Patents

Literature

58results about How to "Good thermal radiation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

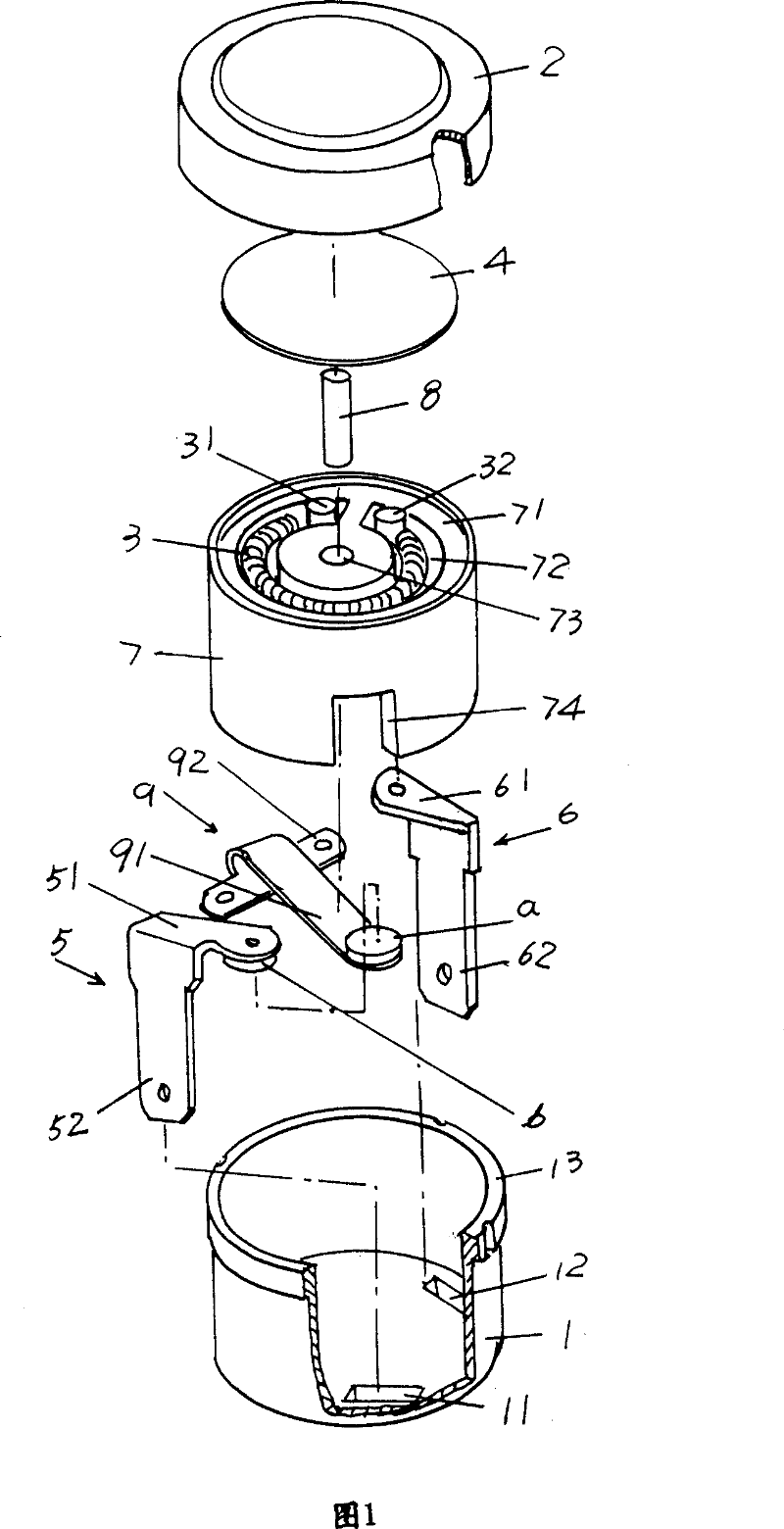

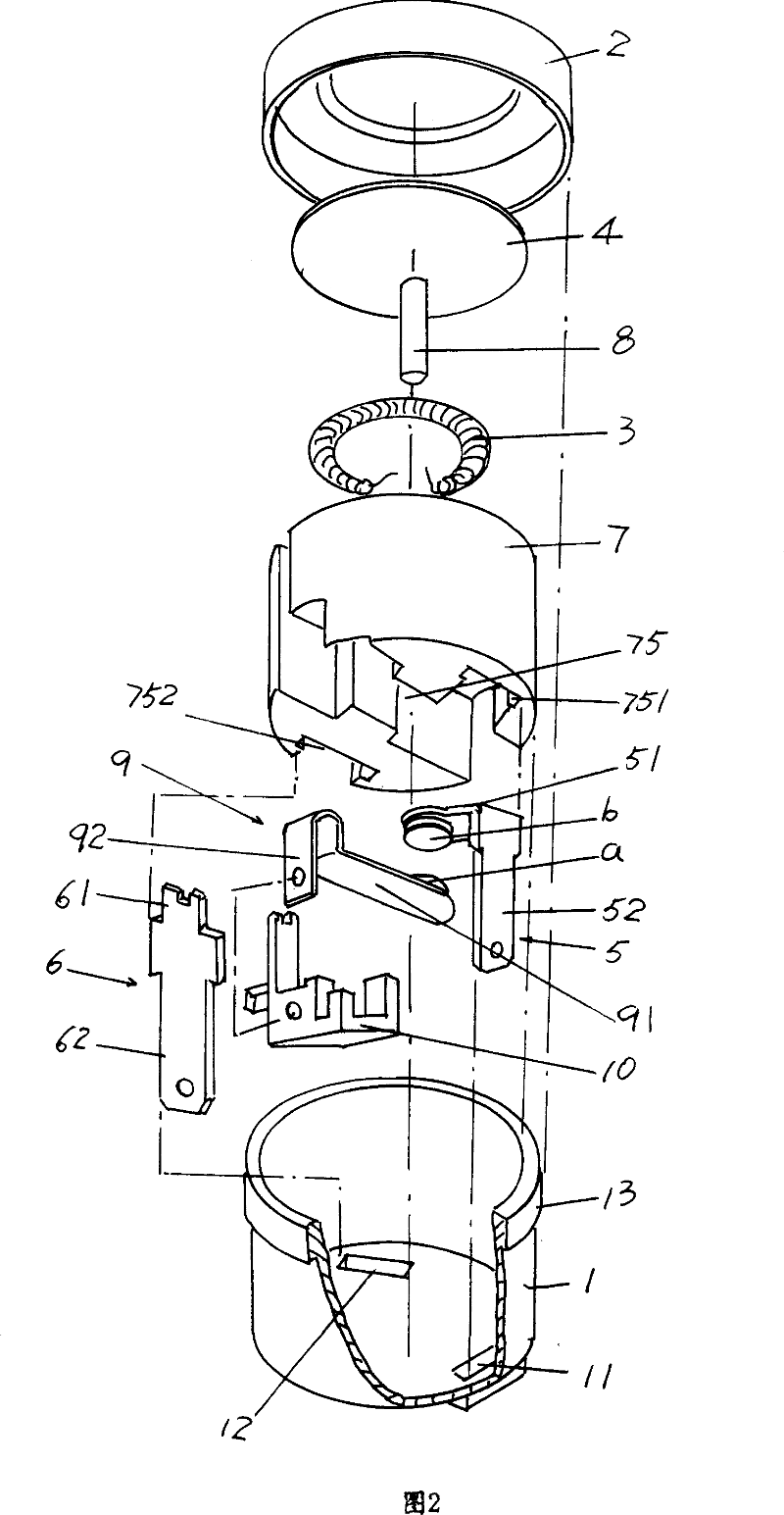

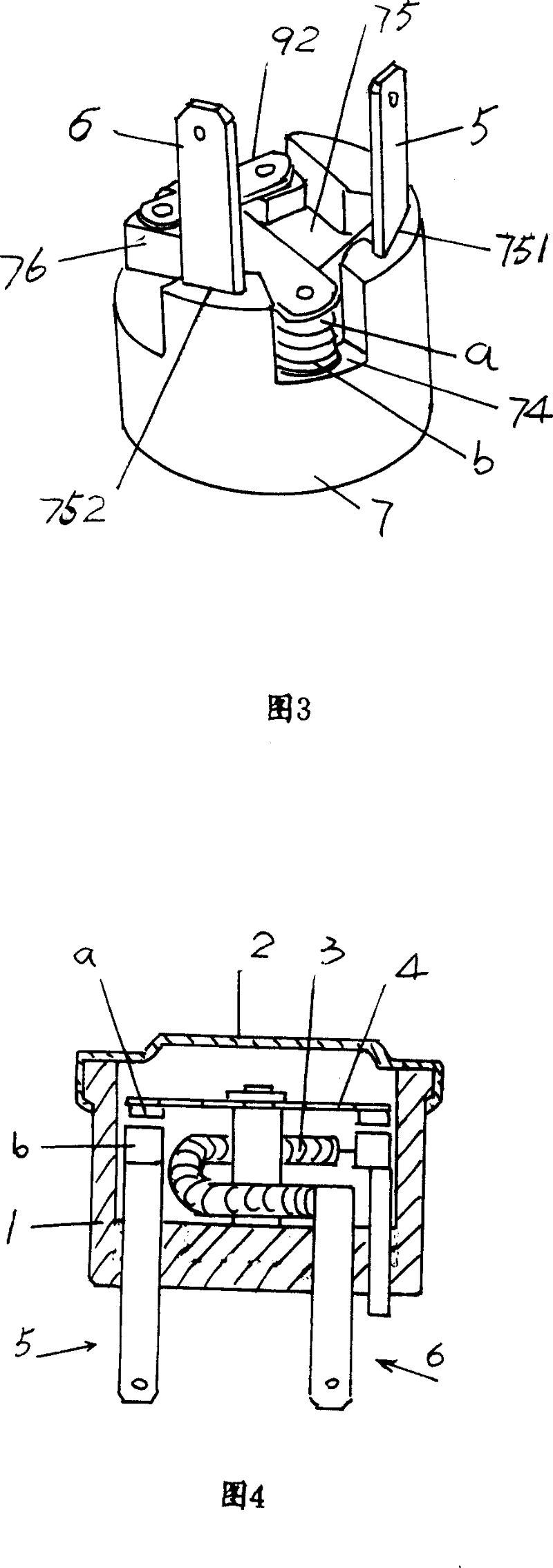

Overload protector of single-phase AC motor

ActiveCN100356652CEliminate temperature driftAvoid always-on conditionsElectrothermal relaysEmergency protective circuit arrangementsFistRefrigeration compressor

The invention relates to a single phase ac motor over current protector in the field of compression refrigerating machine motor protector. It comprises a casing, a cover, an electric-heat wire, a double mental sheet, a fist hook, a second hook, a moving contact, a static contact, a fixed base and a trigger mechanism, wherein the static contact is fixed on the first hook; the electric-heat wire is fixed positioned inside the electric-heat wire channel by a pair of first and second column; the second column is connected with the second hook; the double mental sheet is disk type and positioned on the double mental sheet base upper to the electric-heat wire; the trigger mechanism comprises a top rod and a spring sheet; the top rod is positioned in the top rod hole of the fixed base; the top end and the low end of the double mental sheet are corresponding with the spring sheet; the fixed end of the spring sheet is fixed on spring sheet fixed base which is the lower part of the fixed base; the free end extents to the contact space-limit which is the channel lower part of the fixed base; the moving contact is fixed on the free end and is corresponding with the static contact.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

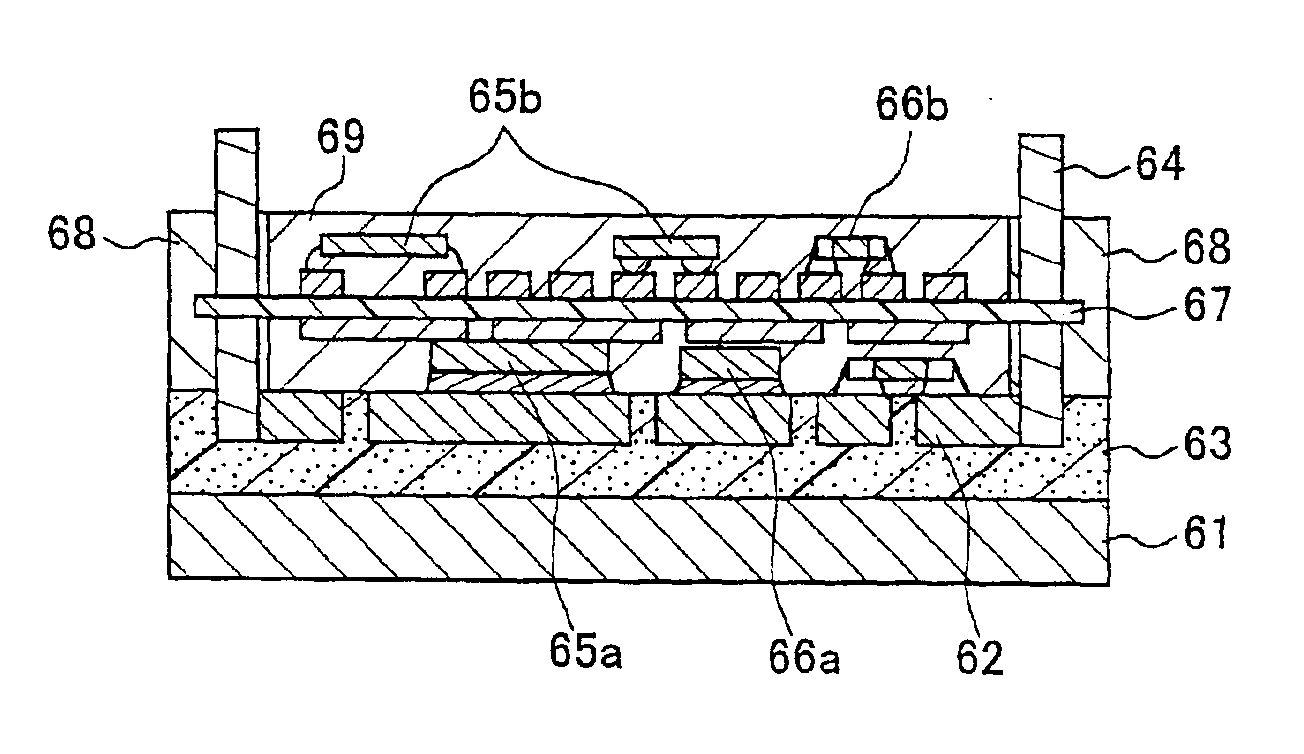

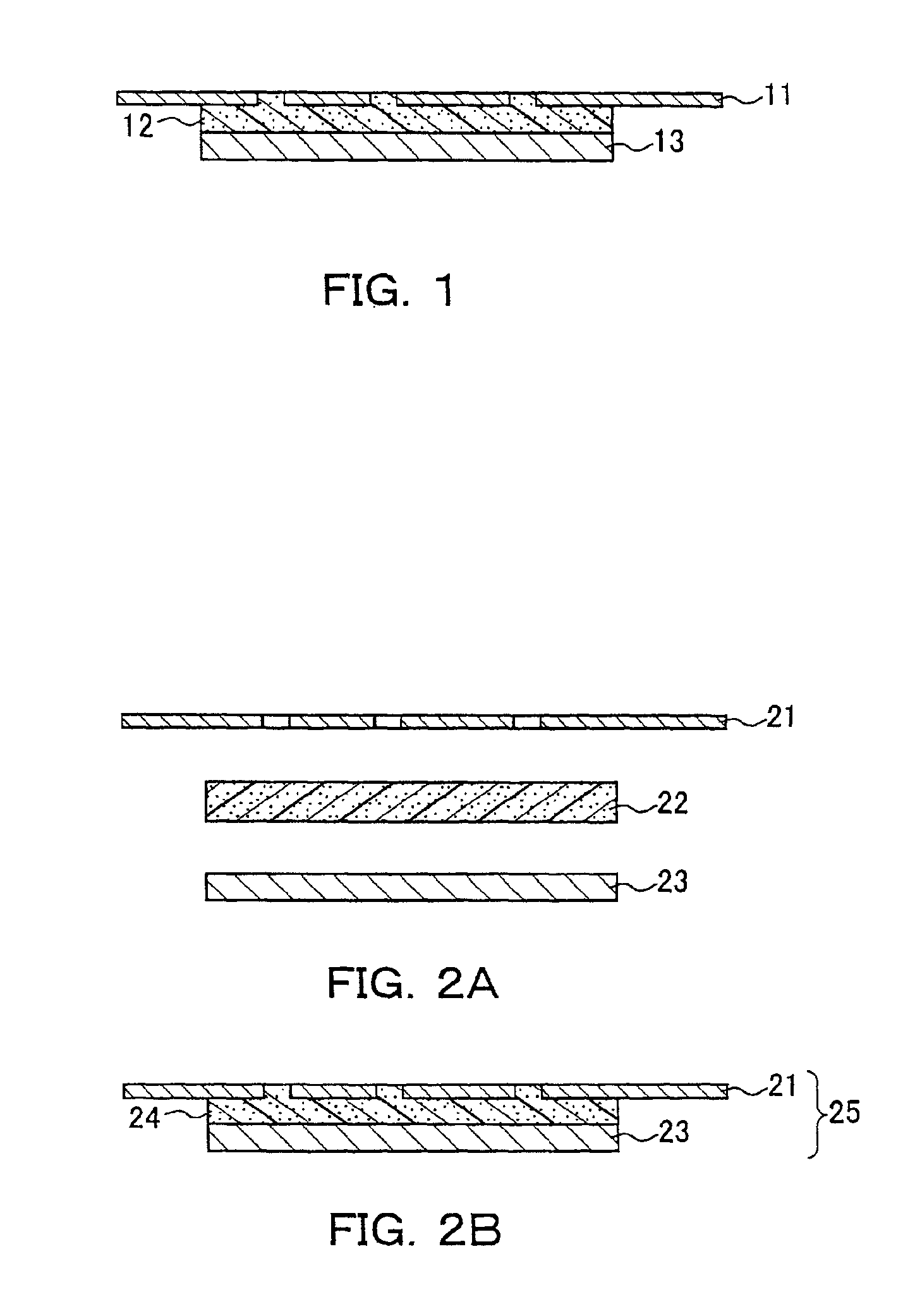

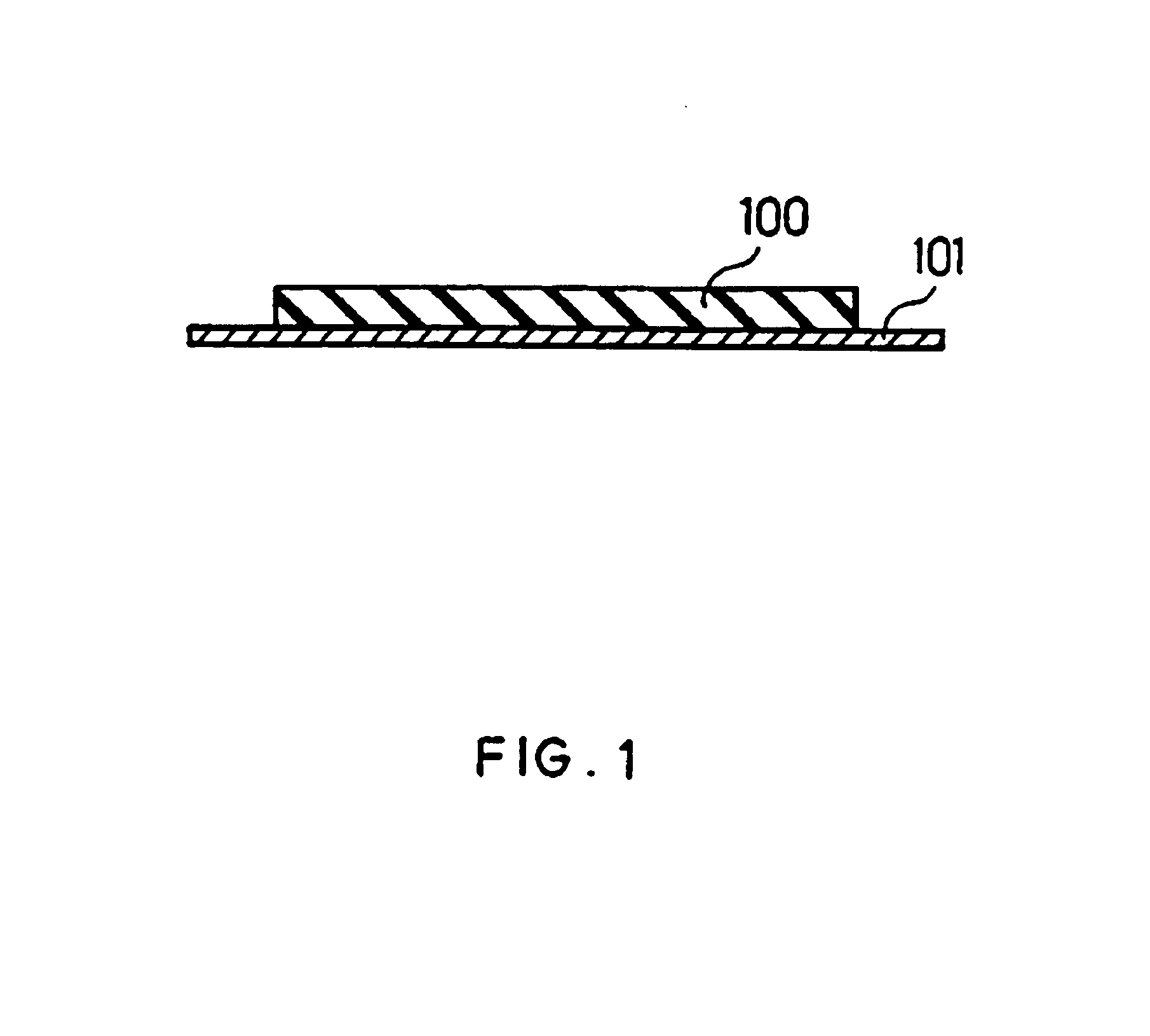

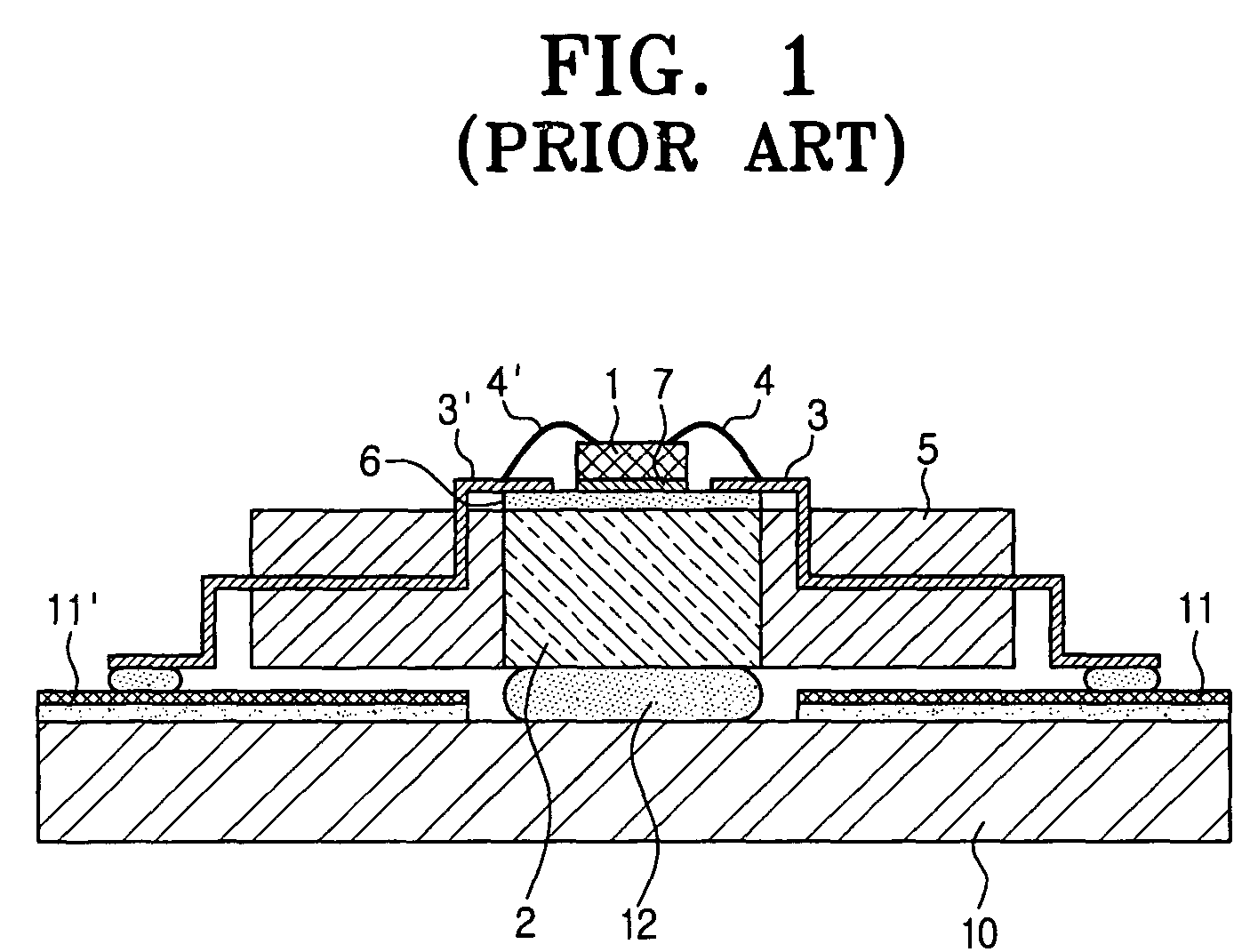

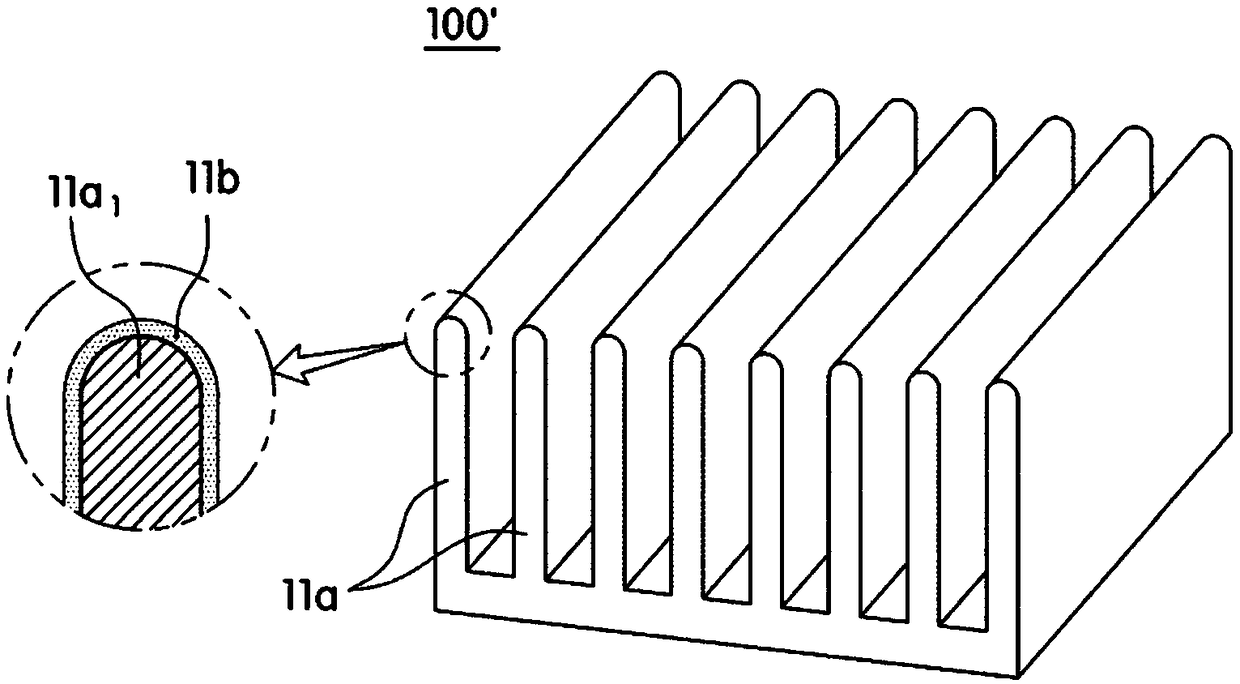

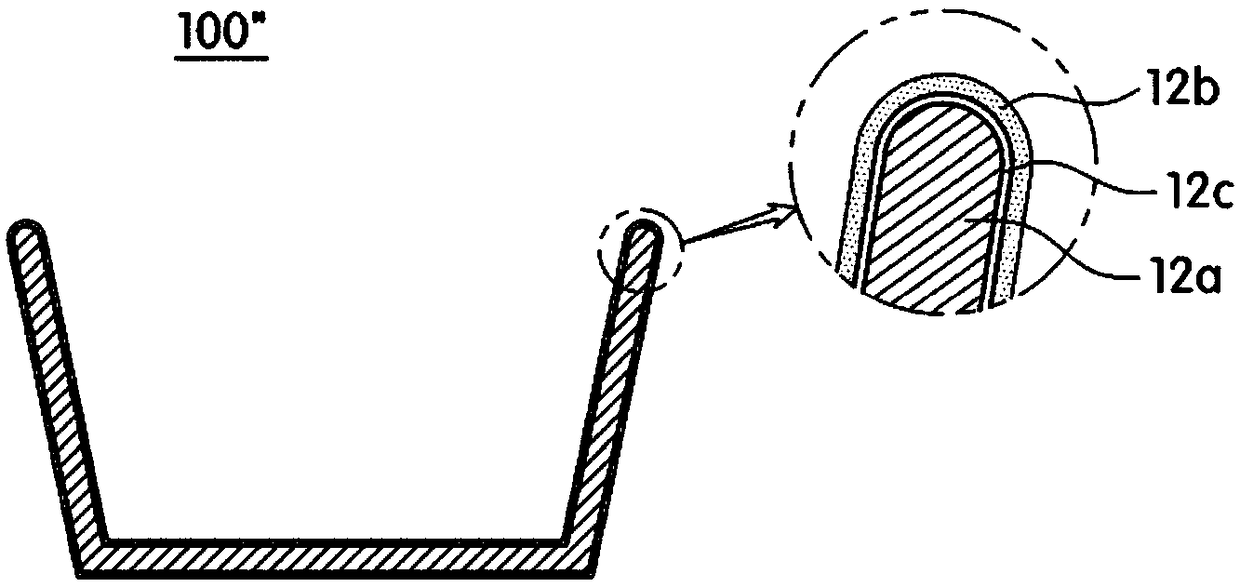

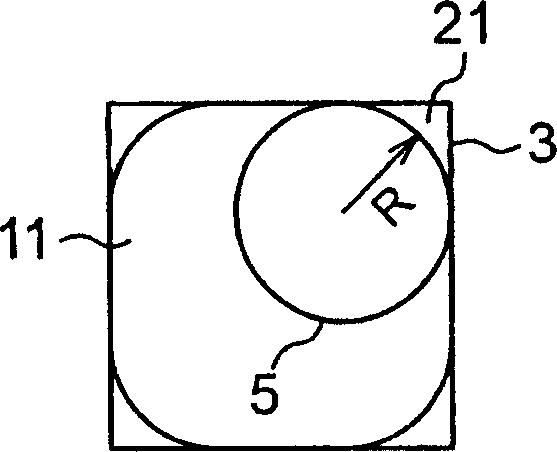

Thermal conductive substrate and semiconductor module using the same

InactiveUS6958535B2Good thermal radiation performanceReduce crackingSemiconductor/solid-state device detailsSolid-state devicesThermal radiationSemiconductor

A semiconductor module includes a circuit substrate composed of a wiring pattern, an electrical insulating layer and a thermal radiation board, and in use is fixed to an external thermal radiation member, in which the electrical insulating layer is composed of a thermal conductive mixture containing 70-95 wt % of an inorganic filler and 5-30 wt % of a thermosetting resin. A warping degree of the circuit substrate with respect to the external thermal radiation member is at most 1 / 500 of a length of the substrate, and the circuit substrate warps to protrude toward the thermal radiation board as the temperature rises. Accordingly, the thermal radiation property does not deteriorate even when the temperature rises in use. At a time of fixing the circuit substrate to the external thermal radiation member, the thermal resistance is kept to be a sufficiently low level. The thermal resistance is kept in a low level without sacrificing the contact between a module and the external thermal radiation member even at a high temperature during an operation of the device or the like, and the thermal conductive substrate is resistant to fractures or cracks and thus is highly reliable.

Owner:PANASONIC CORP

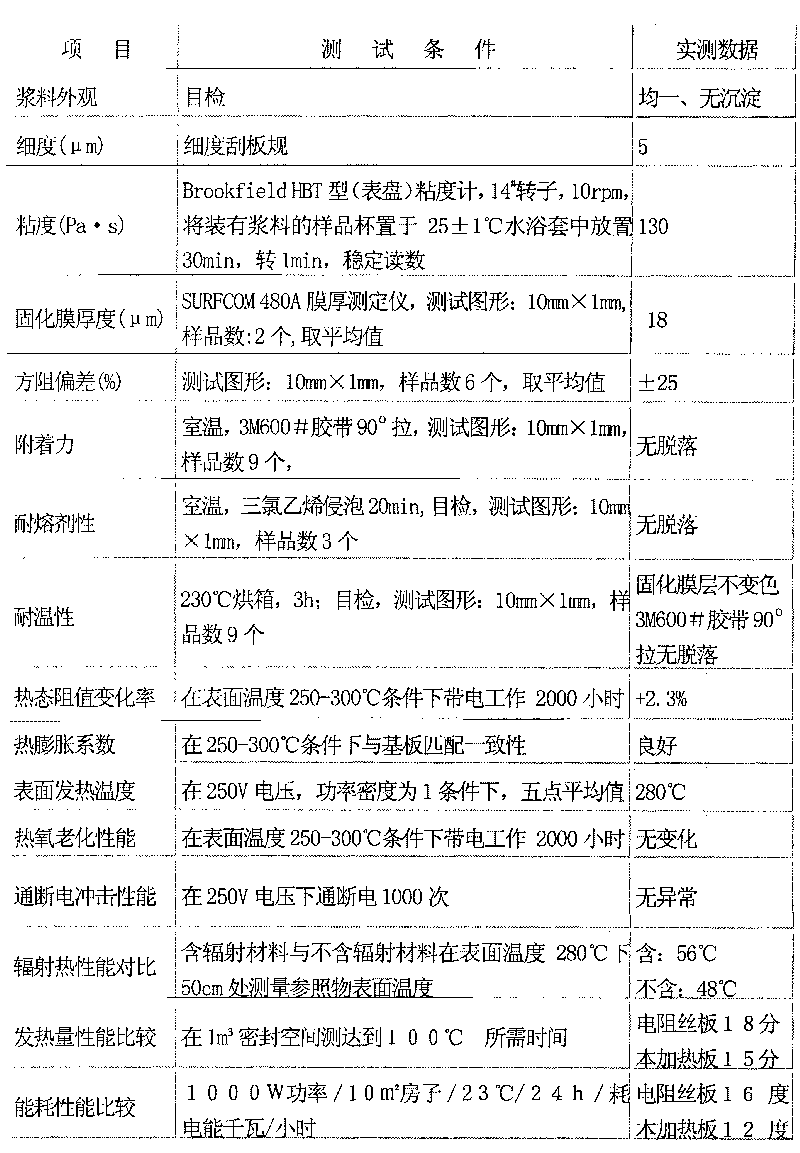

Electrothermal organic power resistance slurry for heater

InactiveCN101735561ALow temperature curingWith high temperature useHeating element materialsLow temperature curingUltra fine

The invention relates to an electrothermal organic power resistance slurry for a heater. The main formula of the slurry comprises the following components by weight percent: 28%-60% of resin I, 5%-13% of flame-retardant heat-resistant polymer containing boron element, 3%-6% of latent curing agent, 1%-2% of latent curing accelerator, 0-30% of resin II, 10%-15% of nano-carbon series conductive filler, 4%-5% of temperature coefficient adjustment additive, 0-5% of ultra-fine base metal alloy powder conductive filler, 0-3% of silicon series far infrared radiating material and 0-4% of ultra-fine mica powder, in addition to the main formula, the slurry further contains a small amount of function auxiliary phase. The slurry can solve the problems that the ordinary slurry is difficult to realize thinness, light weight or special shape; furthermore, the slurry has the properties of low temperature curing and high temperature use and can be directly used for printing or spraying and meet the technical development requirements of an electric heater on the trends of miniature, thinness, light weight and (shape and purpose) special shape.

Owner:西安宏星电子浆料科技股份有限公司

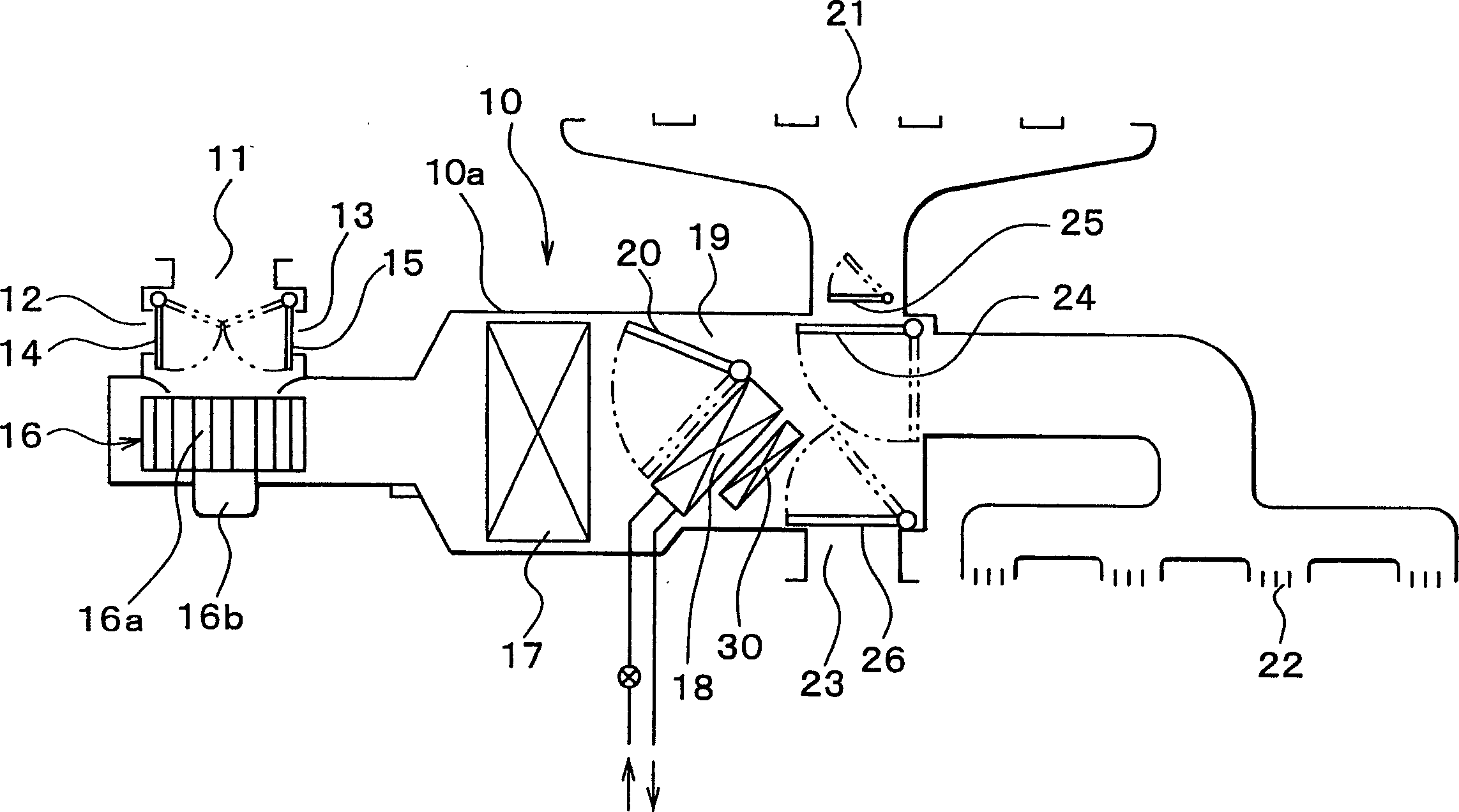

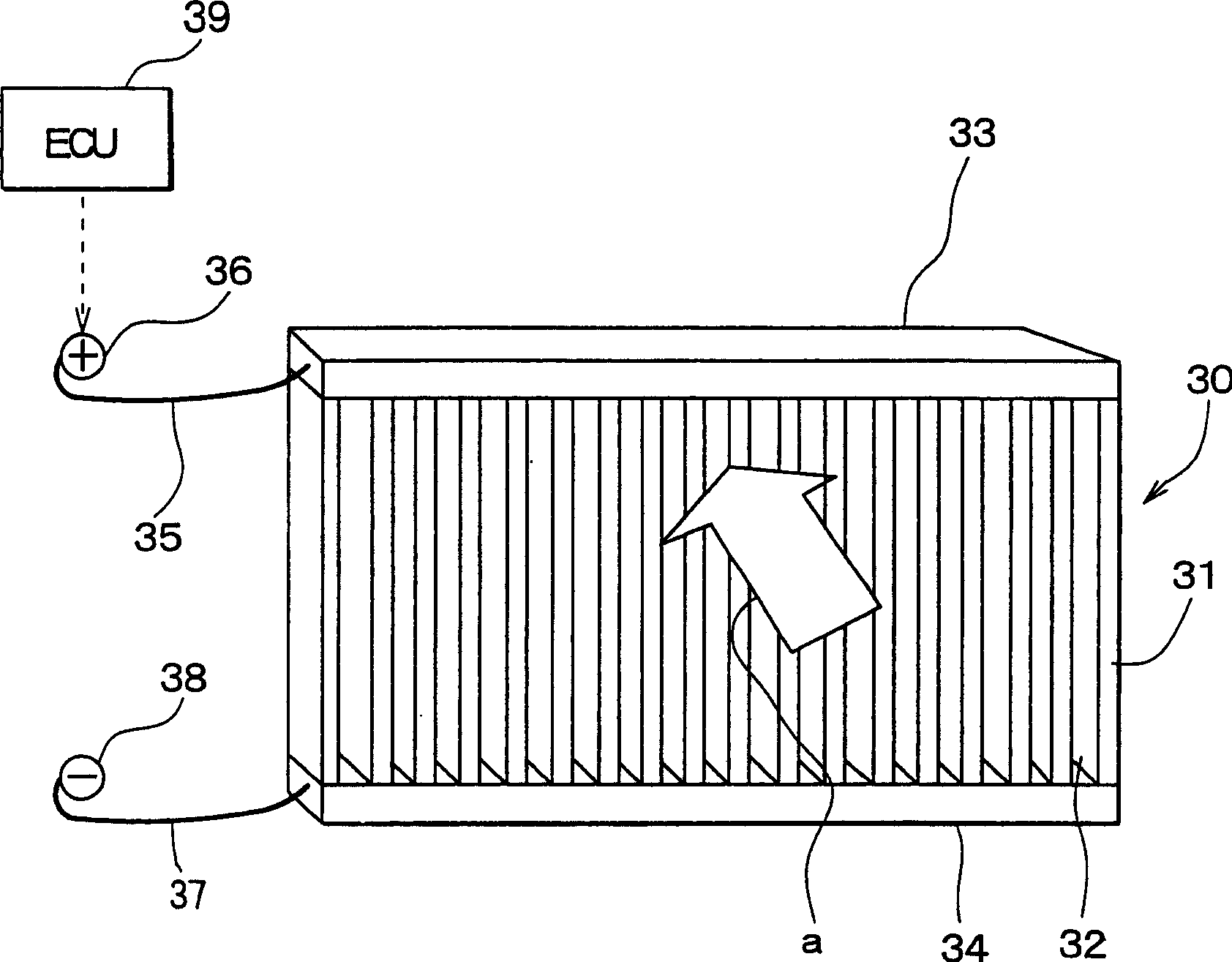

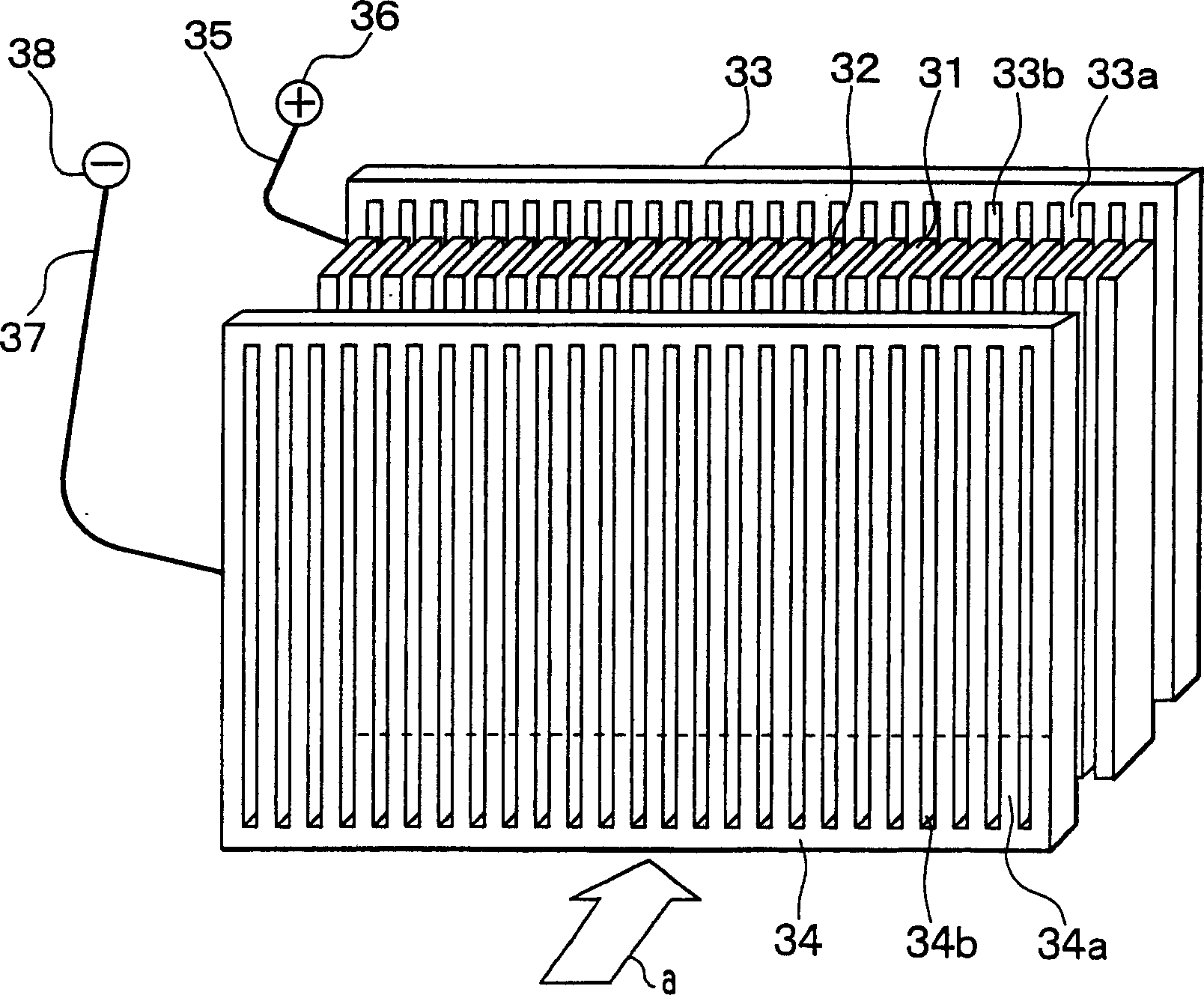

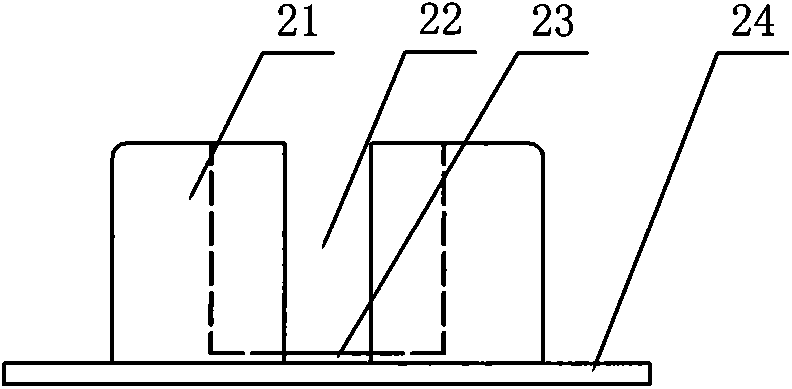

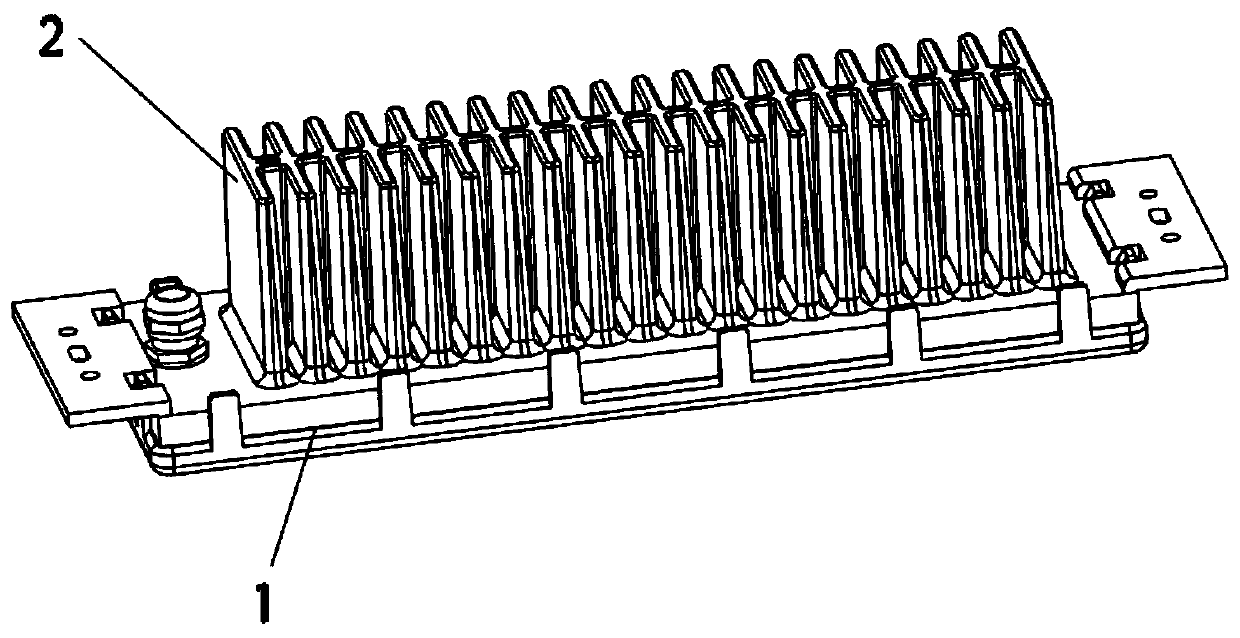

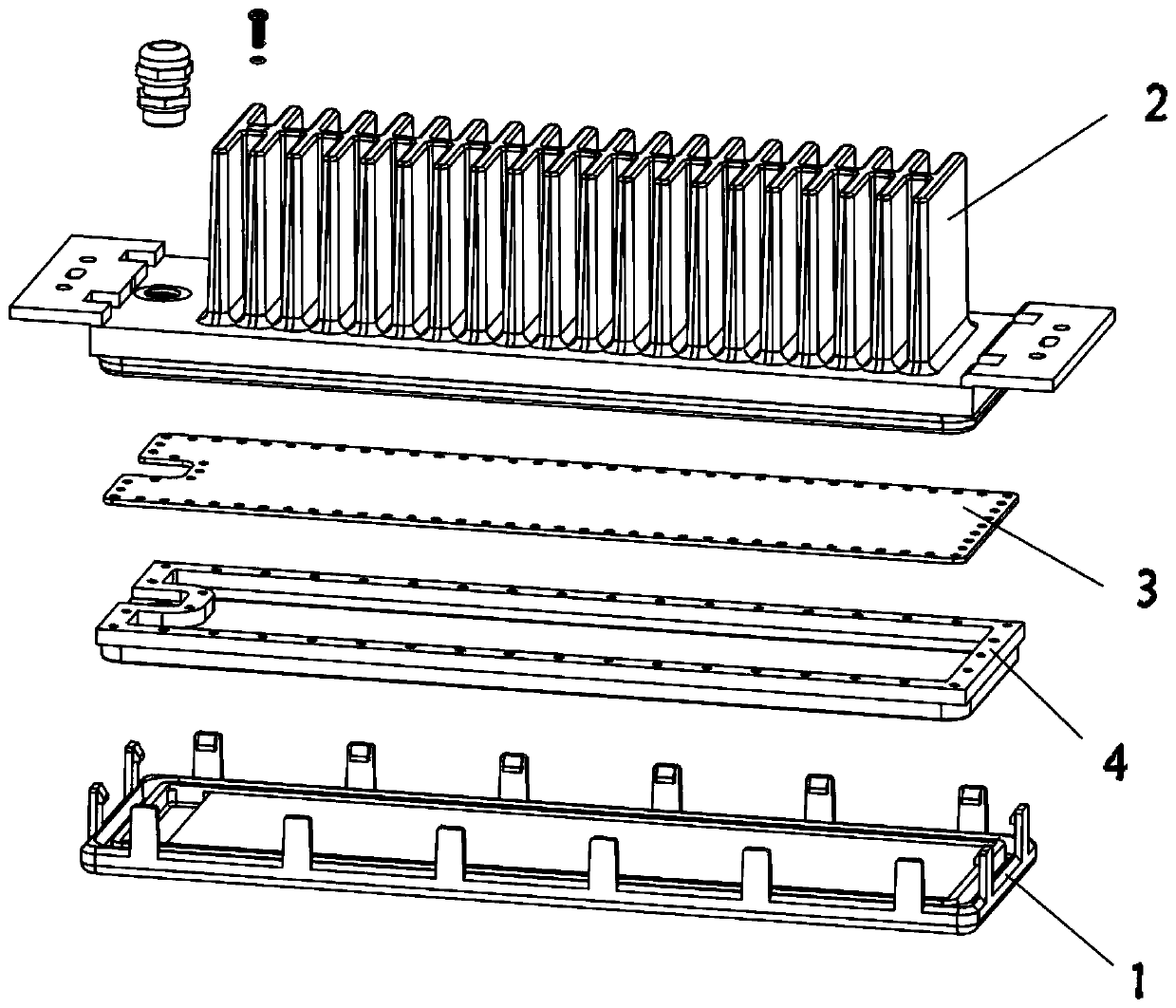

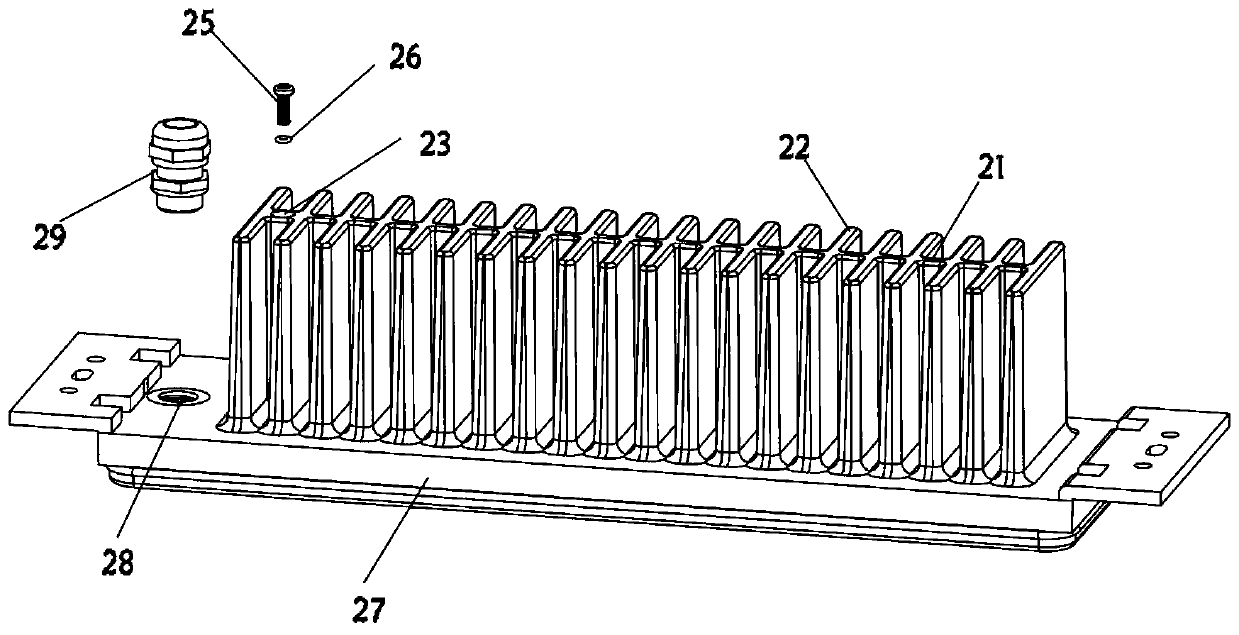

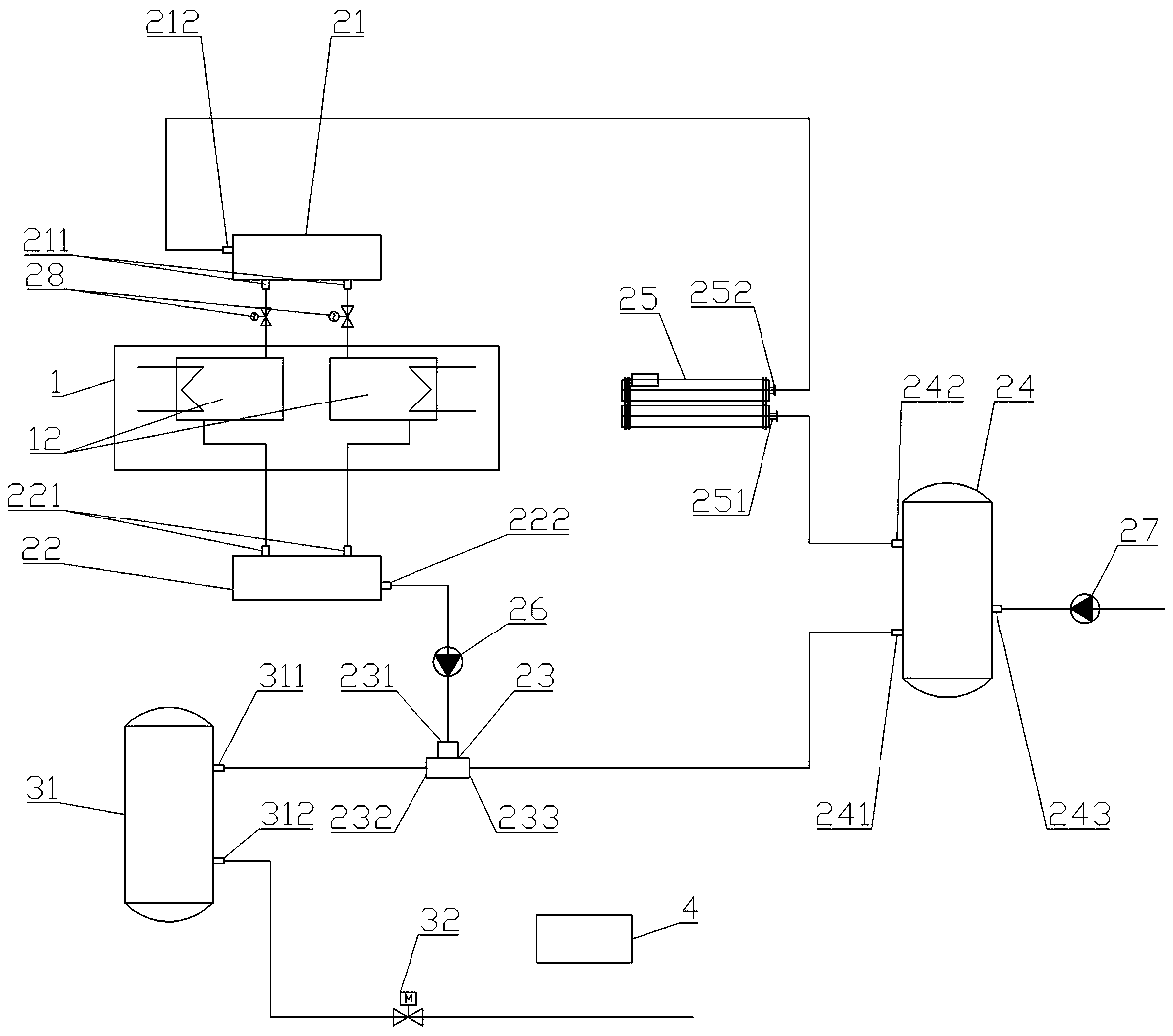

Electrical heater, heating heat exchanger and vehicle air conditioner

InactiveCN1575046ASimple structureGood thermal radiation performanceAir-treating devicesAir heatersDirect heatingPlate fin heat exchanger

An electrical heater includes plural heating body plates (31) arranged in parallel with each other to define an air passage (32) between adjacent two thereof, a positive electrode member (33) joined to one end side of each heating body plate, and a negative electrode member (34) joined to the other end side of each heating body plate. In the electrical heater, the heating body plates are arranged to directly heat air passing through the air passage when electrical power is supplied to the heating body plates through the electrode members. Accordingly, the electrical heater can effectively heat air with a simple structure.

Owner:DENSO CORP

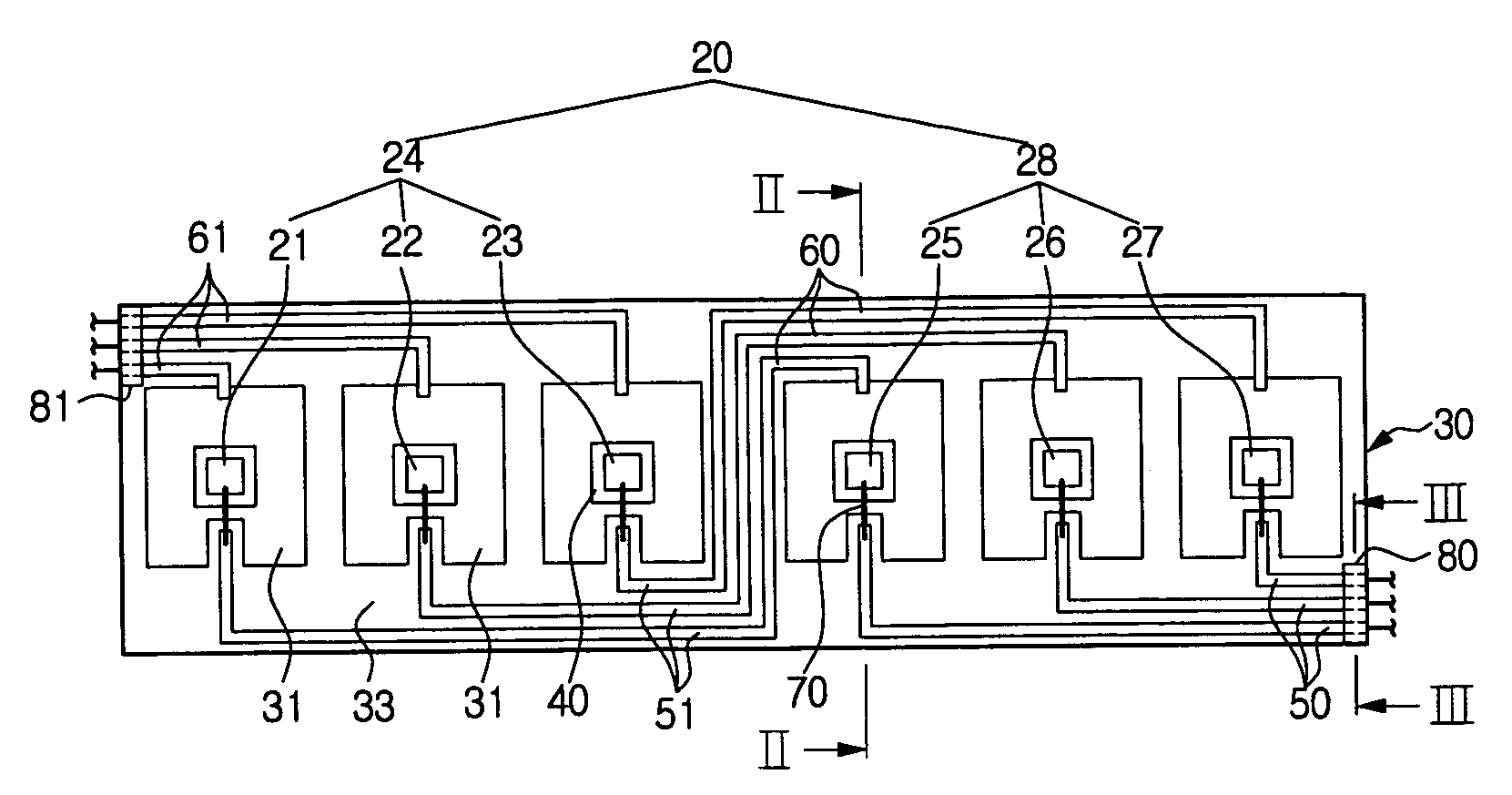

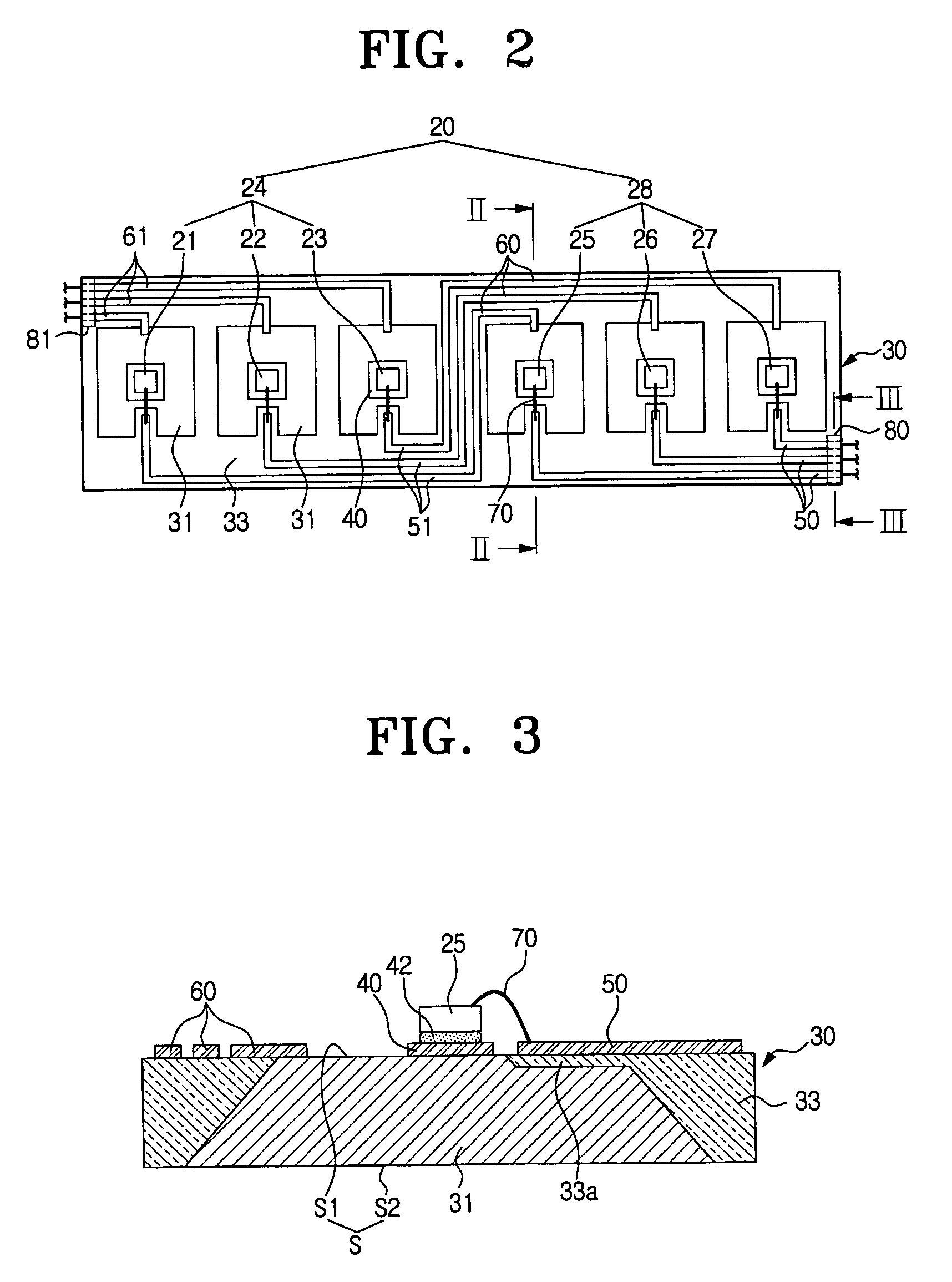

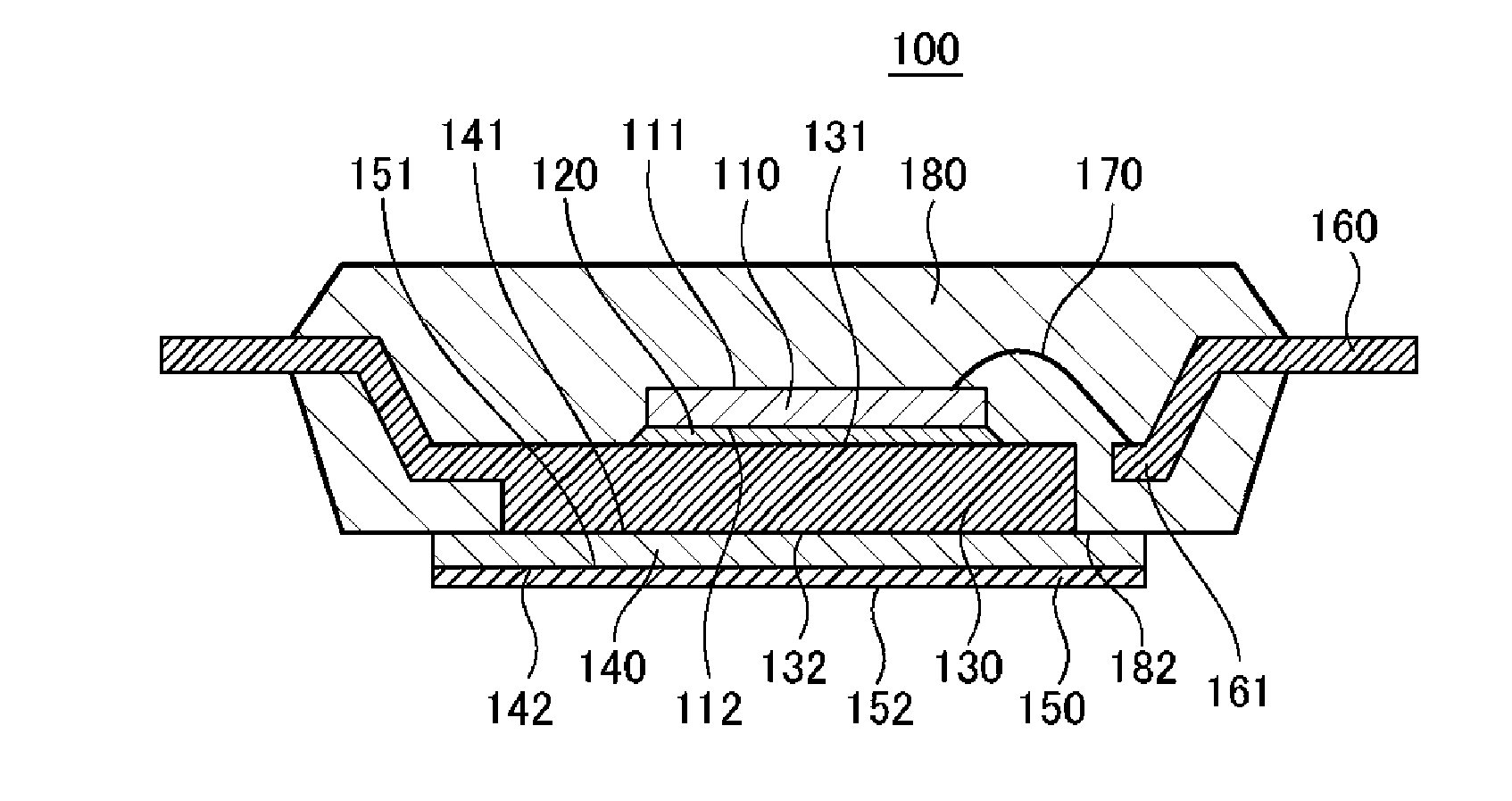

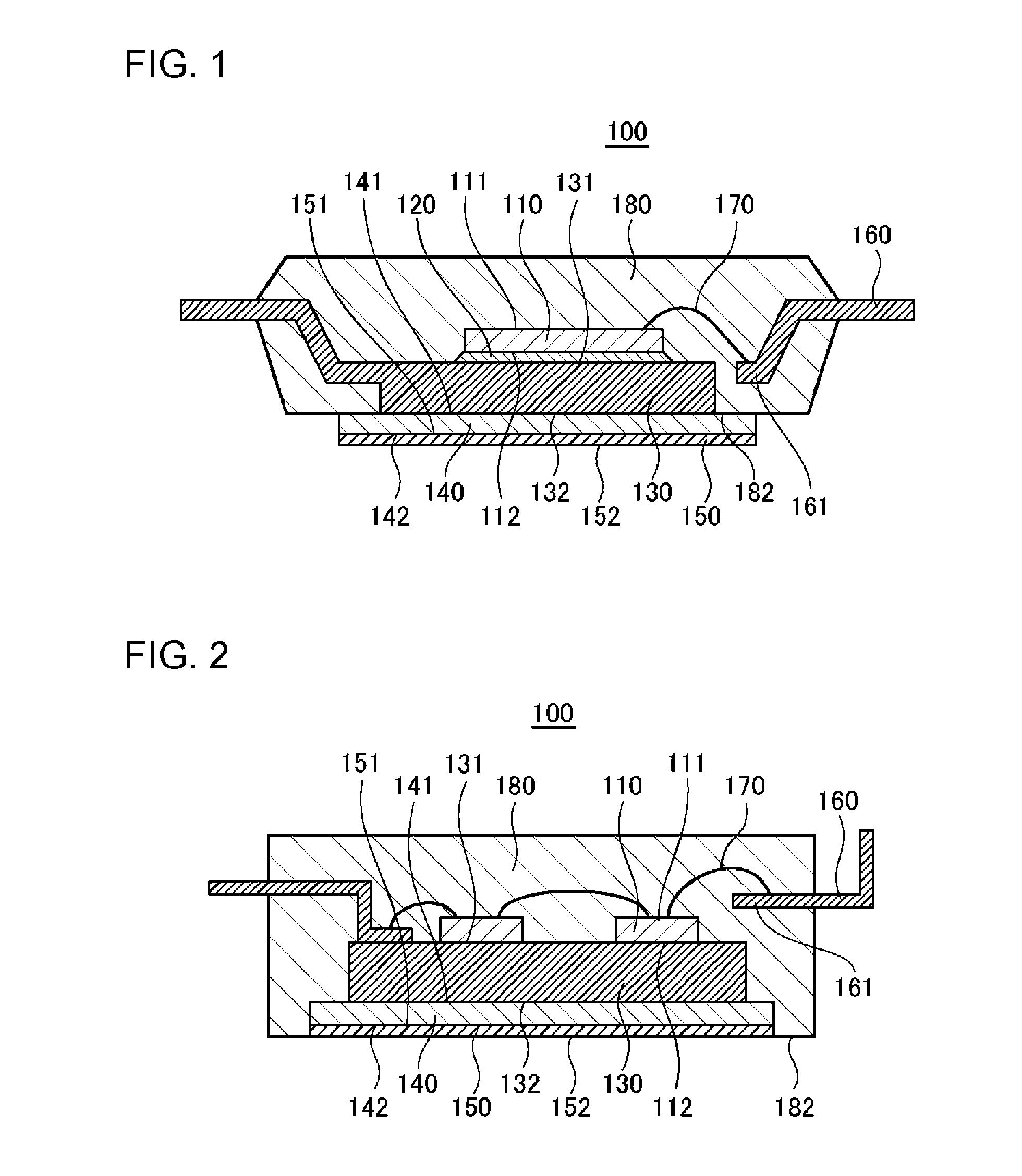

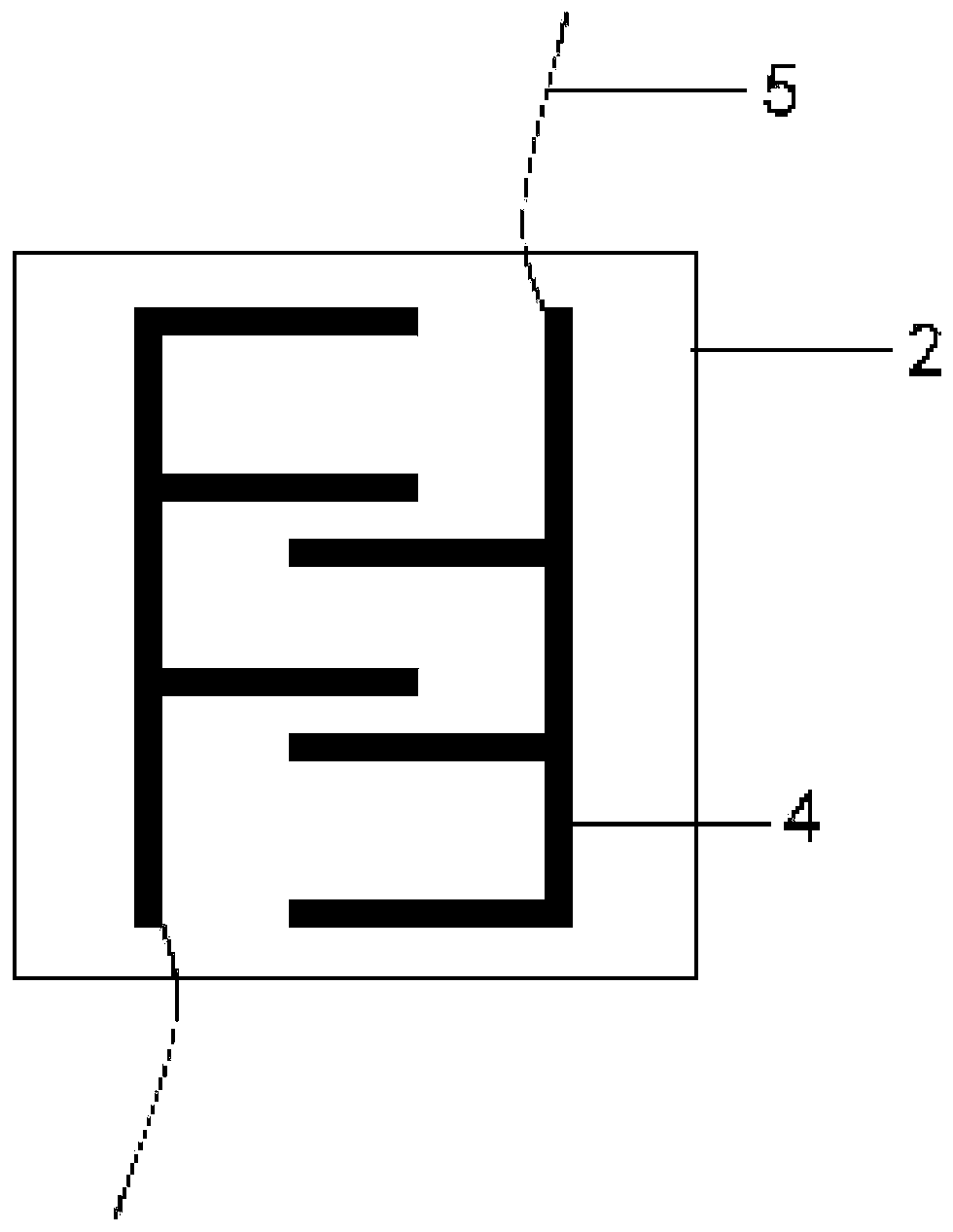

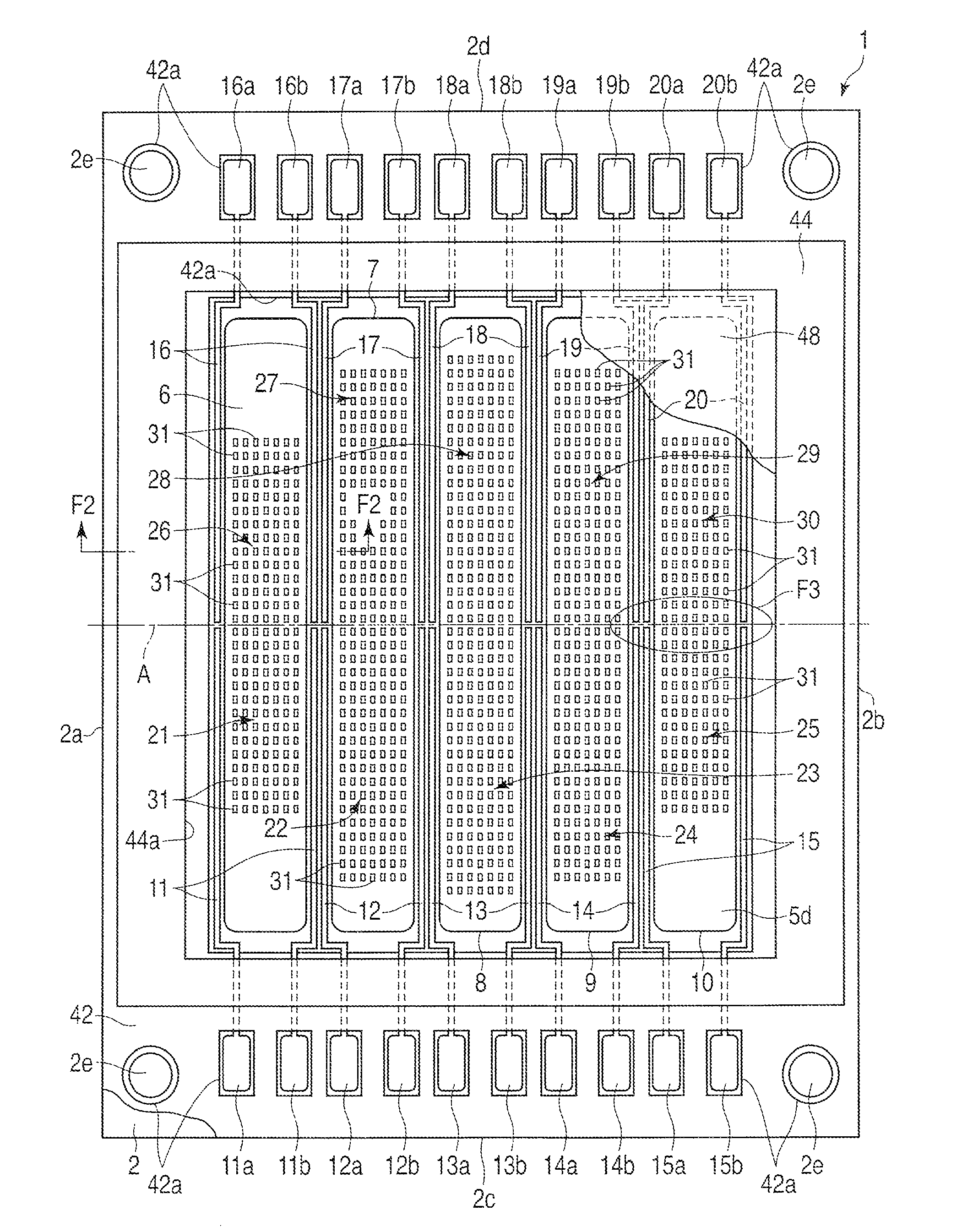

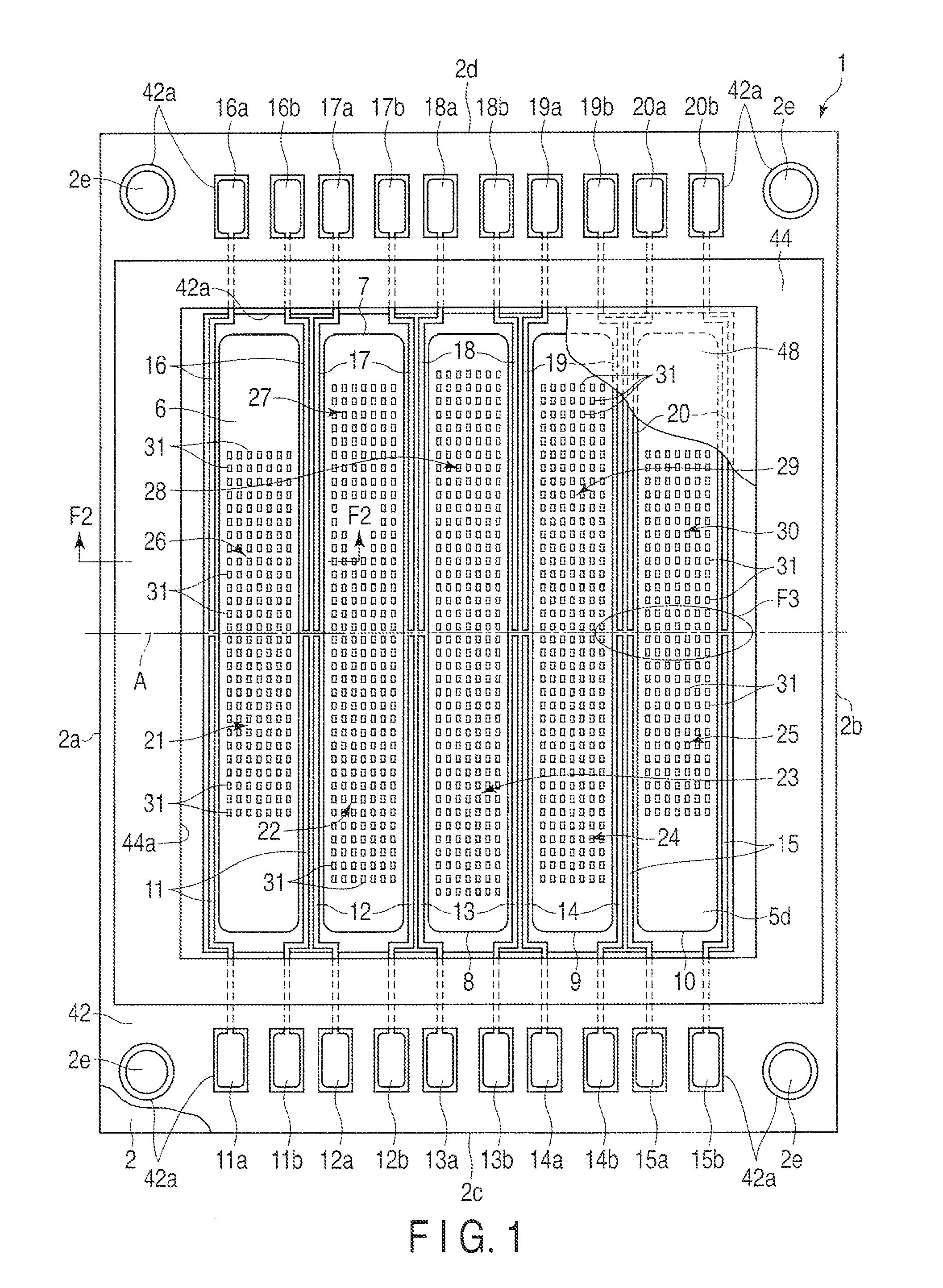

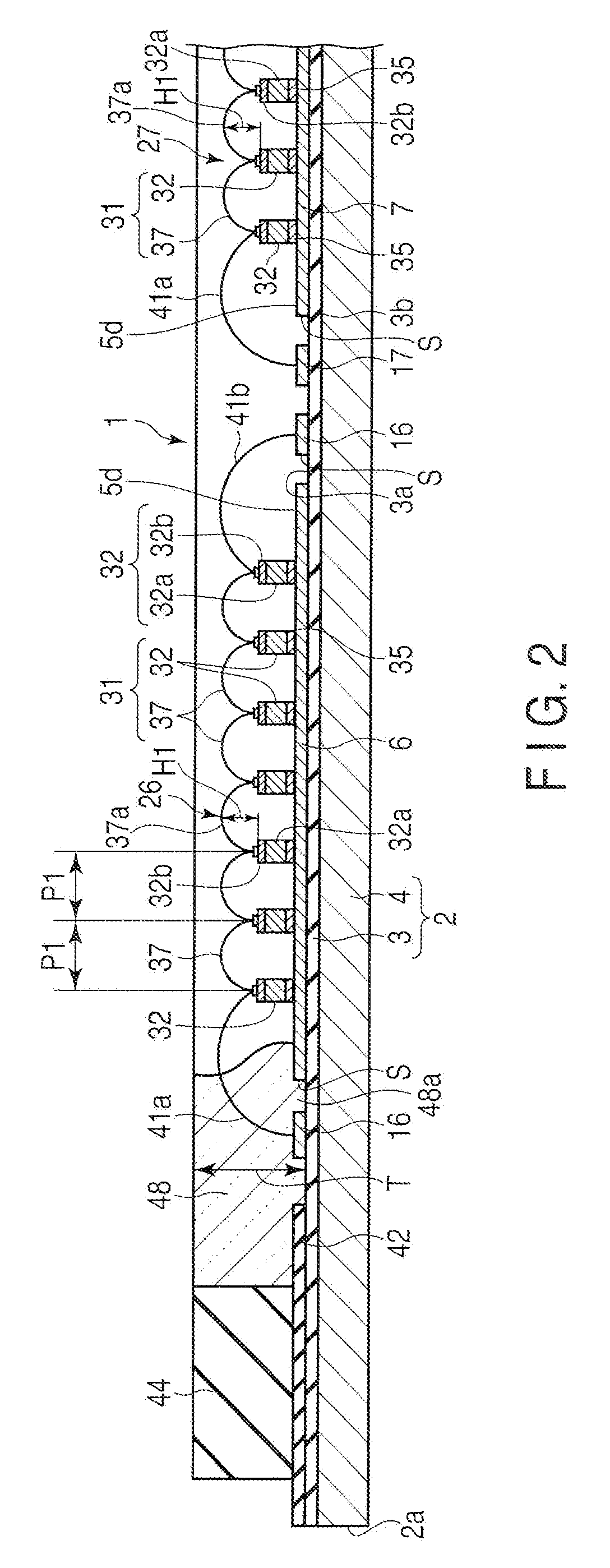

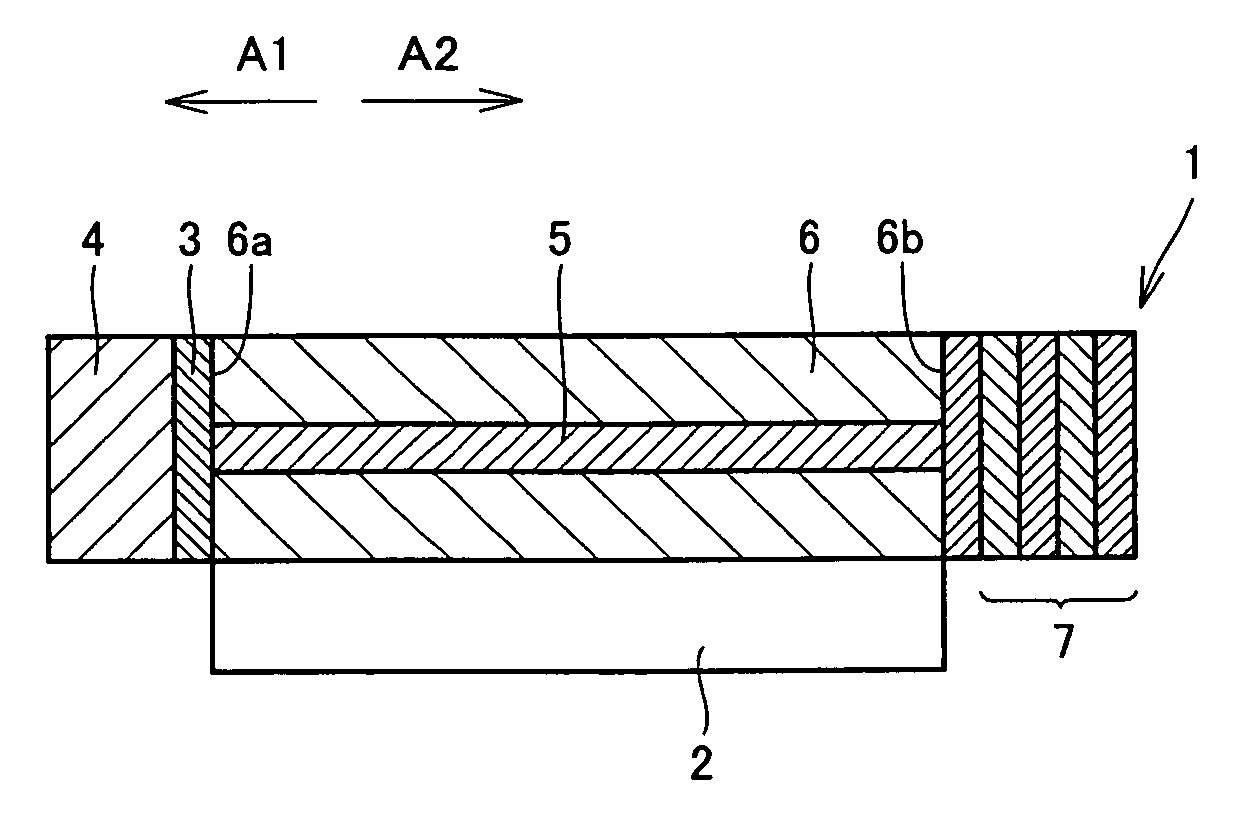

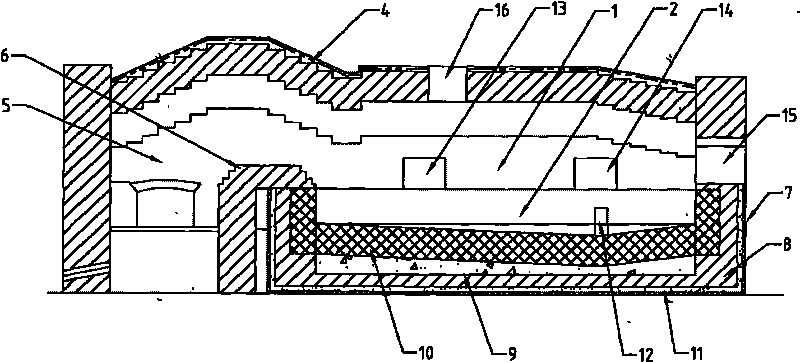

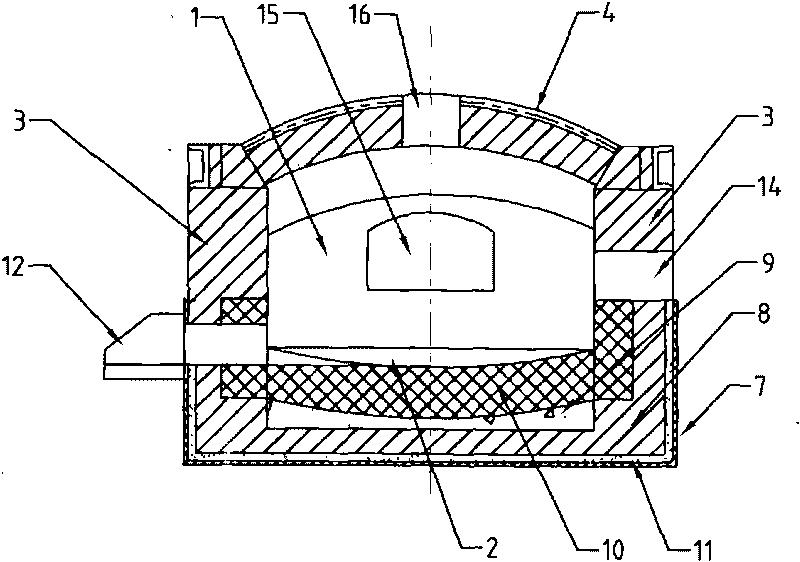

Light emitting module and illumination apparatus

InactiveUS20110303927A1Convenience to workImprove production efficiencyPlanar light sourcesPoint-like light sourceLight-emitting diodeDiode

A light emitting module (1) comprises a module substrate (2), a light emitting diode string (31), and a sealing member (48). The light emitting diode string (31) includes light emitting diode elements (32) and bonding wires (37) which connect the light emitting diode elements (32). The light emitting diode element (32) has a pair of element electrodes (33, 34) and has a rectangular shape extending in a direction along which the element electrodes (33, 34) are aligned. The sealing member (48) is laminated on the module substrate (2) to seal the light emitting diode string (31). The light emitting diode elements (32) are arranged at intervals in a direction crossing the direction along which the element electrodes (33, 34) are aligned, and the element electrodes (33, 34) with the same polarity are aligned to be adjacent to each other in an arrangement direction of the light emitting diode elements (32) between the light emitting diode elements (32) adjacent to each other. Each bonding wire (37) is obliquely wired with respect to the arrangement direction of the light emitting diode elements (32) to connect the element electrodes (33, 34) with different polarities of the light emitting diode elements (32) adjacent to each other.

Owner:TOSHIBA LIGHTING & TECH CORP

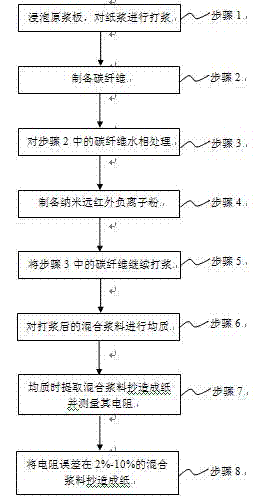

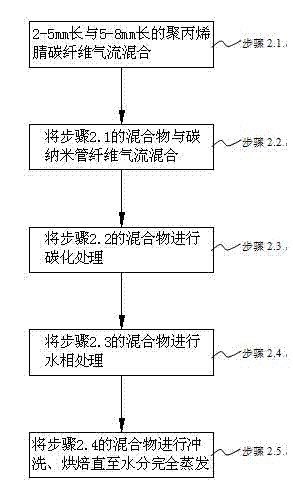

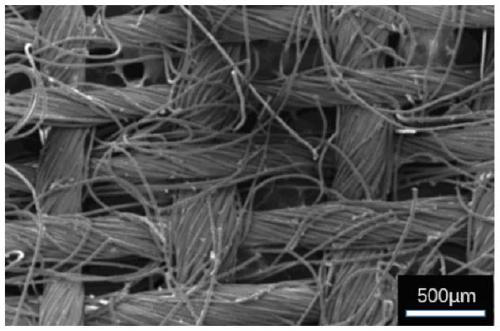

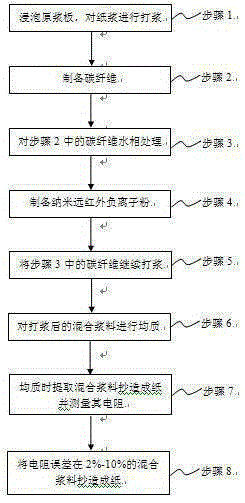

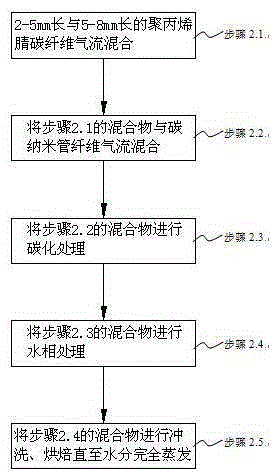

Far infrared carbon fiber low temperature conductive heating paper and preparation method thereof

InactiveCN102226325AIncrease surface areaPass wellNon-fibrous pulp additionSpecial paperFiberCarbon fibers

A far infrared carbon fiber low temperature conductive heating paper comprises an original pulp board, carbon fibers, nano far infrared negative ion powder and a diffusant. According to the invention, paper pulp is beaten and added with carbon fibers treated with carbonization processing, water phase processing and hydrophilism processing for dipping; after homogenizing and beating again, resistor of a mixed slurry is measured, and mixed slurry with a resistor within 2%-10% is manufactured into paper. The far infrared carbon fiber low temperature conductive heating paper prepared by the invention can heat uniformly, has high thermal conversion efficiency, near zero electromagnetic radiation, extremely small current density, and is safe for usage. In addition, the radiated far infrared light wave can activate water molecules in human body, raise blood oxygen content, enhance cell vitality, improve human body microcirculation and promote metabolism.

Owner:SHANGHAI RELI TECH GRP CO LTD

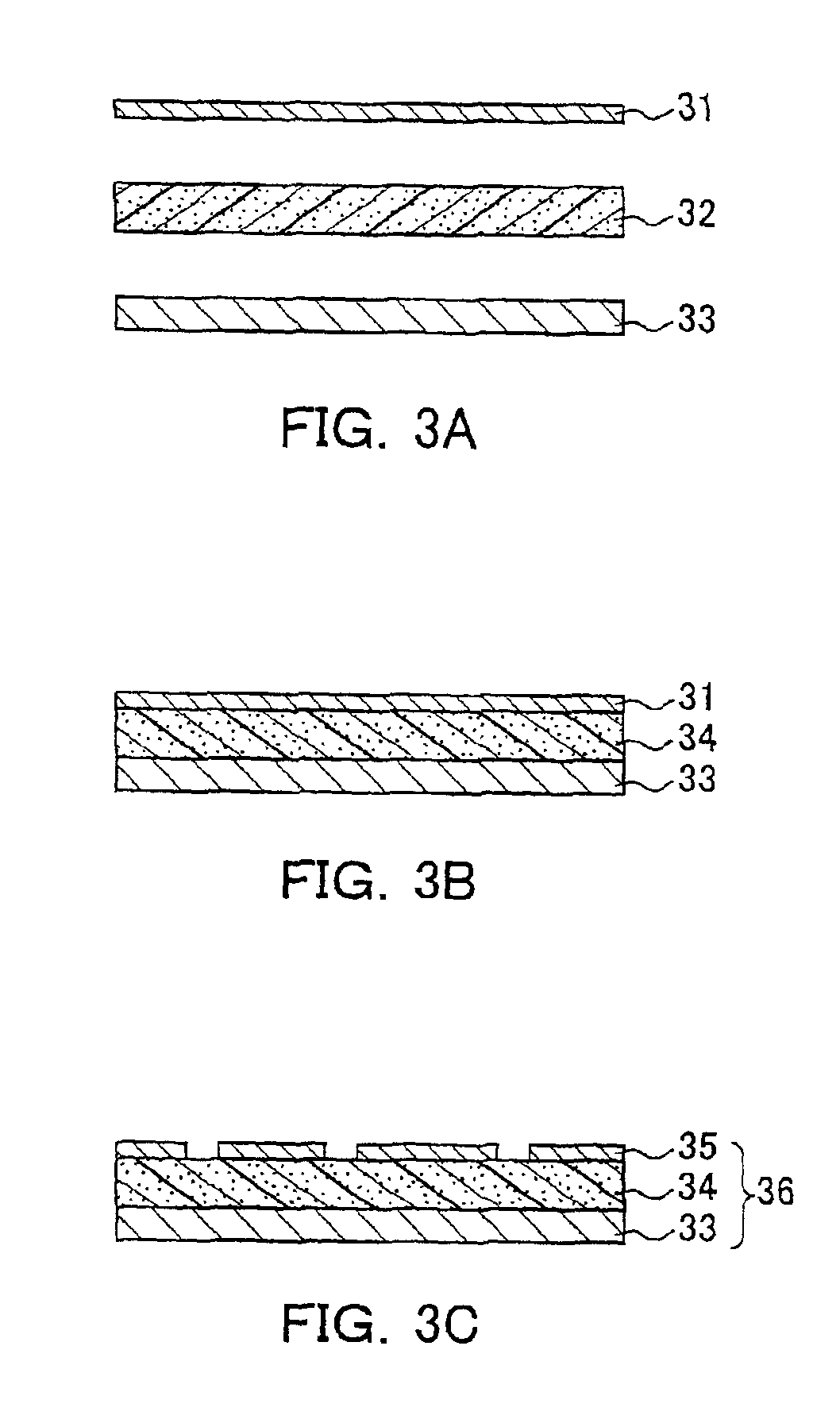

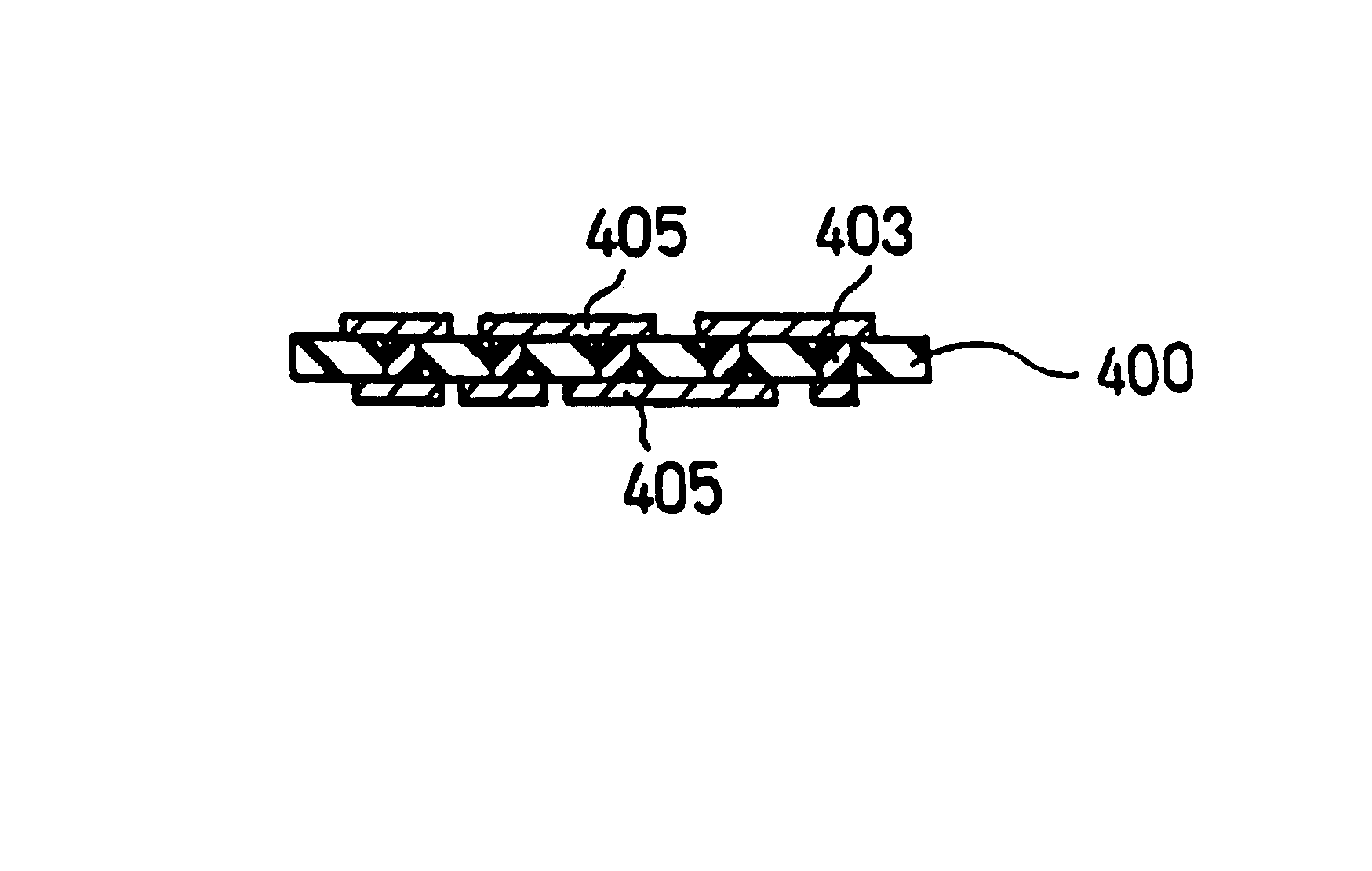

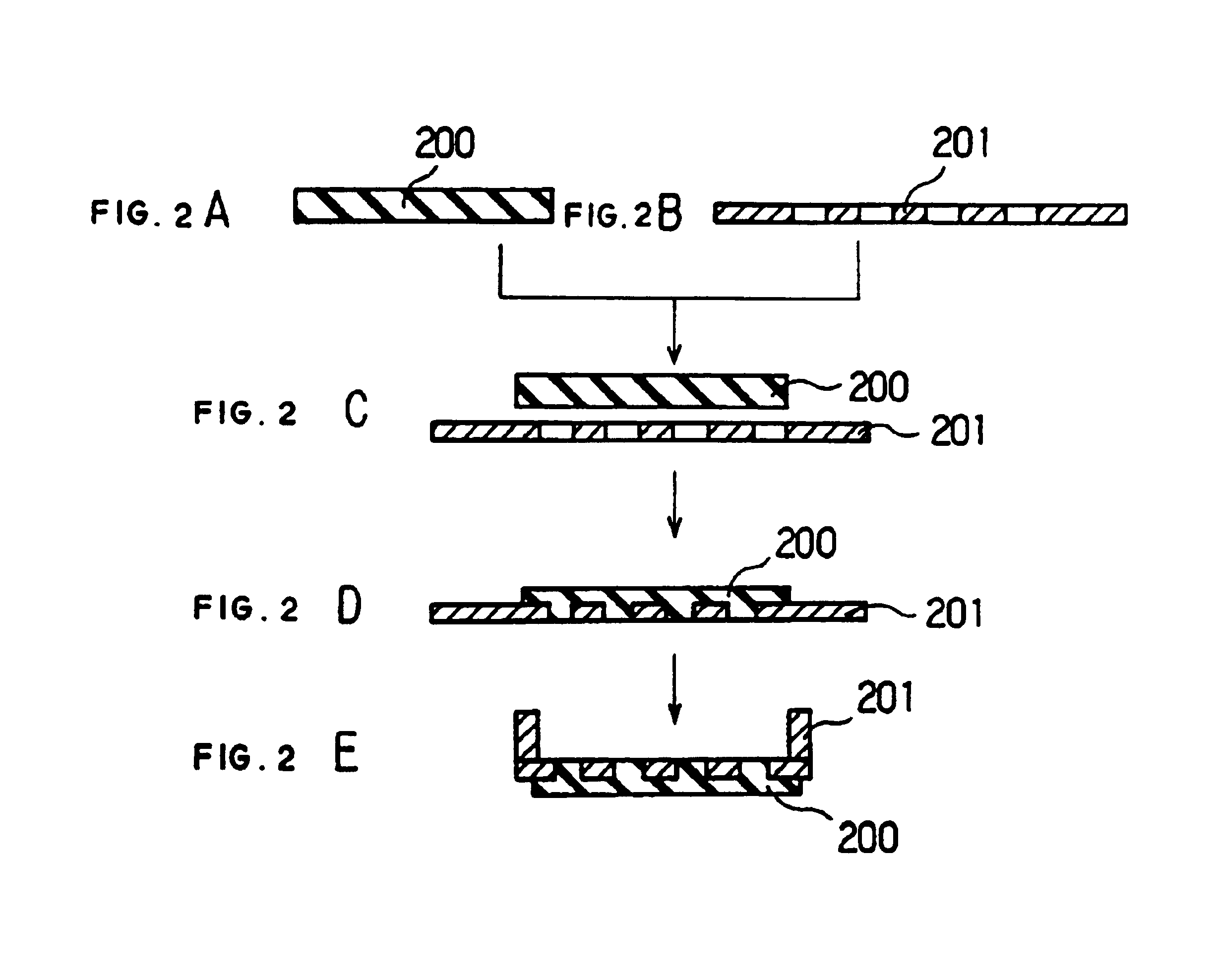

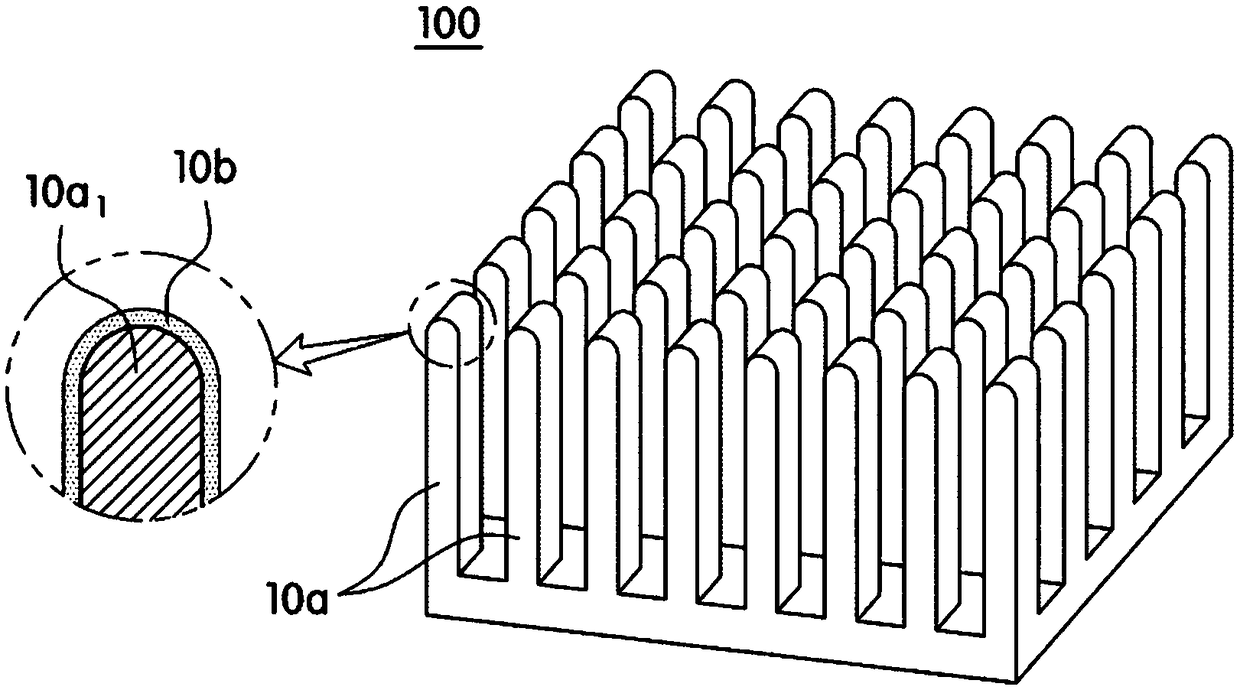

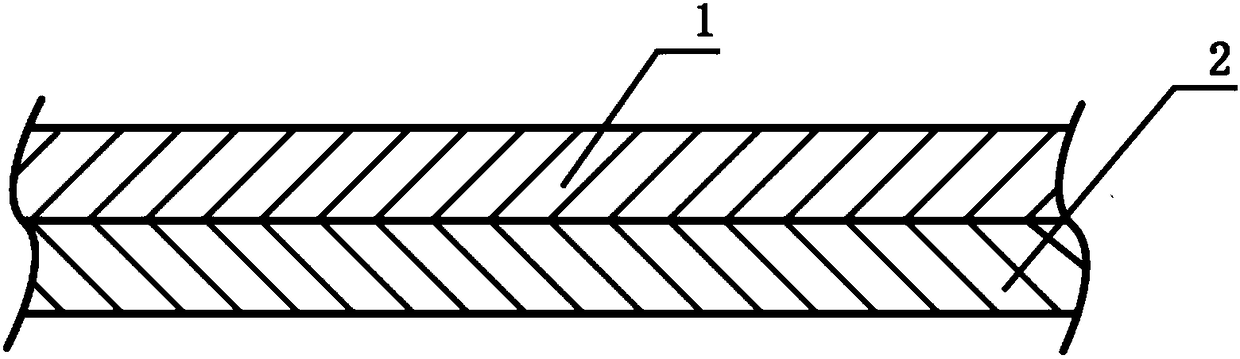

Sheet for a thermal conductive substrate, a method for manufacturing the same, a thermal conductive substrate using the sheet and a method for manufacturing the same

InactiveUS6863962B2Good thermal radiation performanceImprove thermal conductivitySemiconductor/solid-state device detailsLaminating printed circuit boardsThermal radiationLead frame

A thermally conductive substrate having a structure in which inorganic filler for improving the thermal conductivity and thermosetting resin composition are included. The thermosetting resin composition has a flexibility in the not-hardened state, and becomes rigid after hardening. The thermally conductive substrate has excellent thermal radiation characteristics. The method of manufacturing the thermally conductive substrate includes: piling up (a) the thermally conductive sheets comprising 70 to 95 weight parts of an inorganic filler, and 4.9 to 28 weight parts of a thermosetting resin composition, the thermosetting resin composition comprising at least one thermosetting resin, a hardener and a hardening accelerator, and (b) lead frame on which a wiring is formed; thermal pressing the pile; filling the thermally conductive sheet to the surface of the lead frame; hardening the thermosetting resin; cutting excess sections of the thermally conductive substrate; and processing the bending perpendicularly for making a removable electrode.

Owner:PANASONIC CORP

LED package structure and manufacturing method, and LED array module

InactiveUS7821027B2Good thermal radiation performanceLow costThyristorSemiconductor/solid-state device detailsLed arrayEngineering

An LED package includes a substrate having an electrically conductive portion and an electrically non-conductive portion composed of an oxide of the conductive portion; an LED mounted on the conductive portion and electrically connected to the conductive portion; a first electrode disposed on the non-conductive portion and electrically connected to the LED by a wire; and a second electrode disposed on the substrate and electrically connected to the LED.

Owner:SAMSUNG ELECTRONICS CO LTD

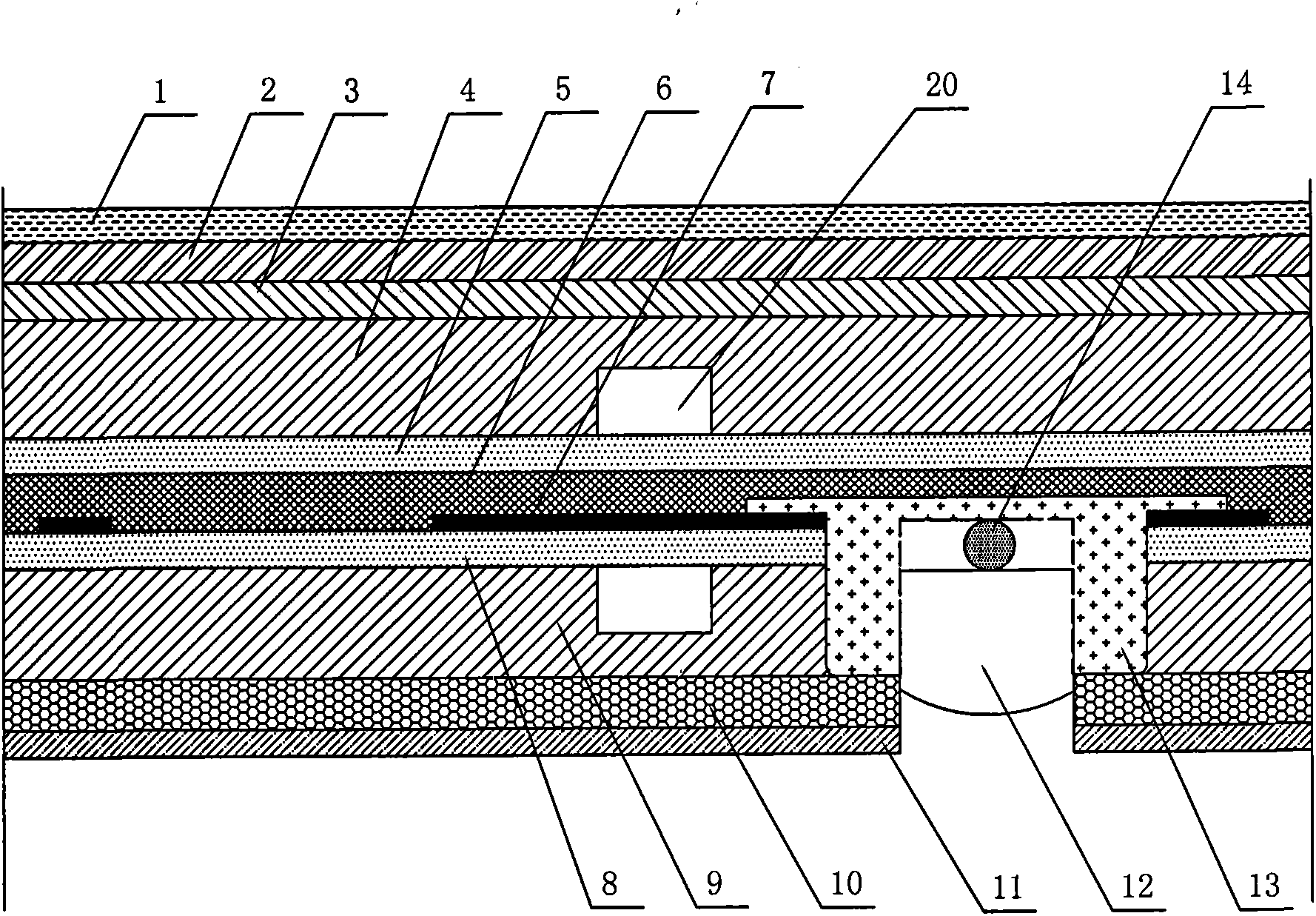

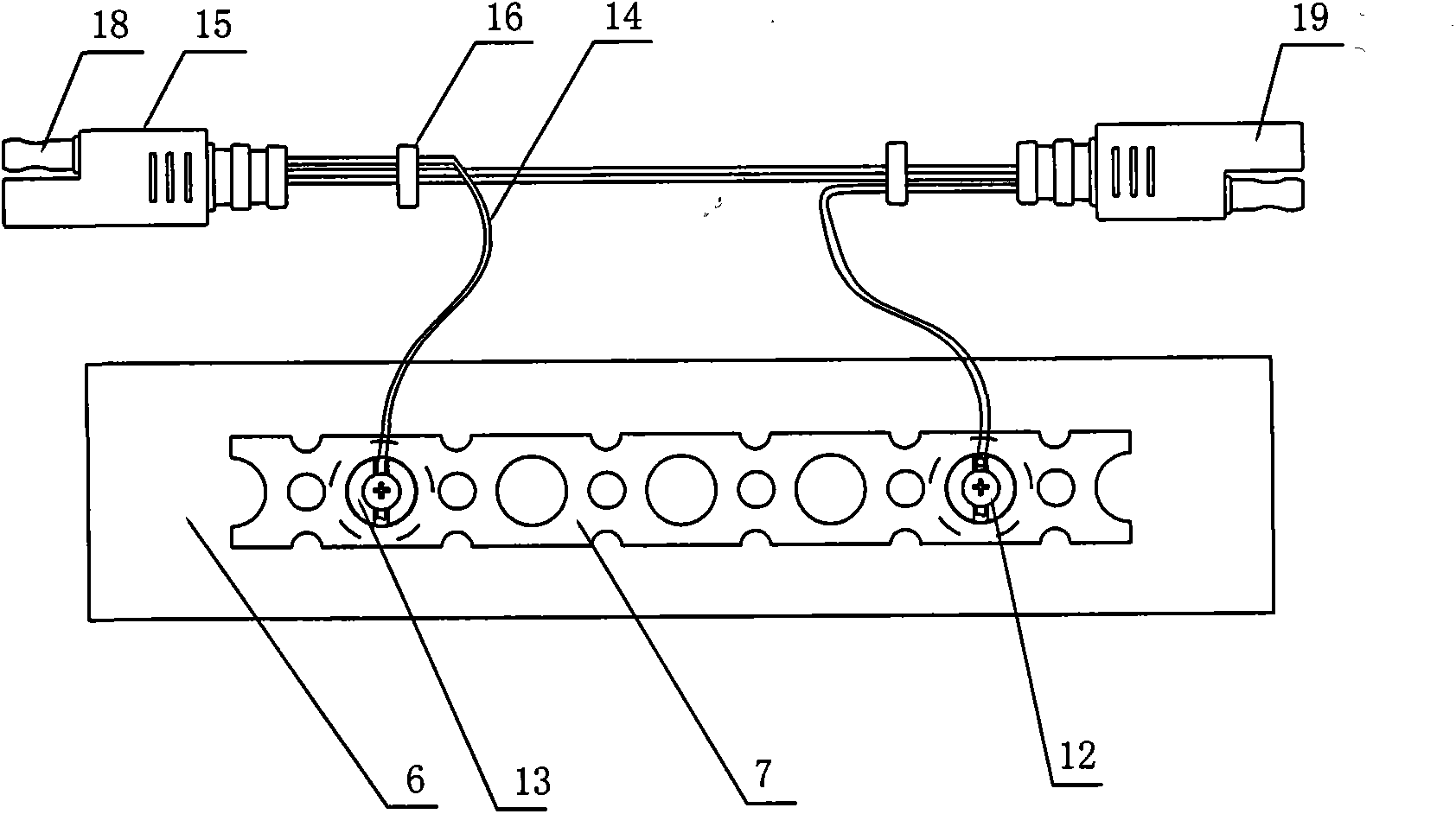

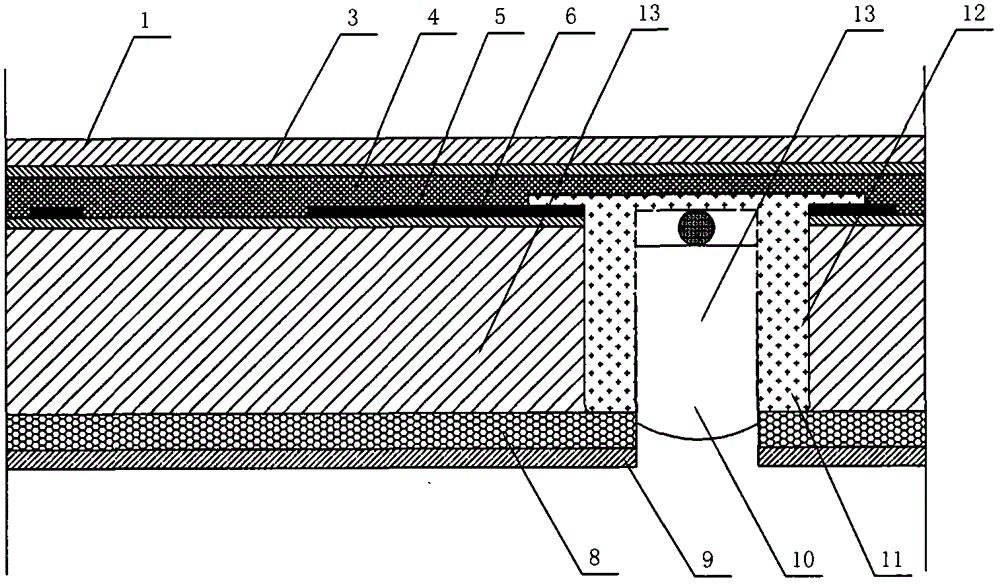

Heating enhanced floor

InactiveCN103644595AFix security issuesSolve efficiency problemsLighting and heating apparatusElectric heating systemFiberInsulation layer

The invention discloses a heating enhanced floor, and belongs to the technical field of wood floors. The heating enhanced floor comprises wear-resistant paper, decorative paper, balance paper, a substrate, impregnated paper, far-infrared carbon fiber heating paper, a conducting metal plate for a heating floor, a connection terminal, a waterproof two-way male and female plug power cord, a heat insulation layer and an aluminum foil. The heating enhanced floor is manufactured by the steps: preparing raw materials; preparing the substrate; assembling a plate blank; fitting the plate blank; laminating the heating enhanced floor; sawing a plate; mounting the waterproof two-way male and female plug power cord; performing inspection by electrifying; mounting a male and female plug junction box; treating the heat insulation layer; covering the aluminum foil; packaging the heating enhanced floor. The enhanced wood floor has the advantages of safety, energy conservation, high heat efficiency, high speed, simplicity in use, low cost, long service life and health care and maintenance.

Owner:欧邦智能家居(武汉)有限公司

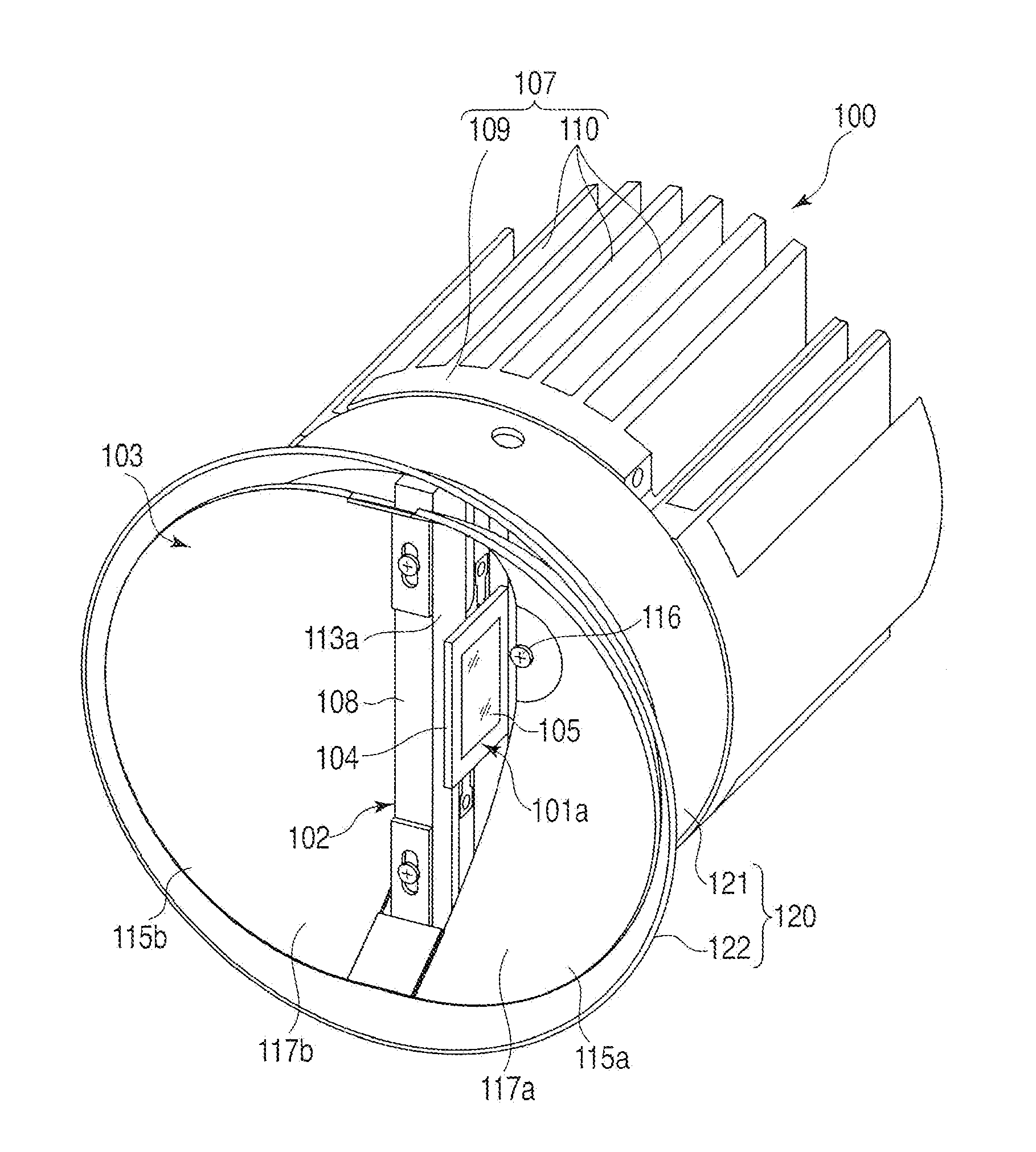

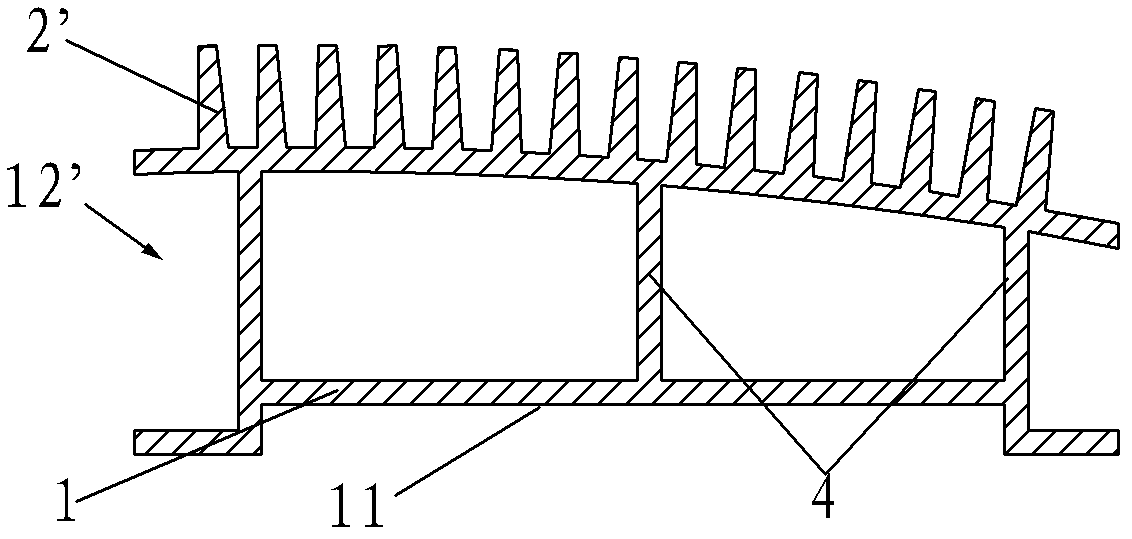

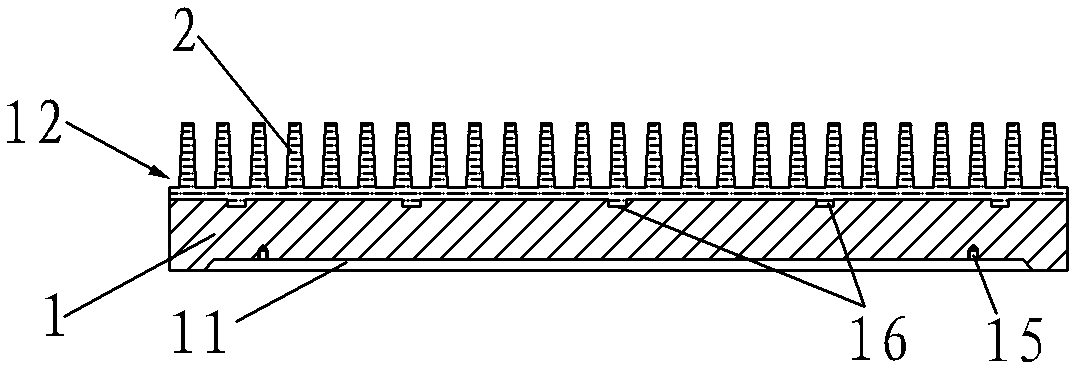

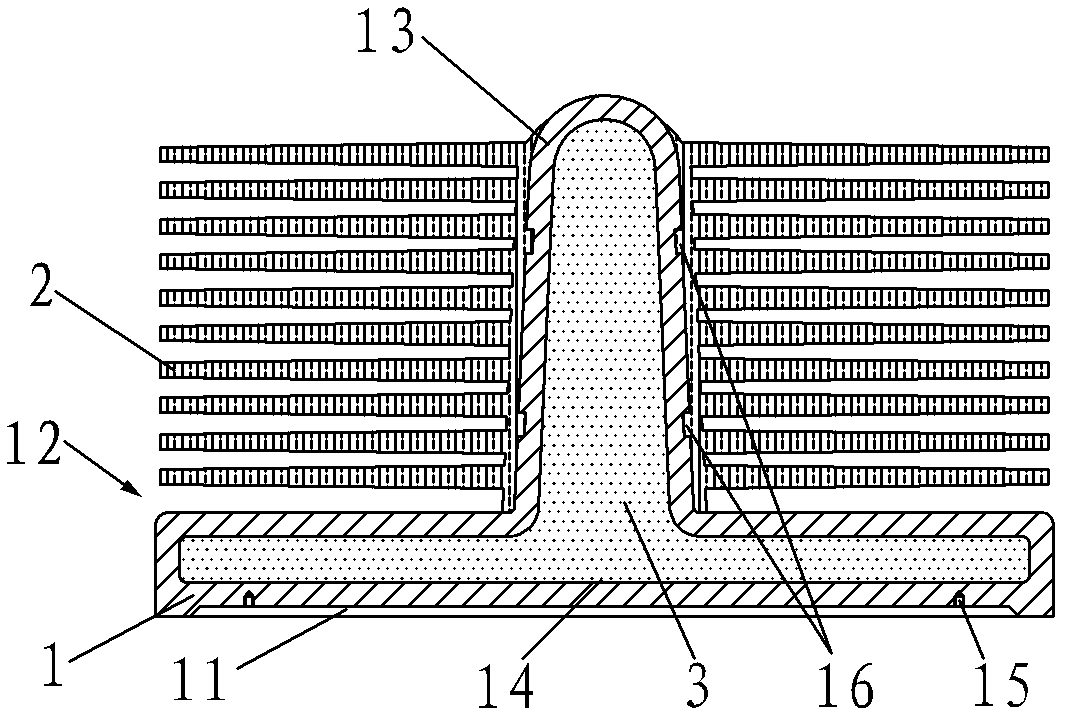

Heat sink for LED (light-emitting diode) lamp holder

InactiveCN102654280AExtended service lifeGood thermal radiation performancePoint-like light sourceLighting heating/cooling arrangementsEngineeringGraphite

The invention relates to the technical field of electronic cooling devices, in particular relates to a heat sink for an LED (light-emitting diode) lamp holder. The heat sink for the LED lamp holder is characterized by comprising a metal heat dissipation base plate, the other side of the base plate is a heat dissipation surface, the heat dissipation surface is provided with a graphite heat dissipation fin, when an LED lamp is arranged on the heat sink, heat produced by a chip is conducted onto the metal base plate, the metal base plate rapidly conducts the heat to the graphite heat dissipation fin, the heat conducted to the fin can be lost in a convection current manner and a radiation manner as graphite has good thermal radiation effect, and the heat produced by a chip of an LED circuit board can be effectively conducted away even in poor airflow or airtight environment, and a phenomenon that the LED lamp is invalid owning to overheating can be avoided, thus the service life of the LED lamp is prolonged; and hidden troubles, such as a fire, caused by overheating can be avoided.

Owner:东莞市盈通光电照明科技有限公司

Insulating and heat dissipating coating composition, and insulating and heat dissipating unit formed thereby

PendingCN109153868AImprove adhesionGood dispersionEpoxy resin coatingsCooling/ventilation/heating modificationsPolymer scienceOrganic solvent

An insulating and heat dissipating coating composition is provided. According to one embodiment of the present invention, the insulating and heat dissipating coating composition contains: a coating layer formation component comprising a base resin; and an insulating and heat dissipating filler. Therefore, the coating composition has excellent thermal conductivity and excellent heat dissipation, thereby exhibiting excellent heat dissipation performance and simultaneously enabling an insulating and heat dissipating coating layer having insulation to be implemented. In addition, a heat dissipation coating layer implemented thereby has very excellent adhesion to a surface to be coated, thereby remarkably preventing the separation of a coating layer during use and, after the coating layer is formed, enabling the durability of a coating layer to be maintained even in the presence of physical and chemical stimuli such as external heat, organic solvents, moisture, and impact. Furthermore, theformed insulating and heat dissipating coating layer has a very smooth surface and excellent smoothness so as to have excellent surface quality, thereby being widely applicable to all industries requiring simultaneous insulation and heat dissipation.

Owner:AMOGREENTECH CO LTD

Graphene mica double-layer paper, preparation method and application of paper and mica electric heating plate containing paper or mica electric heating device containing paper

InactiveCN108797190AGood thermal radiation performanceThermally stableDefoamers additionPaper coatingPapermakingMica

The invention provides graphene mica double-layer paper, a preparation method and application of the paper and a mica electric heating plate containing the paper or a mica electric heating device containing the paper. The graphene mica double-layer paper is good in heat resistance, nonflammable and resistant to acid and alkali, has good heat dissipation performance and can be applied to the thermoelectric device, heat generated when the electric heating device runs is quickly and evenly dispersed into the surrounding environment through an infrared radiation mode, the reliability of the thermoelectric device during running is improved, and the service life of the thermoelectric device is prolonged. Meanwhile, graphene and mica are used as raw materials, the paper is obtained through mica smashing, separation, papermaking and graphene spraying, and the graphene mica double-layer paper has the advantages that the raw materials are easily obtained, the preparation method involves steps easy and convenient to implement, and the prepared graphene mica double-layer paper has the good heat dissipation performance.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

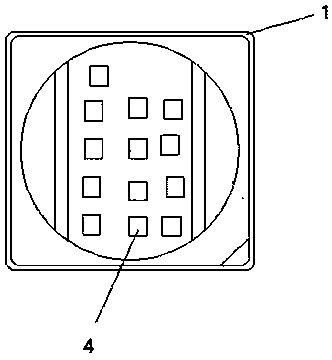

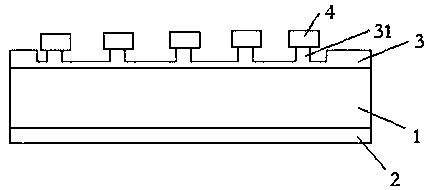

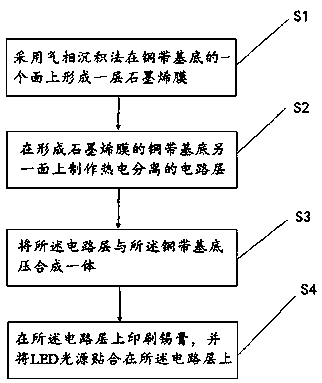

Flexible LED (light-emitting diode) light-emitting structure based on graphene material and manufacturing method thereof

The invention provides a flexible LED (light-emitting diode) light-emitting structure based on graphene material. The flexible LED (light-emitting diode) light-emitting structure based on the graphenematerial is characterized in that the flexible LED light-emitting structure comprises a copper tape substrate, a graphene film arranged on one side of the copper tape substrate, and a circuit layer disposed on the other side of the copper tape substrate; a plurality of LED light sources are attached to the circuit layer; due to the excellent thermal and thermal radiation properties of the graphene film, thermal conductivity becomes easy; the flexible LED light structure of the whole being light and thin can be used directly and achieve a certain degree of free bending with no metal radiatorsneeded to be attached; thus, directly through the heat sink of the LED light sources, all the heat is directly transferred to the copper tape substrate provided with the graphene film, and the graphene film on one side of the copper tape substrate can quickly dissipate the heat generated by the LED light sources. The flexible LED light-emitting structure has the advantage of having good heat dissipation effect. Further provided is a manufacturing method of the flexible LED light-emitting structure based on the graphene material.

Owner:SHENZHEN GUANGMAO ELECTRONICS

Far infrared energy-saving paint and preparation method therefor

InactiveCN104844139ASuitable for a wide temperature rangeImprove general performanceFar infraredKiln

The present invention relates to a far infrared energy-saving paint and a preparation method therefor, which belong to the technical field of ceramic paint, and are mainly used for high-temperature kiln furnaces, steam boilers, fuel automobiles, ships and other industries to achieve energy saving purposes. The paint includes the following components in parts by weight: 20 to 40 parts of ceramic micro powder, 30 to 50 parts of binding agent, 1 to 5 parts of accessory ingredient, and 10 to 30 parts of water. The preparation method comprises: first the accessory ingredient and water are added to a reaction kettle in proportion and uniformly mixed, then the ceramic micro powder and the binding agent are added to the reaction kettle in proportion, and the mixture is stirred at 300 to 600 rev / min for 30 to 60 minutes, finally the far infrared energy saving paint of the present invention is obtained.

Owner:DOSHAN NEW STRATEGY INTPROP CULTURECO

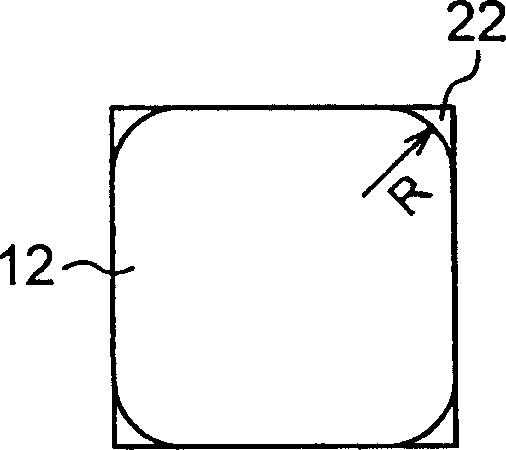

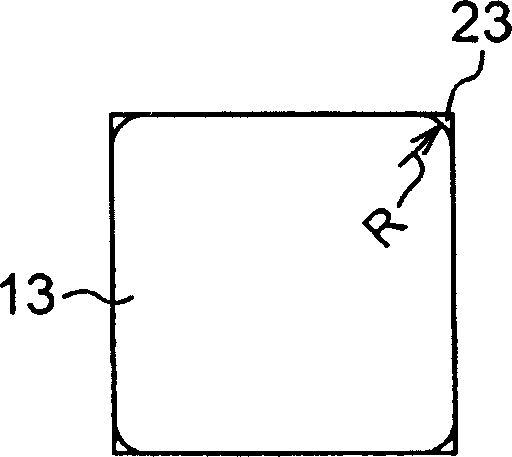

Wire for coil

InactiveCN1617268AImprove performanceGuaranteed reliabilityNon-insulated conductorsTransformers/inductances coils/windings/connectionsSquare cross sectionEngineering

In the coil wire having a square cross-sectional shape, arc-shaped chamfers are provided at four corners of the square cross-section. The cross-sectional area of the coil wire with the chamfer is set to be at least 1.15 times the cross-sectional area of a circle having the same diameter as the length of one side of the square.

Owner:GOTO DENISH CO LTD

Thermally conductive sheet, cured product thereof, and semiconductor device

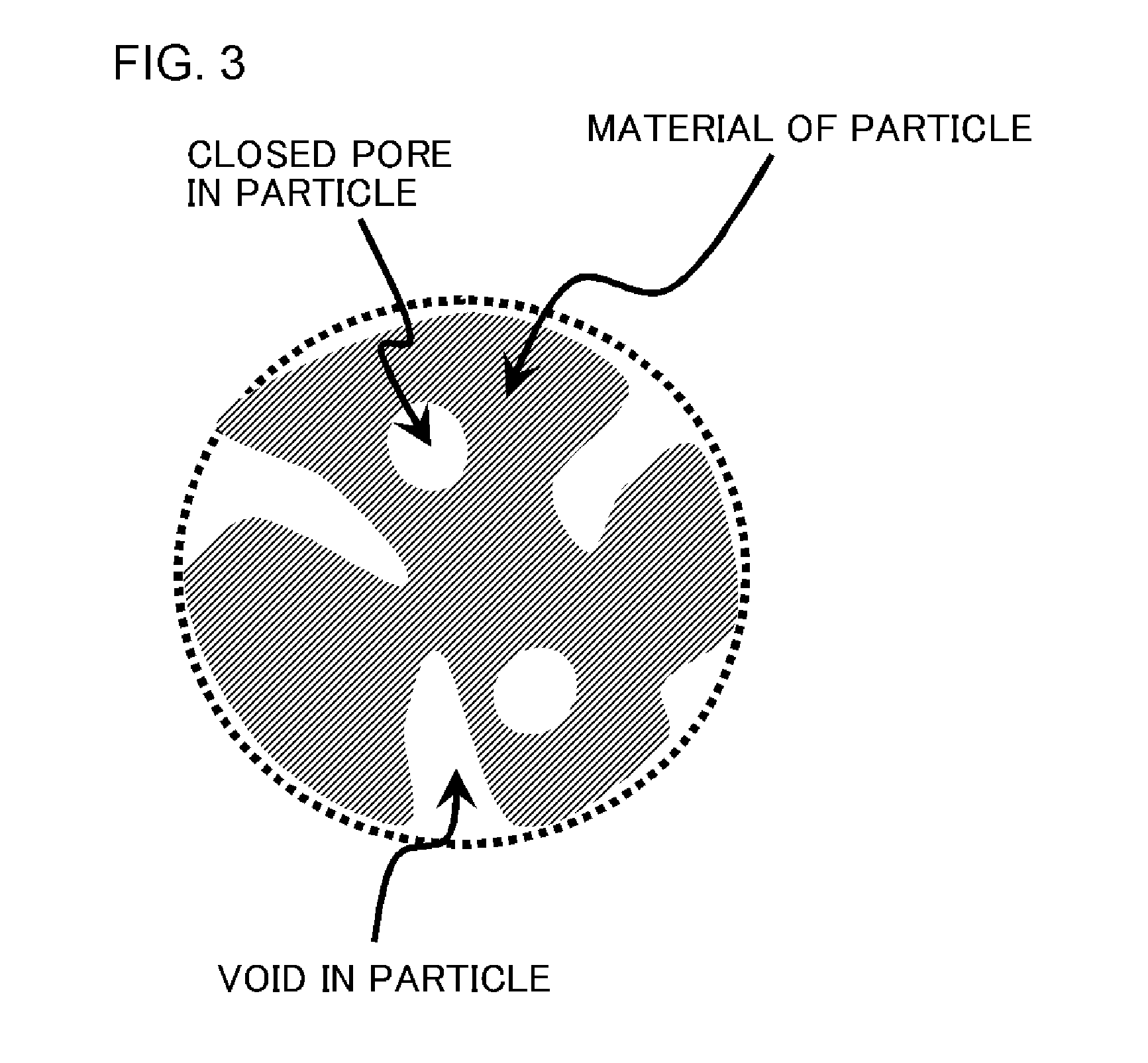

InactiveUS20160002445A1Improve reliabilityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesPore diameterIncineration

A thermally conductive sheet includes a thermosetting resin and an inorganic filler material dispersed in the thermosetting resin. Measuring a pore diameter distribution through mercury intrusion technique for the inorganic filler material included in an incineration residue after a cured product of the thermally conductive sheet is heated and incinerated at 700° C. for four hours, a porosity of the inorganic filler material represented as 100×b / a is greater than or equal to 40% and less than or equal to 65% given that a is the volume of particles of the inorganic filler material included in the incineration residue, and b is the volume of voids in the particles of the inorganic filler material included in the incineration residue. An average pore diameter of the inorganic filler material included in the incineration residue is greater than or equal to 0.20 μm and less than or equal to 1.35 μm.

Owner:SUMITOMO BAKELITE CO LTD

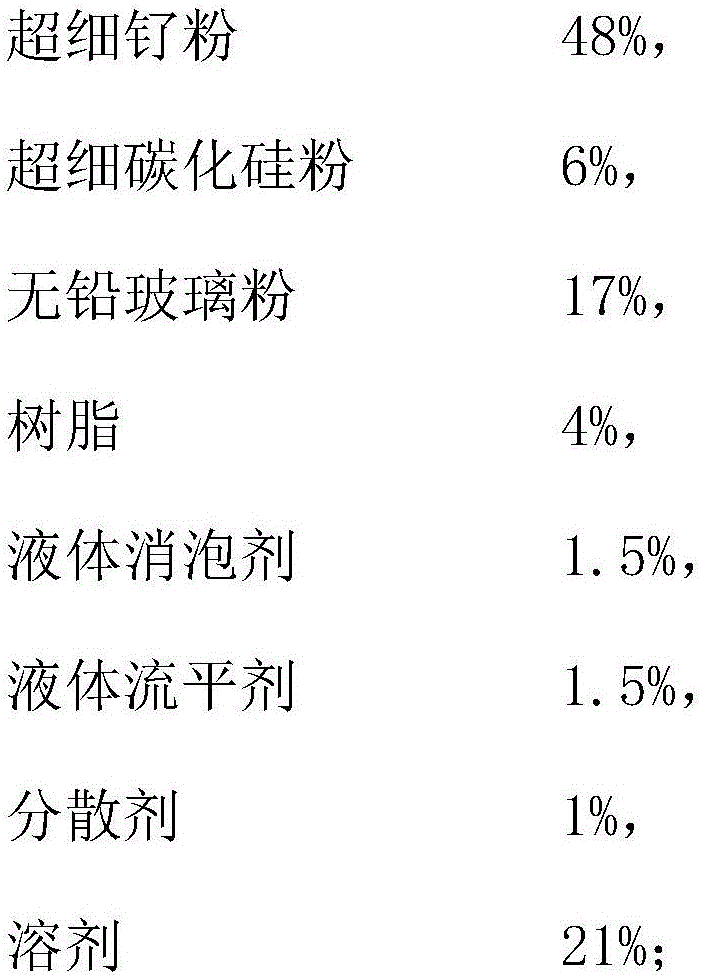

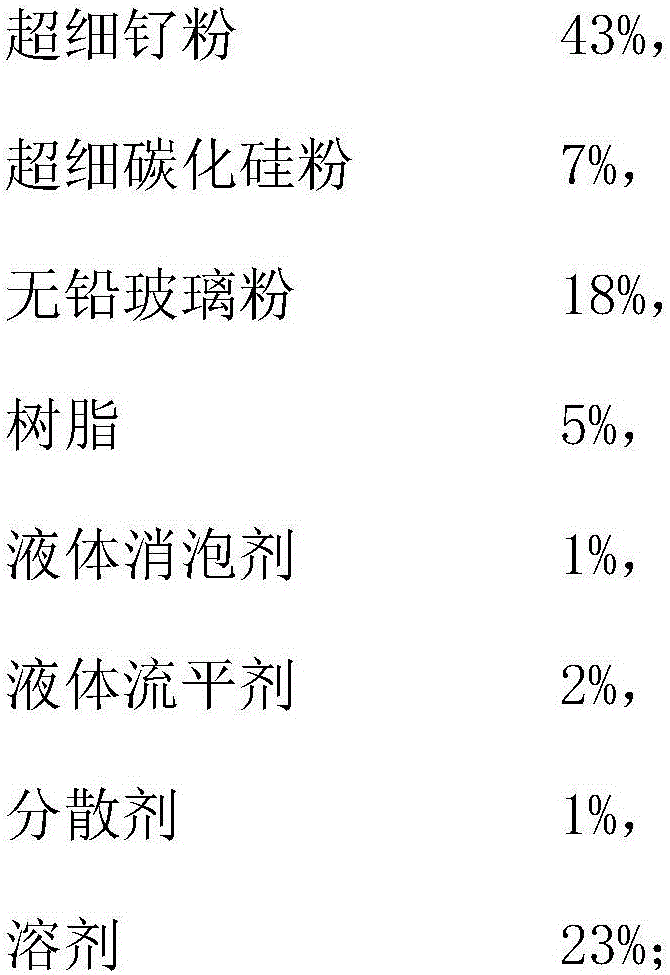

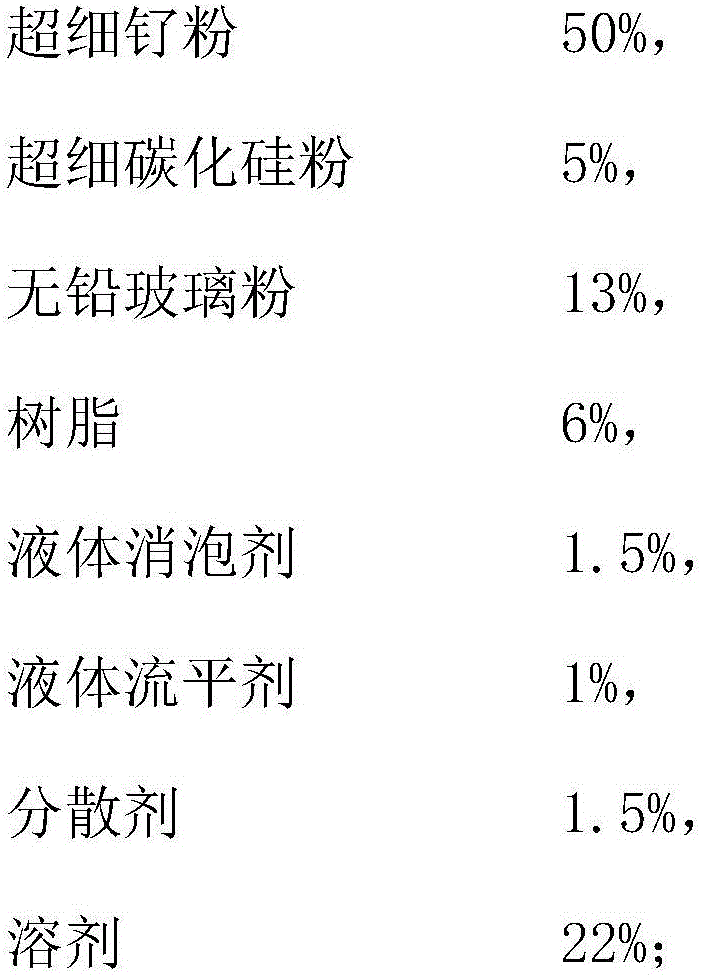

Silicon carbide-ruthenium resistance slurry and preparation method therefor

InactiveCN106211379AIncreased Design FreedomWide coefficient of power variationHeating element materialsDispersityRuthenium

The invention discloses silicon carbide-ruthenium resistance slurry. The silicon carbide-ruthenium resistance slurry comprises a functional phase and an organic carrier, wherein the functional phase comprises ultrafine ruthenium powder, ultrafine silicon carbide powder and lead-free glass powder; the organic carrier comprises resin, a solvent and additives; the resin is ethylcellulose; the solvent is one or mixture of two of butyl carbitol, terpilenol and a DBE solvent; and the additives comprise a liquid defoaming agent, a liquid flatting agent and a lubricating dispersing agent. The invention also discloses a preparation method for the silicon carbide-ruthenium resistance slurry. The silicon carbide-ruthenium resistance slurry is high in dispersity and cosolvency, high in adhesive force with a base material, excellent in temperature resistance, safe to use, and low in preparation cost.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

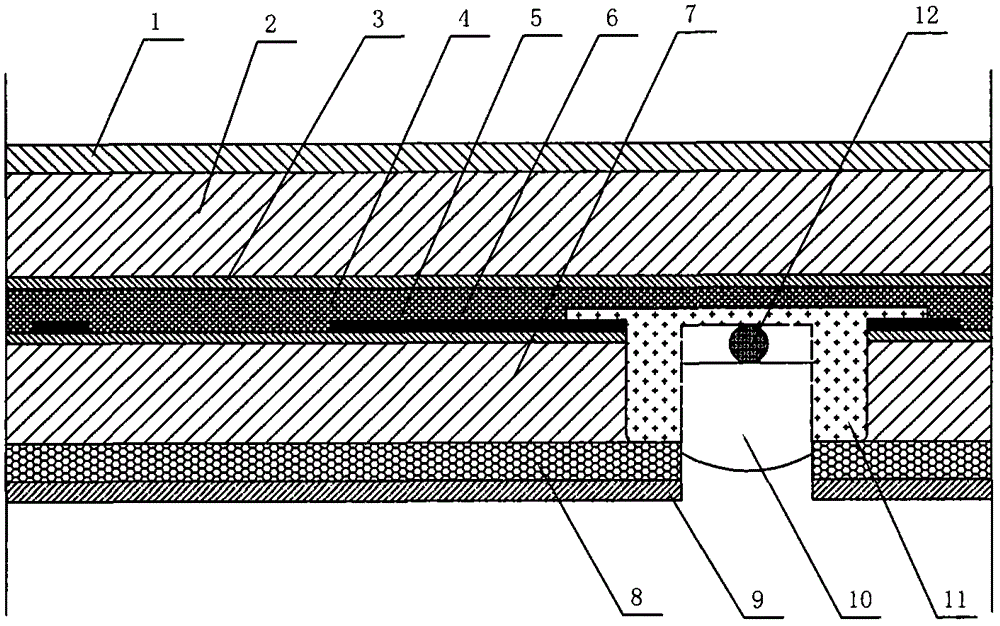

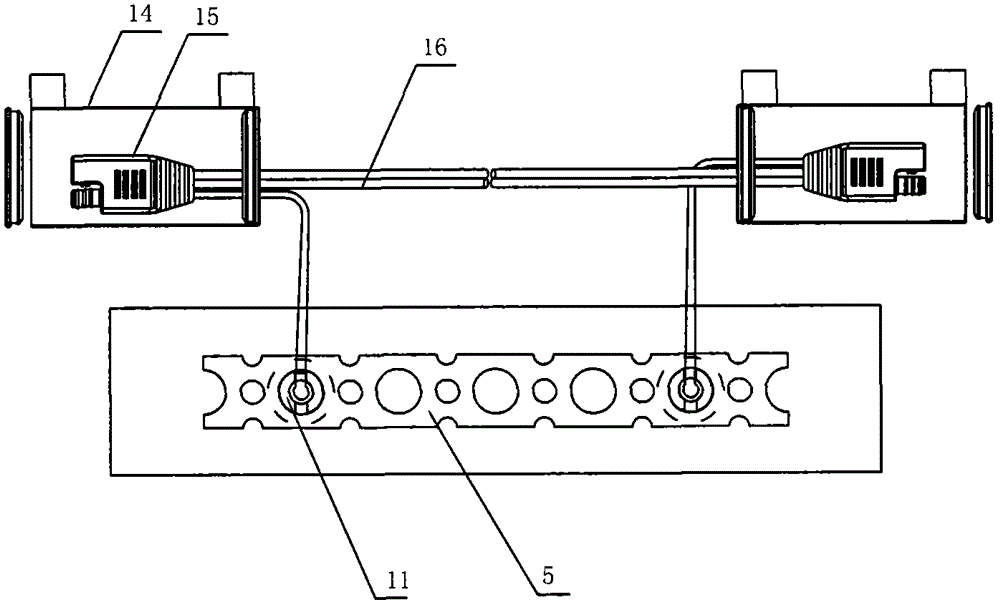

Multilayer solid wood heating floor

InactiveCN103982934AFix security issuesSolve efficiency problemsLighting and heating apparatusElectric heating systemEnvironmental resistanceSolid wood

The invention provides a multilayer solid wood heating floor and belongs to the technical field of wood floors. The multilayer solid wood heating floor comprises a substrate plate, a decorative layer, far-infrared carbon fiber heating paper, an insulating layer, an aluminum foil, a heating floor conductive metal sheet and heating floor connecting terminals, wherein the substrate plate, the far-infrared carbon fiber heating paper and the decorative layer are pressed and integrally molded into a floor blank; the lower surface of the floor blank is provided with the insulating layer and the aluminum foil layer; two ends of the far-infrared carbon fiber heating paper in the floor bland are respectively provided with one heating floor connecting terminal; the connecting terminals are connected to a power supply by virtue of heating floor waterproof two-way male / female insulated plug power lines. The multilayer solid wood heating floor is characterized in that the substrate plate is prepared by pressing solid wood veneer; the far-infrared carbon fiber heating paper is arranged in the substrate plate and also can be arranged between the substrate plate and the decorative layer. The multilayer solid wood heating floor has the characteristics of safety, energy conservation, high thermal efficiency, high speed, simplicity in use, low cost and long service life; the solid veneer is adopted, so that the multilayer solid wood heating floor is environment-friendly and pollution-free.

Owner:欧邦智能家居(武汉)有限公司

Carbon glue thick-film resistor sizing

InactiveCN104464892AImprove printing effectImprove wettabilityNon-conductive material with dispersed conductive materialNon-adjustable resistorsCelluloseUltra fine

The embodiment of the invention discloses carbon glue thick-film resistor sizing. The carbon glue thick-film resistor sizing comprises, by mass, 3 parts of anti-flaming temperature-resistance high-molecular polymer including boron, 1.5 parts of nanometer carbon system electric conduction packing, 12 parts of electric conduction phase graphite powder, 4 parts of ultra-fine base metal ally powder electric conduction packing, 0.6 part of tributyl citrate, 0.6 part of cellulose nitrate, 32 parts of o-methyl novolac epoxy resin, 5-10 parts of silver and palladium alloy powder, 5 parts of coupling agent, 25 parts of linear phenolic resin, 13 parts of ethylene glycol diglycidyl ether and 7 parts of microcrystal glass powder. Through tests and analyses, it is shown that a resistor prepared through the carbon glue thick-film resistor sizing is good in performance.

Owner:CHANGSHU LIANMAO ELECTRONICS TECH

Far infrared radiation carbon fiber electric-thermal composite fabric and preparation method thereof

ActiveCN111186183AImprove heat resistanceImprove thermal stabilityOhmic-resistance electrodesCarbon fibresFiberCarbon fibers

The invention discloses a far infrared radiation carbon fiber electric-thermal composite fabric and a preparation method thereof. The composite fabric comprises a far infrared radiation carbon fiber fabric arranged between two layers of flexible fabric matrixes; and an electrode plate is arranged in the far infrared radiation carbon fiber fabric. The preparation method comprises the following steps: pretreating the carbon fiber fabric to obtain a desized carbon fiber fabric; dipping the carbon fiber fabric in a dopamine solution to obtain a dopamine biomimetic modified carbon fiber fabric; spraying far infrared slurry on the dopamine biomimetic modified carbon fiber fabric to obtain a far infrared radiation carbon fiber fabric; and compounding all the layers to obtain the far infrared radiation carbon fiber electric-thermal composite fabric. The composite fabric prepared by the invention not only ensures the electric-thermal stability and heating uniformity of the fabric, but also hasgood far-infrared radiation performance, and can realize the application of the electric-thermal fabric in the fields of human body clothing, intelligent wearable articles, cold-proof thermal insulation materials, greenhouse heat sources and the like.

Owner:DONGHUA UNIV

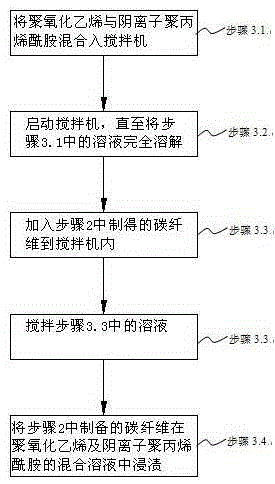

A kind of far-infrared carbon fiber low-temperature conductive heating paper and preparation method thereof

InactiveCN102226325BIncrease surface areaPass wellNon-fibrous pulp additionSpecial paperFiberCarbon fibers

A far infrared carbon fiber low temperature conductive heating paper comprises an original pulp board, carbon fibers, nano far infrared negative ion powder and a diffusant. According to the invention, paper pulp is beaten and added with carbon fibers treated with carbonization processing, water phase processing and hydrophilism processing for dipping; after homogenizing and beating again, resistor of a mixed slurry is measured, and mixed slurry with a resistor within 2%-10% is manufactured into paper. The far infrared carbon fiber low temperature conductive heating paper prepared by the invention can heat uniformly, has high thermal conversion efficiency, near zero electromagnetic radiation, extremely small current density, and is safe for usage. In addition, the radiated far infrared light wave can activate water molecules in human body, raise blood oxygen content, enhance cell vitality, improve human body microcirculation and promote metabolism.

Owner:SHANGHAI RELI TECH GRP CO LTD

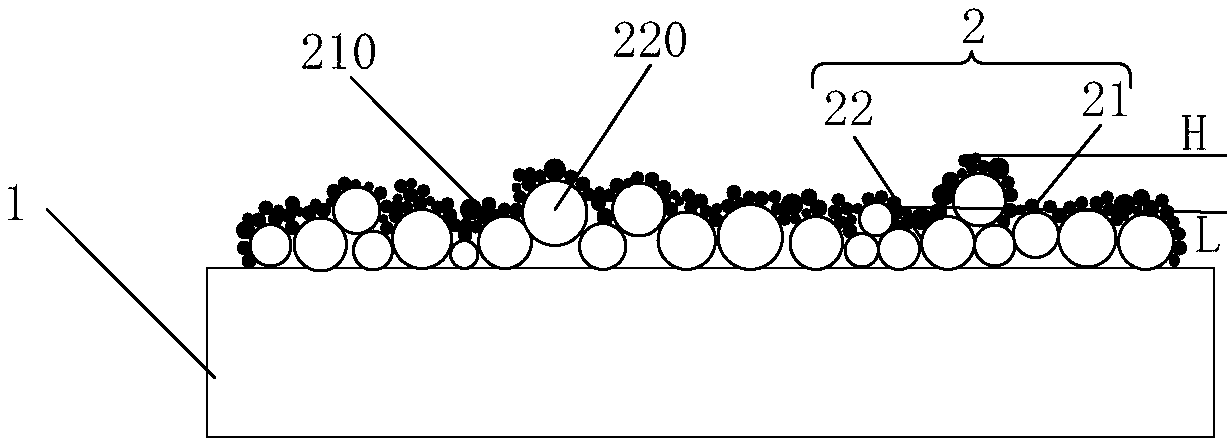

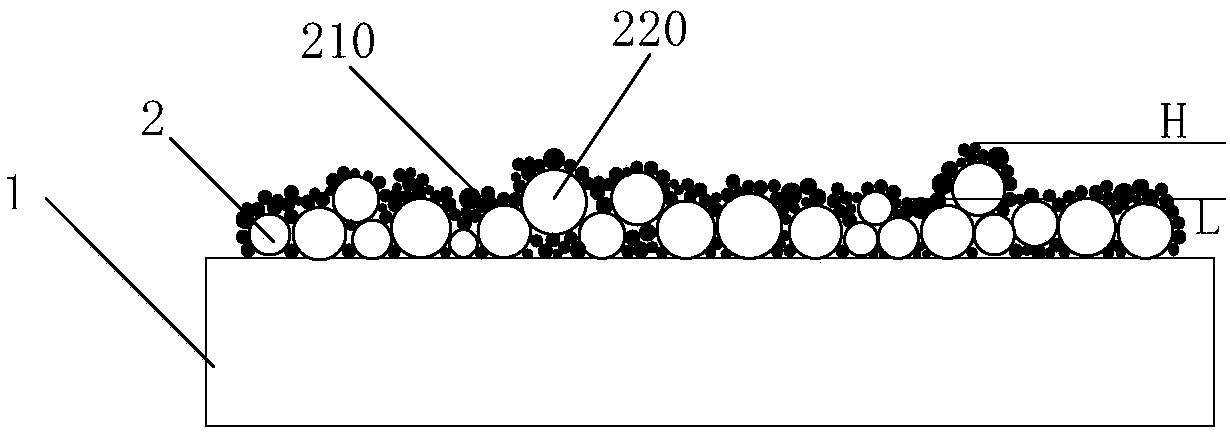

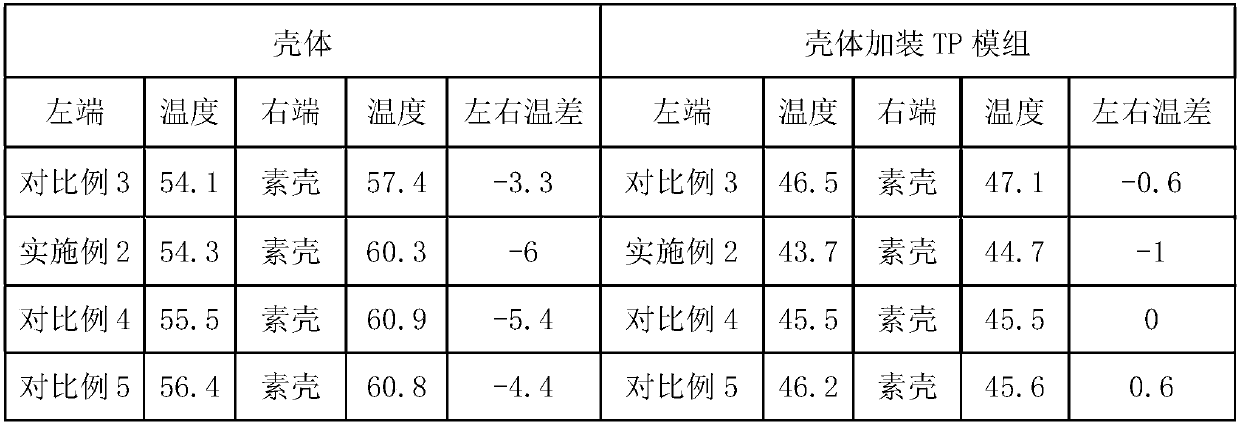

Shell of terminal equipment and processing method of shell

InactiveCN110621135AImprove cooling effectFast heat conductionModifications by conduction heat transferTerminal equipmentMetal particle

The invention provides a shell of terminal equipment and a processing method of the shell. The shell comprises a shell body and a heat conduction layer sprayed on a surface of the shell body, whereinnano carbon particles and heat conduction metal particles are contained in the heat conduction layer, and a surface of the heat conduction layer is provided with an uneven heat dissipation microstructure. The nano carbon particles have excellent heat conduction and heat radiation performance, the heat conduction performance is mainly reflected in heat diffusion transfer, the heat diffusion speed of the nano carbon particles is larger than or equal to 200 mm<2> / S, a heat radiation coefficient is 0.92-0.95, the nano carbon particles have excellent heat conduction performance, moreover, the carbon nanoparticles can form a continuous heat conduction channel on the surface of the shell after being dried, so heat conduction performance can be enhanced, and the heat can be conducted out more quickly. The particle size of the heat conduction metal particles is large, the nano carbon particles and the heat conduction metal particles can form the uneven heat dissipation microstructure on the surface of the shell body, the heat radiation area can be increased, and thereby heat dissipation performance of the heat conduction layer is further improved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

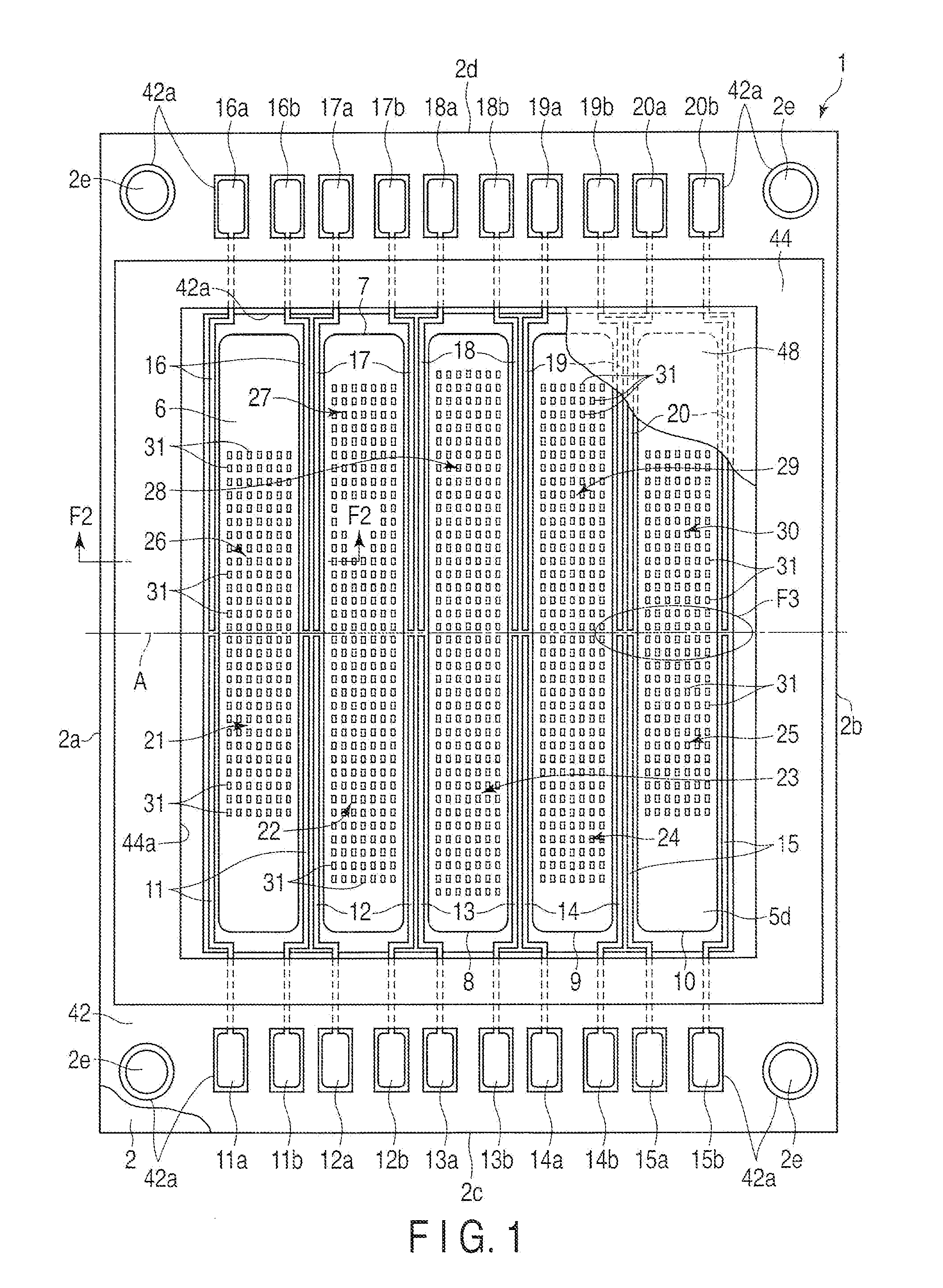

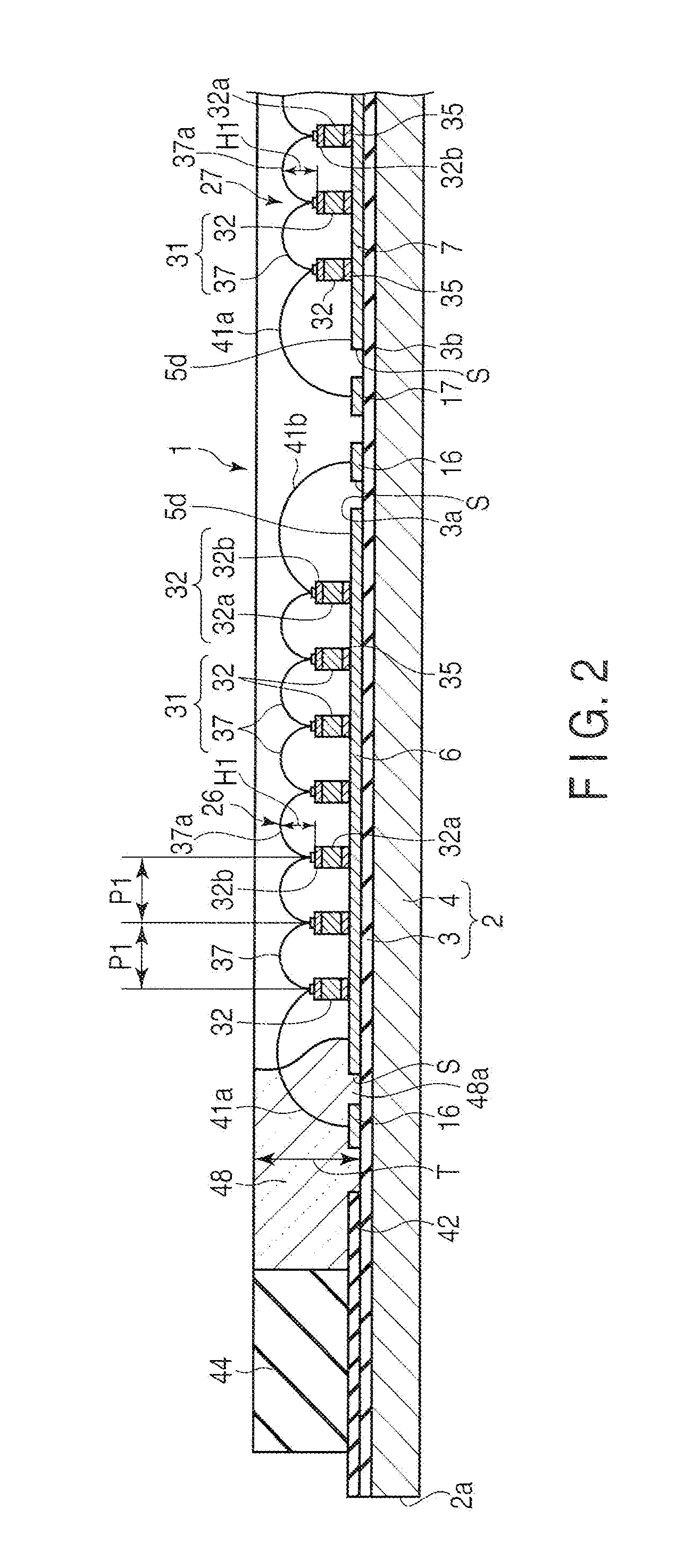

Light emitting module and illumination apparatus

InactiveUS8773612B2Reduce air permeabilityMaintain light reflection propertiesPlanar light sourcesPoint-like light sourceElectrical polarityLight-emitting diode

A light emitting module (1) comprises a module substrate (2), a light emitting diode string (31), and a sealing member (48). The light emitting diode string (31) includes light emitting diode elements (32) and bonding wires (37) which connect the light emitting diode elements (32). The light emitting diode element (32) has a pair of element electrodes (33, 34) and has a rectangular shape extending in a direction along which the element electrodes (33, 34) are aligned. The sealing member (48) is laminated on the module substrate (2) to seal the light emitting diode string (31). The light emitting diode elements (32) are arranged at intervals in a direction crossing the direction along which the element electrodes (33, 34) are aligned, and the element electrodes (33, 34) with the same polarity are aligned to be adjacent to each other in an arrangement direction of the light emitting diode elements (32) between the light emitting diode elements (32) adjacent to each other. Each bonding wire (37) is obliquely wired with respect to the arrangement direction of the light emitting diode elements (32) to connect the element electrodes (33, 34) with different polarities of the light emitting diode elements (32) adjacent to each other.

Owner:TOSHIBA LIGHTING & TECH CORP

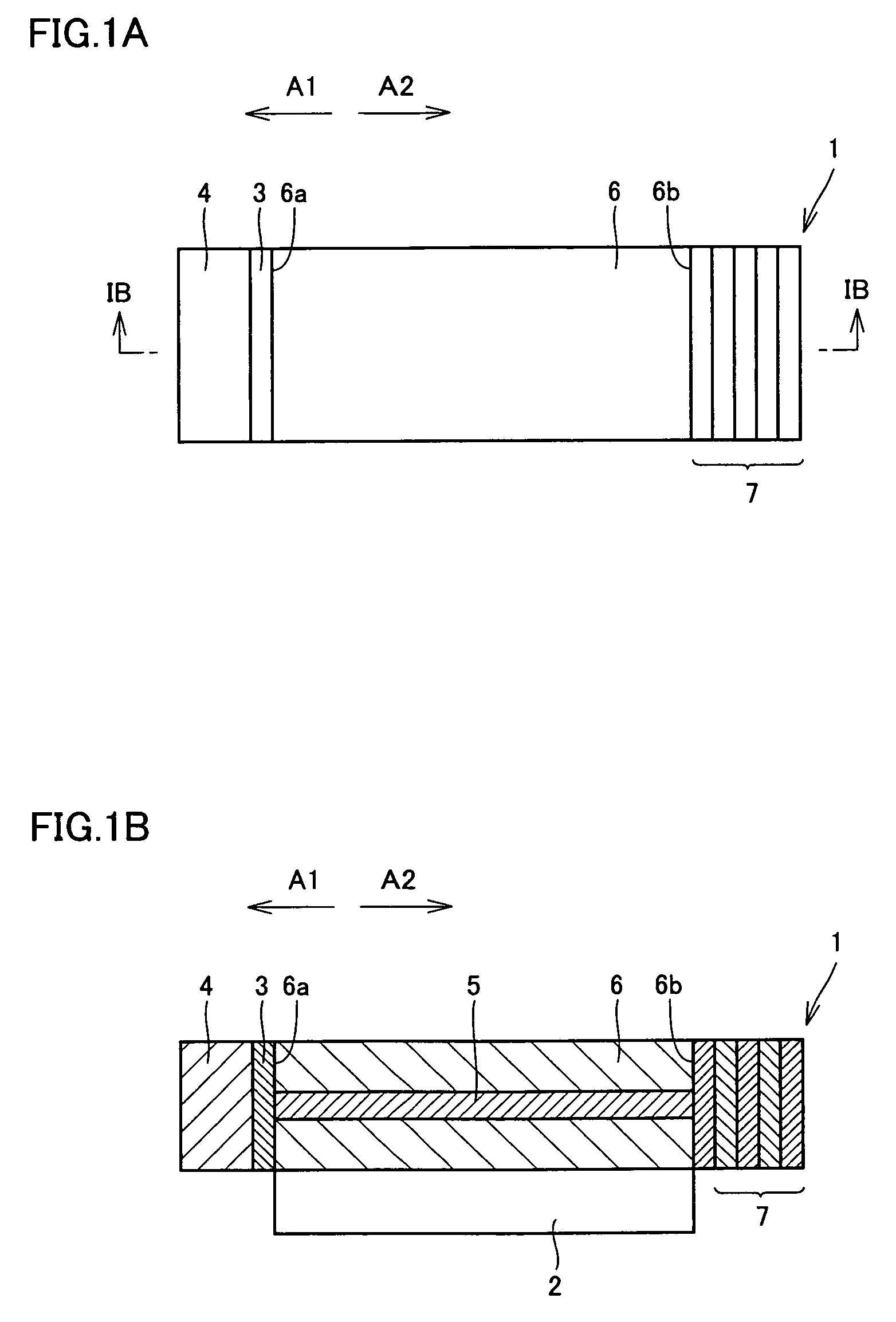

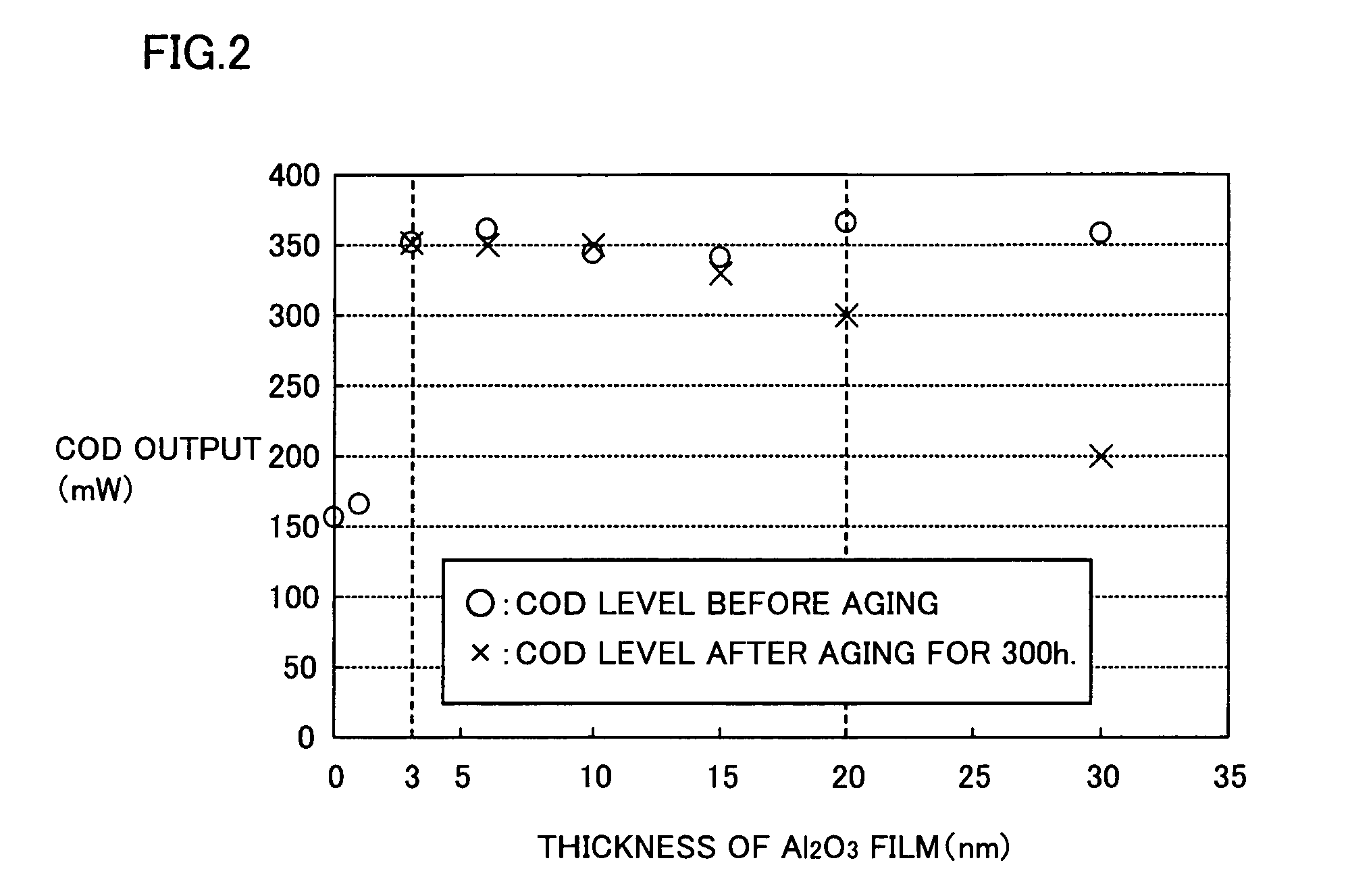

Semiconductor laser diode

ActiveUS7697585B2Reduce yieldSufficient initial characteristicLaser detailsNanoopticsCatastrophic optical damageActive layer

A semiconductor laser diode comprising a semiconductor substrate having an active layer with a pair of cavity facets opposed to each other on both ends of active layer as well as a first dielectric film of an oxide and a second dielectric film of an oxynitride successively stacked on one cavity facet has sufficient initial characteristics with a film structure having excellent heat radiability for allowing stable high-output lasing over a long period without reducing a catastrophic optical damage level on an emission end.

Owner:SHARP FUKUYAMA LASER CO LTD

Carbon fiber composite conductive paper and preparation method thereof

ActiveCN113699824APass wellEase of evacuationNon-fibrous pulp additionSpecial paperFiberCarbon fiber composite

The invention provides carbon fiber composite conductive paper. The carbon fiber composite conductive paper is prepared from raw materials in percentage by mass as follows: 55%-95.9% of matrix fibers, 2%-37.5% of short carbon fibers, 0.2%-2% of a graphene mixture, 0.1%-0.5% of a dispersant and 1.8%-5% of hot-melt adhesive fibers. The invention further provides a preparation method of the carbon fiber composite conductive paper. The problems that an electric heating material prepared from existing conductive paper is uneven in surface heating, too large in temperature difference, unstable in heating performance, short in service life, low in infrared radiance and the like are effectively solved. The carbon fiber composite conductive paper can be widely applied to various planar far infrared electric heating elements.

Owner:上海骏珲新材料科技有限公司 +1

Anticorrosive paint for die-cast aluminum heating radiator and preparation method of anticorrosive paint

InactiveCN107118693ALow surface treatment requirementsNo peelingFireproof paintsNatural resin coatingsPhenolphthaleinPhenol

The invention relates to anticorrosive paint for a die-cast aluminum heating radiator. The anticorrosive paint is composed of the following components in parts by weight: 35-55 parts of Ca-Zn-Se borophosphate, 15-25 parts of ceramic microbeads, 8.5-10 parts of betulin acid, 5-8 parts of modified phenolphthalein, 3-5 parts of iridium-acetylacetonate, 1.5-3.5 parts of acrylic acid, 0.6-1.2 parts of a wetting dispersant, 2.4-2.8 parts of tribenzyl phenol polyoxyethylene ether, 0.3-0.6 part of a thickening agent and 0.65-1.5 parts of an antifoaming agent. The anticorrosive paint disclosed by the invention has the advantages that 1, the production process is simple and reasonable, the input equipment is less, and the production cost is low; 2, the coating surface treatment requirement is low, the adsorption effect is excellent, the adhesive force is high, and the coating does not flake or discolor; 3, leveling and heat radiation effects are excellent, the heat transfer speed is high, and the heat efficiency is high; 4, the anticorrosive paint is resistant to acid, base and salt corrosion and seawater corrosion and excellent in anticorrosive effect; 5, the wear resistance and impact resistance are high.

Owner:ZHEJIANG YANGMING IND & TRADE CO LTD

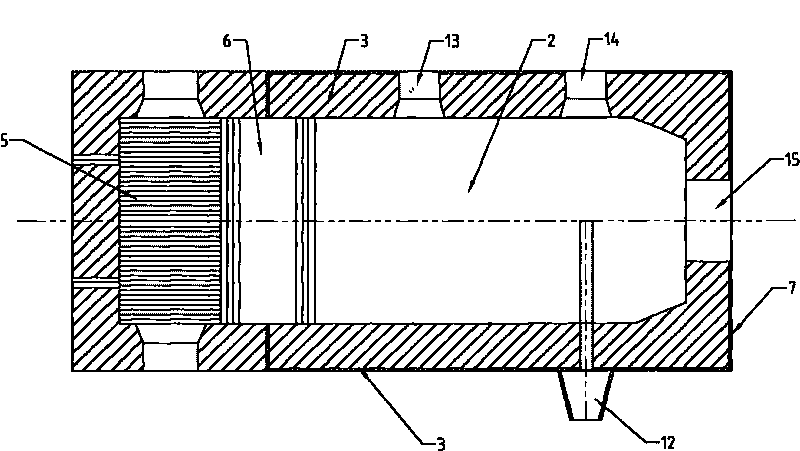

Reflecting furnace for smelting tin lead materials

ActiveCN101762150AReduce headroomHeating fastLighting and heating apparatusProcess efficiency improvementMelting tankSlag

The invention relates to a reflecting furnace for smelting tin lead materials, belonging to smelting equipment. The reflecting furnace is mainly composed of a furnace hearth (1), a furnace bottom smelting tank (2), a furnace wall (3) and a furnace top (4), wherein the furnace bottom smelting tank (2) is positioned below the furnace hearth (1), and a low fire baffle wall (6) is arranged between a fire chamber (5) in the furnace wall and the furnace hearth (1). A slag discharging opening (12) for discharging tin lead alloy is arranged on one side wall of the furnace near the position of a furnace tail, two working doors (13, 14) are arranged on the other side wall of the furnace, a smoke outlet (15) is arranged on the furnace wall at the tail part, and a charging opening (16) is arranged on the furnace top (4). The arc shape of the furnace top on the low fire baffle wall (6) is shown to press down towards the two sides; the position of the furnace top to the furnace hearth (1) is horizontal, and the position of the furnace top to the furnace tail is pressed towards the furnace tail in an inclined manner. The reflecting furnace has the advantages of high heat efficiency, quick material smelting, low cost and less coal consumption with the coal combustion rate of 42 to 48%.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

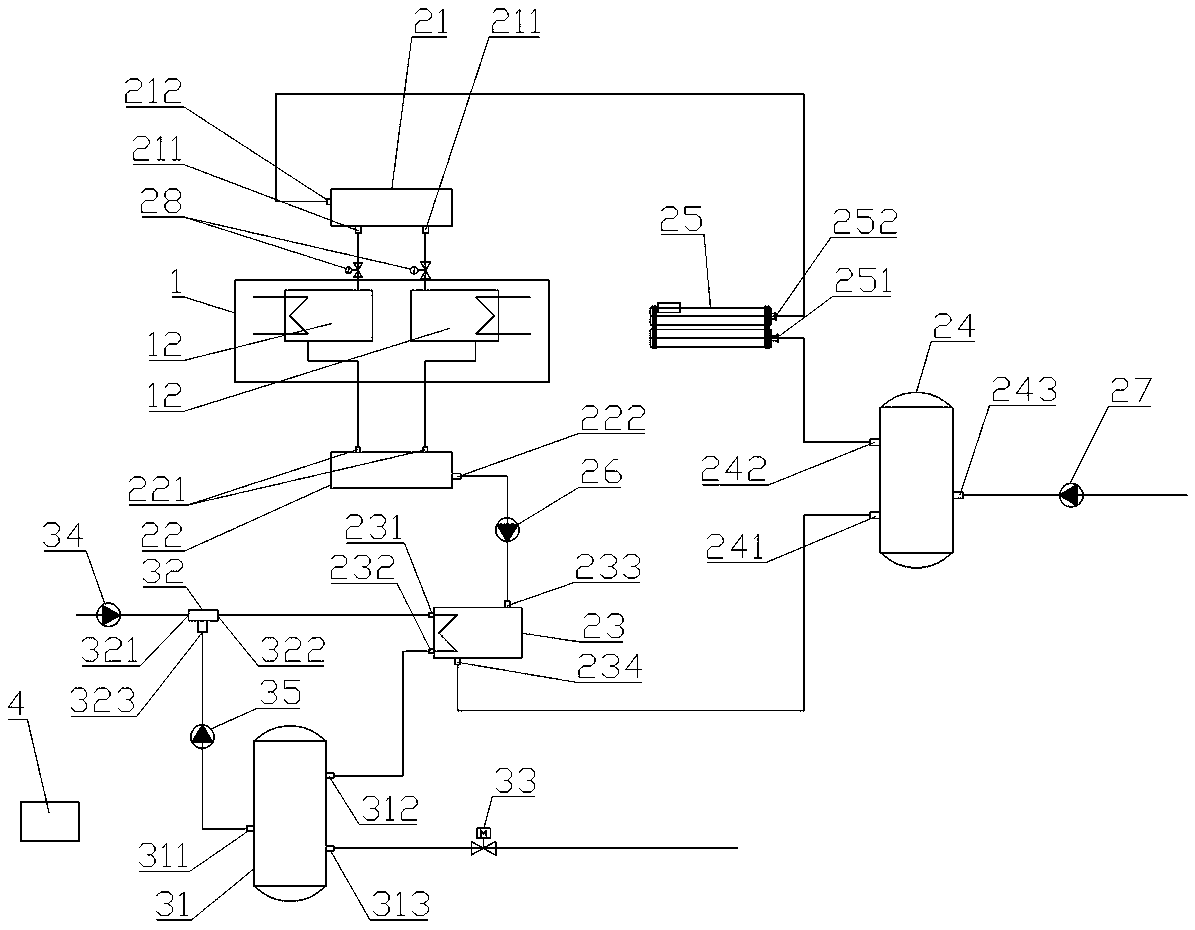

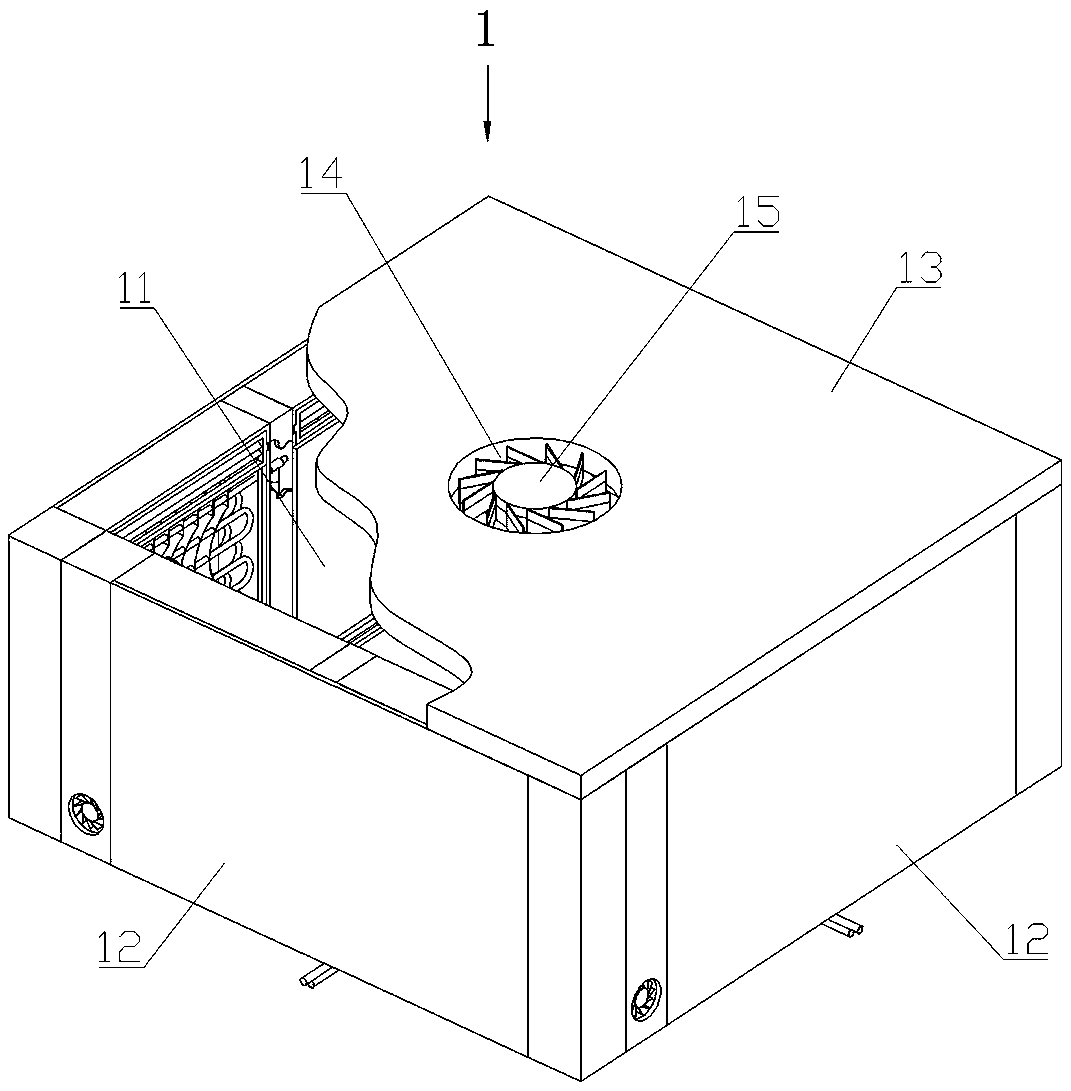

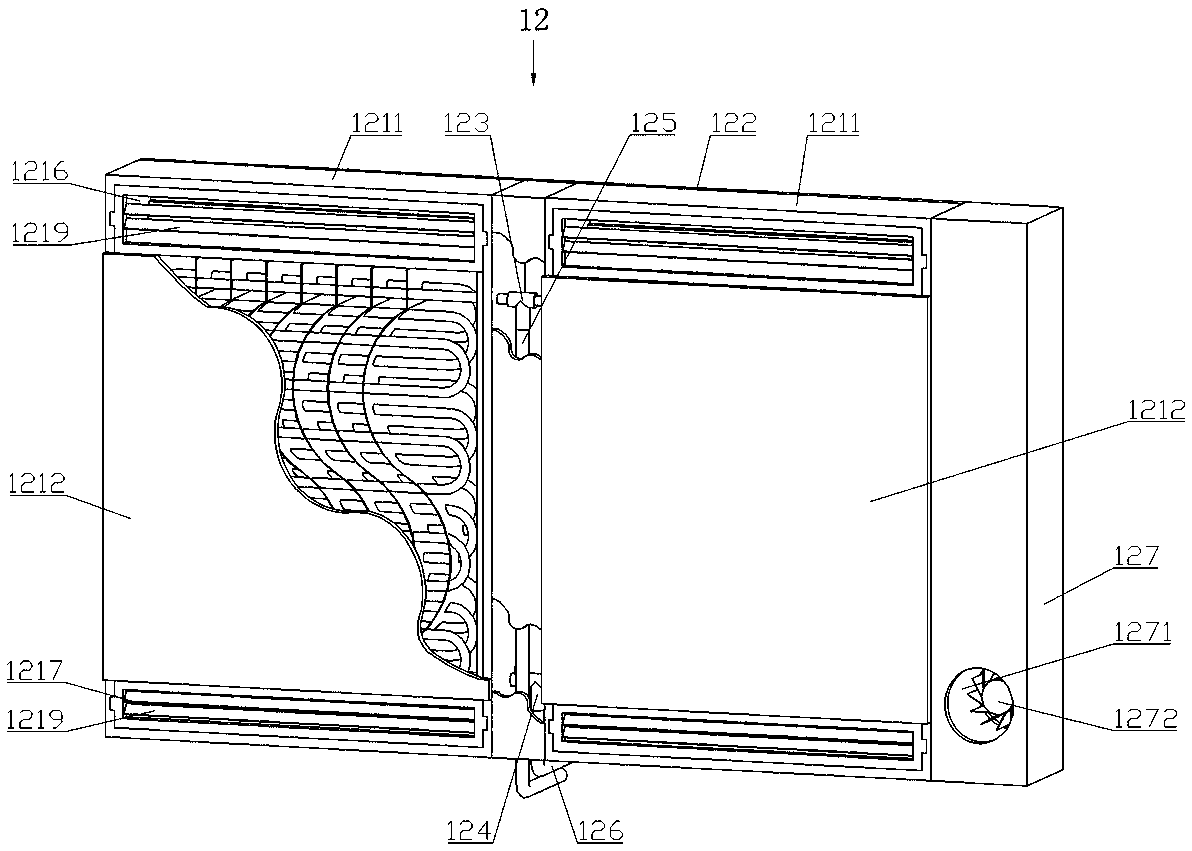

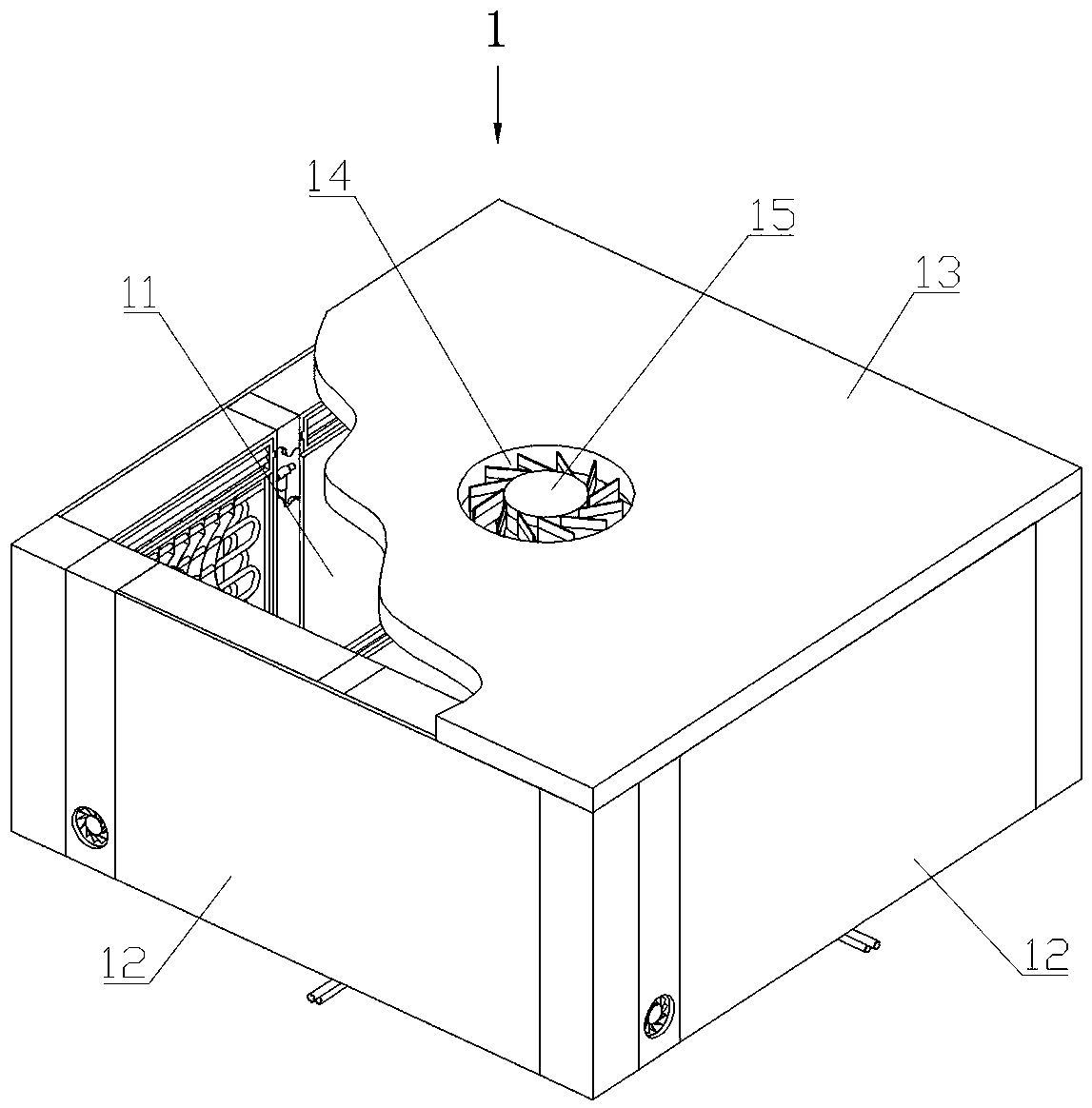

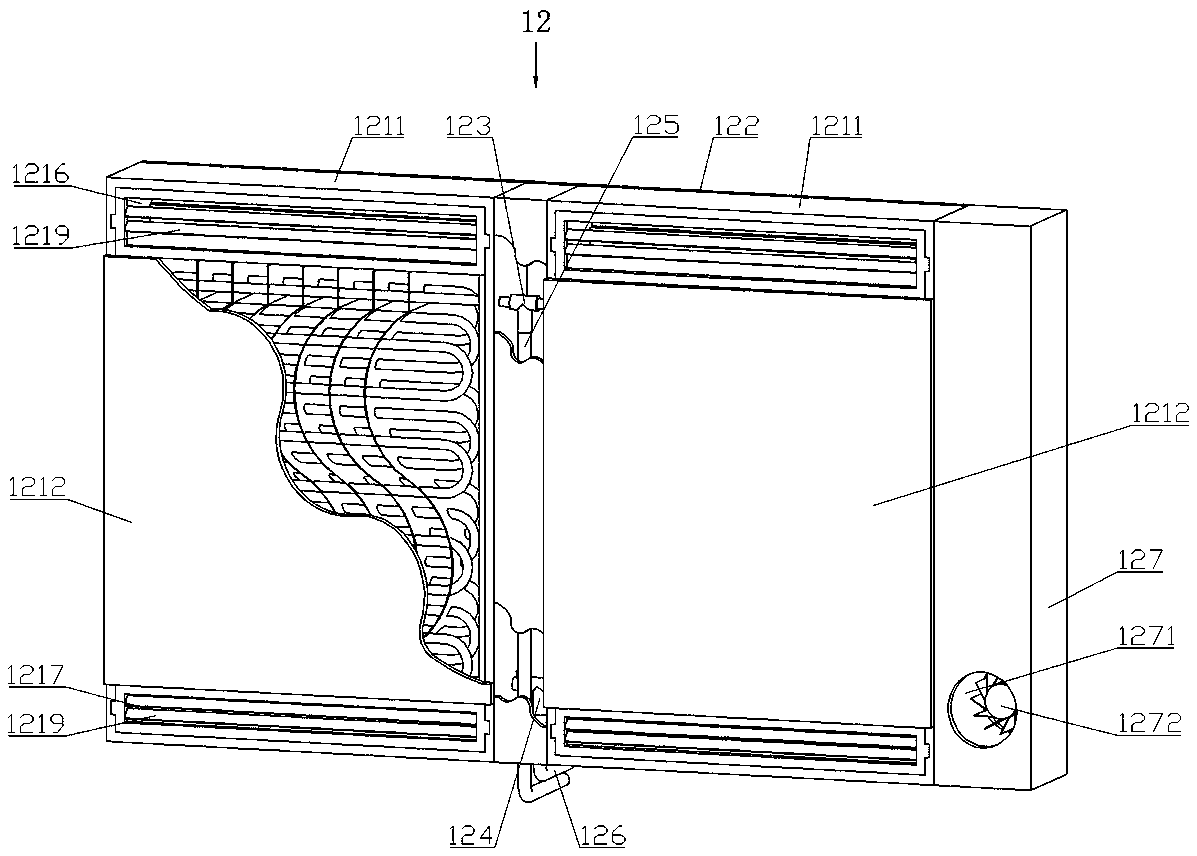

Heat dissipating and cooling system as well as heat dissipating and cooling method aimed at high-temperature heat source equipment

PendingCN110671953AContinuous coolingEfficient heat dissipation and coolingWallsEnergy industryThermal comfortEngineering

The invention provides a heat dissipating and cooling system aimed at high-temperature heat source equipment. The heat dissipating and cooling system comprises a heat insulating and cooling hood, a water-cooling circulation device, and a waste heat utilization device, wherein the heat insulating and cooling hood is constructed by utilizing a side wall and a top wall; the side wall is composed of heat insulating and cooling walls; a heat insulating plate serves as the top wall; and the heat insulating and cooling walls comprise wall body units. The invention further provides a heat dissipatingand cooling method aimed at the high-temperature heat source equipment. The heat dissipating and cooling method comprises the following steps: the heat insulating and cooling hood is constructed outside the high-temperature heat source equipment; intake fans and an exhaust fan are started, and then the high-temperature heat source equipment is subjected to continuous heat dissipating and cooling;and the circulation flow of circulation water is enabled, and then the high-temperature heat source equipment is subjected to continuous heat dissipating and cooling. The heat dissipating and coolingsystem provided by the invention has the beneficial effects that through the heat insulating and cooling hood, the high-temperature heat source equipment is covered as well as continuously and efficiently subjected to heat dissipating and cooling, so that the temperature of the surrounding area of the high-temperature heat source equipment can be effectively reduced and the diffusion of heat generated by the high-temperature heat source equipment to the surrounding area can be greatly reduced; and accordingly, the formation of local high-temperature areas inside a workshop can be avoided and the heat comfort requirements of workers can be met.

Owner:NANHUA UNIV

LED road lamp module with plastic cooler and manufacture method thereof

PendingCN110375282AGood thermal radiation performanceDisperse quickly and evenlyMechanical apparatusLighting heating/cooling arrangementsCooling effectEngineering

The invention relates to the technical field of lighting equipment, in particular to an LED road lamp module with a plastic cooler and a manufacture method thereof. The LED road lamp module comprisesa lens and a plastic cooler. In the LED road lamp module with the plastic cooler and the manufacture method thereof, heat is produced by an LED bulb on a lamp panel, the bulb emits light and at the same time produces the heat, the temperature of the lamp panel is raised, an aluminum base plate on the back of the lamp panel is in contact with liquid in the plastic cooler, the heat is transferred into the liquid, dynamic circulating liquid heat convection is formed in the plastic cooler, the heat is uniformly and rapidly dispersed onto the surface of the plastic cooler, and a cooling process isfinished after heat exchange is carried out with surrounding air. The LED road lamp module has the advantages that although a difference between the temperature of the bulb and the surface temperatureof the cooler is small, a difference between the surface of the cooler and the temperature of the surrounding air is large, the heat radiation capability of plastics is great, and therefore, the whole cooling effect is great; and the material cost of the plastic cooler is low, the following processing procedures are few, the production efficiency is high, a cooling system is simple and easy, andthe popularization property is strong.

Owner:广州融捷照明科技有限公司

Cooling and heat dissipation system aiming at high-temperature heat source equipment and cooling and heat dissipation method

PendingCN110763046AContinuous coolingEfficient heat dissipation and coolingWallsEnergy industryThermal comfortProcess engineering

The invention relates to a cooling and heat dissipation system aiming at high-temperature heat source equipment. The system comprises a heat insulation cooling cover, a water cooling circulating device and a hot water diversion device, wherein the heat insulation cooling cover is formed by building a side wall composed of a heat insulation cooling wall and a top wall composed of a heat insulationplate, and the heat insulation cooling wall comprises a wall unit. The cooling and heat dissipation method aimed at the high-temperature heat source equipment comprises the following steps that the heat insulation cooling cover is built outside the high-temperature heat source equipment; an air inlet fan and an air exhaust fan are started to continuously perform cooling and heat dissipation on thehigh-temperature heat source equipment; and circulating water is enabled to flow in a circulating mode to continuously perform cooling and heat dissipation on the high-temperature heat source equipment. According to the system, the high-temperature heat source equipment is enveloped by the heat insulation cooling cover, the high-temperature heat source equipment is continuously and efficiently cooled, the temperature of a peripheral area of the high-temperature heat source equipment is effectively reduced, heat generated by the high-temperature heat source equipment is greatly reduced to be diffused to the periphery, and the situation that a local high-temperature area is formed in a factory building is avoided, so that the thermal comfort requirement of workers is met.

Owner:NANHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com