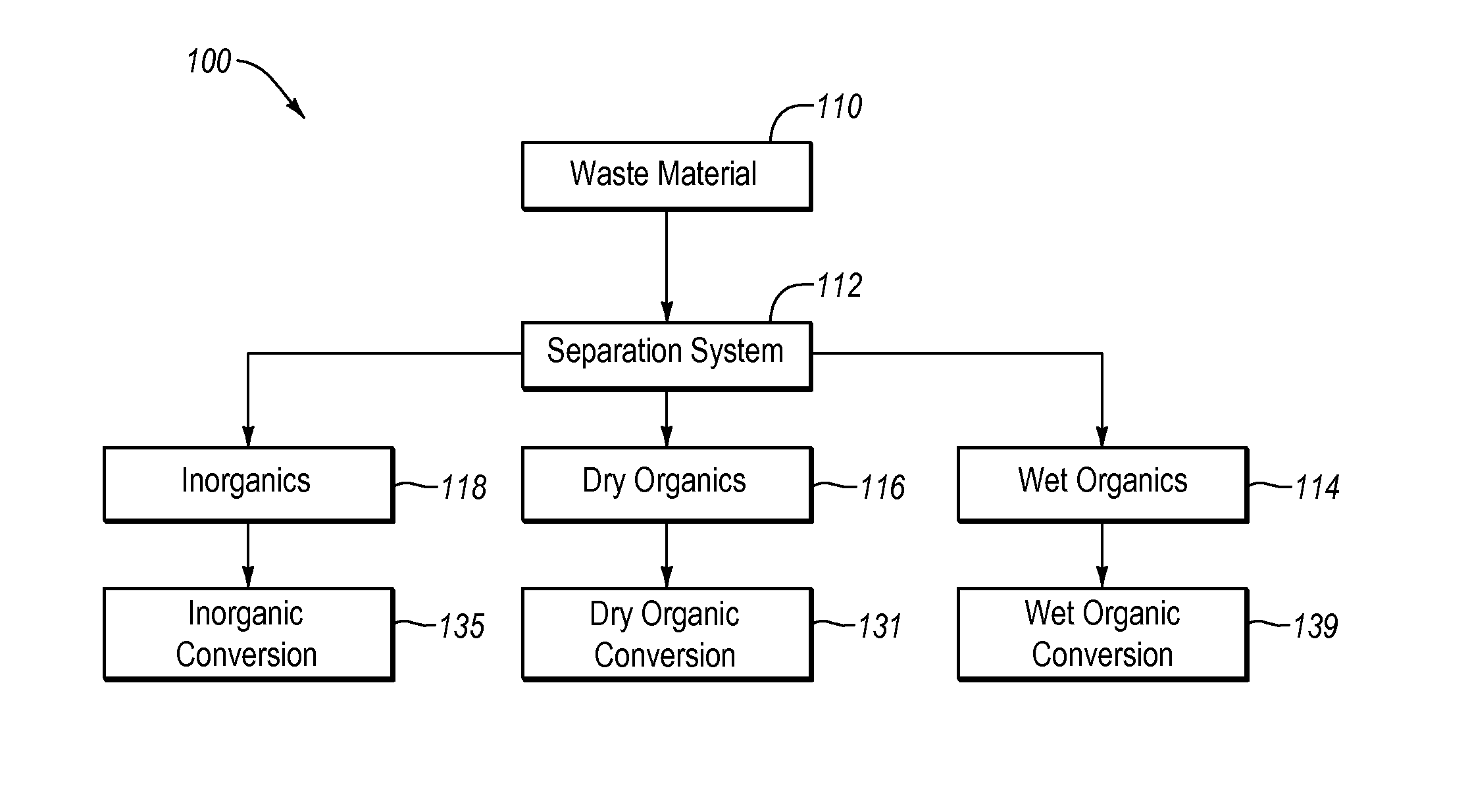

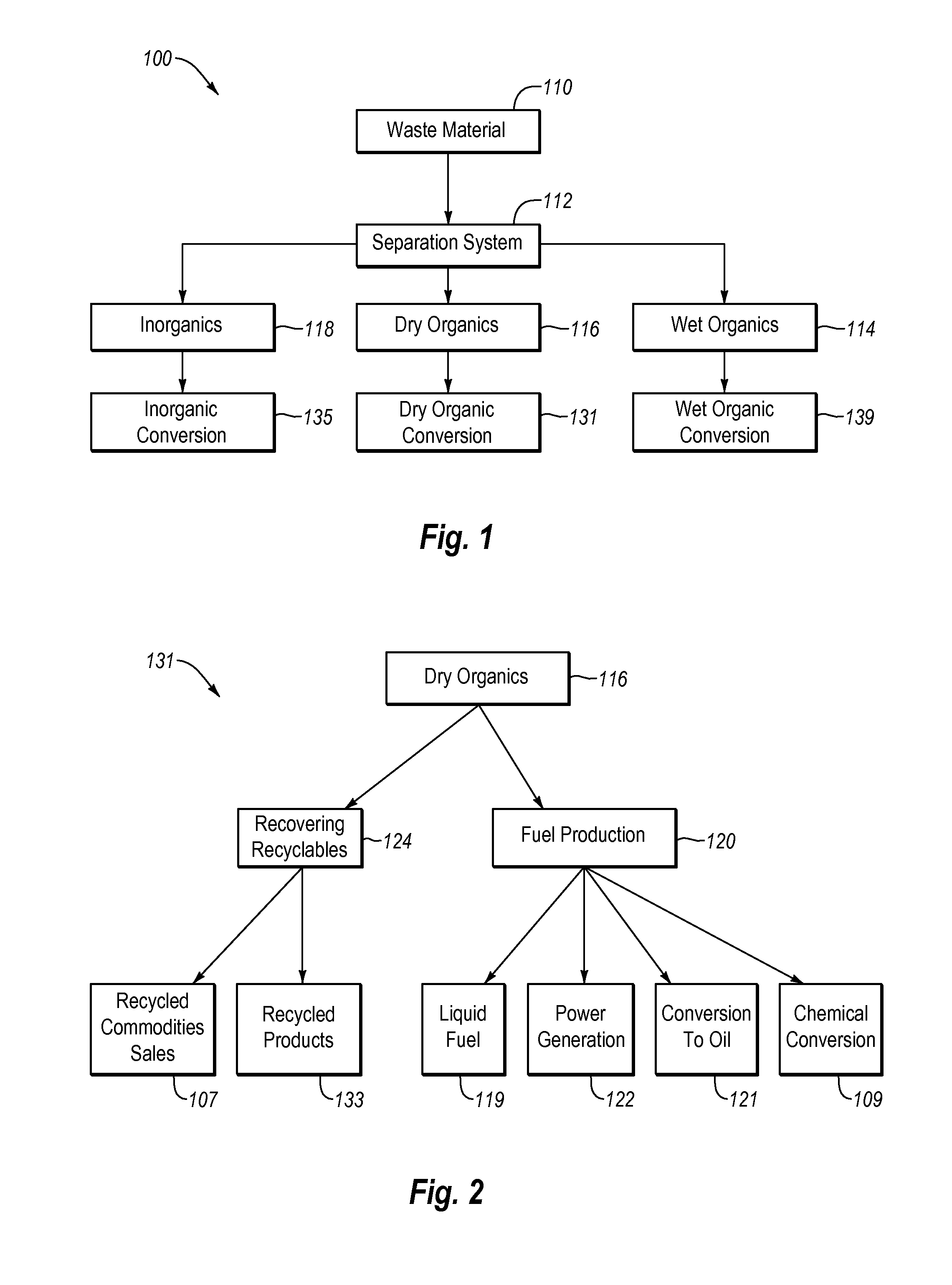

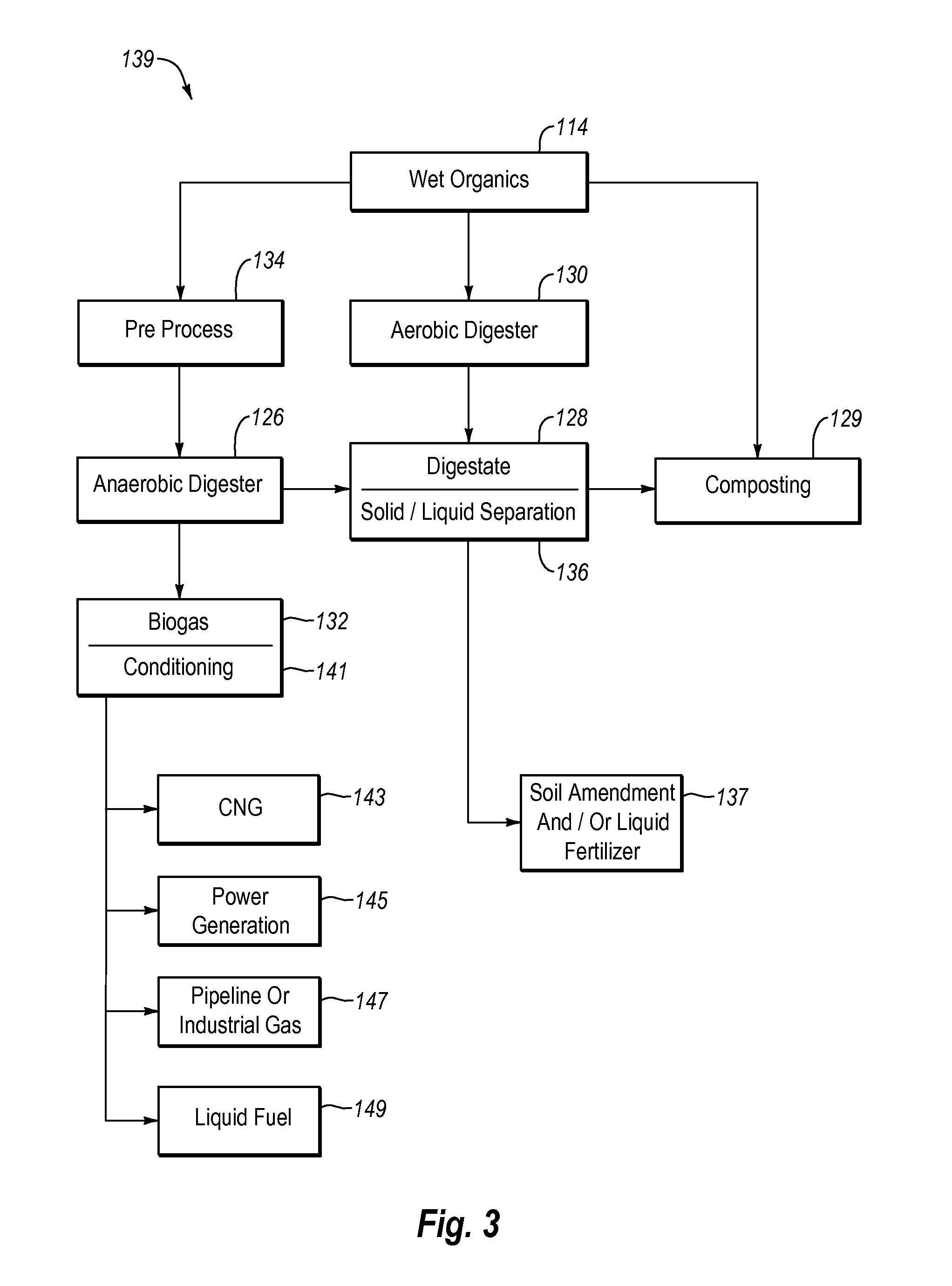

Systems and methods for processing mixed solid waste

ActiveUS20120190102A1Efficient extractionMaximize efficiencyInternal combustion piston enginesWaste processingEnvironmental chemistry

Solid waste that includes a mixture of wet organic material and dry organic material can be are separated using mechanical separation to produce a wet organic stream enriched in wet organics and a dry organic stream enriched in dry organics. The separated wet organic stream and dry organic stream are separately converted to renewable or recyclable products using different conversion techniques particularly suited for the separated wet and dry organic streams.

Owner:UPLAND ROAD IP HOLDCO LLC +2

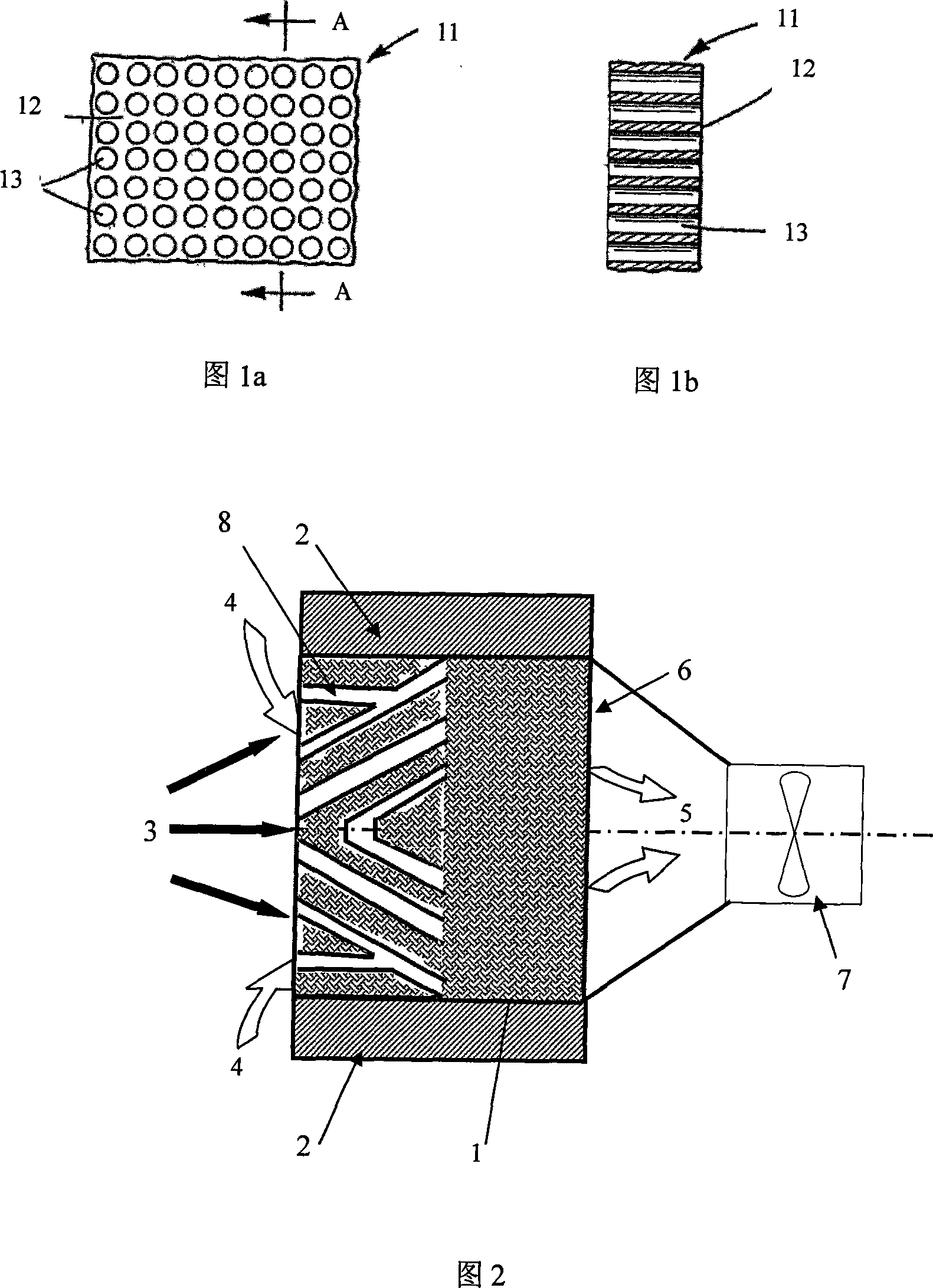

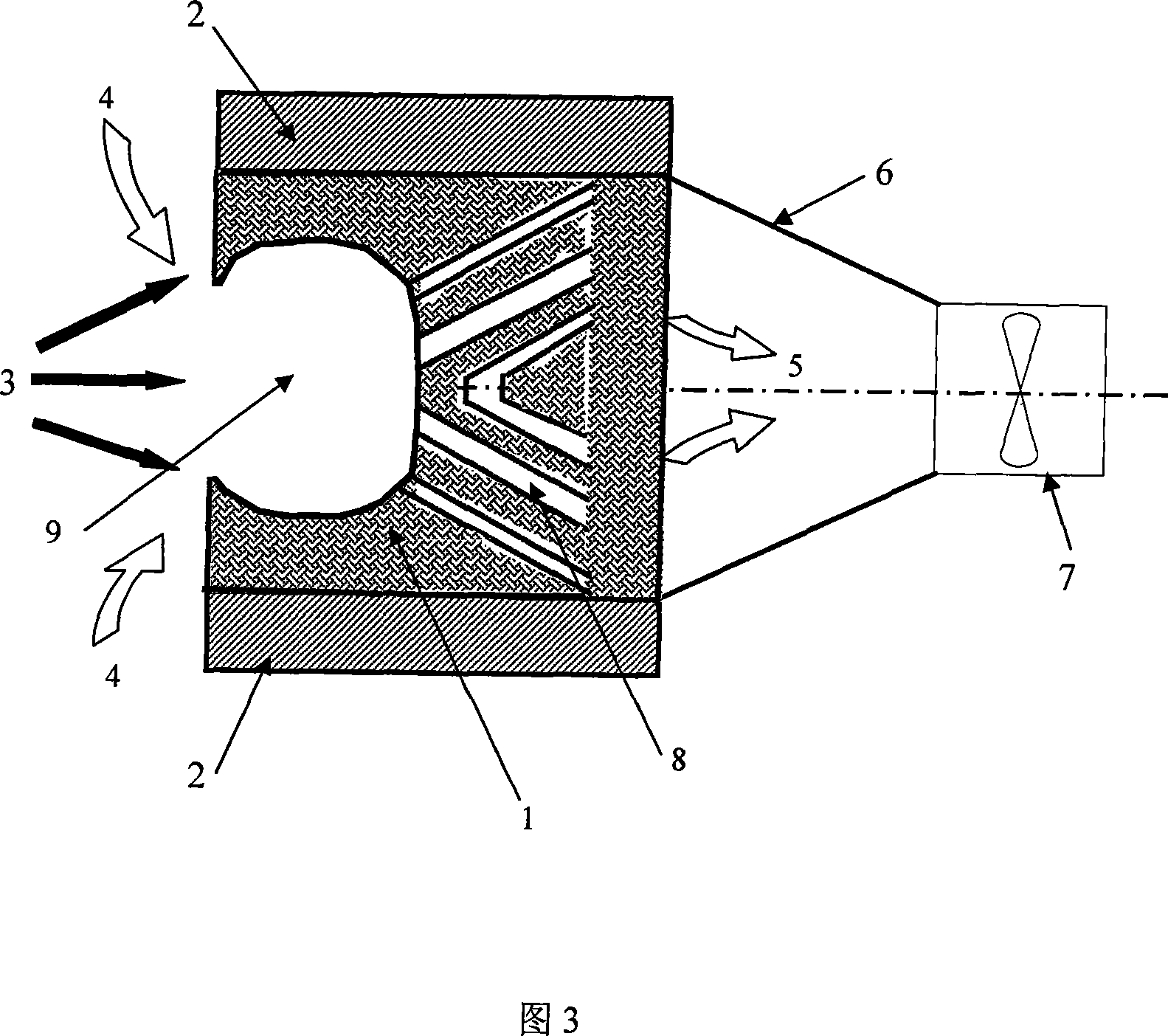

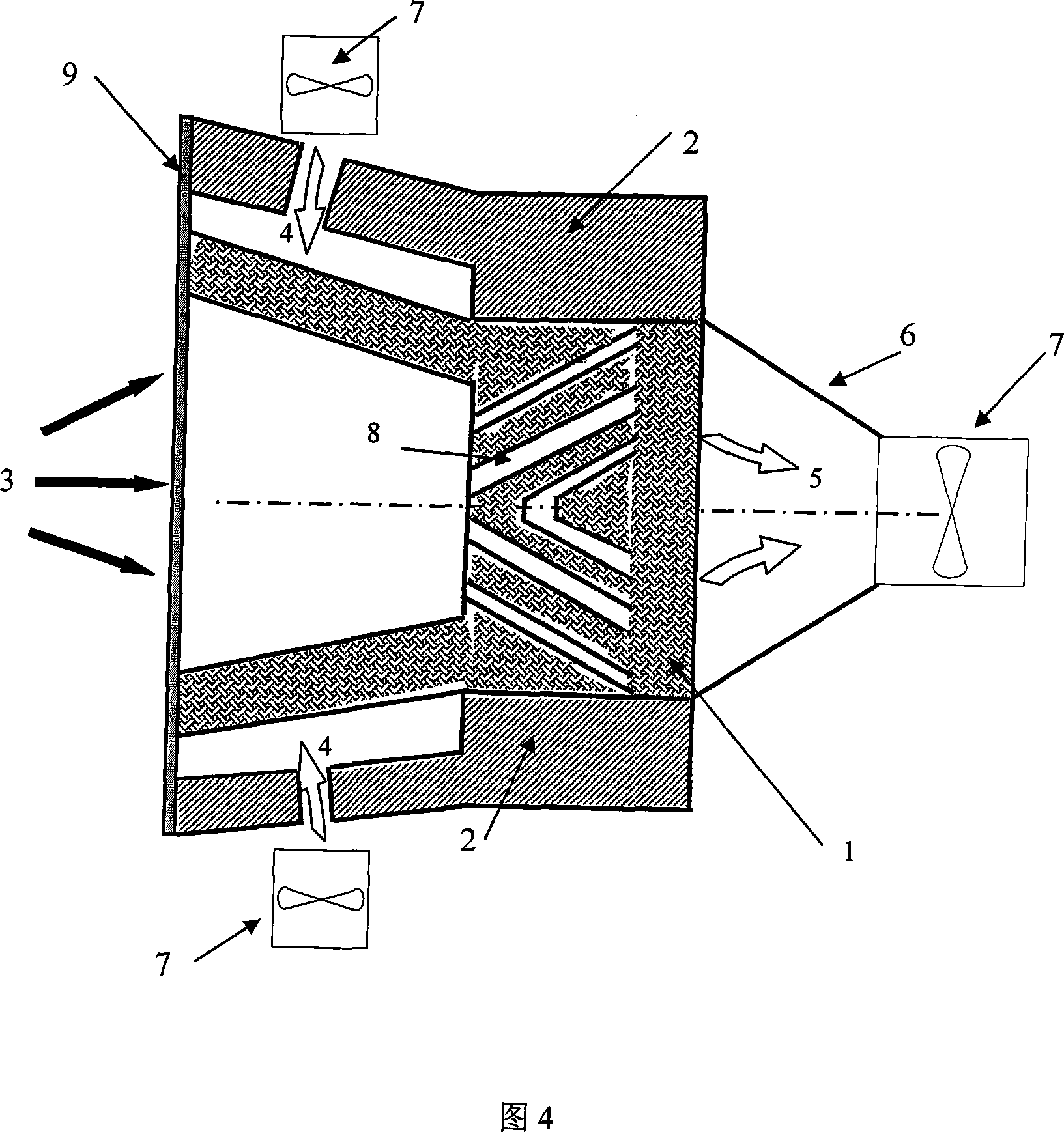

Silicon carbide foam ceramic solar energy air heat-absorbing device

InactiveCN101122425AImprove thermal conductivityFacilitate conductionSolar heating energySolar heat devicesCold airBlackbody cavity

A silicon carbide ceramic foam solar energy air heat absorber uses silicon carbide ceramic foam materials as solar energy absorber. The silicon carbide ceramic foam absorber is wrapped with an insulating layer (2). A radiant heat flux (3) projects onto the surface of the silicon carbide ceramic foam absorber (1) or into an artificial blackbody cavity (9) and is received by the silicon carbide ceramic foam absorber (1). Cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3). Hot air (5) is obtained through heat exchange of thecold air and the radiant heat flux. Or the cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3) or back to the radiant heat flux (3). The hot air (5) of 700 to 1300 DEG C is obtained through the heat exchange of the cold air and the radiant heat flux through a quartz window (10). The silicon carbide ceramic foam absorber (1) buries an air diversion channel (8) beforehand. The invention can effectively receive radiant heat and emit heat to the air and take advantage of self-sensible heat to store heat at the same time.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

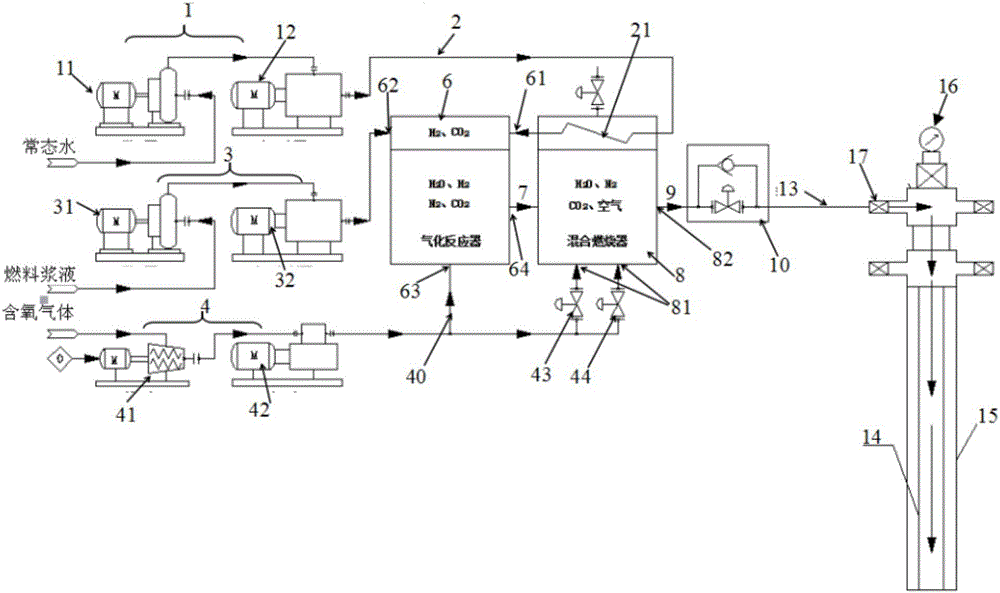

Supercritical multisource multielement thermal fluid injection-production system and injection-production method

InactiveCN106640008AImprove insulation effectLow thermal conductivityLiquid fuel feeder/distributionFluid removalCombustionProduct gas

The invention discloses a supercritical multisource multielement thermal fluid injection-production system and injection-production method. The system comprises a supercritical multisource multielement thermal fluid generating system and an oil tube. The oil tube is arranged in an exploiting shaft; the supercritical multisource multielement thermal fluid generating system comprises a supercritical gasification reactor and a supercritical mixed combustion reactor; in the presence of supercritical water, a gasification reaction is performed on fuel slurry in the supercritical gasification reactor, and the gasification product of the reaction and oxygen-containing gas dissolved in the supercritical water combust in the supercritical mixed combustion reactor to form a supercritical multisource multielement thermal fluid containing supercritical water and carbon dioxide; the supercritical mixed combustion reactor is connected to the oil tube. The supercritical multisource multielement thermal fluid injection-production system provided by the invention has the effects that thermal efficiency is high, the viscosity of thickened oil is reduced, the flowability of the thickened oil is improved and the recovery efficiency is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

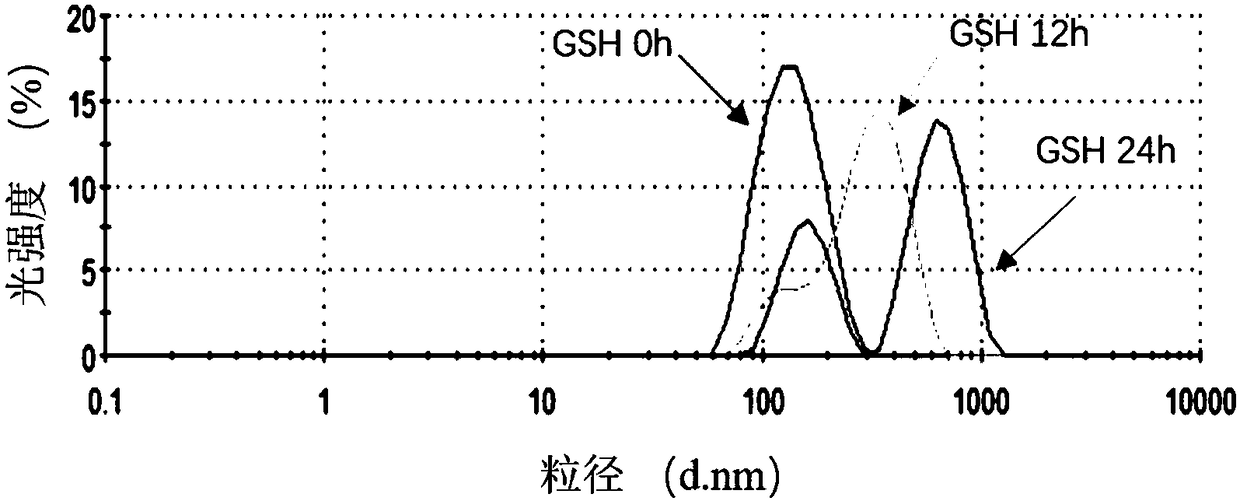

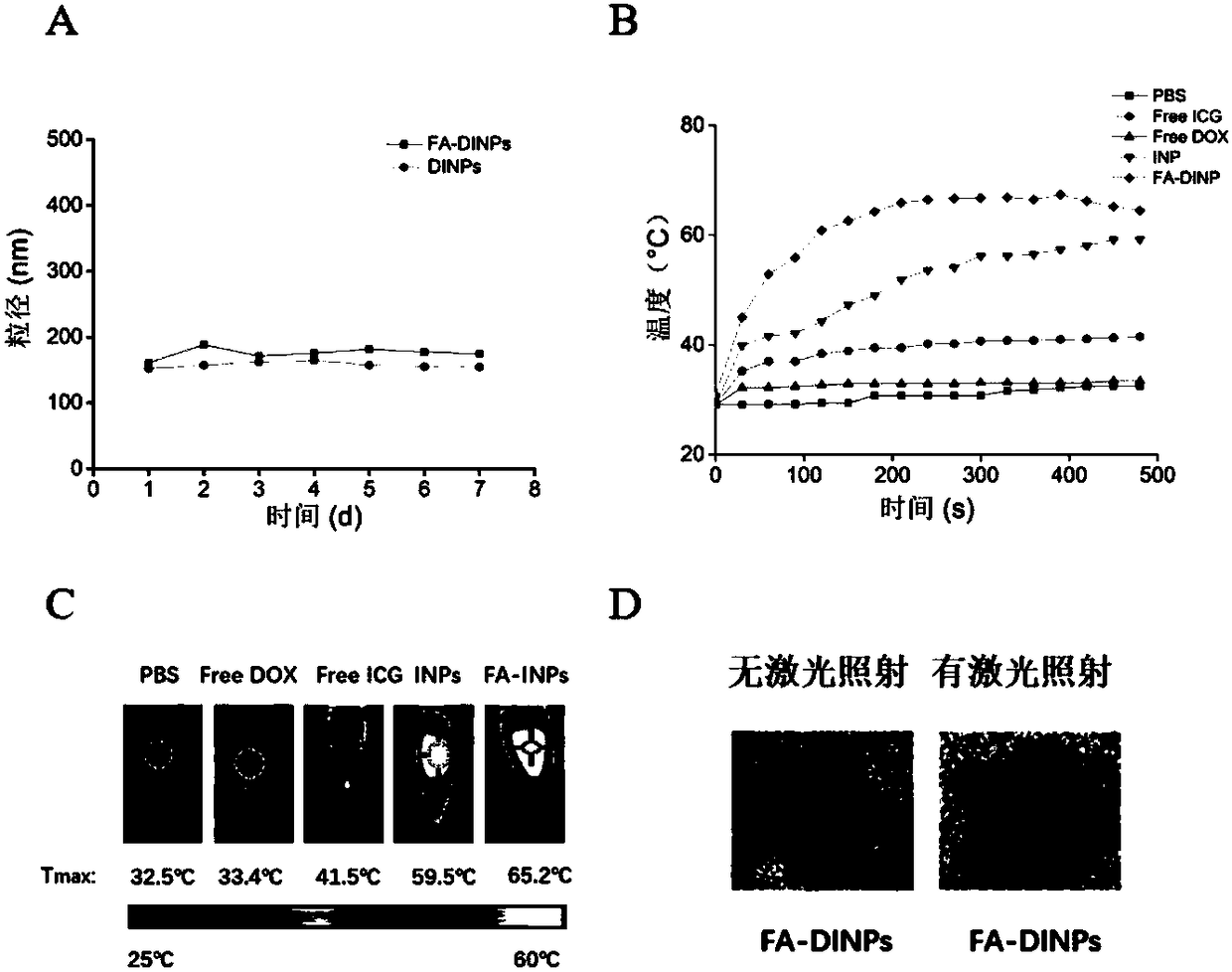

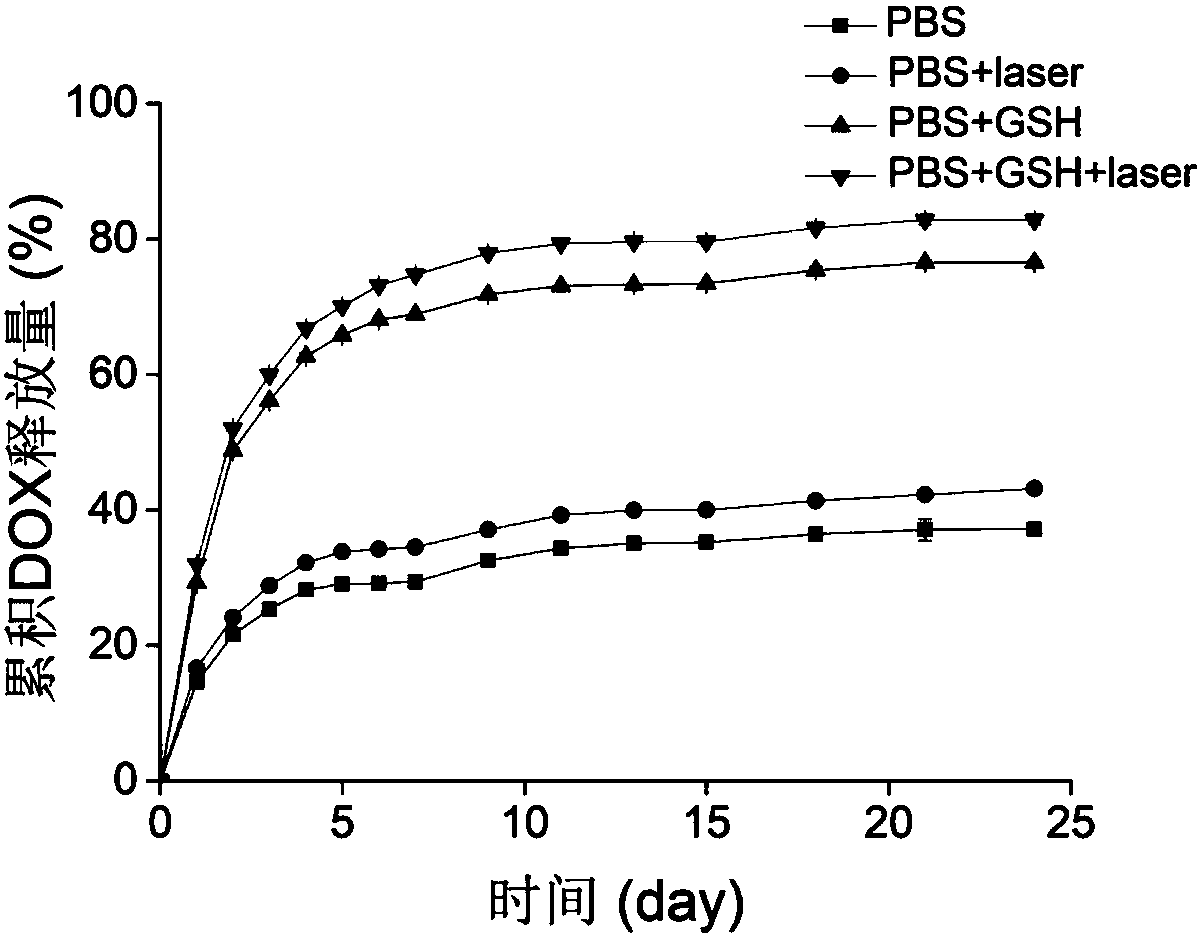

Folate-targeted reduction sensitive drug-carrying polymer nano-micelle as well as preparation method and application thereof

InactiveCN108478531AEfficient packagingEfficient entryOrganic active ingredientsEnergy modified materialsTumor targetPolymer science

The invention relates to a folate-targeted reduction sensitive drug-carrying polymer nano-micelle as well as a preparation method and application thereof. The delivery carrier is prepared by taking anamphiphilic triblock copolymer PCL-ss-PEG-ss-PCL as a material, and a chemotherapeutic drug adriamycin amycin and a photosensitizer indocyanine green are entrapped in a hydrophobic core of the micelle. Besides, phospholipid DSPE-PEG-NH2 with an active group is introduced into the preparation process, the DSPE end of the phospholipid has strong hydrophobic property and is inserted into the hydrophobic PCL core of the polymer micelle, the flexible hydrophilic PEG long chain exists on the outer surface of the micelle, FA with a targeting effect is connected to a PEG active distal end of the surface of the polymer micelle, and functions of active tumor targeting and reduction response drug release are integrated. The folate-targeted reduction sensitive drug-carrying polymer nano-micelle disclosed by the invention has the advantages of being small in particle size, high in dispersion property, high in drug loading capacity and encapsulation efficiency and excellent in photothermal conversion effect, can realize reduced trigger drug release, fluorescence imaging of tumor sites, tumor targeting drug delivery and chemotherapy-photothermal combination therapy and improve the tumor inhibition effect, and has wide application prospects in the targeted combination therapy aspect of tumors.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

Downconversion frequency shift infrared radiation enhanced coating and preparation method thereof

InactiveCN101712816AHigh heat conversion efficiencyImprove absorption rateCoatingsEmissivityFrequency shift

The invention relates to an infrared radiation enhanced coating and a preparation method thereof. The downconversion frequency shift infrared radiation enhanced coating is characterized by consisting of the following components in percentage by mass: 20 to 50 percent of radiation synergistic enhancer, 1 to 7 percent of downconversion frequency shift additive, 15 to 45 percent of high-temperature resistant base stock, 32 to 50 percent of high-temperature binder, 1 to 4 percent of flexibilizer and 1 to 4 percent of coating auxiliary agent, and the sum of the mass percentage of the components is 100 percent. The coating not only has high emissivity and good thermal shock resistance, but also can convert visible light into infrared radiation; and the thermal conversion efficiency of the coating is effectively improved.

Owner:WUHAN YINFURUI NEW MATERIAL

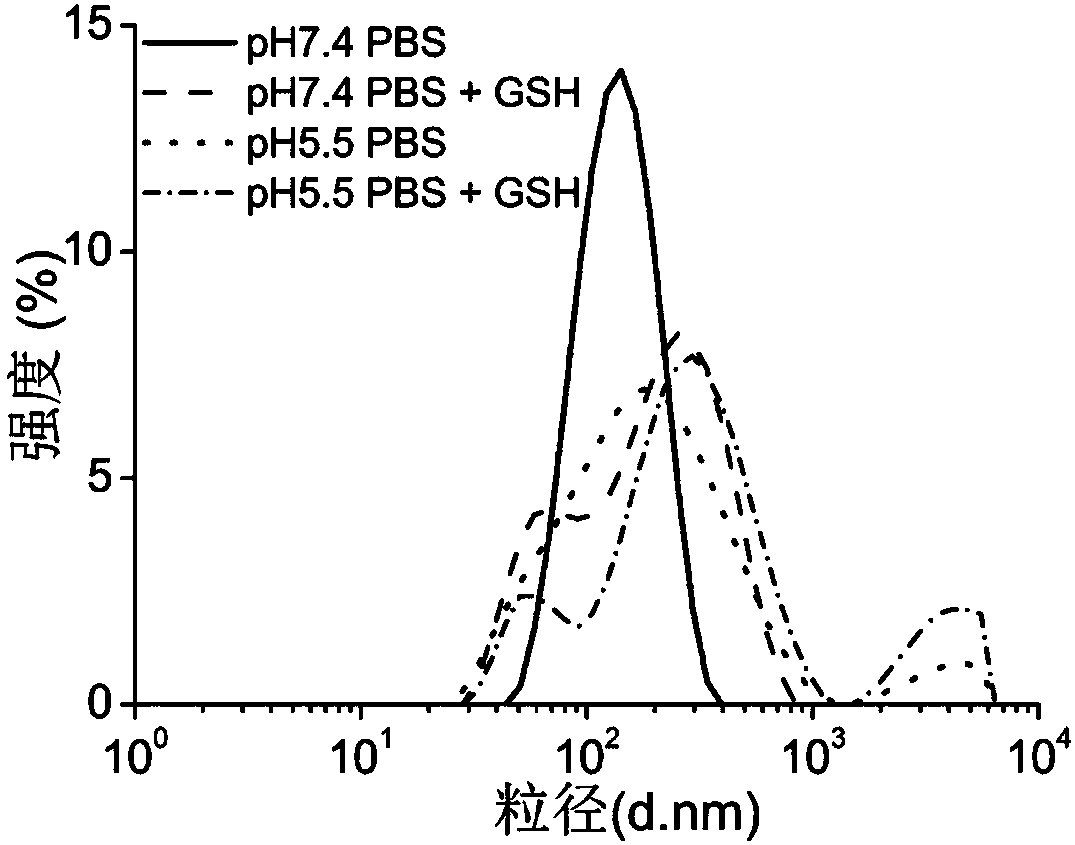

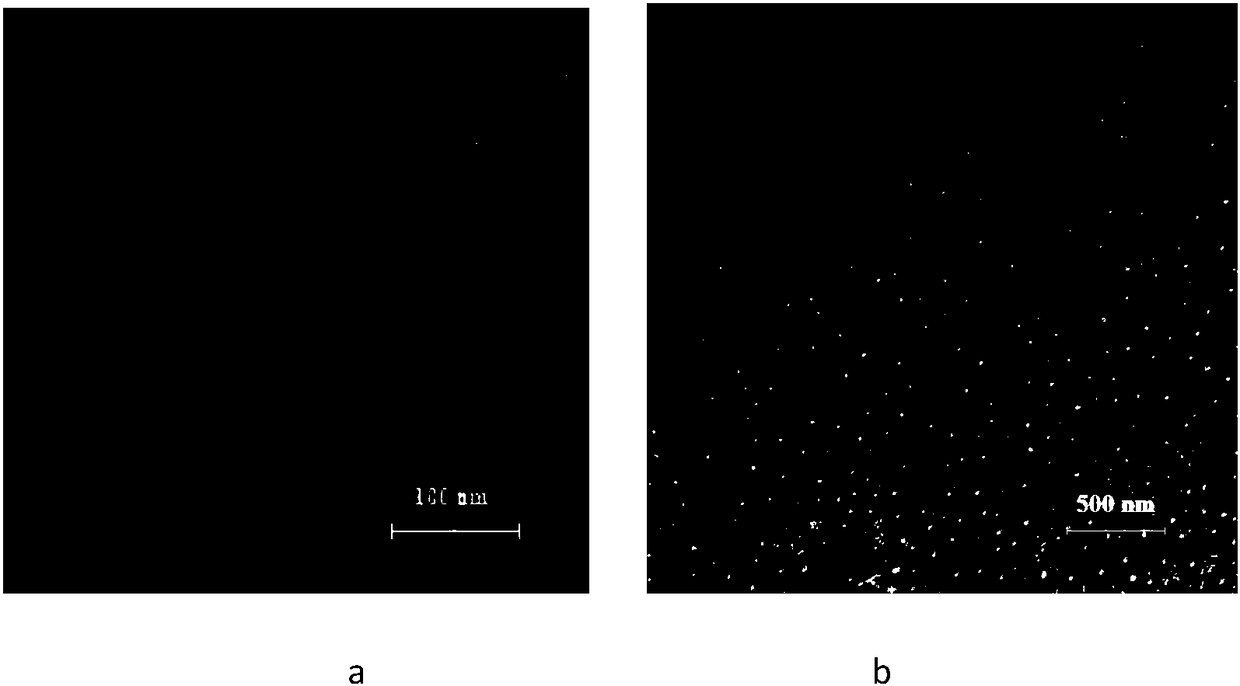

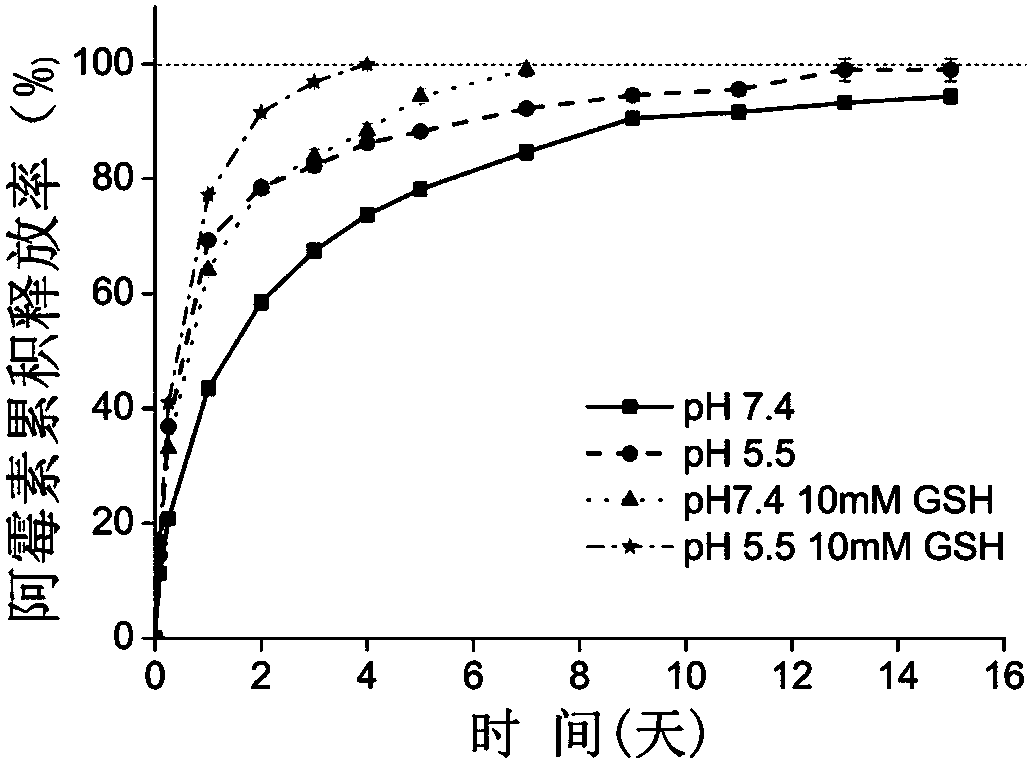

PH/reduction dual-sensitive multifunctional nano-micelle for tumor chemotherapy and photothermal combined therapy and application of pH/reduction dual-sensitive multifunctional nano-micelle

InactiveCN108354901AReduction-sensitiveWith pH/reduction smart responsivenessOrganic active ingredientsEnergy modified materialsDispersityTumor target

The invention relates to a pH / reduction dual-sensitive multifunctional nano-micelle for tumor chemotherapy and photothermal combined therapy and application of the pH / reduction dual-sensitive multifunctional nano-micelle. The pH / reduction dual-sensitive multifunctional nano-micelle is characterized in that a PCL-acetal-PEG polymer with pH sensitive characteristic, a PCL-ss-PEG-ss-PCL polymer withreduction sensitive characteristic and a phospholipid DSPE-PEG-NH2 with an active group are used as raw materials and are blended to prepare a pH / reduction intelligent responsive polymer nano-micelleas a carrier; a chemotherapeutic drug and a photosensitizer coat a hydrophobic core of the micelle; a casing is made of hydrophilic PEG and has the characteristic of long circulation and space stability; a folic acid targeting group is modified on the surface of the micelle by a covalent bond; the drug loading capacity is 4 to 10 percent, and the mass ratio of the chemotherapeutic drug to the photosensitizer is 0.5 to 2; the particle size is smaller than 200 nm. The pH / reduction dual-sensitive multifunctional nano-micelle disclosed by the invention has the advantages of good dispersity, smallparticle size, better photothermal conversion effect and high drug loading capacity and encapsulation efficiency; the effect of improving tumor suppression by tumor targeted administration, fluorescence imaging of a tumor site, pH / reduction triggered drug release and chemotherapy and photothermal combined therapy can be realized; the pH / reduction dual-sensitive multifunctional nano-micelle has a broad clinical application prospect in combined targeting therapy of tumors.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

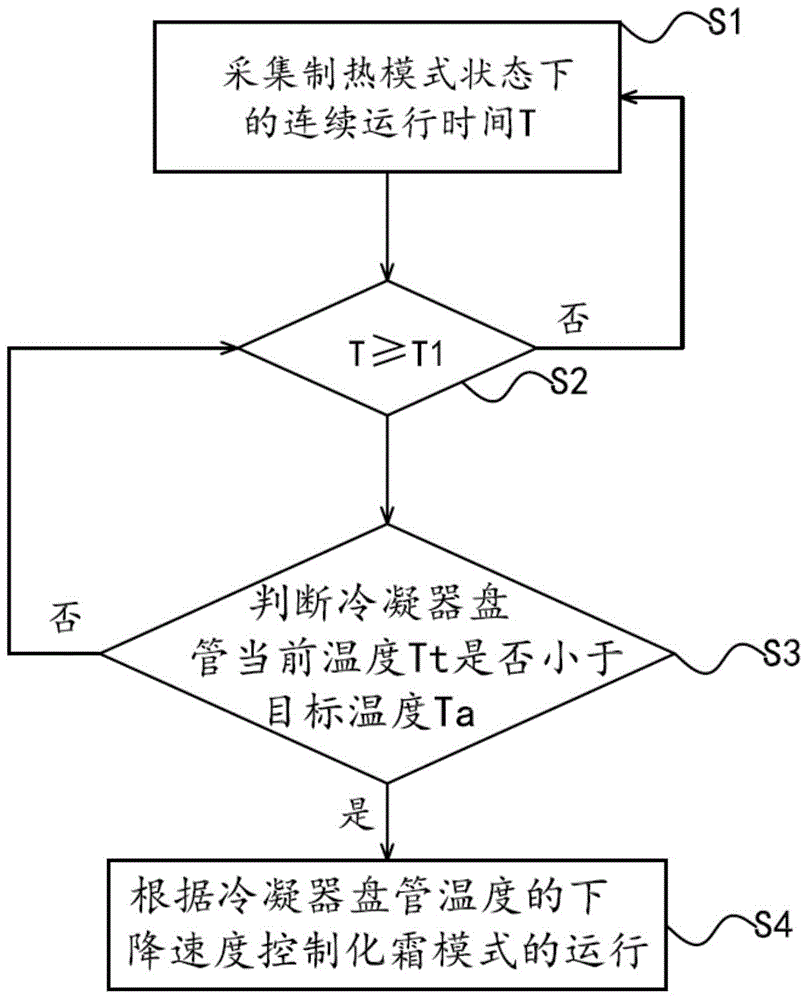

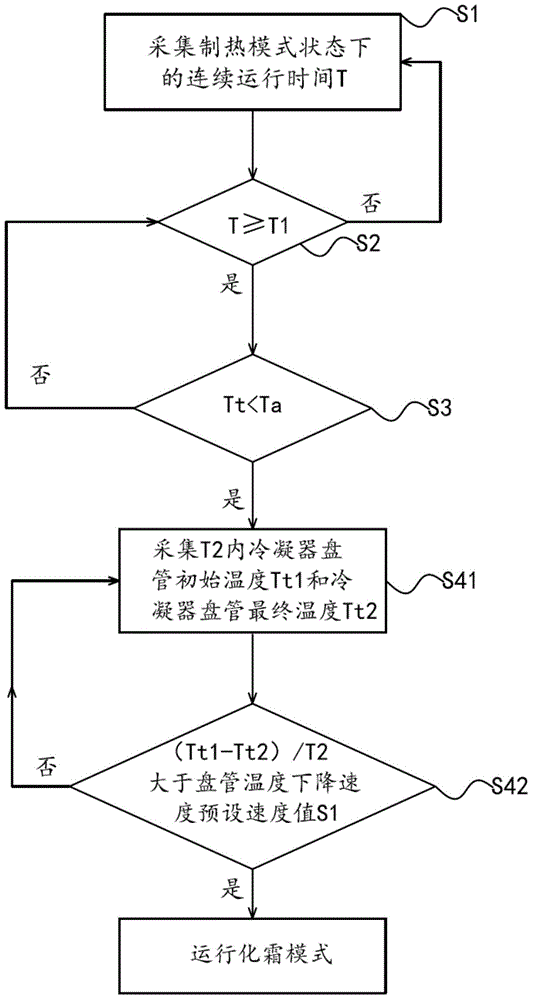

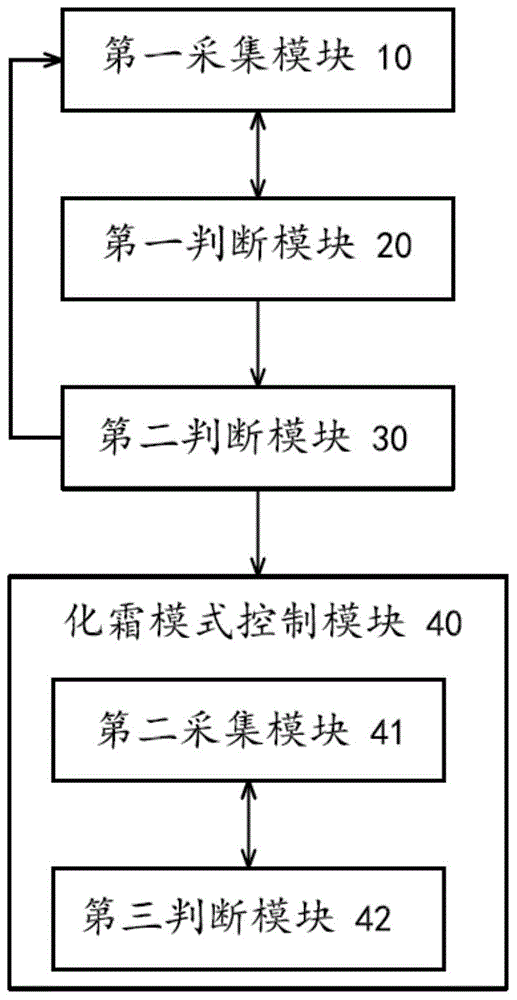

Control method and system for defrosting judgment of air conditioner

InactiveCN104791954AImpact misjudgmentAccurate Reaction ThicknessMechanical apparatusSpace heating and ventilation safety systemsFrostHeating effect

The invention relates to a control method and system for defrosting judgment of an air conditioner. The control method for defrosting judgment of the air conditioner comprises the following steps that S1, the continuous operation time T in a heating mode state is collected; S2, whether the continuous operation time T is lager than or equal to a target time T1 is judged, the step S3 is executed if yes, and the step S1 is executed again if not; S3, whether the current temperature Tt of a condenser coiler is smaller than a target temperature Ta or not is judged, the step S4 is executed if yes, and the step S2 is executed again if not; S4, operation in the defrosting mode is controlled according to the dropping speed of the temperature of the condenser coiler. According to the control method and system for defrosting judgment of the air conditioner, whether defrosting is needed for a condenser or not is judged by dynamically acquiring the dropping speed of the temperature of the condenser coiler, the thickness of a frost layer can be intelligently and accurately reflected by the dropping speed of the temperature of the condenser coiler, and the problems that due to the fact that the defrosting mode is started frequently, the heating effect of the air conditioner is affected, fluctuation of the indoor temperature is caused, and use comfort is affected are solved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

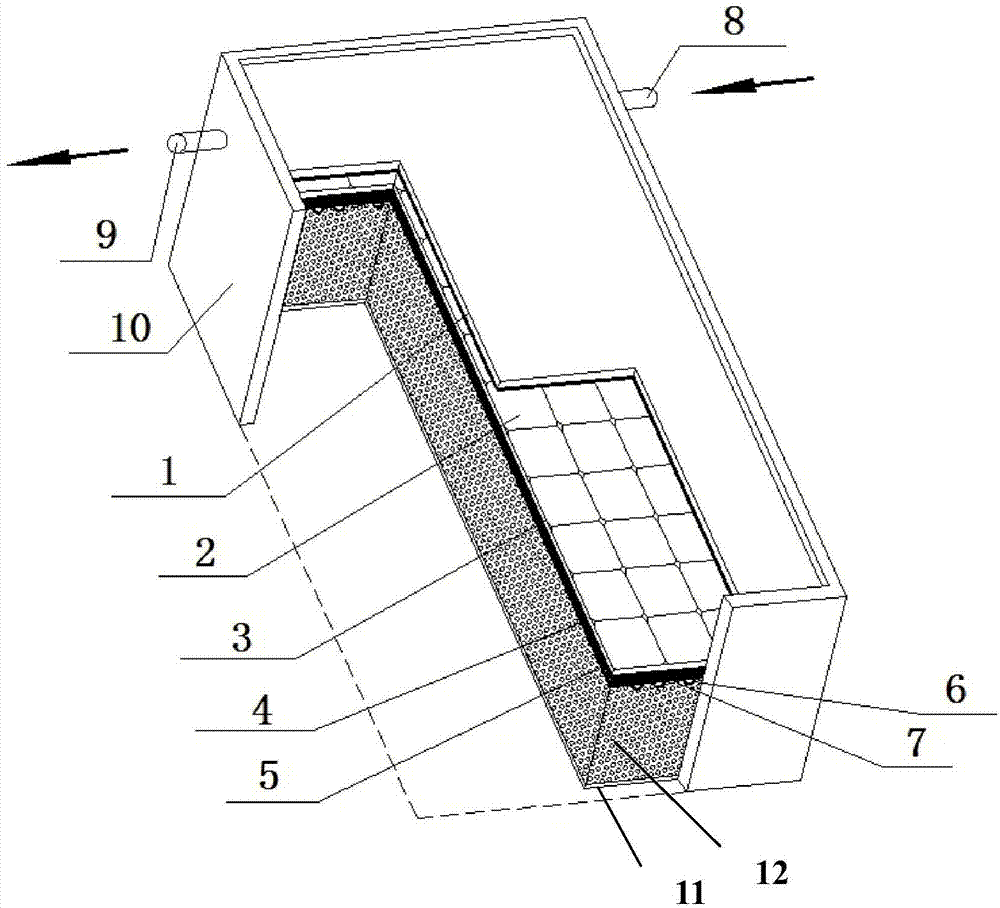

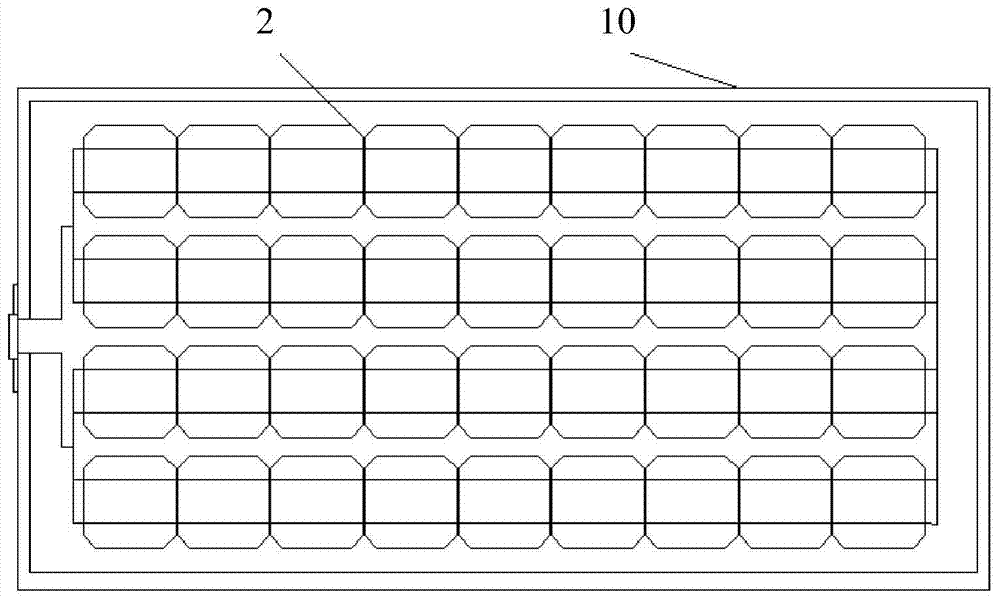

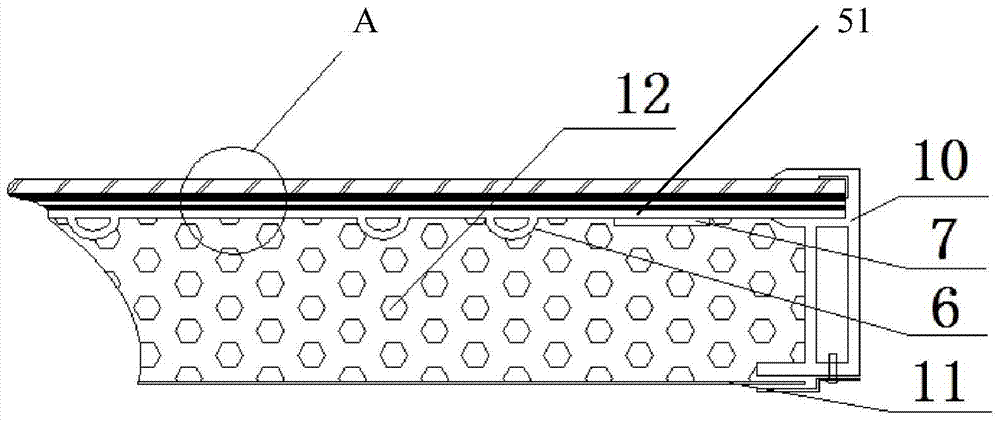

Heat tube type photovoltaic photo-thermal member

InactiveCN103591708AImprove absorption rateAchieve absorptionSolar heating energySolar heat devicesGlass coverEngineering

The invention discloses a heat tube type photovoltaic photo-thermal member which comprises a glass cover plate, solar battery pieces, a packaging material TPT, a solar spectrum selective absorption coating, a tube plate type heat absorption plate, a heat insulation layer and an outer section frame, wherein the solar battery pieces are in series connection and parallel connection in rows, and the solar spectrum selective absorption coating is used for absorbing the infrared wave band of the solar spectrum; the glass cover plate, the solar battery pieces, the TPT packaging material and the solar spectrum selective absorption coating are sequentially laminated and attached from top to bottom; the tube plate type heat absorption plate is mainly formed by a plate body and a heat collection tube arranged on the lower surface of the plate body, the cross section of the heat collection tube is of a downwards protruding arc shape; the upper surface of the plate body is fixed on the lower surface of the solar spectrum selective absorption coating to form a strong platy body; the heat insulation layer covers the lower surface of the tube plate type heat absorption plate and is supported by a base plate, and the heat insulation layer and the strong platy body are jointly fixed in the outer section frame. By the adoption of the heat tube type photovoltaic photo-thermal member, an air interlayer is decreased, and therefore heat conversion efficiency is enhanced; in addition, because the heat collection tube is of the arc shape, the contact area can be enlarged, pressure-bearing can be enhanced, and it can be guaranteed that the member runs stably for a long time.

Owner:SUN YAT SEN UNIV

Systems and methods for processing mixed solid waste

ActiveUS20170253891A1Efficient extractionMaximize efficiencyInternal combustion piston enginesWaste processingEnvironmental chemistryMaterial flow

Solid waste that includes a mixture of wet organic material and dry organic material can be are separated using mechanical separation to produce a wet organic stream enriched in wet organics and a dry organic stream enriched in dry organics. The separated wet organic stream and dry organic stream are separately converted to renewable or recyclable products using different conversion techniques particularly suited for the separated wet and dry organic streams.

Owner:UPLAND ROAD IP HOLDCO LLC

Biodegradable macromolecule composite material with shape memory function and its preparation method and use

InactiveCN101240116AGood magnetic responseHigh elastic modulusStentsSurgeryPolypyrroleMechanical property

The invention relates to a biodegradable polymer composite material having shape memory function, comprising a biodegradable polymer material, which is characterized in that the molecular weight of the biodegradable polymer material is 20000 to 1500000, 1 to 20 parts of nano-scopic or micron-sized organic conductive particles and / or inorganic magnetic particles are added in the 100 parts by weight of the polymer, wherein, the organic conductive particles is one of polypyrrole, polyaniline, poly3,4-dioxane ethyl thiophene or the mixture of them, the inorganic magnetic particles is one of ferroferric oxide and ferric oxide magnetic particles or the mixture of them. The mechanical property and mechanical property of the materials, with good elasticity modulus, well elasticity, high shape recovery rate, easy shape memory and changing operation and fast shape recovery speed.

Owner:SOUTHWEST JIAOTONG UNIV

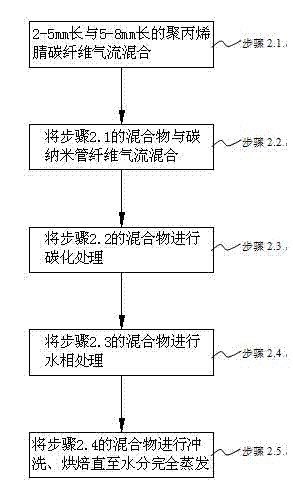

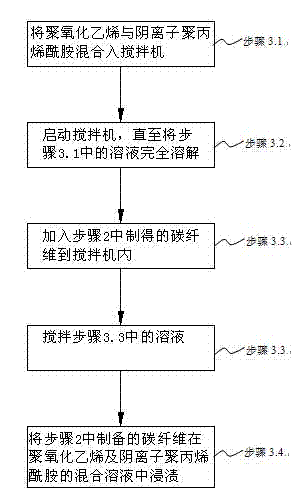

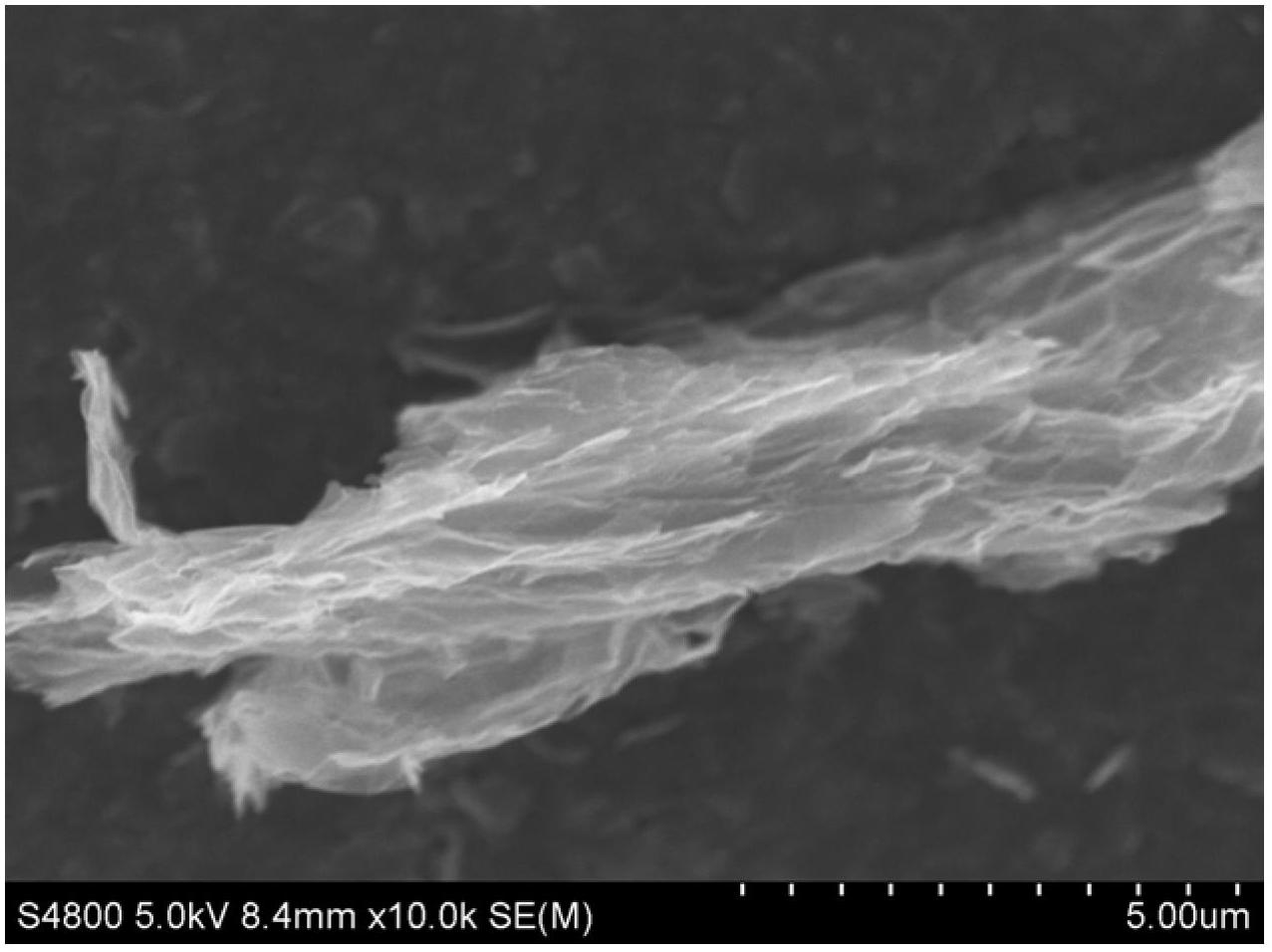

Far infrared carbon fiber low temperature conductive heating paper and preparation method thereof

InactiveCN102226325AIncrease surface areaPass wellNon-fibrous pulp additionSpecial paperFiberCarbon fibers

A far infrared carbon fiber low temperature conductive heating paper comprises an original pulp board, carbon fibers, nano far infrared negative ion powder and a diffusant. According to the invention, paper pulp is beaten and added with carbon fibers treated with carbonization processing, water phase processing and hydrophilism processing for dipping; after homogenizing and beating again, resistor of a mixed slurry is measured, and mixed slurry with a resistor within 2%-10% is manufactured into paper. The far infrared carbon fiber low temperature conductive heating paper prepared by the invention can heat uniformly, has high thermal conversion efficiency, near zero electromagnetic radiation, extremely small current density, and is safe for usage. In addition, the radiated far infrared light wave can activate water molecules in human body, raise blood oxygen content, enhance cell vitality, improve human body microcirculation and promote metabolism.

Owner:SHANGHAI RELI TECH GRP CO LTD

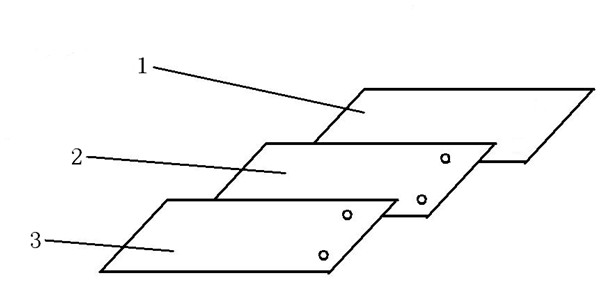

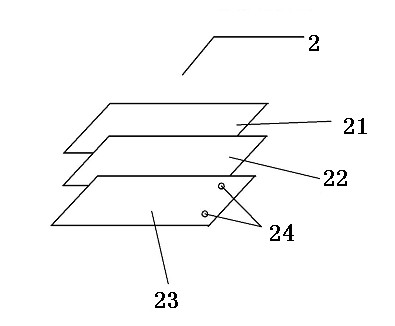

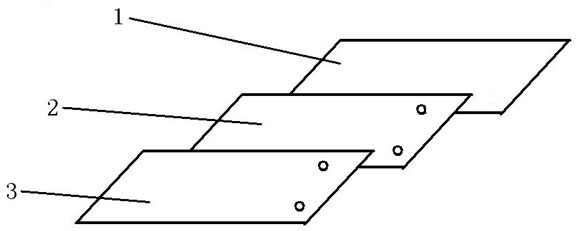

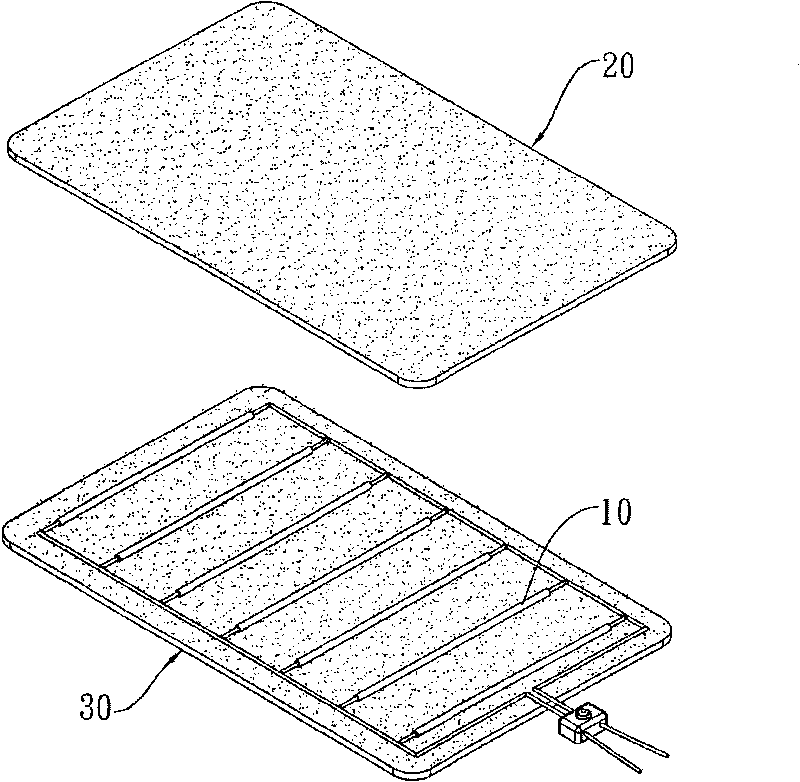

Low-temperature plane waterproof heating floor module and manufacturing method thereof

InactiveCN102383571AHigh heat conversion efficiencyImprove safety performanceLighting and heating apparatusElectric heating systemFiberEpoxy

The invention discloses a low-temperature plane waterproof heating floor module, which comprises an external decorating waterproof surface layer, a heating base material layer and an external decorating waterproof bottom layer which are sequentially overlapped and stuck, wherein the heating base material layer consists of an upper base material layer, a heating layer and a lower base material layer which are sequentially stuck; the heating layer is carbon fiber conducting paper; a pair of electrodes is arranged on the carbon fiber conducting paper; and a pair of conducting holes corresponding to the electrodes is respectively arranged on the lower base material layer and the external decorating waterproof bottom layer. According to the low-temperature plane waterproof heating floor module and a manufacturing method thereof disclosed by the invention, a heating element of the heating floor is subjected to sealing insulated treatment by using tailored epoxy resin, a polyvinyl chloride plastic board and other materials, and thereby corrosive damage of an outside material to the heating element is avoided and durable and safe use of the low-temperature plane waterproof heating floor module disclosed by the invention is ensured.

Owner:SHANGHAI RELI TECH GRP CO LTD

Systems and methods for processing mixed solid waste

ActiveUS8632024B2Maximize efficiencyImprove efficiencyInternal combustion piston enginesWaste processingEnvironmental chemistry

Solid waste that includes a mixture of wet organic material and dry organic material can be are separated using mechanical separation to produce a wet organic stream enriched in wet organics and a dry organic stream enriched in dry organics. The separated wet organic stream and dry organic stream are separately converted to renewable or recyclable products using different conversion techniques particularly suited for the separated wet and dry organic streams.

Owner:UPLAND ROAD IP HOLDCO LLC +2

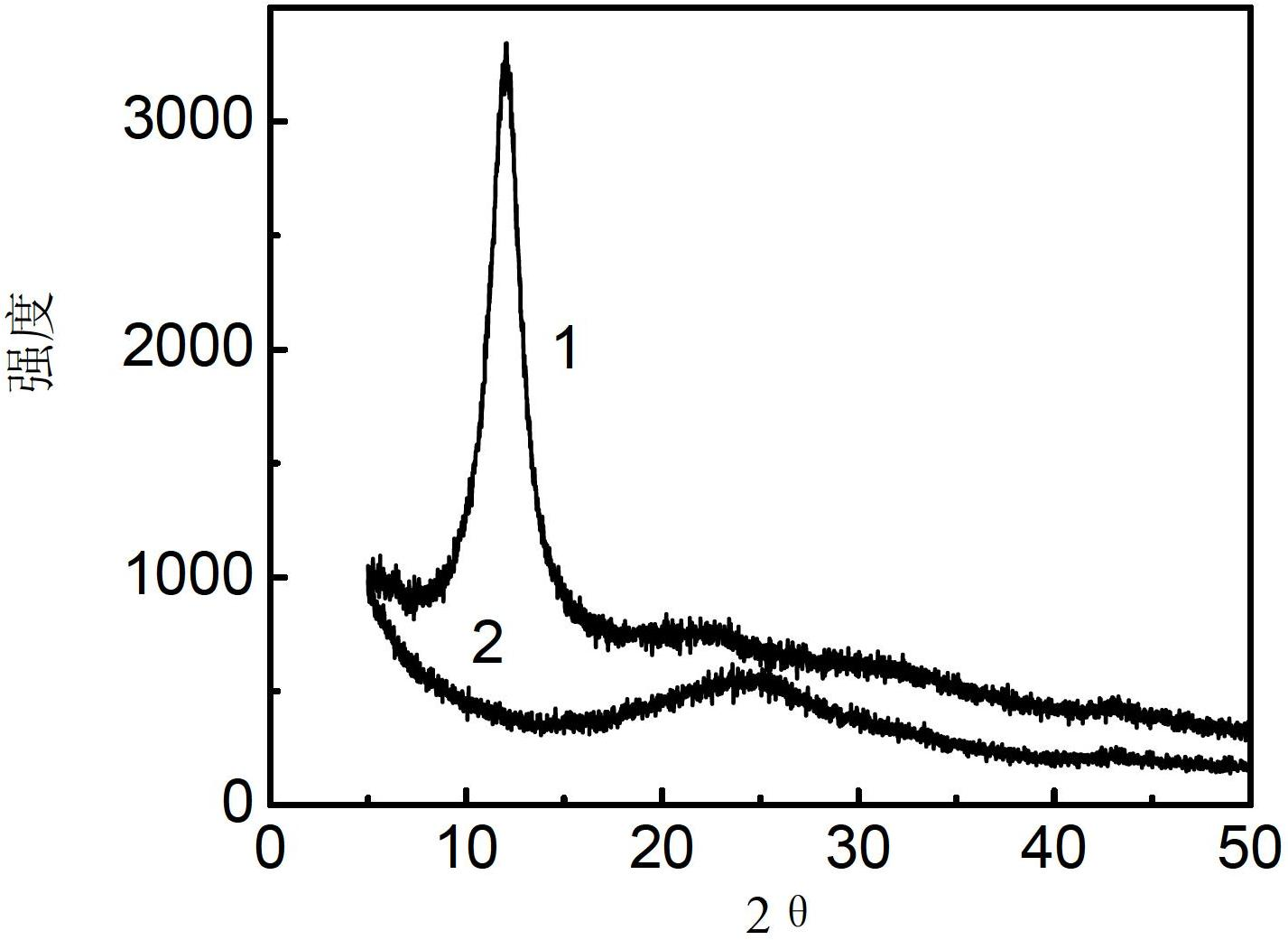

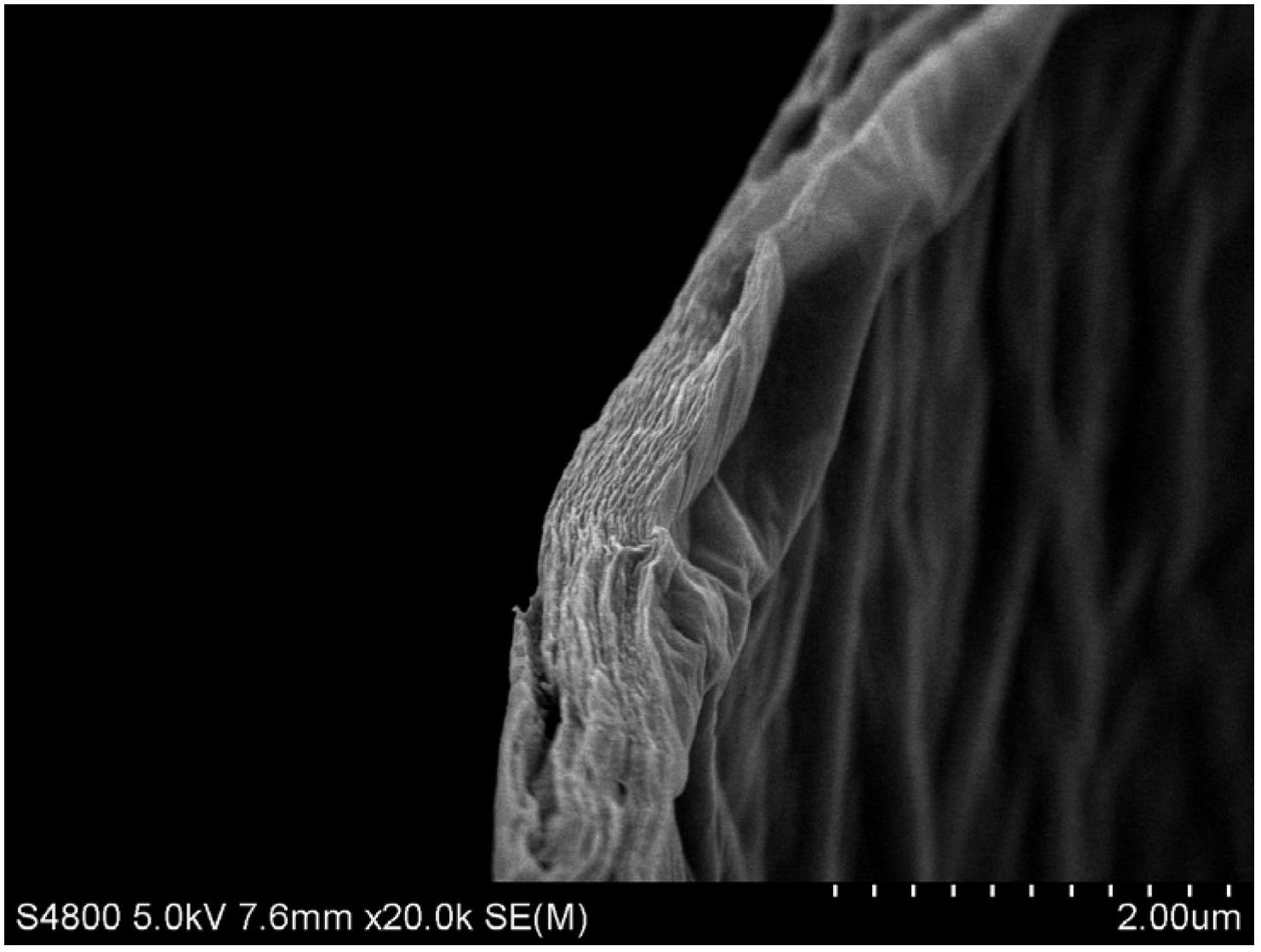

Method for preparing graphene/polymer composite material based on infrared irradiation

The invention discloses a method for preparing a graphene / polymer composite material based on infrared irradiation. The method comprises the following steps: 1) mixing a graphite oxide solution with a polymer solution or polymer emulsion to obtain a mixed solution, casting or spinning, and drying until the weight percentage of the total solvent is less than or equal to 50 percent so as to obtain a composite product; and 2) removing the solvent from the composite product under the irradiation of an infrared heating lamp, and performing reduction reaction of graphite oxide to obtain the graphene / polymer composite material. By the preparation method, the graphene / polymer composite material is prepared under the irradiation of the infrared heating lamp, the process is simple and convenient, the production cost is low, the method is suitable for large-scale industrial production, different polymers can be selected for preparing different graphene / polymer composite materials so as to meet the production and use requirements, and the graphene / polymer composite material has a wide application prospect in the fields such as conductive polymer composite materials, films and fibers.

Owner:ZHEJIANG UNIV

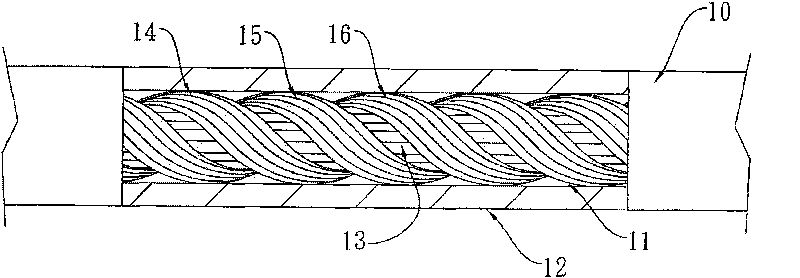

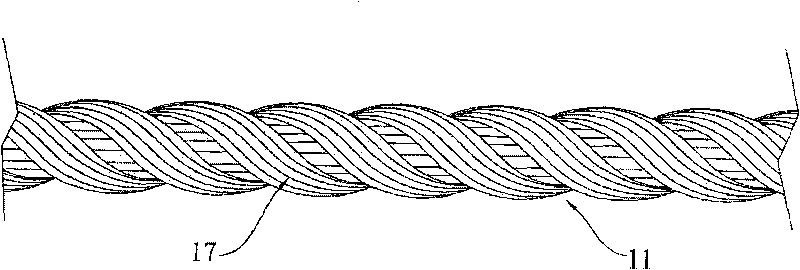

Electric blanket, pad or cotton quilt

InactiveCN101731892ASimple structureExtended service lifeStuffed mattressesSleeping rugGlass fiberFiber bundle

The invention provides an electric blanket, pad or cotton quilt. The electric blanket, pad or cotton quilt comprises an upper cotton layer, a lower cotton layer and a flexible carbon heating pipe arranged between the upper cotton layer and the lower cotton layer, wherein the flexible carbon heating pipe contains a heating element and an insulating sleeve covered outside the heating element; the heating element comprises the carbon fiber bundle, the carbon fiber bundle surrounds one or more of glass fiber bundle, rock fiber bundle and ceramic fiber bundle, the surface of the heating element is covered with functional powder; the insulating sleeve is a flexible glass fiber braided tube, fluorine elastic tube, silicone tube, PU tube, PVC pipe, PE pipe, PP pipe, PET pipe, Nylon pipe or PI pipe; and the functional powder is one or more of oxidation-resistant material powder, heat-dispersing material powder, far-infrared powder, negative ion powder, tourmaline powder and rare earth material powder.

Owner:刘 宁和 +1

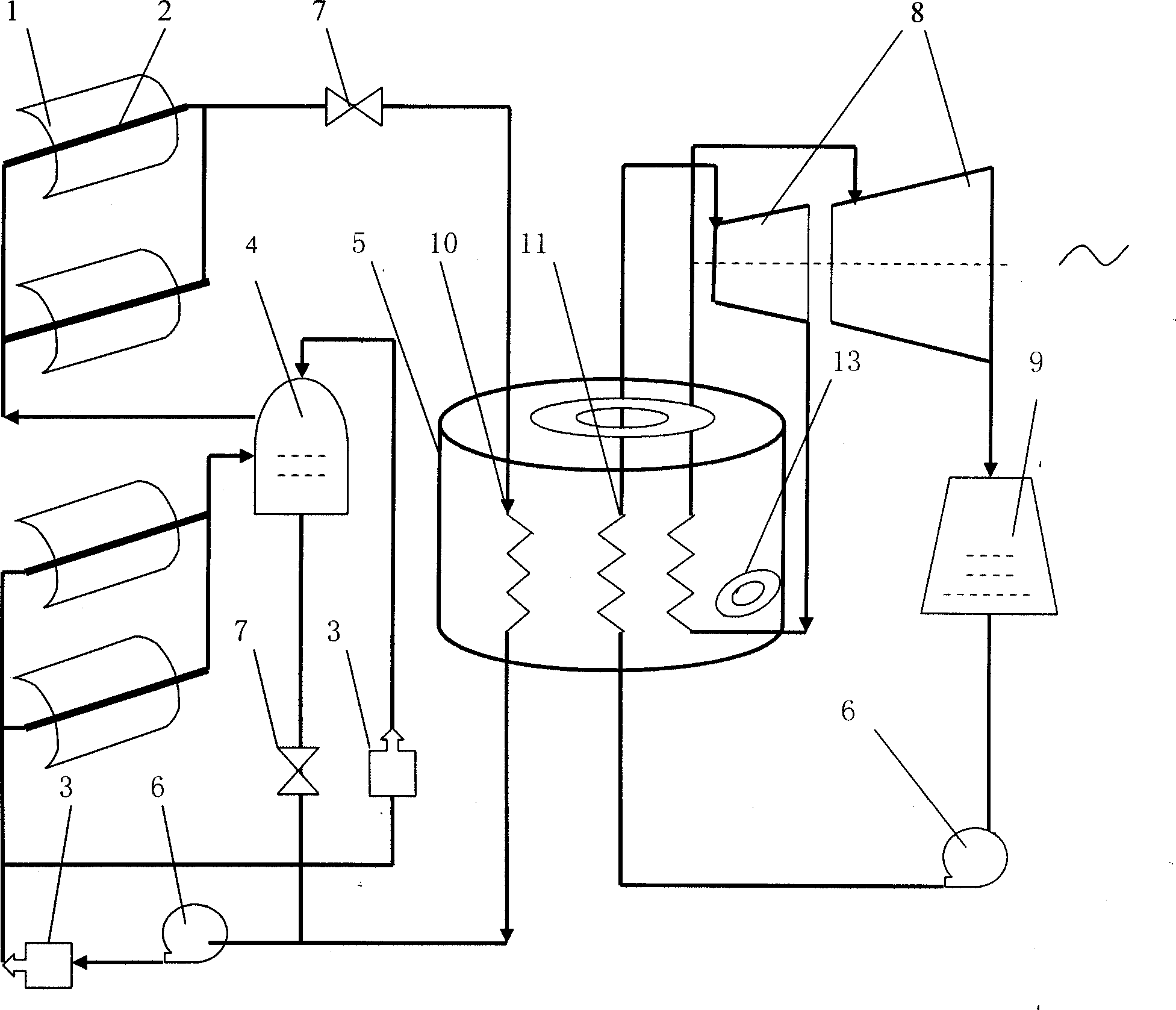

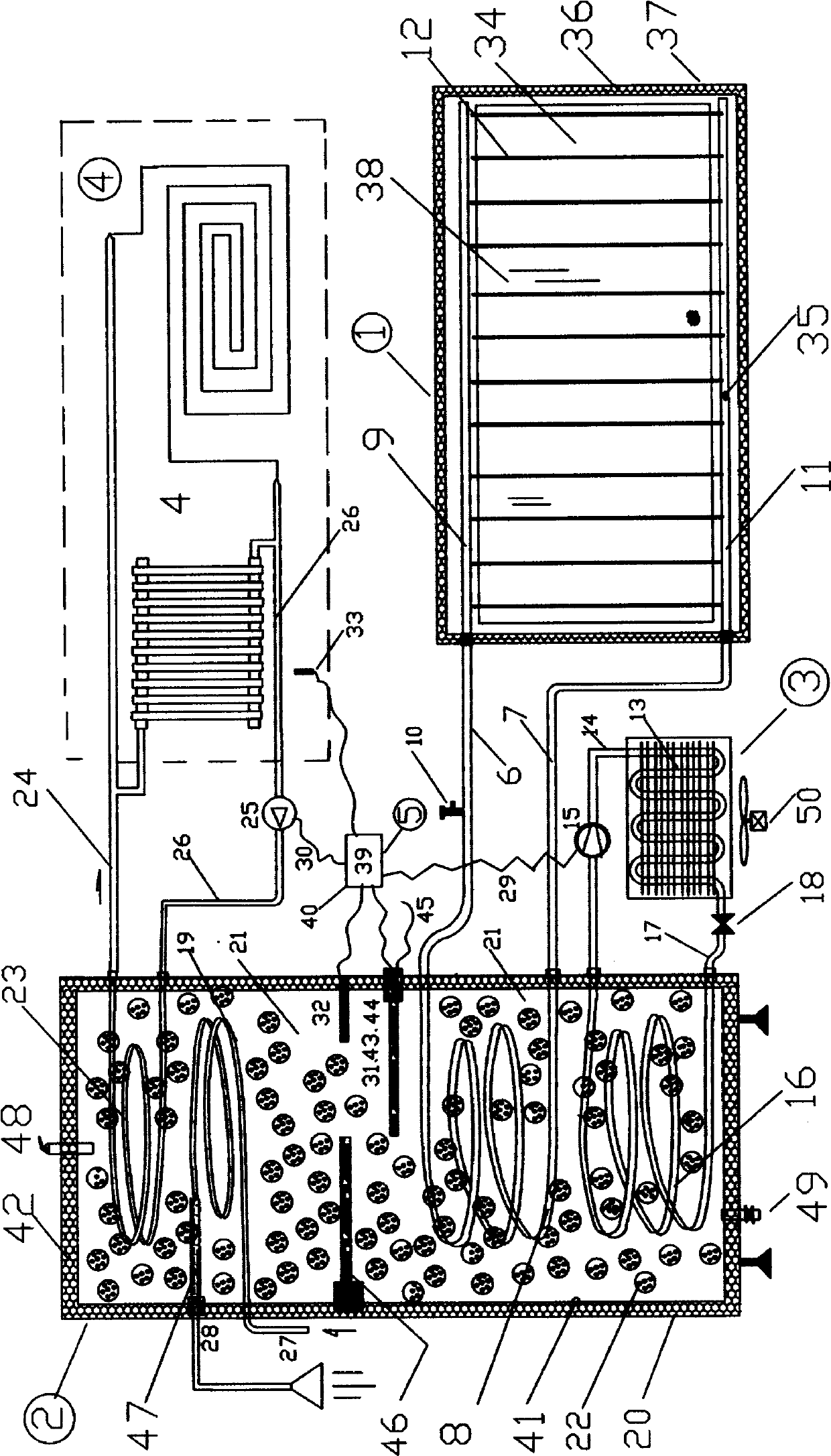

Trough type solar middle-high temperature integrated concentrating solar power device

InactiveCN102979689AIncrease working temperatureOperating conditionsFrom solar energySteam engine plantsPlate heat exchangerEvaporation

The invention discloses a trough type solar middle-high temperature integrated concentrating solar power (CSP) device, and belongs to the technical field of concentrated solar power. The trough type solar middle-high temperature integrated CSP device is composed of parabolic trough condensation arrays, a heat exchanger, a heat accumulation evaporating tank, heat accumulation working medium, an evaporator, steam power machines, a condenser, a complementary boiler and the like. The trough type solar middle-high temperature integrated CSP device adopts a direct steam generation (DSG) heat transfer mode, achieves integral operation of heat transfer, heat accumulation, evaporation, heat supplement through the heat accumulation evaporating tank of the complementary boiler and fused salt and other heat accumulation medium, greatly simplifies integral construction, is favorable for lowering trough trough type concentrating solar power equipment cost, and is favorable for improving temperature of working conditions and power generating efficiency.

Owner:张建城

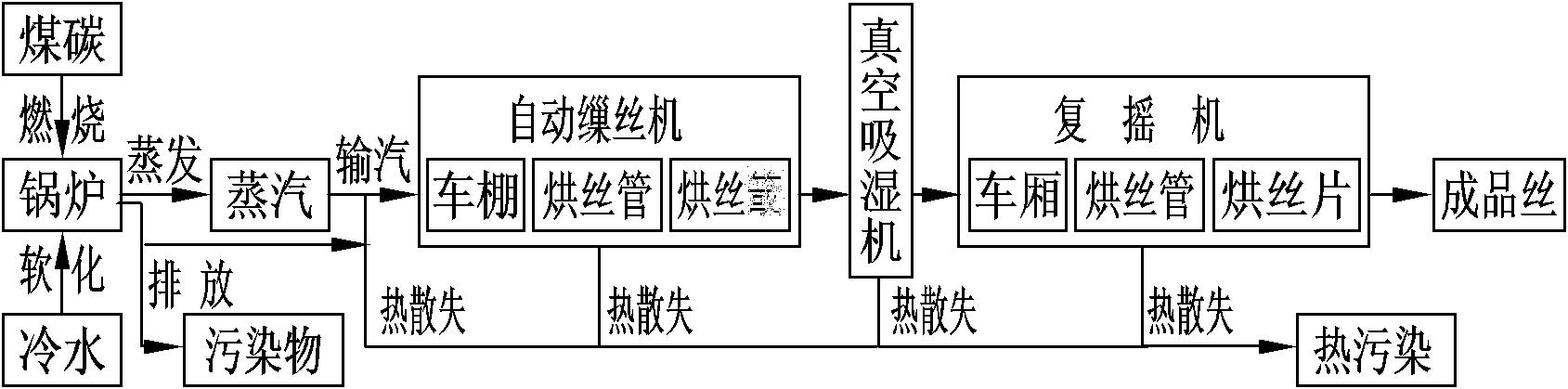

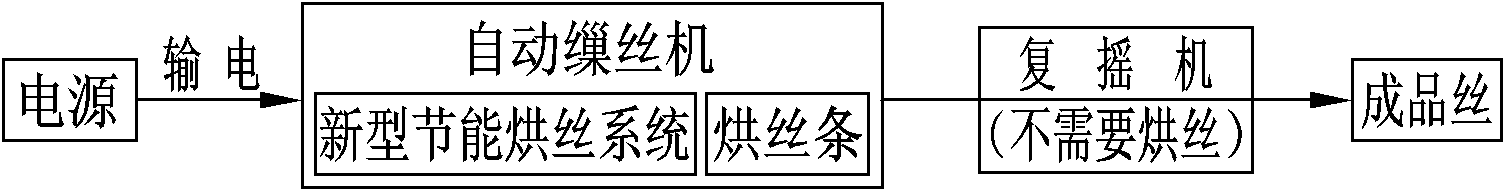

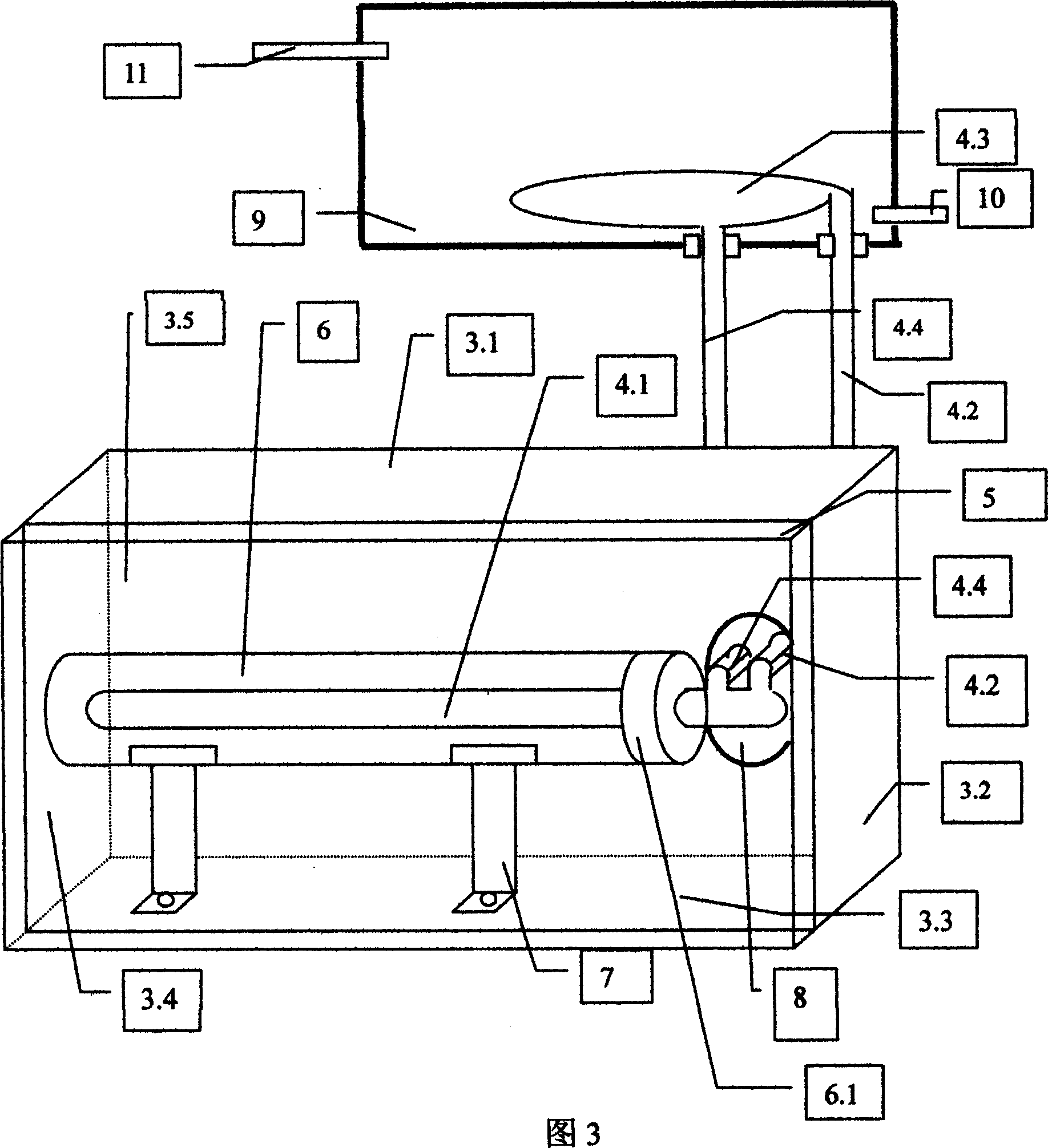

Novel energy-conservation silk drying system of automatic silk reeling machine

ActiveCN101984156AImprove production efficiency and product qualityReduce manufacturing costArtificial filament washing/dryingSilk reelingProcess engineeringEnergy loss

The invention relates to an automatic silk reeling machine in the technical field of raw silk production in the silk reeling industry, in particular to a novel energy-conservation silk drying system of an automatic silk reeling machine. The novel energy-conservation silk drying system comprises a compensation drum wheel, a traverse rod, a silk arranging drum wheel and a small silk-collecting tool. The technical scheme of the invention is as follows: a silk drier inlet drum wheel is arranged at the silk outlet of the compensation drum wheel, a far infrared silk drier is arranged adjacent to the silk drier inlet drum wheel, a photoelectric automatic silk moving mechanism is arranged at the silk outlet of the far infrared silk drier, and the silk outlet of the photoelectric automatic silk moving mechanism is provided with the silk arranging drum wheel. In the invention, less air is heated to heat wet raw silks, the raw silks are evenly dried at a high speed, and silk drying can be finished in the silk reeling machine once, thus the novel energy-conservation silk drying system not only saves energy, but also is favorable for lowering the workshop temperature, the silk reeling operation environment is improved, the problems of multiple working procedures, large energy loss and high workshop temperature of the traditional silk steam drying system for silk reeling production can be thoroughly solved, and according to incomplete statistics, the silk reeling energy consumption is greatly reduced compared with the silk coal-fired steam drying process.

Owner:SICHUAN RES INST OF SILK SCI

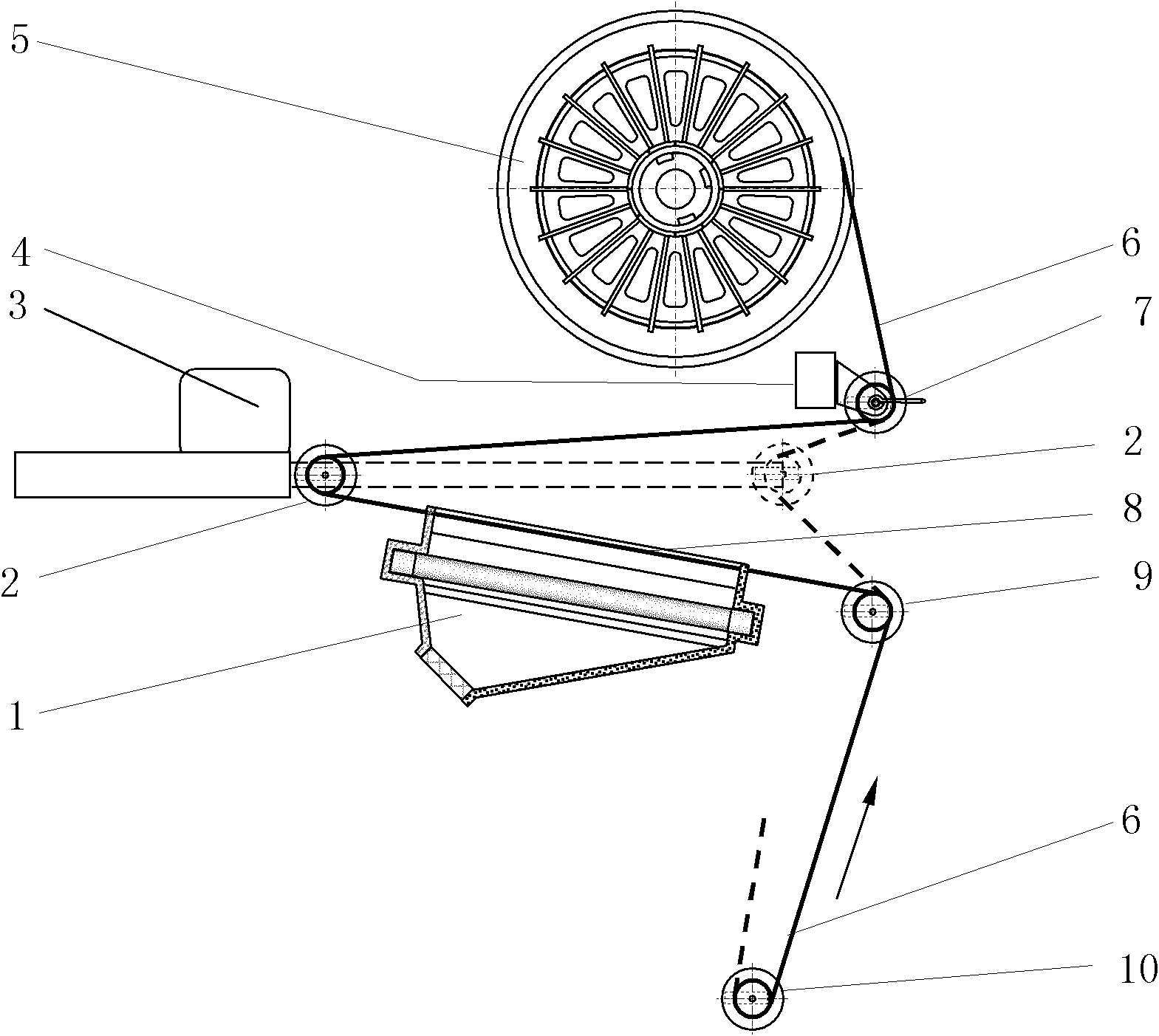

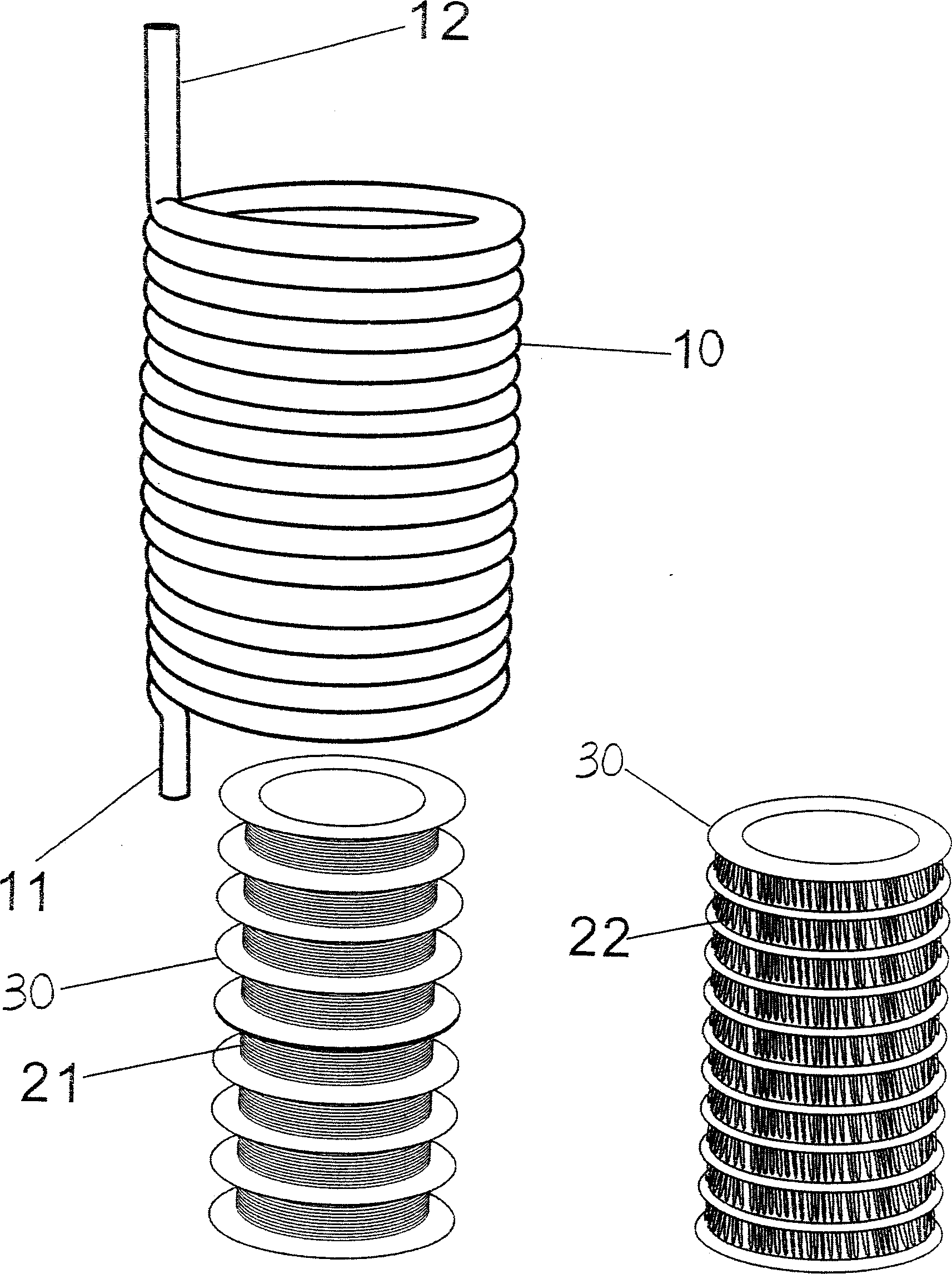

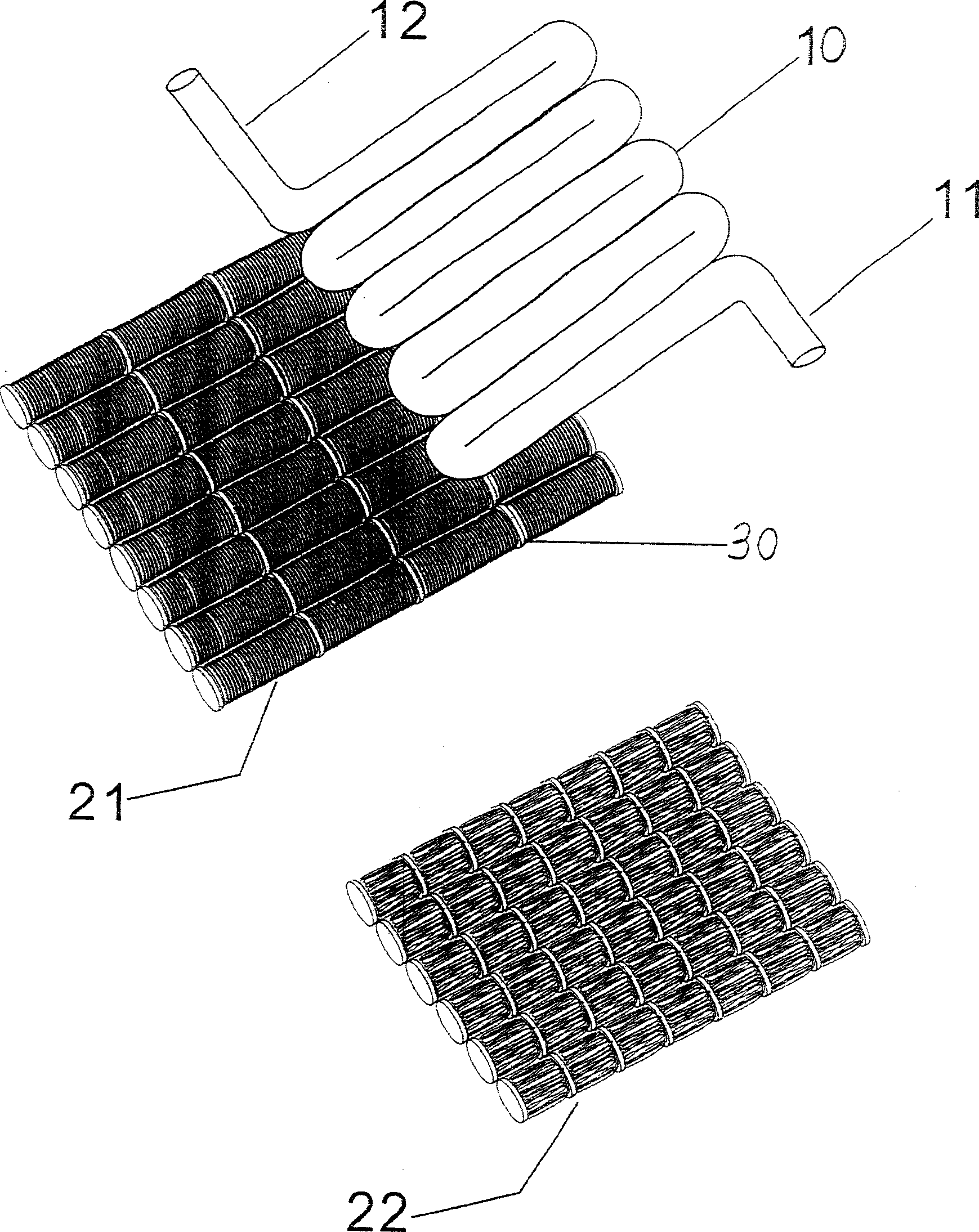

Electromagnetic heating method and device in electric water heater

InactiveCN1873340ARun fastIncreased resistance heating efficiencyWater heatersInduction current sourcesAlternating currentElectromagnetic heating

The present invention relates to an electromagnetic heating method of electric water heater and its device. Said method is characterized by that under the action of alternating current it utilizes electromagnetic coil to produce alternating magnetic field, said alternating magnetic field can utilize insulating stand and magnetic conductive metal water tube to produce loop, and utilize shielding magnetic ring to make magnetic field line have directivity and can prevent electromagnetic leakage, in the magnetic conductive metal water tube winded into a certain form said magnetic field line can be formed into vortex induced current, and the energy of said electric current can be converted into heat energy by means of resistor in the magnetic conductive metal tube interior. Said device includes electromagnetic coil, insulating stand, magnetic conductive metal water tube, shielding magnetic ring and frequency variable control circuit.

Owner:李文庆

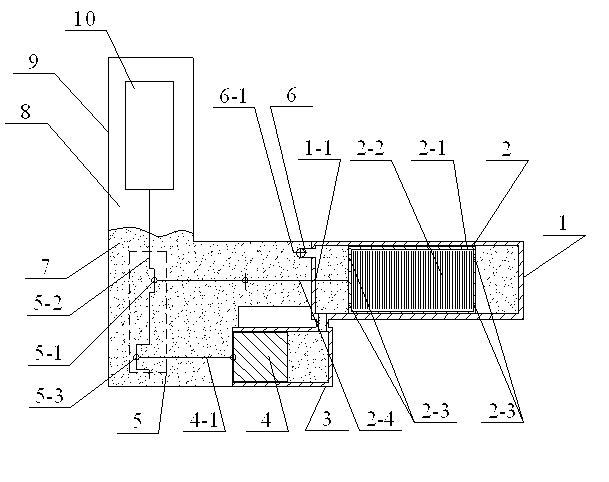

Supercritical fluid-type external-combustion heat engine

ActiveCN102797589AHigh heat conversion efficiencyAchieving Zero LeakageHot gas positive displacement engine plantsStirling engineHeat engine

The invention relates to the technical field of heat energy conversion and discloses a supercritical fluid-type external-combustion heat engine for overcoming the problems of low heat conversion efficiency and atmospheric pollution caused by incomplete combustion, and high noise in the present internal-combustion engines, the problems of low power / weight radio and incapability of zero leakage due to difficulty in sealing in the present Stirling engines. According to the invention, carbon dioxide and a gas working medium are filled in an airtight shell, the pressure in the airtight shell ranges from 7.4 MPa to 10 MPa, so that the carbon dioxide is in a supercritical carbon dioxide fluid state; and the interior of a gas guide cylinder cavity, a gas guide piston, the interior of a work-applying cylinder cavity, a work-applying piston, a flywheel crankshaft assembly and a valve are all immersed in the supercritical carbon dioxide fluid, the heat end temperature of the gas guide cylinder cavity is set to be between 60 DEG C and 130 DEG C, and the cold end temperature of the gas guide cylinder cavity is set be between 32 DEG C and 40 DEG C. By the supercritical fluid-type external-combustion heat engine disclosed by the invention, the heat energy at a temperature being higher than 50 DEG C can be directly and efficiently converted to mechanical energy and then to electrical energy, and then zero leakage can be realized. The efficiency of the heat energy-mechanical energy conversion is 20-80%.

Owner:HARBIN XIANGKAI TECH DEV

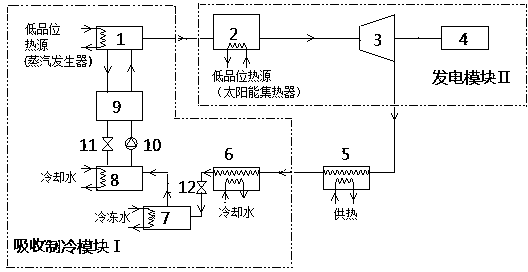

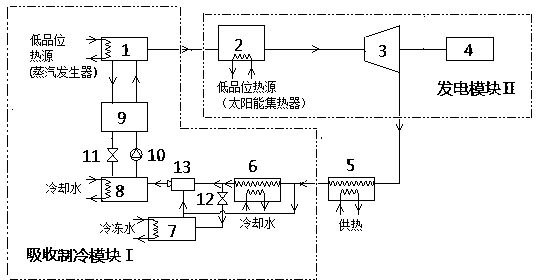

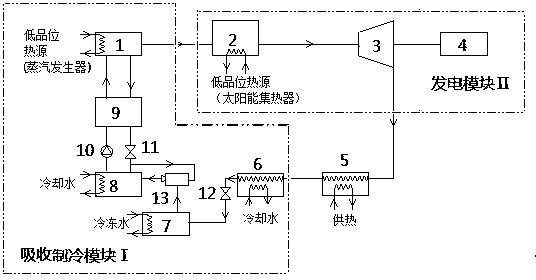

Low-grade energy driving CO2 absorption type combined cooling heating and power system

InactiveCN103868278AReduce outlet steam pressureImprove net power generation efficiencyClimate change adaptationEnergy efficient heating/coolingCo2 absorptionProcess engineering

The invention discloses a low-grade energy driving CO2 absorption type combined cooling heating and power system, which consists of a low-grade energy driving absorption refrigeration module, a power generating module, an afterheat recoverer and an ejector. The low-grade energy driving CO2 absorption type combined cooling heating and power system has the advantages that the refrigeration efficiency, the heat conversion efficiency and the system net power generating efficiency of the low-grade energy driving CO2 absorption type combined cooling heating and power system are improved, peripheral equipment of the low-grade energy driving CO2 absorption type combined cooling heating and power system is simplified, the stability and the reliability of the low-grade energy driving CO2 absorption type combined cooling heating and power system are improved, the efficient utilization of unstable and discontinuous low-grade energy is realized, and the foundation is laid in the efficient utilization of the low-grade energy in the absorption type combined cooling heating and power system.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

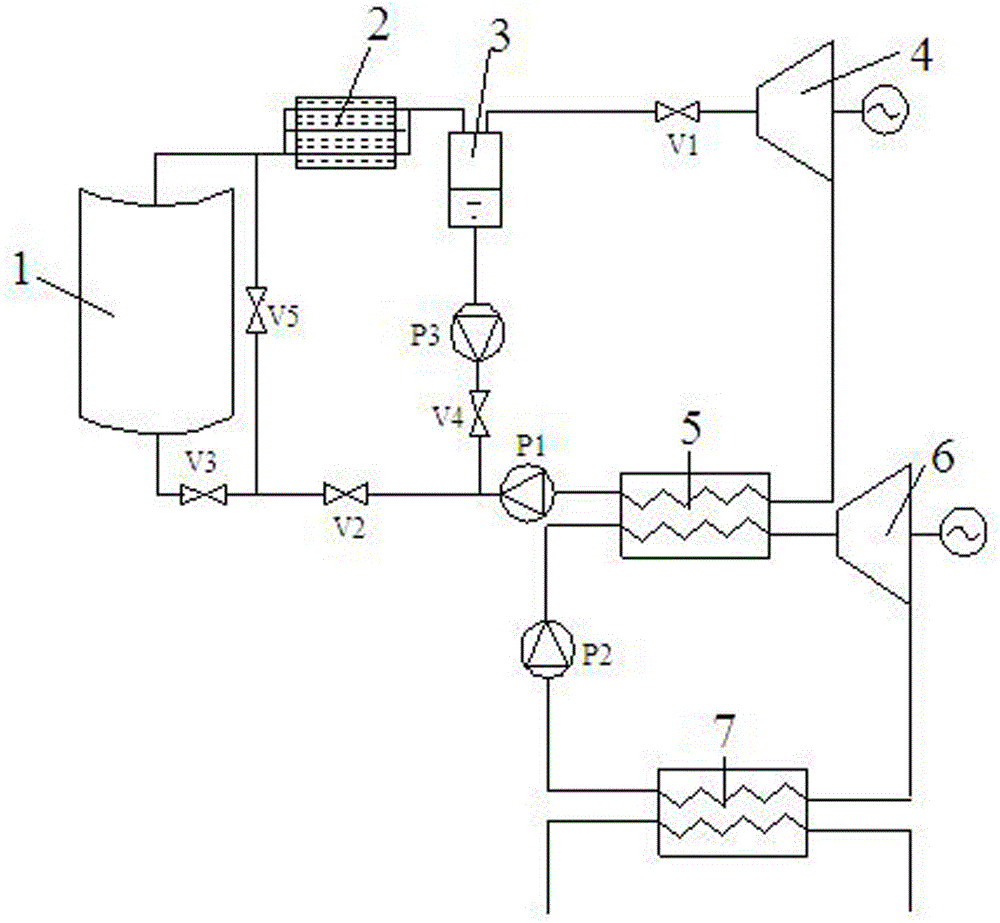

Direct-expansion solar thermal power generation system based on cascade Rankine cycle

InactiveCN105464914ASimple designImprove responseFrom solar energySteam engine plantsOrganic Rankine cycleEngineering

The invention belongs to the technical field of thermal power generation and in particular relates to a direct-expansion solar thermal power generation system based on a cascade Rankine cycle. The direct-expansion solar thermal power generation system based on the cascade Rankine cycle comprises a parabolic trough collector array and the cascade Rankine cycle; the cascade Rankine cycle comprises a steam Rankine cycle located at the top and an organic Rankine cycle located at the bottom. Compared with the prior art, the direct-expansion solar thermal power generation system based on the cascade Rankine cycle has the following advantages at the same time: ability of well running at low environmental temperatures, higher power generation efficiency, suitability for small-scale distributed construction, extremely low technical requirements on heat collection and heat accumulation, and high stability and high reliability.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

Parallel type superconducting solar heat pump hot water bathing and heating system

ActiveCN104930584ASimple structureLow costLighting and heating apparatusSpace heating and ventilation detailsEngineeringBathing

A parallel type superconducting solar heat pump hot water bathing and heating system is composed of a superconducting flat plate solar thermal circulation part, an accumulator, a heat pump hot water unit heating circulation part, a heater and an automatic controller, and is characterized in that the superconducting flat plate solar thermal circulation part and the heat pump hot water unit heating circulation part are connected in parallel, independent of each other and mutually complemented for heat collection; the accumulator stores heat in a sensible heat and latent heat storage mode; heating and domestic hot water are provided in a heat exchange mode of an efficient heat exchanger under control of the automatic controller. The parallel type superconducting solar heat pump hot water bathing and heating system is simple in structure, high in heat conversion efficiency, long in yearly running time, free of pollution and remarkable in energy conservation, is not limited by weather or use conditions and well achieves solar bathing, heating and refrigeration.

Owner:青岛润泽馨洁环保科技有限公司

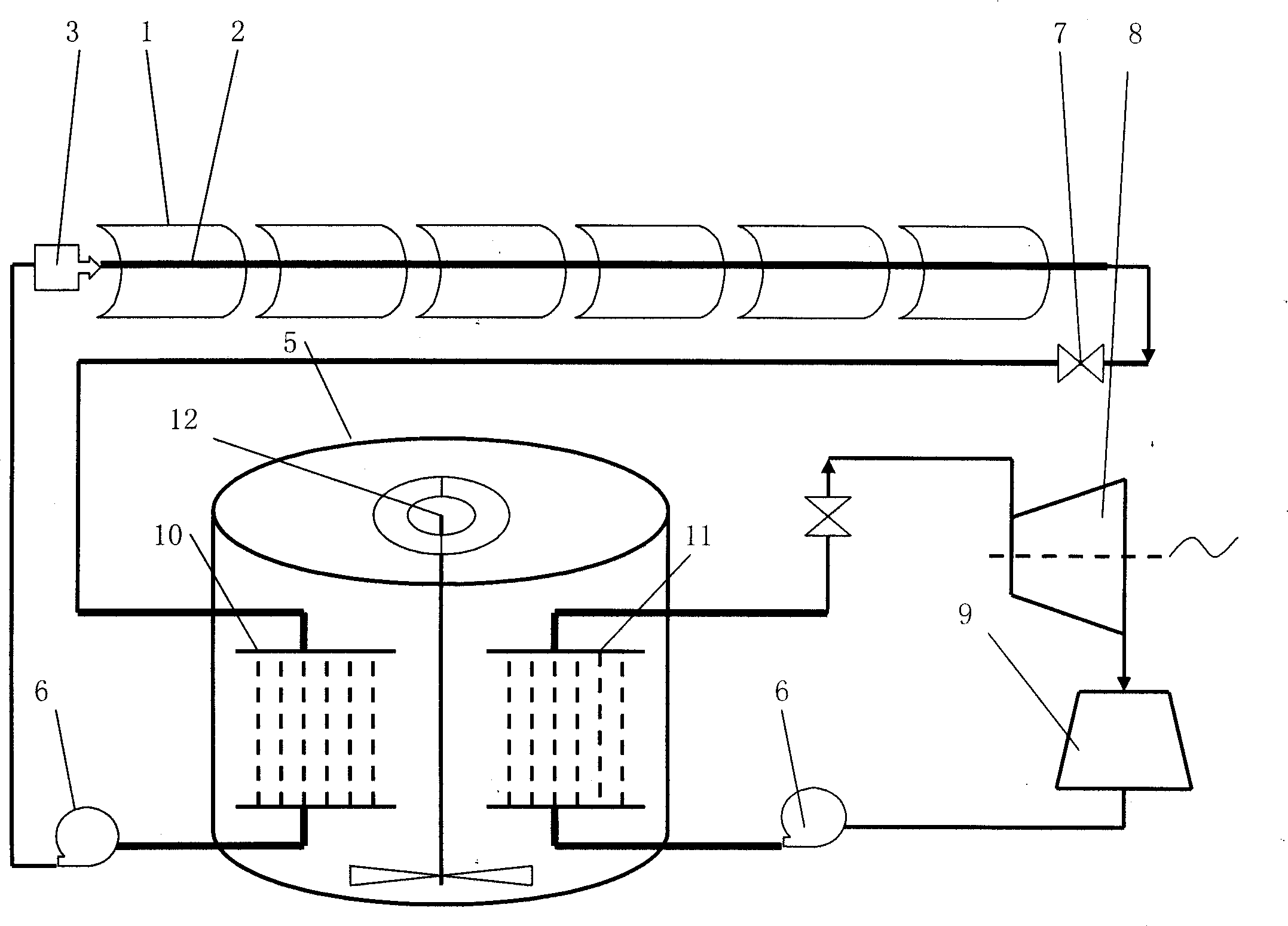

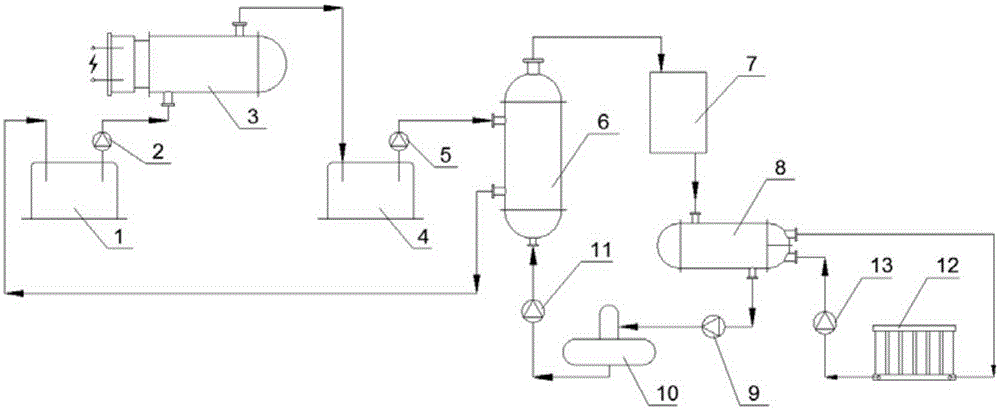

Stepped heat supply system for energy storage through electric heating of molten salt

InactiveCN105222205ARealize cascade utilizationImprove utilization efficiencyCentral heating with accumulated heatLighting and heating apparatusSystem pressureEngineering

The invention discloses a stepped heat supply system for energy storage through electric heating of molten salt. The system comprises a low-temperature salt storage tank (1), a low-temperature molten salt pump (2), a molten salt electric heating furnace (3), a high-temperature molten salt tank (4), a high-temperature molten salt pump (5), a molten salt steam generator (6), an industrial steam equipment (7), a heat exchanger (8), a condensation water pump (9), a deaerator (10), a water feeding pump (11), a radiator (12) and a circulating water pump (13). The molten salt electric heating furnace (3) uses low-valley-period electric power or photovoltaic power, wind power and the like to heat molten salt for energy storage, steam production and industrial production; and medium-temperature waste steam exhausted in the industrial production is used for heating circulating water for user warming, so that full energy utilization is realized. The system adopts the molten salt as a heat transmission and heat accumulation medium, has such advantages as stable heat transmission and heat accumulation, low system pressure, higher heat efficiency, safety and reliability, and is simple in equipment, small in floor area, low in cost and suitable for large-scale promotion and application.

Owner:百吉瑞(天津)新能源有限公司

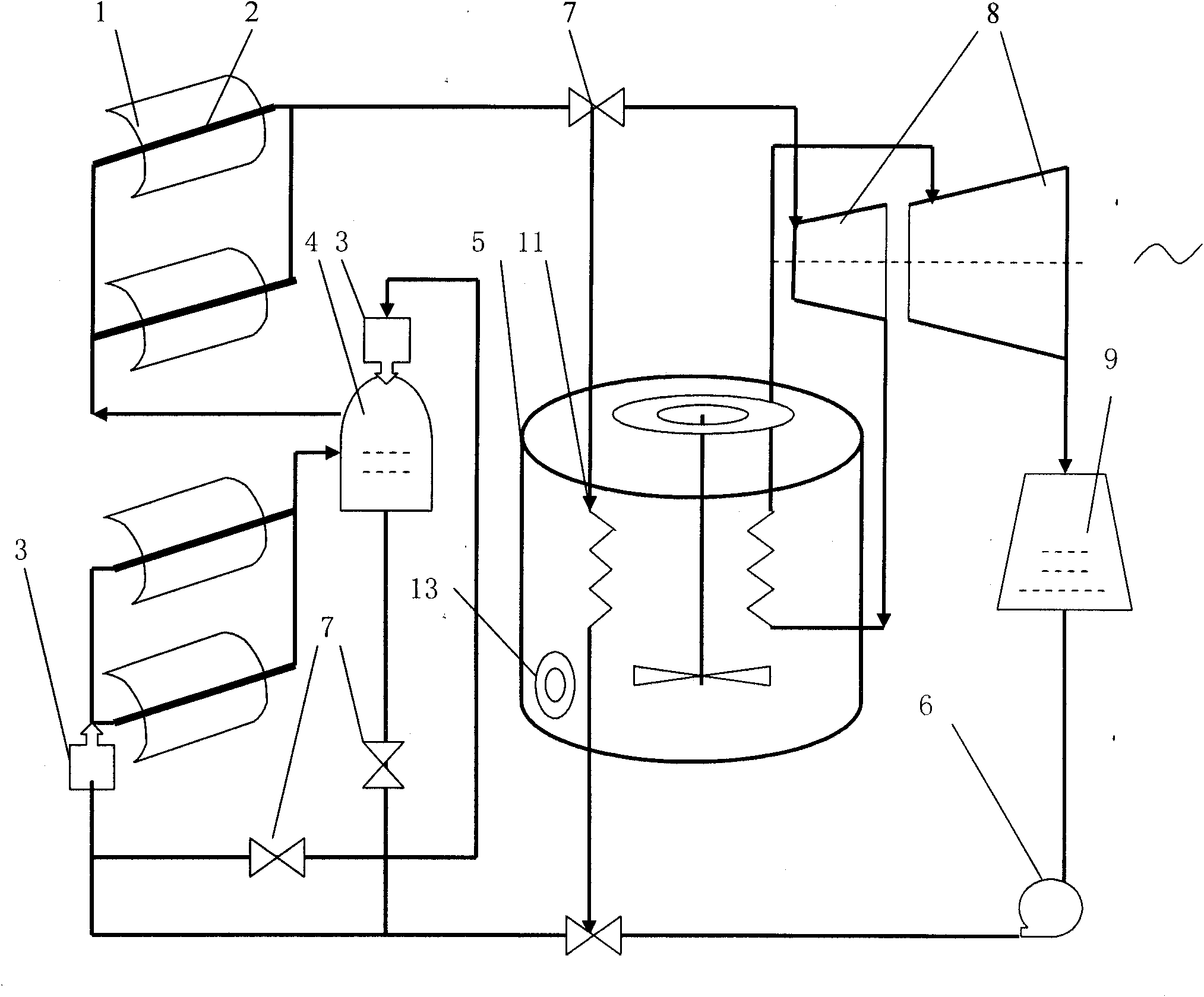

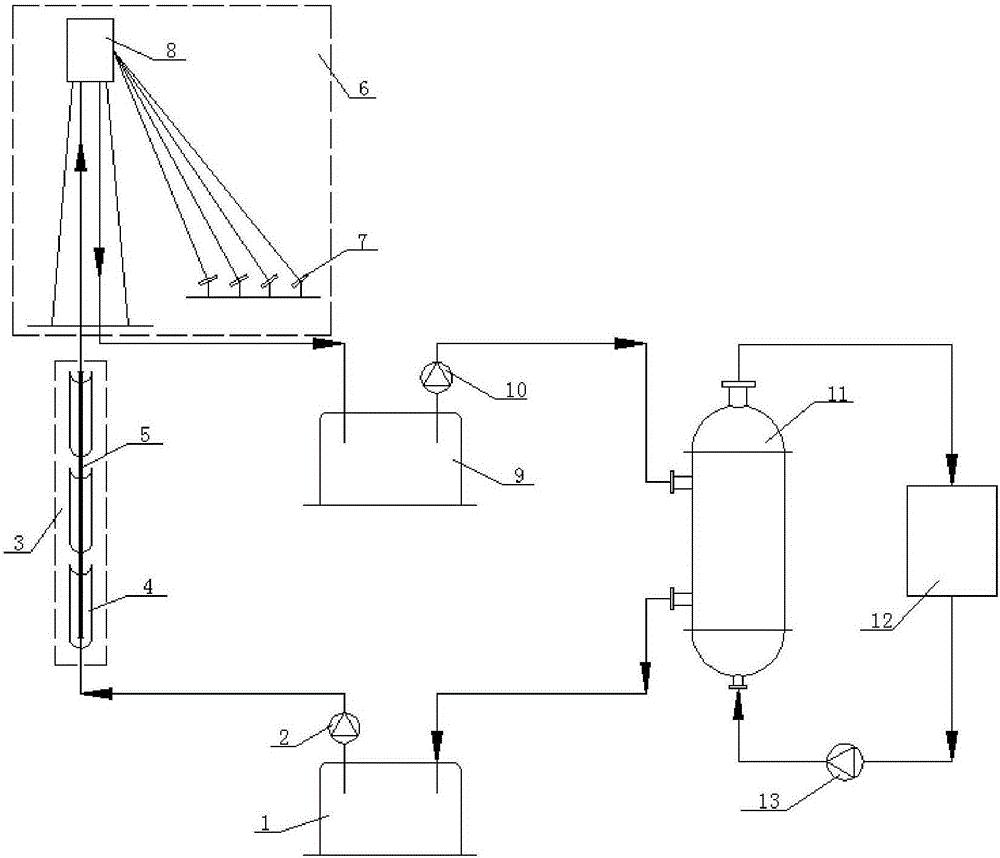

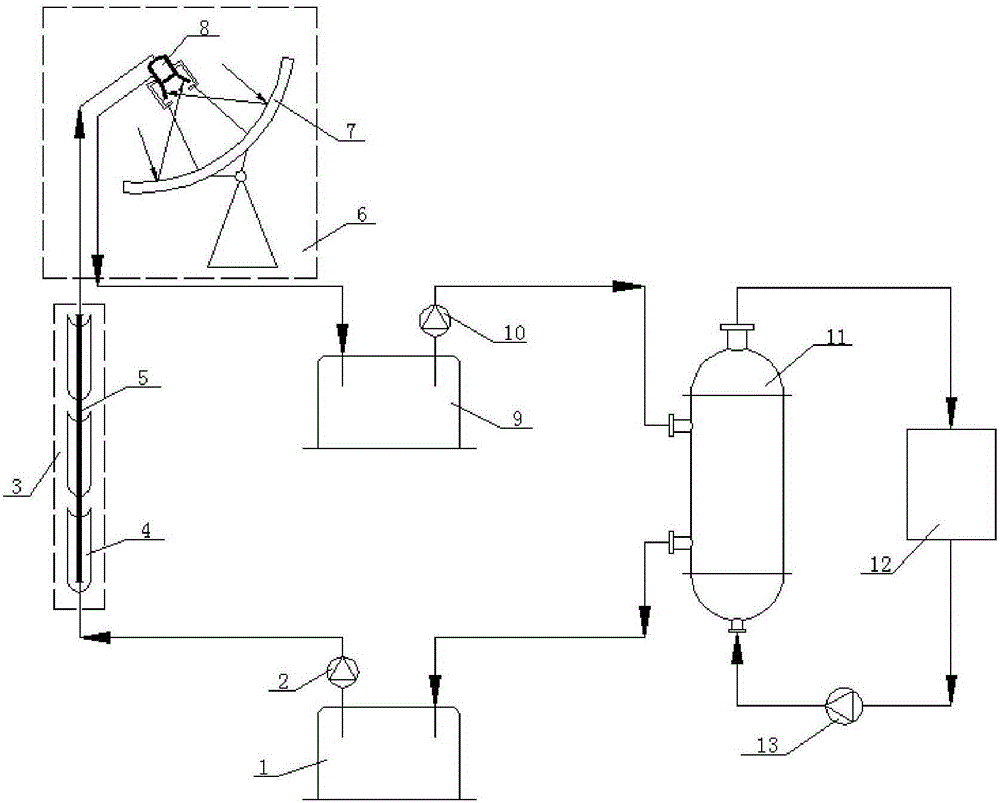

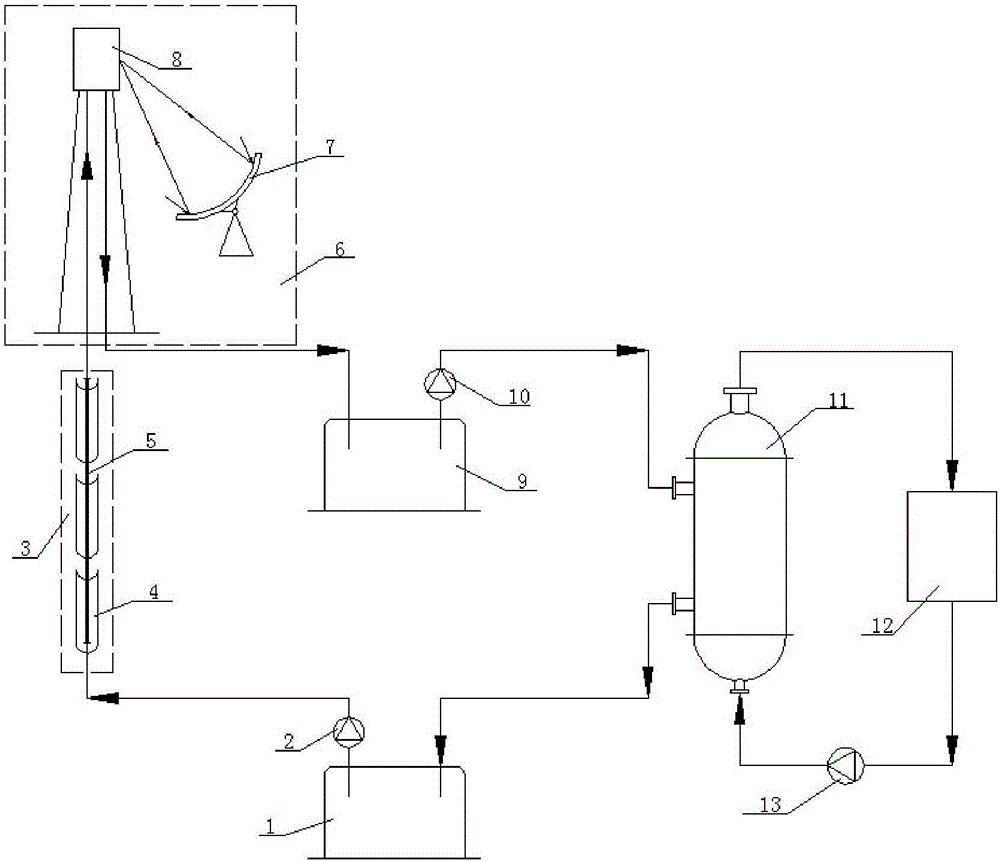

Solar stepped heating high-temperature heat collecting system based on molten salt heat transmission and heat accumulation

InactiveCN105222368ASafe and stable operationPrevents reduction in heat utilization efficiencySolar heating energySolar heat devicesEngineeringSmall range

The invention discloses a solar stepped heating high-temperature heat collecting system based on molten salt heat transmission and heat accumulation. The system comprises a low-temperature salt storage tank (1), a high-temperature salt storage tank (9), a low-temperature molten salt pump (2), a high-temperature molten salt pump (10), a medium-temperature heat collecting section (3), a high-temperature heat collecting section (6), a molten salt-working medium heat exchanger (11), heat use equipment (12) and a circulating pump (13). The medium-temperature heat collecting section (3) consists of a groove type paraboloid mirror (4) and a heat collecting tube (5); the molten salt temperature in the heat collecting tube (5) is lower than 400 DEG C; the high-temperature heat collecting section (6) consists of a condenser (7) and a receiver; and the molten salt temperature in the receiver (8) can reach above 550 DEG C. The molten salt operation temperature of the medium-temperature heat collecting section (3) is controlled within 400 DEG C, so that the heat loss of the heat collecting tube (5) is in a smaller range; and as the high-temperature heat collecting section (6) is added, the molten salt operation temperature reaches above 550 DEG C, and the heat conversion efficiency of the system is correspondingly improved.

Owner:百吉瑞(天津)新能源有限公司

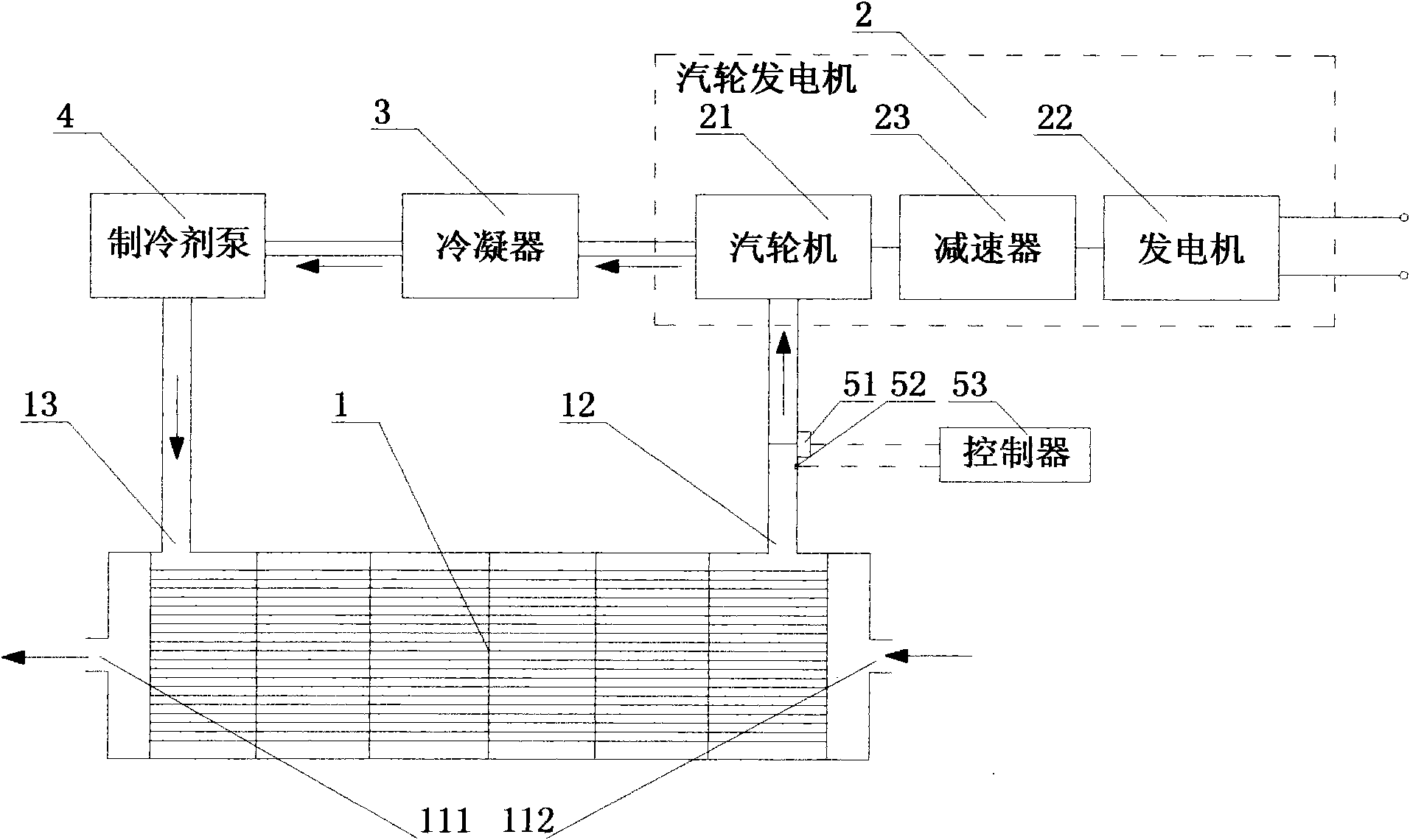

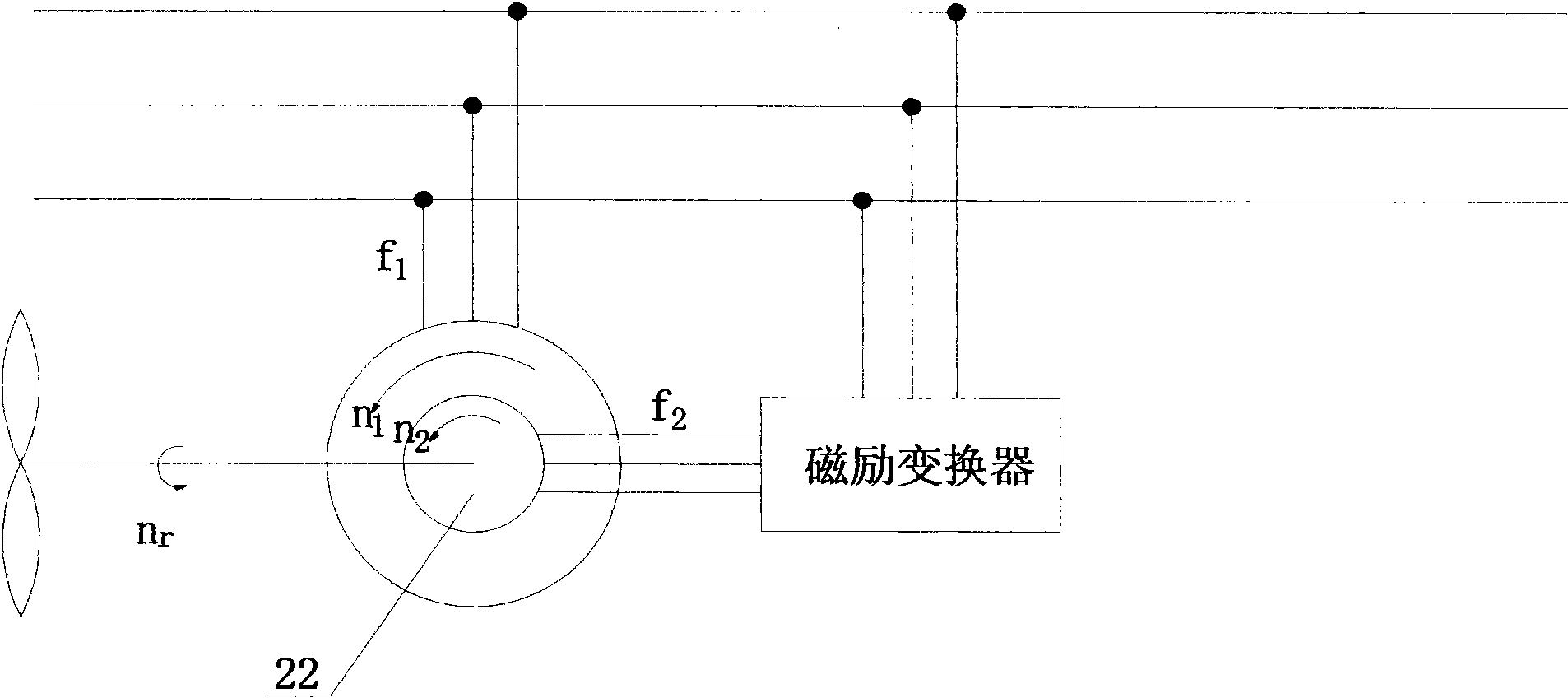

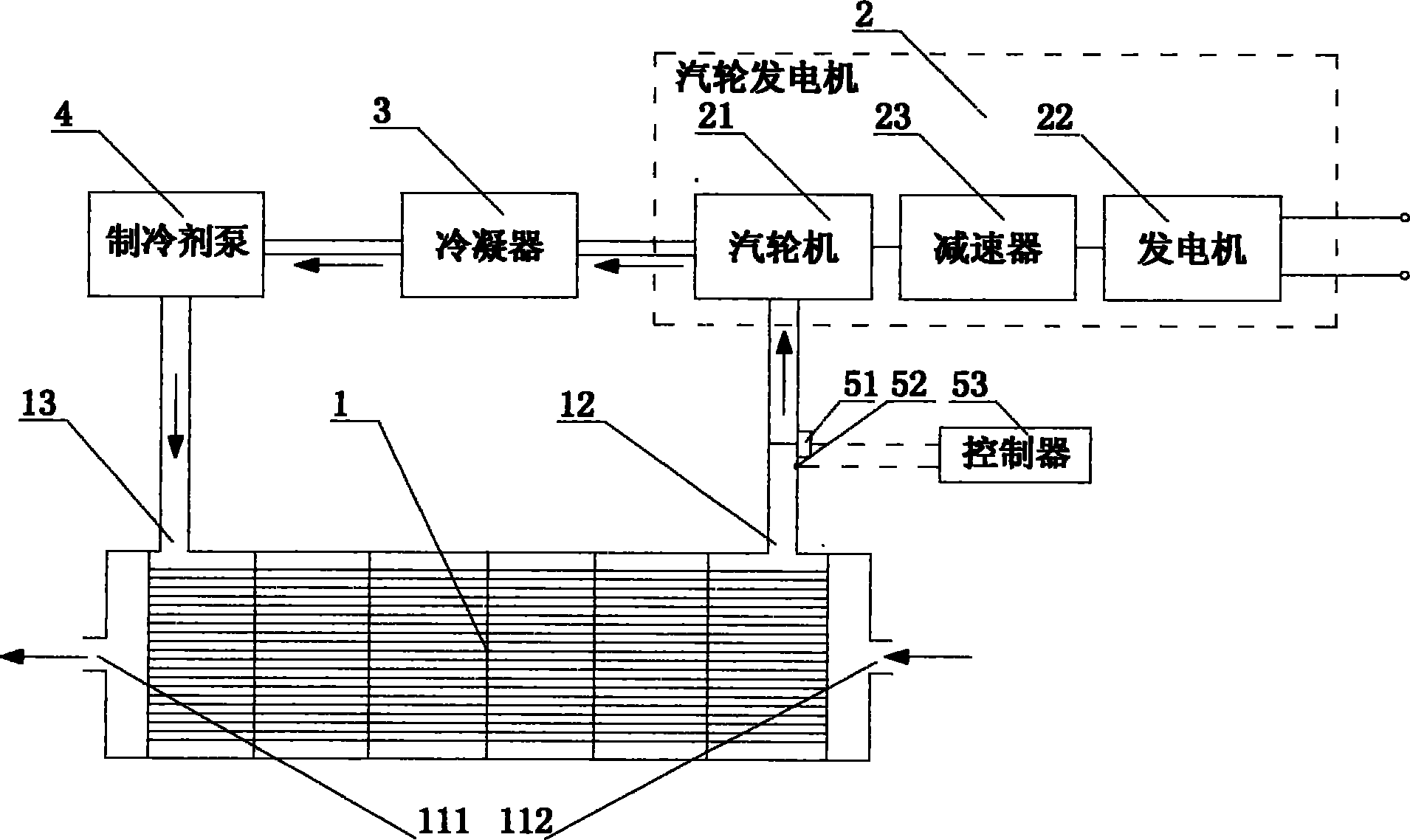

Low-medium temperature heat energy recovery power generation device

The invention discloses a low-medium temperature heat energy recovery power generation device which comprises a heat exchanger, a turbine generator, a condenser and a refrigeration agent pump, wherein the heat exchanger is provided with a heat source outlet, a heat source inlet, a refrigeration agent outlet and a refrigeration agent inlet, wherein the refrigeration agent outlet is connected with the turbine generator; the turbine generator, the condenser and the refrigeration agent pump are sequentially connected with one another; an outlet of the refrigeration agent pump is connected with the refrigeration agent inlet; the heat exchanger can be used for driving turbine generator to generate electricity by vaporizing the liquid refrigeration agent by using heat of a heat source flowing through the heat source inlet; the condenser is used for condensing the refrigeration agent after the refrigeration agent pushes an impeller to rotate, and then outputting the condensed refrigeration agent to the refrigeration agent pump; and the refrigeration agent pump is used for sending the condensed refrigeration agent back to the heat source inlet. The low-medium temperature heat energy recovery power generation device can be used for generating electricity by utilizing waste low-medium temperature heat energy, and has the advantages of high energy conversion rate, good applicability and stable output.

Owner:上海尚实航空发动机股份有限公司

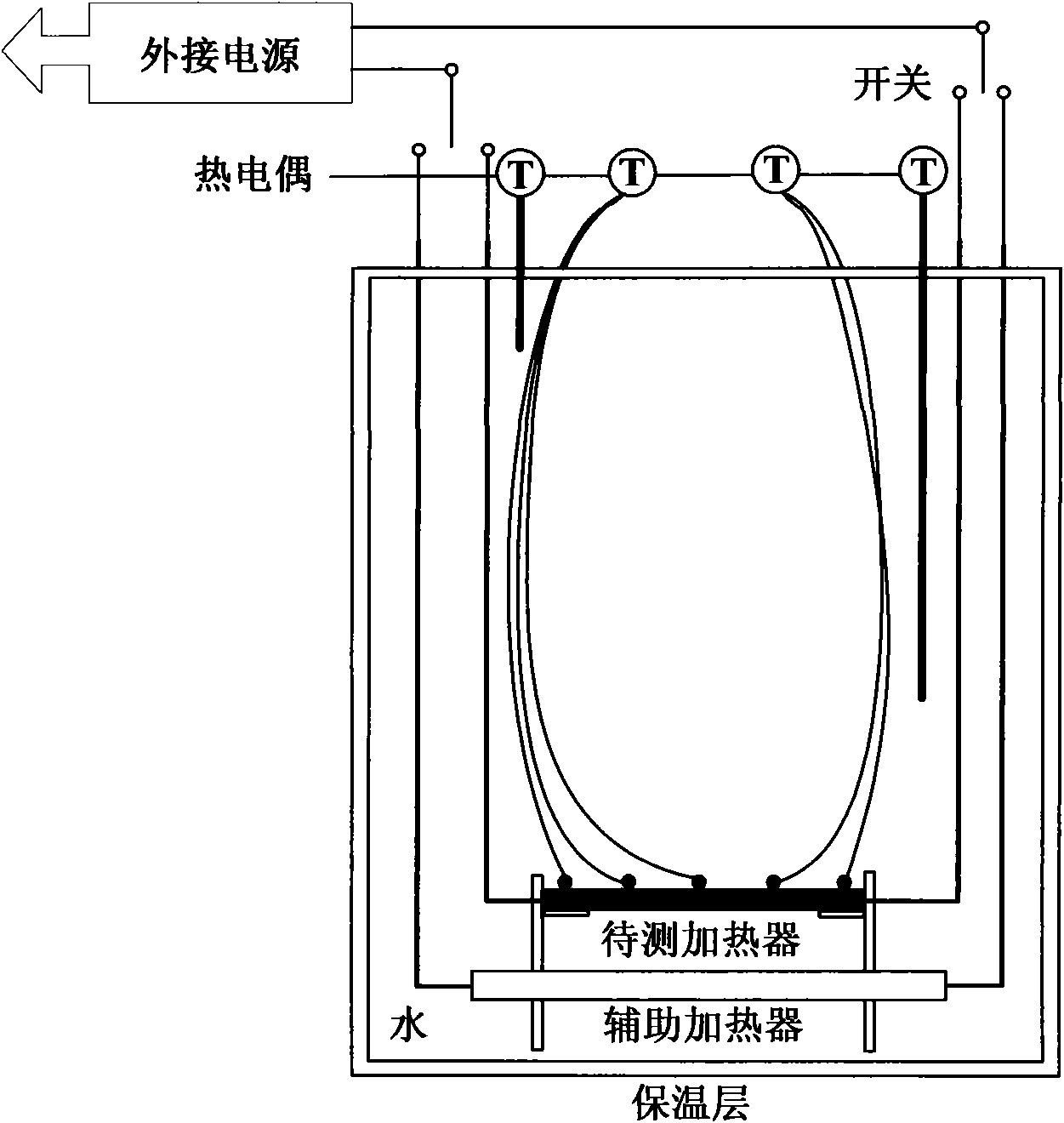

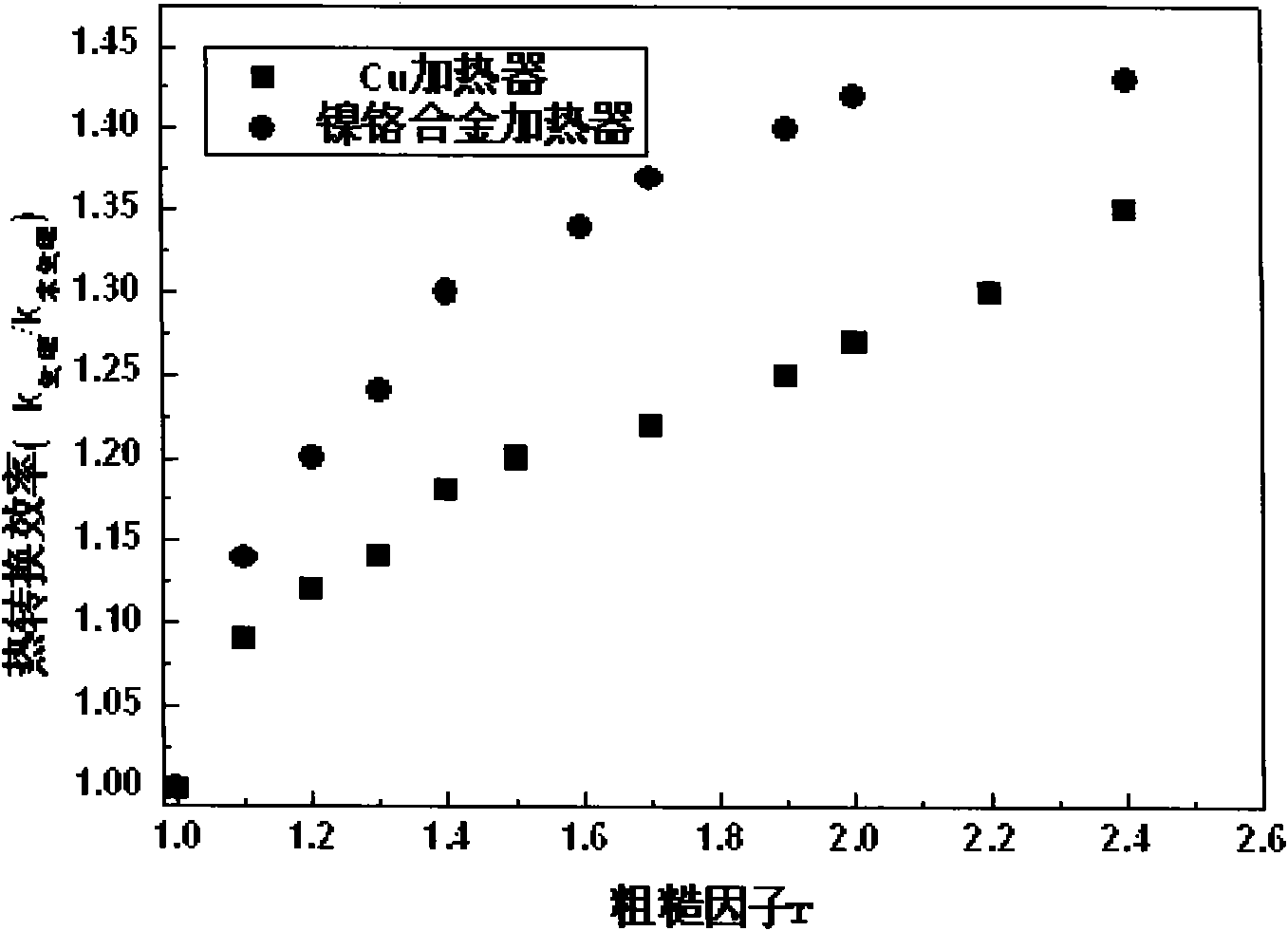

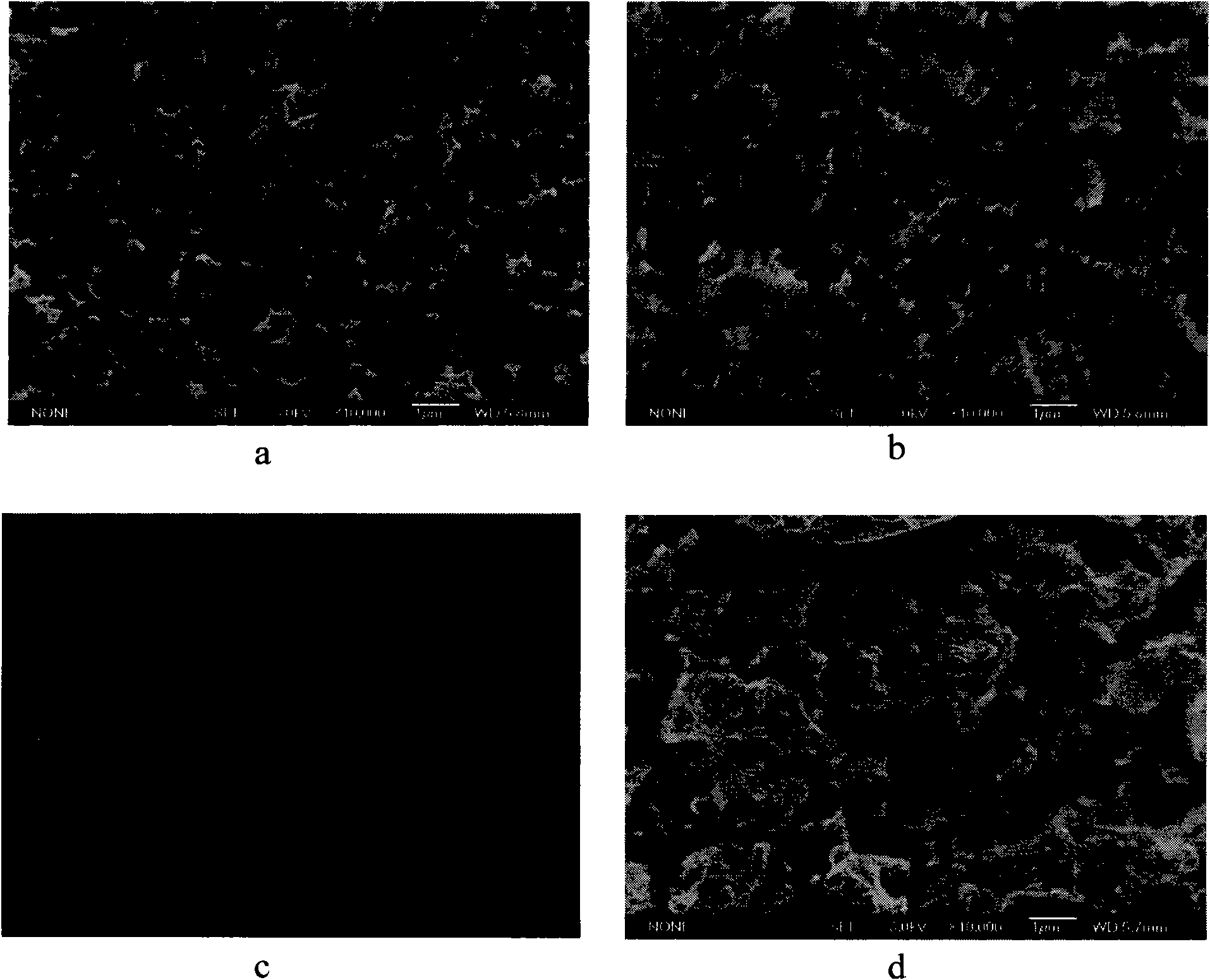

Film with high heat conduction efficiency and antifouling capability and preparation method thereof

InactiveCN101556126AImprove thermal conductivityImprove antifouling performanceHeat transfer modificationLaser etchingBoiling process

The invention relates to a film with high heat conduction efficiency and antifouling capability for a heater and a preparation method thereof, in particular to a film with special wettability based on the surface of metal or a metal alloy and a preparation method thereof. The film of the invention is obtained on the surface of the metal or the metal alloy for heat exchange by adopting a method combining an electrochemistry method, a hydro-thermal reaction method, a chemical vapor deposition method, a sol-gel method, a laser etching method and chemical vapor deposition, or a method combining laser etching and sol-gel; and by evaluation on the antifouling capability, the boiling process in water and the heat exchange efficiency of the film, various performances of the obtained metal or metal alloy heater containing the film of the invention are markedly improved compared with a metal or metal alloy heater without the film of the invention.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Solar heat collector unitary with building

InactiveCN1553124AIncrease the heat collecting areaAvoid the embarrassment of incoordinationSolar heating energySolar heat devicesFresnel lensBuilding integration

In the present invention, heat collection tank is embedded on wall surface facing towards the sun, cylindrical surface Fresnel lens is set on heat collection tank front panel along local line axial level direction, evaporation section of heat pipe is placed in heat collection tank and is parallel to cylindrical surface Fresnel lens as well as is located on focal line axis of cylindrical surface Fresnal lens, and level position of heat pipe condensation section is placed higher than level position of its evaporation section.

Owner:蚌埠市华兴高新技术发展有限责任公司

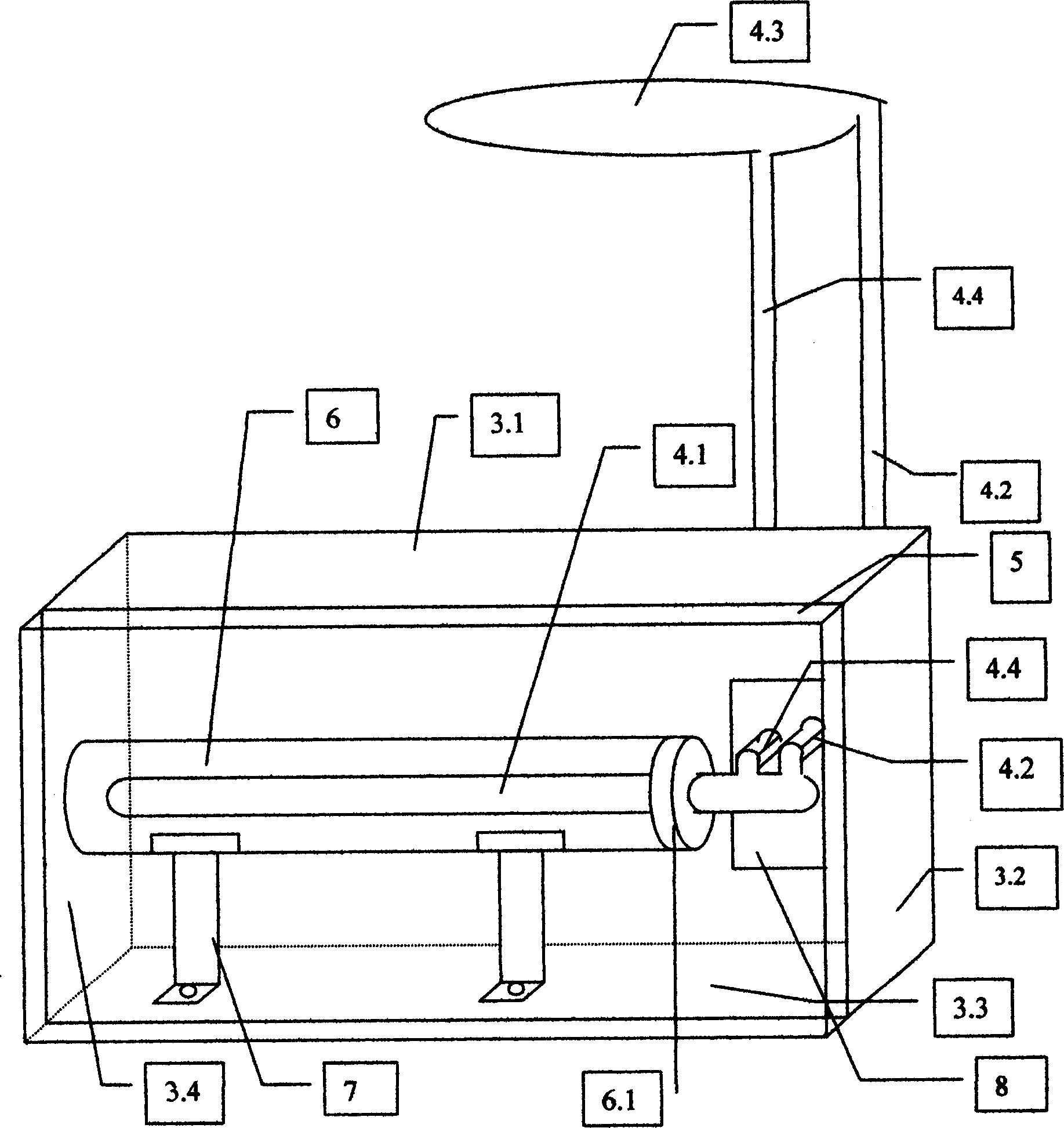

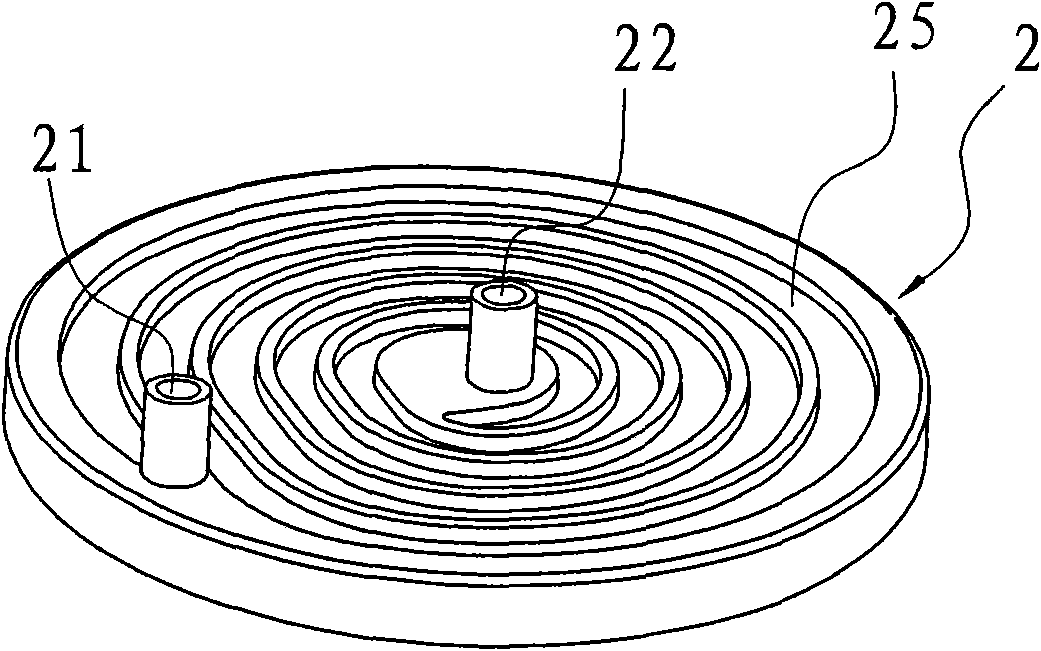

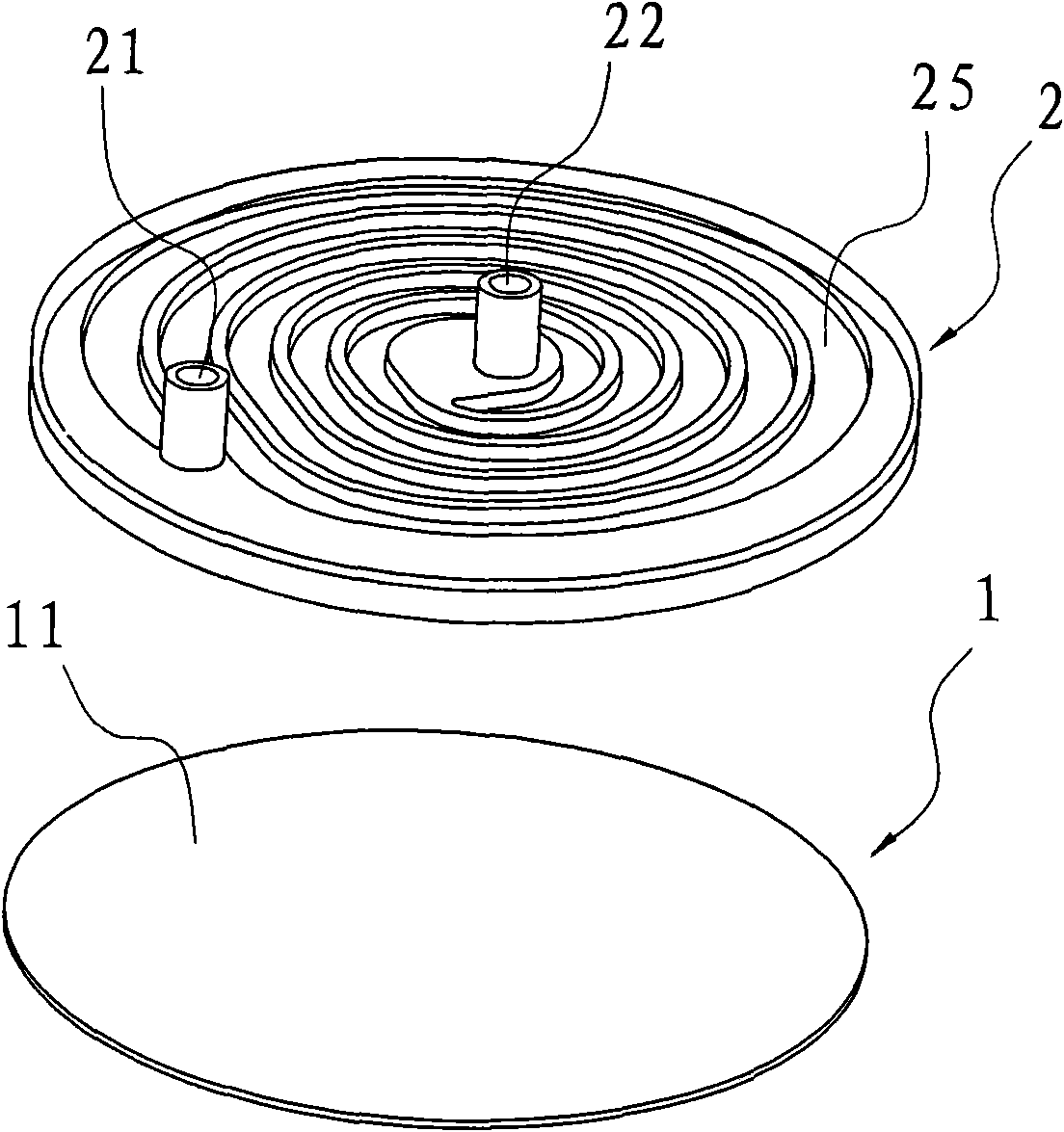

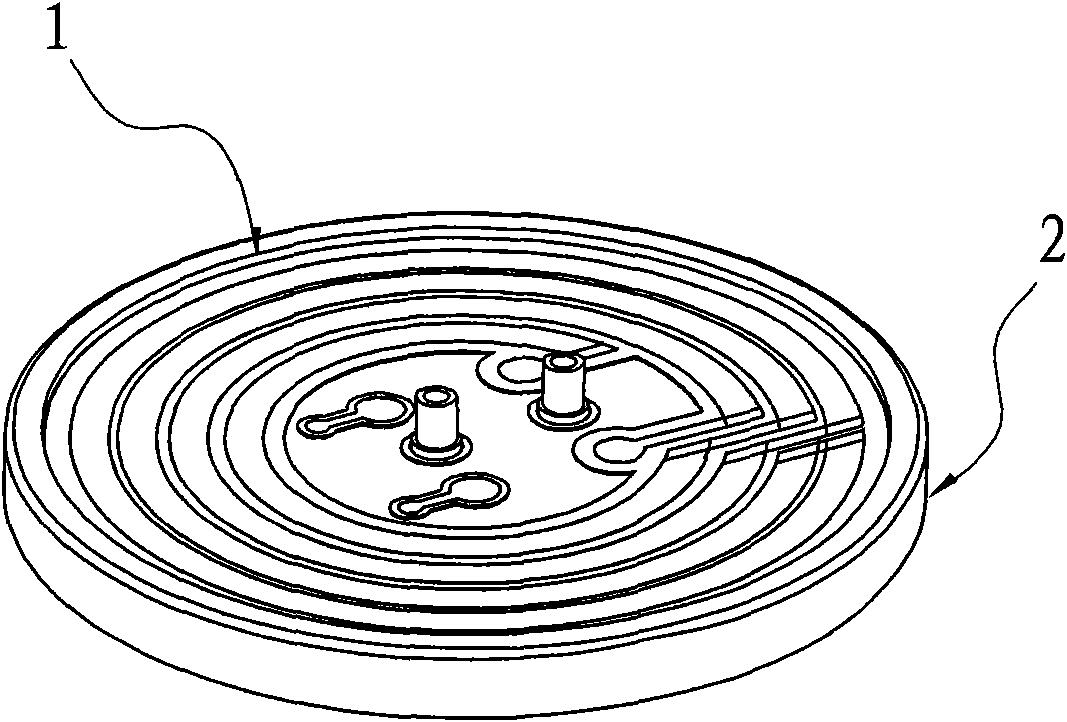

Liquid-heating unit

The invention relates to a liquid-heating unit comprising a flat heating element, a guiding plate and a meandrous liquid flowing passage. The guiding plate forms border sealing connection with one side of the flat heating element; the meandrous liquid flowing passage is formed between the guiding plate and the flat heating element; and the guiding plate is provided with a liquid inlet and a liquid outlet which are respectively communicated with a liquid inlet end and a liquid outlet end of the liquid flowing passage. The liquid-heating unit is characterized in that the liquid inlet and the liquid outlet are respectively arranged at the border part and the center part of the guiding plate, and the liquid flowing passage is spirally arranged. Compared with the prior art, the invention has the advantages that the integral size of the liquid-heating unit is not increased on a basis that the length of the liquid-heating unit is increased, and the heat-exchanging efficiency is very high.

Owner:NINGBO WAHO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com