Far infrared carbon fiber low temperature conductive heating paper and preparation method thereof

A technology of far-infrared carbon fiber and heating paper, which is applied in special paper, synthetic cellulose/non-cellulose material pulp/paper, and fiber raw material processing, etc. It can solve the problem of uneven heating on the surface of electric heating materials, excessive leakage current on the surface of finished products, Unstable heating performance and other issues, to achieve the effect of improving human microcirculation, large surface area, and easy heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

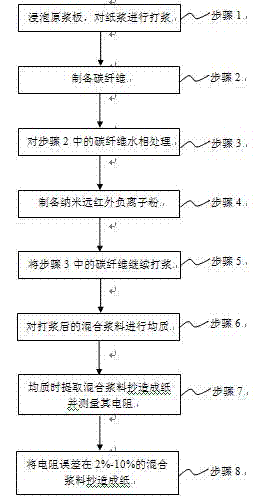

[0055] Please see attached figure 1 , attached figure 2 and attached image 3 Shown, the preparation method of a kind of far-infrared carbon fiber low-temperature conductive heating paper of the present invention, this method is raw material with raw material board, carbon fiber, nanometer far-infrared negative ion powder and diffusing agent, is made far-infrared carbon fiber low-temperature conductive by wet papermaking process Fever paper. The method at least includes the following steps:

[0056] Step 1, soak the raw pulp board in water for 10 minutes to 15 minutes, and then add it to the beater. The raw pulp board is soaked to make the plant fiber absorb water and swell, and the pulp formed by it is beaten; the pulp beating time is 60 minutes - between 120 minutes.

[0057] Step 2, preparing carbon fibers.

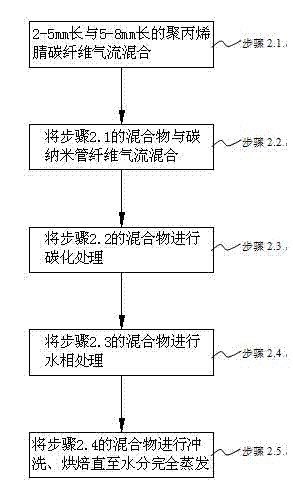

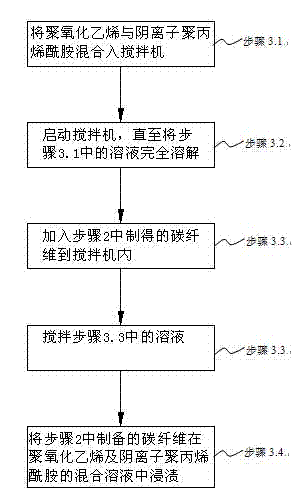

[0058] In step 2.1, polyacrylonitrile carbon fibers with a diameter of 4 μm to 10 μm and a length of 2 mm to 5 mm are mixed with polyacrylonitrile carbon fibers ...

Embodiment 1

[0077] Select directly commercially available pulp, the weight of which is 94% of the total weight, put the raw pulp board into water and soak for 10 minutes, put it into a beater and beat the pulp, after the pulp is beaten for 75 minutes, add water phase treatment and disperse Carbon fiber solution and nanometer far-infrared negative ion powder accounting for 1% of the total weight. The weight of carbon fiber is 4.5% of the total weight, the diffusion agent is made of polyethylene oxide and anionic polyacrylamide mixed at a weight ratio of 1:1, the weight of the diffusion agent mixture is 2% of the total weight, and the concentration of the diffusion agent solution is 5 %, using the above water phase dispersion to obtain a carbon fiber solution with good dispersibility, uniformity and hydrophilicity. Continue beating for 45 minutes, and the beating degree of the mixed slurry is stopped at 25 ° SR. Then 80 minutes after the homogenization of the mixed slurry, the homogenizati...

Embodiment 2

[0079] Identical as example 1 method, the weight of pulp is 89.5% of gross weight, and the weight of carbon fiber is 6% of gross weight, and the weight of diffusion agent mixture is 3.5% of gross weight, and the weight of nanometer far-infrared anion powder is 1% of gross weight %. The main technical indicators of the carbon fiber far-infrared low-temperature conductive heating paper made by this program: the resistance value of the carbon fiber far-infrared low-temperature conductive heating paper is 400-440Ω / m2, the resistivity is 10-20Ω cm, and the fixed weight is 55-60g / m ㎡, can be widely used in far-infrared low-temperature plane heating materials.

[0080]In summary, the heating element of the far-infrared carbon fiber low-temperature conductive heating paper of the present invention has a large surface area, and its entire surface is a heating surface and a heat dissipation surface, so the heat is even, and the surface temperature can reach 50°C-60°C, and the heat It i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com