Reflecting furnace for smelting tin lead materials

A reverberatory furnace and material technology, applied in the field of reverberatory furnace, can solve the problems of not being able to smelt tin-rich slag, slow melting of materials when heated, and slow temperature rise of the furnace, and achieve the effects of short smelting cycle, fast heating and reduced coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

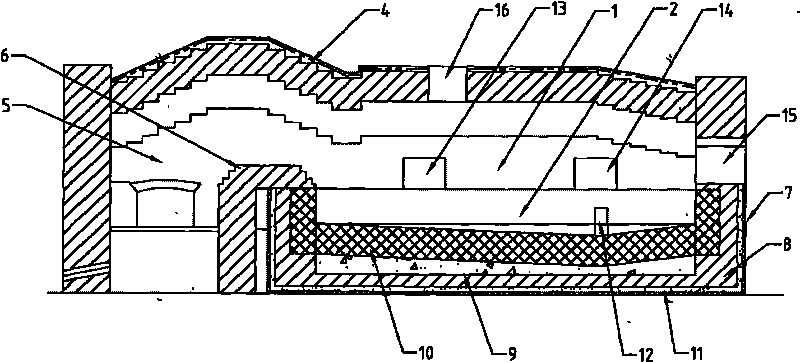

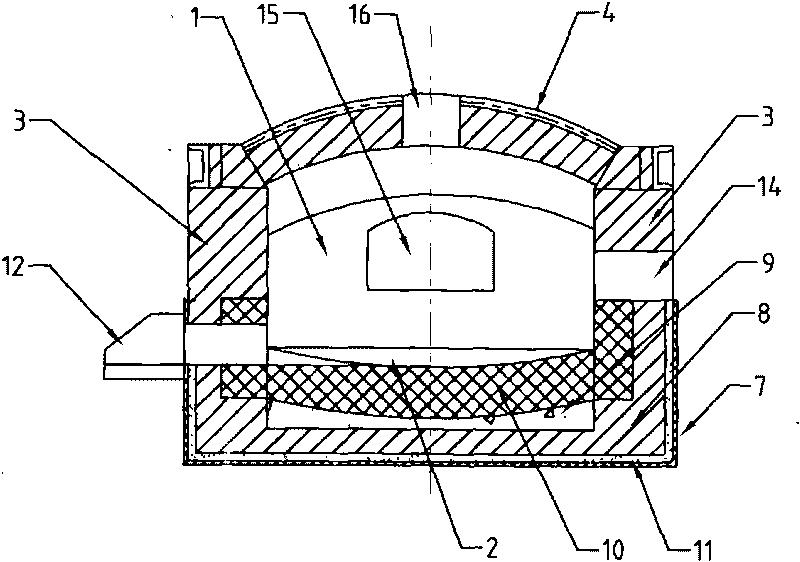

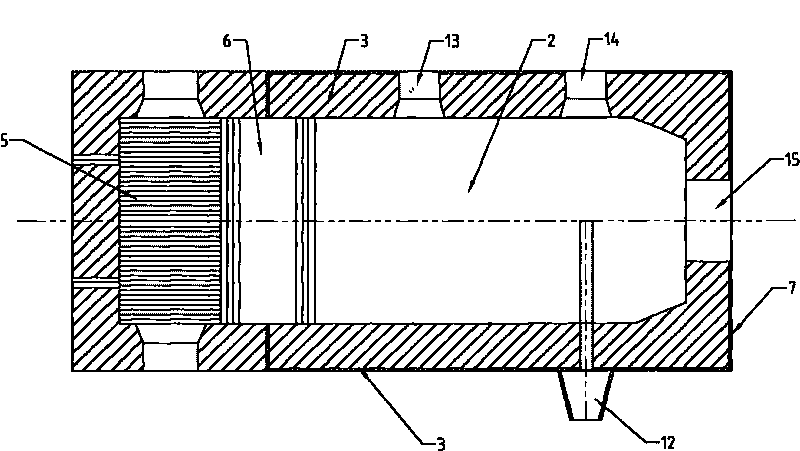

[0010] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention will be described in further detail:

[0011] refer to figure 1 , 2 And 3, a reverberatory furnace for smelting tin-lead materials, the main structure is composed of a furnace hearth 1, a furnace bottom molten pool 2, a furnace wall 3 and a furnace roof 4; below the furnace hearth 1 is a furnace bottom molten pool 2, and the fire in the furnace wall There is a low fire wall 6 between the chamber 5 and the furnace 1; the furnace bottom molten pool 2 is composed of a furnace shell 7, a high-alumina brick layer 8, a packing layer 9, and an inverted arch furnace bottom brick layer 10; the entire furnace bottom molten pool 2. It is supported on the furnace foundation made of concrete and block stones; the side height of the furnace shell 7 is 1.0m, and it is welded with 20mm thick steel plates to prevent the leakage of high-temperature liquid tin-lead alloy; There are asbesto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com