Method and device for producing coal gas by pulverized coal pyrolysis

A technology of production device and production method, which is applied in gas dust removal, combustible gas production, combustible gas purification, etc., can solve the problems of low cost, high nitrogen content, low gas calorific value, etc., and achieves low coal quality conversion cost and purification. Simple system and high calorific value of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

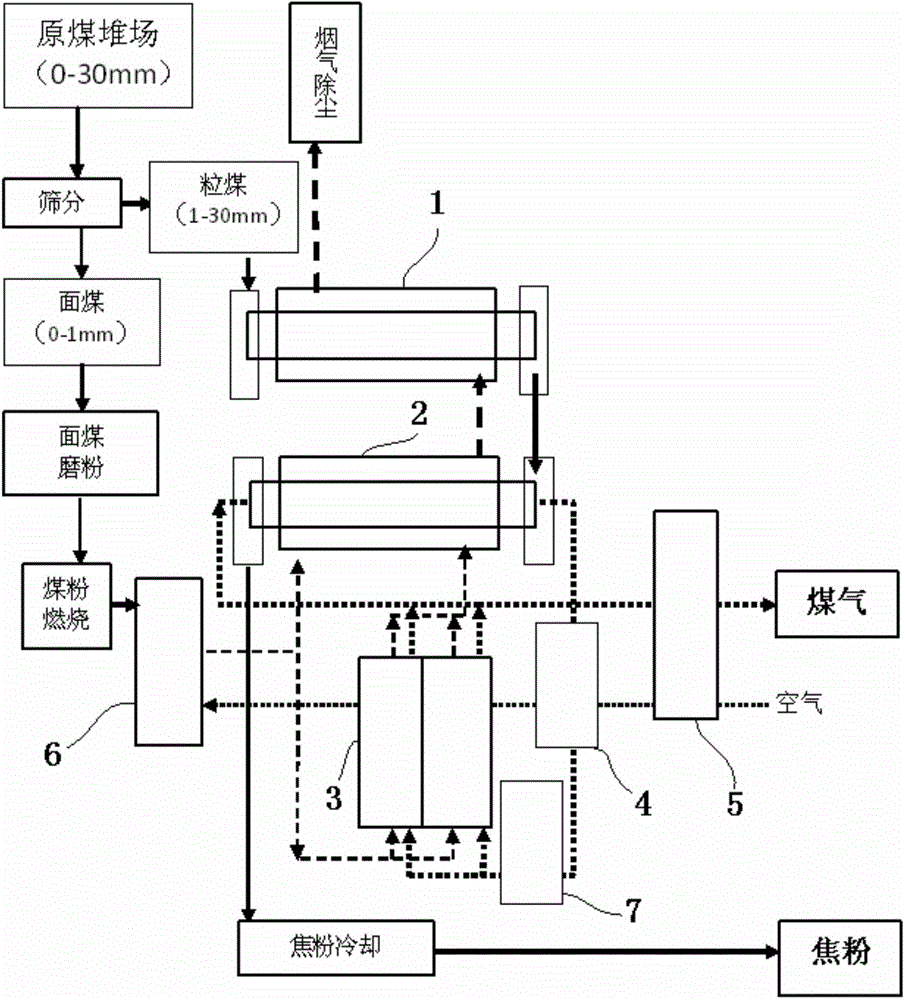

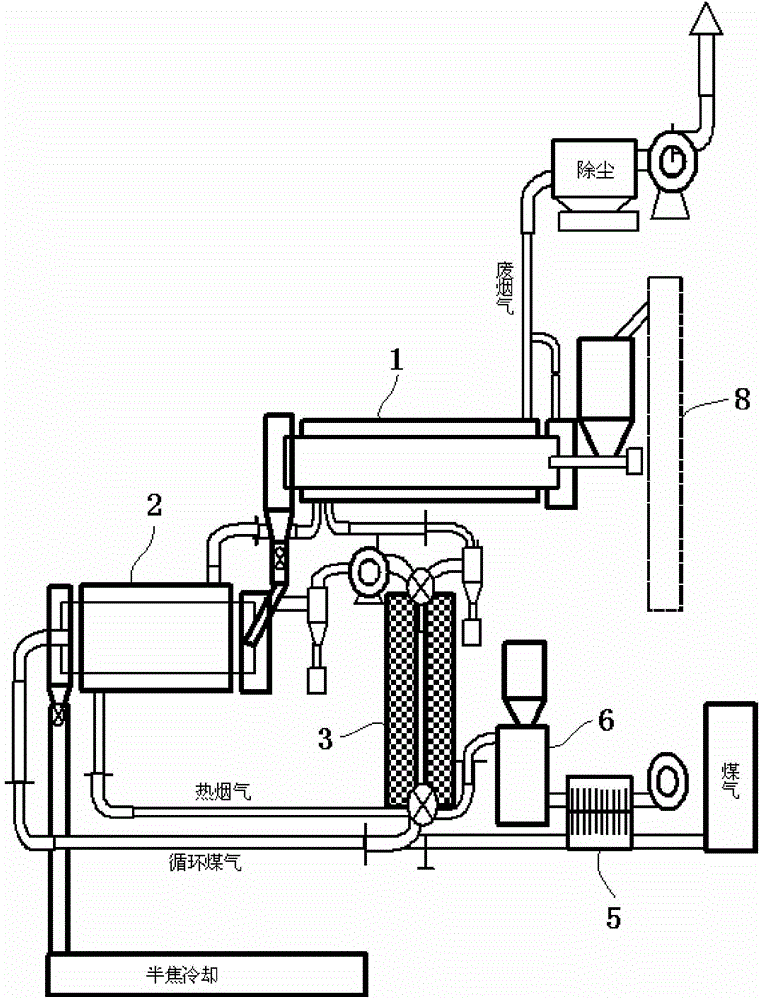

[0050] refer to figure 1 and figure 2 , the device of this embodiment comprises a drying furnace 1, a dry distillation furnace 2, a regenerator 3 and a hot blast furnace 6;

[0051] Drying furnace 1 is a flue gas external heating drying furnace, dry distillation furnace 2 is a rotary furnace combining external heating and internal heating, and the regenerator 3 includes two regenerator monomers. The two monomers have the same structure and are both Including the container body and the heat storage material filled in the container body, the two regenerator cells adopt the method of regular reversing to realize the heat exchange of hot flue gas and coal gas;

[0052] Wherein the drying furnace 1 is located above the carbonization furnace 2, and the outlet of the drying furnace 1 is connected with the inlet of the carbonization furnace 2, the crude gas outlet of the carbonization furnace 2 is connected with the inlet of the cyclone dust collector 4, and the outlet of the cyclon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com