Lead paste smelting process

A processing technology and lead paste technology, which is applied in the field of lead paste smelting and processing technology, can solve the problems such as the purity of metal lead cannot meet the requirements, and achieve the effects of improving production capacity, strong reducing ability and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A process for melting and processing lead paste, comprising the steps of:

[0050] The first step, raw material pretreatment: waste lead plaster, the dismantled product of waste lead-acid batteries, is washed with water until the pH value is 6.8, then dried at 110°C, ground, and passed through a 180-mesh sieve;

[0051] The second step, impurity removal: waste lead paste with 3mol / L H 2 SO 4 The solution was soaked at a temperature of 95°C for 50 minutes, and after liquid-solid separation, it was washed with water until the pH value was 6.8 to obtain an acid-treated lead paste;

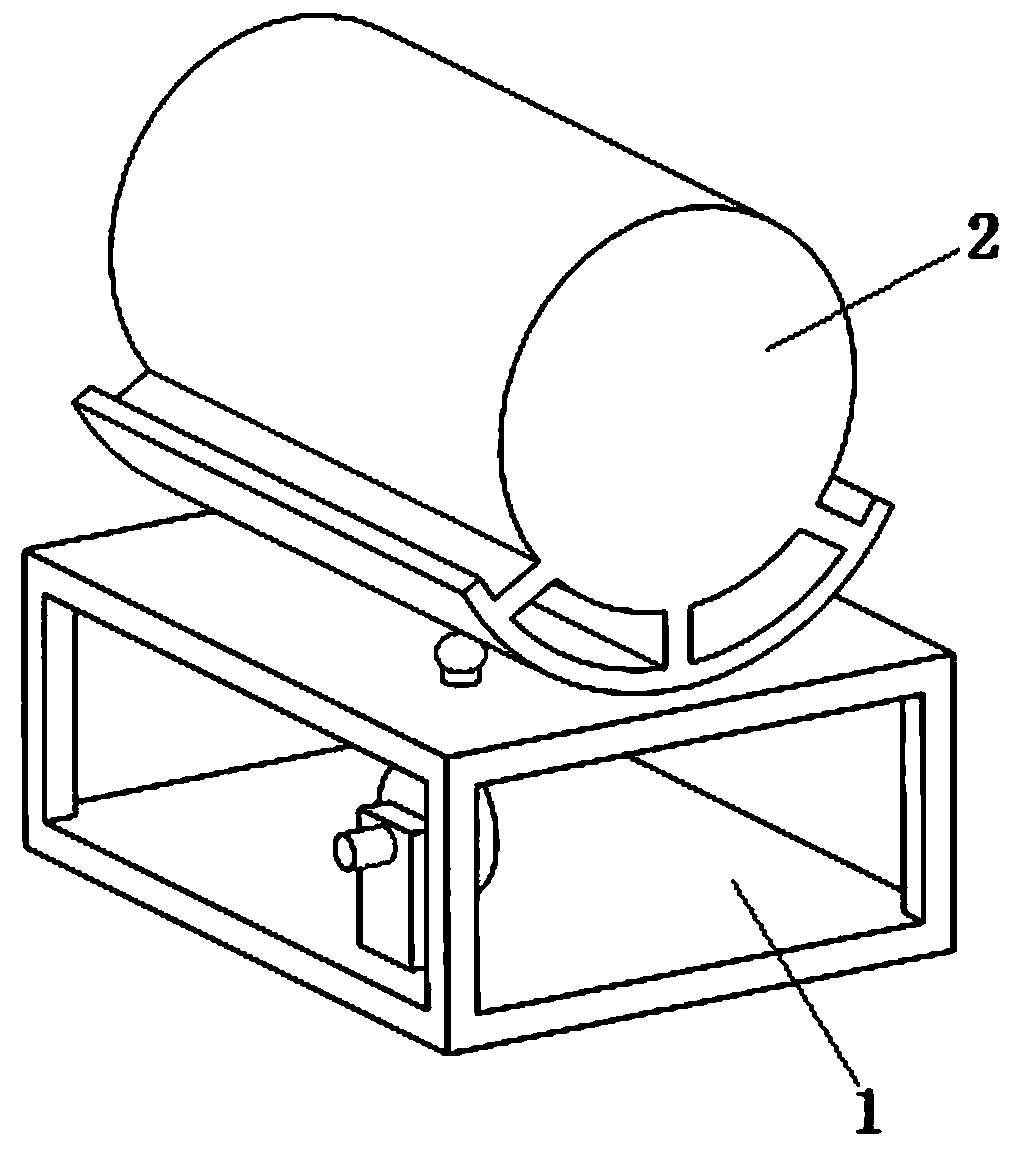

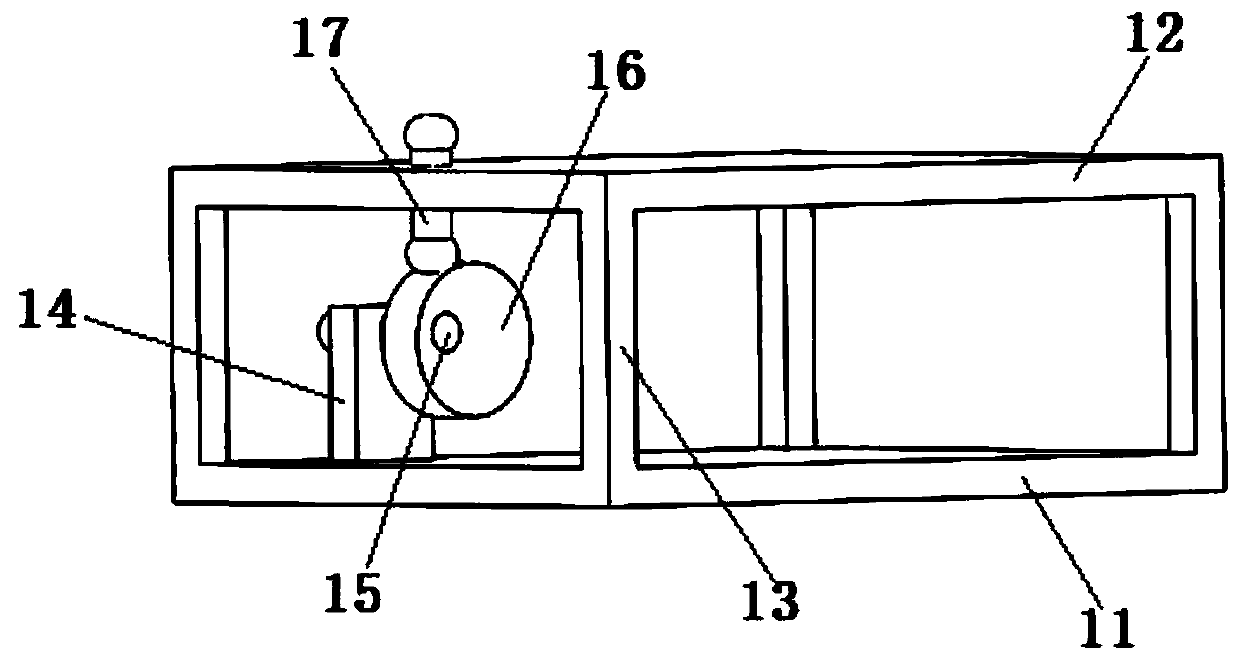

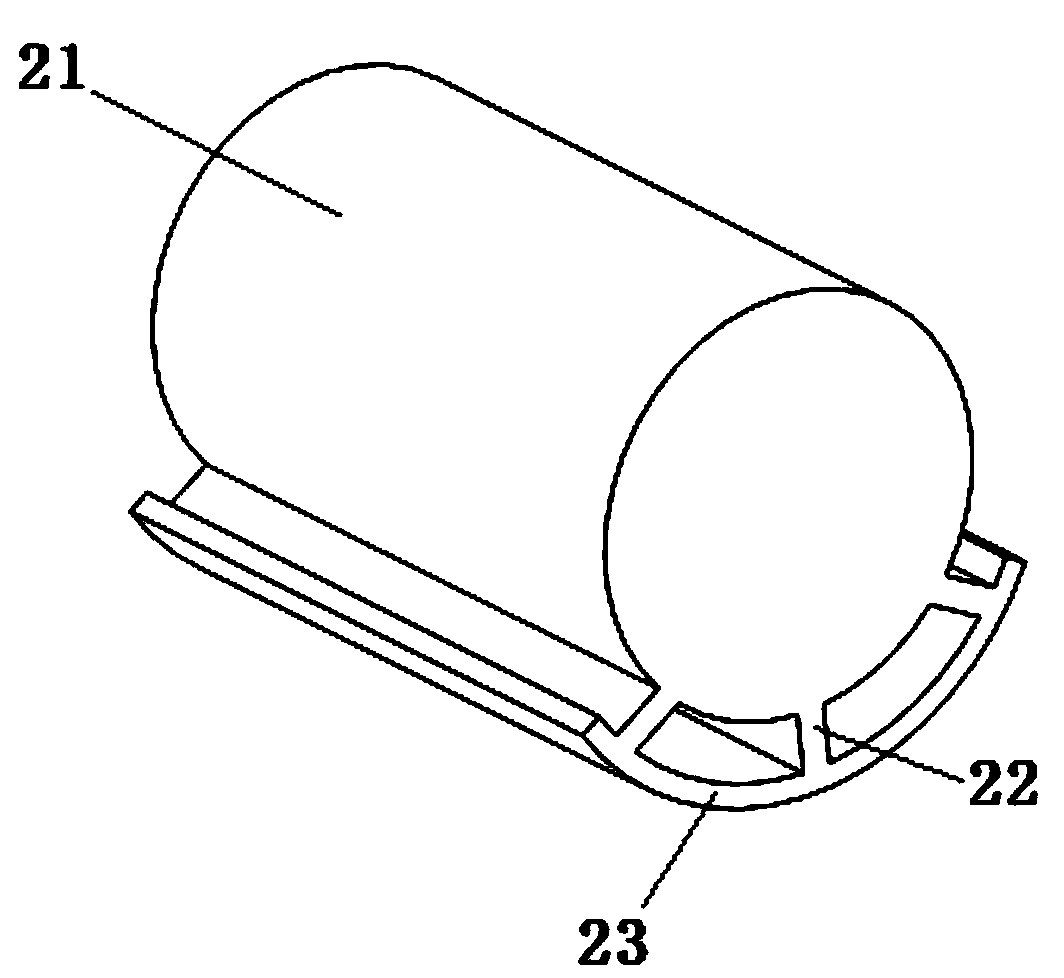

[0052] The third step, the first smelting: add the acid-treated lead paste into the furnace body 21 of the smelting furnace, and add it in three to four times. Cause the furnace body to swing, loosen and flatten the pile of materials until the acid-treated lead paste is completely added, turn on the heating to melt the acid-treated lead paste in the melting furnace, then add the mixture of le...

Embodiment 2

[0057] A process for melting and processing lead paste, comprising the steps of:

[0058] The first step, raw material pretreatment: waste lead plaster, the dismantled product of waste lead-acid batteries, is washed with water until the pH value is 6.9, then dried at 110°C, ground, and passed through a 180-mesh sieve;

[0059] The second step, impurity removal: waste lead paste with 3mol / L H 2 SO 4 The solution was soaked at a temperature of 96°C for 55 minutes, and after liquid-solid separation, it was washed with water until the pH value was 6.9 to obtain an acid-treated lead paste;

[0060] The third step, the first smelting: add the acid-treated lead paste into the furnace body 21 of the smelting furnace, and add it in three to four times. Cause the furnace body to swing, loosen and flatten the pile of materials until the acid-treated lead paste is completely added, turn on the heating to melt the acid-treated lead paste in the melting furnace, then add the mixture of le...

Embodiment 3

[0065] A process for melting and processing lead paste, comprising the steps of:

[0066] The first step, raw material pretreatment: waste lead plaster, the dismantled product of waste lead-acid batteries, is washed with water until the pH value is 7, then dried at 110°C, ground, and passed through a 180-mesh sieve;

[0067] The second step, impurity removal: waste lead paste with 3mol / L H 2 SO 4 The solution was soaked at a temperature of 98°C for 60 minutes, and after liquid-solid separation, it was washed with water until the pH value was 7 to obtain an acid-treated lead paste;

[0068] The third step, the first smelting: add the acid-treated lead paste into the furnace body 21 of the smelting furnace, and add it in three to four times. Cause the furnace body to swing, loosen and flatten the pile of materials until the acid-treated lead paste is completely added, turn on the heating to melt the acid-treated lead paste in the melting furnace, then add the mixture of lead o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com