Vertical shaft stock bin for scrap steel preheating processing

A technology of preheating processing and vertical shaft, which is applied in the field of silos, can solve the problems of inability to form high-temperature foam slag, affect the temperature of the melting furnace, and reduce the smelting efficiency, so as to achieve good preheating effect of scrap steel, improve steel smelting efficiency, and shorten the smelting cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

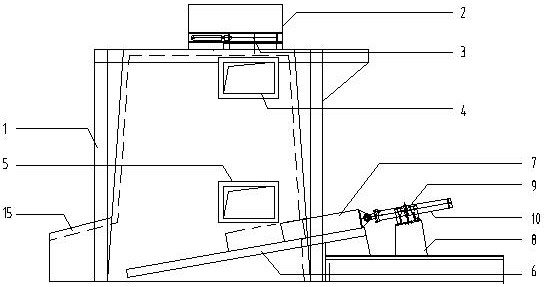

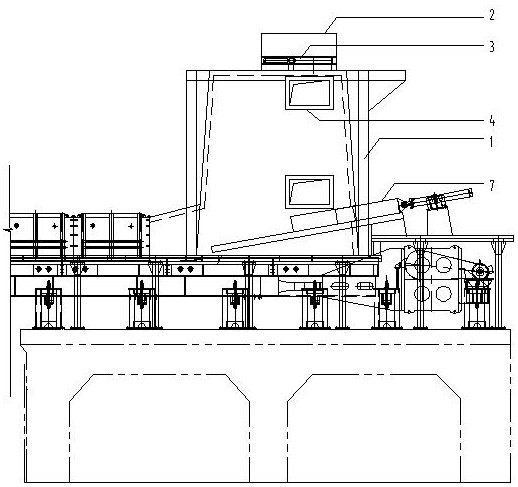

[0022] As shown in the accompanying drawings, the shaft silo for preheating processing of scrap steel according to the present invention includes a silo body 1, and a feed port 2 and a sealing system are arranged on the upper part of the silo body 1 . By setting the feed port and the sealing system, when feeding, the scrap steel enters the interior of the bin from the feed port, and at the same time, the wild wind that enters synchronously with the scrap steel feeding is sucked away through the sealing system, thereby preventing the influence of the external wild wind The melting furnace temperature situation occurs.

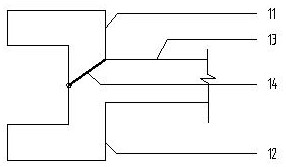

[0023] Specifically, the sealing system includes a valve 3, an upper air outlet 4 and a lower air outlet 5, the valve 3 is arranged at the feed inlet 2, and the valve 3 is preferably an oil cylinder valve. The upper air outlet 4 and the lower air outlet 5 are arranged on the bin body of the bin body 1 up and down. The valve 3, the upper air outlet 4 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com