Patents

Literature

48results about How to "Enough calories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nutritional dietary system, formulation, kit and method for use in preparing an individual for a predetermined activity

InactiveUS20030180393A1Enough caloriesWithout loss of nutritional benefitBiocideOrganic active ingredientsBiotechnologyReady to eat

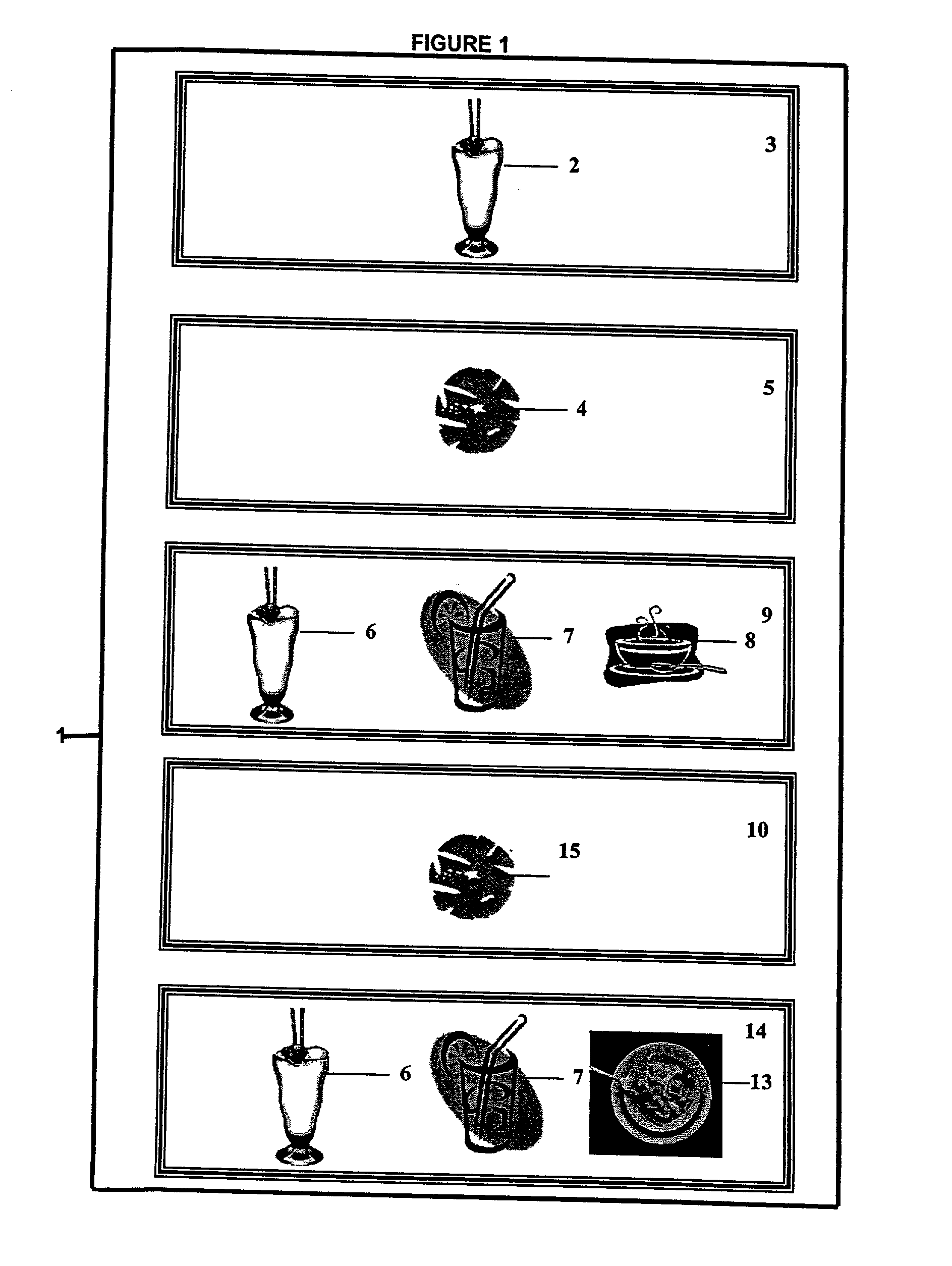

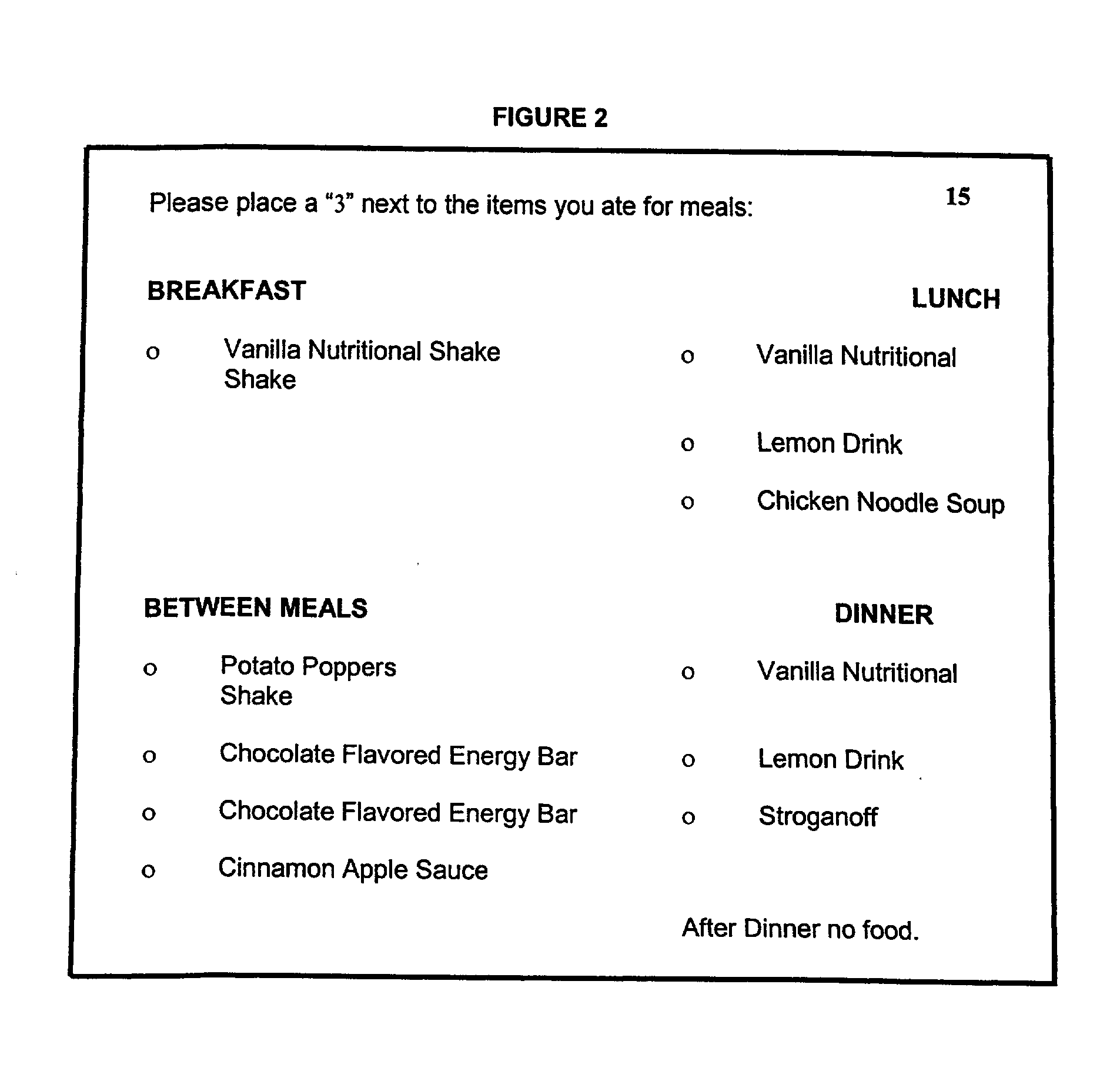

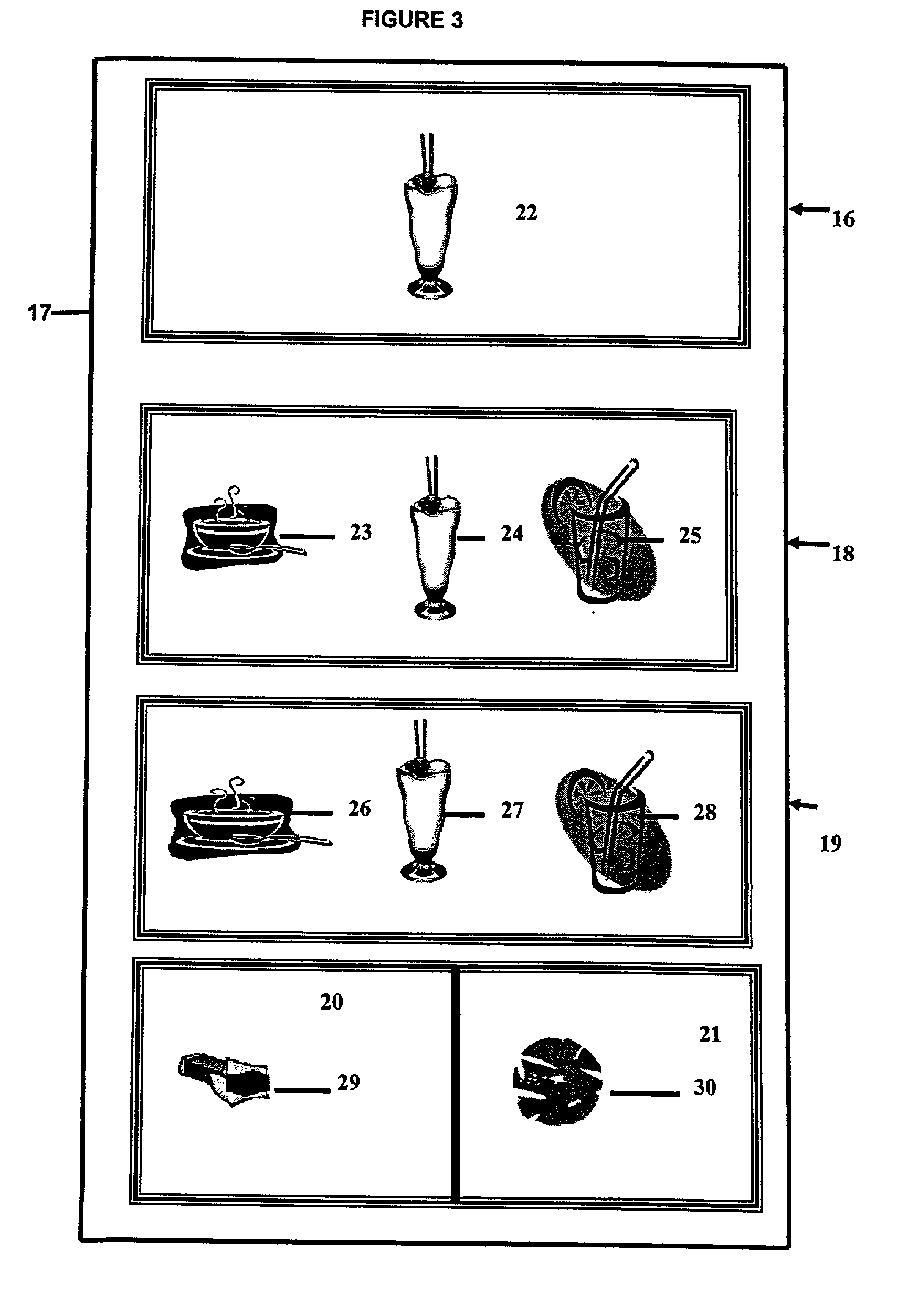

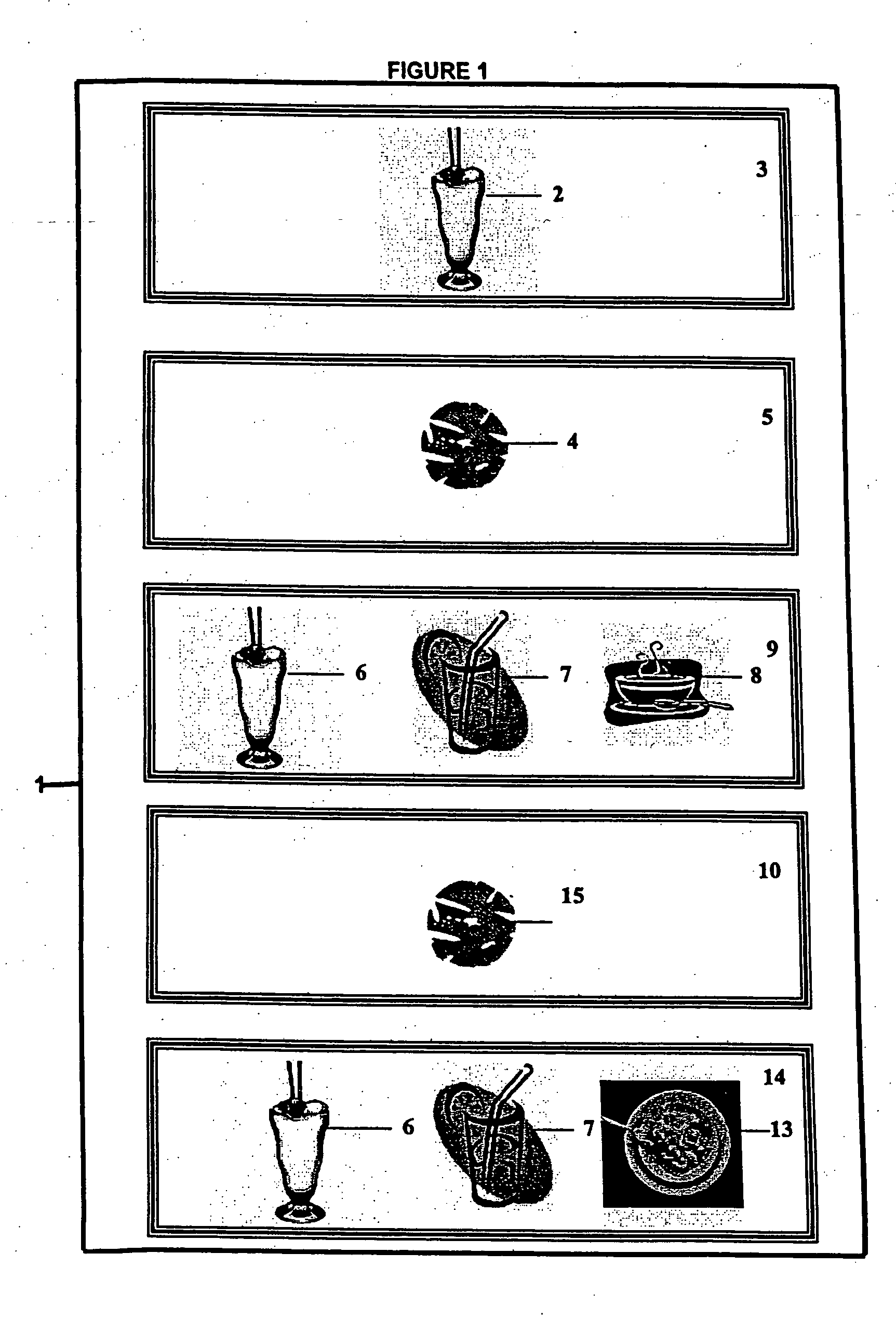

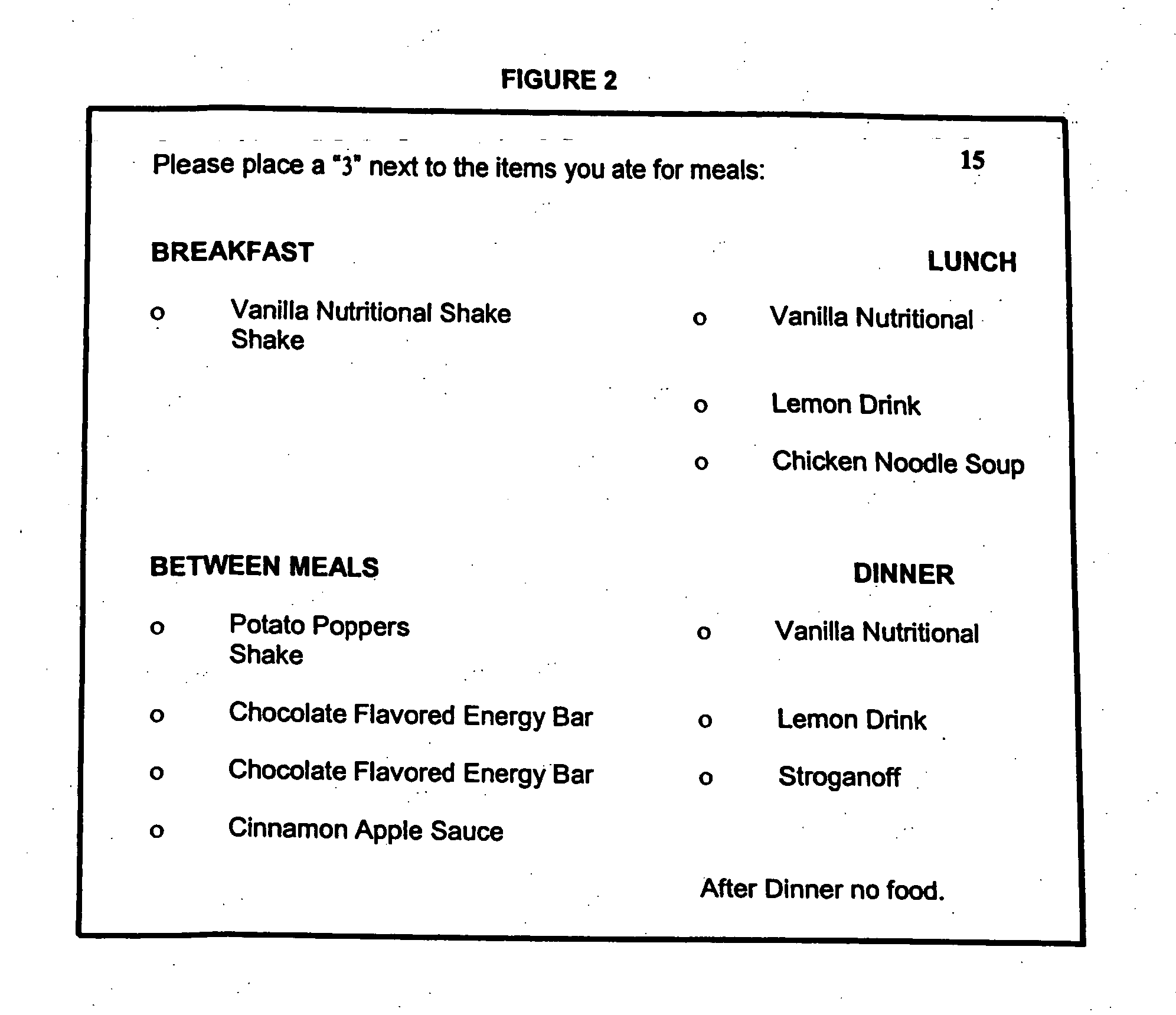

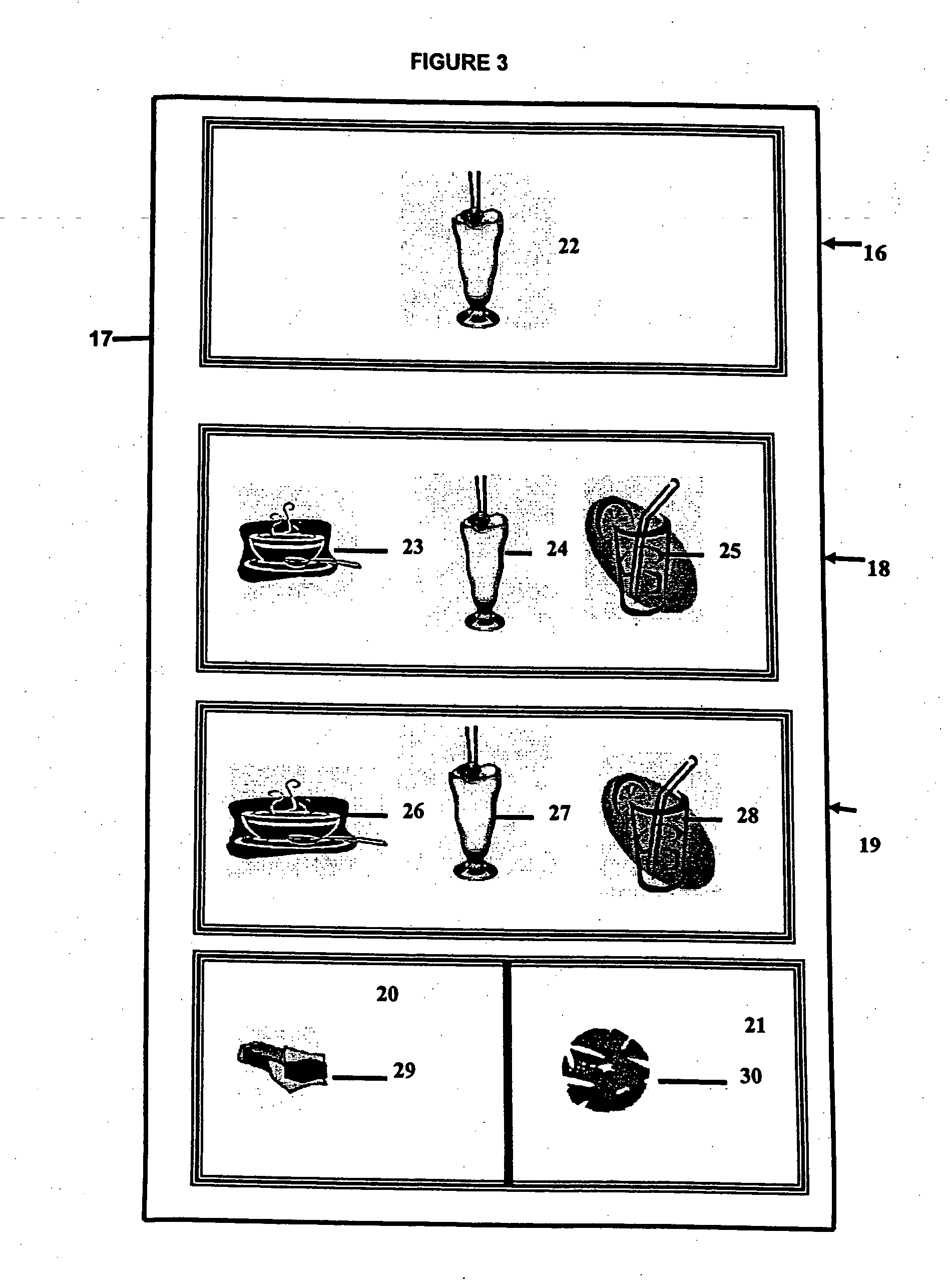

This invention relates to a nutritional dietary system, formulation, kit and method for use in preparing an individual for a predetermined activity which requires a clean digestive tract, particularly the colon. Such predetermined activities include, but are not limited to, gastrointestinal surgery and colon screenings. Specifically, the present invention provides an individual low amounts of fat, dietary fiber and solid food content to minimize stool formation and / or facilitate removal of stool from the digestive tract prior to the predetermined activity. The present invention also provides the individual with sufficient calories and nutrition to enable the individual to conduct daily, routine activities while utilizing the present invention. In one alternative embodiment, the dietary regimen of the present invention provides a variety of pre-packaged, ready to eat or easy to prepare nutritional liquid or solid foods which, when coordinated with a laxative regimen, result in removal of residue such that a medically and / or diagnostically useful procedure can be performed on the digestive tract.

Owner:BRACCO DIAGNOSTICS

Nutritional dietary kit for use in preparing an individual for a gastrointestinal procedure

InactiveUS20050112178A1Sufficient solid matterEnough caloriesOrganic active ingredientsEnzymologyReady to eatRegimen

Owner:BRACCO DIAGNOSTICS

Blast furnace blow-in burdening method

ActiveCN105506203AReduce slag generationImprove breathabilityBlast furnace detailsLiquid ironBloomery

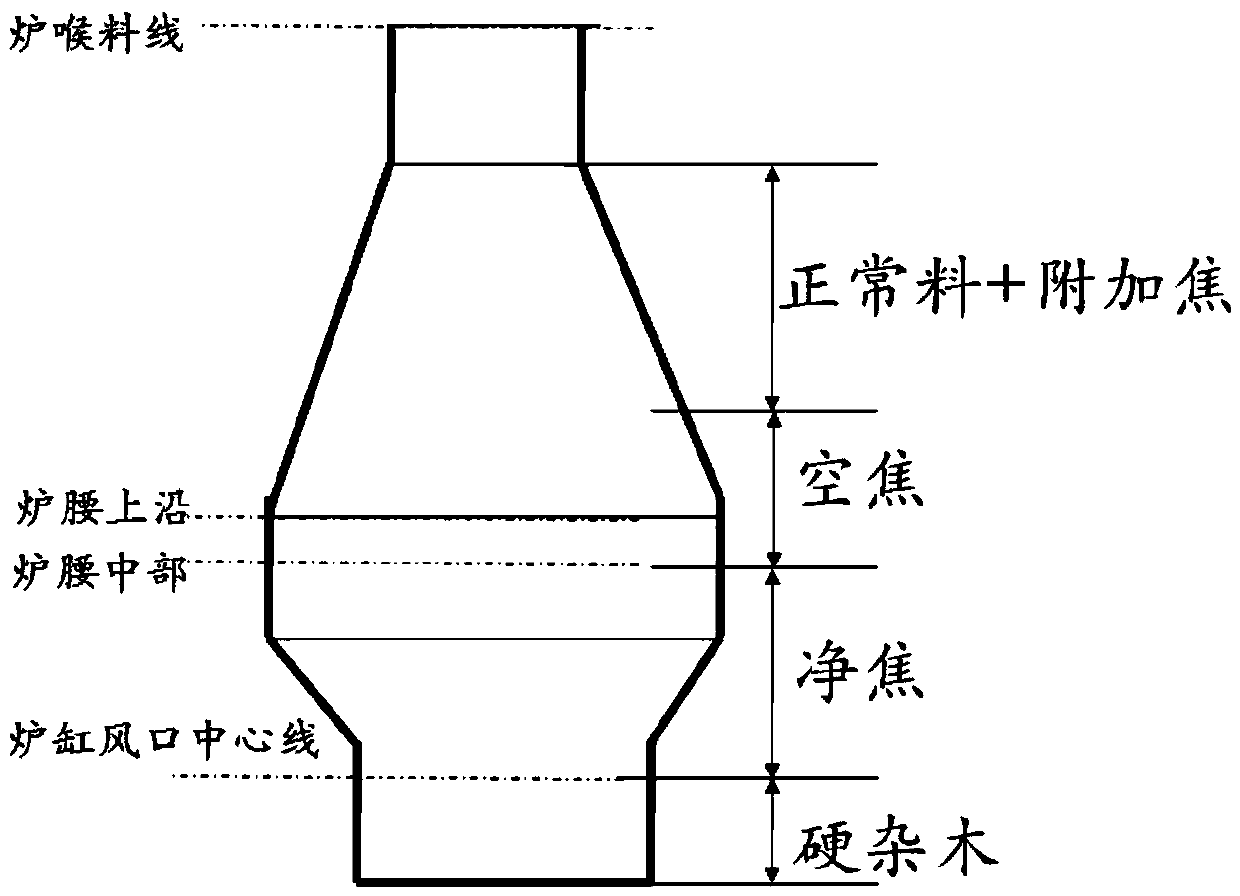

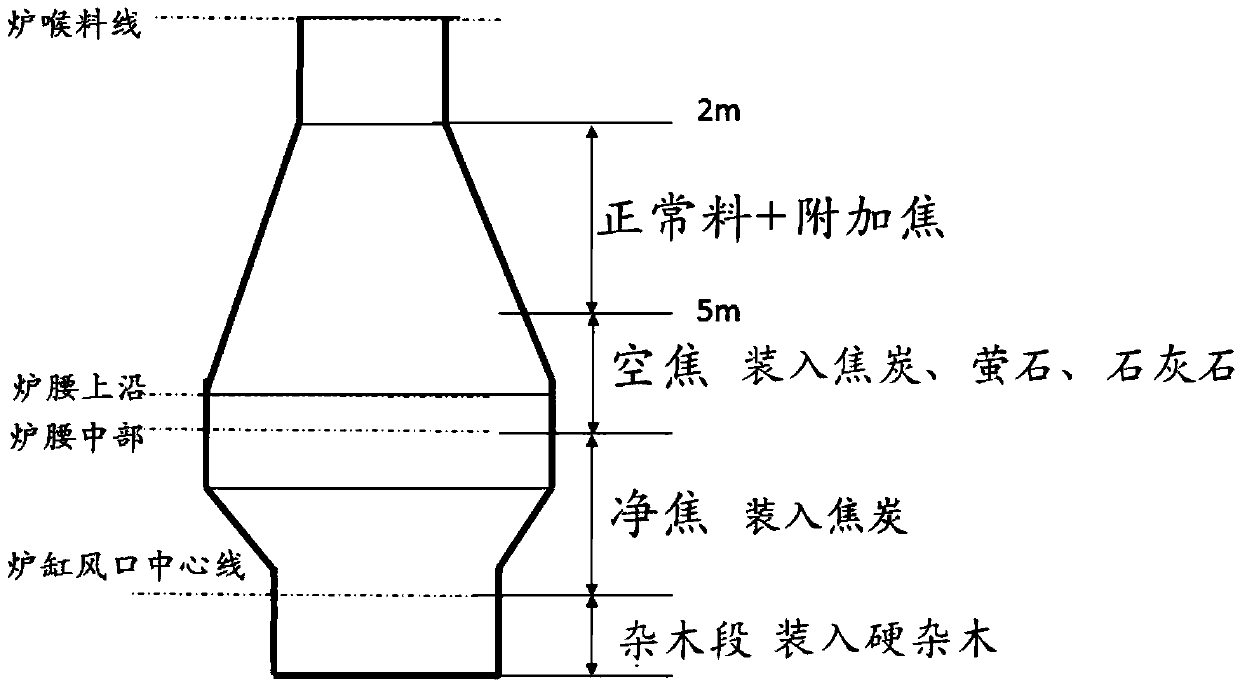

The invention discloses a blast furnace blow-in burdening method. The furnace burden of a blast furnace is divided into four segments, namely a wood segment, a net coke segment, a blank coke segment and a normal material segment; hard wood is loaded into the wood segment; all-clinker blowing-in with the hard wood rather than a wooden sleeper is adopted, such that the generation amount of furnace slag may be greatly reduced and the gas permeability of a cohesive zone may be improved; especially in 6-10 hours at the preliminary blowing-in stage, the formation time of the cohesive zone is shortened, the blowing-in process is accelerated and the production condition of the blast furnace is stabilized. Coke is loaded into the net coke segment; blank coke is loaded into the blank coke segment and satisfies the following blank coke matching conditions: furnace slag binary basicity R2=1.05, CaF2 in slag ranging from 2% to 6% and [Si] in liquid iron=2.5%. Normal materials are loaded into the normal material segment and the matching of the normal materials is enabled to satisfy the following conditions: furnace slag binary basicity R2=1.1, CaF2 in slag ranging from 2% to 6%, [Si] in liquid iron=4%, a slag ratio being less than 400kg / thm, and a liquid material load level maintained within 2.5.

Owner:SHOUGANG CORPORATION

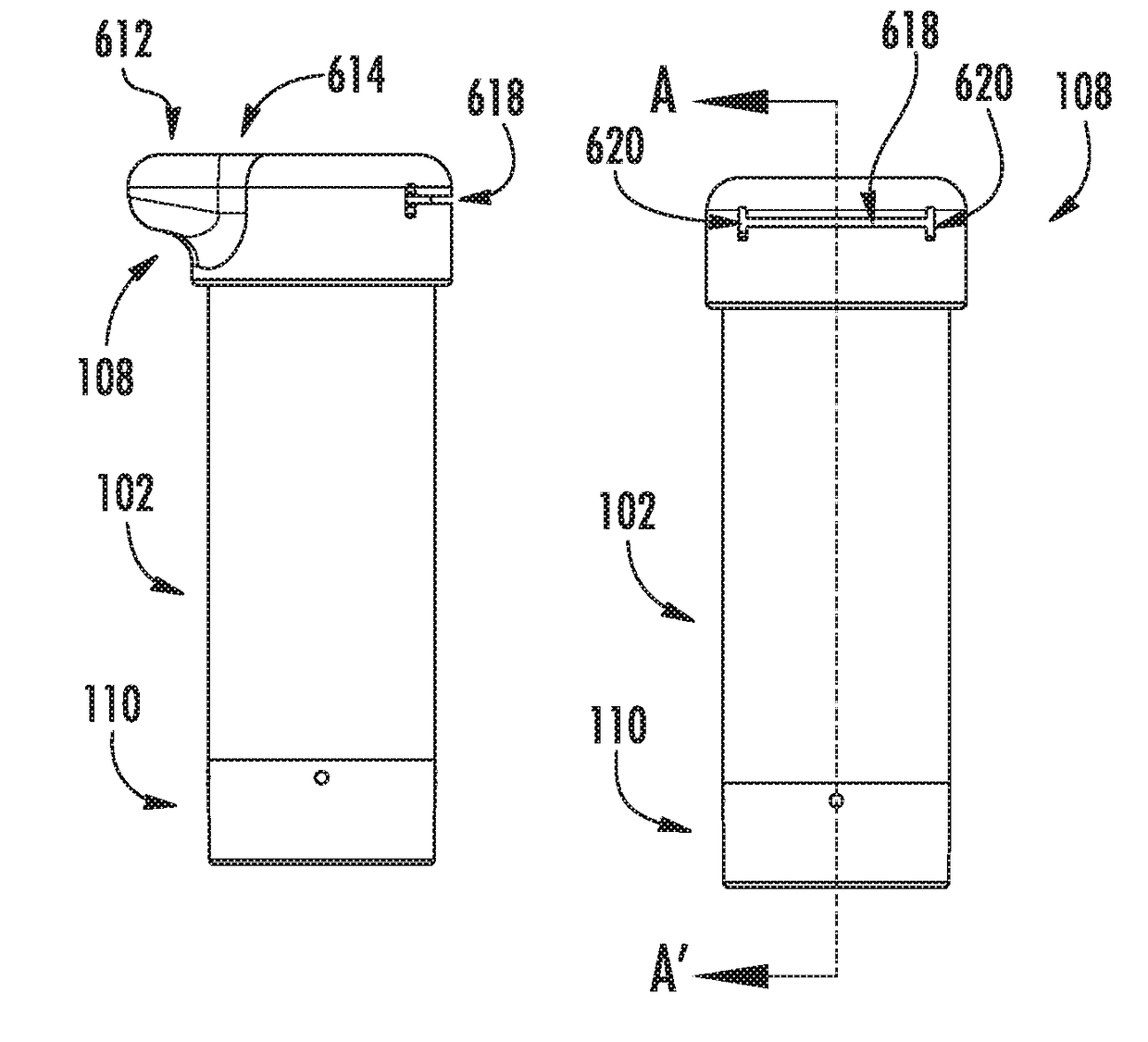

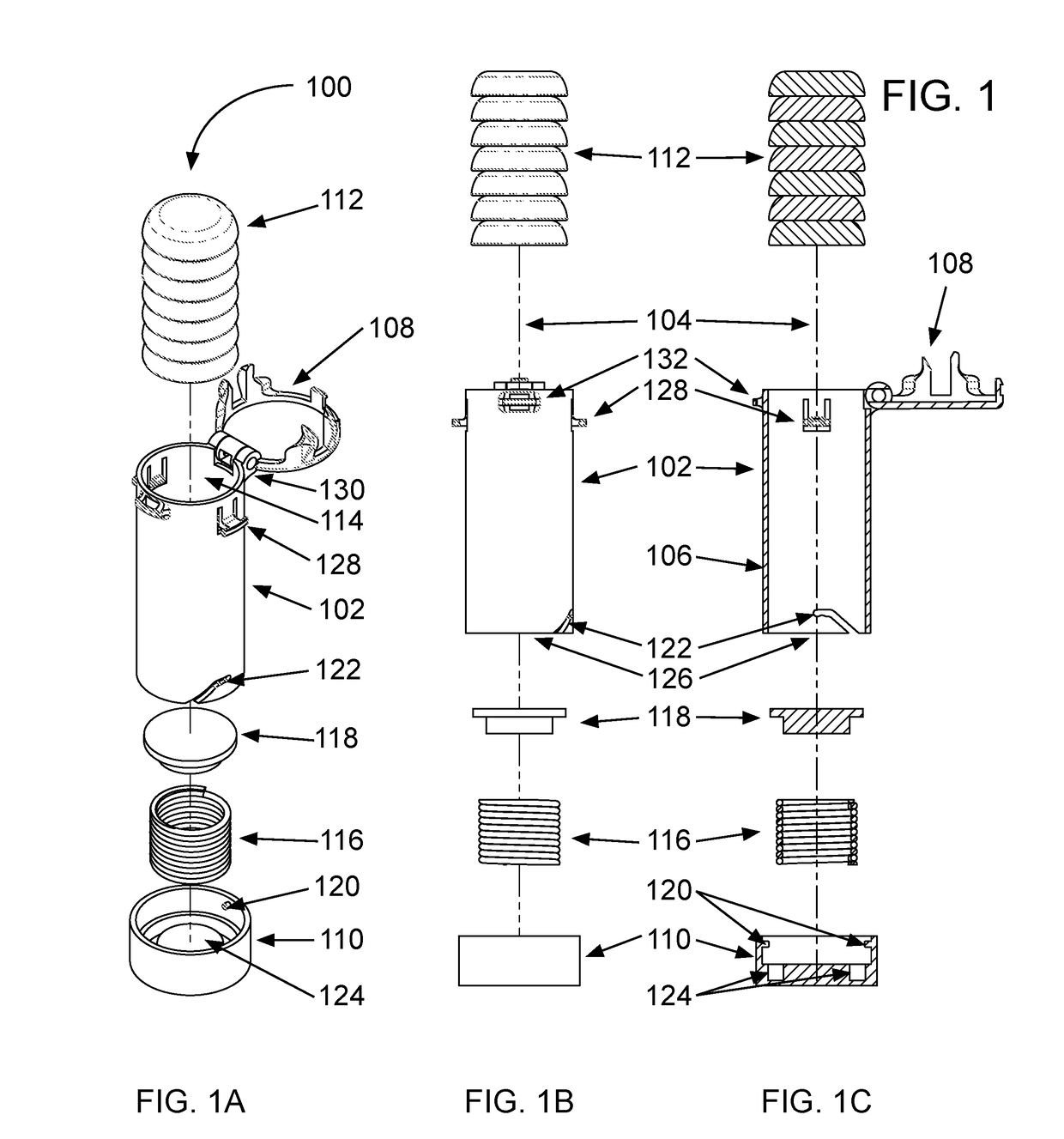

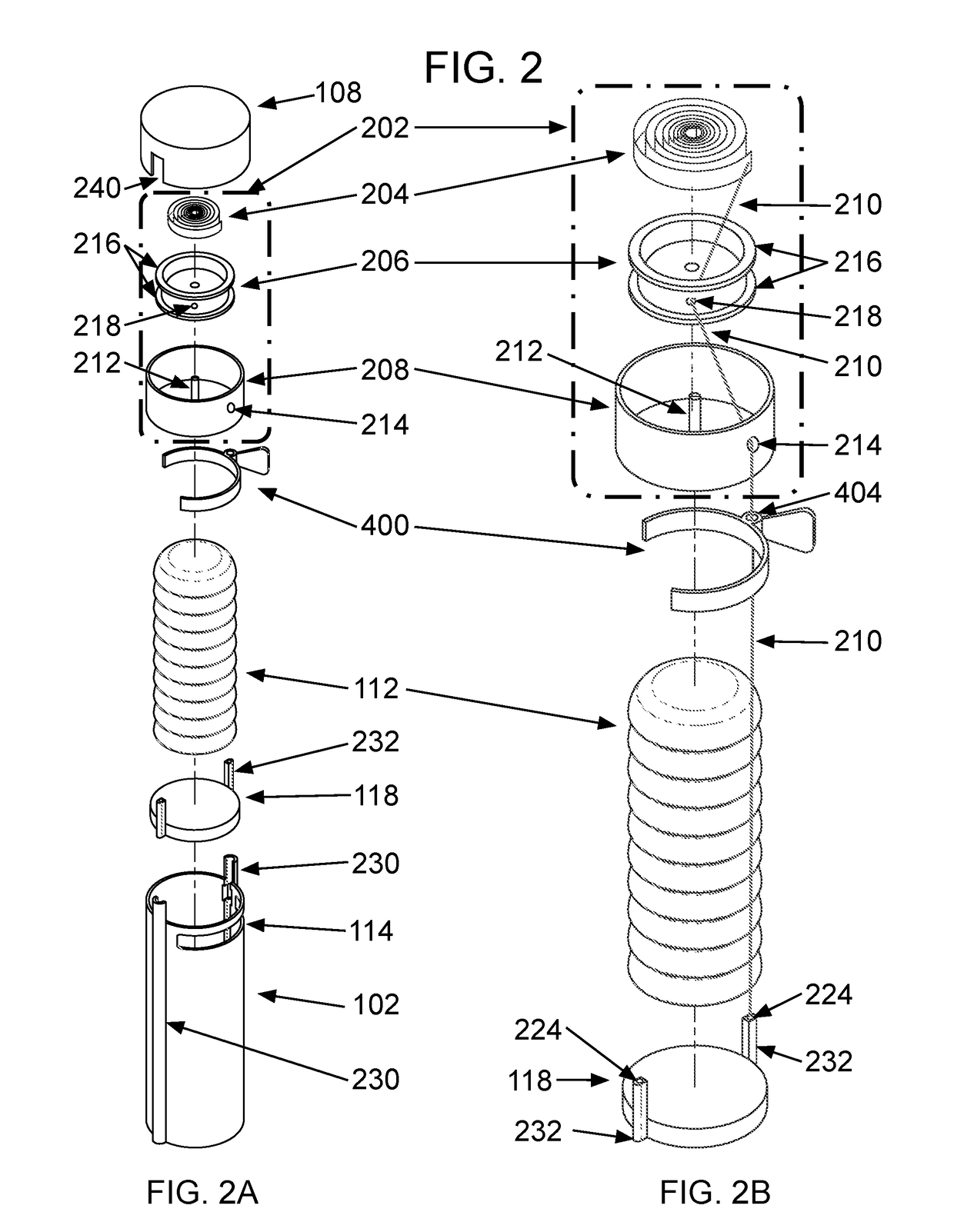

Device for Storing and Dispensing Food Items

InactiveUS20170225873A1Offset the calorie deficitEasy to operateSmall article dispensingSpecial dispensing meansEngineeringNutritional content

A device for storing and dispensing food items for a customizable nutrition supply is provided. The food items are loaded by the user, allowing customization of nutritional content and sequence. The device may be portable and operated with one hand, and is sufficiently sealed to store the food items securely, away from air, dust, and moisture. When the device is operated by being opened or triggered, it dispenses the next food item, so that the user may dispense the food item directly into the user's mouth. The device then closes or is closed.

Owner:FOUGERE BRUCE

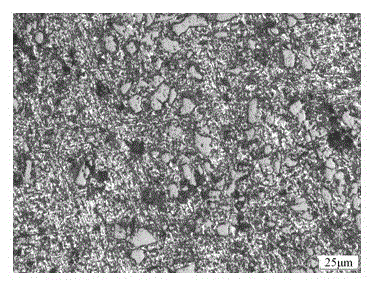

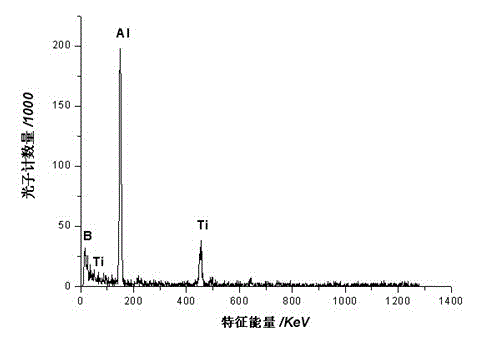

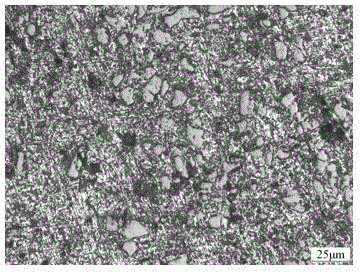

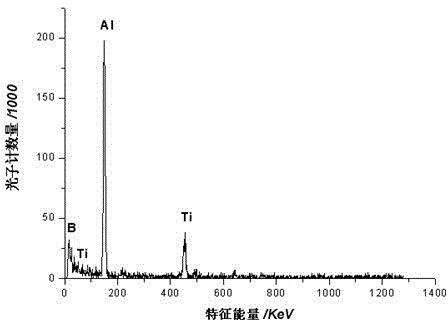

Preparation method of aluminum-titanium-boracium mater alloy

The invention discloses a preparation method of aluminum-titanium-boracium mater alloy. The aluminum-titanium-boracium mater alloy is prepared from the following raw materials in mass ratio: 50-70 percent of Al, 25-40 percent of CaSO425, 1-9 percent of TiO2, 0.2-4 percent of B and 3-5 percent of CaF2. The method comprises the following steps that the raw materials are uniformly stirred; the uniformly mixed materials are placed into a reaction cavity of graphite, an igniter is spread into the reaction cavity, and the materials are compacted and ignited; and liquid metal flows into a forming model from a small hole below the reaction cavity at a high temperature to prepare the aluminum-titanium-boracium mater alloy. According to the preparation method disclosed by the invention, thermit reaction of aluminum and calcium sulfate and thermit reaction of the aluminum and titanium oxide are applied, and Ti which is a product of the thermit reactions and redundant Al powder and B powder in the raw materials form the aluminum-titanium-boracium mater alloy; and as large equipment (such as electrolyzers and smelting furnaces), the external energy and the like are not needed, the production cost is greatly lowered, the technological time is shortened, and an aluminum-titanium-boracium mater alloy refiner with high quality is obtained.

Owner:SHENZHEN YUANSIDACHENG TECH

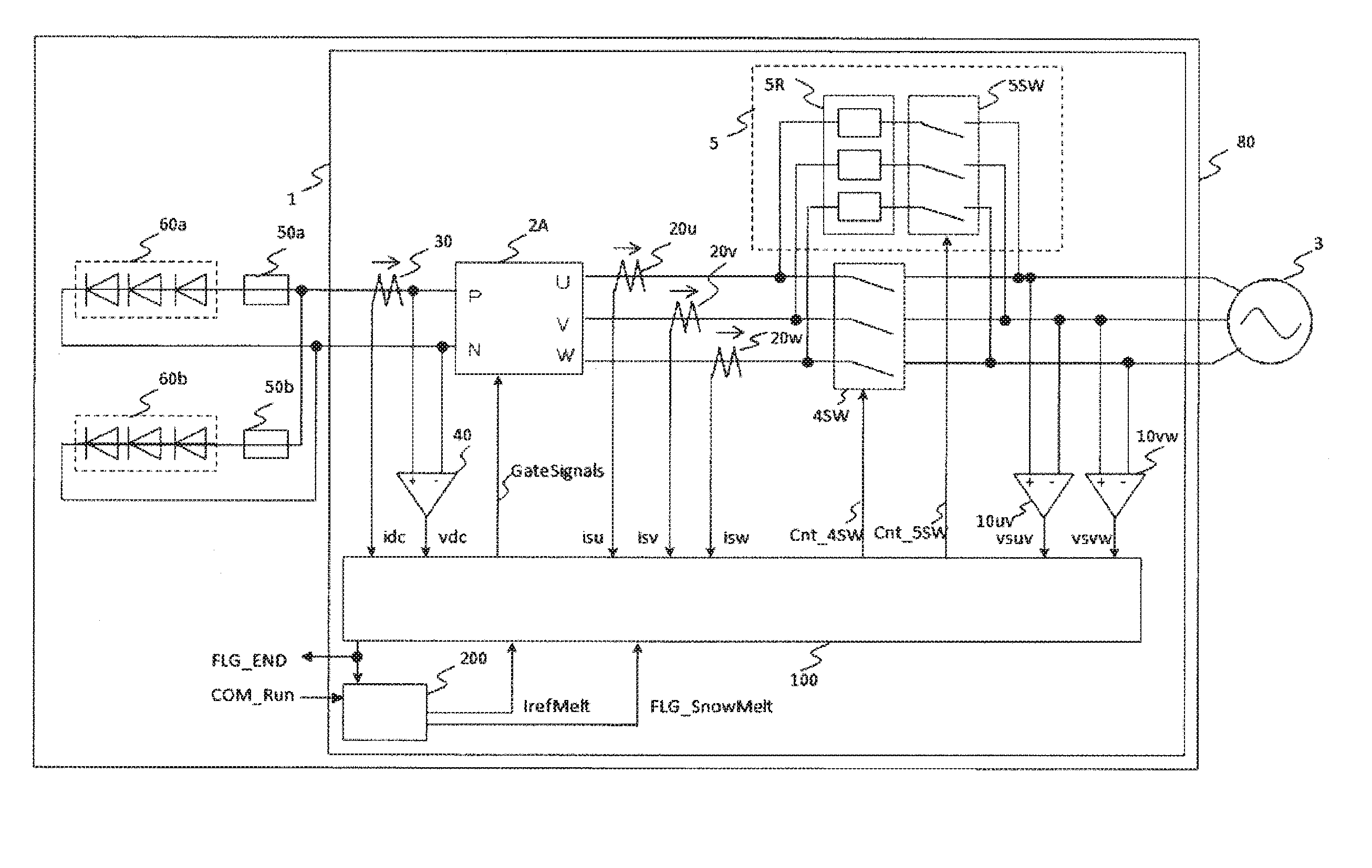

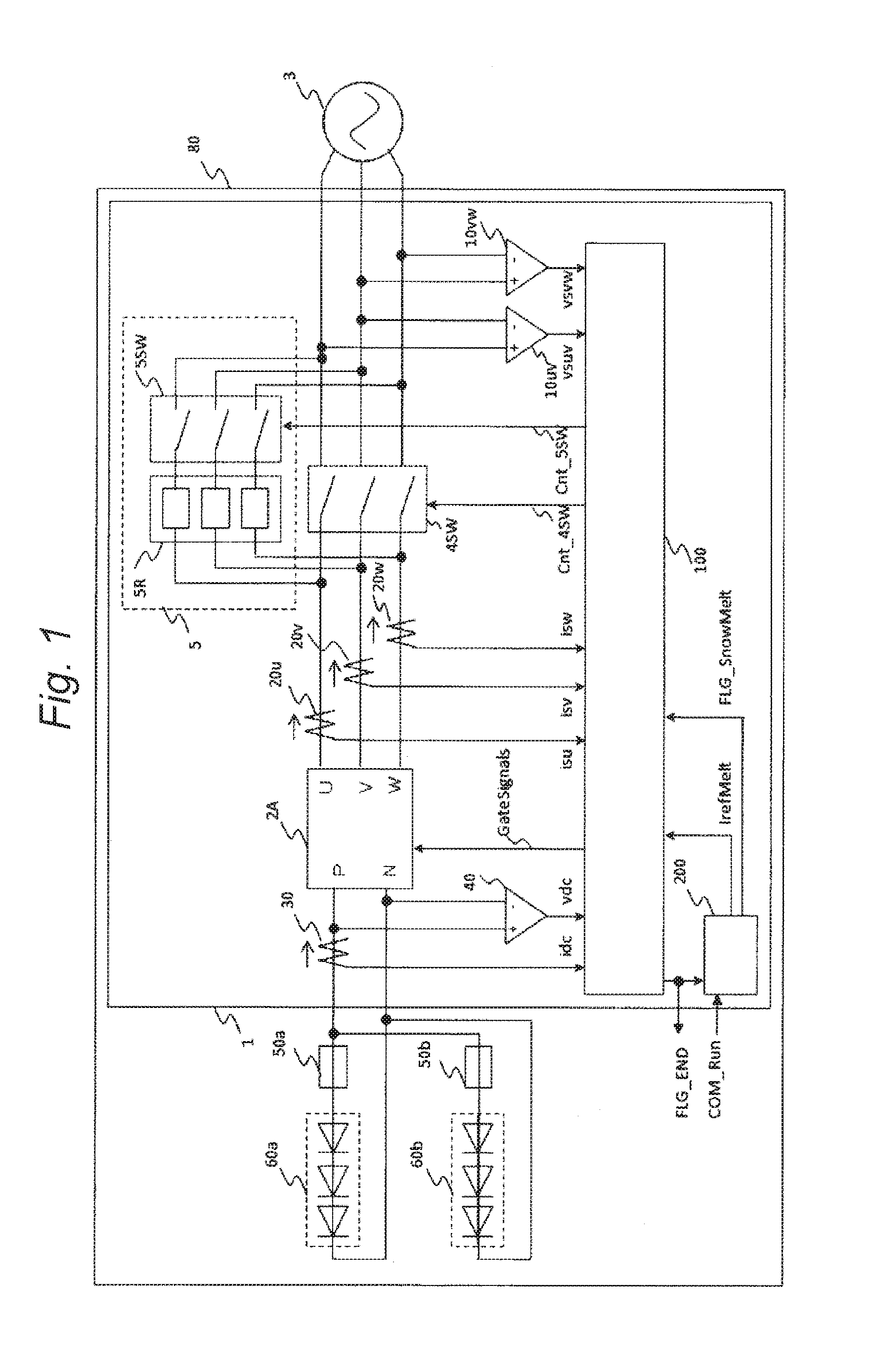

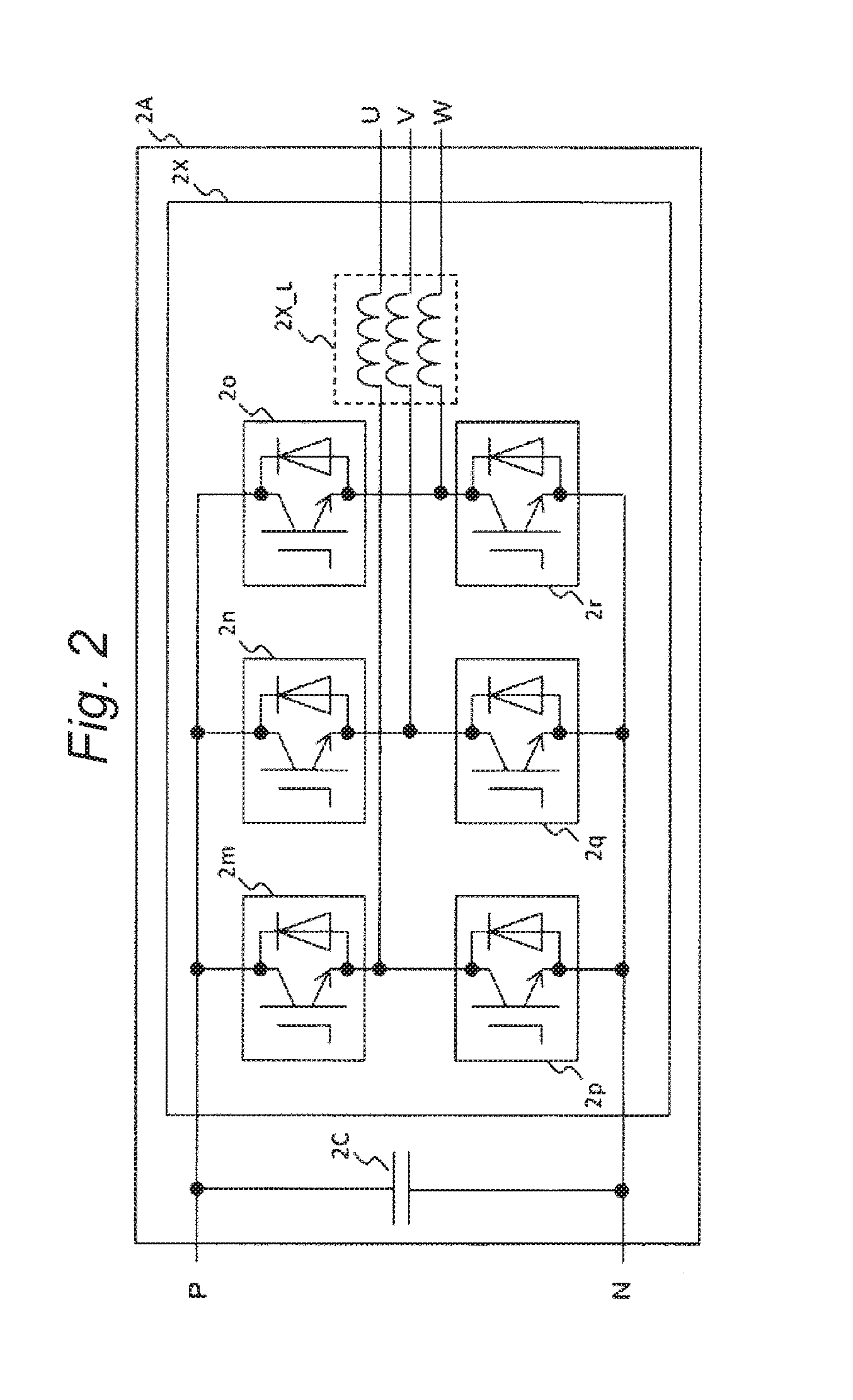

Power Conversion Apparatus and Photovoltaic System

InactiveUS20160254780A1Enough caloriesPrevent overcurrentPhotovoltaicsPhotovoltaic energy generationElectric power systemSnow melting

A power conversion apparatus that is connected between a solar panel and a power system, in which the power conversion apparatus includes a power generating mode that converts a generated power of the solar panel into an alternating current power, and a snow melting mode that heats the solar panel by obtaining the power from the power system, and supplying the power to the solar panel, and at the time of the snow melting mode, the power conversion apparatus controls a voltage which is output to the solar panel such that a first current value being a value where a current that is supplied to the solar panel from the power conversion apparatus is smaller than an overcurrent level of the solar panel flows in a predetermined period.

Owner:HITACHI LTD

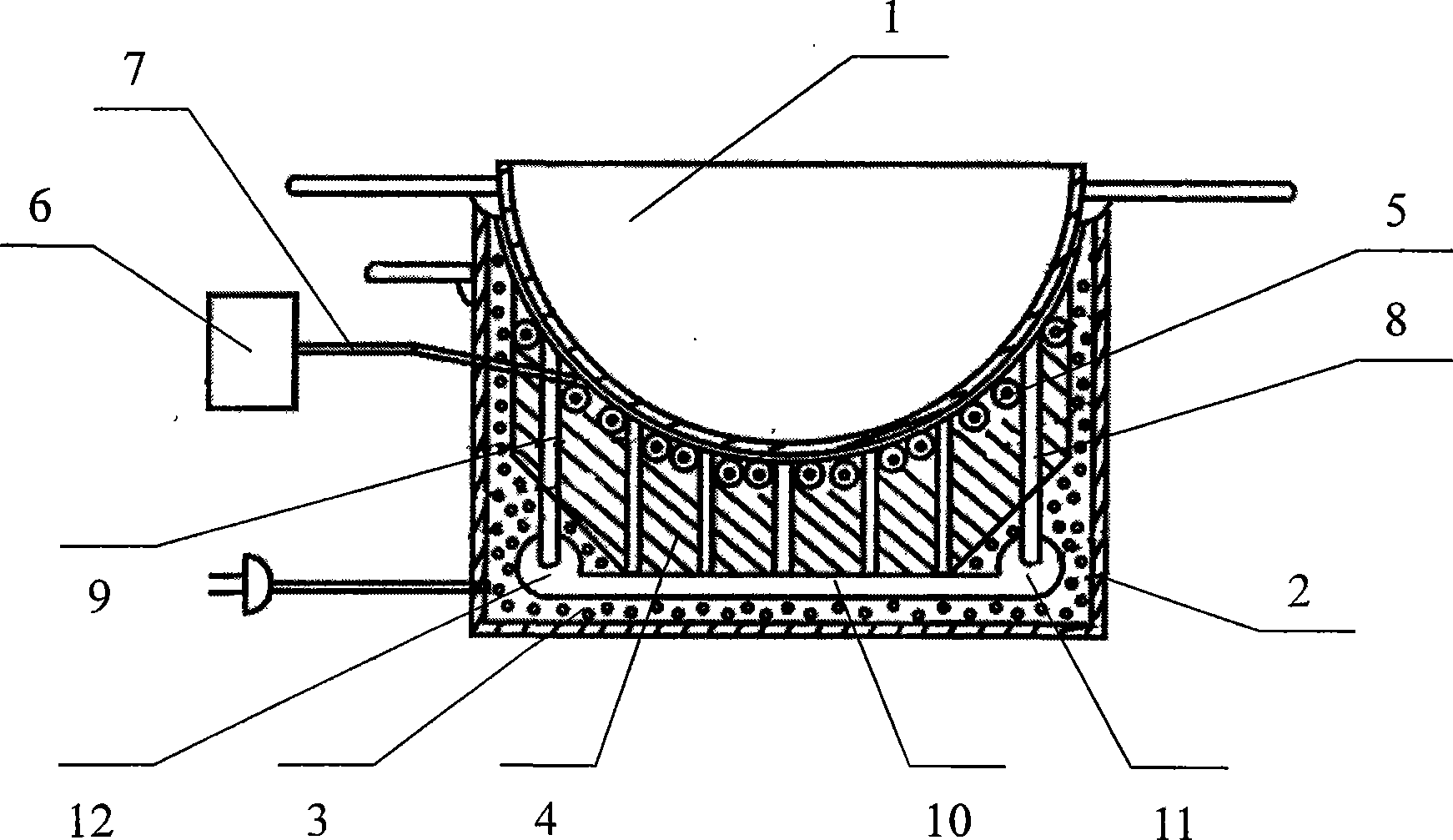

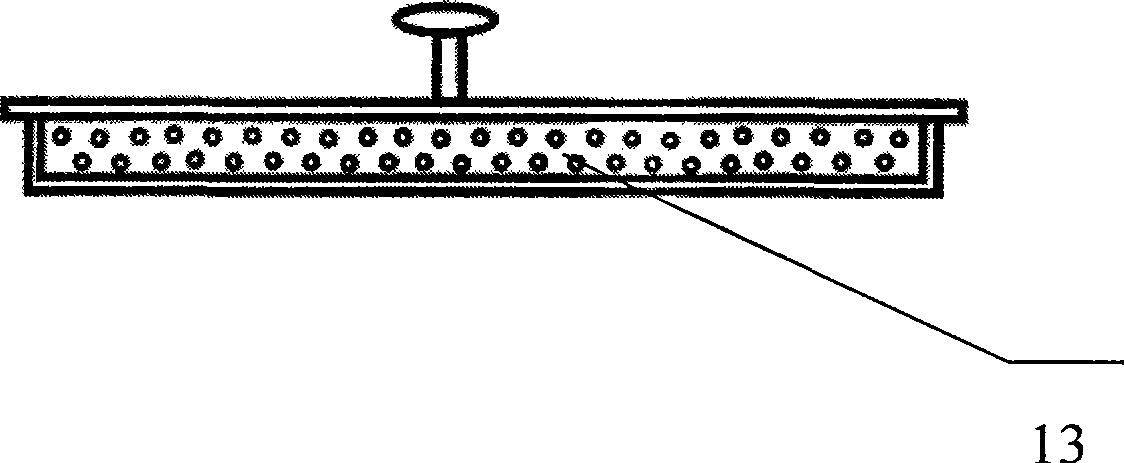

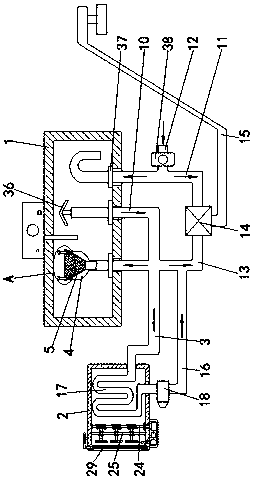

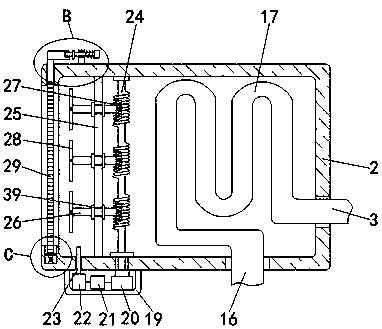

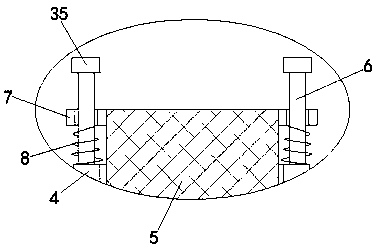

Heat-storage electric pan

The invention pertains to the field of kitchen tools, in particular to a heat accumulation-typed electric frying pan, which comprises a frying pan (1), a casing (2), an insulating layer (3), a heat accumulation layer (4), heating cords (5), a temperature regulator (6), a thermograph (7), an air inlet pipe (8), an air outlet pipe (9), a vent-pipe (10), a fan (11), a exhaust fan (12) and a heat preservation cover (13). The heat accumulation-typed electric frying pan has simple structure, and temperature is high, heat is sufficient, furthermore, owing to the special function of heat accumulation thereof, part of energy can be saved, and the pan is convenient and practical.

Owner:XIANGMING MIDDLE SCHOOL SHANGHAI

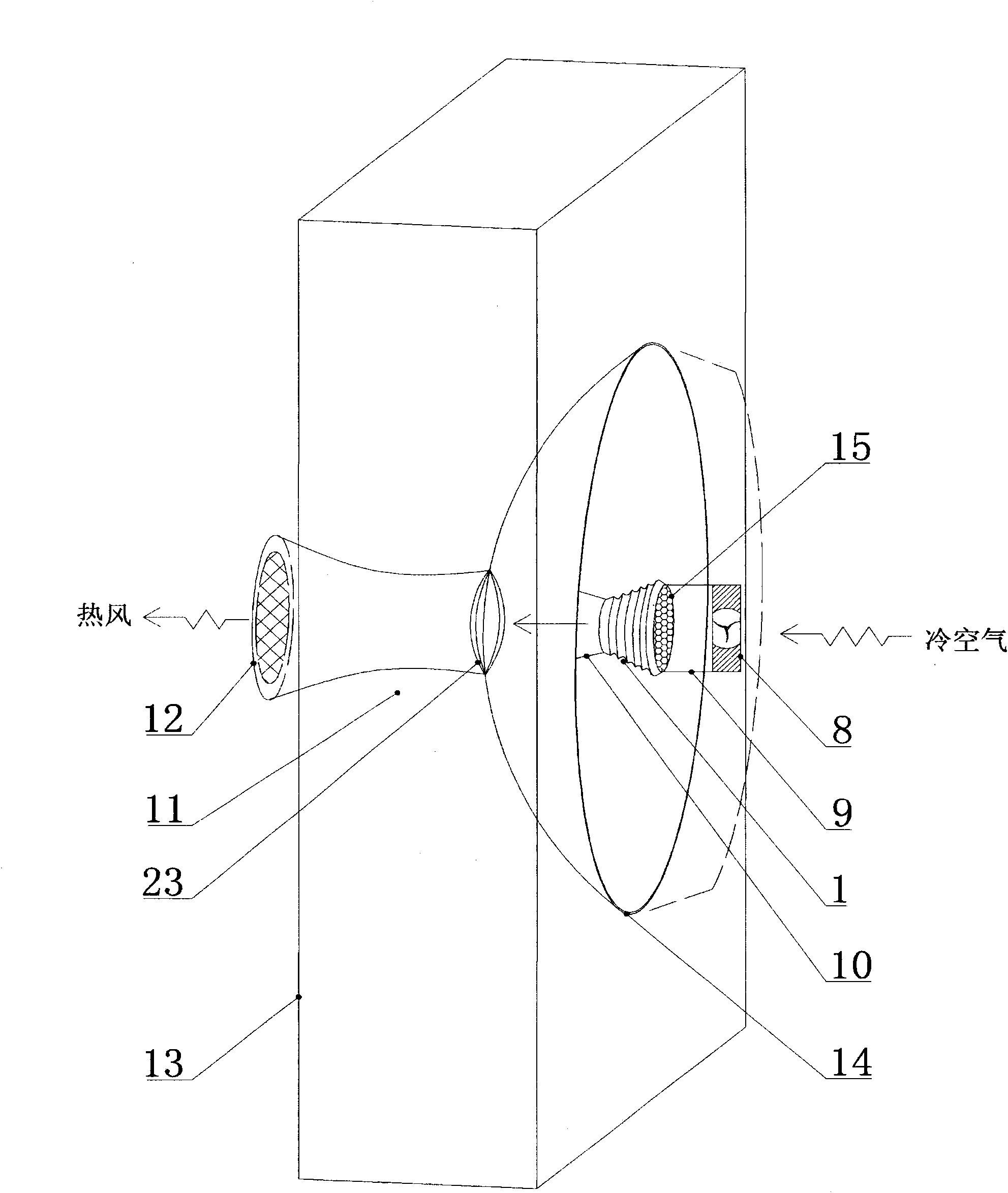

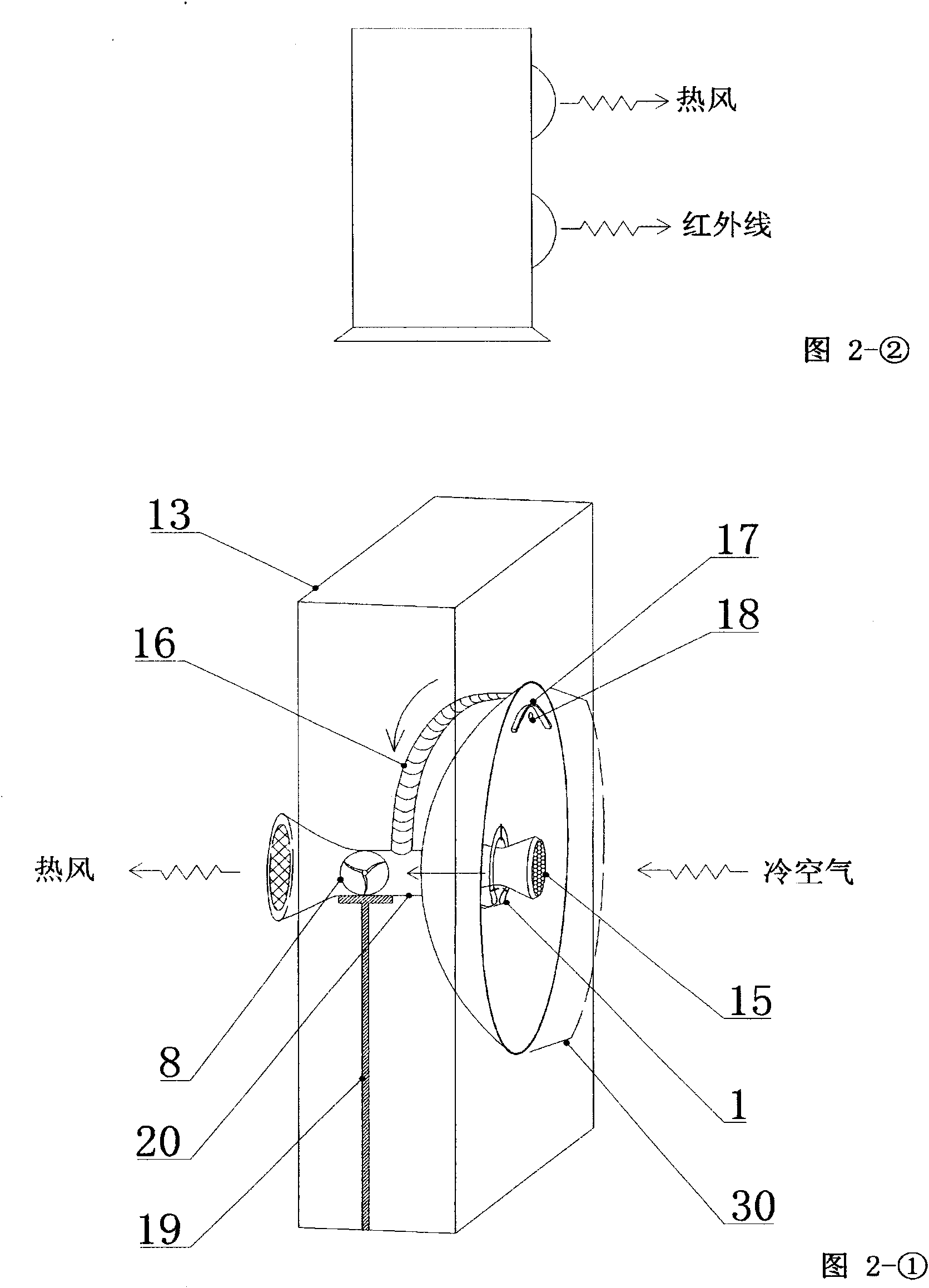

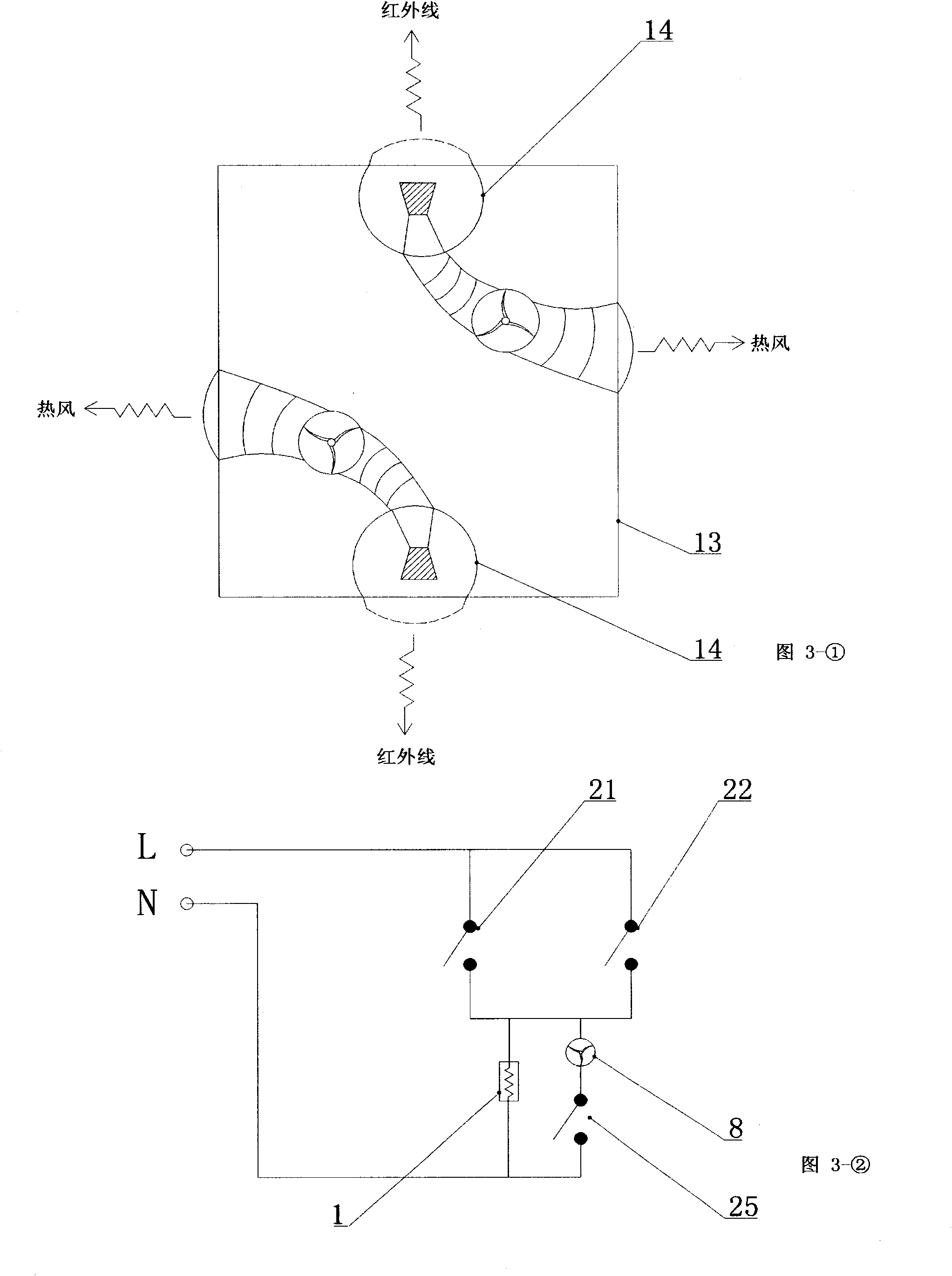

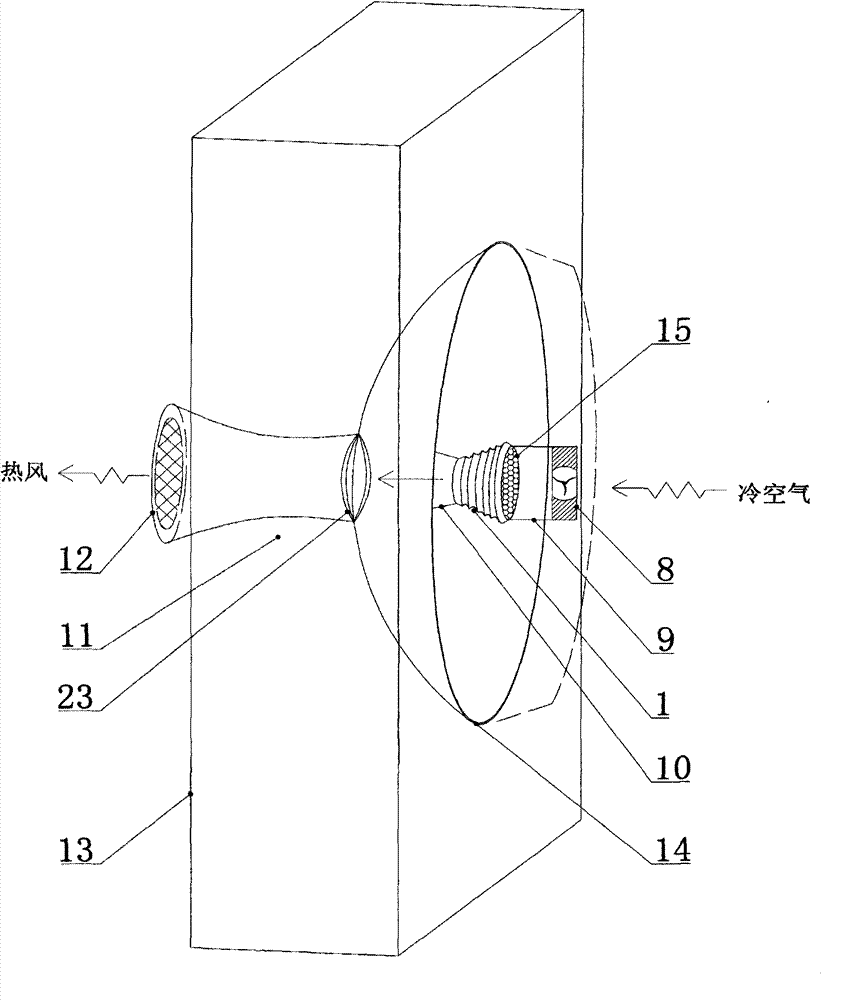

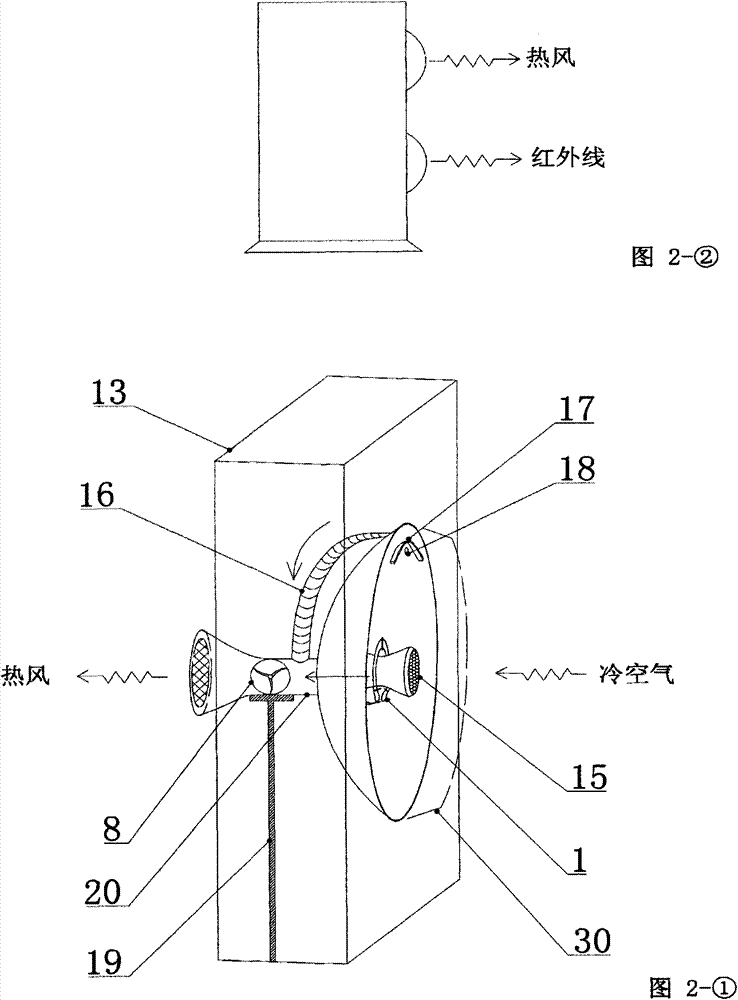

Excess/waste heat reutilization structure of little sun heater

ActiveCN101943436AIncrease temperatureEnough caloriesLighting and heating apparatusElectric heating systemInfraredThermodynamics

The invention discloses an excess / waste heat reutilization structure of a single / double heat source little sun heater, which is technical improvement on invention 201010206382.5. In the structure, a blower forms hot air originally lost due to flow and heat energy carried by a heat source carrier into a hot wind, and blows or draws the hot wind to the space above, below and behind an infrared radiation region as well as the left and the right outside the infrared radiation region so as to independently heat a human body. At the same time, the invention also designs special heating units for feet and hands and forms a plurality of heating points. When the invention is used in a four-pan heater for supplying heat in four sides, other two sets of heating units (including two sets of reflectors, heat sources, electrical switches and other spare and accessory parts) can be replaced by hot wind in two sides, and the saved cost of the two sets of accessory parts can be used to counteract the cost of newly increased accessory parts, thereby reducing half of the electric power and saving half of the accessory parts. Thus, the invention has the advantages of simple structure, low cost and easy manufacturing, and can realize fast popularization and sale.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Method for blowing-in operation of steel-making blast furnace

InactiveCN101713005AShorten cool down timeImprove breathabilityBlast furnace detailsEngineeringTuyere

The invention discloses a method for blowing-in operation of a steel-making blast furnace. By adopting the modes of blocking a wind port, loading against the wind, blowing in the semi-charging furnace, mounting an air conduit by segments, controlling the top temperature and pursuing a stock line moderately for blowing in furnace, the method not only can avoid unfavorable influences on the blowing-in operation of the blast furnace caused by equipment accident and human error accident during operation, but also can avoid excessive moisture in the coal gas sticking to a cloth bag or burning the cloth bag caused by overhigh temperature of the coal gas after air bleeding; the method is suitable for blowing in the furnace aiming at a blast furnace system under the complex condition, and particularly aiming at the blast furnace which is not subjected to various debugging or is not well debugged; and the influence of the equipment accident on the furnace condition can be extremely relieved so as to reduce the furnace blowing-in accident to the minimal degree.

Owner:ANYANG IRON & STEEL

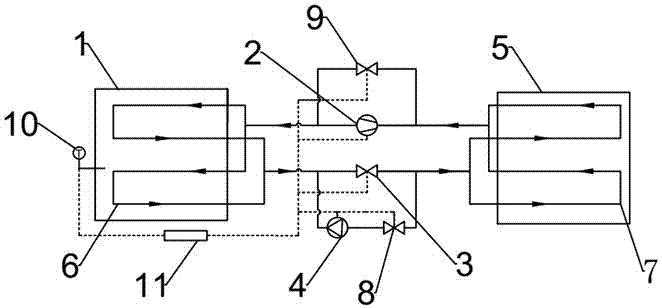

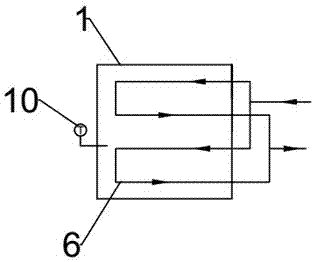

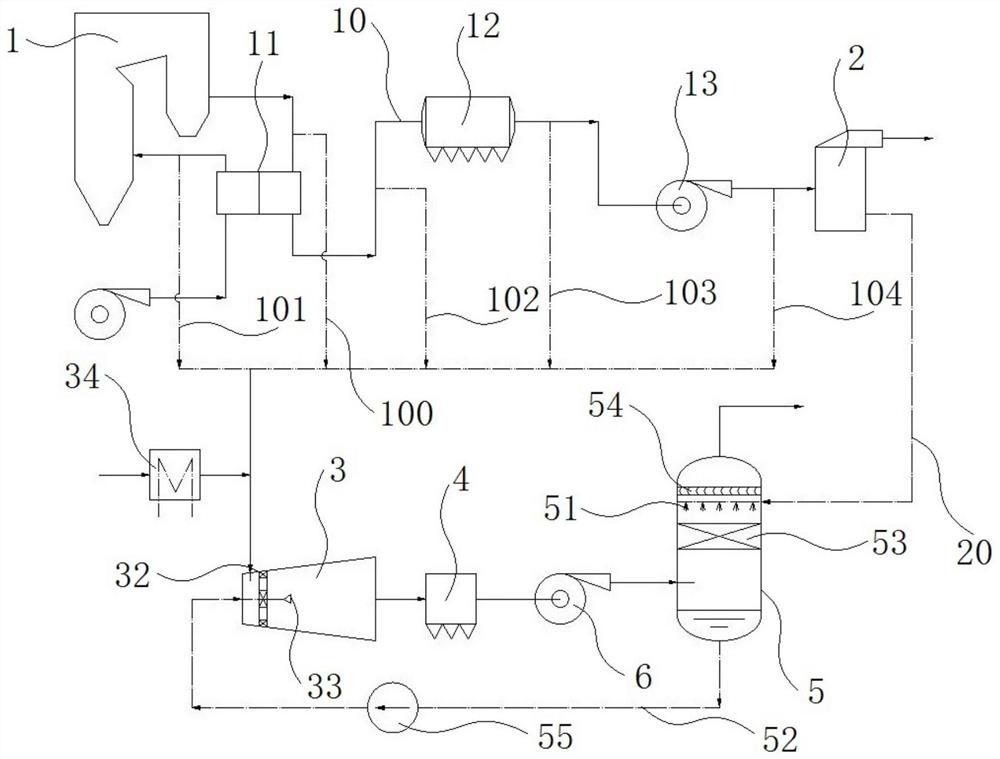

Biogas anaerobic fermentation tank waste heat utilization and temperature increasing system

InactiveCN107400630AUniform and stable temperatureAvoid the problem of sharp decline in heat transfer efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsHeat conductingSlurry

A biogas anaerobic fermentation tank waste heat utilization and temperature increasing system is composed of three parts of an anaerobic fermentation tank, a heat pump / a heat pump unit, and a biogas residue and biogas slurry tank. Biogas residues and biogas slurry serve as low-grade heat sources to transmit heat to a heat conducting medium through a concrete pre-embedded coil pipe integrated radiation tail end, and the heat conducting medium is compressed into high-temperature and high-pressure gas through the heat pump unit and then releases the heat to the fermentation tank through the concrete pre-embedded coil pipe integrated radiation tail end, so that the temperature required by biological anaerobic fermentation is guaranteed; and when the temperature of the fermentation tank is high and the fermentation temperature requirement can be met directly by fluoroplastic pump circulation, the heat pump unit is shut down. The characteristic of high viscosity of fermentation liquid is fully considered, and the concrete pre-embedded coil pipe integrated radiation tail end replaces a traditional heating coil pipe, so that the problem that the traditional heating coil pipe is likely to scale, and consequently, the heat exchange efficiency is sharply reduced is effectively avoided, and the structure is simple; and meanwhile, the waste heat of the biogas residues and the biogas slurry are used for increasing the temperature of the anaerobic fermentation tank through a direct-expansion type heat pump system, so that high efficiency and energy saving are achieved.

Owner:TAIYUAN UNIV OF TECH

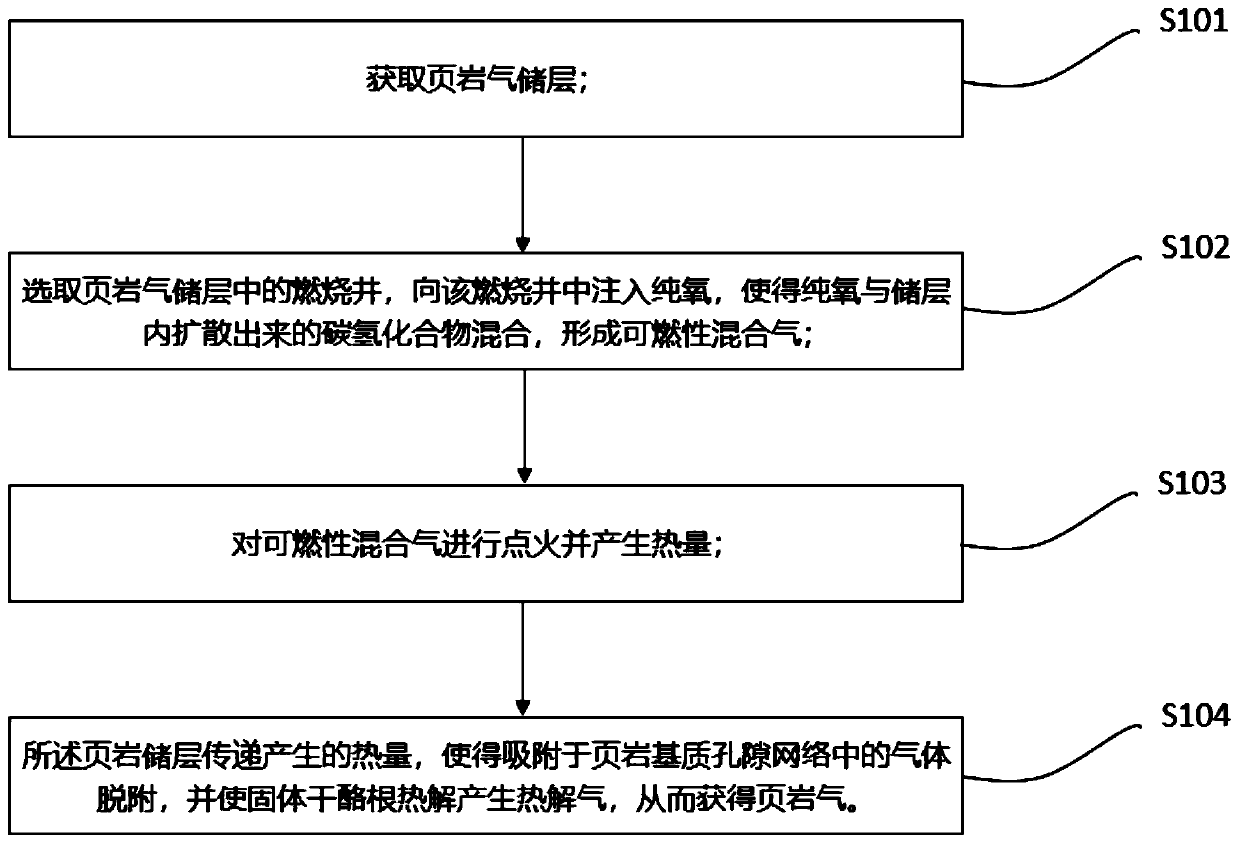

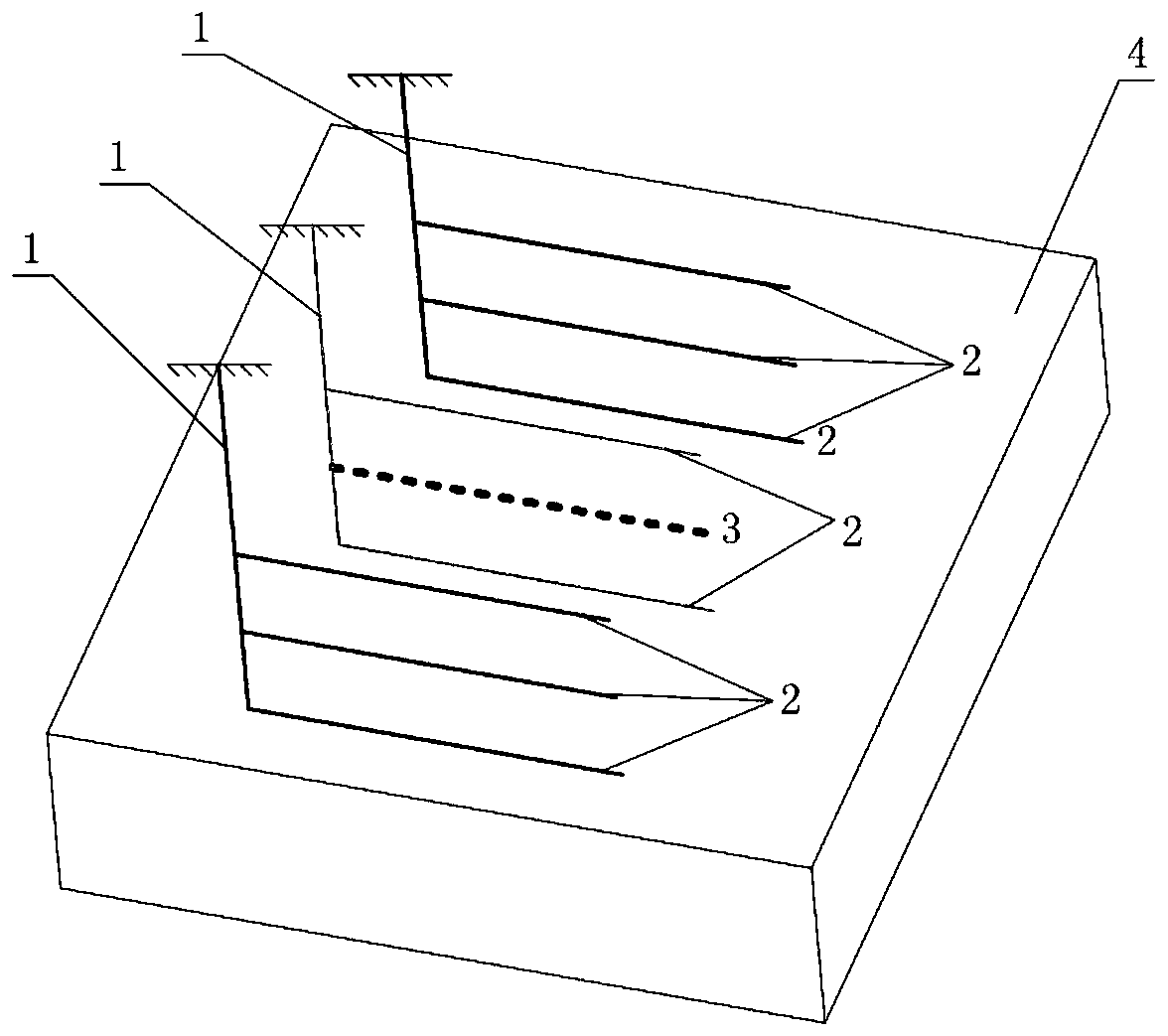

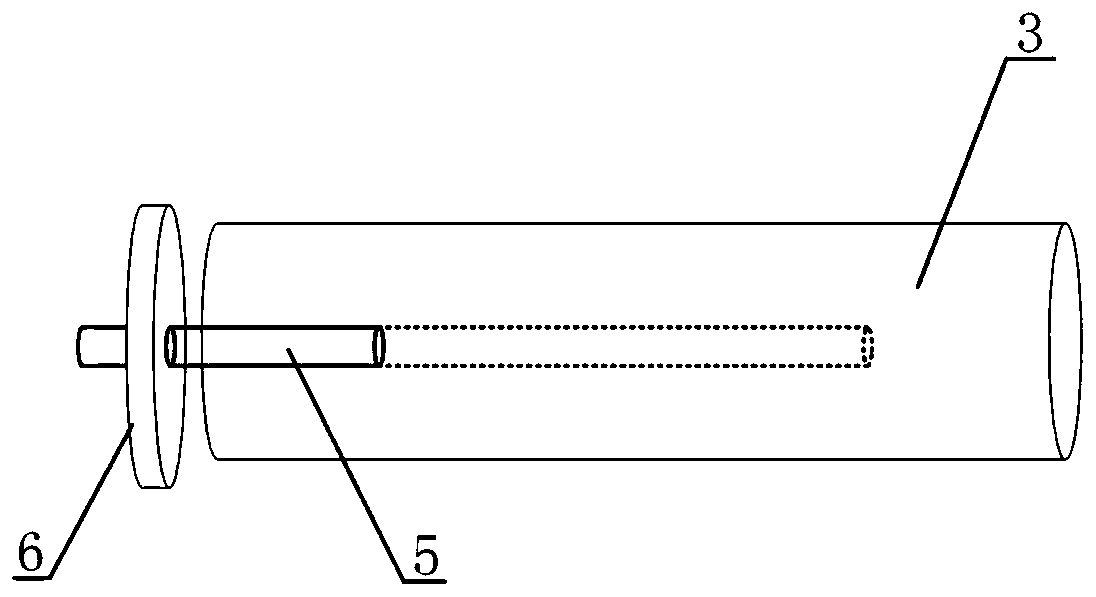

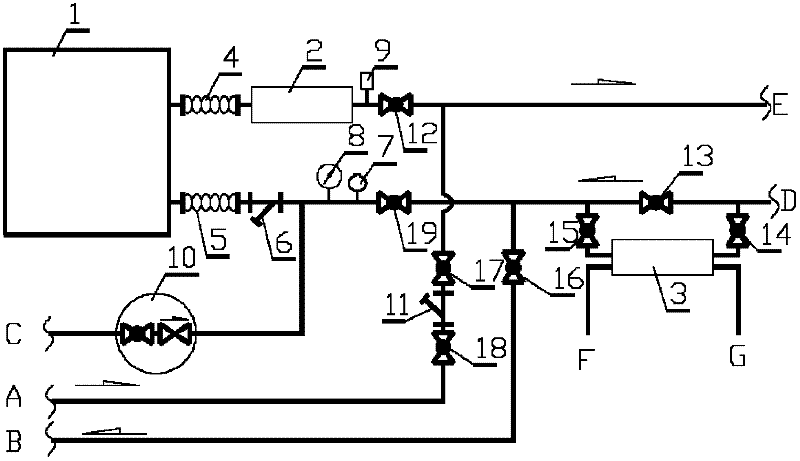

Shale gas exploitation method and system

InactiveCN110017125ASimple structureImprove mining efficiencyOther gas emission reduction technologiesFluid removalOil shale gasKerogen pyrolysis

The invention discloses a shale gas exploitation method and system. The method comprises the following steps: pure oxygen is introduced into a shale gas reservoir, free-state shale gas preferentiallydiffused in a horizontal well and the reservoir is subjected to controllable combustion, thermal generated by combustion is transferred to a shale gas storage layer, the free energy of shale gas is improved, the intermolecular interaction force is reduced, methane and other gases adsorbed in a shale matrix pore network are desorbed, solid kerogen is pyrolyzed to generate pyrolysis gas, and thus shale gas is obtained. The system comprises a gas injection module, a gas collection module and a gas flow regulation module. The system is simple in structure and convenient to implement, the combustion degree can be controlled through the oxygen supply amount, no additional fuel is needed for heating, the economical efficiency is good, and combustion products are mainly water and carbon dioxide, so that environmental pollution is small.

Owner:SUZHOU UNIV

Energy-saving air-conditioning system

InactiveCN102494374ASave a lot of spaceIncrease the scope of applicationSpace heating and ventilation safety systemsLighting and heating apparatusPipingCentral air conditioning

The invention discloses an energy-saving air-conditioning system, which comprises an indoor unit, an electric auxiliary heater, a centralized heat supply pipe network, an automatic water replenishing system, a heat exchanger, a fan coil and a plurality of valves, wherein the fan coil comprises a fan coil water return pipe and a fan coil water supply pipe; the centralized heat supply pipe network comprises a centralized heat supply water return pipeline and a centralized heat supply water supply pipeline; the fan coil water return pipe, the heat exchanger, the centralized heat supply water return pipeline and the automatic water replenishing system are connected in parallel, and are connected to the inlet of the indoor unit together; the outlet of the indoor unit is connected with one end of the electric auxiliary heater; and the other end of the electric auxiliary heater is connected with the centralized heat supply water supply pipeline and the fan coil water return pipe. The centralized heat supply pipeline is connected to a central air-conditioning system, so that the pavement of radiating fins and pipelines thereof is saved; the fan coil of an air conditioner is taken as a radiator, so that a large amount of space is saved; and meanwhile, residual heat of the heat supply water return pipeline is used for preheating a water inlet pipe of a water heater, so that living hot water is provided simultaneously, and the aim of saving energy is fulfilled.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

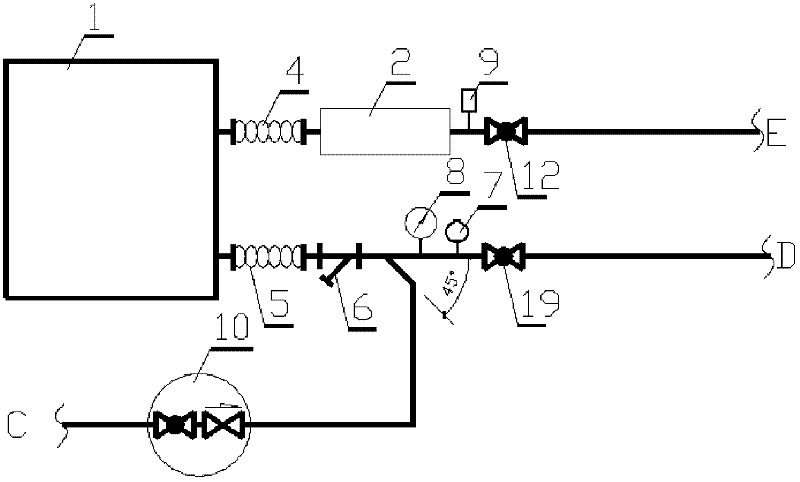

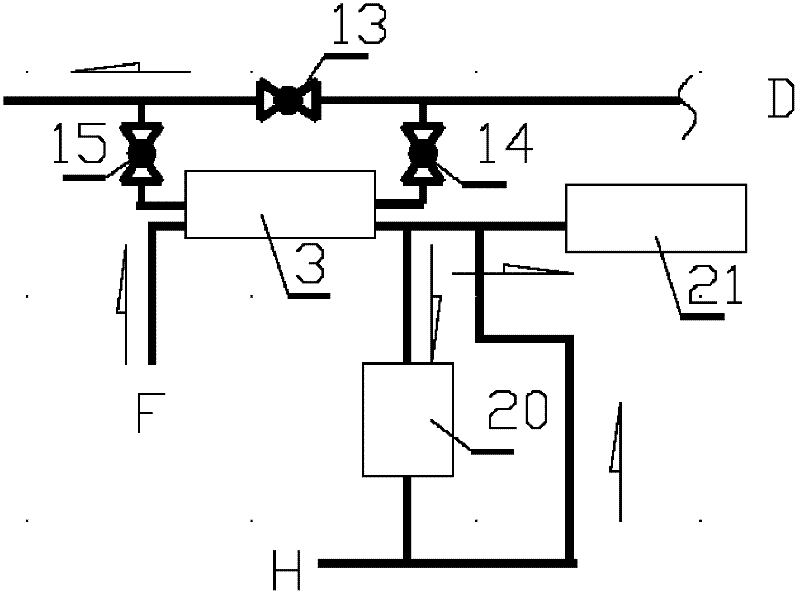

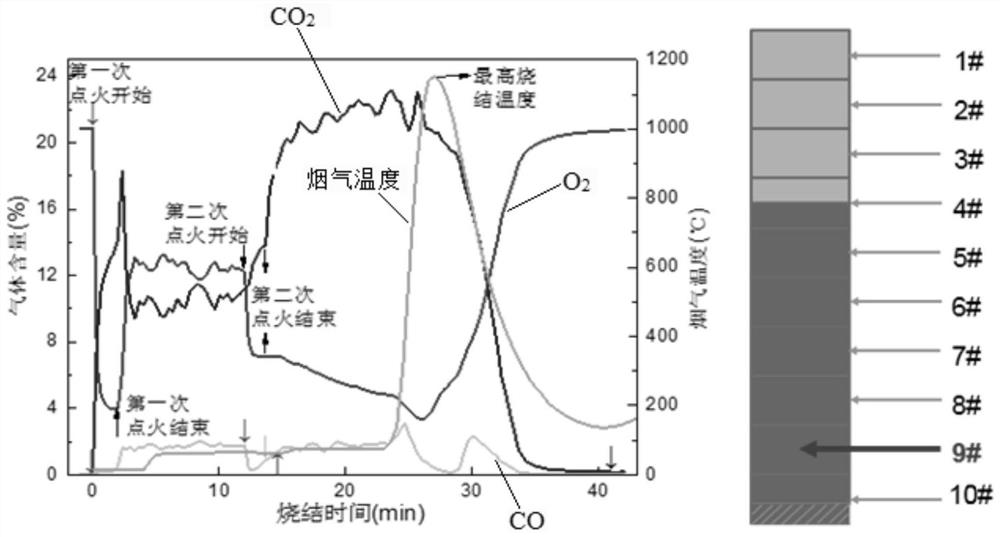

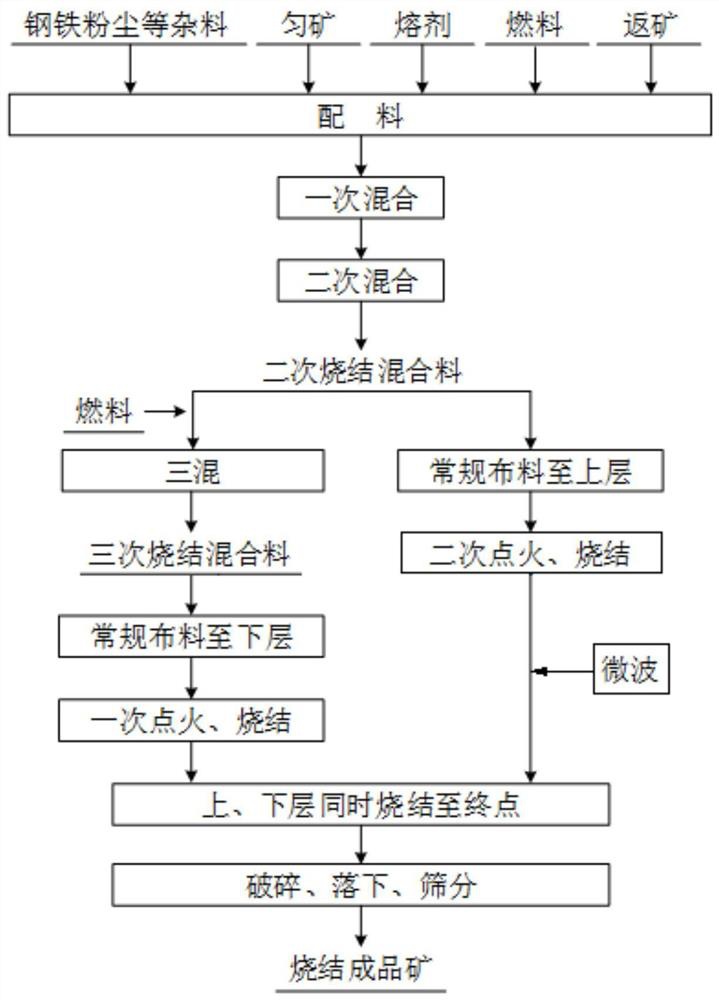

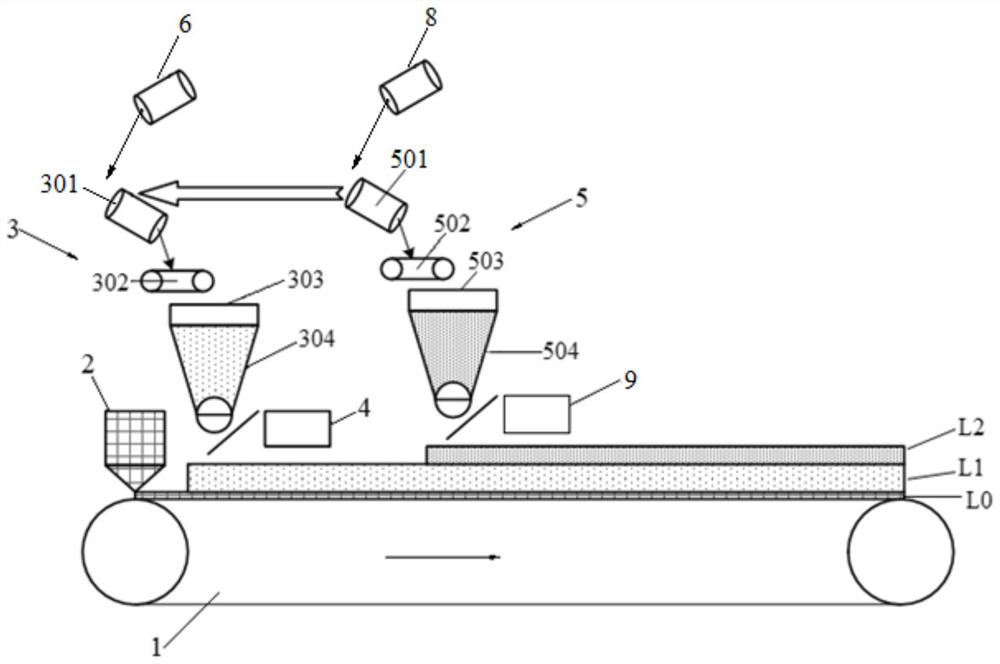

Double-layer sintering method and sintering device

ActiveCN112410544AIncrease production capacitySolve technical problemsHeat conservationBedding Material

The invention relates to a double-layer sintering method, which comprises the following steps: 1) proportioning an iron-containing raw material, a flux and a fuel, and preliminarily mixing the proportioned materials to obtain a sintered preliminary mixture; 2) adding fuel into the preliminary sintering mixture, and mixing again to obtain a sintered remixed mixture; 3) paving a bedding material ona sintering trolley, paving the sintered remixed mixture on the bedding material to obtain a first distribution layer, and then performing primary ignition sintering on the first distribution layer; and (4) paving the sintered preliminary mixture on the first distribution layer to obtain a second distribution layer, carrying out secondary ignition sintering on the second distribution layer, and providing an external heat source for heating and heat preservation of the second distribution layer. According to the double-layer sintering method and sintering device provided by the invention, the fuel is innovatively distributed in the material layer according to the mode that the upper layer content is low and the lower layer content is high, so that the oxygen amount consumed by the upper layer sintered mixture is reduced, it is guaranteed that the lower layer sintered mixture can obtain the sufficient oxygen amount, and the problems that according to an existing double-layer sintering process, the lower layer sintering oxygen content is insufficient, and the sintering ore strength is poor are solved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

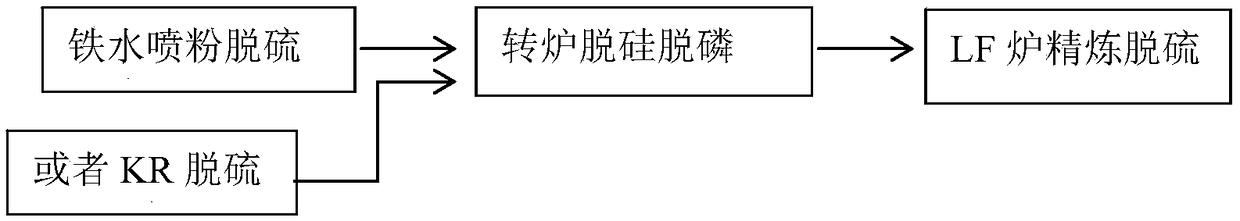

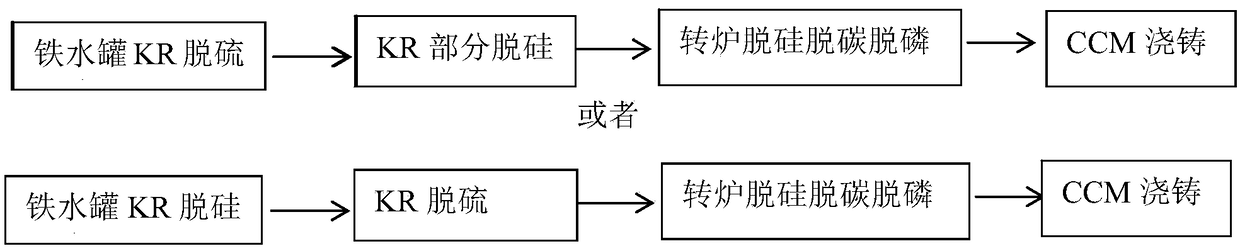

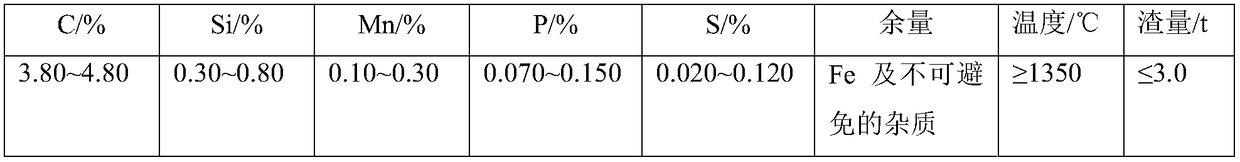

Method for smelting low phosphorus and sulfur steel with desulfurization and desiliconization of hot metal ladle and less converter slag

ActiveCN109468426AEnough caloriesImprove economic indicatorsManufacturing convertersProcess efficiency improvementSlagSulfur

The invention relates to a method for smelting a low phosphorus and sulfur steel with desulfurization and desiliconization of a hot metal ladle and less converter slag, belonging to the technical field of steel making. The method comprises the process steps: the hot metal pretreatment desulfurization is carried out in the hot metal ladle by KR method, and sulfur in the hot metal is removed to 0.002% or below in the hot metal ladle; the hot metal pretreatment desiliconization is carried out in the hot metal ladle by the KR method, and the silicon in the hot metal is removed to 0.20%-0.40%, at the end, the temperature of the hot metal is controlled to be 1250 DEG C or above and then the ladle is removed out; the low-silicon hot metal after desulfurization and desiliconization is put into a converter for decarburization, desiliconization and dephosphorization, and the low-silicon hot metal is exchanged into the converter for decarburization, desiliconization and dephosphorization, and thetop-bottom double-blowing process of top blowing oxygen and bottom blowing argon is used for smelting. At the end of smelting, the weight percentage of C in molten steel is 0.05% to 0.30%, and the end point [P]+[S] is smaller than or equal to 200ppm, the converter is subjected to tapping, the molten steel is discharged into a ladle directly for continuous casting or pouring after RH refining. Theadvantage is that compared with the prior art, the process flow is short, the total amount of phosphorus and sulfur at the end of the molten steel is low, and the total amount of slag is small.

Owner:CENT IRON & STEEL RES INST

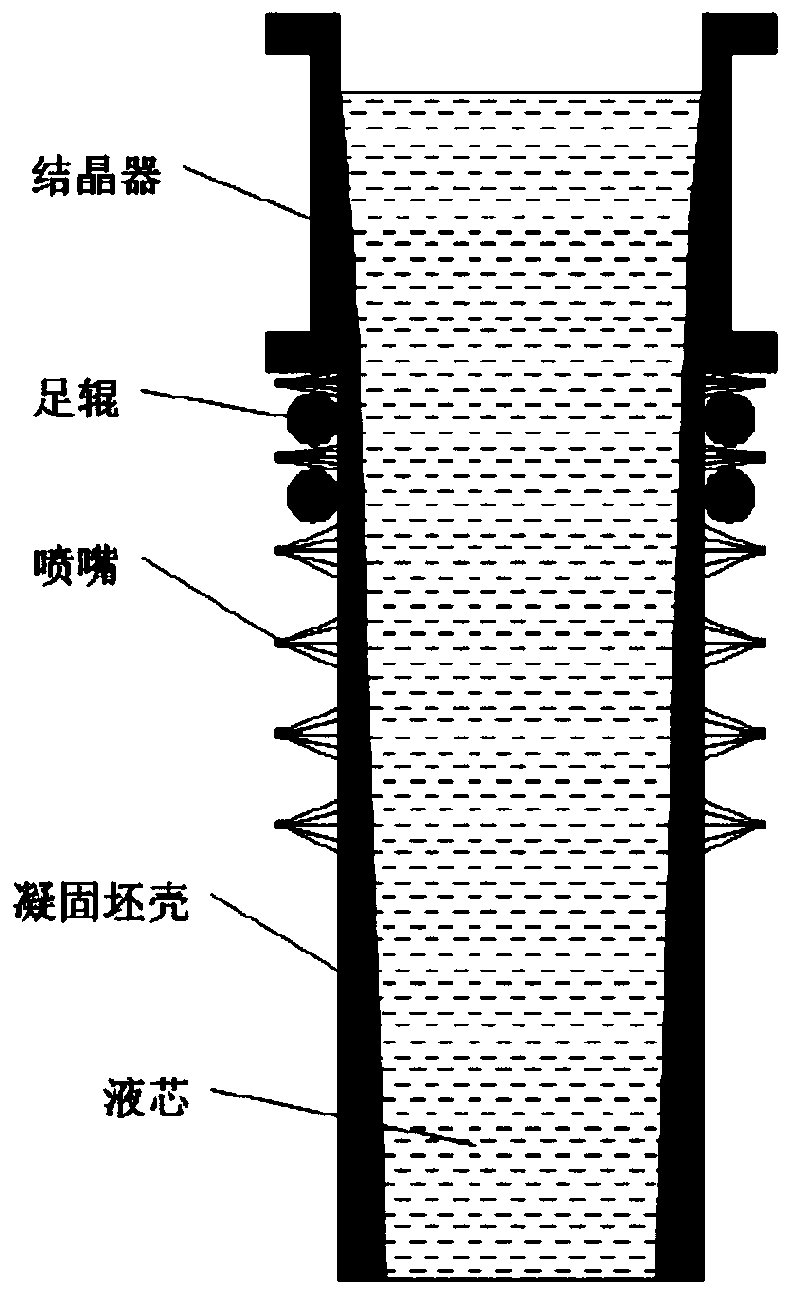

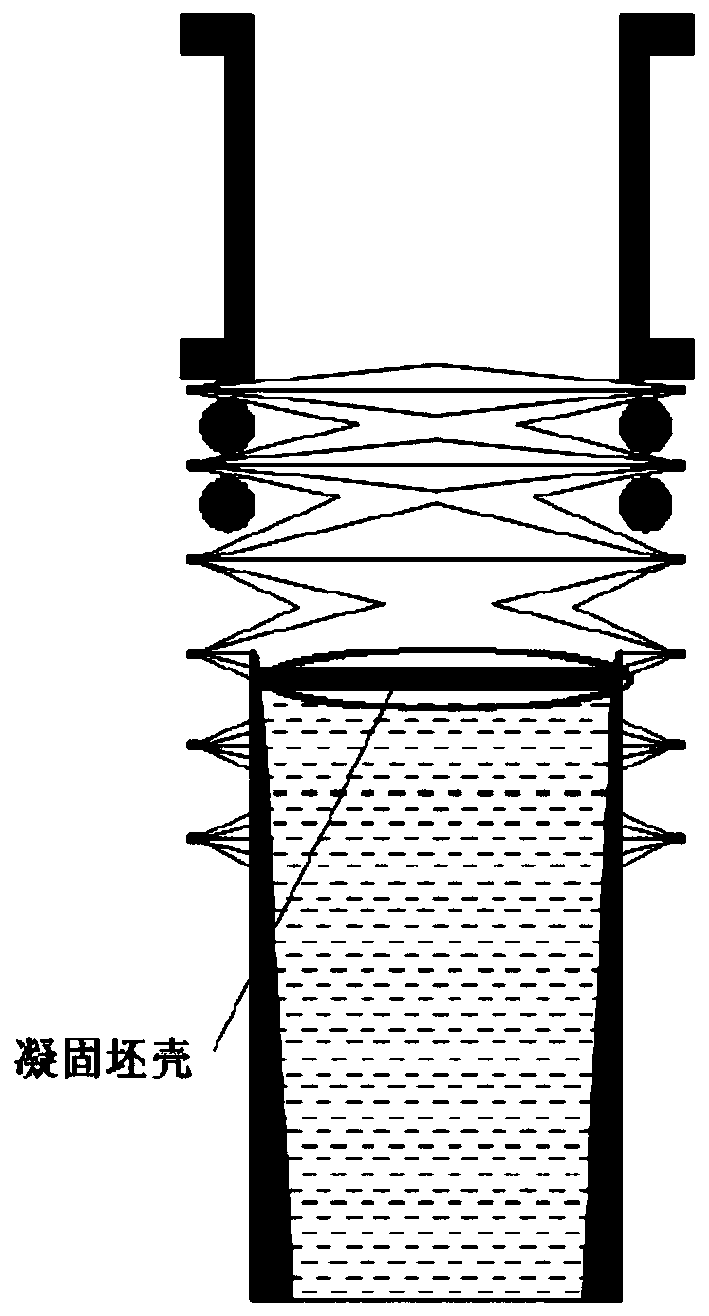

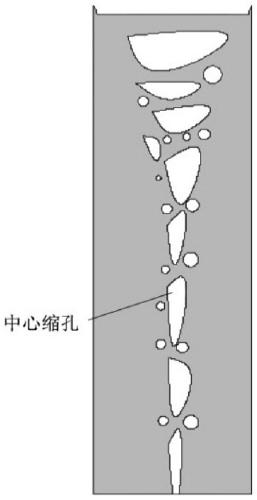

Process method for improving quality and yield of continuous casting tail billet

The invention discloses a process method for improving the quality and yield of continuous casting tail billet, and belongs to the technical field of metallurgical continuous casting. The process method includes the steps that when the tail billet is obtained after continuous casting, a special metallurgical heating agent is evenly sprinkled into a mold liquid level, and when the tail billet is about to be pulled out of a mold, the secondary cooling water is closed sequentially from top to bottom. The metallurgical heating agent can be in chemical reaction with liquid steel of the tail billet,heat is continuously released, and in the absence of the cooling effect of the secondary cooling water, the top of the tail billet remains in a high temperature liquid state, so that the solidification time of the tail billet is prolonged, the volume shrinkage of a liquid core is supplemented by metal iron generated by exothermic reaction and iron of the heating agent, and the purposes of improving the solidification structure quality of the tail billet and the yield rate of the molten steel of the tail billet are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

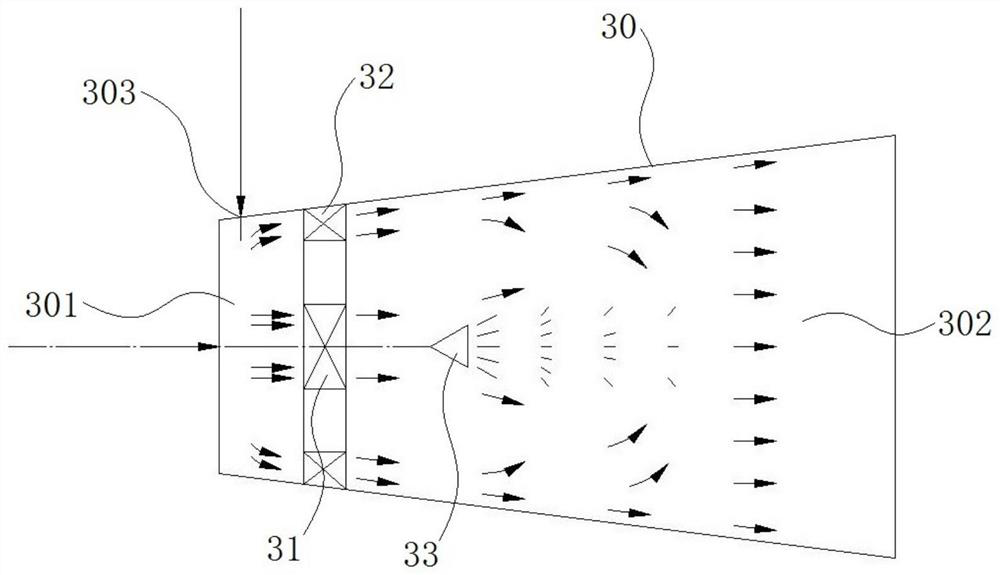

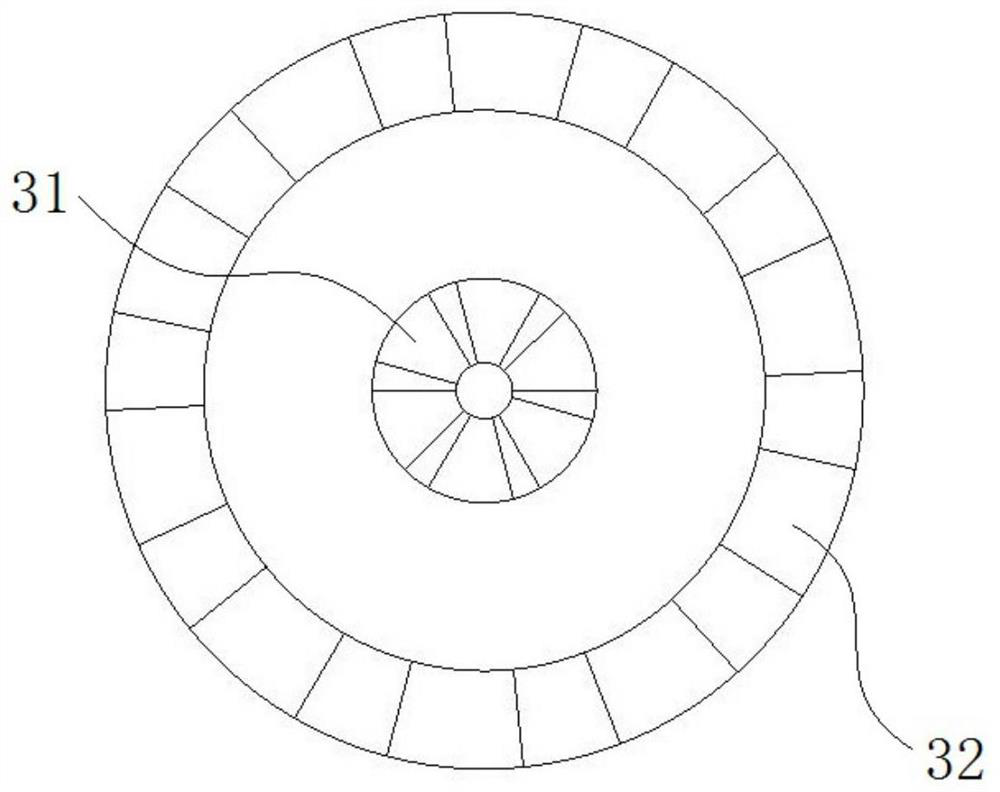

Evaporation treatment system for salt-containing wastewater

ActiveCN113104916AImprove evaporation efficiencyStable heat inputGeneral water supply conservationWater/sewage treatment by heatingGas heaterDust control

The invention provides an evaporation treatment system for salt-containing wastewater, belonging to the field of wastewater treatment. The evaporation treatment system comprises a boiler, a desulfurization tower, a rotational-flow atomization evaporator, an exhaust gas dust remover and a spraying device, wherein a smoke outlet of the boiler communicates with an air inlet of the rotational-flow atomization evaporator, a water inlet pipeline is arranged between and connected with a sewage outlet of the desulfurization tower and the spraying device, and the exhaust gas dust remover is arranged between and connected with the rotational-flow atomization evaporator and the spraying device; the rotational-flow atomization evaporator comprises a shell, a swirler and a sprayer, the swirler communicates with a gas inlet of the rotational-flow atomization evaporator, and the gas inlet of the rotational-flow atomization evaporator is connected with a gas heater; the spraying device comprises a tank body and a spraying head, the upper part of the tank body is provided with a wet exhaust gas outlet, the lower part of the tank body is provided with a wastewater discharge outlet, and the tank body is provided with an exhaust gas inlet arranged at the lower part of the spraying head; and an exhaust port of the exhaust gas dust remover communicates with the exhaust gas inlet, and a water supply pipeline is arranged between and connected with the wastewater discharge outlet and the sprayer of the rotational-flow atomization evaporator.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Method for planting collybia radicata in winter

InactiveCN109566270AImprove growing conditionsPromote growthCultivating equipmentsMushroom cultivationMushroomBiology

The invention discloses a method for planting collybia radicata in winter. At an earlier stage, through scientific and sterile mycelium culture, excellent hyphae are obtained, then after cultivation,a strict management method is implemented, wherein through accurate temperature and humidity control, the best growth conditions of mushrooms are guaranteed, meanwhile, the feature of low temperaturein winter is considered, in combination with kinds of anti-cold procedures which include laying and scattering of quick lime for increase in temperature and further include steam pipeline laying whichcan provide sufficient heat energy for the interior of a mushroom greenhouse at night, meanwhile, air humidity is kept, a warm-keeping quilt covers the exterior of the greenhouse additionally to ensure the stability of temperature difference at night in winter jointly, in daytime, according to sunlight, black thin films are set up to improve the effect of heat absorbing and realize sun shieldingappropriately to keep moisture on the surfaces of mushroom beds, and all the procedures jointly guarantee that collybia radicata grow well in winter; powerful technical supports are provided for anti-season planting of collybia radicata, meanwhile, the all-the-year demands for collybia radicata in the market are met, and the economic benefits of production families are increased.

Owner:安徽省百麓现代农业科技有限公司

Method of hydrotreatment of fischer-tropsch synthesis products

InactiveUS20170335208A1Simple processHigh densityTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsWaxLiquid product

A method of hydrotreatment of Fischer-Tropsch synthesis products, the method including: 1) mixing Fischer-Tropsch wax with a sulfur-containing liquid crystal, contacting a resulting mixture with hydrogen, feeding a hydrogen-containing mixture to a first reaction region, feeding an effluent from the first reaction region to a second reaction region, and carrying out hydrocracking reaction; 2) feeding a hydrocracking product from the second reaction region and Fischer-Tropsch naphtha and diesel fuel to a third reaction region, carrying out hydrofining reaction; feeding an effluent from the hydrofining reaction to a fourth reaction region, and carrying out hydroisomerizing pour-point depression reaction; and 3) feeding an effluent from the fourth reaction region to a gas-liquid separation system to yield hydrogen-rich gas and liquid products, recycling the hydrogen-rich gas, and feeding the liquid products to a distilling system.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

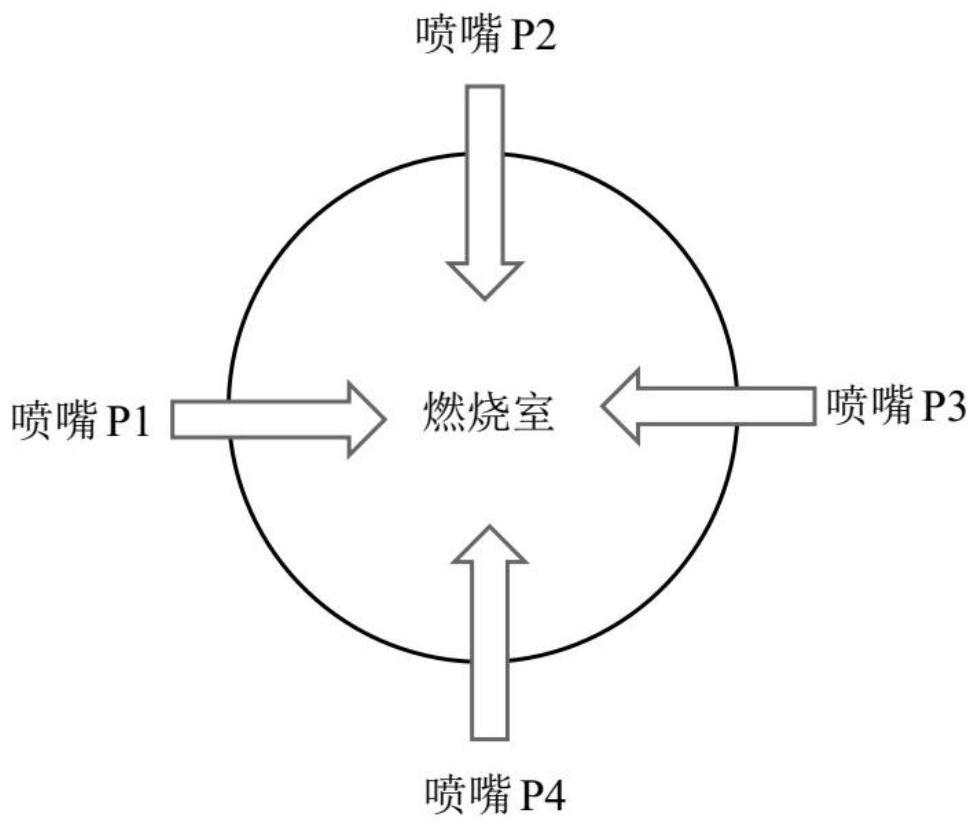

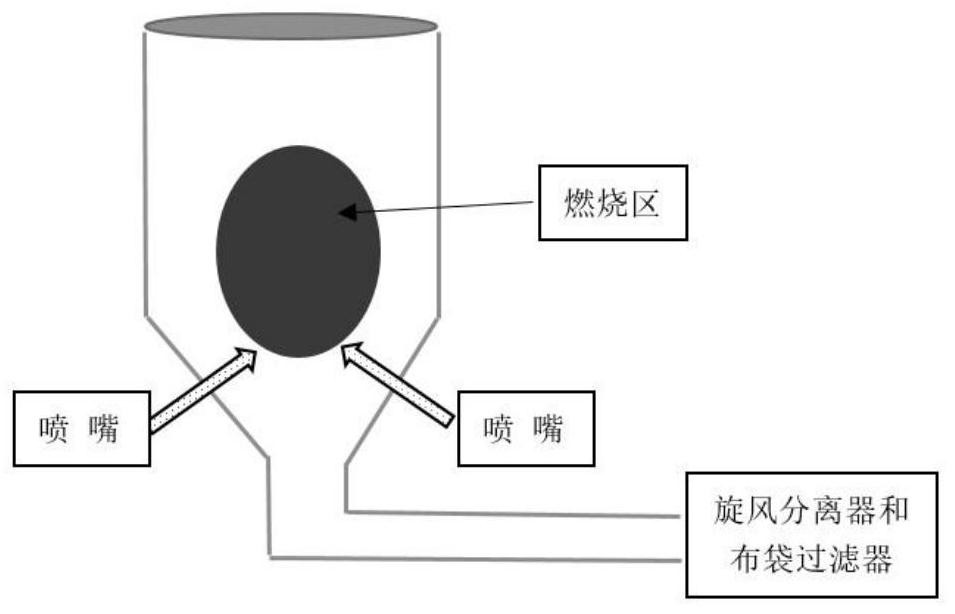

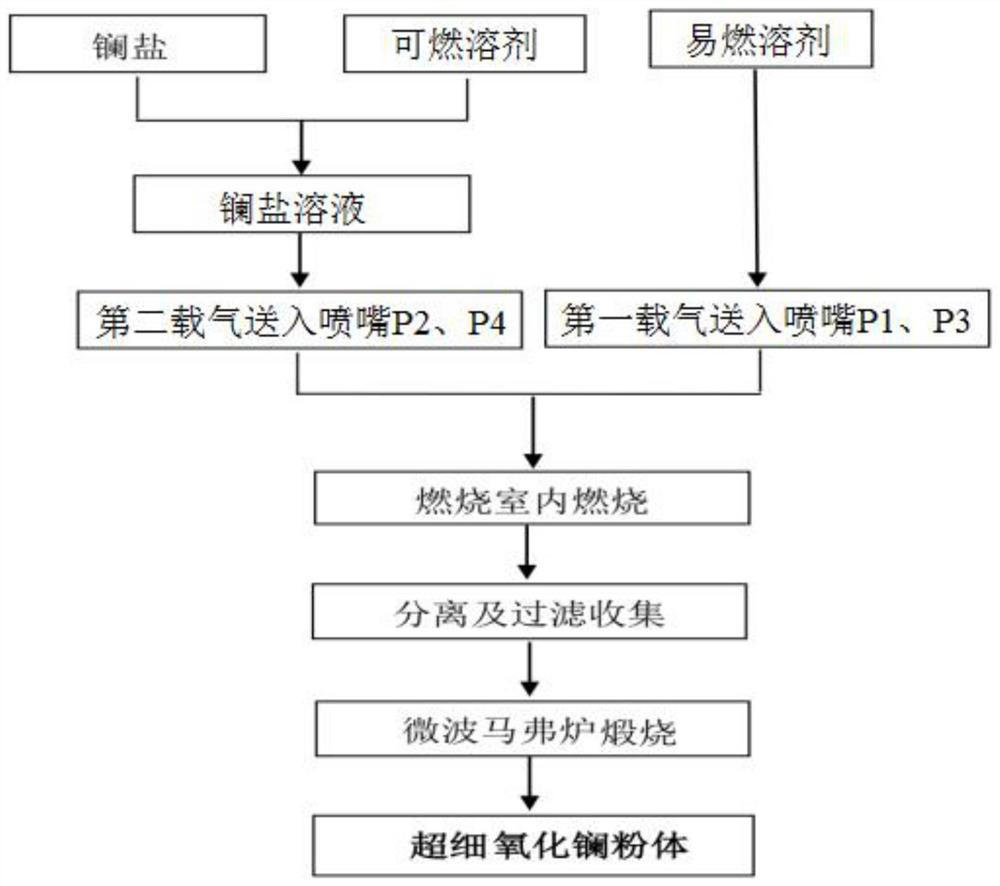

Combustion chamber and method for synthesizing ultrafine lanthanum oxide powder through combustion

ActiveCN112707430AGood dispersionUniform particle sizeLanthanum oxide/hydroxidesRare earth metal compounds preparation/treatmentCombustion chamberAtomizer nozzle

The invention relates to the technical field of rare earth oxide powder, and provides a combustion chamber and a method for synthesizing ultrafine lanthanum oxide powder through combustion. A combustion chamber comprising four atomizing nozzles is adopted to synthesize superfine lanthanum oxide powder, a first atomizing nozzle and a third atomizing nozzle are symmetrically distributed, and a second atomizing nozzle and a fourth atomizing nozzle are symmetrically distributed; the method comprises the following steps: feeding a flammable solvent into the combustion chamber from the first atomizing nozzle and the third atomizing nozzle under the action of a first carrier gas for ignition, feeding a lanthanum salt solution into the combustion chamber from the second atomizing nozzle and the fourth atomizing nozzle under the action of a second carrier gas for combustion, combusting more than 85% of lanthanum salt to generate lanthanum oxide in the combustion process, and subjecting the combustion product to microwave oxidation calcination to convert a small amount of residual lanthanum salt into lanthanum oxide. The method provided by the invention is simple in process, short in flow, easy to operate and low in cost, and the obtained ultrafine lanthanum oxide powder is good in dispersity, high in purity and uniform in particle size.

Owner:JIANGXI UNIV OF SCI & TECH

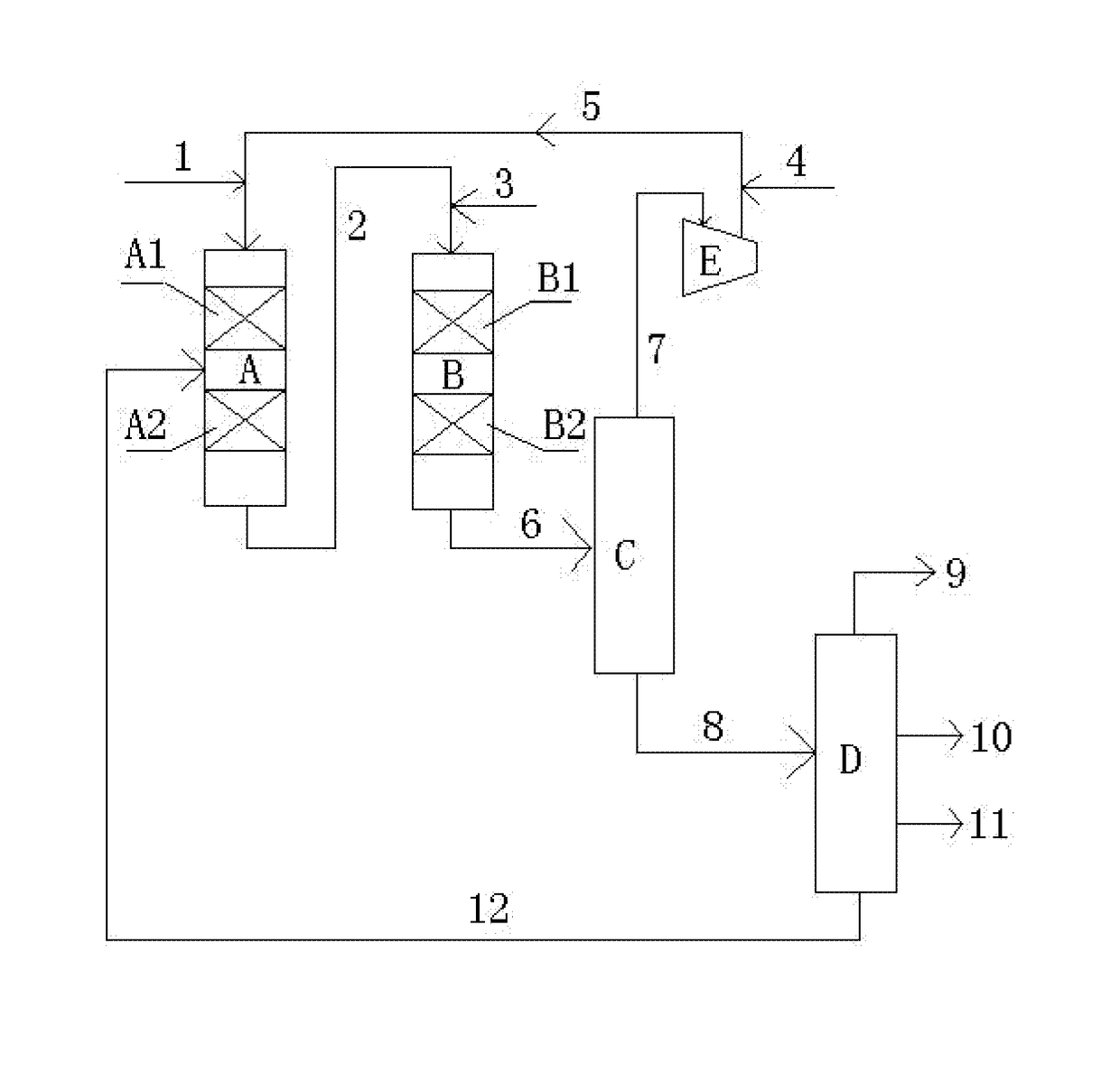

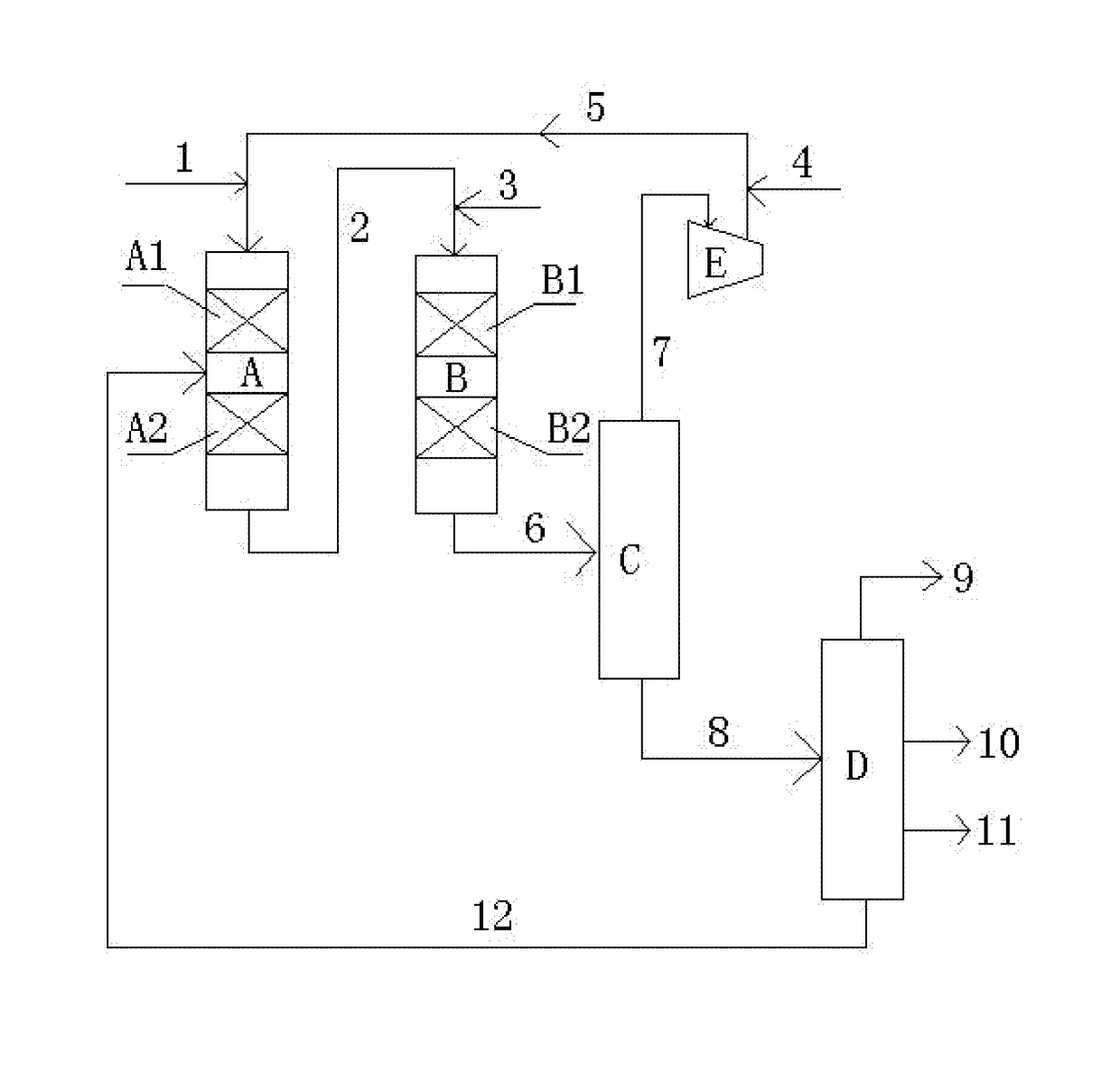

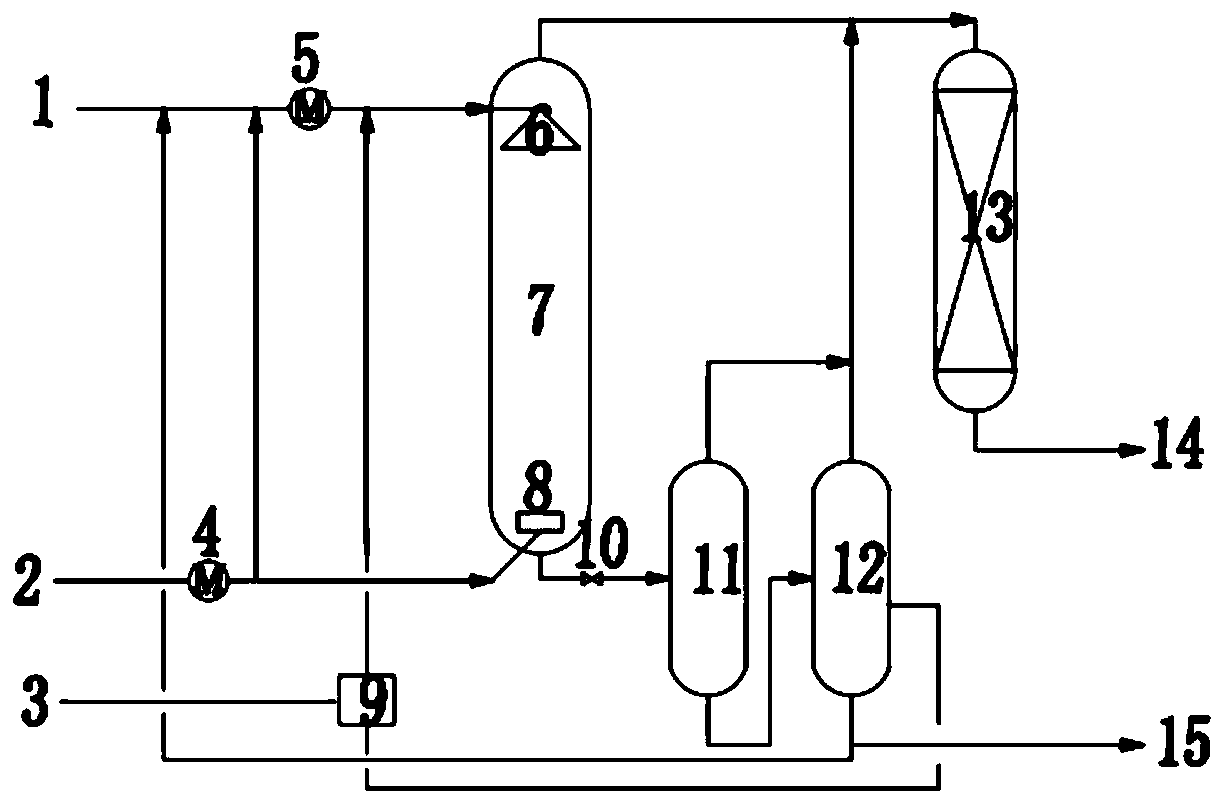

Reaction and separation integrated countercurrent hydrogenation reaction process

InactiveCN111575054AReduce contact timeReduced activityTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

Disclosed is a reaction and separation integrated countercurrent hydrogenation reaction process. A reaction raw material is mixed with part of hydrogen, heating is performed, a mixed feed is formed with catalyst slurry, the mixed feed is sprayed into a hydrocracking reactor from the upper part of the reactor, the reaction hydrogen is heated and boosted and then enters the hydrocracking reactor from the bottom of the reactor, and the reaction raw material and hydrogen are subjected to countercurrent heat and mass transfer and a hydrocracking reaction in the reactor; a gas-phase product directlyenters a fixed bed hydrogenation device from a top outlet of the reactor, so that clean fuel is obtained; a liquid (solid) phase product is depressurized and degassed and enters an atmospheric and vacuum distillation device from the bottom of the reactor; and side oil of the atmospheric and vacuum distillation device enters the fixed bed for hydrogenation, and bottom oil residues are partially directly discharged out of the device and partially circularly enter a raw material system.

Owner:SHAANXI YANCHANG PETROLEUM GRP

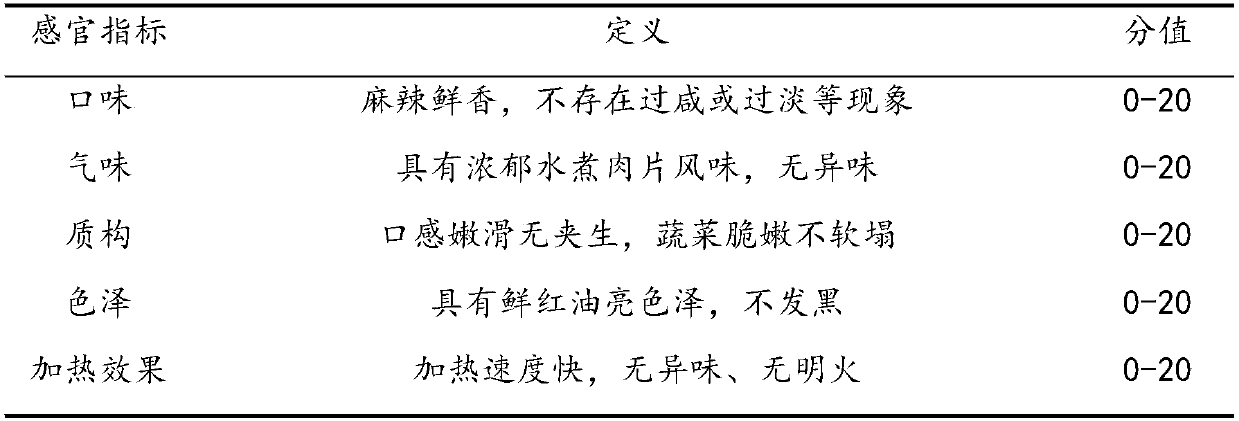

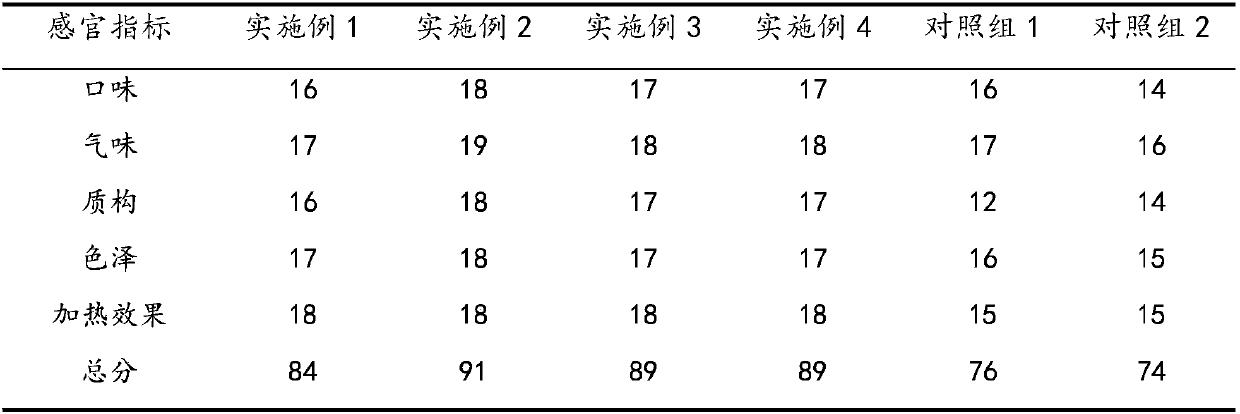

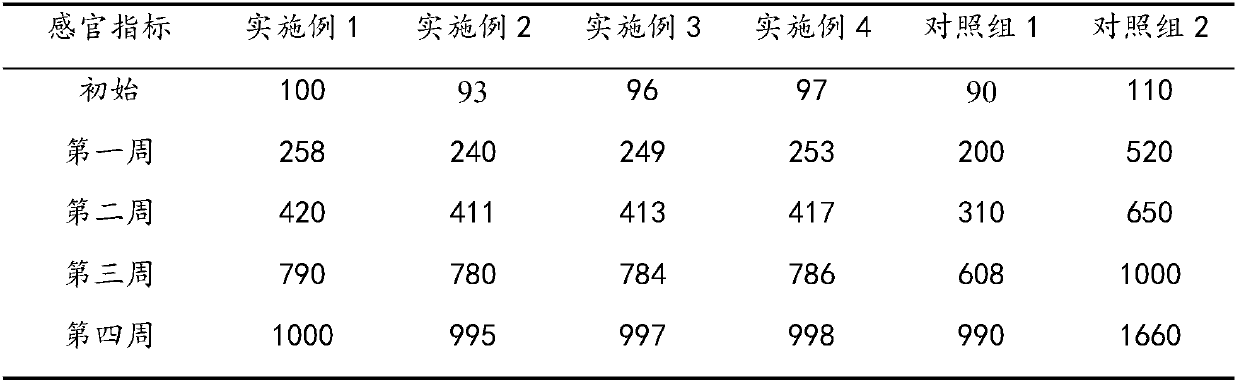

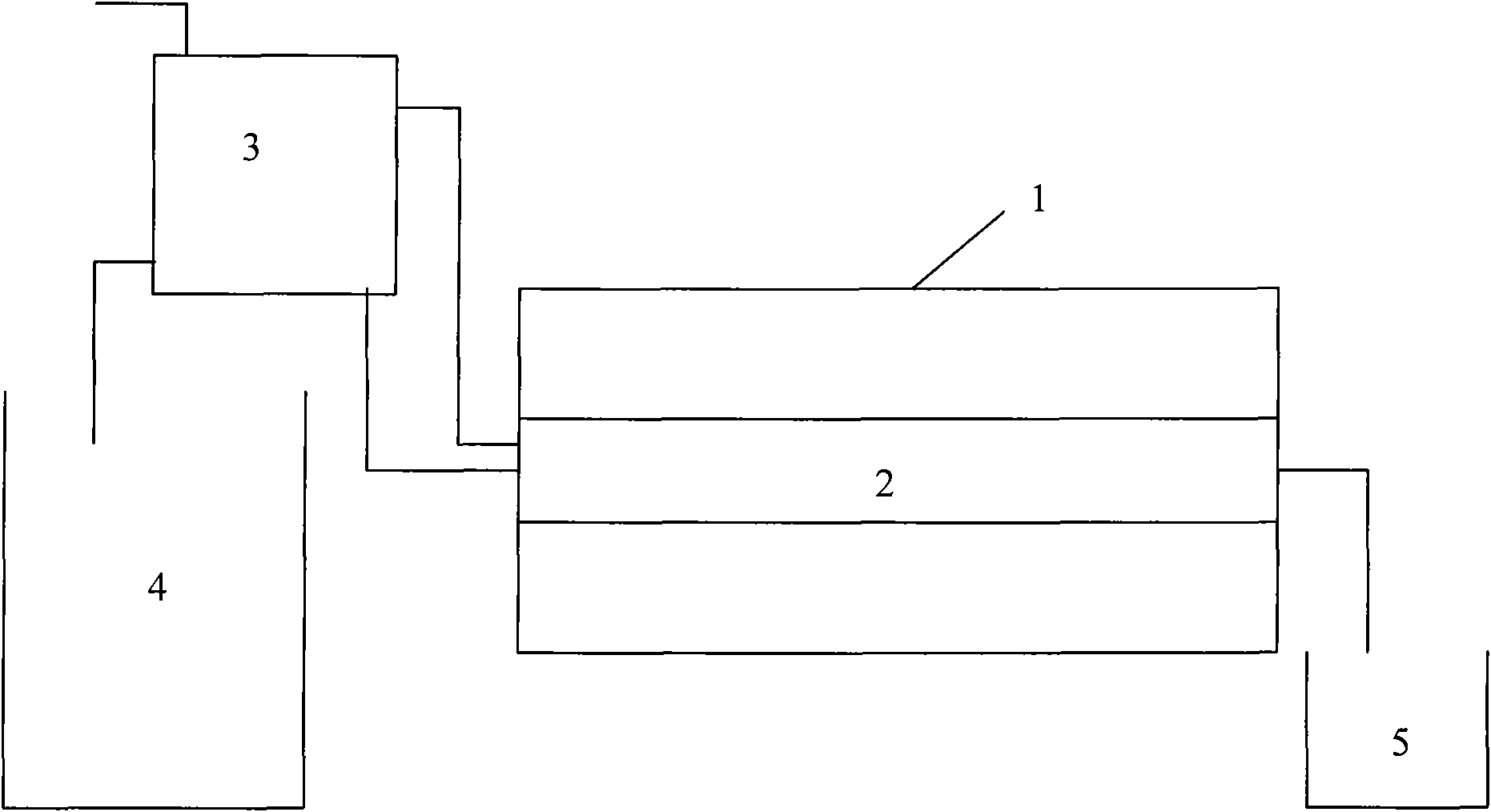

Self-heating poached spicy pork slices and preparation method thereof

InactiveCN107927595AAuthentic flavorHeating evenlyBio-packagingContainers for heating foodMonosodium glutamateVegetable oil

The invention relates to self-heating poached spicy pork slices and a preparation method thereof, and belongs to the field of food. The method comprises a finished product of the poached spicy pork slices, and a food self-heating tank, wherein the volume ratio of soup to solid content of the finished product of the poached spicy pork slices is (1.4-1.6):1. The poached spicy pork slices comprise the following raw materials: lean pork, vegetable oil or salad oil, thick broad-bean sauce, pickled chilies, pickled rod chilies, ginger, garlic, welsh onions, red Chinese prickly ash powder, white sugar, chili powder, table salt, monosodium glutamate, water, lettuces, bean sprouts, marinating materials for meat, spices and dry seasonings. The food self-heating tank comprises a water storage bag, anotch-shaped heating bag, an outer tank and an inner tank, wherein the top of the outer tank is provided with a tank cover, and the inner side of the tank cover is provided with a toothpick. The preparation method comprises the following steps: A, slicing and pickling; B, material stir-frying; C, cooking; and D, and filling and sterilization. The self-heating poached spicy pork slices of the invention are authentic in flavor, spicy, fresh, and fragrant, can be stored at normal temperature for a long time, and has the advantages of uniform heating, sufficient heat and high safety coefficient during self-heating process. The preparation method is simple and convenient, and is suitable for large-scale production.

Owner:SICHUAN MANJIANGHONG FOOD TECH

Cylinder light gathering seawater desalting device

InactiveCN101570351ALow costObvious beneficial effectGeneral water supply conservationSeawater treatmentEngineeringSea salt

The invention relates to a cylindrical light gathering seawater desalting device. Two key parts of a light gathering cylinder and an evaporating pipe are innovatively designed. The seawater desalting device has unique and novel structure and can obtain a great amount of solar energy to heat and boil the seawater at high temperature so as to generate steam, and fresh water and sea salts are prepared by condensing. The seawater desalting device has high heating-up speed, steady temperature, sufficient heat, normal pressure production, security guarantee, simple structure, easy purchase of materials, easy manufacture and low cost and can save the investment, reduce the cost and improve the benefit. The seawater desalting device can be designed into a single set of a huge device and can also be designed into various types and specifications in large, medium and small sizes, and even a plurality of sets of devices can be designed for integrated operation so as to enlarge the scale of production and obtain better economic benefit. The seawater desalting device has wide applicability and can be built on land, mounted over mudflats and also arranged on decks of ships and platforms over water. Therefore, the problem of exhausted fresh water resources can be solved, and the hardship of water break of the ships can be overcome. The seawater desalting device has zero power consumption, zero pollution discharge, environment protection and conservation culture and is a new technology utilizing the solar energy to desalt the seawater with low cost and high efficiency.

Owner:韩统

Air heating equipment based on electric water heater

InactiveCN107676975APrevent backflowTake advantage of freedomFluid heatersHeating fuelThermodynamicsEngineering

The invention discloses air heating equipment based on an electric water heater. The air heating equipment based on the electric water heater comprises an electric water heater body and a heating box.The electric water heater body communicates with the heating box through a first hot water main pipe. The end, located in the electric water heater body, of the first hot water main pipe is fixedly connected with a fixed sleeve. A one-way valve is inserted into the fixed sleeve. Two sliding rods are symmetrically and fixedly connected to the top of the fixed sleeve. The sliding rod is slidably sleeved with a sliding block. One end of the sliding block is fixedly connected with the one-way valve. The sliding rod is sleeved with a first spring. The two ends of the first spring are fixedly connected with the sliding block and the fixed sleeve correspondingly. A hot water branch pipe is arranged in the electric water heater body. According to the air heating equipment based on the electric water heater, when hot water in the electric water heater is not used in time, heat returns into the heating box in time to achieve cyclic utilization of hot air, heat energy of the hot water is well utilized, and thus energy is saved.

Owner:陆玉仓

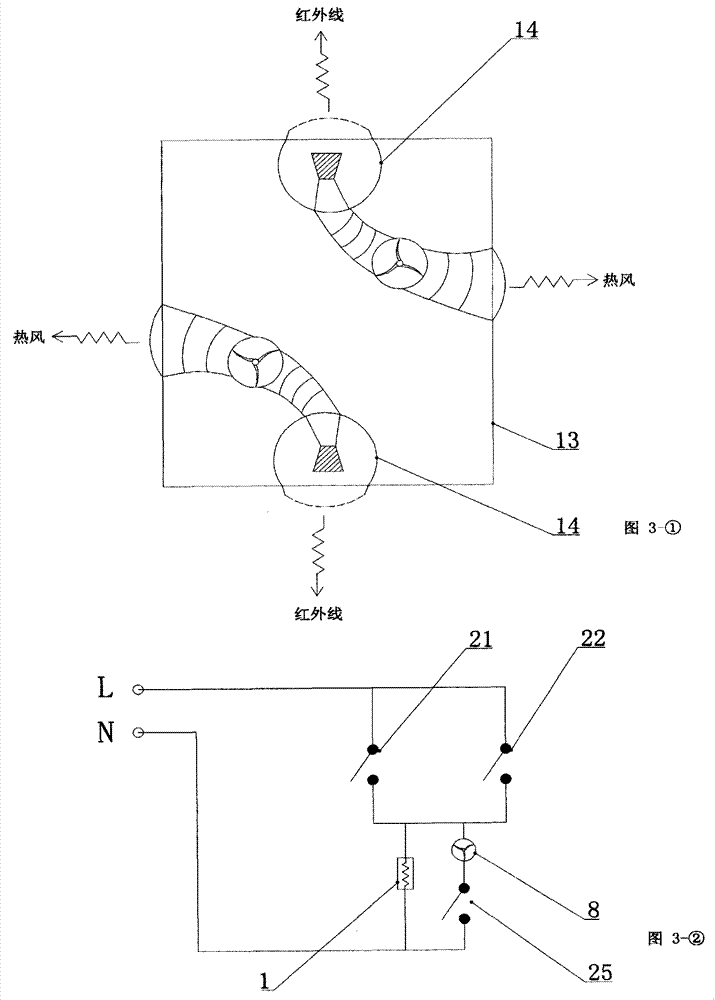

Multifunctional small solar heater structure based on excess and waste heat utilization technology

The invention discloses a multifunctional small solar heater structure based on excess and waste heat utilization technology. An air outlet of an air supply pipe (11) is directly fixed or fixed below the outside of a reflecting cover through a movable hook (31), a safety protecting net (12) and an additionally-made movable pipe orifice fastening cover are arranged at the pipe orifice of the air supply pipe, and a pipe body of the air supply pipe (11) is fixedly or movably butted with a pipeline led from a foot and hand heating device (27) via a three-way branch pipe (26). Without increasing power consumption and reducing original infrared heating effect, original rising lost hot air and heat energy carried by a heat source carrier form hot air through the fan, the hot air is blown or sucked onto the heating device specially used for feet and hands, excess and waste heat is fully utilized to solve the problem about heating of feet and hands of another person outside an infrared radiation area, electric heat utilization rate of a heater is doubled, and energy-saving effect is remarkable.

Owner:CIXI FUYUN ELECTRIC APPLIANCE

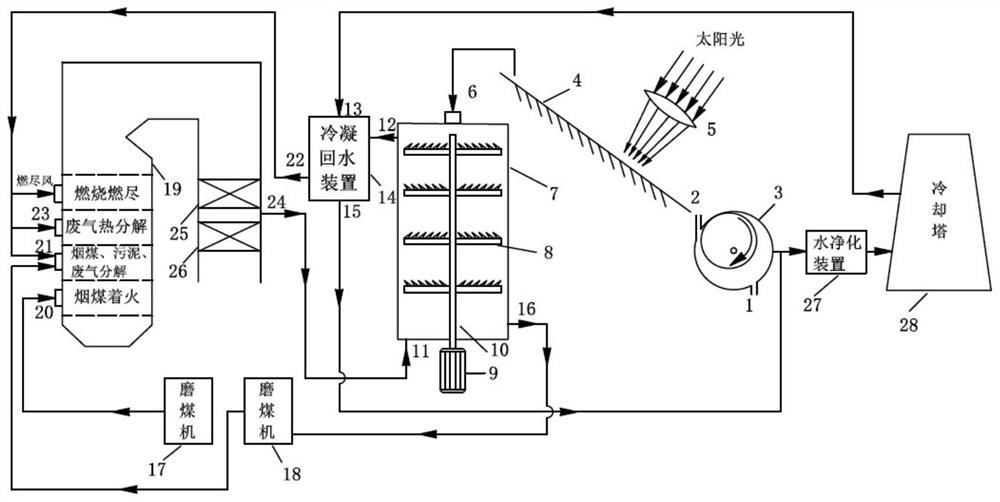

A system and method for drying and high-efficiency co-firing treatment of high-moisture solid waste

ActiveCN111410395BRealize cascade utilizationRealize comprehensive utilizationSludge treatment by de-watering/drying/thickeningGrain treatmentsPower stationCombustion

The invention discloses a system and method for drying high-moisture solid waste and high-efficiency co-firing treatment. In view of the fact that the moisture content of high-moisture solid waste such as sludge usually exceeds 80% and has a certain calorific value, the present invention proposes a three-stage drying system consisting of extrusion dehydration, solar focused preheating drying and flue gas strong convection drying. The solid waste drying system realizes the cascade utilization of energy in the process of drying sludge. The dried sludge is sent to the power plant boiler for high-efficiency co-combustion. By setting the combustion area reasonably and optimizing the combustion conditions, not only the heat of the sludge is fully utilized, but the harmful substances in the sludge are fully degraded. The system recovers the water in the sludge while treating the sludge, and realizes the harmless treatment of the sludge and the full utilization of energy.

Owner:XI AN JIAOTONG UNIV

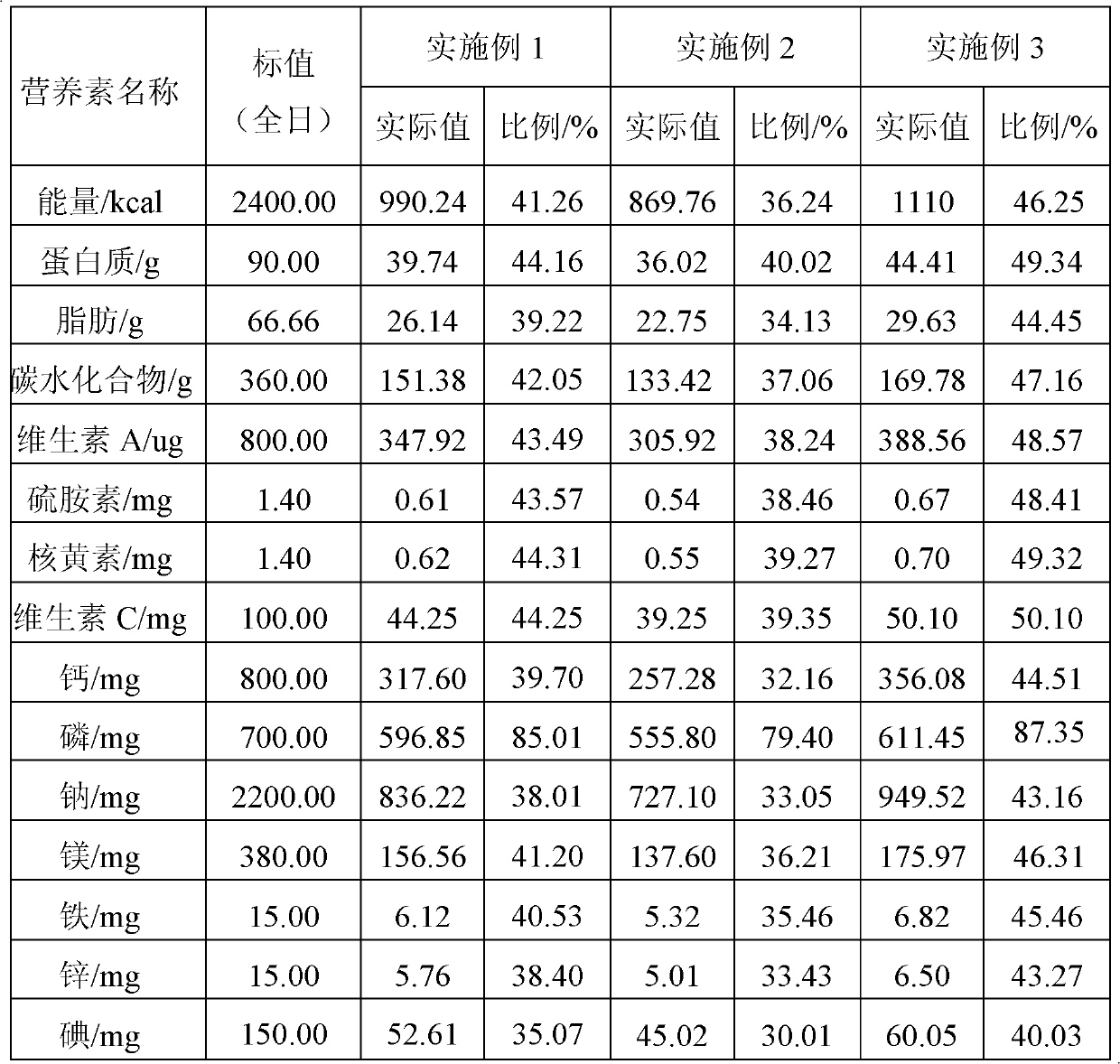

Adult meal composition

The invention provides an adult meal composition. The adult meal composition comprises a component I, a component II, a component III, a component IV and a component V. The composition provided by the invention has the advantages of reasonable composition, comprehensive and balanced nutrition, wide raw material source, simple and convenient making method and salubrity; the needs of human body arepreferably satisfied; sufficient heat energy is provided to adults and abundant learning and working energy are assured.

Owner:姜同滨

Furnace lining maintenance process for furnace front pig iron slag repairing and patching combined furnace protection

InactiveCN111349748AReduce consumptionFast recoveryManufacturing convertersEngineeringProcess engineering

The invention discloses a furnace lining maintenance process for furnace front pig iron slag repairing and patching combined furnace protection. The furnace lining maintenance process comprises the following steps that (1), for a furnace front large surface, large surface material pour repairing is replaced with pig iron slag repairing; (2), each class performs pig iron slag repairing for 2-3 times by utilizing equal-rhythm time, a furnace repairing plan is arranged according to measurement data for each class, pig iron slag repairing operation is performed for 2-3 times in front of the furnace before furnace patching, 2 tons of pig iron blocks are directly poured in front of the furnace after tapping by utilizing equal-stop time, then the furnace body is shaken to 90 DEG C, standing is performed for 5 minutes and slag splashing is performed, furnace slag is not prone to being splashed dry, certain fluidity is guaranteed, the furnace body is shaken to 90 degrees after slag splashing, patching operation is started, patching can be conducted for 1-2 t according to needs, and patch materials are burnt out through enough heat in the furnace; (3), oxygen is supplied by adopting a tubular oxygen lance according to the content of asphalt and tar in the patch materials; and (4), after the patch materials are burnt out, spray repairing operation can be performed.

Owner:XINJIANG BAYI IRON & STEEL

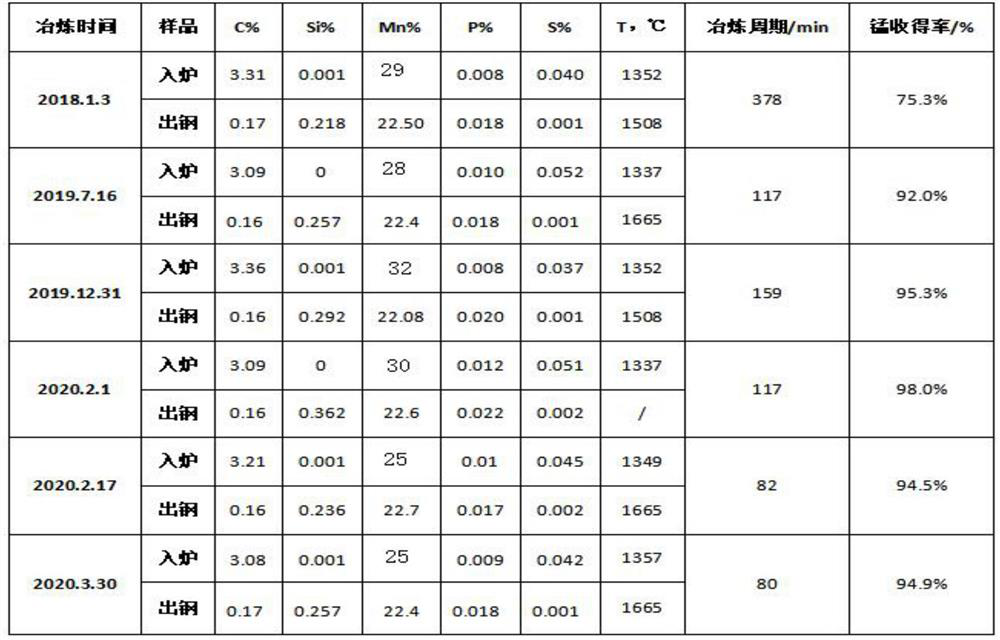

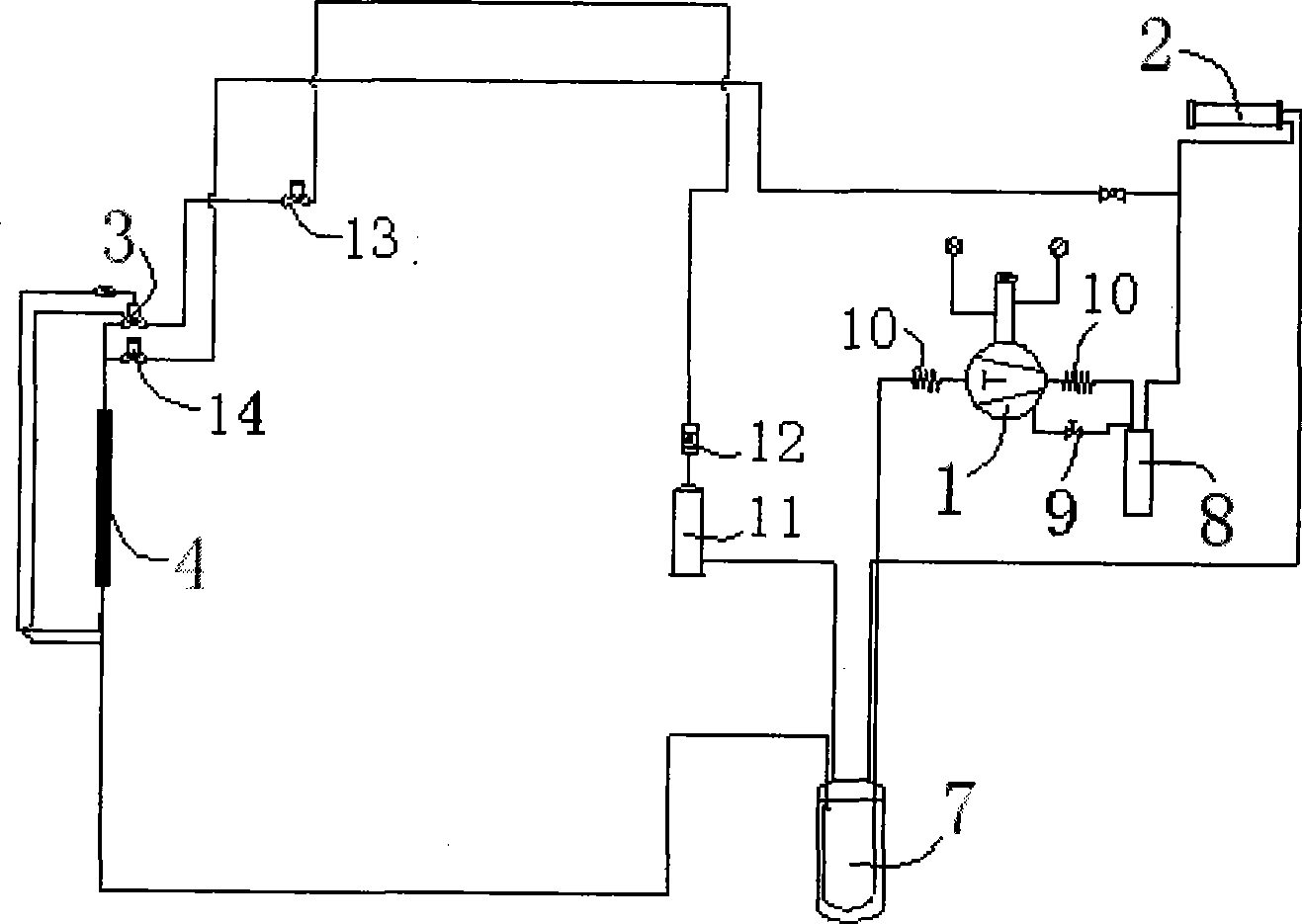

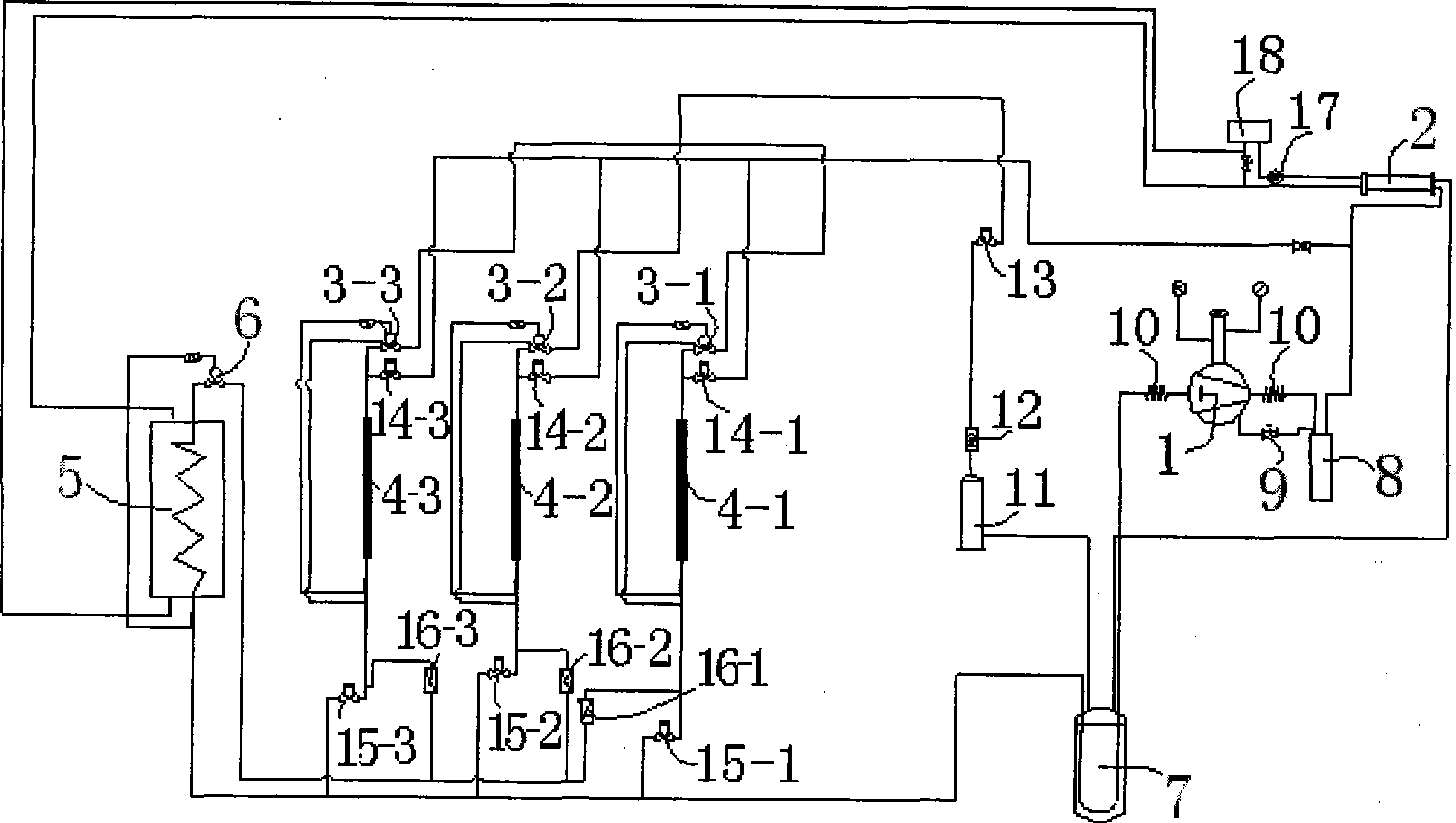

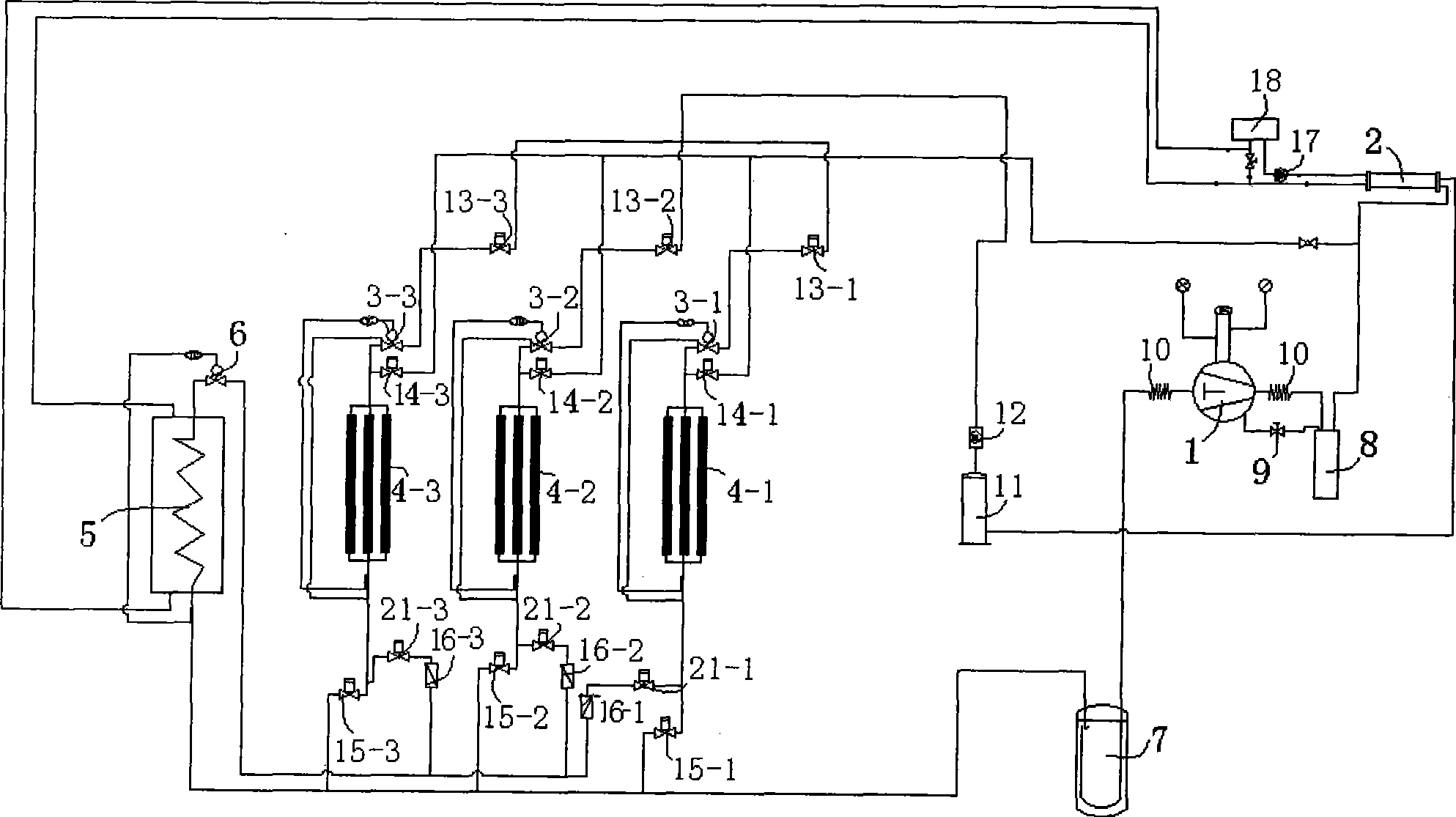

Non-electric furnace aluminum heating mode manganese alloying method for ultra-high manganese steel

InactiveCN112301180AReduce subsequent converter loadImprove converter productivityManufacturing convertersManganeseFerrosilicon

The invention belongs to the technical field of metallurgy, and particularly relates to a non-electric furnace aluminum heating mode manganese alloying method for ultra-high manganese steel. The invention provides the non-electric furnace aluminum heating mode manganese alloying method for the ultra-high manganese steel. The method utilizes chemical heat generated by an oxidation exothermic reaction of oxygen and a large amount of alloy elements such as silicon iron, aluminum particles and the like to replace electric heat of an electric furnace to melt manganese alloy in the process of rapiddecarburization under excellent dynamic conditions of a converter and oxygen blowing in the converter process. According to the technology, the current situation that manganese alloying of the ultra-high manganese steel can only be completed through an electric furnace or an intermediate frequency furnace for a long time is changed, and the problems that in the electric furnace manganese alloyingprocess of a traditional technology, the melting time period of a large number of manganese alloys is long, molten steel uniformity is poor, the manganese yield is poor, and cost is high are solved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Ice making system

ActiveCN101135520BImprove efficiencySmall temperature fluctuationsIce productionCompression machines with several evaporatorsEngineeringRefrigerant

An ice-making system includes compressor, condenser, throttling mechanism, ice-making device set, bypath heat exchanger, liquid supply valve, heat supply valve, air return valve and one-way valve. The compressor output pipeline divides into two branch pipelines, one branch is connected with the liquid supply valve via the condenser, and then is connected with the ice-maker set via the throttling mechanism; the other branch is connected with the ice making device via the heat supply valve; there are at least two group ice making device set. The pipeline from the ice making device set divides into two branches, one branch is connected with the air return valve, and then converged to a main pipeline and is connected with the compressor; the other branch is connected with the one-way valve, and then converged to a main bypath pipeline, and is connected with the bypath heat exchanger, then is connected with the compressor.

Owner:广州冰泉制冷设备有限责任公司

Preparation method of aluminum-titanium-boracium mater alloy

The invention discloses a preparation method of aluminum-titanium-boracium mater alloy. The aluminum-titanium-boracium mater alloy is prepared from the following raw materials in mass ratio: 50-70 percent of Al, 25-40 percent of CaSO425, 1-9 percent of TiO2, 0.2-4 percent of B and 3-5 percent of CaF2. The method comprises the following steps that the raw materials are uniformly stirred; the uniformly mixed materials are placed into a reaction cavity of graphite, an igniter is spread into the reaction cavity, and the materials are compacted and ignited; and liquid metal flows into a forming model from a small hole below the reaction cavity at a high temperature to prepare the aluminum-titanium-boracium mater alloy. According to the preparation method disclosed by the invention, thermit reaction of aluminum and calcium sulfate and thermit reaction of the aluminum and titanium oxide are applied, and Ti which is a product of the thermit reactions and redundant Al powder and B powder in the raw materials form the aluminum-titanium-boracium mater alloy; and as large equipment (such as electrolyzers and smelting furnaces), the external energy and the like are not needed, the production cost is greatly lowered, the technological time is shortened, and an aluminum-titanium-boracium mater alloy refiner with high quality is obtained.

Owner:SHENZHEN YUANSIDACHENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com