Insulating and heat dissipating coating composition, and insulating and heat dissipating unit formed thereby

A heat dissipation coating and heat dissipation unit technology, applied in the direction of epoxy resin coating, coating, electrical components, etc., can solve the problem that the insulating heat dissipation coating is difficult to achieve durability, heat dissipation performance, poor surface quality of the insulating heat dissipation coating, It is difficult to solve problems such as heat dissipation and electrical insulation to achieve excellent heat dissipation performance, excellent surface quality, and excellent smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

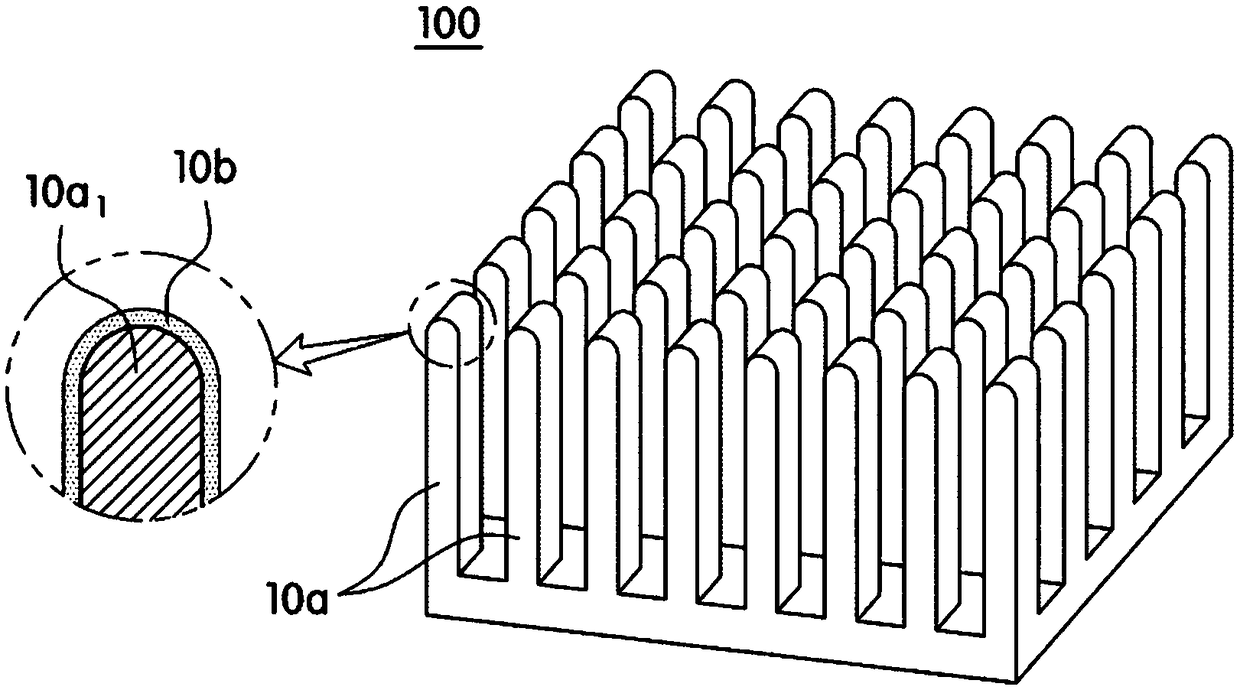

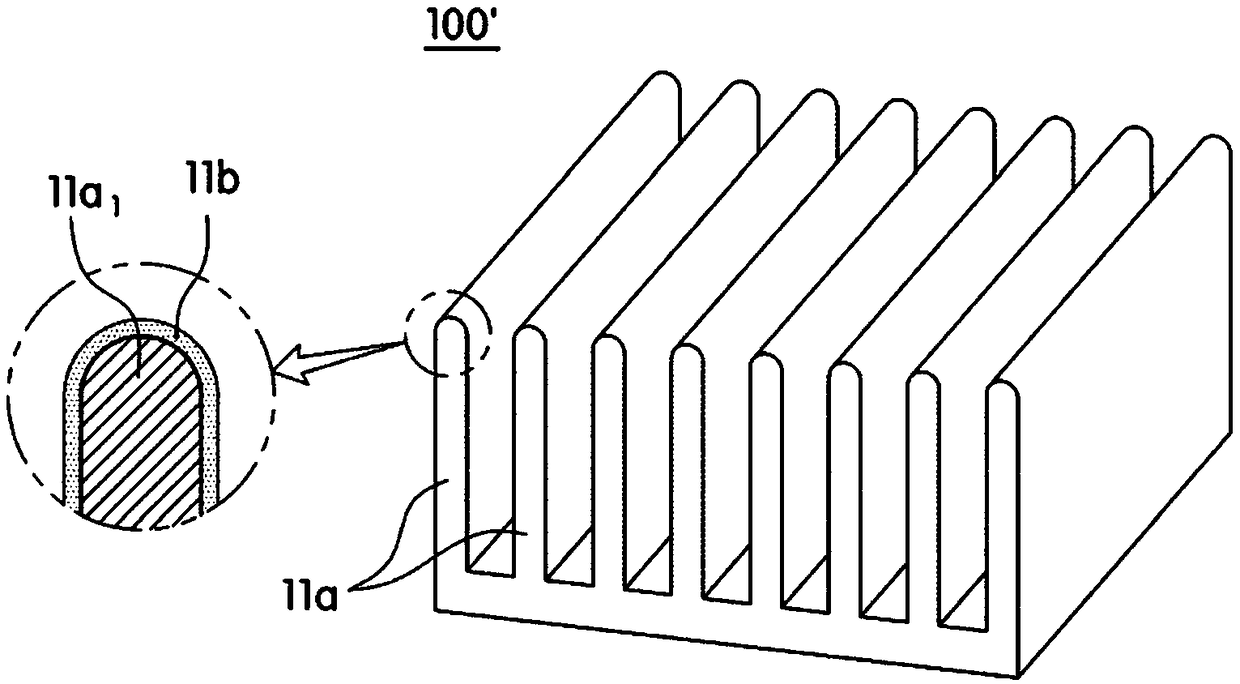

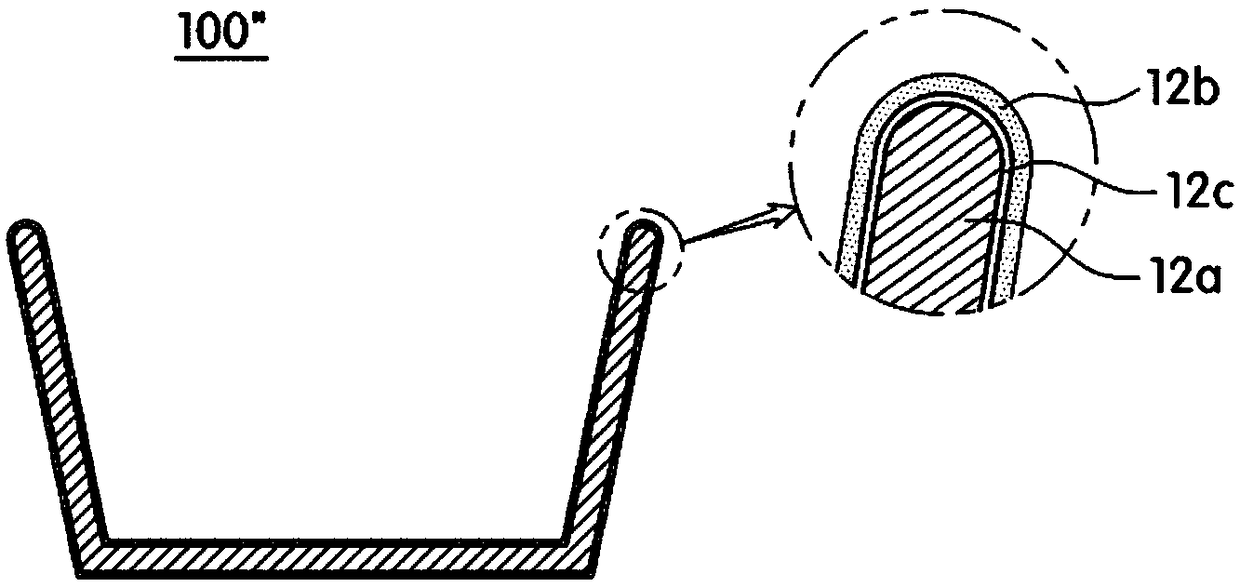

Image

Examples

Embodiment 1

[0126] Mixing and stirring a compound, that is, a coating forming component including 60 parts by weight of a curing agent in a weight ratio of 1:1 with respect to 100 parts by weight of a compound represented by the following Chemical Formula 1 as a main resin Comprising polyethylene polyamine as a first curing agent and 2,4,6-tris[N,N-dimethylamino]methyl]phenol as a second curing agent, 47 parts by weight have an average particle diameter of 5 μm and The ratio of D50 and D97 is silicon carbide of 1:1.6, 3 parts by weight of a physical property enhancing component (Shanghai Tech Polymer Technology, Tech-7130) as an epoxy silane compound, 44 parts by weight of talc as a colorant, 44 parts by weight 2-(2'-hydroxy-3,5'-di( 1,1-dimethylbenzyl-phenyl)-benzotriazole, 1 part by weight of 2-hydroxyphenylbenzothiazole as an antioxidant, 5 parts by weight of isobutyraldehyde and urea as a dispersant Condensate, 13 parts by weight of 1-butanol as solvent, 13 parts by weight of n-butyl...

Embodiment 2~23

[0131] In addition to changing the average particle size, particle size distribution, weight ratio of curing agent, and molecular weight of the main resin of the insulating heat-dissipating filler as shown in Table 1, Table 2 or Table 3, the rest are prepared in the same manner as in Example 1. The insulating heat-dissipating coating composition shown in Table 1, Table 2, Table 3 or Table 4.

experiment example 1

[0135] The heat-dissipating coating compositions prepared in Examples and Comparative Examples were spray-coated on the entire surface of a substrate formed of an aluminum material (Al1050) with a thickness of 1.5 mm, a width of 35 mm, and a length of 34 mm to be treated so that the final thickness 25 μm, and then heat treatment at a temperature of 150° C. for 10 minutes to prepare a heat dissipation unit formed with an insulating heat dissipation coating, and then evaluate the following physical properties, which are shown in Table 1 to Table 4.

[0136] 1. Thermal conductivity evaluation

[0137] After placing the cooling unit at the center of an acrylic chamber with a width, length and height of 32cm×30cm×30cm, respectively, the temperature of the chamber and the sample were adjusted to 25±0.2°C. After that, an LED having a width and a length of 20 mm×20 mm, respectively, was adhered to a heat dissipation unit by TIM (conductive tape: 1 W / mk) to serve as a heat source, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com