Ice making system

A technology of ice maker and branch pipeline, which is applied in the direction of ice making, ice making, refrigerator, etc. It can solve the problems of affecting deicing, insufficient heating, and increased power consumption, so as to improve the utilization rate of electric energy and increase the production capacity. Ice time, the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

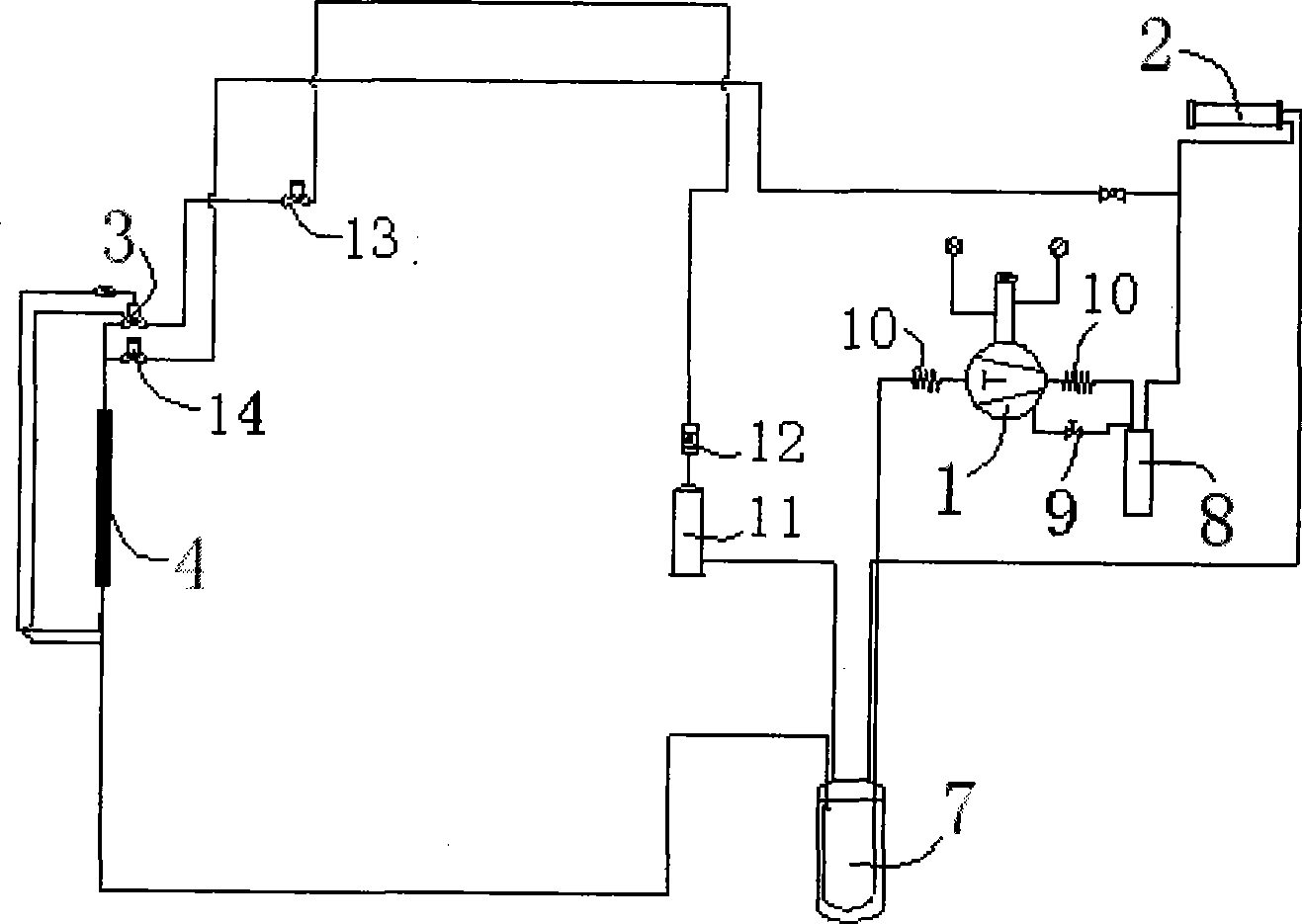

Embodiment 1

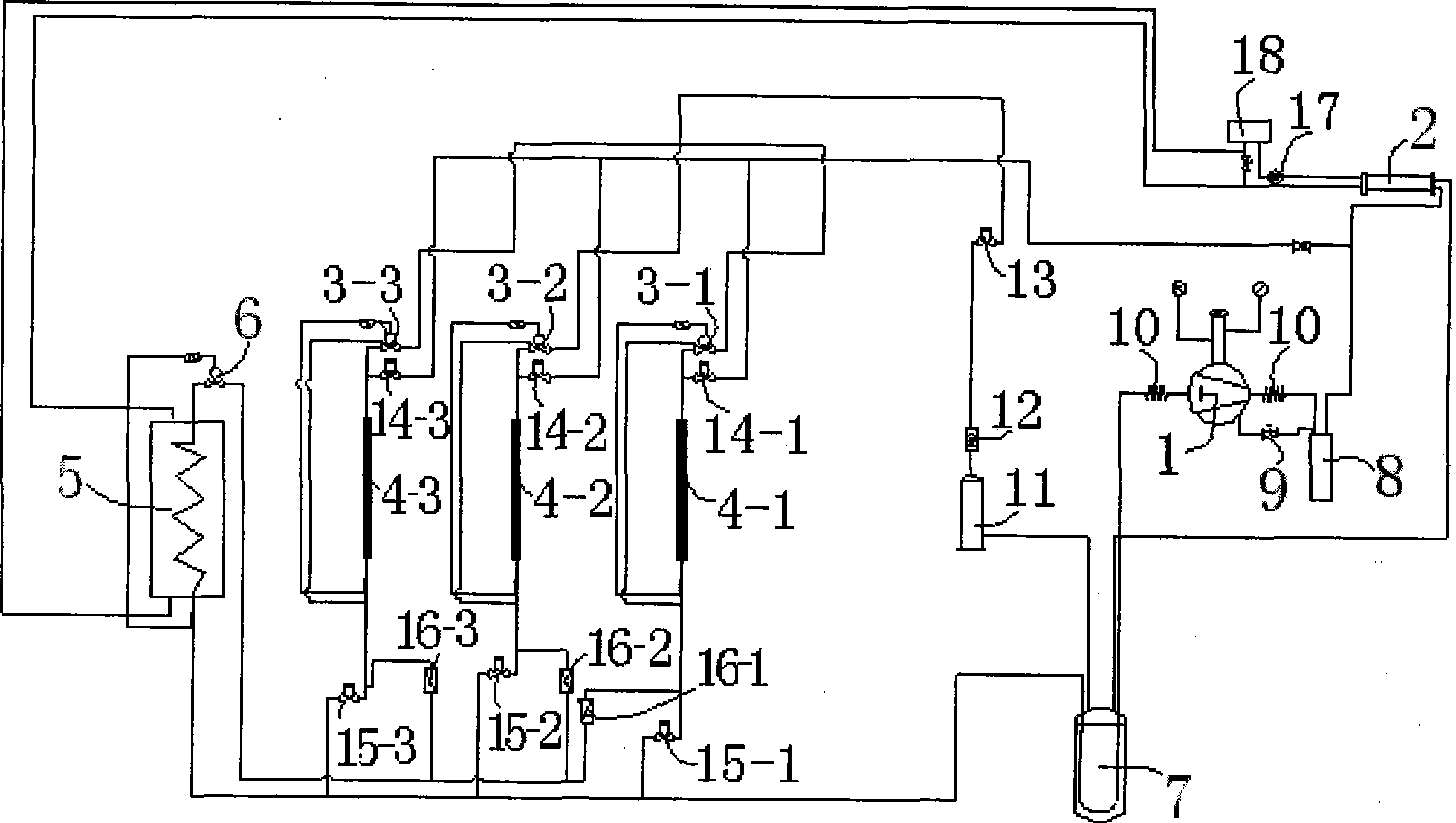

[0035] Such as figure 2 As shown, the ice maker group 4 can be provided with three groups. The pipeline from the condenser 2 passes through the gas-liquid separator 7 and is connected to the filter 11 and the sight glass 12 , and then connected to the liquid supply valve 13 . The pipeline behind the liquid supply valve 13 is provided with three branch pipelines, which respectively pass through the throttling mechanism 3-1, the throttling mechanism 3-2 and the throttling mechanism 3-3 and the corresponding ice maker group 4-1 to make ice The ice maker group 4-2 is connected with the ice maker group 4-3, and the pipeline from the ice maker group of each group is provided with two branch pipelines, and one branch pipeline passes through the air return valve 15-1 and the air return valve respectively. 15-2 and the air return valve 15-2 converge in one main pipeline, and then connect to the compressor 1 after passing through the gas-liquid separator 7, and the other branch pipelin...

Embodiment 2

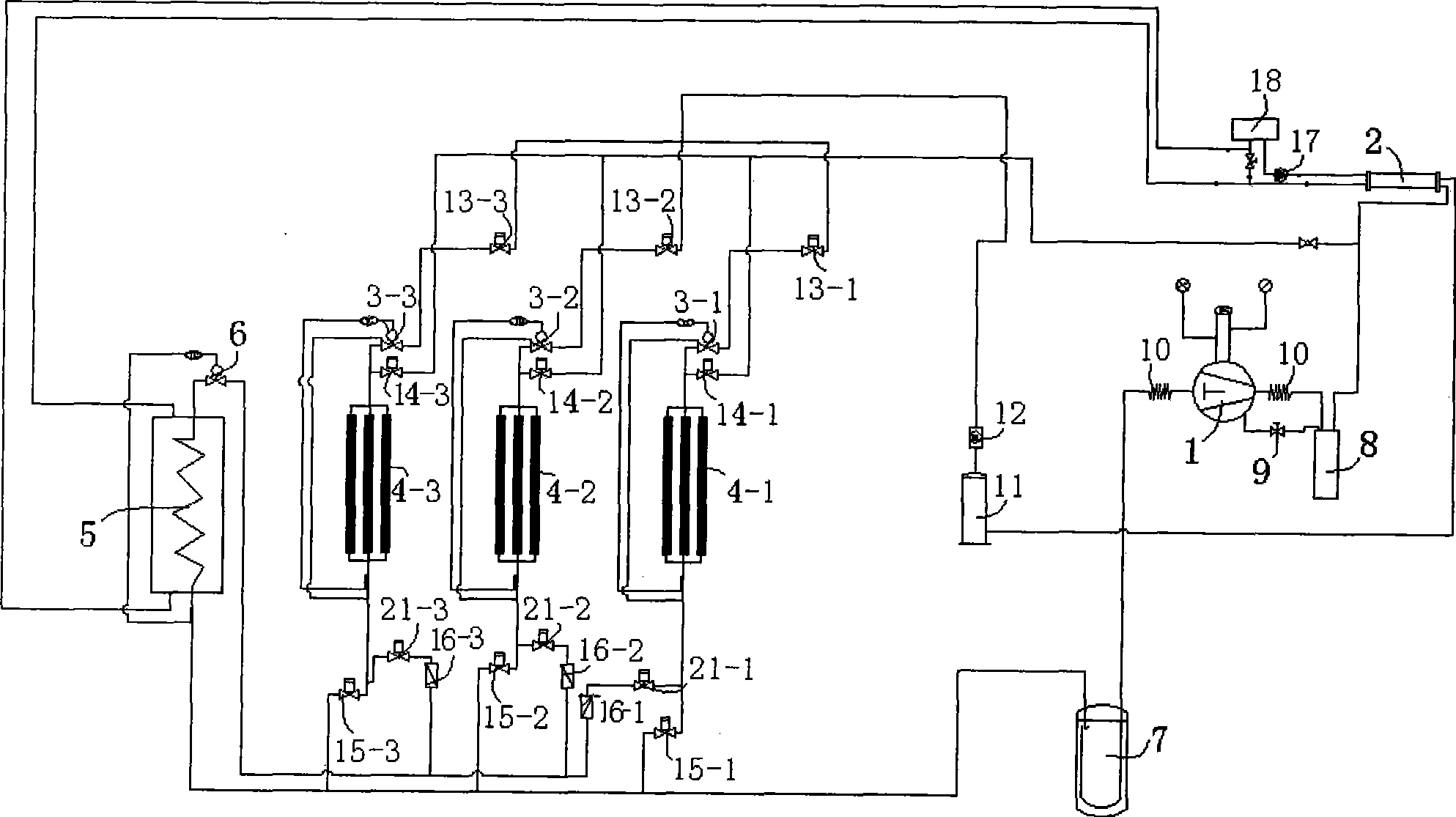

[0038] Such as image 3 As shown, there are three groups of ice maker groups, which are ice maker group 4-1, ice maker group 4-2 and ice maker group 4-3, and each ice maker group can be equipped with three ice makers , the pipeline from the condenser 2 can be provided with three branch pipelines after the gas-liquid separator 7, the filter 11 and the sight glass 12, respectively connected to the liquid supply valve 13-1, the liquid supply valve 13-2 and the liquid supply valve. The valve 13-3 is connected to the corresponding ice maker group 4-1, ice maker group 4-2 and ice making unit respectively through the throttling mechanism 3-1, throttling mechanism 3-2 and throttling mechanism 3-3. The pipelines from each ice maker group are connected with two branch pipelines, and one branch pipeline passes through the air return valve 15-1, the air return valve 15-2 and the air return valve 15- 3 are gathered in one main pipeline, and then connected to the compressor 1 after passing...

Embodiment 3

[0041] Such as Figure 2~3 As shown, the heat exchange medium pipeline of the bypass heat exchanger 5 is connected with the cooling tower 18, the cooling tower 18 is connected with the pipeline of the condenser 2, and the pipeline of the condenser 2 is connected with the bypass heat exchanger 5; the bypass heat exchanger 5. The condenser 2 and the cooling tower 18 form a cooling water recycling system. A cooling water pump 17 is arranged on the pipeline between the cooling tower 18 and the condenser 2 . Under the action of the cooling water pump 17, the cooling water enters the condenser 2 to exchange heat with the high-temperature and high-pressure gaseous refrigerant, changing the refrigerant from a gaseous state to a liquid state. Outflow is divided into two paths, one path flows through the bypass heat exchanger, and heat exchange is performed with the refrigerant in the bypass heat exchanger, heat is released, and the temperature is lowered, and flows back to the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com