Non-electric furnace aluminum heating mode manganese alloying method for ultra-high manganese steel

A manganese alloying and ultra-high manganese technology, applied in the field of metallurgy, can solve the problems of poor dynamic conditions of electric furnace or intermediate frequency furnace, long manganese alloying cycle, poor composition uniformity, etc., to achieve shortened smelting cycle, short smelting cycle, high heat sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

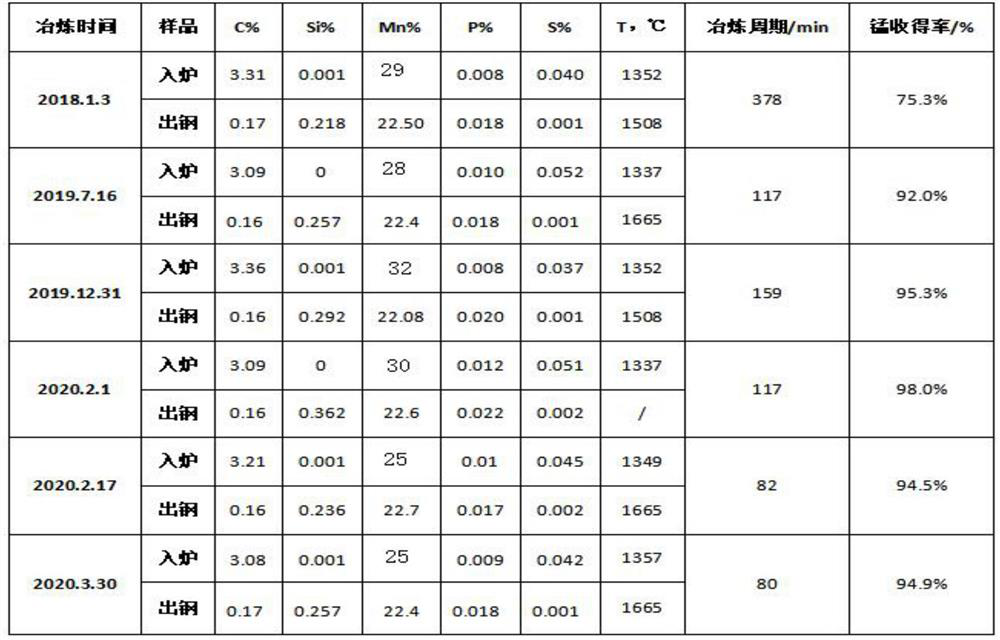

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention are clearly and completely described below, obviously, the described embodiments are only some embodiments of the present invention, not all implementation examples.

[0023] In order to achieve the purpose, the present invention specifically adopts the following technical solutions.

[0024] A method for manganese alloying of ultra-high manganese steel in non-electric furnace aluminum heating mode, comprising the following steps:

[0025] Process flow: molten iron pretreatment→main decarburization and heating→primary manganese alloying→deoxidation→secondary manganese alloying→reduction→slag removal→qualified manganese alloyed molten steel→LF→continuous casting.

[0026] In the molten iron pretreatment, the initial carbon content of the dephosphorized molten iron is generally 2.8%-3.5%, the initial temperature is generally between 1350°C-1400°C, and the dephosphorization treatment of the blast furnace m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com