Multilayer solid wood heating floor

A technology for flooring and solid wood, applied in the field of wood flooring, can solve problems such as hidden safety hazards and heating efficiency, and achieve the effect of solving low heating efficiency and solving hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

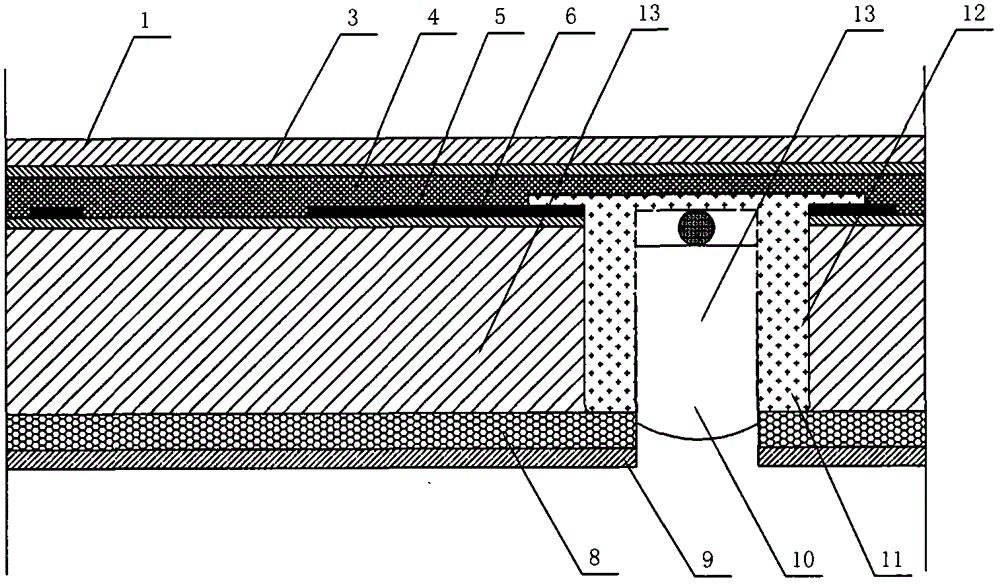

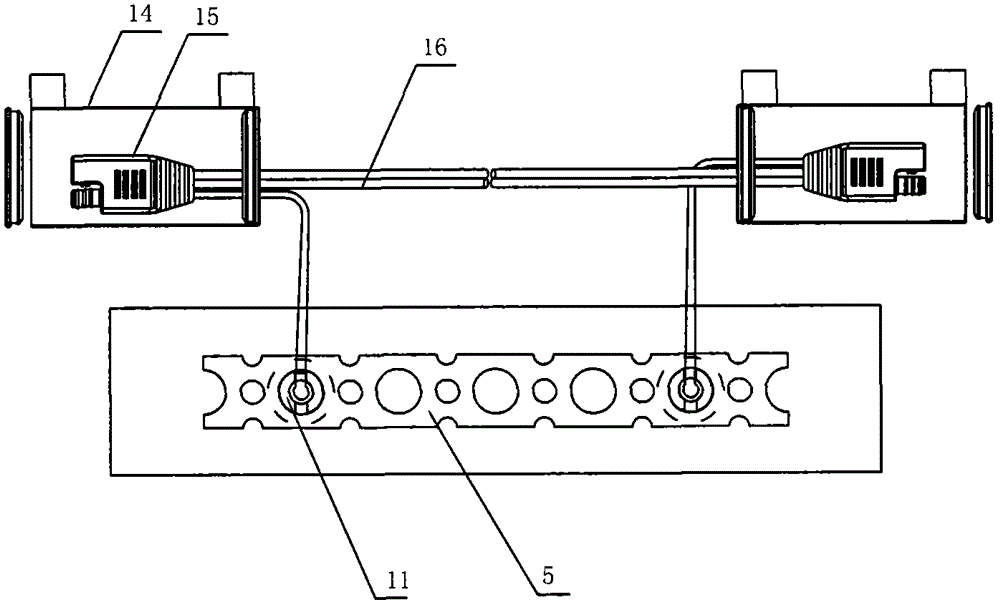

[0020] Example 1, such as figure 1 , 2 , 4, and 5, the manufacturing process of the multi-layer solid wood heating floor in which the far-infrared carbon fiber heating paper is arranged in the base plate is: 1, raw materials: a, base material, two 4-layer veneer pressed base materials Board, single layer thickness 1.7-2.2mm; format size 1230mm×1230mm×7~7.2mm, moisture content ≤12%; density: ≥600kg / m 3The thickness is between 7.0 and 7.2mm; b. Heating material, the heating material used is far-infrared nano-carbon fiber heating paper, the format size is 1120mm×140mm, and the surface quality requires no holes, no wrinkles, no fiber clusters, and neat cuts No burr; c, conductive material, the conductive material used is divided into terminal 11, conductive metal sheet 5 and special cable; d, insulation, waterproof and heat preservation material, using PU foam material to make it insulating and waterproof; 2 1. Preparation of substrate: two 4-layer solid wood veneer-pressed subs...

Embodiment 2

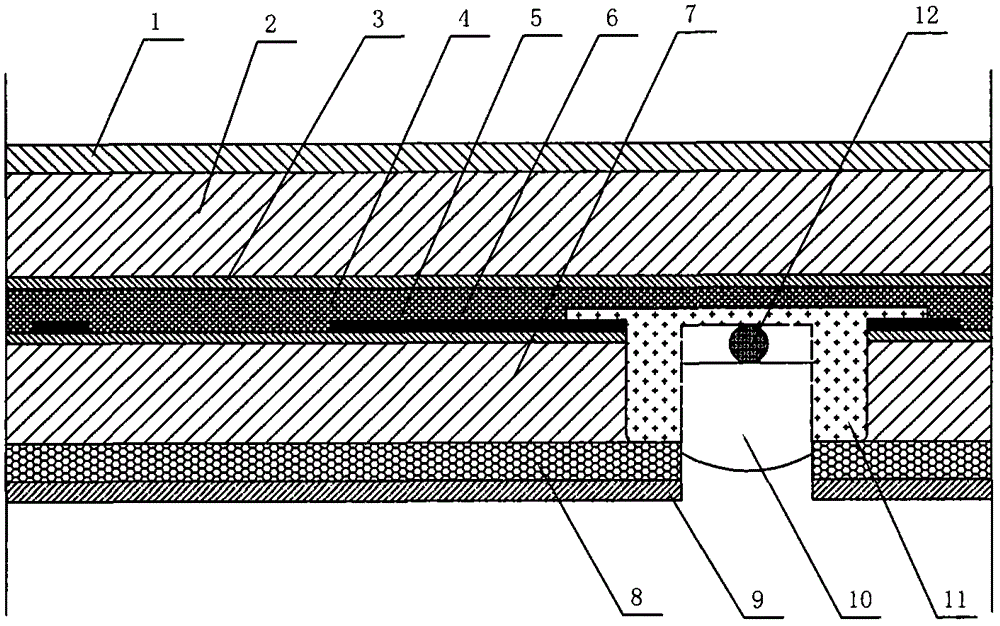

[0021] Embodiment 2, as figure 2 , 3 , shown in 6, the multi-layer solid wood heating floor processing and manufacturing procedure that described far-infrared carbon fiber heating paper is arranged between base plate 13 and decorative layer 1 is: 1, raw material: a, base material, adopt a sheet of 8 layers Multi-layer solid wood board pressed by veneer, single-layer thickness 1.7-2.2mm; format size 1230mm×1230mm×13.8-14mm, moisture content ≤ 12%; density: ≥ 600kg / m 3 The thickness is between 13.8 and 14mm; b. Heating material, the heating material used is far-infrared nano-carbon fiber heating paper, and the format size is 1120mm×118mm. The surface quality requires no holes, no wrinkles, no fiber clusters, and neat cuts. Burr; c, conductive material, the conductive material adopted is divided into connection terminal 11, conductive metal sheet 5 and special cable; d, insulation, waterproof and heat preservation material, adopts PU foam material to make its insulation heat pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com