Far infrared radiation carbon fiber electric-thermal composite fabric and preparation method thereof

A technology of far-infrared radiation and carbon fiber fabric, which is applied in the direction of carbon fiber, cellulose plastic material layered products, fiber treatment, etc., can solve the problems of short service life of metal resistance wire, restriction of normal human activities, and potential safety hazards, etc., to achieve suitable Resistivity, design tailoring performance is good, and the effect of improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

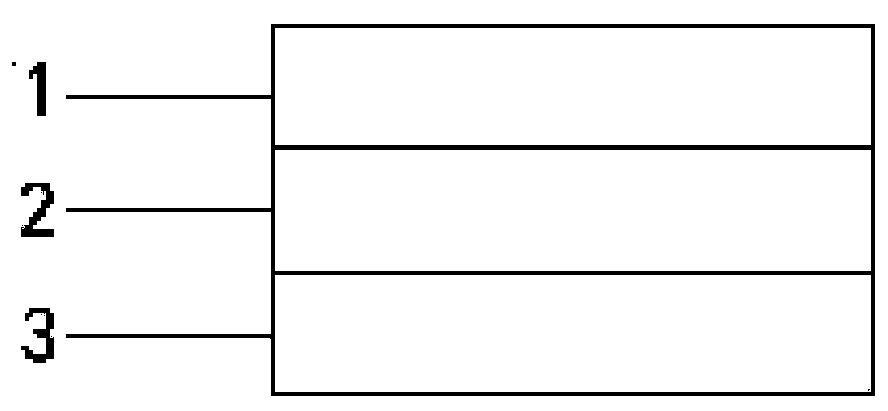

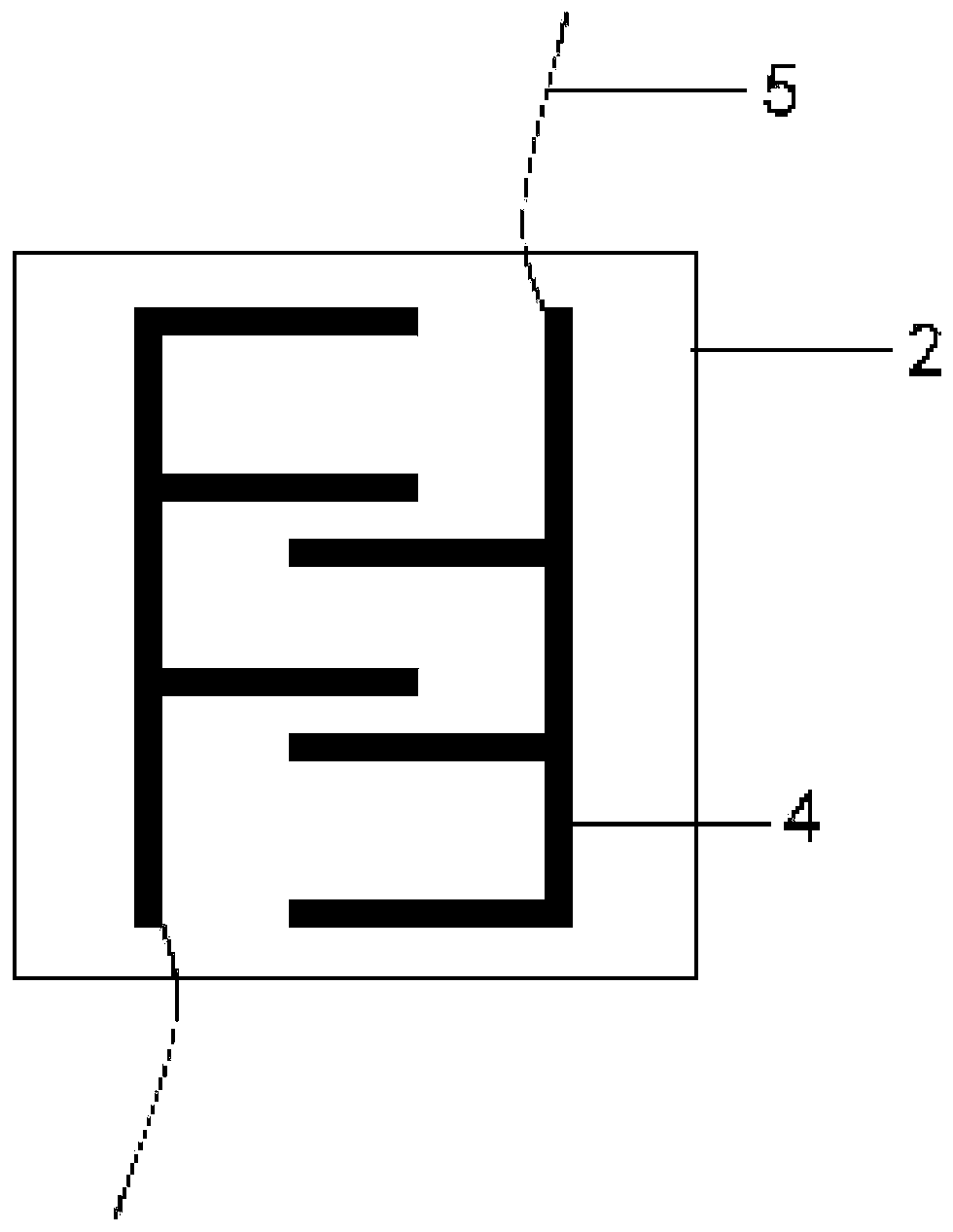

[0034] The preparation method of the above-mentioned far-infrared radiation carbon fiber electric-thermal composite fabric is characterized in that, comprising:

[0035] The first step: using the carbon fiber surface coating removal treatment method, the carbon fiber fabric is pretreated to obtain a desized carbon fiber fabric;

[0036] The second step: using the dopamine biomimetic modification method, dissolving dopamine hydrochloride in Tris buffer solution to obtain a dopamine solution, and immersing the desized carbon fiber fabric obtained in the first step in the dopamine solution to obtain a dopamine biomimetic modified carbon fiber fabric;

[0037] The third step: using the fabric post-finishing method, first prepare the far-infrared slurry for enhancing the far-infrared performance, and then use the slurry spraying method to spray the far-infrared slurry on the dopamine biomimetic modified carbon fiber fabric prepared in the second step , to obtain far-infrared radiat...

Embodiment 1

[0040]A preparation method of far-infrared radiation carbon fiber electric-thermal composite fabric:

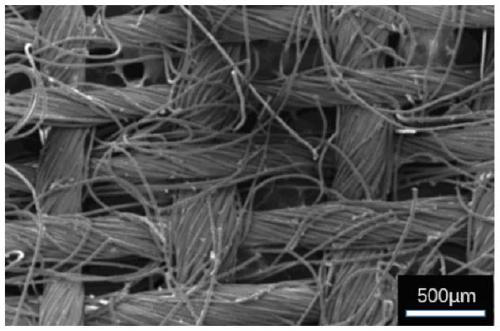

[0041] The first step: use the acetone soaking method to prepare 80% acetone solution, first take 80mL acetone and 20mL deionized water, mix them, and soak 5cm×5cm carbon fiber plain cloth in 80% acetone solution, at room temperature (25°C) Dipping for 48h to obtain a desized carbon fiber plain weave fabric;

[0042] Step 2: Dissolve 1.2114g Tris (trishydroxymethylaminomethane) in 1L deionized water, stir for 5min, add 0.1mol / L dilute hydrochloric acid to the solution to adjust the pH until the pH meter shows 8.5 , to obtain a 10mmol / L Tris buffer solution. 2 g of dopamine hydrochloride was dissolved in the prepared Tris buffer solution, and stirred for 5 min to obtain a 2 g / L dopamine solution. The desized carbon fiber plain weave fabric obtained in the first step was immersed in dopamine solution, the bath ratio was 1:50, the reaction time was 4 hours, and the reaction te...

Embodiment 2

[0047] A preparation method of far-infrared radiation carbon fiber electric-thermal composite fabric:

[0048] The first step: use the acetone soaking method to prepare 80% acetone solution, first take 80mL acetone and 20mL deionized water, mix them, and immerse 5cm×5cm carbon fiber unidirectional cloth in 80% acetone solution, room temperature (25 ℃) Under dipping for 60h, the desized carbon fiber unidirectional cloth is obtained;

[0049] Step 2: Dissolve 3.0285g Tris (trishydroxymethylaminomethane) in 1L deionized water, stir for 5min, add 0.1mol / L dilute hydrochloric acid dropwise to the solution to adjust the pH until the pH meter shows 8.5, Obtain the Tris buffer solution of 25mmol / L. 5 g of dopamine hydrochloride was dissolved in the prepared Tris buffer solution, and stirred for 5 min to obtain a 5 g / L dopamine solution. The desized carbon fiber unidirectional fabric obtained in the first step was immersed in the above-mentioned dopamine solution, the bath ratio was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com