Smelting method for special high-copper and high-nickel liquid aluminum alloy for internal combustion engine aluminum piston

An aluminum alloy and engine technology, which is applied in the field of aluminum alloy casting, can solve the problems of increased equipment investment and labor costs, high smelting costs, and long smelting cycle, so as to improve smelting production efficiency, reduce electricity and gas costs, and shorten the smelting cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below by embodiment.

[0027] (1) Determination of main element components of ZL109 aluminum alloy liquid:

[0028] ① Put the ZL109 aluminum alloy liquid for production smelted in the LX1500 gas-fired reflective melting furnace into the 500kg RBG-45-10 resistance holding furnace for pouring, and use the ALP-1000 metamorphic and refining integrated machine to fully stir evenly;

[0029] ② Use a pouring spoon to scoop up the aluminum liquid in the RBG-45-10 type resistance holding furnace, pour it into the sample mold for component detection, and pour the sample for spectral detection;

[0030] ③ After the sample is cooled, use a CL6132A ordinary lathe to process the excitation detection surface of the sample, which requires smooth turning, clear texture, flat, no oil and impurities;

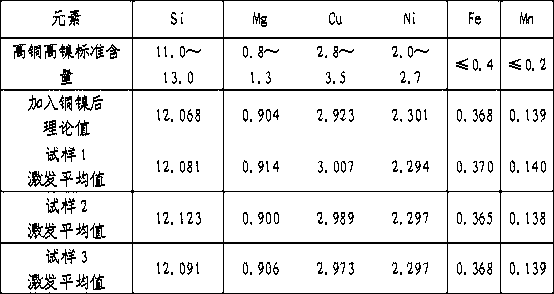

[0031] ④ Use the DF100 direct-reading spectrometer to test the sample three times, one point each time, and take the average value of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com