Patents

Literature

47results about How to "Short smelting cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

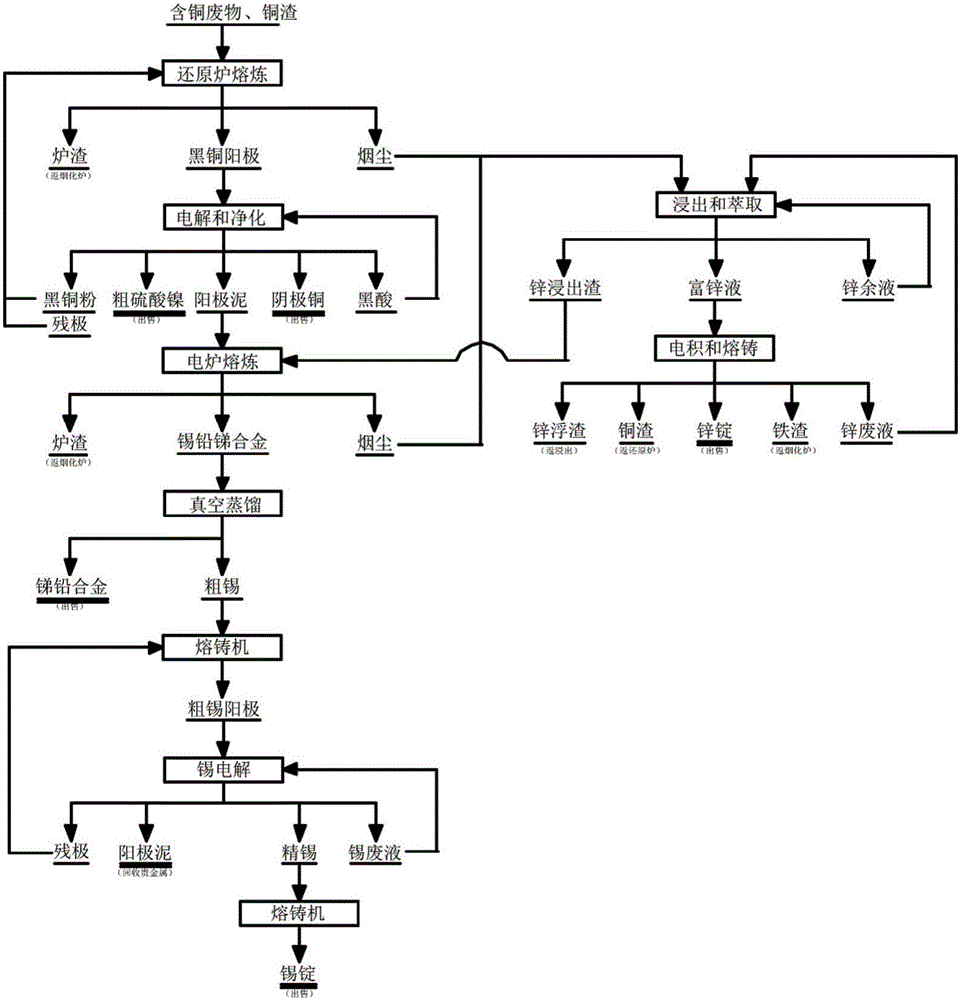

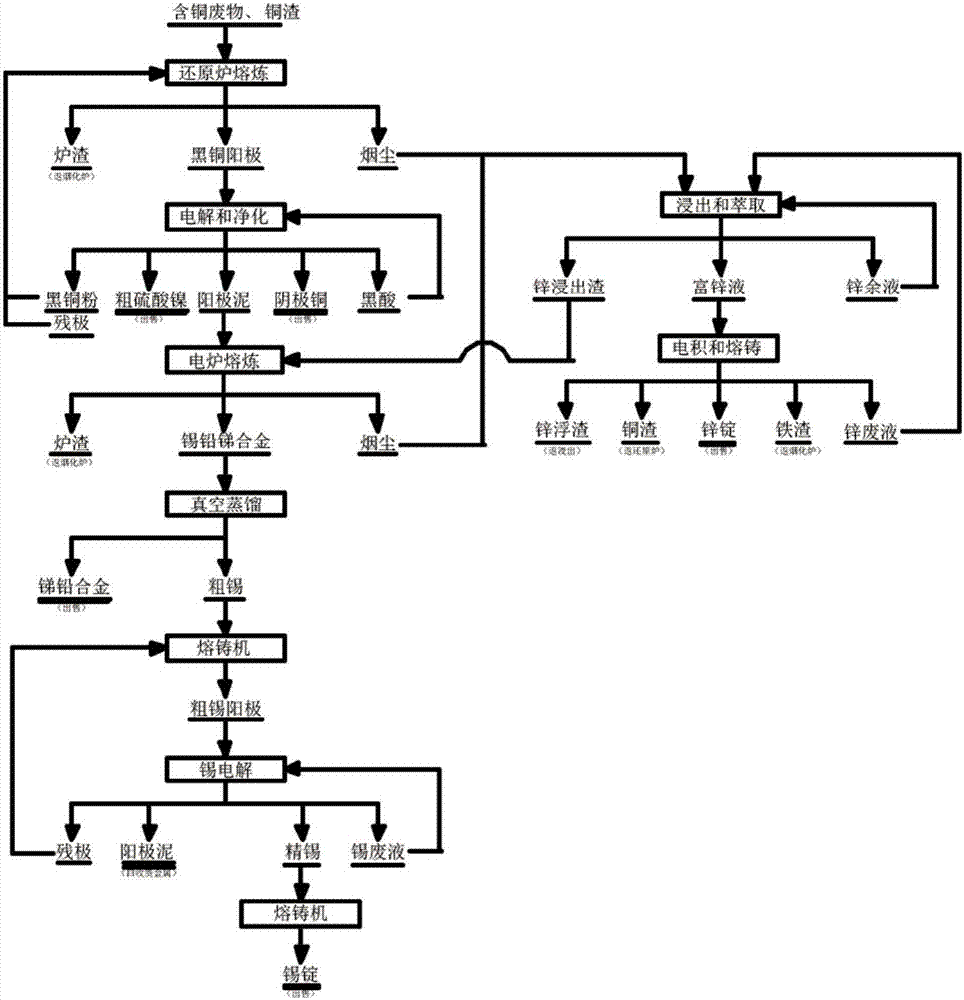

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

Low-metal-loss smelting method of copper alloy

The invention discloses a low-metal-loss smelting method of a copper alloy, which comprises the following steps: (1) adding all the raw materials except fusible and oxidable raw metals into a smelting furnace according to the components contained in the target alloy; after the raw materials are molten, introducing nitrogen or air into the smelting furnace, raising the pressure of the smelting furnace to 1-50 atm, and adding the low-melting raw metals into the smelting furnace; cooling the alloy melt, lowering the pressure of the hearth, and recovering valuable metals by using a micro reducing medium; using high-purity nitrogen, argon or carbon dioxide as a carrier gas, and adding a refining agent into the melt; introducing high-purity nitrogen or argon into the melt by using a rotary sprayer; adding a reducer-slag former mixture into the smelting furnace; and after removing all the furnace slag, adding a covering agent on the surface of the molten metal. The smelting method of the copper alloy can lower the metal loss, effectively remove impurity elements and gas inclusions in the alloy in the smelting process and enhance the refining effect.

Owner:XINJIANG UNIVERSITY +1

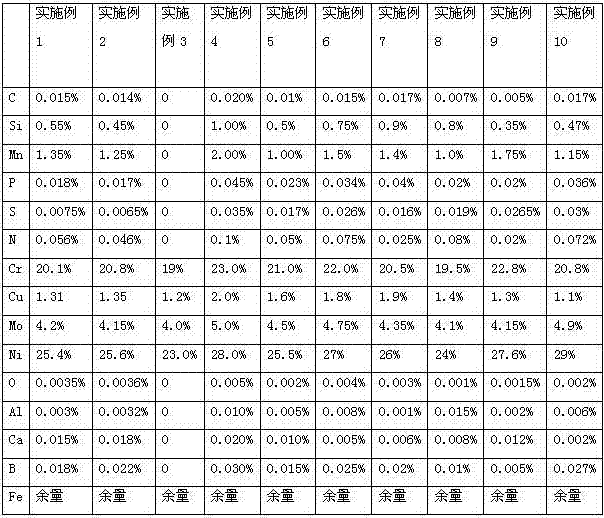

Superaustenitic stainless steel and preparing method thereof

ActiveCN107058905ASolve the smelting and continuous casting technologyImprove corrosion resistanceCopperAustenite

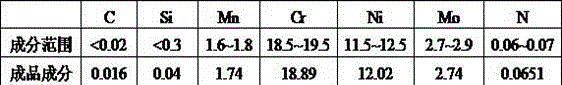

The invention provides superaustenitic stainless steel and a preparing method thereof. The superaustenitic stainless steel is prepared in the following percent by weight: smaller than or equal to 0.020% of C, smaller than or equal to 1.00% of Si, smaller than or equal to 2.00% of Mn, smaller than or equal to 0.045% of P, smaller than or equal to 0.035% of S, smaller than or equal to 0.1% of N, 19.0-23.0% of Cr, 1.2-2.0% of Cu, 4.0-5.0% of Mo, 23.0-28.0% of Ni, smaller than or equal to 0.0050% of O, smaller than or equal to 0.010% of Al, smaller than or equal to 0.020% of Ca, smaller than or equal to 0.030% of B and the balance of Fe. The method adopts a protection process of smelting superaustenitic stainless steel mother liquid by adopting a Consteel electric furnace and an intermediate frequency furnace, AOD, LF and continuous casting of a sheet billet, and can smelt the high-Ni, high-Cr, high-Mo, Cu-containing and low-C superaustenitic stainless steel, and both the surface quality and internal quality of the continuous casting billet are good.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Double-slag-method smelting process

ActiveCN109097523AGood dephosphorization effectShort smelting cycleManufacturing convertersProcess efficiency improvementMaterial consumptionDecarburization

The invention relates to a double-slag-method smelting process, belongs to the technical field of converter steelmaking, and solves the problems of poor dephosphorization effect, high slag material consumption, slag not easy to pour out, long smelting cycle and peroxidation of molten steel in an existing smelting process. The double-slag-method smelting process specifically includes dephosphorization of molten iron, dephosphorization slag discharge, and high-strength oxygen-supplying decarburization steelmaking with less slag; the step of dephosphorization of molten iron includes top-bottom oxygen combined blowing for rapid desiliconization and demanganization, and oxygen blowing at top and inert gas blowing at bottom for dephosphorization; the step of dephosphorization slag discharge includes control on foamed dephosphorization slag, pressing of foamed dephosphorization slag, and purging of foamed dephosphorization slag; and the step of high-strength oxygen-supplying decarburization steelmaking with less slag includes high-strength top-bottom oxygen combined blowing decarburization steelmaking, low-strength top-bottom oxygen combined blowing decarbonization steelmaking, low-strength top-bottom oxygen combined blowing carbon-pulling tapping, and bottom inert-gas blowing tapping. The process disclosed by the invention realizes optimal combination of top oxygen blowing, bottom oxygen blowing and supplying technology of inert gas, realizes reasonable matching of technologies of adding blocky slag materials at top and blowing a powder at bottom, and realizes efficient dephosphorization, low slag material consumption and efficient smelting with less slag.

Owner:CENT IRON & STEEL RES INST

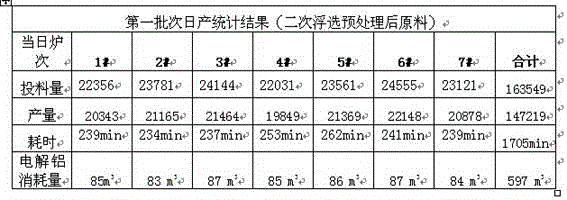

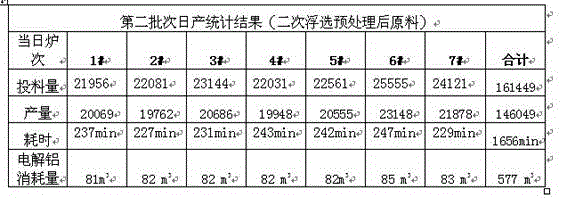

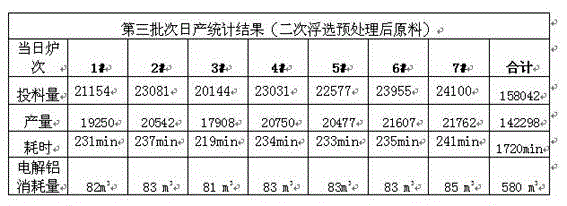

Cleaning, floating and drying integration pre-treating method for scrap aluminum

The invention relates to a cleaning, floating and drying integration pre-treating method for scrap aluminum. The method is characterized in that firstly, pretreatment is carried out, and a scrap aluminum material is cleaned through a two-time rinsing system, so that impurities on the surface of the scrap aluminum material are removed; through one-time floating, magnesium materials and other impurities in the scrap aluminum material are suspended on a liquid surface through one-time floating and then are scraped out; aluminum materials in the scrap aluminum material are screened out through two-time floating; and finally, drying is carried out, the floated aluminum materials are dried through recycled waste heat, and it is ensured that the water content in the aluminum materials is lower than 0.3 percent. The method has the advantages that through cleaning, floating and drying integration treatment, the scrap aluminum material enters a machine device to be cleaned, floated and dried, and a clean pure aluminum material is output; no any repeated production links exist in the method, and therefore before being put into a furnace, the aluminum materials are clear in chemical component and low in water content, and energy consumption is saved; and a smelted renewable aluminum alloy ingot is high in quality.

Owner:南通曼特威金属材料有限公司

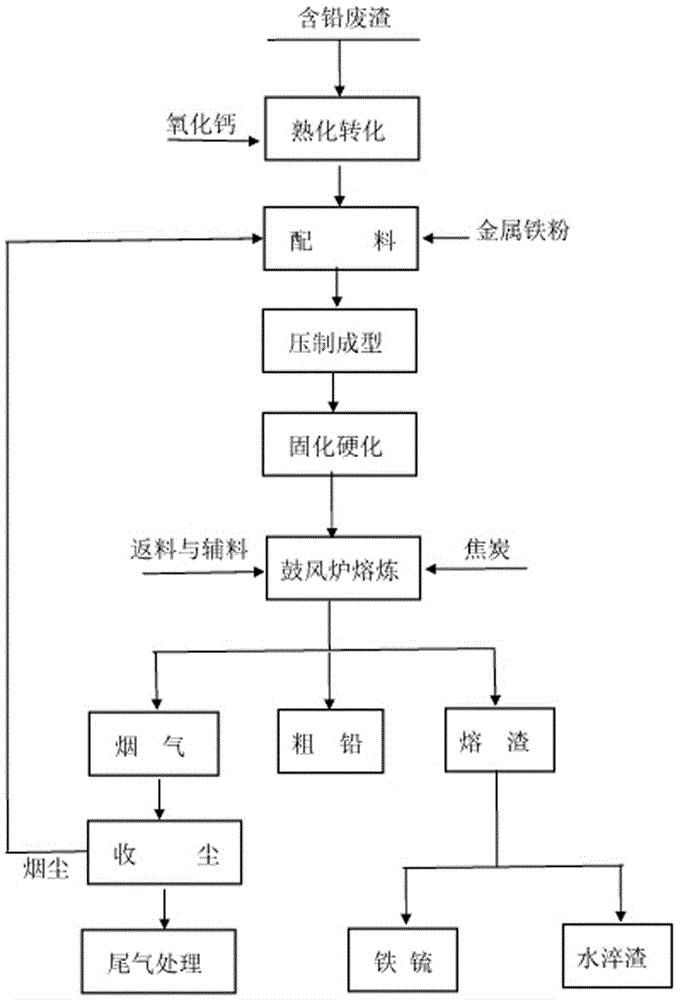

A clean melting method for lead-containing waste slag

InactiveCN106167855AGood melting adaptabilityChange stickinessProcess efficiency improvementBrickIron powder

A clean melting method for lead-containing waste slag is disclosed. The method includes 1) curing and converting, 2) curing and hardening and 3) melting. The method includes firstly mixing the lead-containing waste slag with calcium oxide, curing, converting, fully mixing with iron powder, shaping, making a brick, curing and hardening the brick, then sending the brick into a blast furnace, and performing reduction melting to recover lead and iron-sulfur, thus achieving clean melting. The method significantly improves compactness, strength and temperature resistance of the shaped brick, reduces thermo-collapse and pyrolysis powdering of the shaped brick in a melting process, reduces furnace accretion and dust, and increases the direct recovery rate of lead melting in the blast furnace and the hearth melting period. The method is simple in operation, low in adding amounts of sulfur fixing agents, adhesives, and the like, environmental friendly, high in metal recovery rate and heat utilization efficiency, low in impurity content, low in production energy consumption, and suitable for large-scale industrial production.

Owner:云南业胜环境资源科技有限公司

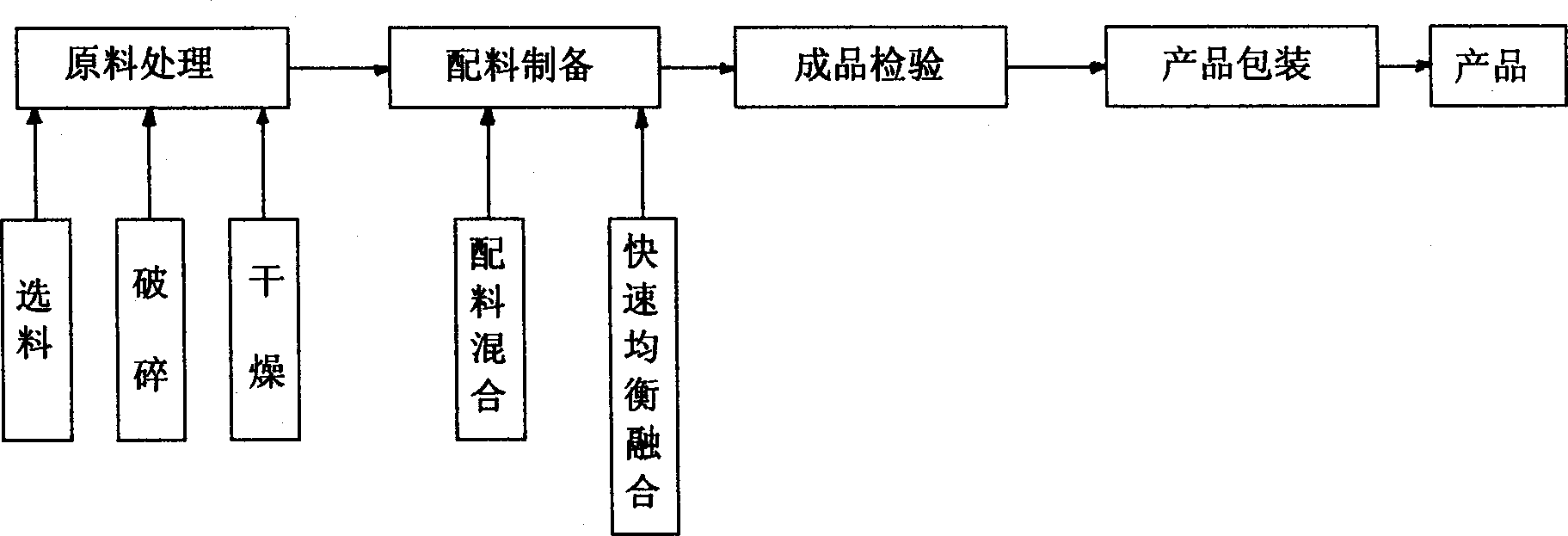

Composite metallurgical refining agent

The present invention relates to a compound refining agent for metallurgy, which it is characterized by that it comprises 10-60% of deoxygenation and desulfurization metal, 10-60% of alkaline earth metal oxide and 0.5-50% of slagging constituent, and can effectively raise internal quality of steel.

Owner:张炼

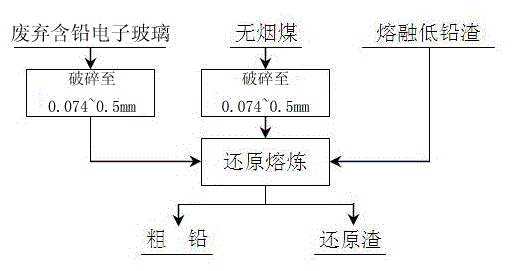

Non-noxious treatment method for waste electronic lead-containing glass

ActiveCN105112682AEasy to separateLow cost of industrializationProcess efficiency improvementSlagProcess engineering

The invention provides a non-noxious treatment method for waste electronic lead-containing glass. The non-noxious treatment method comprises the following process steps: respectively crushing the waste electronic lead-containing glass and anthracite to 0.074-0.5mm, uniformly mixing the waste electronic lead-containing glass and the anthracite to obtain a material mixture, and adding the material mixture into molten low-lead slag melt; and smelting the material mixture for 0.5-1.0 hour at a temperature of 1200-1250 DEG C, thereby obtaining crude lead and reducing slag. The method disclosed by the invention is adopted to treat the lead-containing glass, so that the purity of the crude read is higher than 98%, the lead content of the reducing slag is lower than 2%, and the recovery rate of the lead is higher than 90%. The non-noxious treatment method has the characteristics of being flexible in technology and simple in process, and can sufficiently utilize sensible heat of the molten low-lead slag to realize effective utilization of heat energy while resources are saved; and the non-noxious treatment method is relatively low in industrial cost, and beneficial for enterprises to apply the technology to a simultaneous treatment process of the waste electronic lead-containing glass and the waste lead slag.

Owner:NORTHEASTERN UNIV

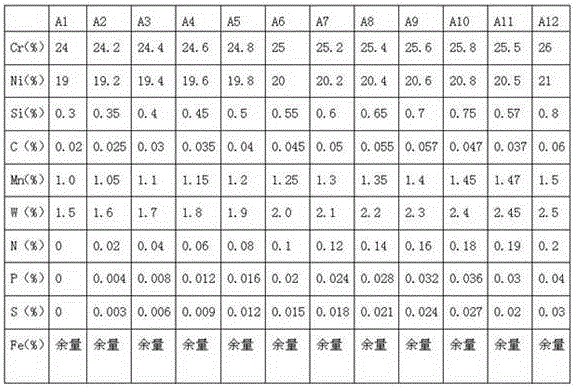

High-temperature-resistant austenitic stainless steel for furnace pipe

InactiveCN105803318AShort smelting cycleReduce smelting energy consumptionElectric furnaceProcess efficiency improvementSS - Stainless steelAustenite

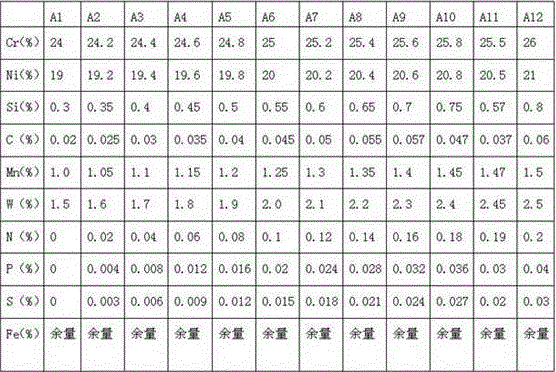

The invention relates to high-temperature-resistant austenitic stainless steel for a furnace pipe. The high-temperature-resistant austenitic stainless steel comprises the following components in percentage by mass: 24-26% of Cr, 19-21% of Ni, 0.3-0.8% of Si, 0.02-0.06% of C, 1.0-1.5% of Mn, 1.5-2.5% of W, less than or equal to 0.2% of N, less than or equal to 0.04% of P, less than or equal to 0.03% of S and the balance of Fe. According to the high-temperature-resistant austenitic stainless steel, high-temperature creep resistance and oxidation resistance which are better than those of 310 heat-resistant stainless steel are provided; and the high-temperature-resistant austenitic stainless steel can be used for a longer time at a temperature above 1000 DEG C.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Composite refiner for metallurgy

The invention was involved in compound refiner in metallurgy. It consist of 30%-50% silicon calcium alloy+ silicon calcium cinder, 10%-30% silicon barium alloy + silicon barium cinder, 15% carbide, 5%lime stone or aluminous, and 20% magnesium+ magnesium cinder. Compared with the exist products, this invention was with short periodic time, low cost, fine effect of deoxidation, desulfuring, removing inclusion in molten steel and improving the effect of denaturation of molten steel. The inside quality of steel was improved by purifying molten steel.

Owner:张炼

Method for smelting pure copper or high-copper alloy material

InactiveCN107739855AMelting process is fastHigh yieldRotary drum furnacesCrucible furnacesCombustionSmelting process

The invention discloses a method for smelting pure copper or a high-copper alloy material. The method comprises the following steps of S1, preparation of a covering agent and a fluxing agent; S2, preparation of a crucible, a smelting unit and tools; S3, preparation of metal furnace charge; S4, addition of a material; S5, replenishment of elements; S6, stirring reaction; and S7, furnace discharging; By means of the method, the smelting process of the material can be enhanced, the smelting cycle can be shortened, and the production efficiency can be improved; oxidation loss and volatilization loss of the alloy can be reduced, and combustion loss of flaming can be eliminated; impurity elements and gas inclusion in the alloy can be efficiently removed, and the metal casting yield can be increased; by manufacturing the low-viscosity powdery and dry slag, metal loss of furnace slag slagging-off is remarkably reduced, charcoal coverage is omitted, and consumption of charcoal is reduced by 20-25 kg / t; by means of the method, environmental pollution can be reduced, the labor environment can be improved, environmental protection equipment and occupied space are omitted, and fixed asset investment and equipment operating cost can be reduced.

Owner:TONGLING HAIYUAN SUPERFINE POWDER

Direct reduction ironmaking method by electric furnace

InactiveCN102703635AShort processReduce manufacturing costElectric furnaceElectric arc furnaceEconomic benefits

The invention discloses a direct reduction ironmaking method by an electric furnace, belonging to the technical field of ferrous metallurgy. An outlet of a multistage reactor is connected with an inlet of the electric furnace, coal powder is put into the electric furnace and heated, generated coal gas ascends and is introduced into the multistage reactor, iron ores are put into a first stage reactor of the multistage reactor after being treated by pelletizing and sequentially pass through the multistage reactor, an iron ore pellet obtained from the multistage reactor is then sent into the electric furnace, and finally the iron ore pellet is heated by the electric furnace and also reacted with the coal powder so as to obtain molten iron after ionmaking by the electric furnace. By developing the technology, the smelting energy consumption can be dramatically lowered, the operation conditions and smelting economic and technical indexes are improved, the economic benefit is increased, and the resource is effectively utilized.

Owner:KUNMING UNIV OF SCI & TECH

Lead paste smelting process

ActiveCN110512078AWide variety of sourcesHigh purityWaste accumulators reclaimingProcess efficiency improvementSmelting processLead oxide

The invention discloses a lead paste smelting process. The process includes the following steps: firstly, raw material pretreatment; secondly, impurity removal; thirdly, primary smelting, wherein acid-treated lead paste is molten in a melting furnace, and then a mixture of lead oxide and starch is added and smelted at a low temperature to obtain first smelt; fourthly, secondary smelting, wherein the first smelt is heated and molten and kept warm, then starch is added to the first smelt, and reaction and discharging are conducted to complete smelting. There are two smelting steps; the primary smelting is low-temperature smelting, in the low-temperature smelting, NaOH is adopted as a desulfurizing agent, starch is adopted as a reducing agent, and polysaccharide starch is adopted as a naturalhigh-molecular substance, sources are wide, no harmful impurities are introduced, the reducing capacity is strong, and the desulfurization conversion and reduction conversion of lead paste are simultaneously realized through a hydrothermal reduction method; in the secondary smelting, starch is directly adopted as a reducing agent for reducing PbO to obtain high-purity lead. After testing, the recovery rate of metal lead can reach 96.0% or above, and the purity of the recovered metal lead reaches 99.95% or above.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

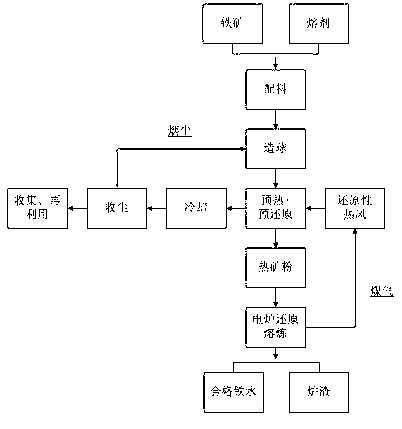

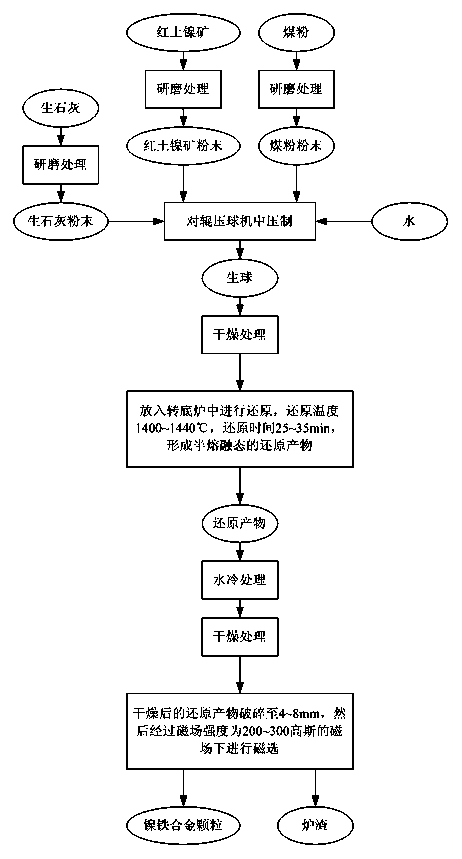

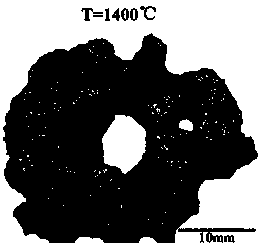

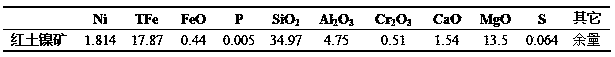

Method for producing ferro-nickel alloy from low-grade laterite-nickel ore in half-molten state

InactiveCN103695634ALow reduction temperatureShort smelting cycleMagnetic separationMolten stateSlag

The invention provides a method for producing a ferro-nickel alloy from low-grade laterite-nickel ore in a half-molten state. In the method, reduction is performed at a relatively low temperature of 1,400-1,440 DEG C, the slag in the reduction product and the reduced ferro-nickel alloy are both in a half-molten state, and then the ferro-nickel alloy is pushed by the slag and gathered by use of the phase interface acting force between the slag and ferro-nickel alloy in the half-molten state, so that the ferro-nickel alloy is mixed in the slag pores in a form of ferro-nickel alloy particles after being cooled; in follow-up steps, the slag-iron separation is performed through magnetic separation without heating the ferro-nickel alloy and slag to a full-molten state for easy flowing before separation. Therefore, the reduction temperature is relatively low, and the reduction time is only 25-35 minutes; compared with the laterite-nickel ore treatment process of the prior art needing high temperature over 1,650 DEG C and reduction time of at least one hour, the method provided by the invention has a short smelting cycle, obviously reduces the energy consumption and effectively controls the smelting cost.

Owner:CHONGQING UNIV

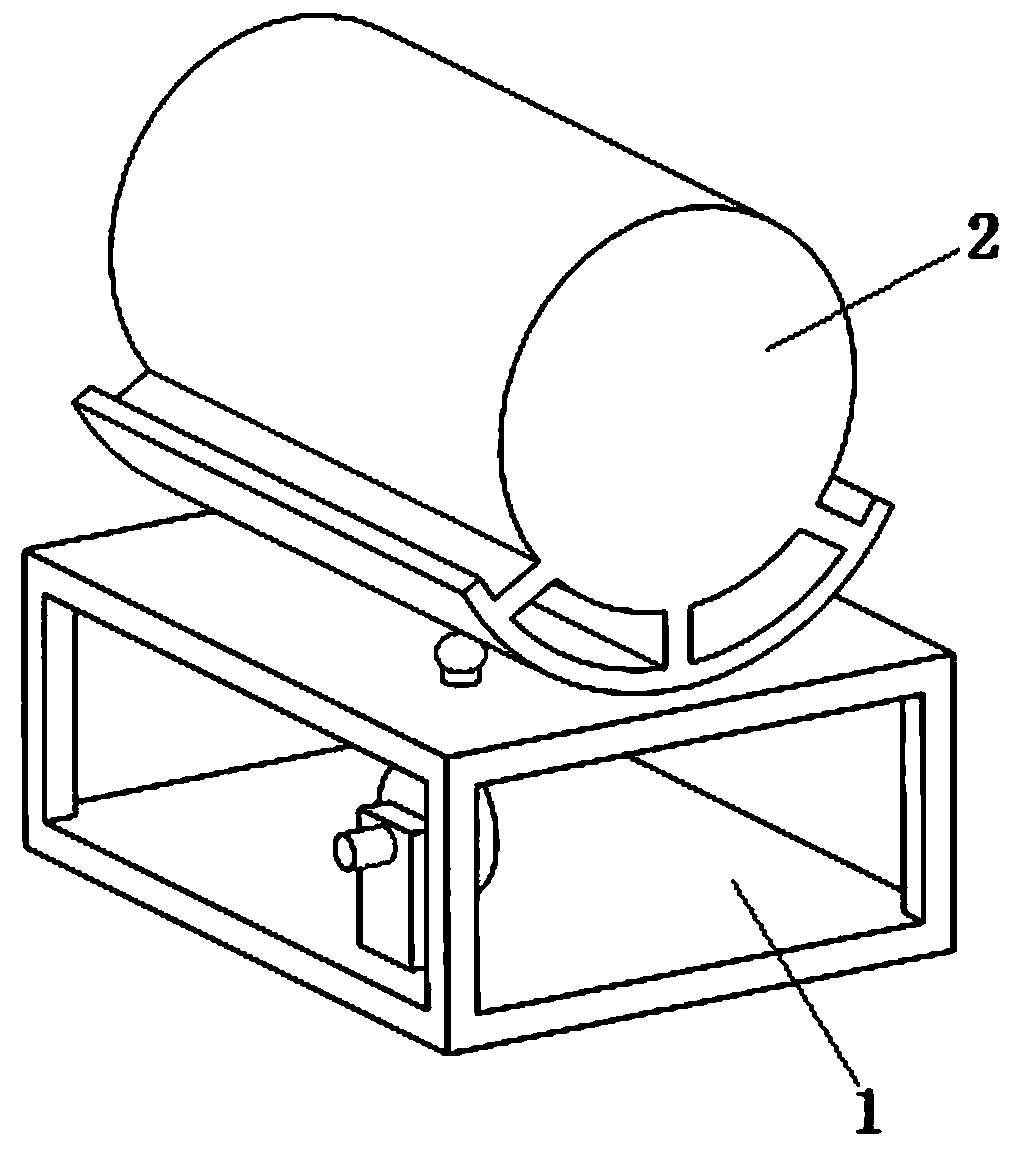

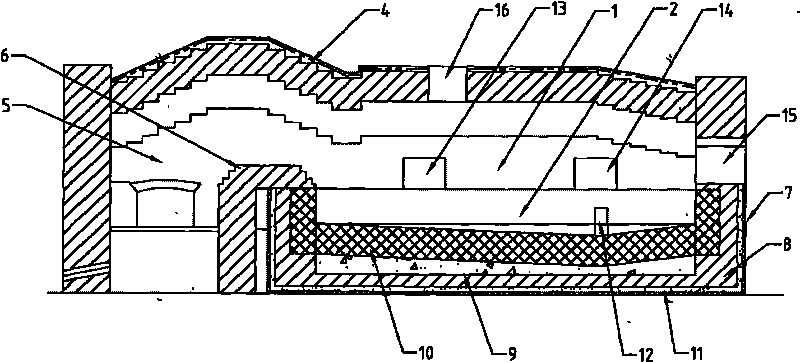

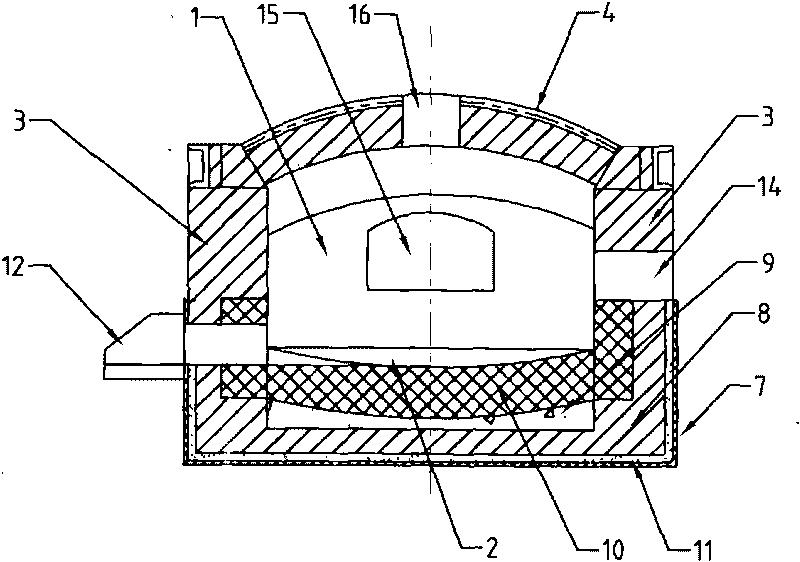

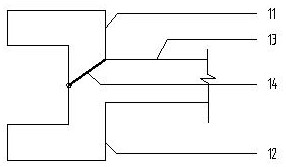

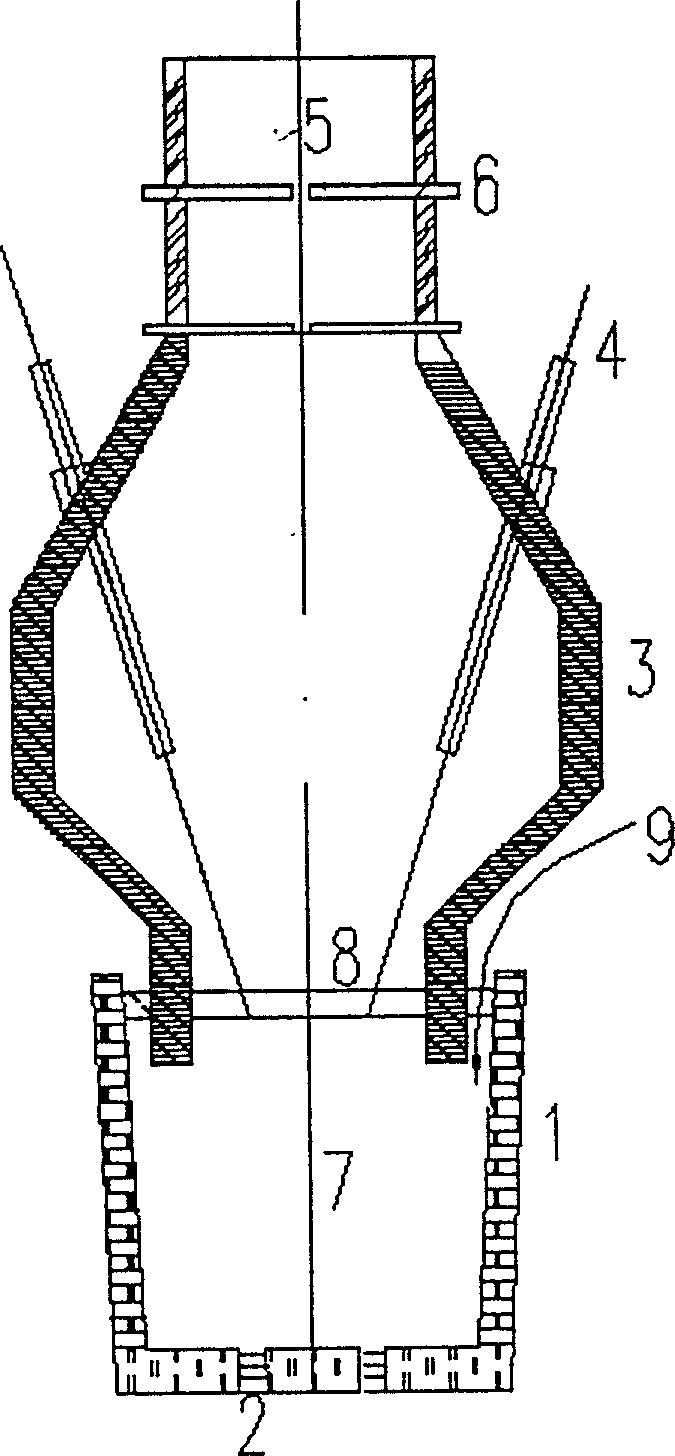

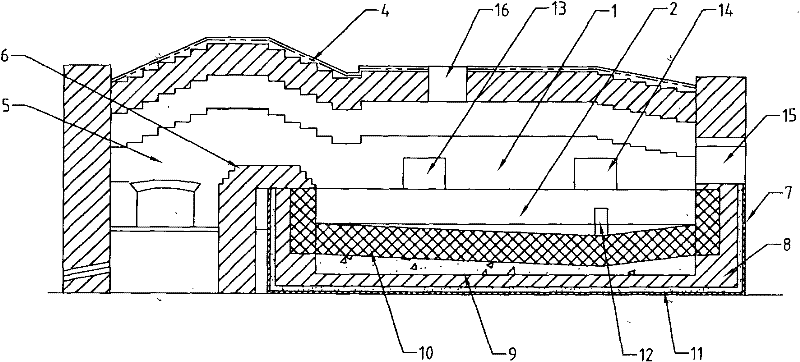

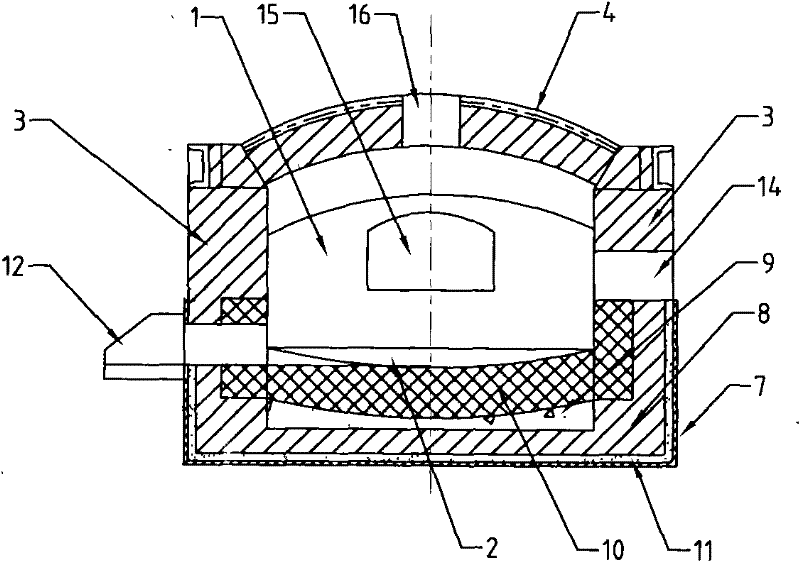

Reflecting furnace for smelting tin lead materials

ActiveCN101762150AReduce headroomHeating fastLighting and heating apparatusProcess efficiency improvementMelting tankSlag

The invention relates to a reflecting furnace for smelting tin lead materials, belonging to smelting equipment. The reflecting furnace is mainly composed of a furnace hearth (1), a furnace bottom smelting tank (2), a furnace wall (3) and a furnace top (4), wherein the furnace bottom smelting tank (2) is positioned below the furnace hearth (1), and a low fire baffle wall (6) is arranged between a fire chamber (5) in the furnace wall and the furnace hearth (1). A slag discharging opening (12) for discharging tin lead alloy is arranged on one side wall of the furnace near the position of a furnace tail, two working doors (13, 14) are arranged on the other side wall of the furnace, a smoke outlet (15) is arranged on the furnace wall at the tail part, and a charging opening (16) is arranged on the furnace top (4). The arc shape of the furnace top on the low fire baffle wall (6) is shown to press down towards the two sides; the position of the furnace top to the furnace hearth (1) is horizontal, and the position of the furnace top to the furnace tail is pressed towards the furnace tail in an inclined manner. The reflecting furnace has the advantages of high heat efficiency, quick material smelting, low cost and less coal consumption with the coal combustion rate of 42 to 48%.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

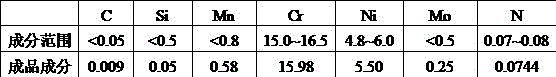

Production process of austenitic stainless steel slab used for high temperature resistant furnace hearth

InactiveCN106011680AShort smelting cycleReduce smelting energy consumptionElectric furnaceProcess efficiency improvementIntermediate frequencyEconomic benefits

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Method for quickly smelting low-nitrogen stainless steel through vacuum induction furnace

ActiveCN105970074AThe reaction process is stable and controllableShort smelting cycleNitrogen atmosphereLow nitrogen

The invention discloses a method for quickly smelting low-nitrogen stainless steel through a vacuum induction furnace, and belongs to the technical field of steel and iron metallurgy. The method comprises the steps of (1) adding steel and iron materials and an alloy material not liable to oxidize into a vacuum induction furnace crucible; (2) firstly, carrying out vacuum pumping, and then, performing energization for heating till the steel and iron materials are melted; (3) after melting, measuring the temperature, and carrying out refining with the vacuum degree and temperature maintained; (4) calculating the required nitrogen pressure, then, filling the furnace with nitrogen with the required pressure, and carrying out nitrogen increase alloying; and (5) carrying out alloying of other alloy materials under the nitrogen atmosphere, and carrying out pouring in the planned steel pouring time. According to the method, nitrogen alloying is carried out through utilizing nitrogen, the alloying of other elements is carried out under the nitrogen atmosphere protection, the reaction process is steady and controllable, the melting cycle is short, and the purpose that the low-nitrogen stainless steel is quickly and accurately smelted is achieved.

Owner:HEBEI IRON AND STEEL

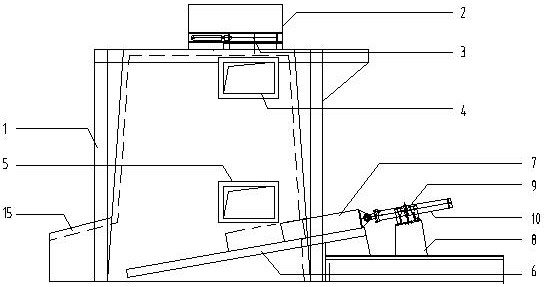

Vertical shaft stock bin for scrap steel preheating processing

PendingCN112299041ARaise the preheat temperatureLower discharge temperatureLoading/unloadingSlagHot work

The invention discloses a vertical shaft stock bin for scrap steel preheating processing. The vertical shaft stock bin comprises a bin body, a feeding port and a sealing system are arranged on the upper portion of the bin body, the sealing system comprises a valve, an upper air suction port and a lower air suction port, the valve is arranged at the feeding port, and the upper air suction port andthe lower air suction port are arranged on a bin main body of the bin body up and down. According to the vertical shaft stock bin, the arrangement manner that a vertical shaft stock bin is directly arranged on a smelting electric furnace in the past is changed, and the problem that the service life of the electric furnace is affected due to large impact to the smelting electric furnace below whensteel scrap with the weight of dozens of tons is discharged is solved; and meanwhile, the vertical shaft stock bin has the characteristics of being good in steel scrap preheating effect and good in sealing performance, the problem that the temperature in the electric furnace is sharply reduced cannot be caused during steel scrap discharging, high-temperature foam slag in the furnace cannot be affected, and therefore the steel smelting efficiency is further improved.

Owner:HENAN TAIHANG QUANLI HEAVY IND

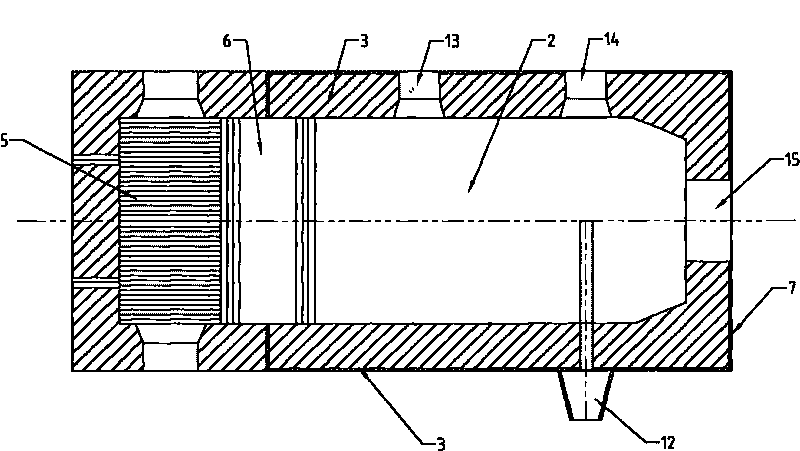

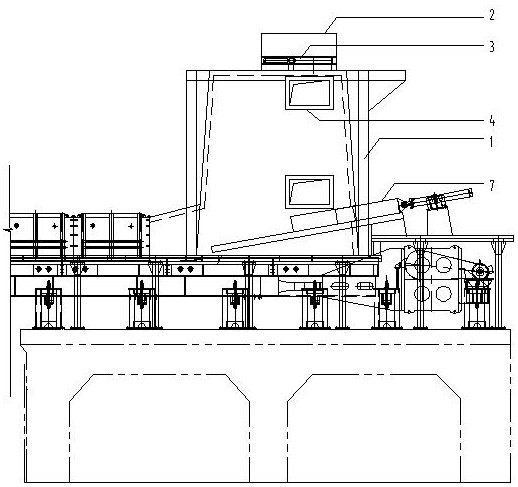

Bucket type closed steel smelting furnace

InactiveCN1603423AQuality improvementReduce pollutionProcess efficiency improvementSteelmakingTemperature control

One kind of barrel type shuts the chest cavity steel-smelting furnace, belongs to the steel-making domain, specially involves a kind of steel-making special purpose equipment. The barrel type steel-smelting furnace (3) is composed by steel ladle (1) and the jack-in type enclosed type chamber, steel ladle (1) on along supposes slag spout, gets down supposes ventilates the brick (2), the enclosed chamber (3) upside (5) is connected with the scrap steel preheating furnace stack, the furnace stack (5) is equipped with feeds in raw material the mouth and the water cooling holds the material arm (6), the stove hall (3) on installs has the oxygen gun (4). The invention equipment quantity few, smelting cycle short, thermal efficiency high, the coal gas quality good, the recycling quantity is big, remarkably reduced the environmental pollution, but also created had continuously measured the temperate sample condition, improved the molten steel ingredient and the temperature control.

Owner:UNIV OF SCI & TECH BEIJING

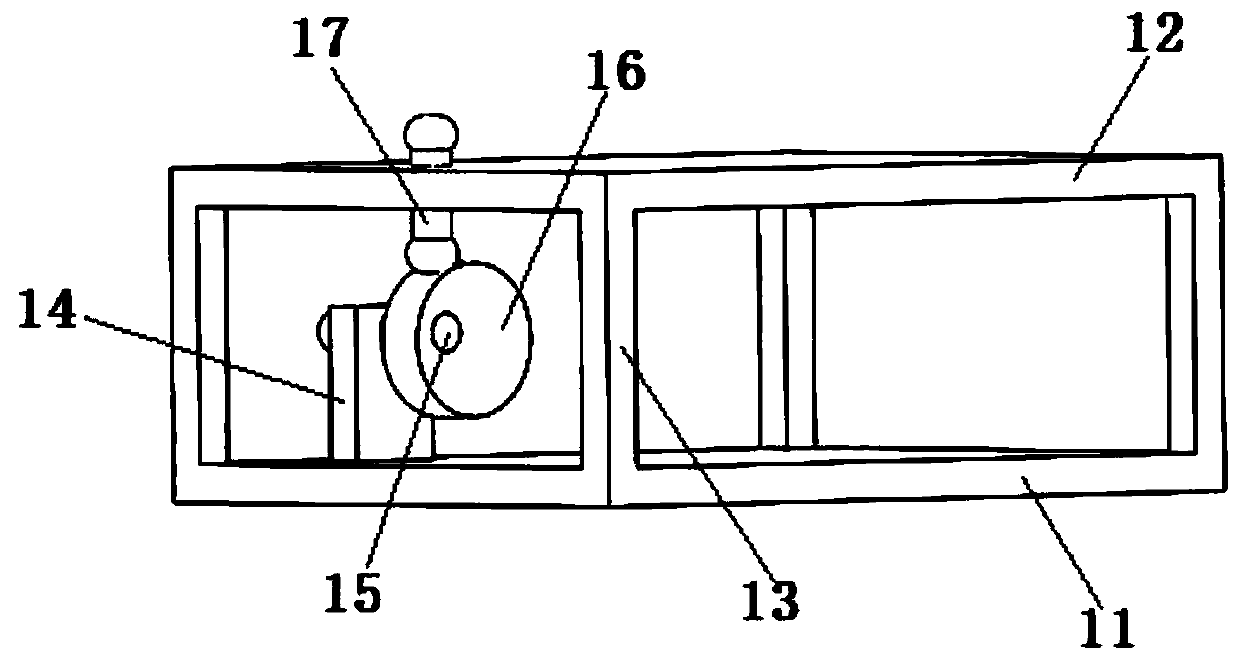

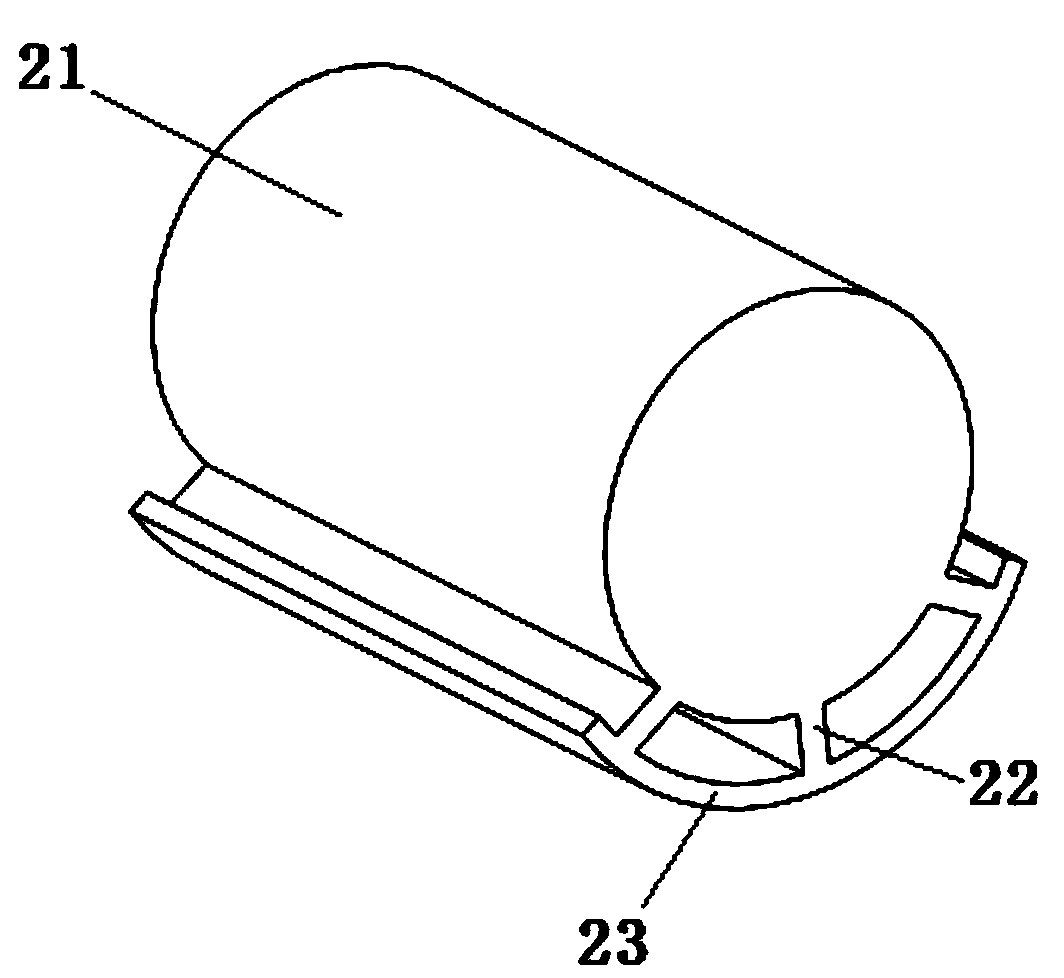

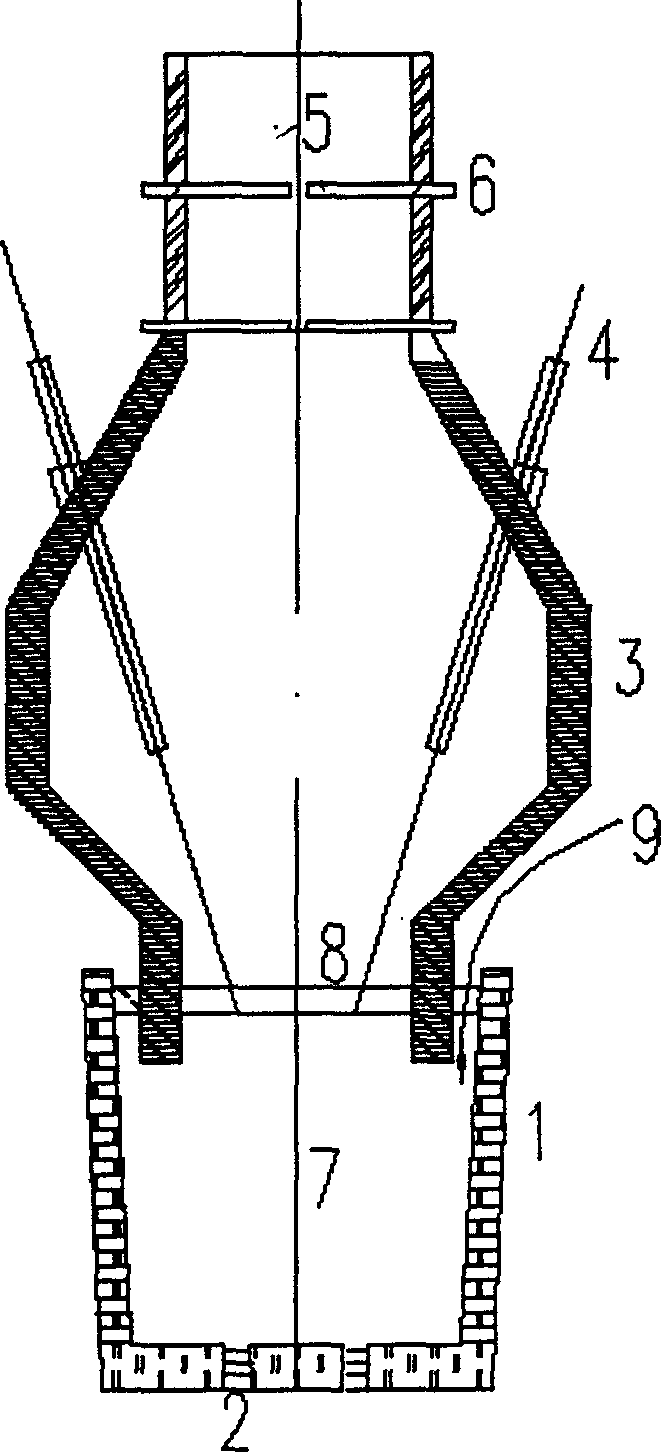

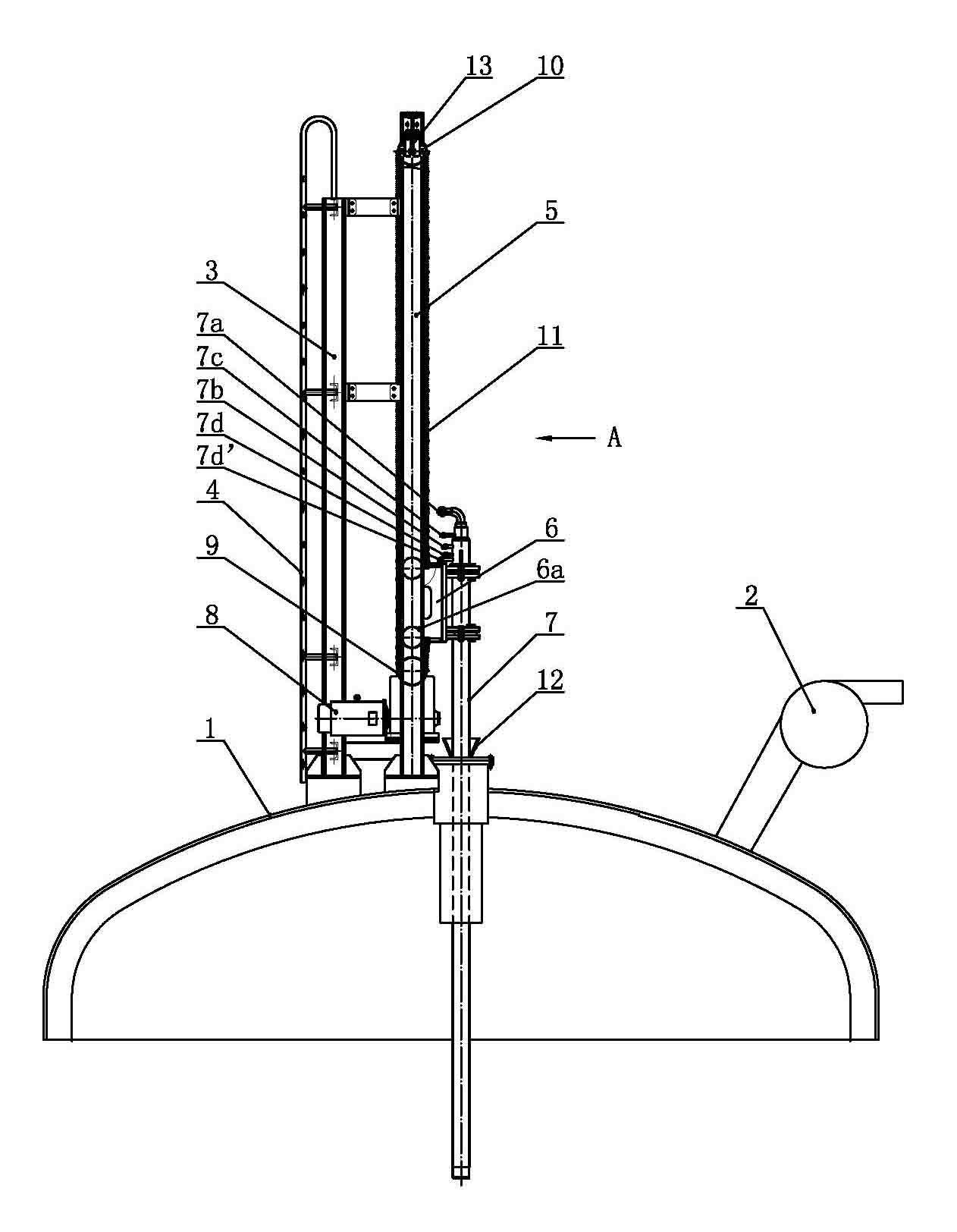

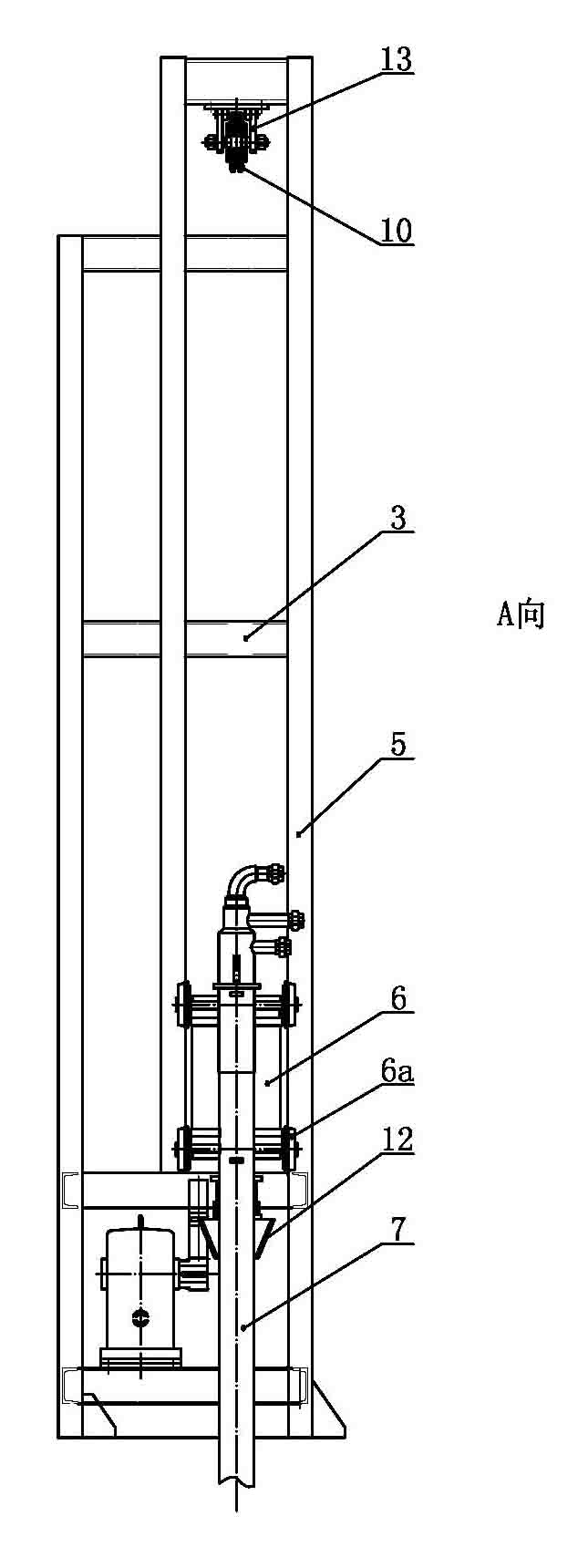

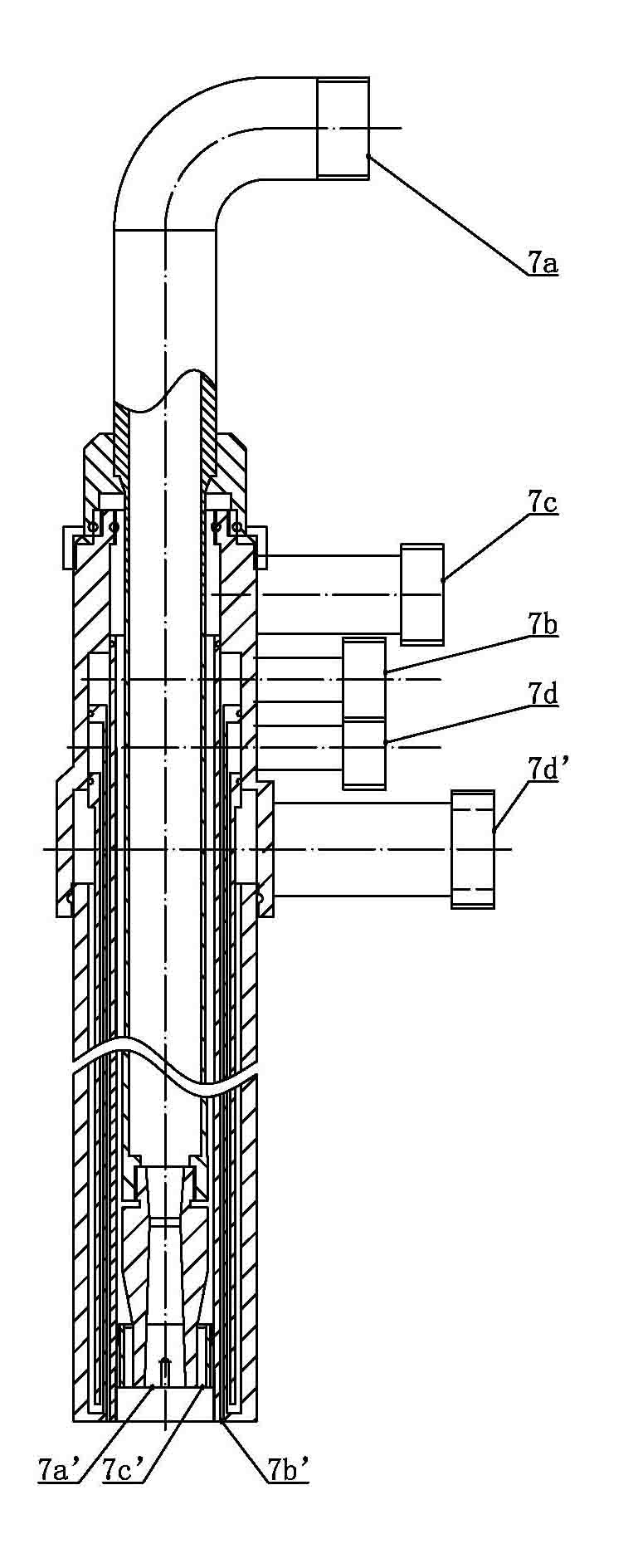

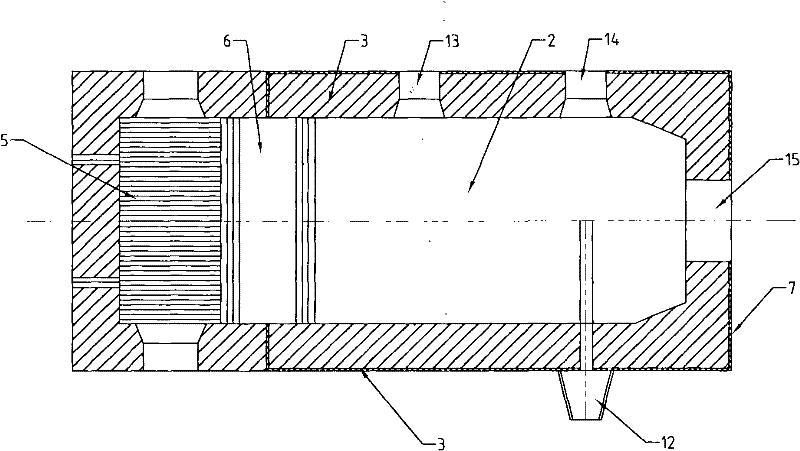

Top oxygen-blowing combustion system for intermediate frequency furnace

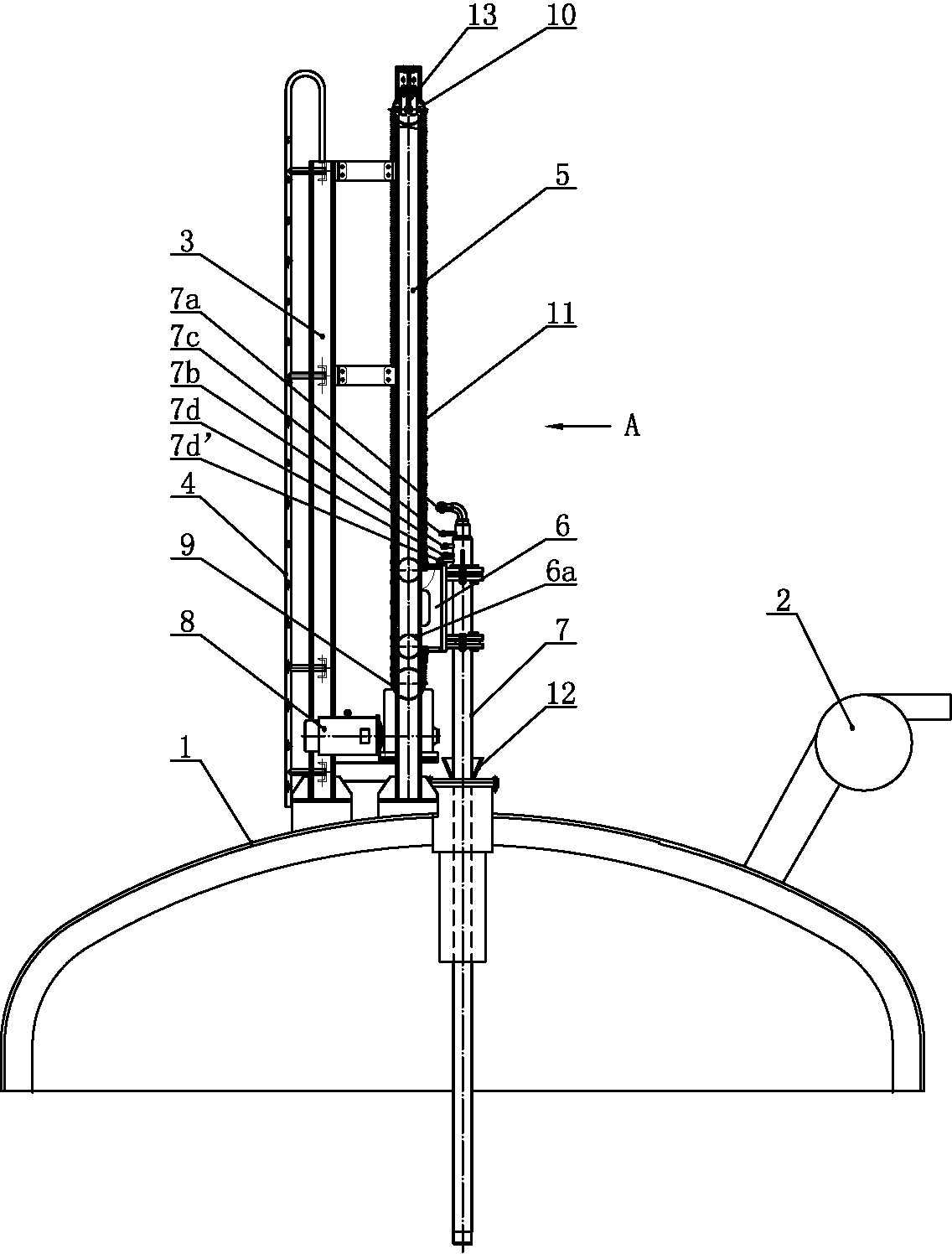

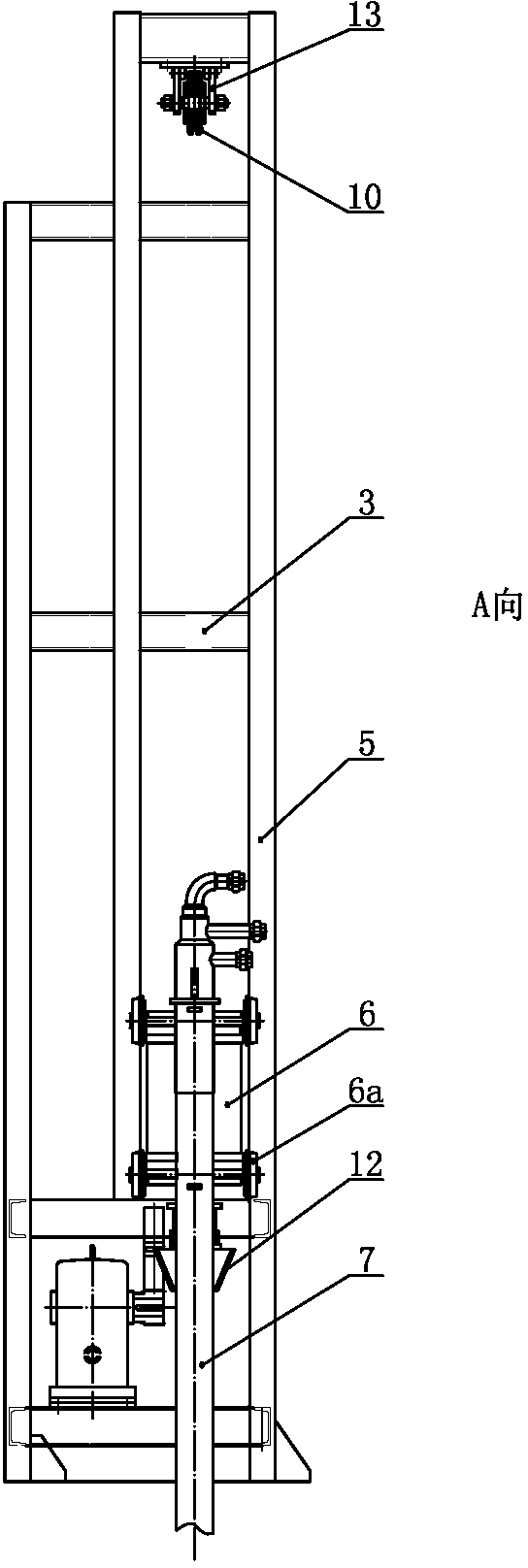

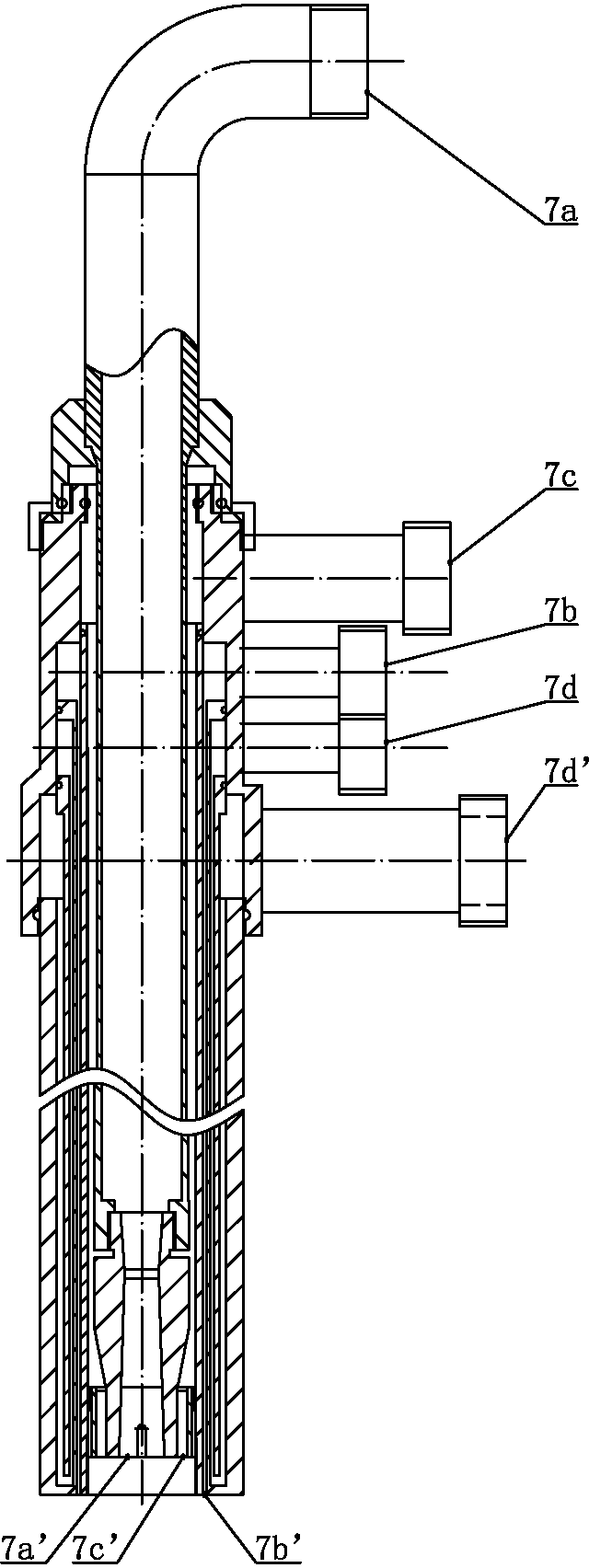

The invention relates to a top oxygen-blowing combustion system for an intermediate frequency furnace and belongs to the technical field of the intermediate frequency furnace. A bracket is arranged above a furnace cover of the intermediate frequency furnace; a vertical guide rail and a lifting trolley are mounted on the bracket; the lifting trolley is supported on the vertical guide rail by idlerwheels and is capable of moving up and down; an upper chain wheel is mounted at the upper end of the vertical guide rail; a lower chain wheel is mounted at the lower end of the vertical guide rail; the upper chain wheel and the lower chain wheel are in transmission connection through a chain; one end of the chain is connected with the upper part of the lifting trolley while the other end is connected with the lower part of the lifting trolley; an intermediate frequency furnace oxygen combustion gun is fixedly arranged on the lifting trolley; and a gun head of the intermediate frequency furnace oxygen combustion gun is vertically inserted into the intermediate frequency furnace from the top of the furnace cover along the axis of the furnace cover. The furnace oxygen combustion gun is capable of spraying baking flame to preheat metal in the earlier stage and then is capable of spraying cutting flame to cut the metal; after the metal is molten, molten iron is stirred and slagged; lastly,decarbonization is realized; no decarbonizing agent is necessary; the smelting period is greatly shortened; the power consumption of an intermediate frequency power supply is reduced; and the tappingquality is high.

Owner:扬州市恒阳冶金科技有限公司

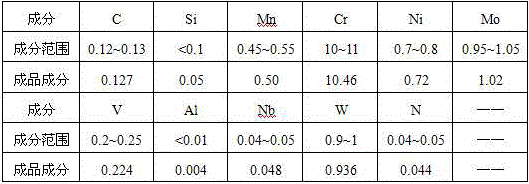

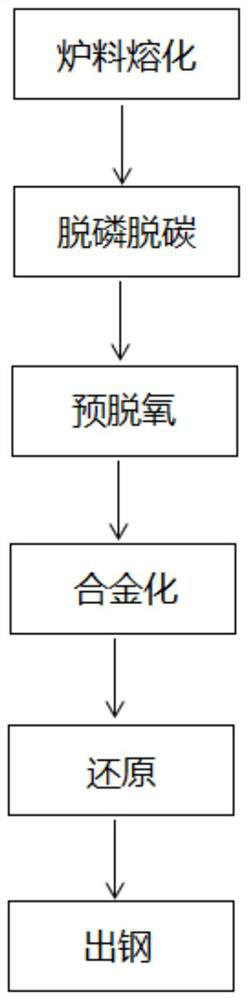

A kind of smelting method of zg06cr13ni4mo steel and zg06cr13ni4mo steel

ActiveCN112662838BImprove purityReduce smelting costProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD

Bucket type closed steel smelting furnace

InactiveCN1236074CQuality improvementReduce pollutionProcess efficiency improvementSteelmakingTemperature control

One kind of barrel type shuts the chest cavity steel-smelting furnace, belongs to the steel-making domain, specially involves a kind of steel-making special purpose equipment. The barrel type steel-smelting furnace (3) is composed by steel ladle (1) and the jack-in type enclosed type chamber, steel ladle (1) on along supposes slag spout, gets down supposes ventilates the brick (2), the enclosed chamber (3) upside (5) is connected with the scrap steel preheating furnace stack, the furnace stack (5) is equipped with feeds in raw material the mouth and the water cooling holds the material arm (6), the stove hall (3) on installs has the oxygen gun (4). The invention equipment quantity few, smelting cycle short, thermal efficiency high, the coal gas quality good, the recycling quantity is big, remarkably reduced the environmental pollution, but also created had continuously measured the temperate sample condition, improved the molten steel ingredient and the temperature control.

Owner:UNIV OF SCI & TECH BEIJING

Method for converting electric furnace into converter

PendingCN114657321ARealize conversionGuaranteed zero power consumption smeltingElectric furnaceSmelting processMolten steel

The invention relates to the field of smelting process control, in particular to a method for converting an electric furnace into a converter. Comprising the following steps: (1) after the last furnace is smelted, the steel remaining amount in the furnace is 10-20% of the steel tapping amount, lifting an electrode to the highest position, screwing out a furnace cover, firstly adding waste steel, and adding molten iron accounting for 75-90% of the total steel material; (2) oxygen blowing is started after molten iron is added, in the first 2-5 minutes, a low-oxygen mode is started, the flow is 3000-3200 Nm < 3 > / h, then a medium-high-oxygen mode is started, the flow is about 4000-6000 Nm < 3 > / h, waste steel is melted down, the temperature is larger than or equal to 1540 DEG C, and sampling and total analysis are conducted; and after the tapping requirement is met, tapping is prepared. The proportion of the molten iron is high, the content of five harmful elements in the molten steel is effectively reduced, the cleanliness of the molten steel is improved, and the quality of steel is effectively improved.

Owner:SHANDONG IRON & STEEL CO LTD

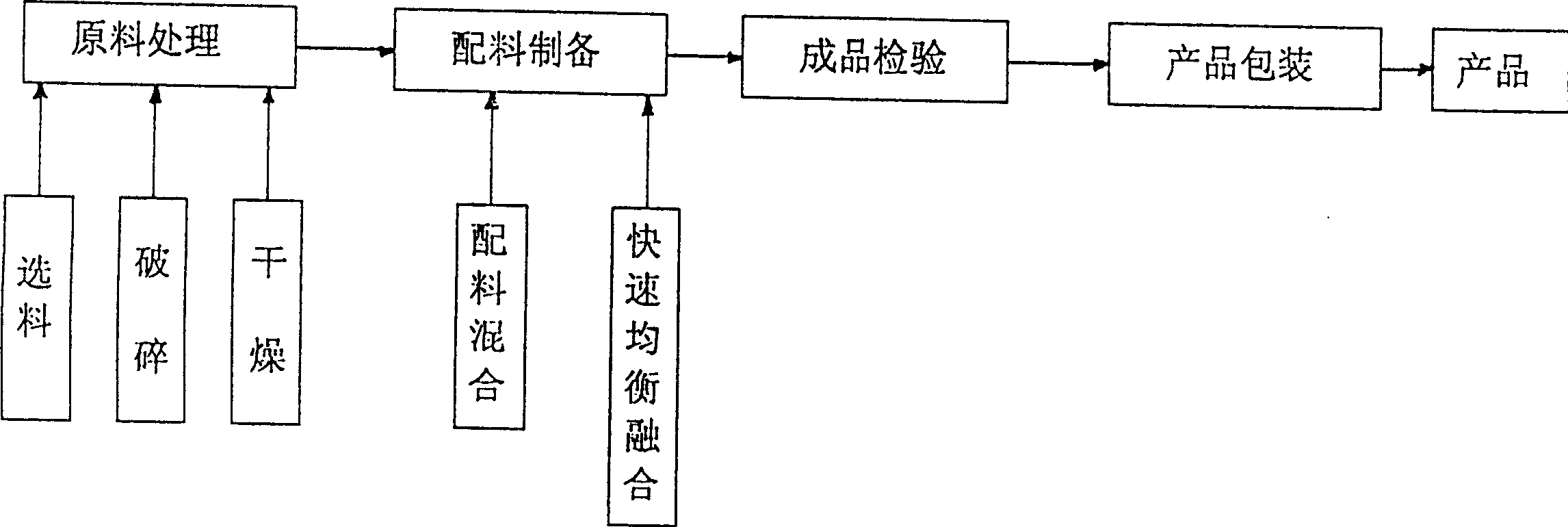

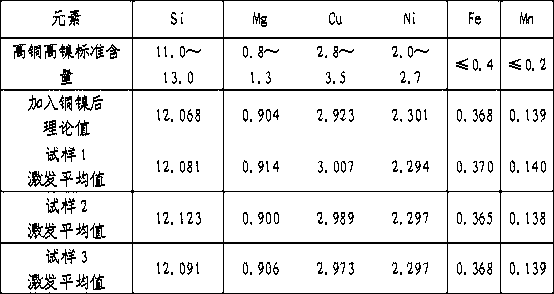

Smelting method for special high-copper and high-nickel liquid aluminum alloy for internal combustion engine aluminum piston

ActiveCN108950265AEfficient productionImprove smelting production efficiencyElement compositionInternal combustion engine

The invention relates to the field of aluminum alloy casting, in particular to a smelting method for special high-copper and high-nickel liquid aluminum alloy for an internal combustion engine aluminum piston. The smelting method is characterized by comprising the following steps of (1) measuring major element compositions of ZL109 liquid aluminum alloy; (2) preparing the high-copper and high-nickel liquid aluminum alloy, calculating the addition quantities of copper and nickel and dissolving and fusing the copper and the nickel; and (3) measuring the content of the copper and the nickel in the high-copper and high-nickel liquid aluminum alloy. The smelting method has the beneficial effects that no additional smelting equipment is required, the smelting cost is saved, and the smelting cycle is shortened.

Owner:SHANDONG SHUANGGANG PISTON

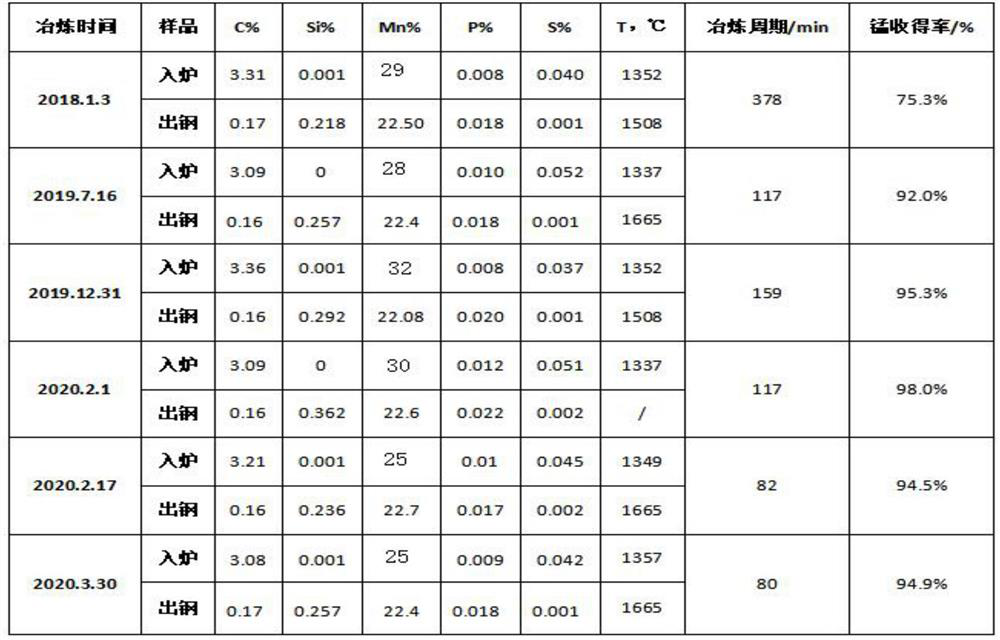

Non-electric furnace aluminum heating mode manganese alloying method for ultra-high manganese steel

InactiveCN112301180AReduce subsequent converter loadImprove converter productivityManufacturing convertersManganeseFerrosilicon

The invention belongs to the technical field of metallurgy, and particularly relates to a non-electric furnace aluminum heating mode manganese alloying method for ultra-high manganese steel. The invention provides the non-electric furnace aluminum heating mode manganese alloying method for the ultra-high manganese steel. The method utilizes chemical heat generated by an oxidation exothermic reaction of oxygen and a large amount of alloy elements such as silicon iron, aluminum particles and the like to replace electric heat of an electric furnace to melt manganese alloy in the process of rapiddecarburization under excellent dynamic conditions of a converter and oxygen blowing in the converter process. According to the technology, the current situation that manganese alloying of the ultra-high manganese steel can only be completed through an electric furnace or an intermediate frequency furnace for a long time is changed, and the problems that in the electric furnace manganese alloyingprocess of a traditional technology, the melting time period of a large number of manganese alloys is long, molten steel uniformity is poor, the manganese yield is poor, and cost is high are solved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Reflecting furnace for smelting tin lead materials

ActiveCN101762150BReduce headroomHeating fastLighting and heating apparatusProcess efficiency improvementMelting tankSlag

The invention relates to a reflecting furnace for smelting tin lead materials, belonging to smelting equipment. The reflecting furnace is mainly composed of a furnace hearth (1), a furnace bottom smelting tank (2), a furnace wall (3) and a furnace top (4), wherein the furnace bottom smelting tank (2) is positioned below the furnace hearth (1), and a low fire baffle wall (6) is arranged between a fire chamber (5) in the furnace wall and the furnace hearth (1). A slag discharging opening (12) for discharging tin lead alloy is arranged on one side wall of the furnace near the position of a furnace tail, two working doors (13, 14) are arranged on the other side wall of the furnace, a smoke outlet (15) is arranged on the furnace wall at the tail part, and a charging opening (16) is arranged on the furnace top (4). The arc shape of the furnace top on the low fire baffle wall (6) is shown to press down towards the two sides; the position of the furnace top to the furnace hearth (1) is horizontal, and the position of the furnace top to the furnace tail is pressed towards the furnace tail in an inclined manner. The reflecting furnace has the advantages of high heat efficiency, quick material smelting, low cost and less coal consumption with the coal combustion rate of 42 to 48%.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for smelting high-quality carbon steel in 120t converter

InactiveCN113201622ASolve the problem of serious splashing and difficult dephosphorizationReduce smelting costManufacturing convertersProcess efficiency improvementSlagFerrosilicon

The invention belongs to the technical field of carbon steel smelting, and particularly relates to a method for smelting high-quality carbon steel in a 120t converter. The method comprises the following steps of preheating scrap steel, diluting molten iron, reserving slag, adding the scrap steel to cover the slag, adding the molten iron, changing a gun, changing the pressure, supplying high-strength oxygen, tapping, and splashing the slag to protect the converter. The method has the advantages of being low in smelting cost, short in smelting period, high in production efficiency and the like, the temperature is low in the processes of low-temperature low-silicon molten iron, heat balance transfer-in, high scrap steel ratio and low-temperature tapping, the carbon-oxygen reaction speed is relatively low, and serious dry returning and splashing are avoided. The full-slag-remaining operation solves the problems that the slag amount of low-silicon molten iron is small, metal splashing is serious, and dephosphorization is difficult. The problems of large slag quantity and serious splashing caused by continuous slag remaining are solved by a back slag discharging process. Based on the gun changing pressure changing operation of the basic gun position, through the whole-process slag opening and low-temperature tapping, the dephosphorization rate of the converter can be remarkably improved, and it is guaranteed that the phosphorus content at the end point is lower than 0.02%.

Owner:山东鲁丽钢铁有限公司

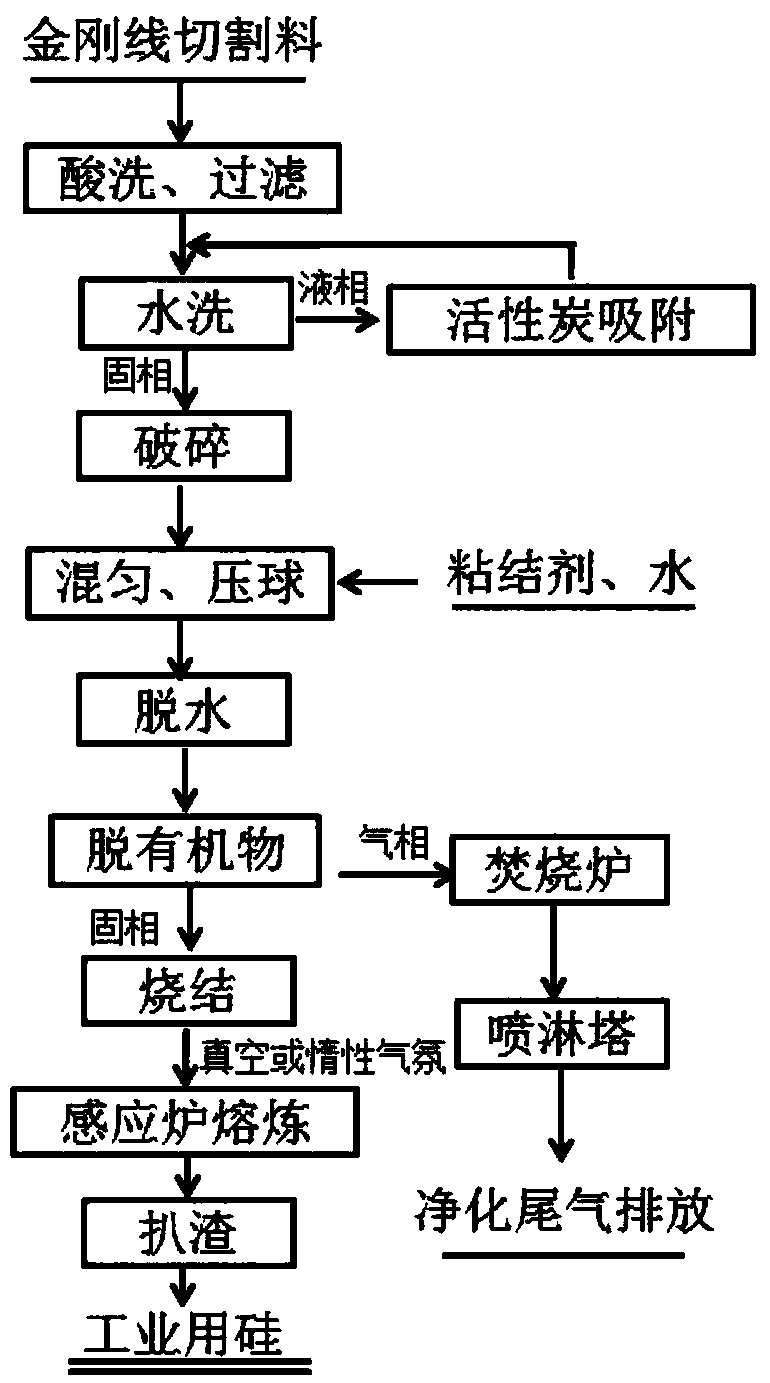

Method for preparing industrial silicon by cutting crystal silicon waste through diamond wires

InactiveCN109399643AHigh strengthHigh compressive strengthSilicon compoundsEnvironmental resistanceDecomposition

The invention provides a method for preparing industrial silicon by cutting crystal silicon waste through diamond wires. The method includes the steps that in percentage by mass: 5-10 wt% of modifiedsodium silicate, 50-65 wt% of the pretreated crystal silicon cutting waste and 30-40 wt% of water are mixed, and a wet ball with the diameter being 1-50 mm is then pressed; low temperature dehydrationis conducted under the condition of 60-90 DEG C until the weight of the wet ball does not change, and a dry ball is obtained; organic matters are removed from the dry ball, the removed organic matters are decomposed, and decomposition products are absorbed by a spray tower and then injected into the atmosphere; the dry ball after removing the organic matters is sintered in an airtight container;the sintered dry ball is smelted in an induction furnace which is lined with a graphite crucible and provided with a graphite bar in the middle; and an alloy is obtained by slagging-off and pouring ofthe smelted products, and the compositions of the alloy are detected. According to the method for preparing the industrial silicon by cutting the crystal silicon waste through the diamond wires, theproduction cycle is short, the dropping strength of the wet and dry balls and the compressive strength are good, and security and environmental protection are achieved.

Owner:NORTHEASTERN UNIV LIAONING

A multi-metal full-path full-valence separation method

ActiveCN105695744BInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementElectrolysisFull Rate

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

Top oxygen-blowing combustion system for intermediate frequency furnace

The invention relates to a top oxygen-blowing combustion system for an intermediate frequency furnace and belongs to the technical field of the intermediate frequency furnace. A bracket is arranged above a furnace cover of the intermediate frequency furnace; a vertical guide rail and a lifting trolley are mounted on the bracket; the lifting trolley is supported on the vertical guide rail by idler wheels and is capable of moving up and down; an upper chain wheel is mounted at the upper end of the vertical guide rail; a lower chain wheel is mounted at the lower end of the vertical guide rail; the upper chain wheel and the lower chain wheel are in transmission connection through a chain; one end of the chain is connected with the upper part of the lifting trolley while the other end is connected with the lower part of the lifting trolley; an intermediate frequency furnace oxygen combustion gun is fixedly arranged on the lifting trolley; and a gun head of the intermediate frequency furnace oxygen combustion gun is vertically inserted into the intermediate frequency furnace from the top of the furnace cover along the axis of the furnace cover. The furnace oxygen combustion gun is capable of spraying baking flame to preheat metal in the earlier stage and then is capable of spraying cutting flame to cut the metal; after the metal is molten, molten iron is stirred and slagged; lastly, decarbonization is realized; no decarbonizing agent is necessary; the smelting period is greatly shortened; the power consumption of an intermediate frequency power supply is reduced; and the tapping quality is high.

Owner:扬州市恒阳冶金科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com