Silicon carbide-ruthenium resistance slurry and preparation method therefor

A technology of resistance paste and silicon carbide, which is applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problem that the thickness consistency of the resistance film is not easy to control, the heater is difficult to miniaturize and thin, and the production of resistance wire or film Complicated process and other issues, to achieve the effect of excellent thermal radiation performance, good printability and wettability, good dispersibility and co-solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

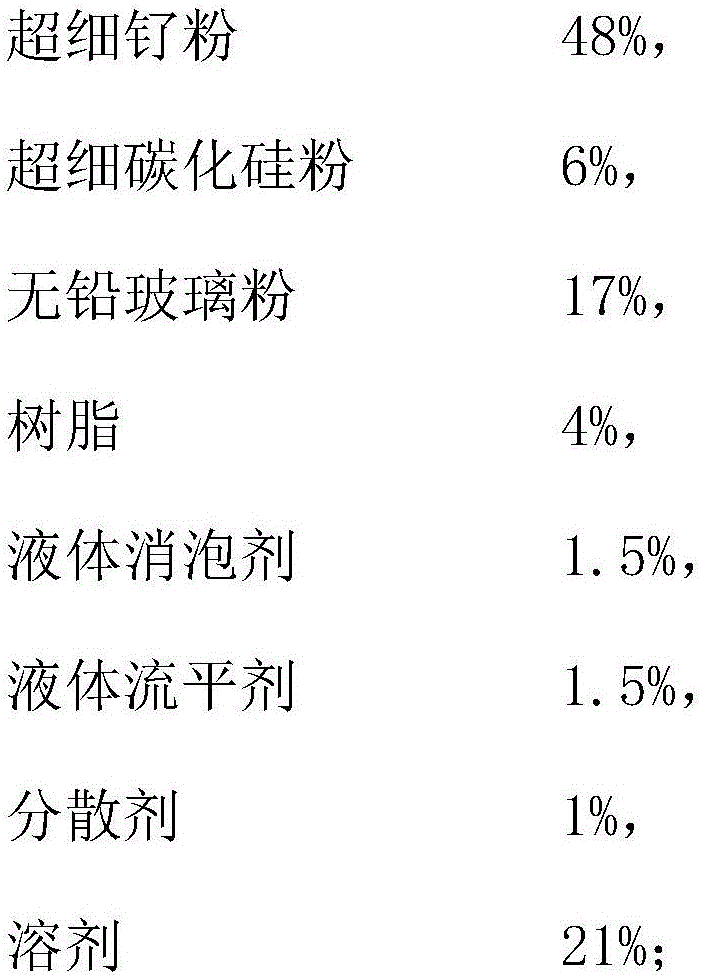

[0043] A silicon carbide-ruthenium resistance slurry, in weight percent, comprises the following components:

[0044]

[0045] Its preparation method comprises the following steps:

[0046] (1) Preparation of functional phase: Mix ultrafine ruthenium powder, ultrafine silicon carbide powder and lead-free glass powder evenly to obtain a functional phase, wherein the particle size of ultrafine ruthenium powder, ultrafine silicon carbide powder and lead-free glass powder 3μm, 3μm, 2.5μm respectively;

[0047] (2) Preparation of additives: Stir and mix liquid defoamer, liquid leveling agent, and wetting and dispersing agent evenly to obtain additives;

[0048] (3) Prepare the organic vehicle: mix the resin and the solvent evenly, stir until the resin dissolves, then add the additive prepared in step (2), and stir evenly to obtain the organic vehicle;

[0049] (4) Weighing the functional phase prepared in step (1) and the organic carrier prepared in step (3), pre-mixing the we...

Embodiment 2

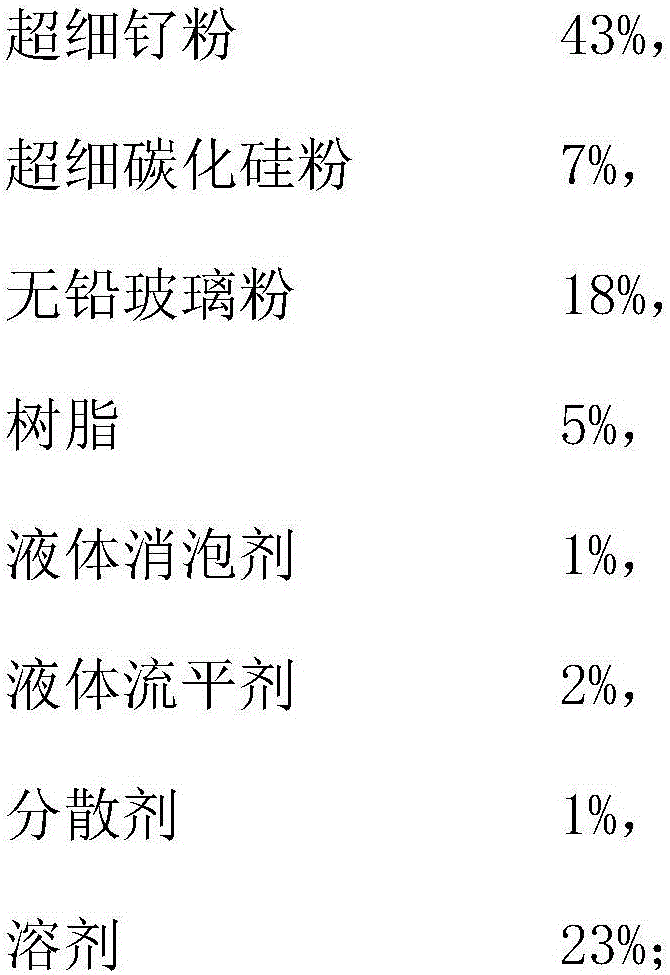

[0052] A silicon carbide-ruthenium resistance slurry, in weight percent, comprises the following components:

[0053]

[0054] Its preparation method comprises the following steps:

[0055] (1) Preparation of functional phase: Mix ultrafine ruthenium powder, ultrafine silicon carbide powder and lead-free glass powder evenly to obtain a functional phase, wherein the particle size of ultrafine ruthenium powder, ultrafine silicon carbide powder and lead-free glass powder 1μm, 1μm, 2μm respectively;

[0056] (2) Preparation of additives: Stir and mix liquid defoamer, liquid leveling agent, and wetting and dispersing agent evenly to obtain additives;

[0057] (3) Prepare the organic vehicle: mix the resin and the solvent evenly, stir until the resin dissolves, then add the additive prepared in step (2), and stir evenly to obtain the organic vehicle;

[0058] (4) Weighing the functional phase prepared in step (1) and the organic carrier prepared in step (3), pre-mixing the weig...

Embodiment 3

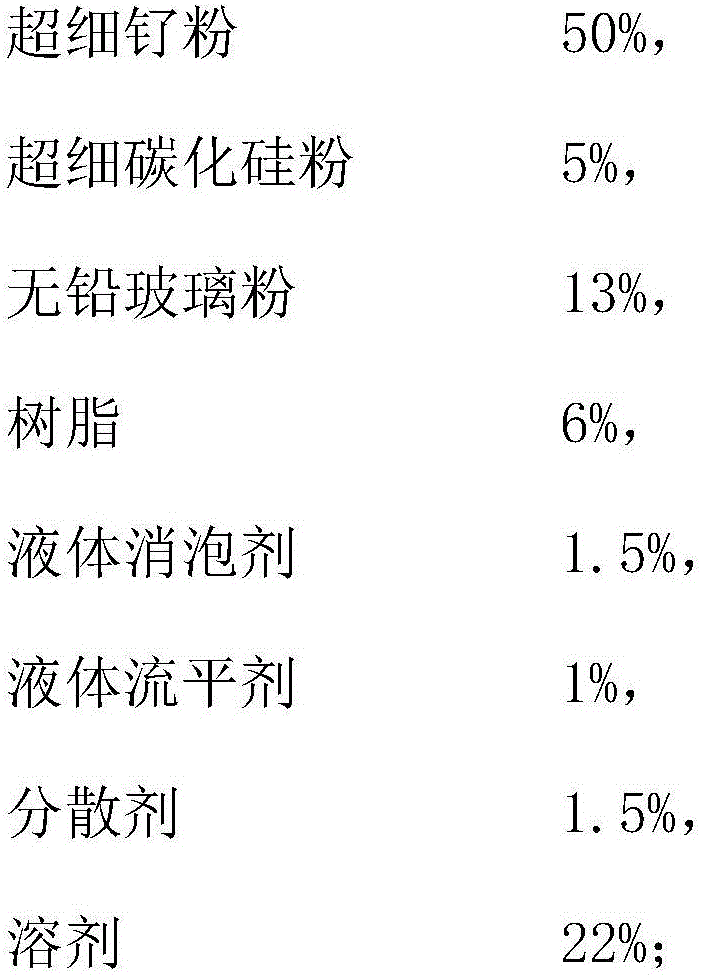

[0061] A silicon carbide-ruthenium resistance slurry, in weight percent, comprises the following components:

[0062]

[0063] Its preparation method comprises the following steps:

[0064] (1) Preparation of functional phase: Mix ultrafine ruthenium powder, ultrafine silicon carbide powder and lead-free glass powder evenly to obtain a functional phase, wherein the particle size of ultrafine ruthenium powder, ultrafine silicon carbide powder and lead-free glass powder 800nm, 500nm, 1μm respectively;

[0065] (2) Preparation of additives: Stir and mix liquid defoamer, liquid leveling agent, and wetting and dispersing agent evenly to obtain additives;

[0066](3) Prepare the organic vehicle: mix the resin and the solvent evenly, stir until the resin dissolves, then add the additive prepared in step (2), and stir evenly to obtain the organic vehicle;

[0067] (4) Weighing the functional phase prepared in step (1) and the organic carrier prepared in step (3), pre-mixing the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com