Patents

Literature

263results about How to "Realize large-scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

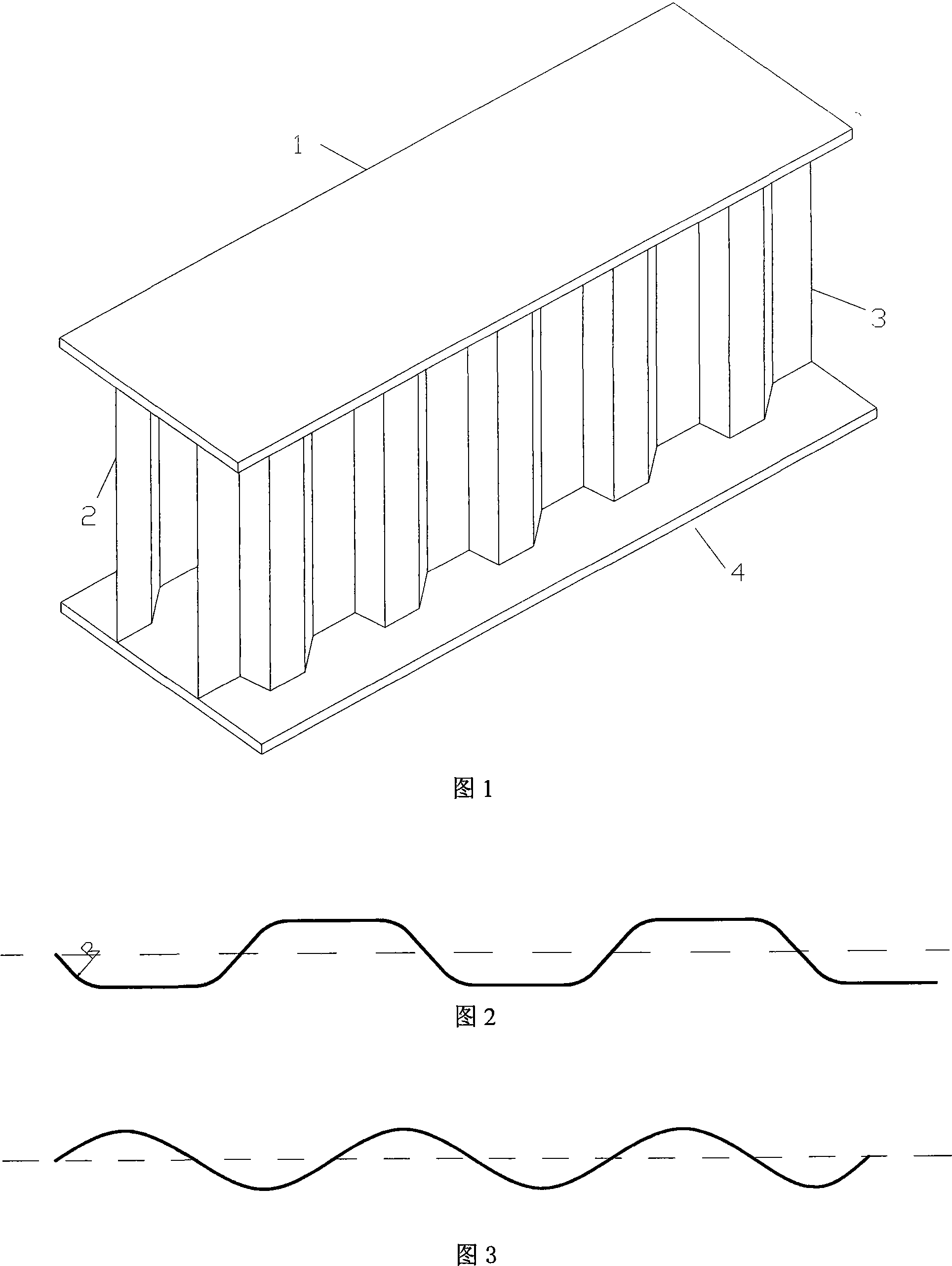

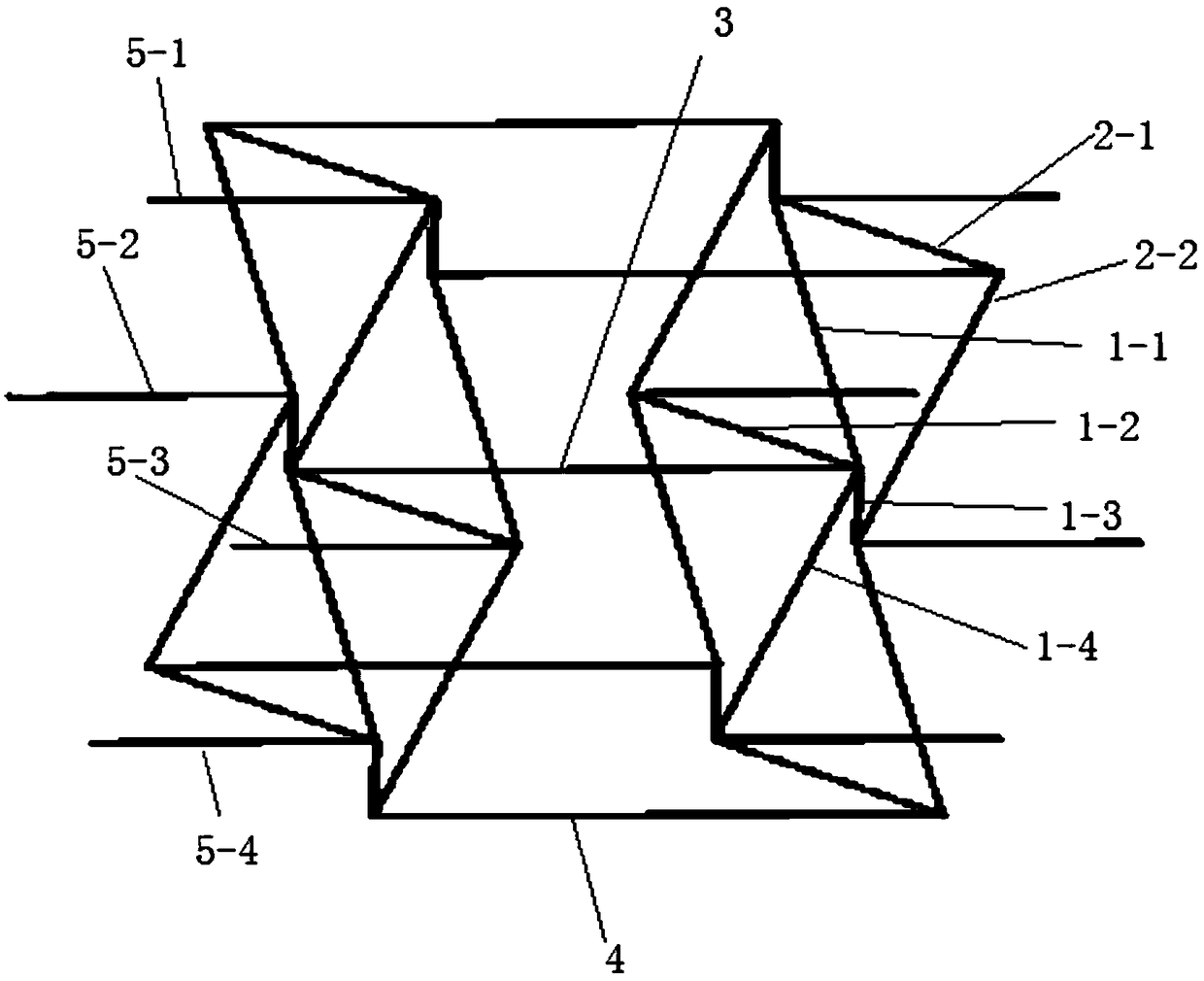

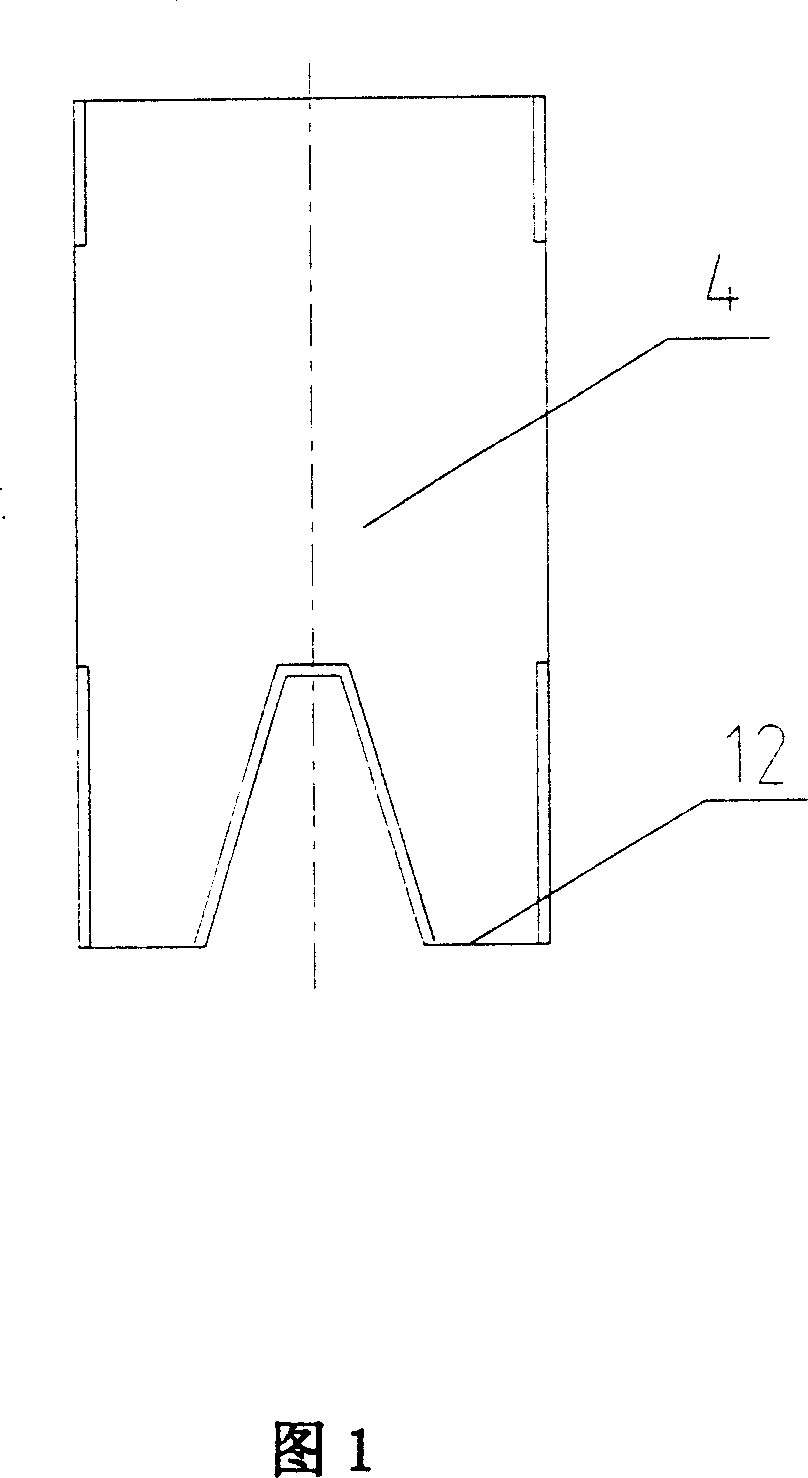

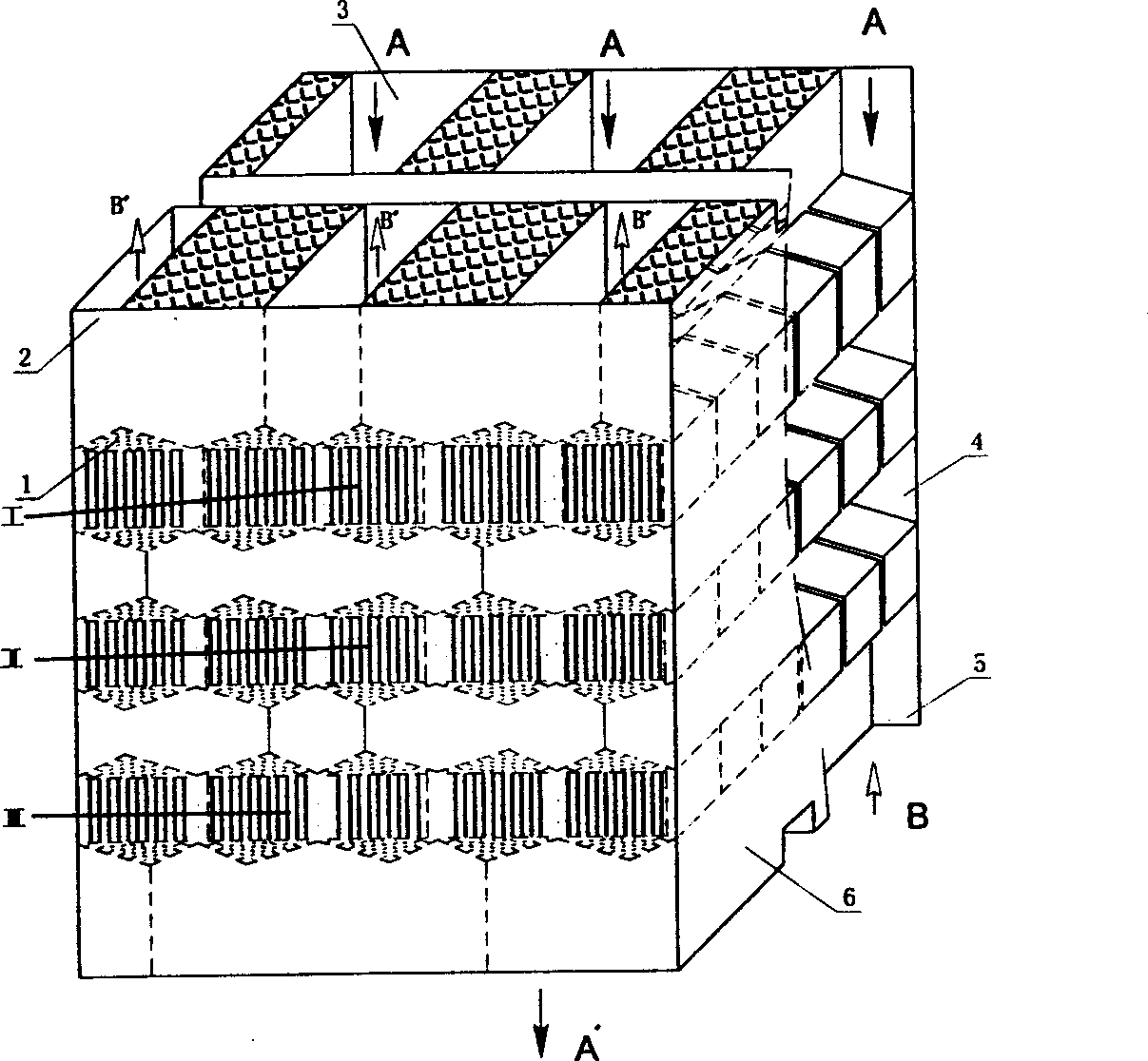

Double corrugated web plate steel box girder

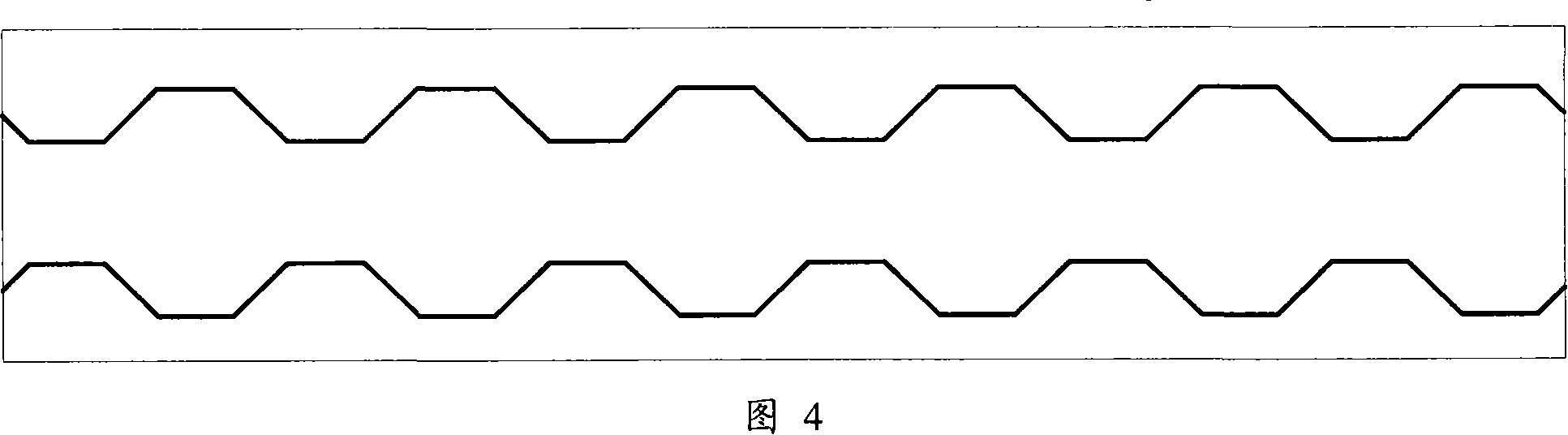

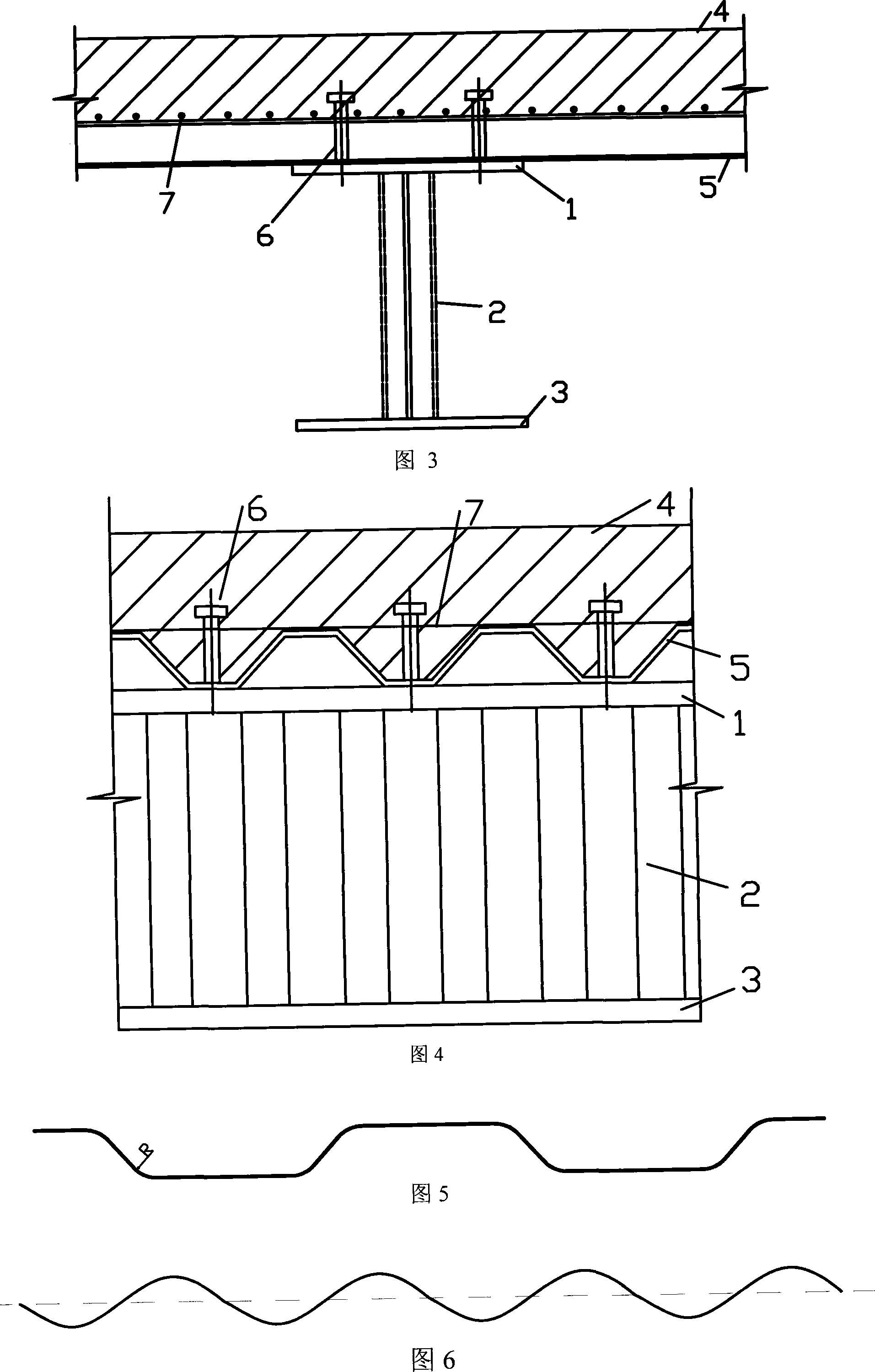

The invention belongs to the technical field of building materials and in particular relates to a double undulated web slab steel box girder. The cross-section fracture shape is composed of a middle web slab, an upper flange and a lower flange which are integrated, wherein the upper flange is parallel to the lower flange, a double web slab is vertically located between the upper flange and the lower flange, the double web slab is arranged symmetrically and takes a honeycomb structure, the web slab and the flange slabs adopt one side fillet weld to connect, the web slab is an undulated web slab whose length direction are periodically repeated evenly or unevenly, and the undulated cross section takes circular arc angle trapezoid and sinusoidal curve. The product can replace products such as normal welded box steel girders, hot rolled H-shaped steel, I-shaped steel and the like, has wider usage compared with the products, and can realize maximization and can be used in the special fields and special places including the building of bridges with large spans, the manufacture of ships and the like.

Owner:TONGJI UNIV +1

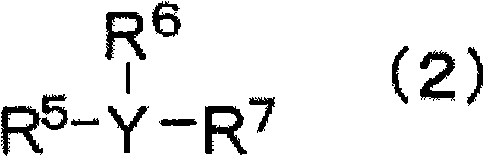

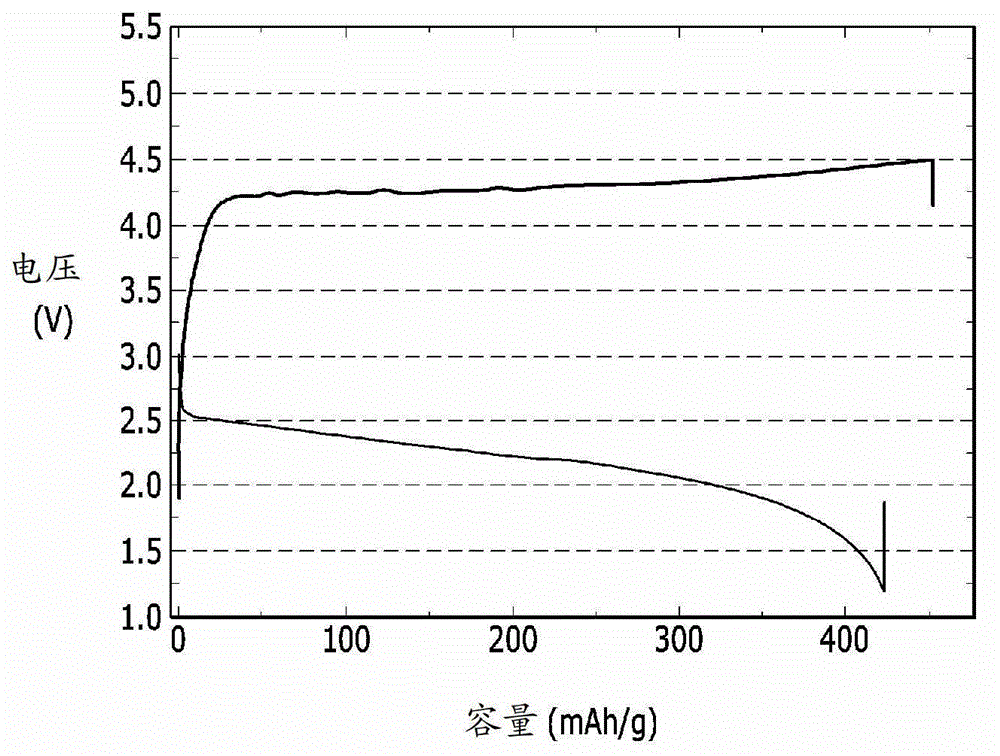

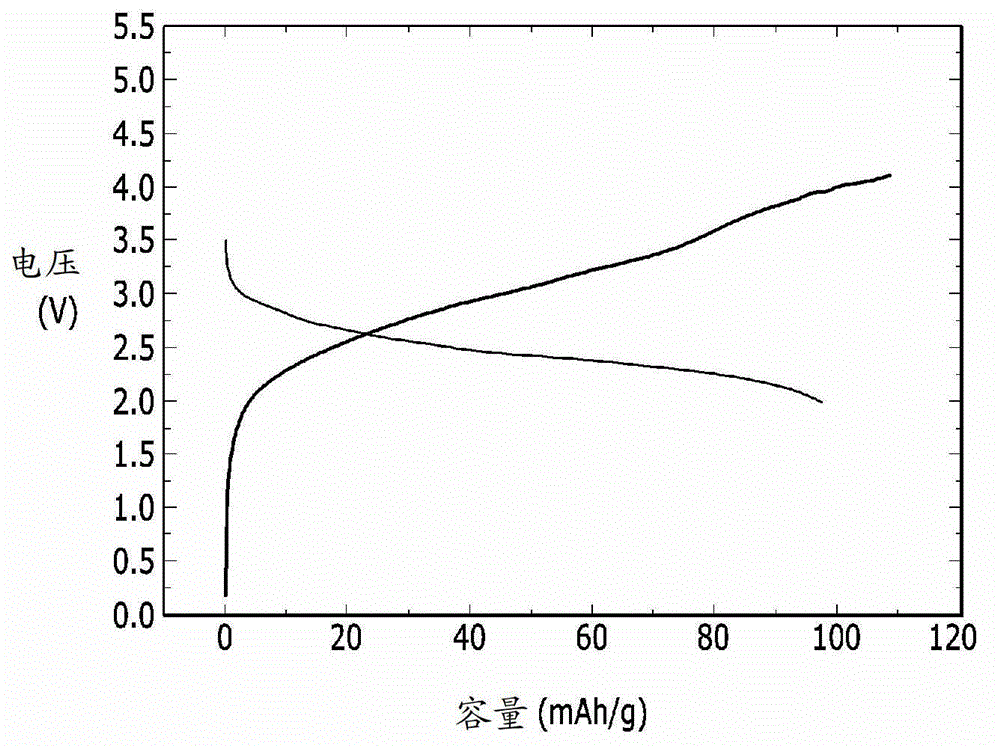

Nonaqueous electrolyte, and rechargeable battery with the nonaqueous electrolyte

InactiveCN101663790AIncrease capacityExcellent cycle characteristicsSecondary cellsHigh current densityChemical structure

A subject is to provide a nonaqueous electrolyte excellent in cycle performances such as capacity retention after cycling, output after cycling, discharge capacity after cycling, and cycle discharge capacity ratio, output characteristics, high-temperature storability, low-temperature discharge characteristics, heavy-current discharge characteristics, high-temperature storability, safety, high capacity, high output, high-current-density cycle performances, compatibility of these performances, etc. Another subject is to provide a nonaqueous-electrolyte secondary battery employing the nonaqueouselectrolyte. The subjects have been accomplished with a nonaqueous electrolyte which contains a monofluorophosphate and / or a difluorophosphate and further contains a compound having a specific chemical structure or specific properties.

Owner:MITSUBISHI CHEM CORP

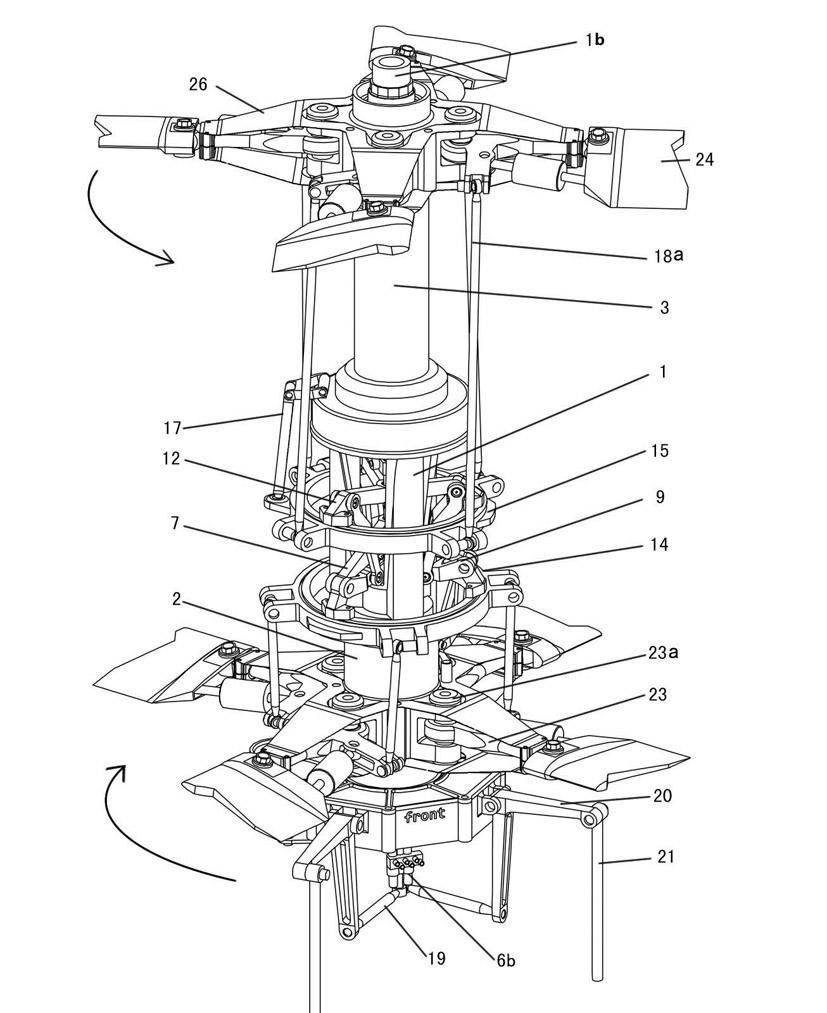

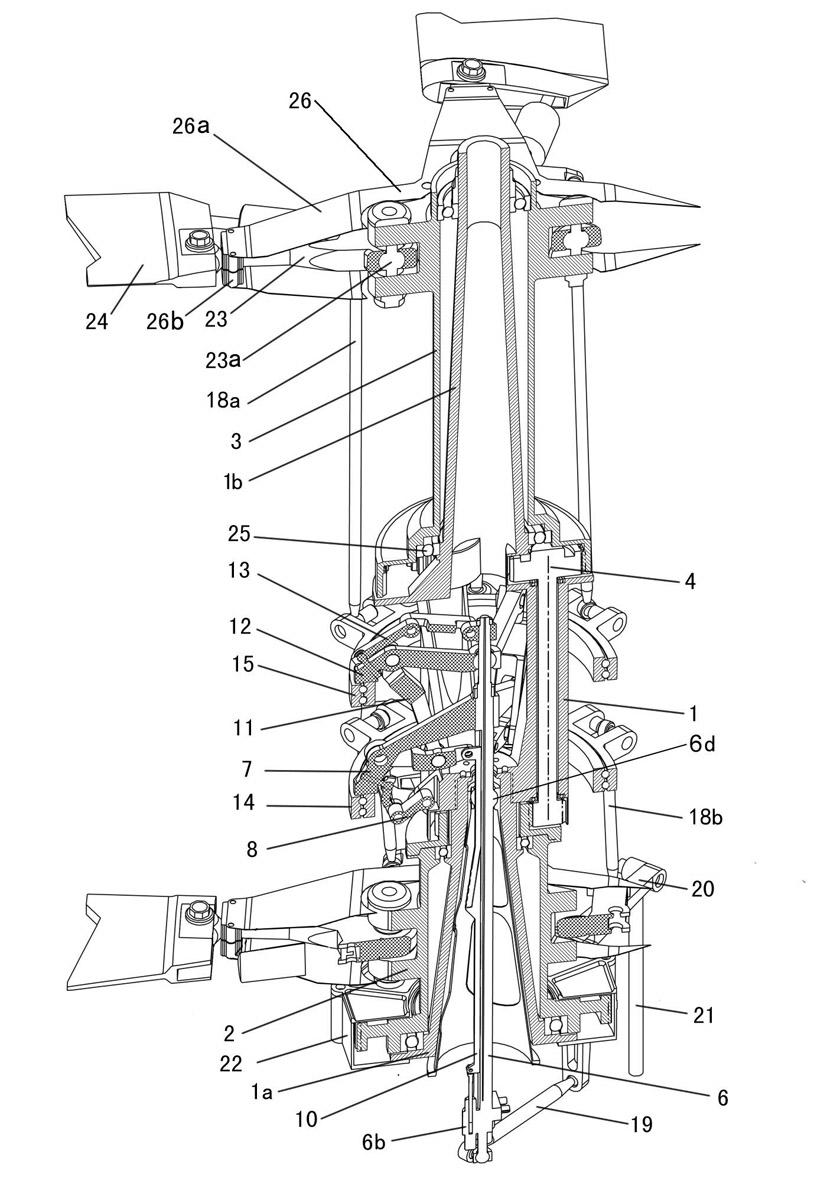

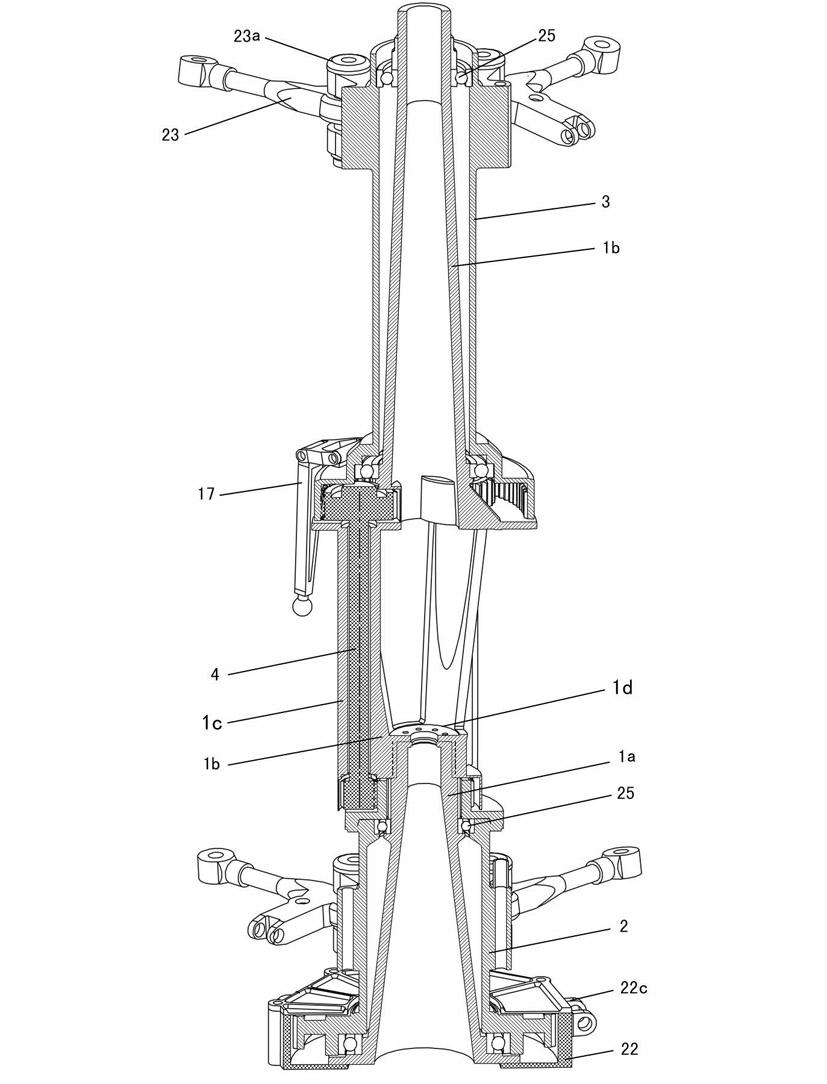

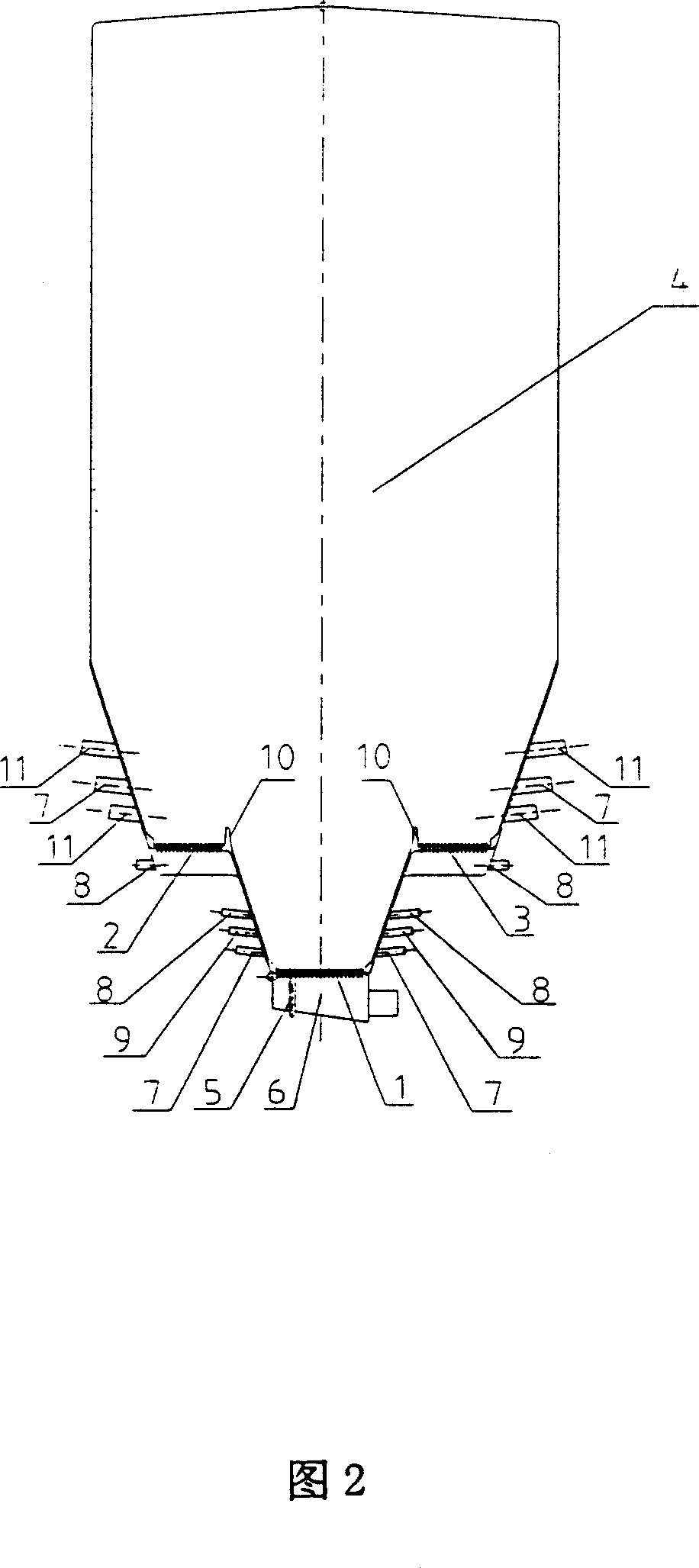

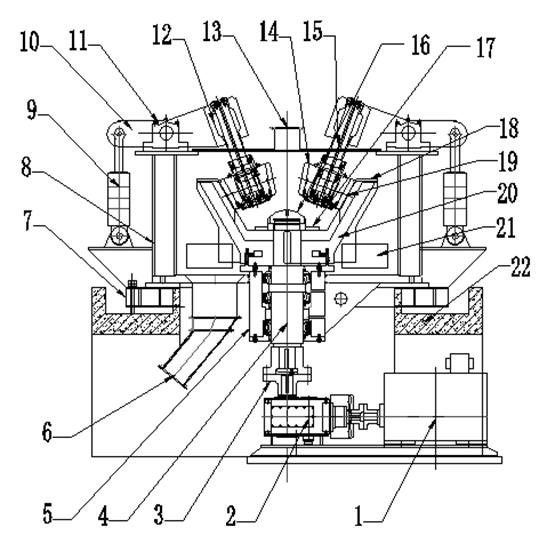

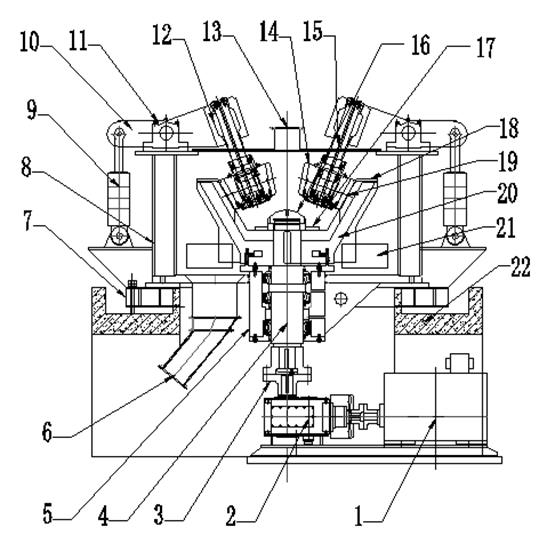

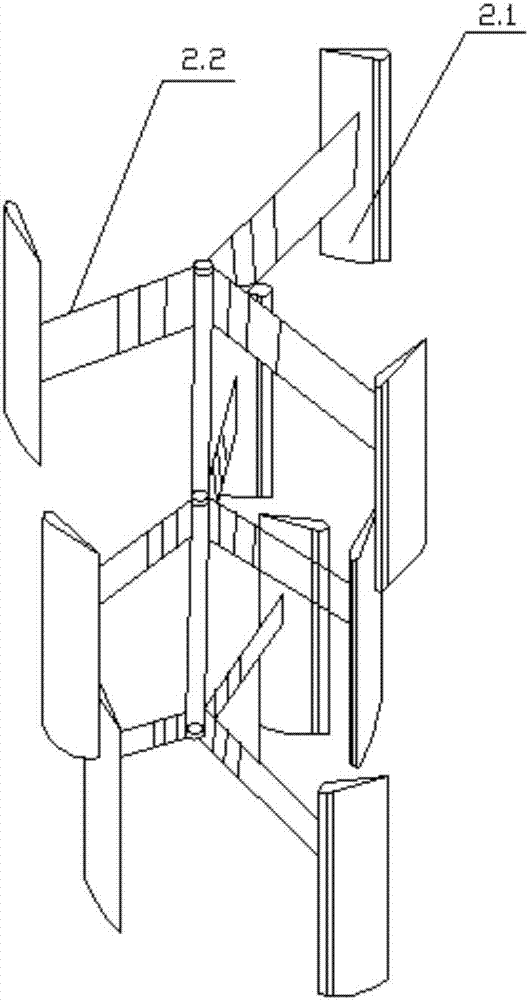

Coaxial drive and control structure for coaxial contrarotation rotor helicopter

The invention relates to a coaxial drive and control structure for a coaxial contrarotation rotor helicopter. A spindle is a hollow fixed shaft, the fixed shaft is provided with an upper rotor hub and a lower rotor hub, the upper rotor hub and the lower rotor hub are connected by virtue of a gearing shaft, the middle section of the fixed shaft comprises multiple support pillars which are uniformly distributed, an upper inclinator support and a lower inclinator support are arranged in spaces among the support pillars, a total propeller pitch sliding sleeve is arranged inside the lower section of the fixed shaft, a primary variable-pitch control rod is arranged in the total propeller pitch sliding sleeve and is located and hinged by virtue of a ball shaft, the upper part of the primary variable-pitch control rod is connected with the upper inclinator support and the lower inclinator support, and the lower end of the primary variable-pitch control rod is respectively hinged with a variable-pitch rocker arms by virtue of two variable-pitch connecting rods; and an upper inclinator and a lower inclinator are arranged between the upper rotor hub and the lower rotor hub and are hinged with an upper rotor control arm and a lower rotor control arm by virtue of an upper rotor control rod and a lower rotor control rod. By adopting the coaxial drive and control structure for the coaxial contrarotation rotor helicopter disclosed by the invention, the defect that a rotation control assembly penetrates a rotating surface is eliminated, thus the coaxial contrarotation rotor helicopter can be provided with more upper rotors and more lower rotors, lifting power of the helicopter is improved, full differentiating control can be realized, and manufacturing and processing costs of the spindle also can be reduced.

Owner:李游

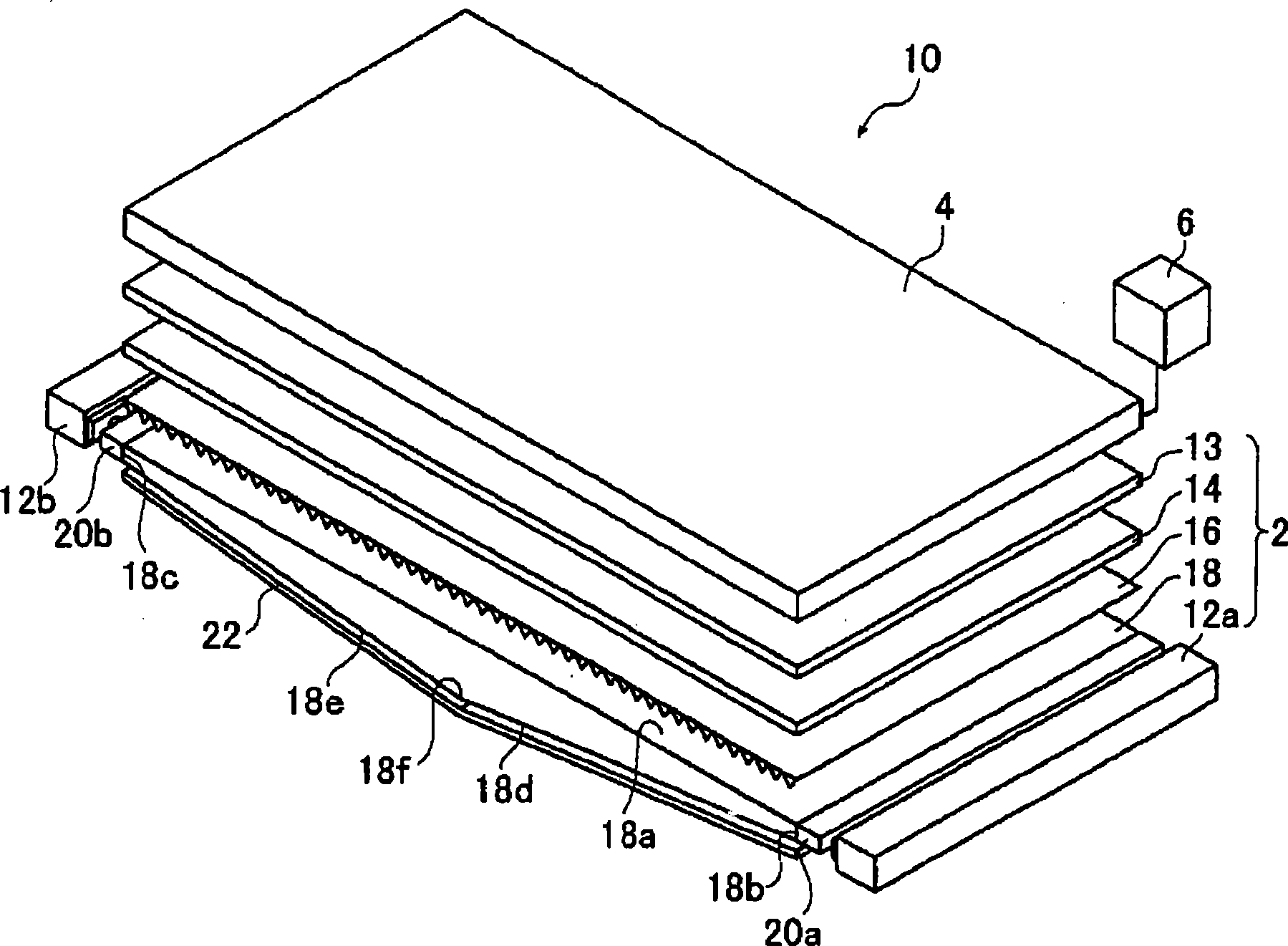

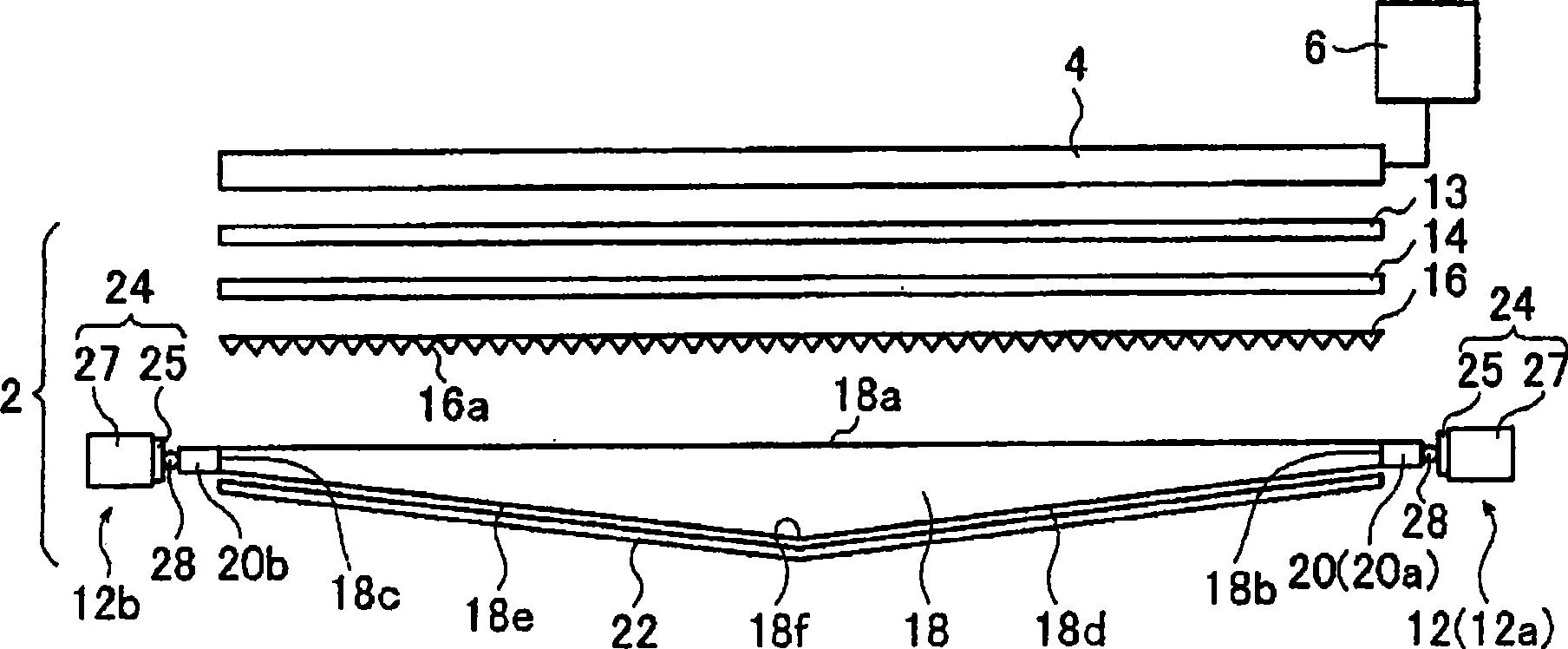

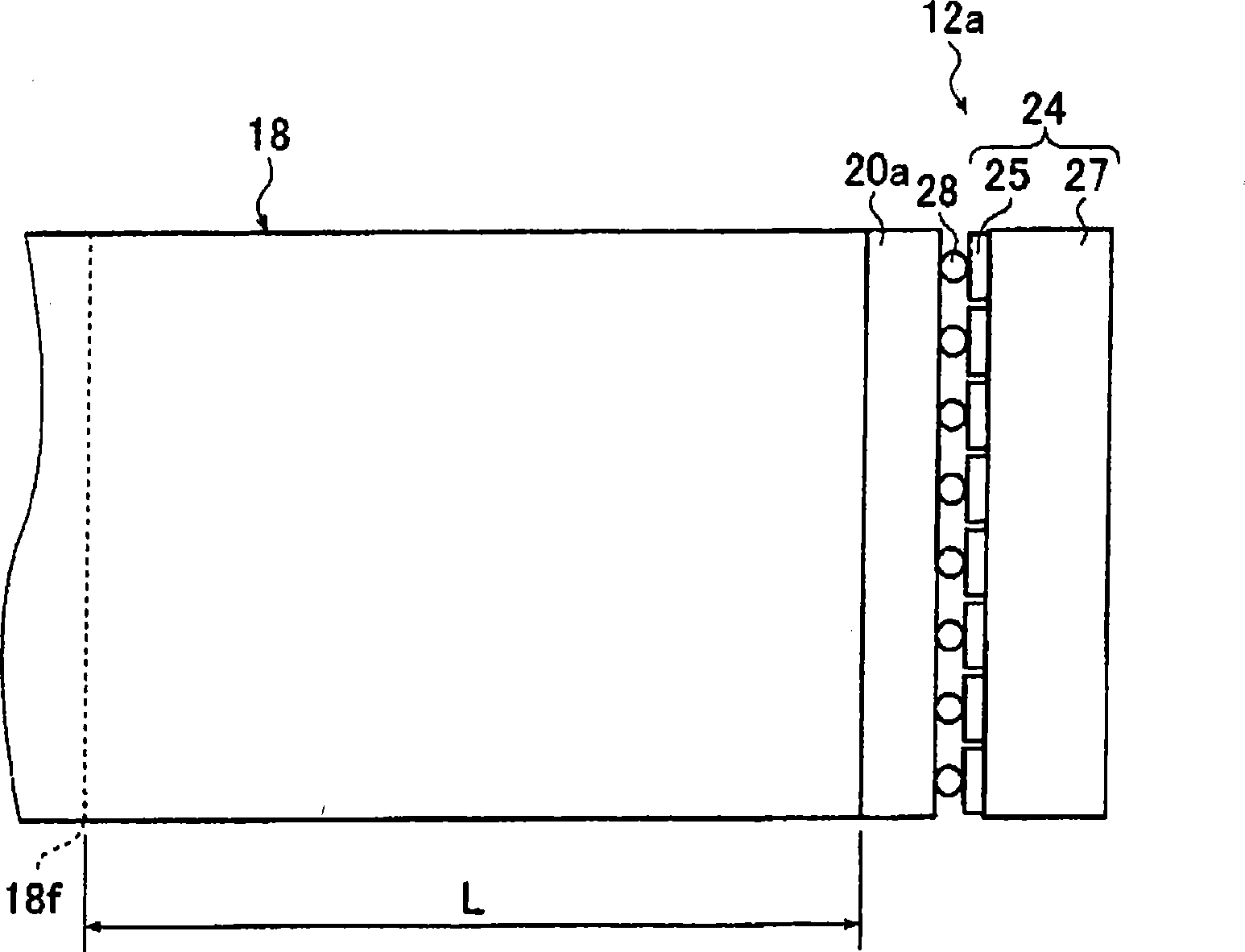

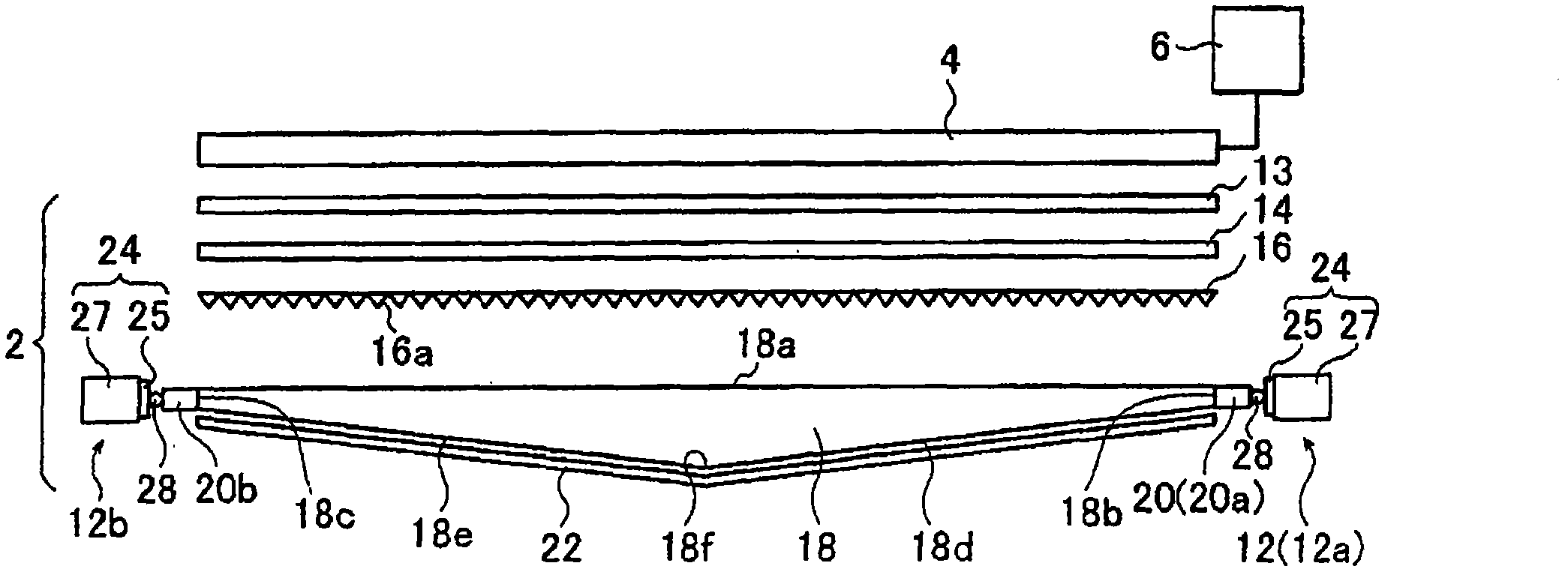

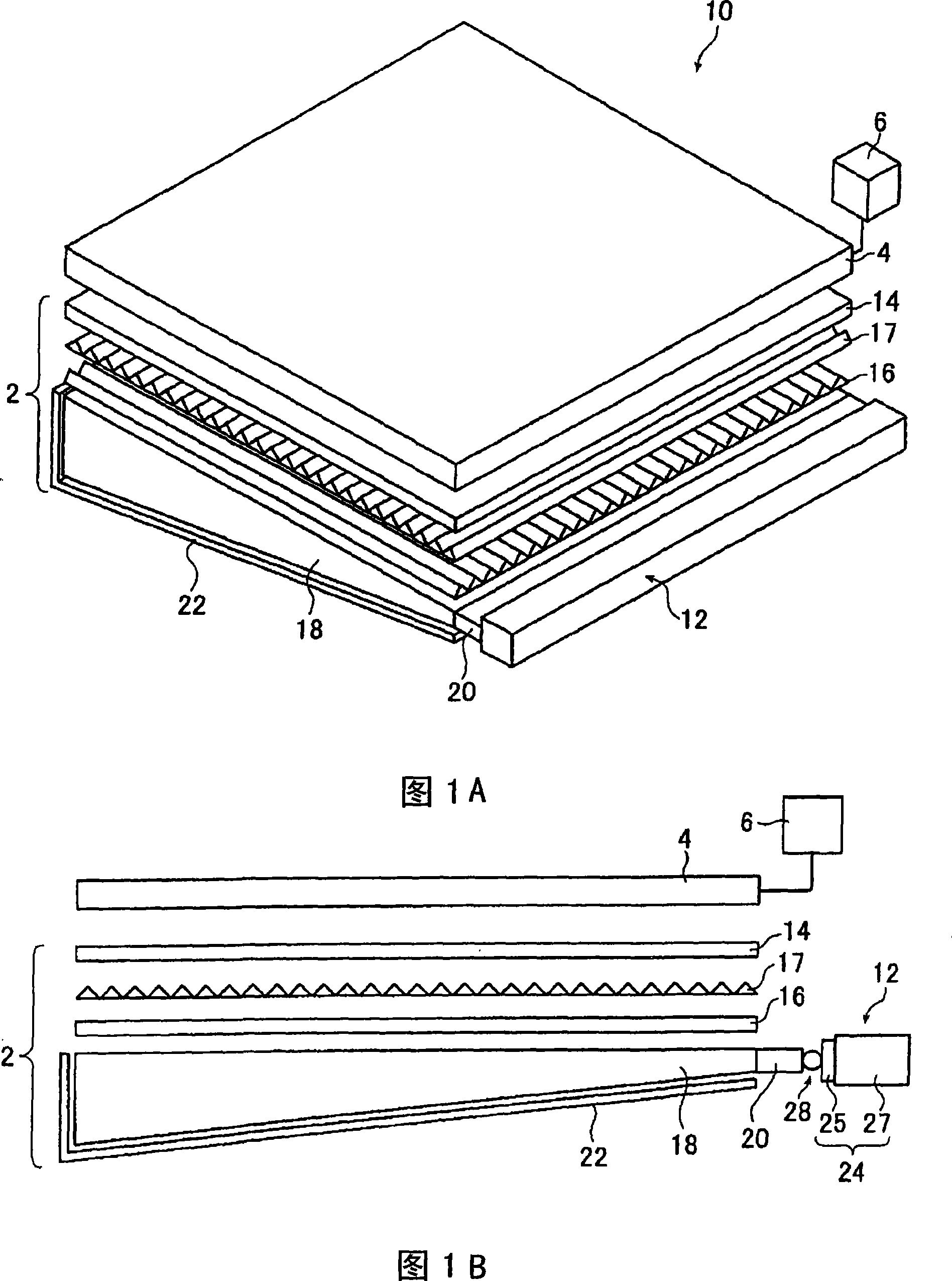

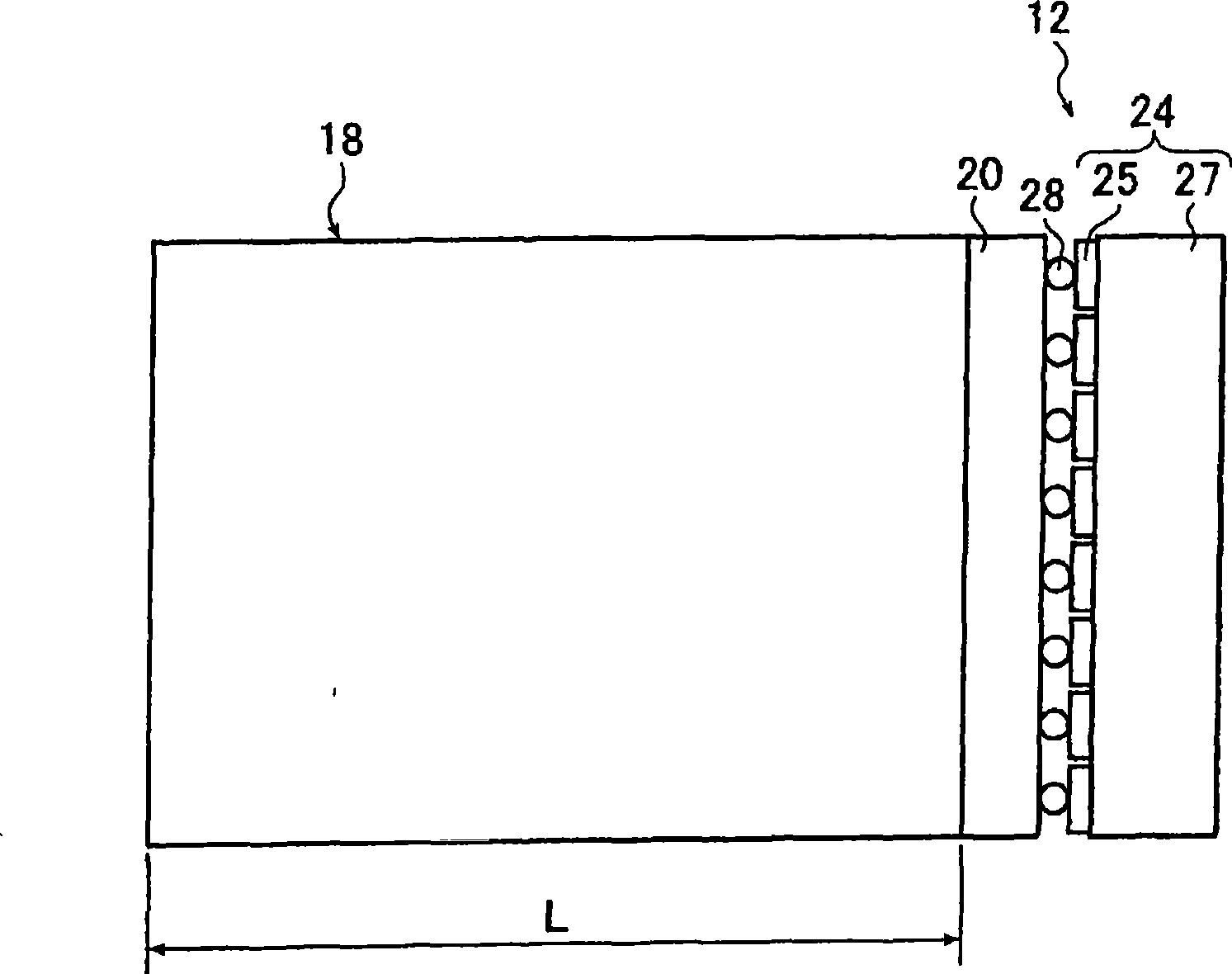

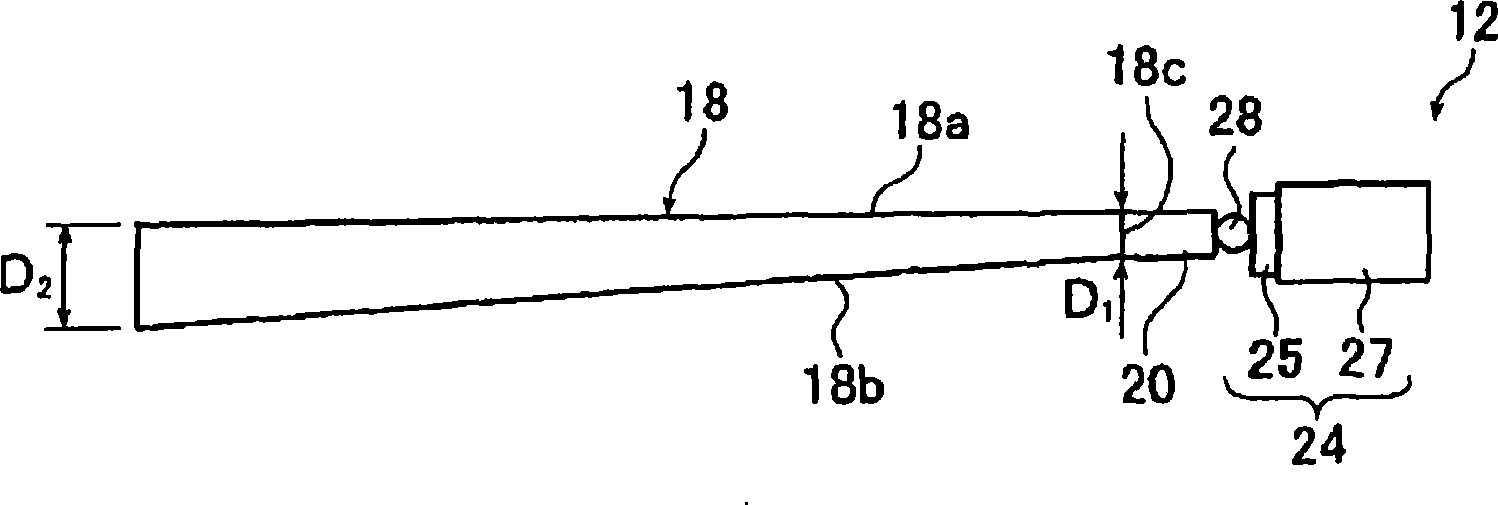

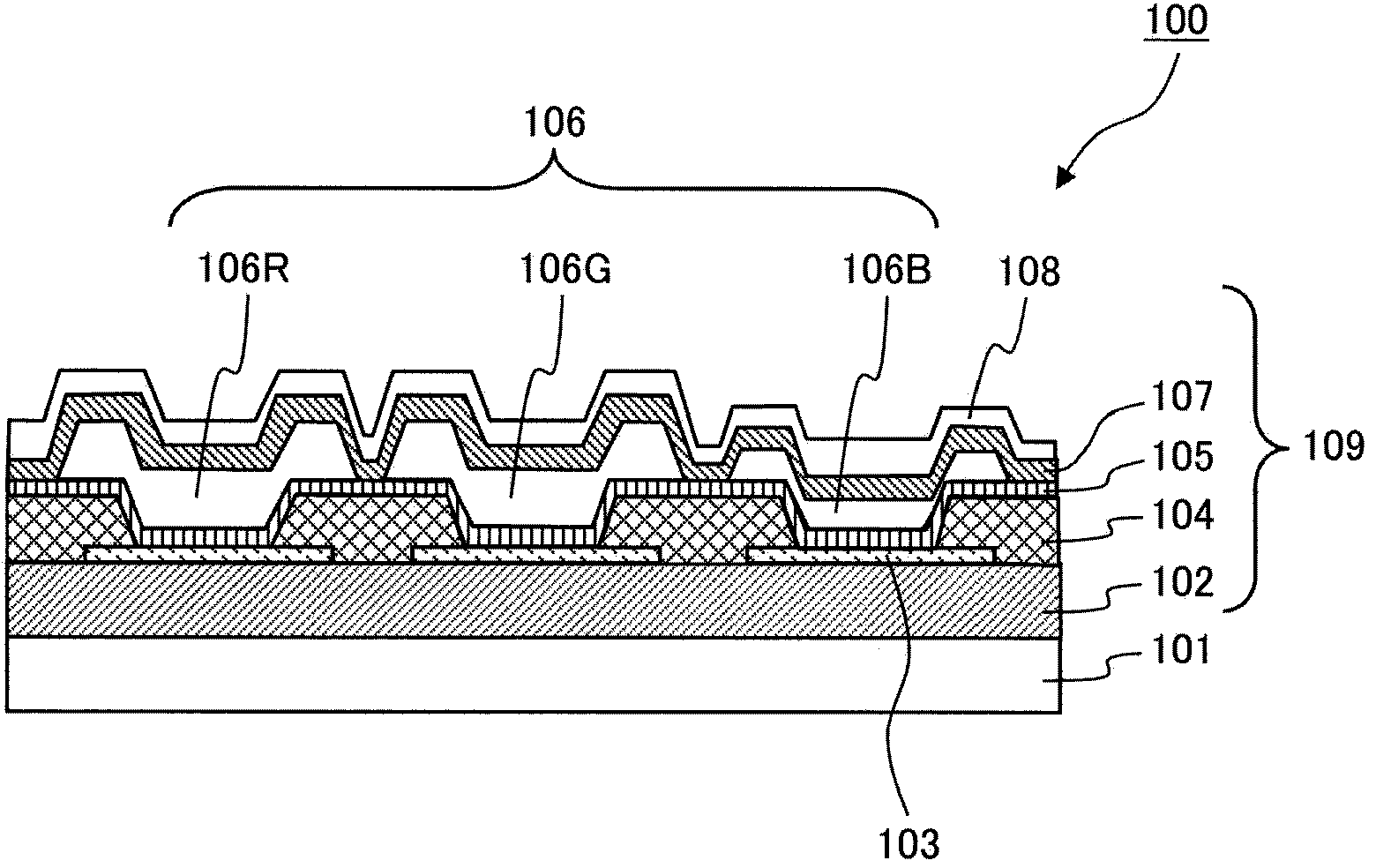

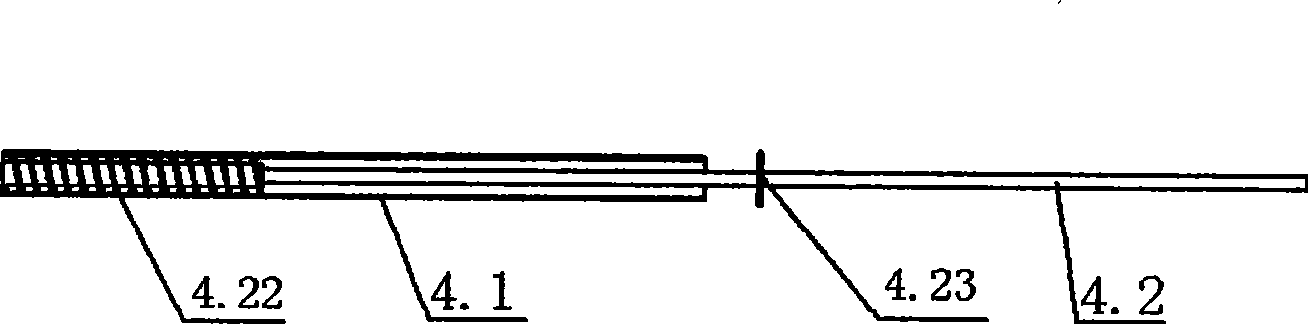

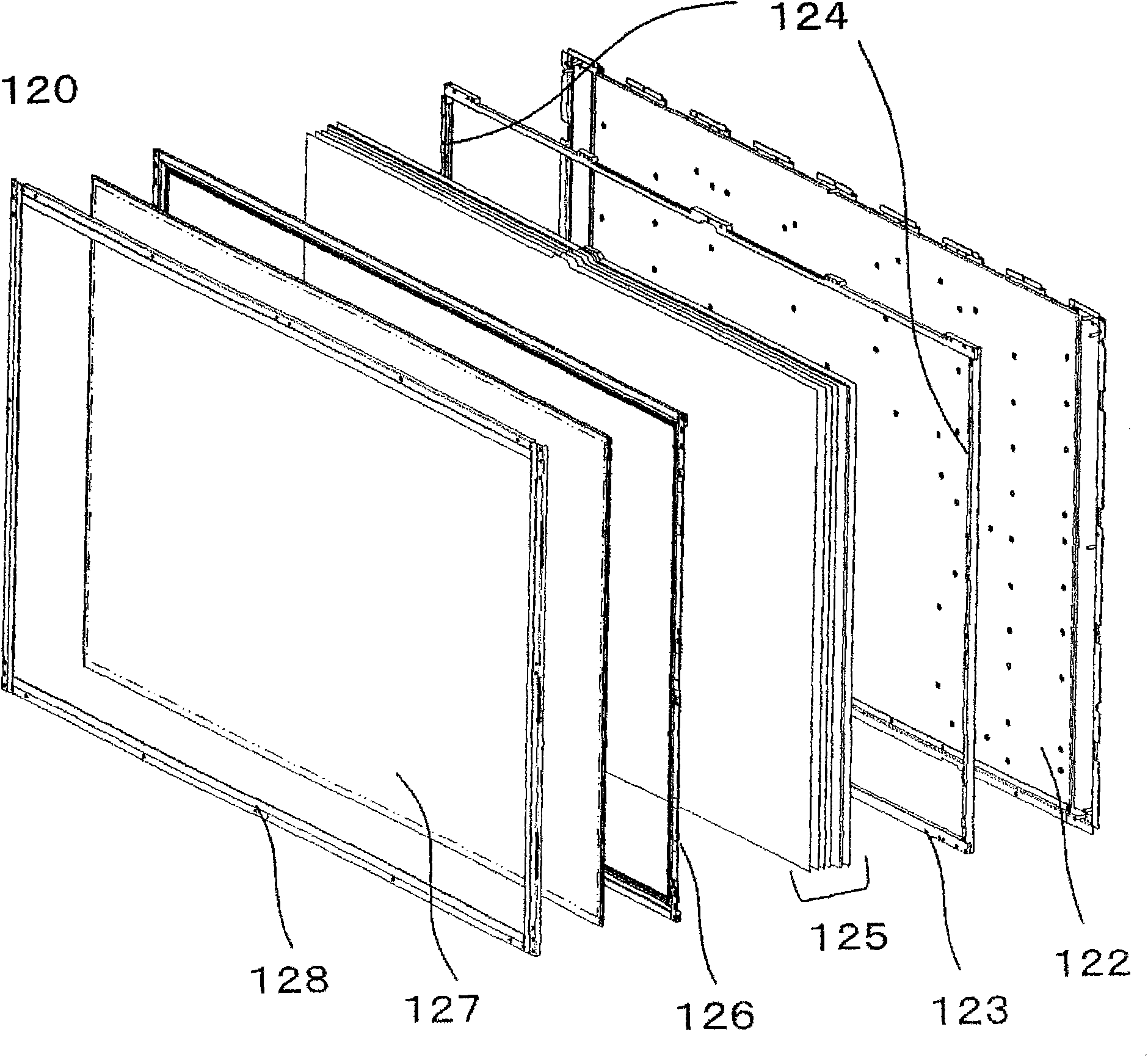

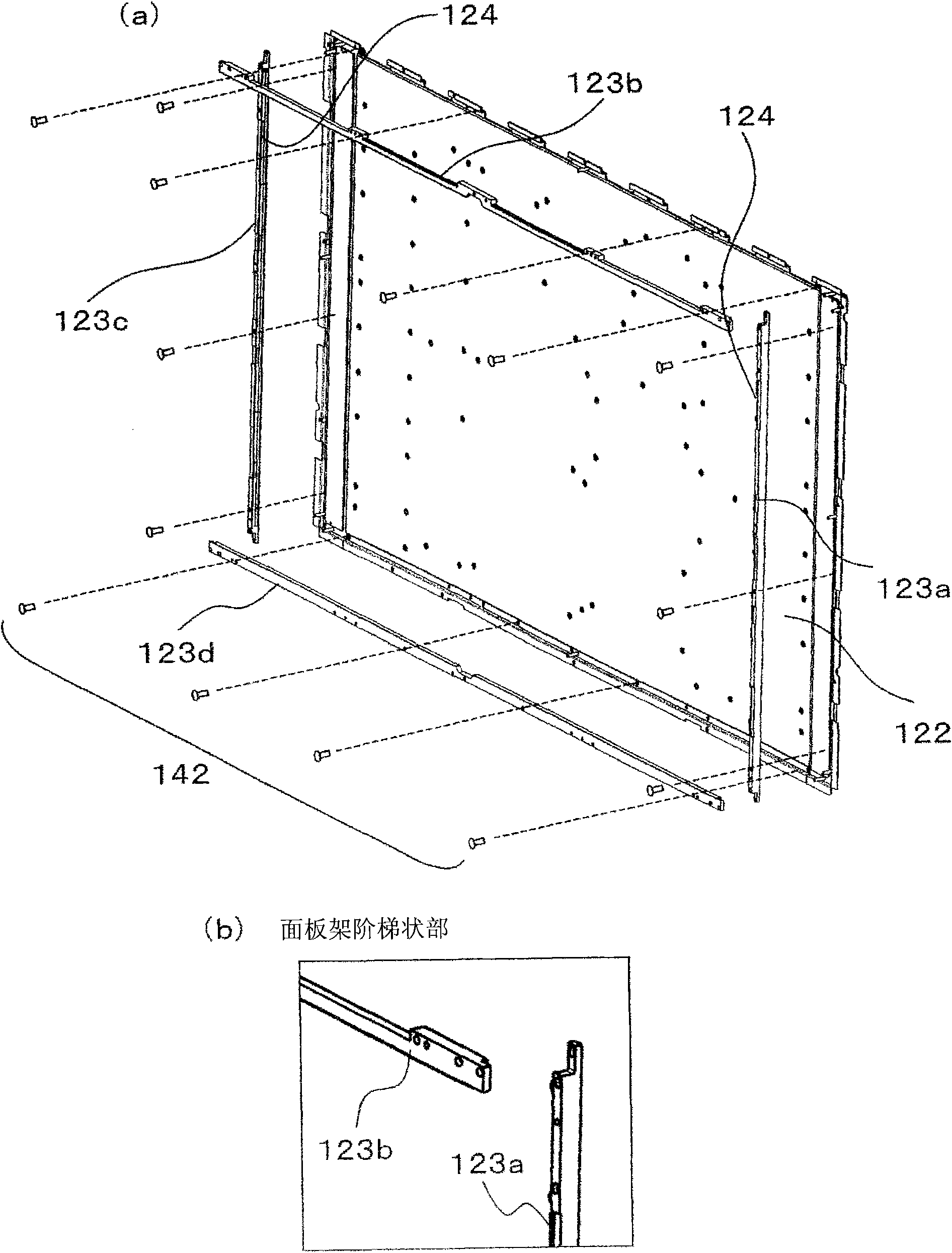

Light guide plate, light guide plate assembly, and surface illuminating device and liquid crystal display device using these

ActiveCN101473167AImprove utilization efficiencyUniform injectionMechanical apparatusPoint-like light sourceNon symmetricLiquid-crystal display

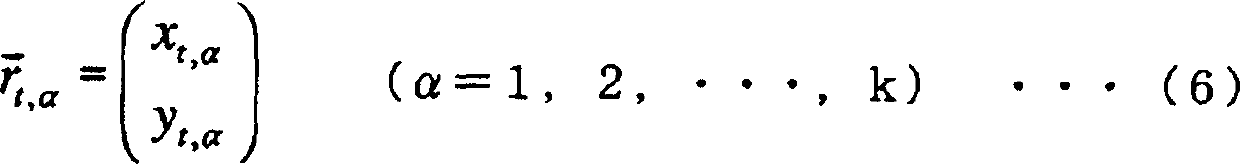

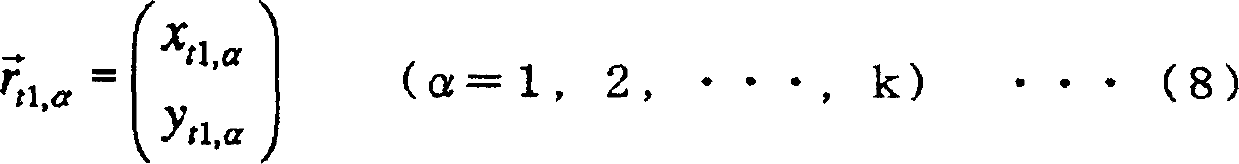

A light guide plate, comprising a light exiting surface and a light entering end, has a shape in which its thickness perpendicular to the light exiting surface increases gradually as it is away from the light entering end and has scattering particles scattered therein. A light guide plate assembly comprises this guide plate, and a prism sheet in which a plurality of prisms are arranged in parallel with the apex angles of the prisms arranged facing the light exiting surface. A surface illuminating device comprises a light guide plate or a light guide plate assembly, and a liquid crystal display device comprises the surface illuminating device. The scattering particles scatter light entering at the light entering end and propagating through the inside and satisfy the following expression (1) and (2), and the apex angles of the prisms of the prism sheet satisfy the following expressions (3) and (4). (F is scattered sectional area, NP is particle density, LG is length of guide plate along incident direction, KC is correction coefficient, phi is apex angle of symmetric prism, and theta1 and theta2 are two apex angles divided by perpendicular of non-symmetric prism.) 1.1<=FNPLGKC<=8.2 ---(1) 0.005<=KC<=0.1 ---(2) 55 DEG<=theta<=80 DEG ---(3) 0 DEG<= theta1<= 15 DEG and 30 DEG<= theta2<= 45 DEG ---(4).

Owner:FUJIFILM CORP

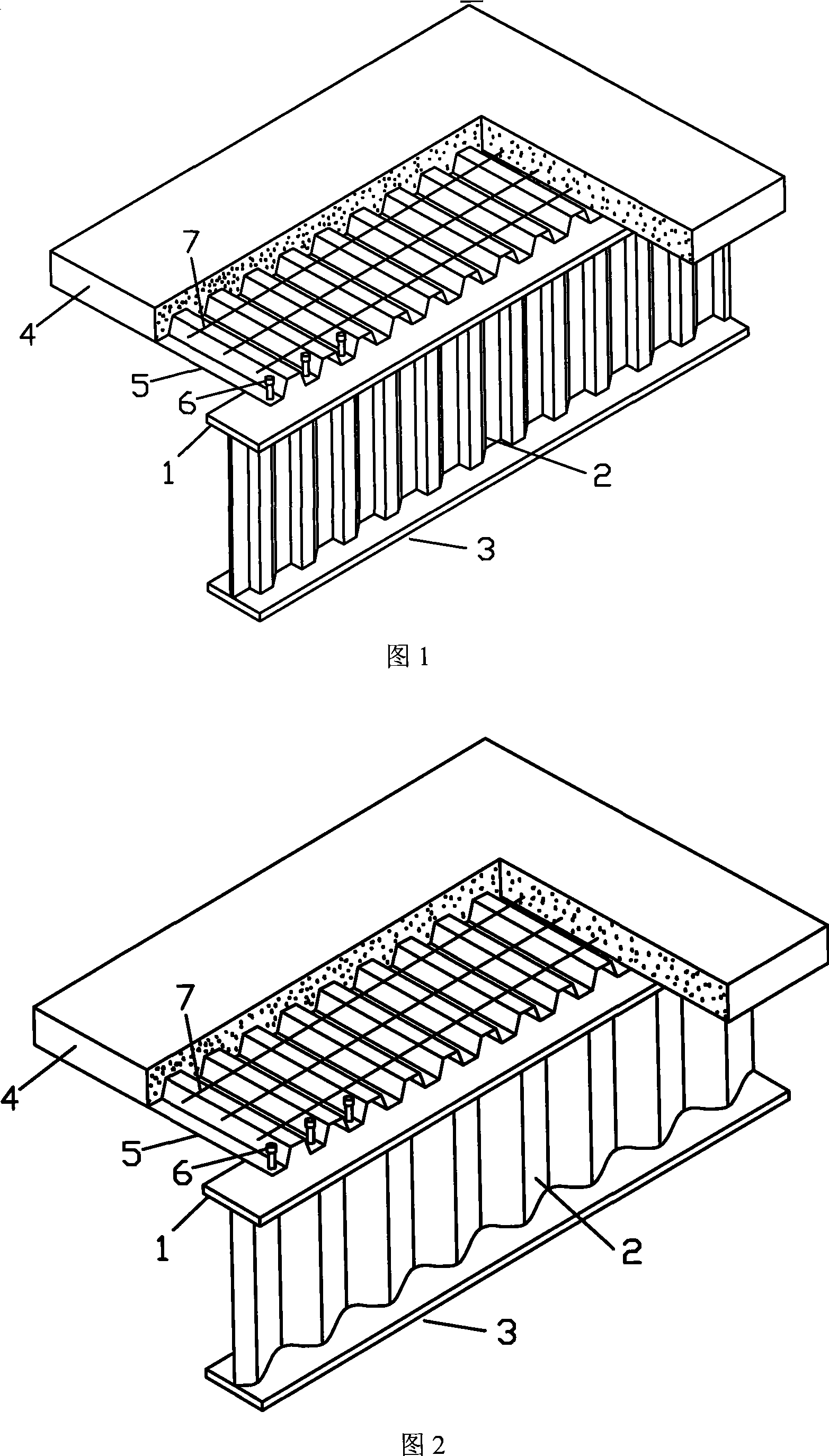

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

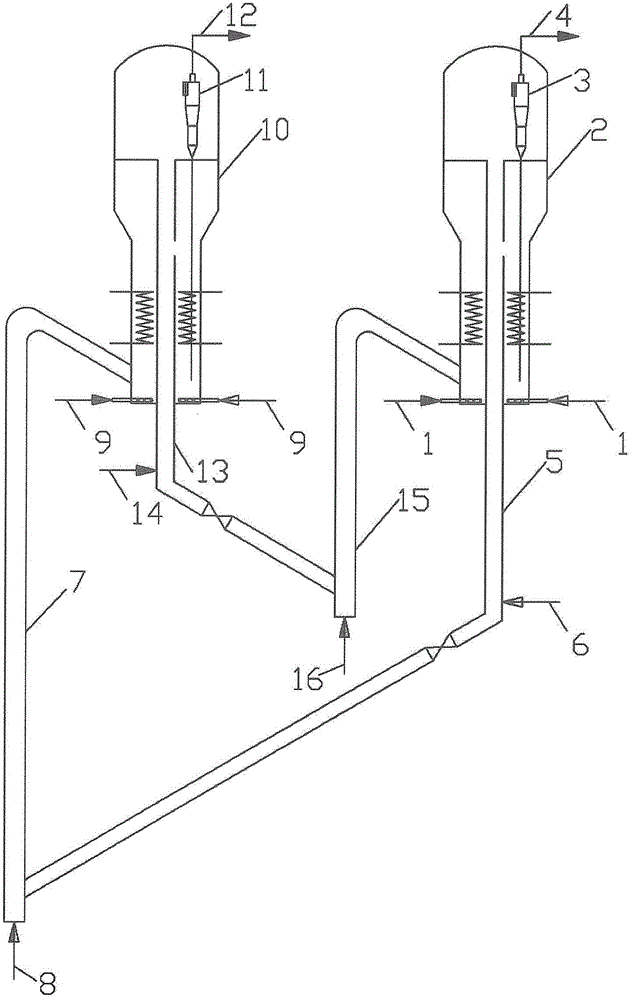

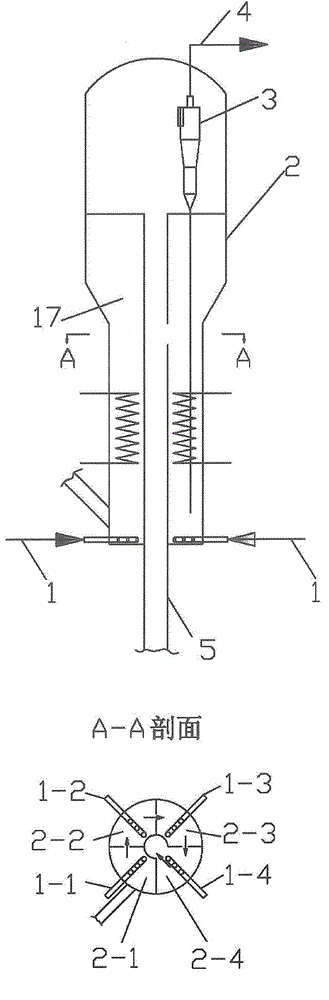

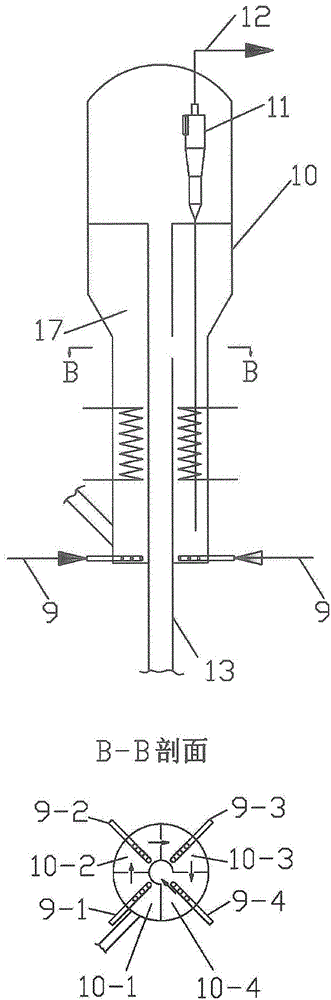

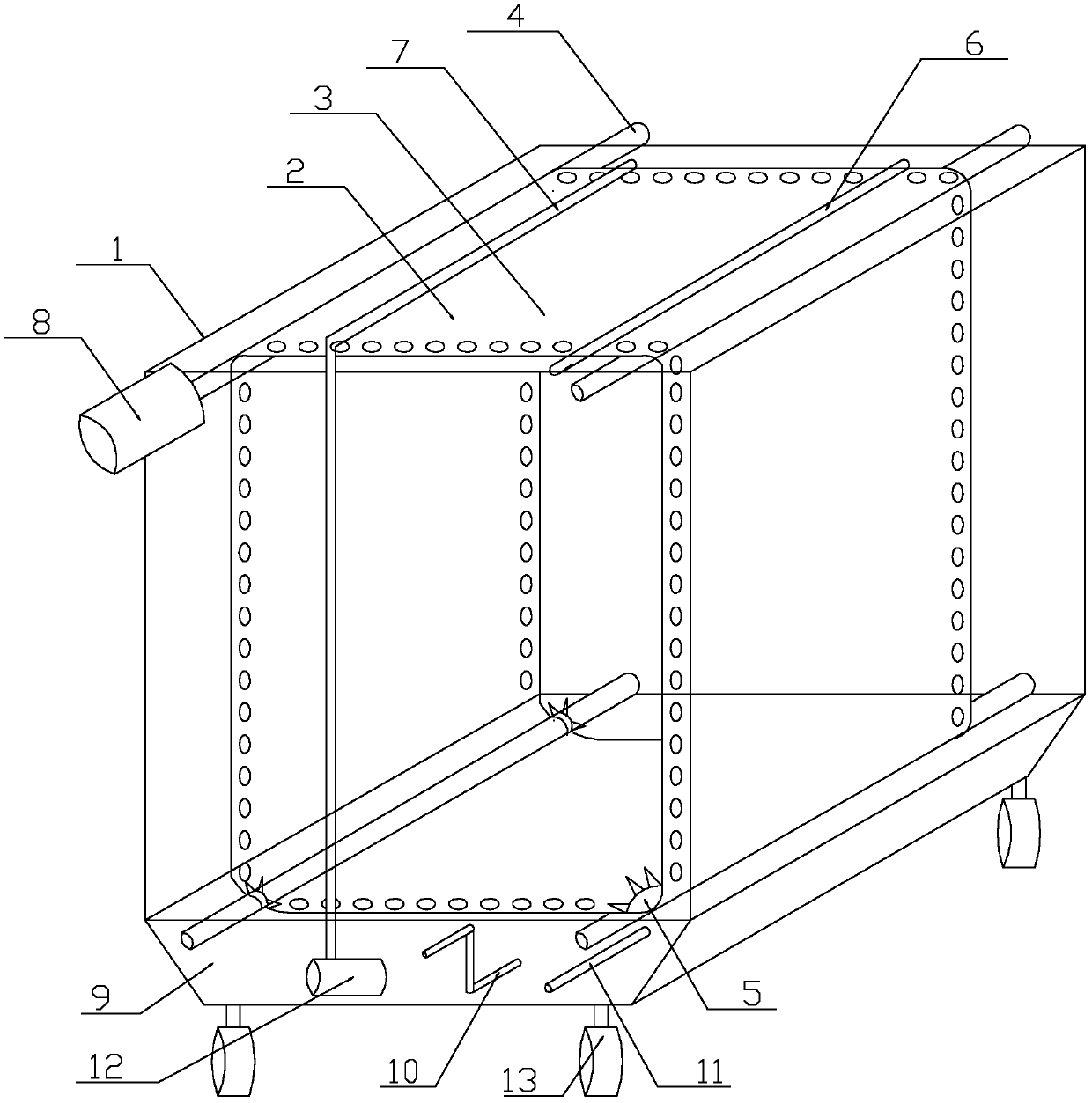

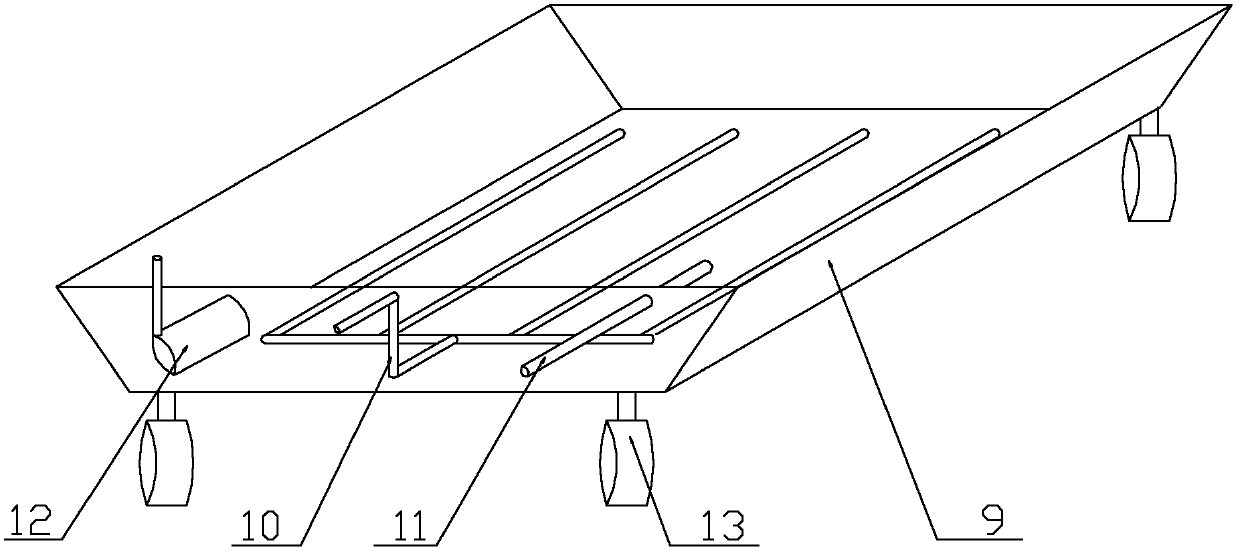

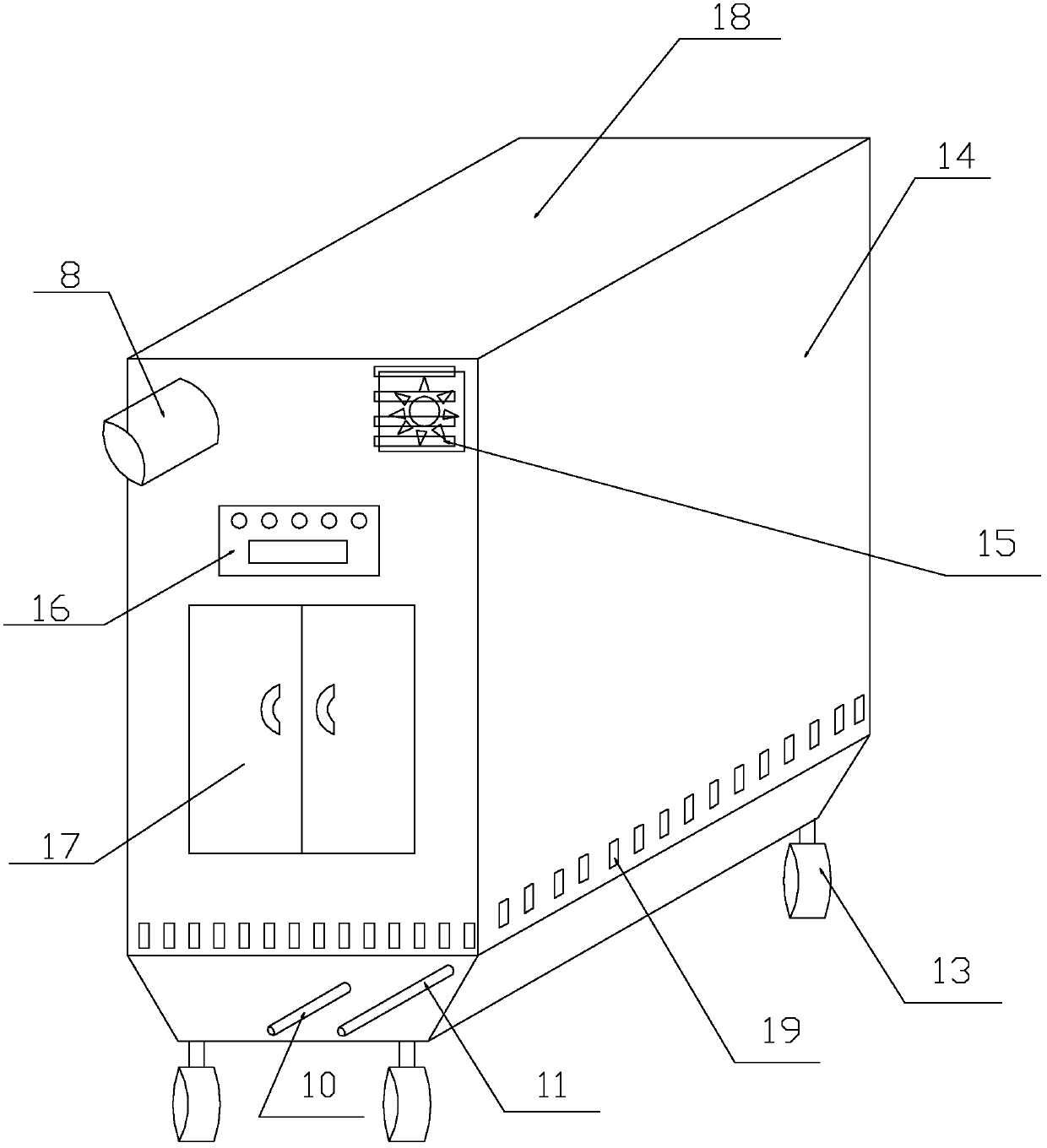

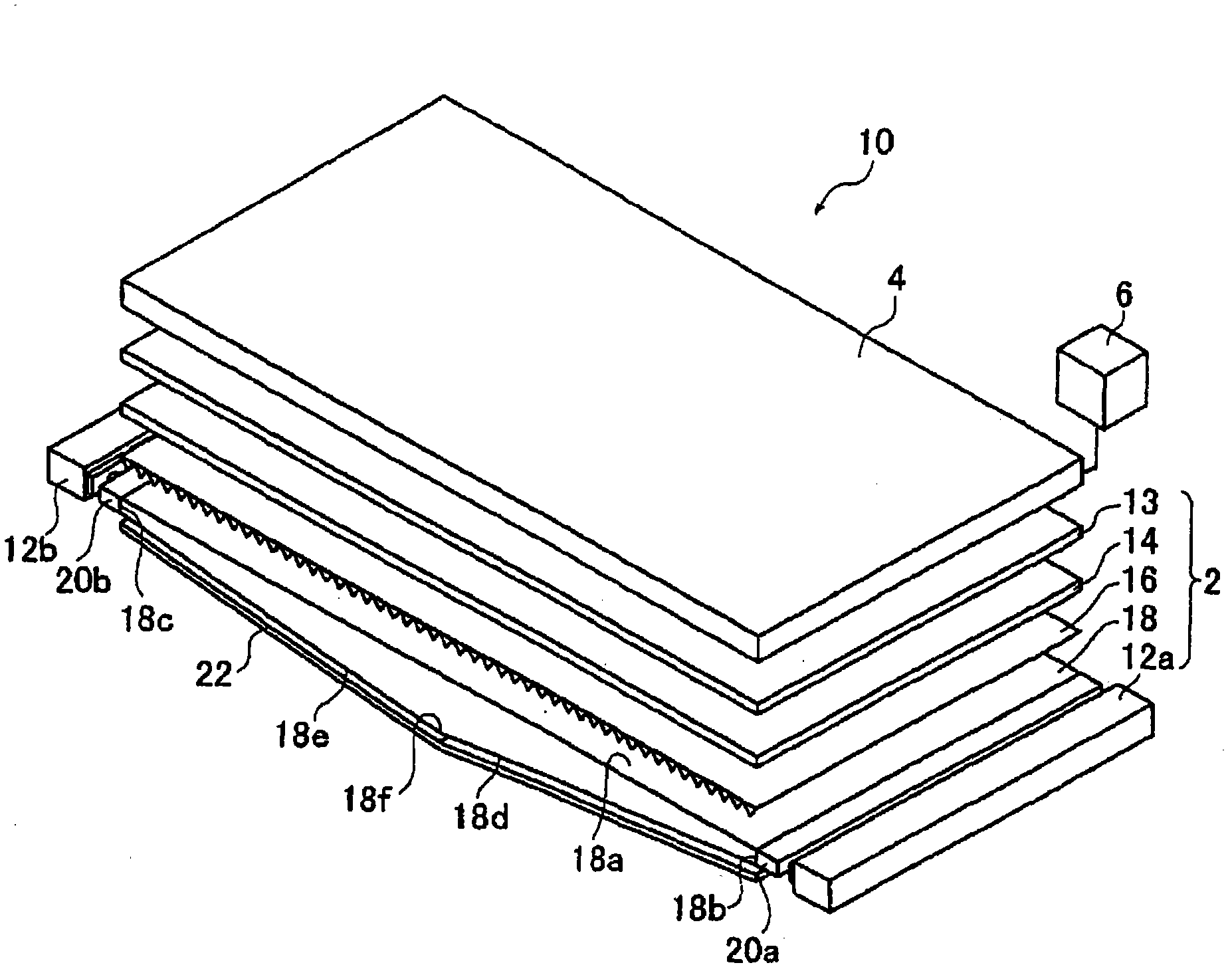

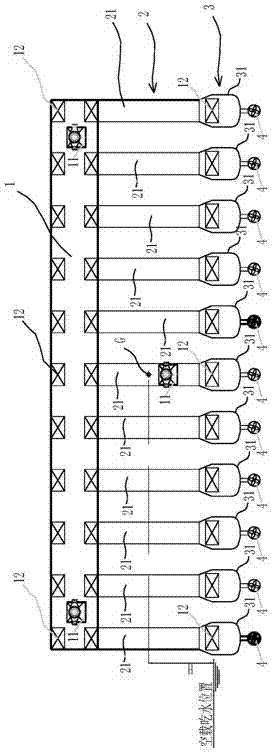

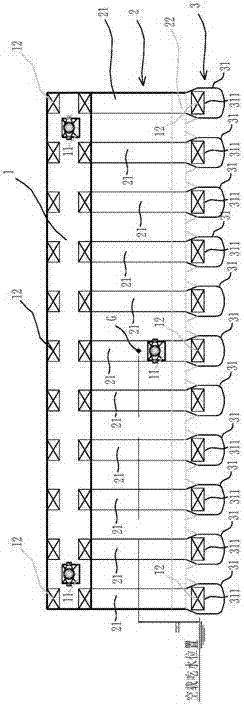

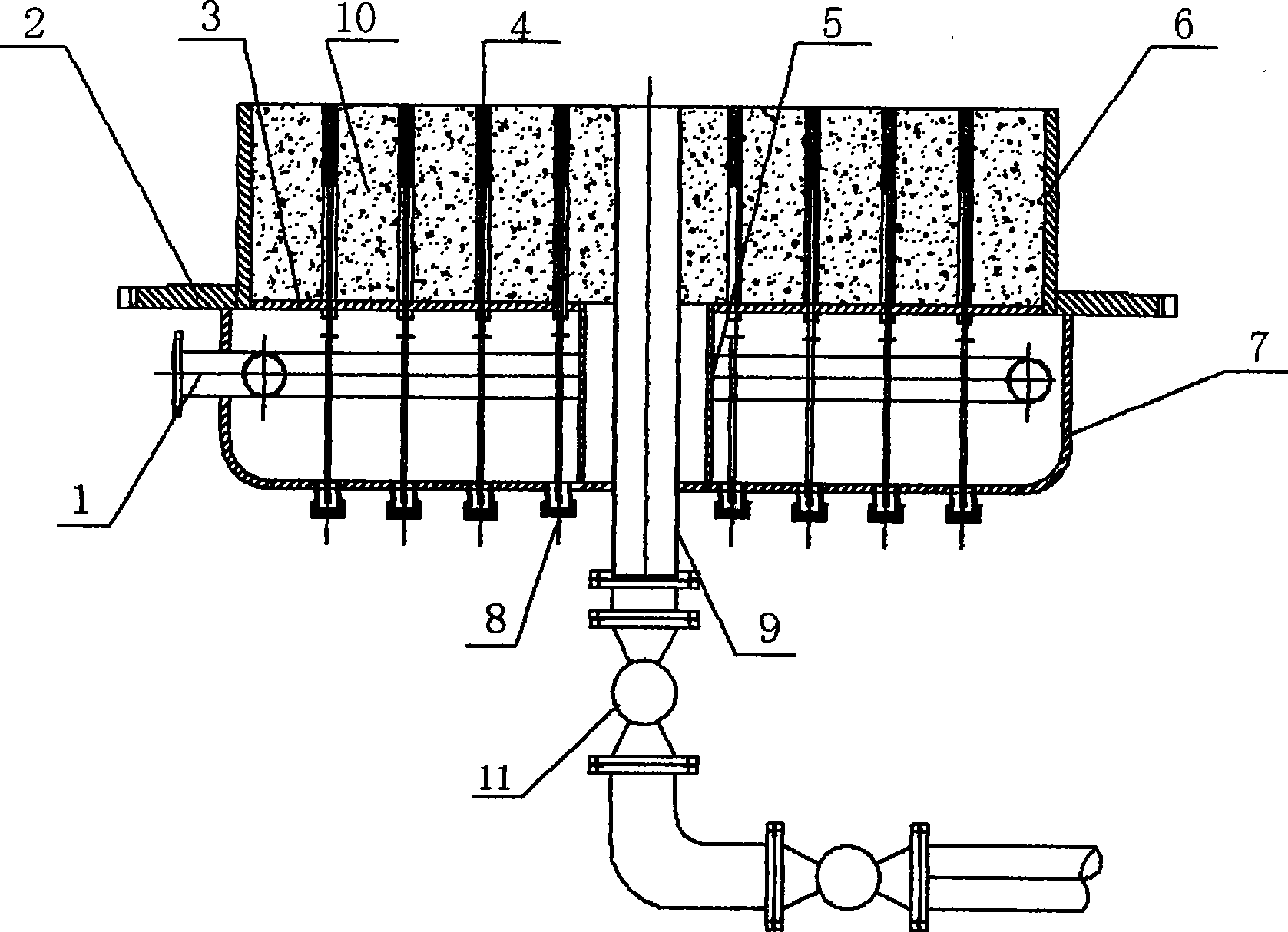

Reaction device for preparing low-carbon olefin by employing methyl alcohol and/or dimethyl ether

ActiveCN104672045AIncrease bed densityReduce wearHydrocarbon from oxygen organic compoundsEthylene productionAlcoholFluidized bed

The invention relates to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether, in particular to a reaction device for preparing low-carbon olefin by employing methyl alcohol and / or dimethyl ether. The reaction device mainly comprises a dense-phase fluidized bed reactor (2), a cyclone separator (3), a stripper (5), a lift pipe (7), a dense-phase fluidized bed regenerator (10), a cyclone separator (11), a stripper (13) and a lift pipe (15), wherein the dense-phase fluidized bed reactor (2) is partitioned into n (n is greater than or equal to 2) secondary reaction zones by material flow controllers (17); and the dense-phase fluidized bed regenerator (10) is partitioned into m (m is greater than or equal to 2) secondary regeneration zones by the material flow controllers (17). By virtue of the reaction device, the problems in the prior art that carbon deposit distribution of a catalyst is uneven and low-carbon olefin selectivity is relatively low are solved.

Owner:中科催化新技术(大连)股份有限公司

Method for smelting titanium slag with electric stove

The invention provides a method for smelting titanium slag by an electric stove. The method comprises the following steps: titanic iron and a reducing agent are mixed to prepare charging materials which are added into the electric stove; the titanium slag is smelted, the power of the electric stove is between 12MV.A and 30MV.A in the smelting process; and the slag is discharged, and the iron is discharged.

Owner:PANGANG GROUP TITANIUM INDAL +1

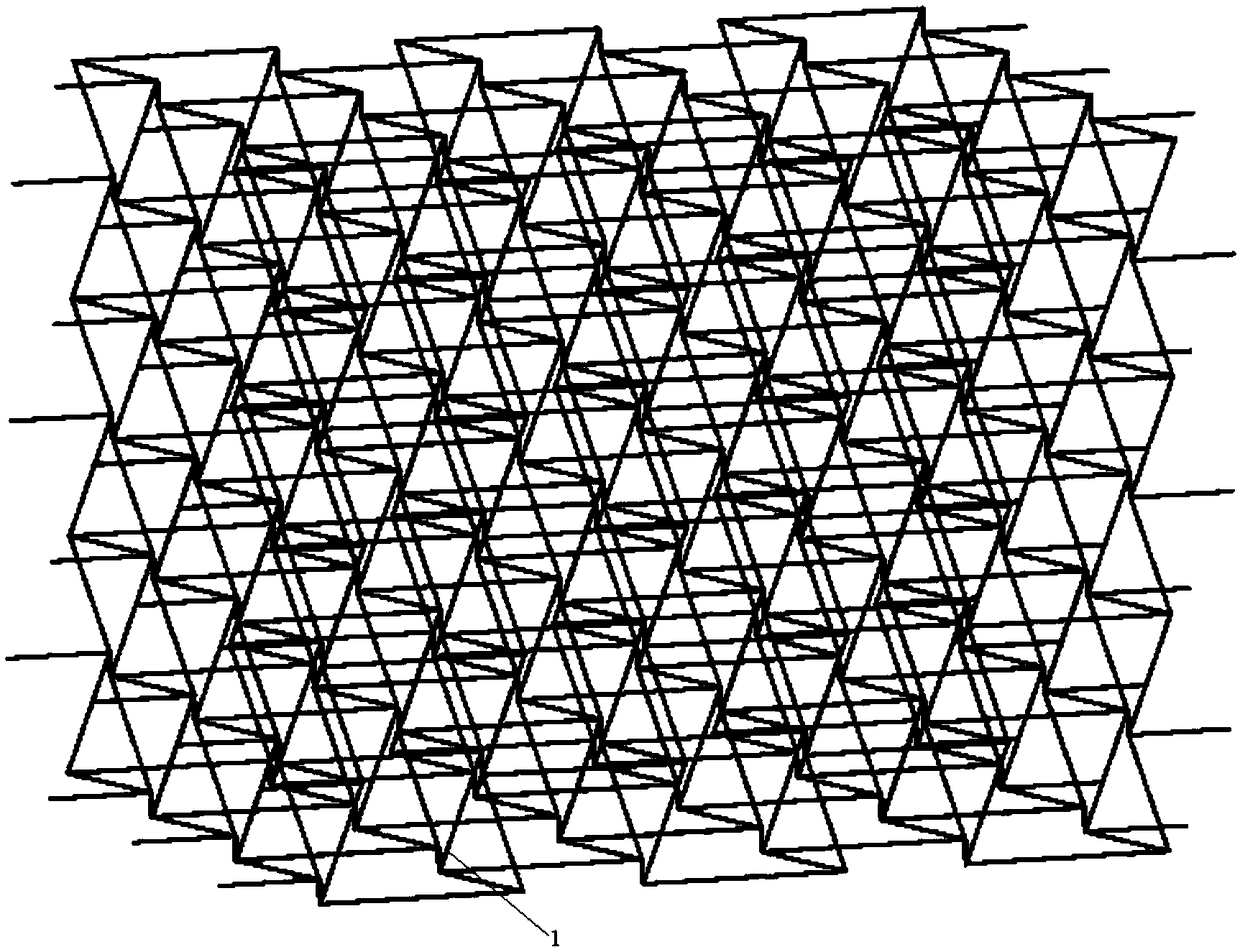

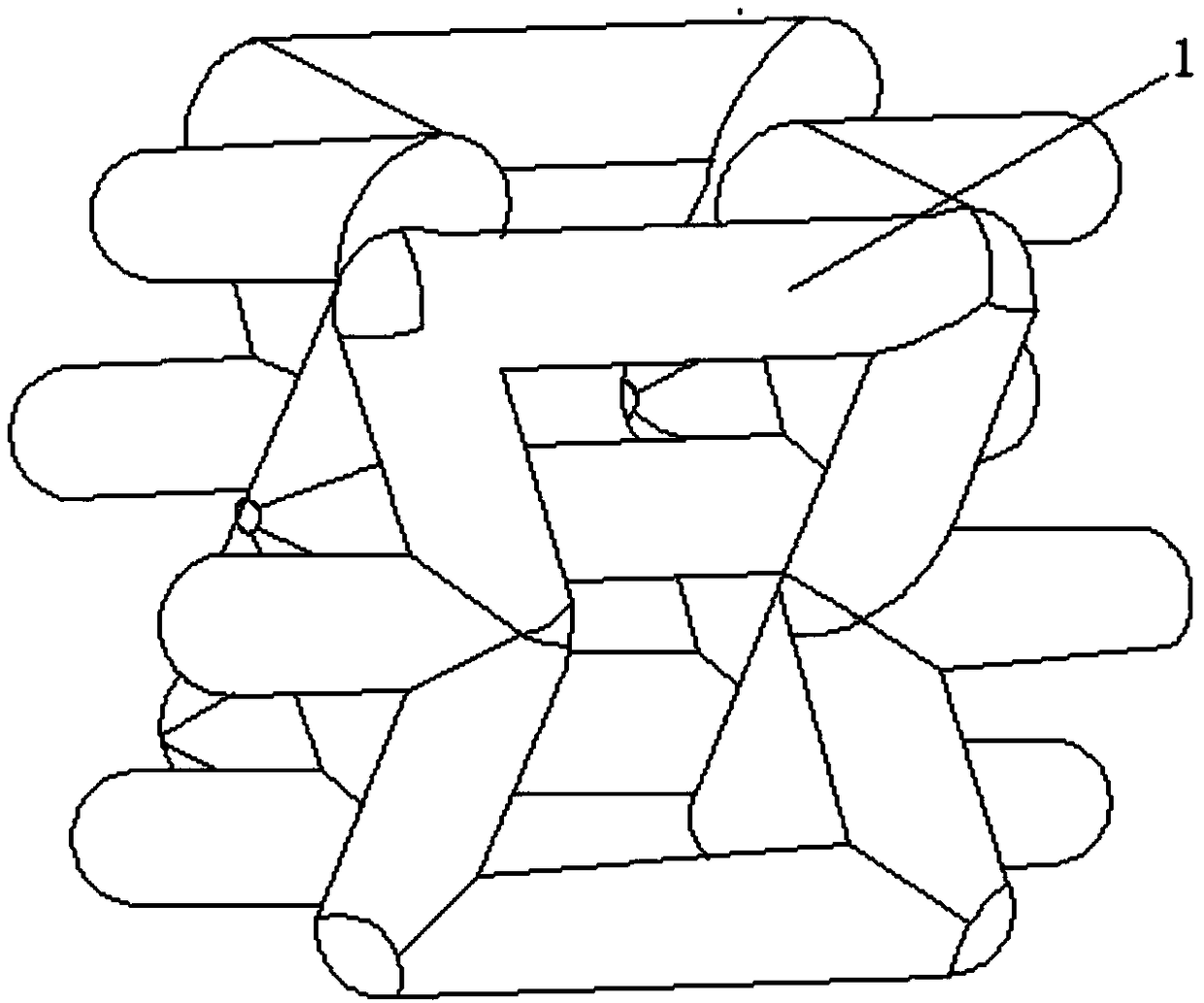

Negative Poisson's ratio aluminum-based lattice structure and preparation method thereof

InactiveCN109365787ARealize configuration diversificationRealize large-scaleAdditive manufacturing apparatusFoundry mouldsPositive pressureMultiple layer

The invention discloses a negative Poisson's ratio aluminum-based lattice structure and a preparation method thereof. The negative Poisson's ratio aluminum-based lattice structure is formed by periodically arranging one or more layers of unit cell structures, the unit cell structures are of pull bulging type three-dimensional negative Poisson's ratio structures, the material is a negative Poisson's ratio material, the negative Poisson's ratio material is industrial pure aluminum or an aluminum alloy, and the unit cell structures are formed by connecting a plurality of horizontally-arranged andslantly-arranged rod units; and the diameter of the unit cell rod units is 0.5-5.0 mm, the length of the unit cell rod units is 0.5-15.0 mm, and the included angle between the slantly-arranged rod units and the projective planes of the rod units is 30-70 degrees; and CATIA software is adopted for modeling and design, a polymer material and a 3D printing technology are adopted for manufacturing amodel, a porous skeleton is made by soluble gypsum, and the aluminum-based negative Poisson's ratio lattice material is prepared by a positive pressure gas pressure percolation technology. The 3D printing and pressure percolation technologies are adopted to prepare the aluminum-based lattice structure in a combined manner; and the negative Poisson's ratio aluminum-based lattice structure which hasthe characteristics of small unit cells, thin rod elements, multiple layer levels, complex configuration and the like is achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

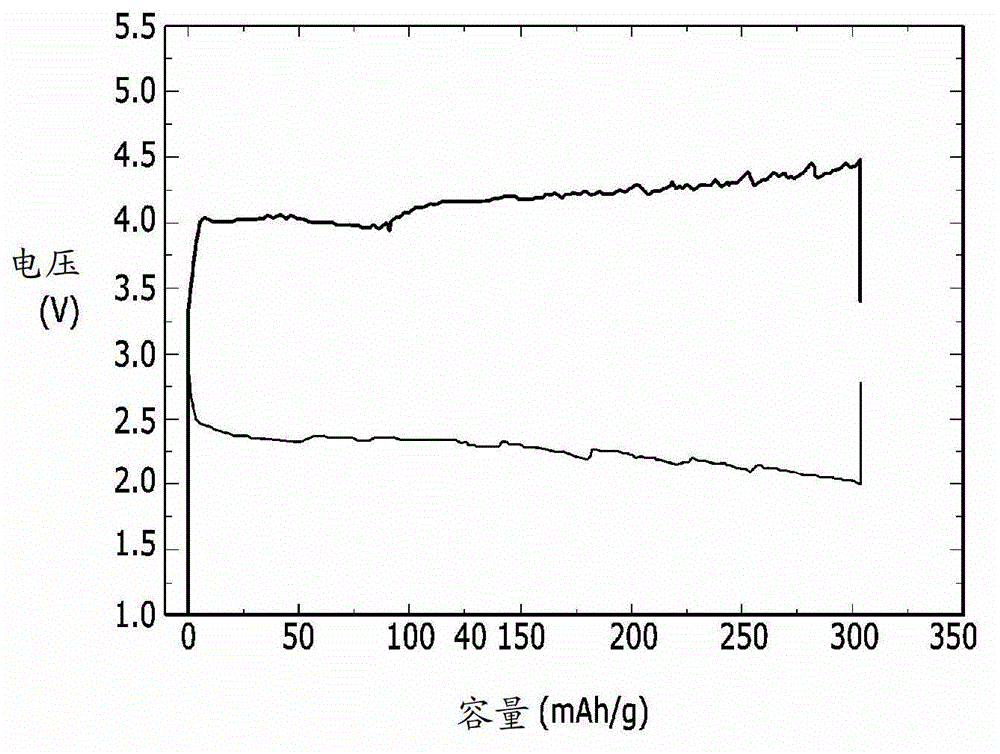

Lithium-air battery

InactiveCN102948006ACommercializationRealize large-scaleFuel and primary cellsFuel and secondary cellsLithium oxideLithium hydroxide

Provided is a lithium-air battery comprising: a positive electrode including a current collector and a positive electrode active material layer which is located on the current collector and includes a positive electrode active material; a negative electrode including a negative electrode active material; and an electrolyte, wherein the positive electrode active material includes lithium peroxide (Li2O2), lithium oxide (Li2O), lithium hydroxide (LiOH), or a combination thereof, and the negative electrode active material includes a lithium alloy, a material which can be doped or undoped with lithium, a transitional metal oxide, or a combination thereof.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

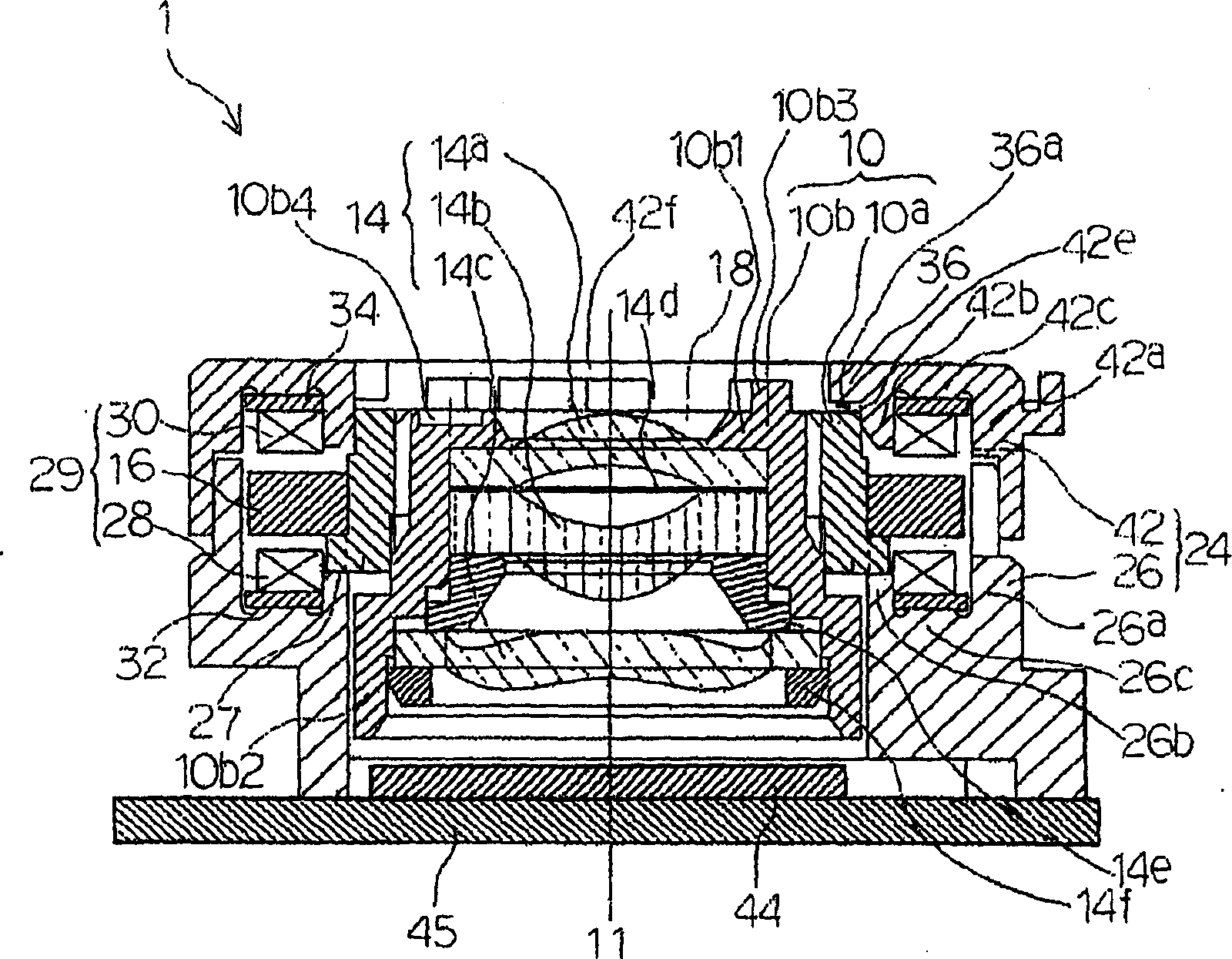

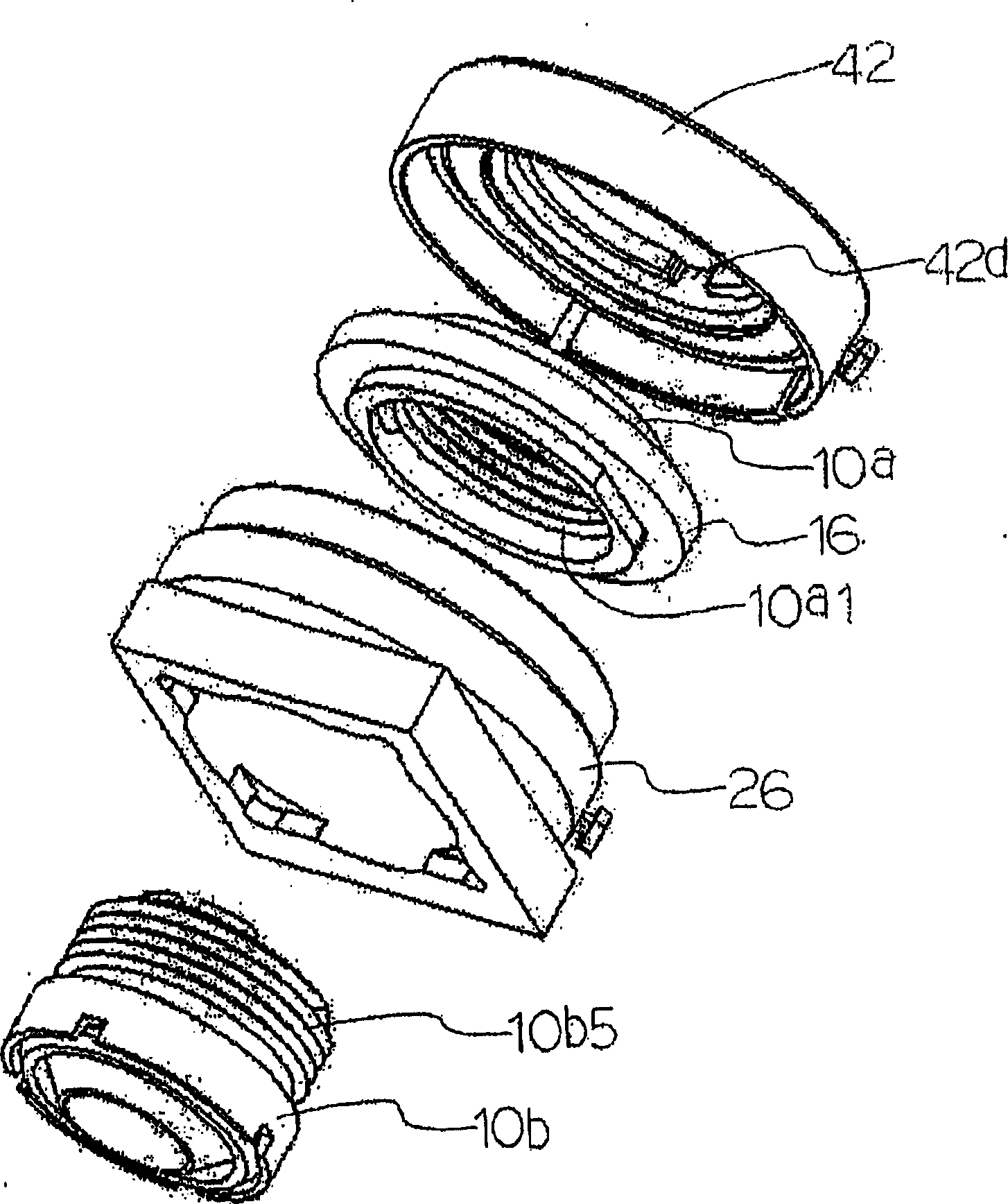

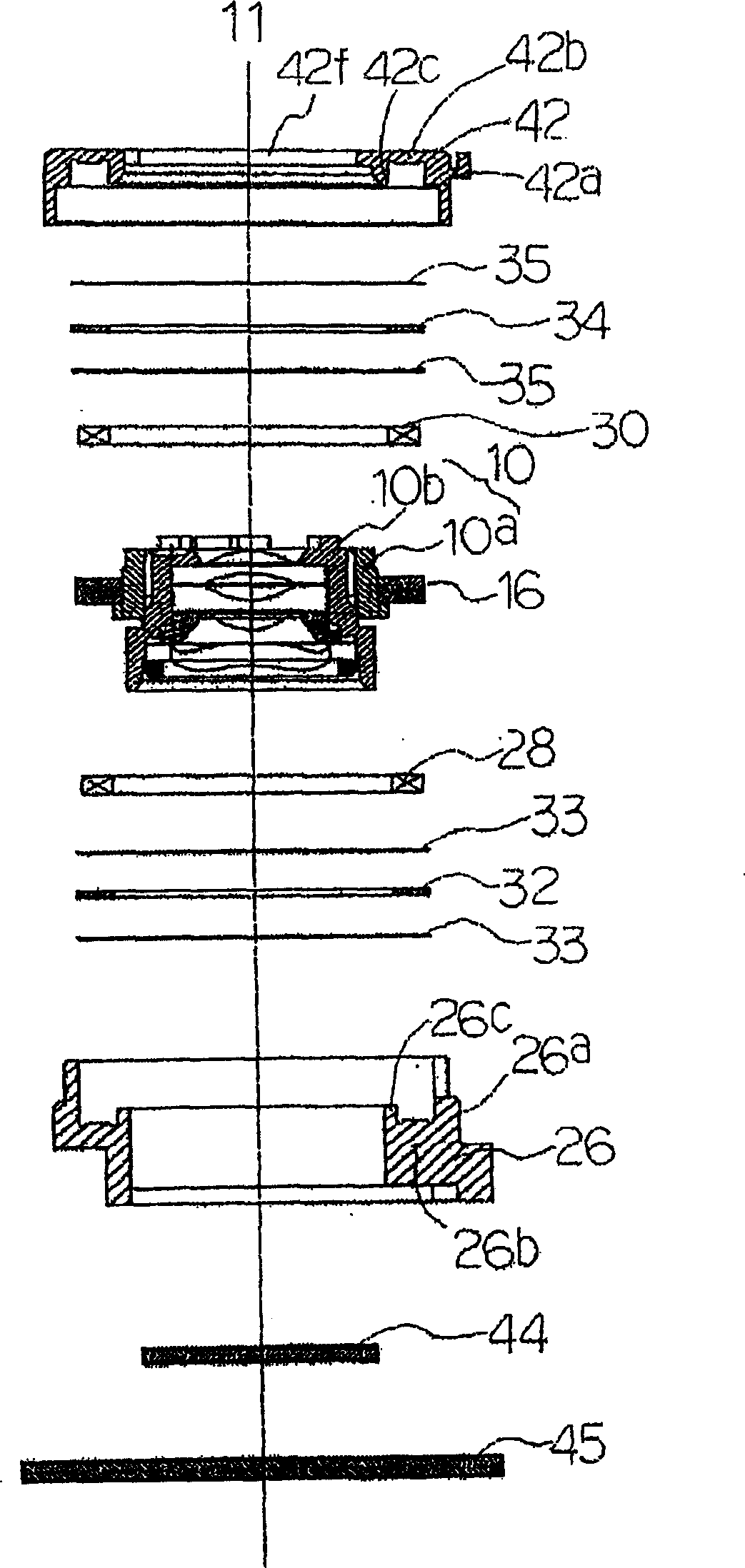

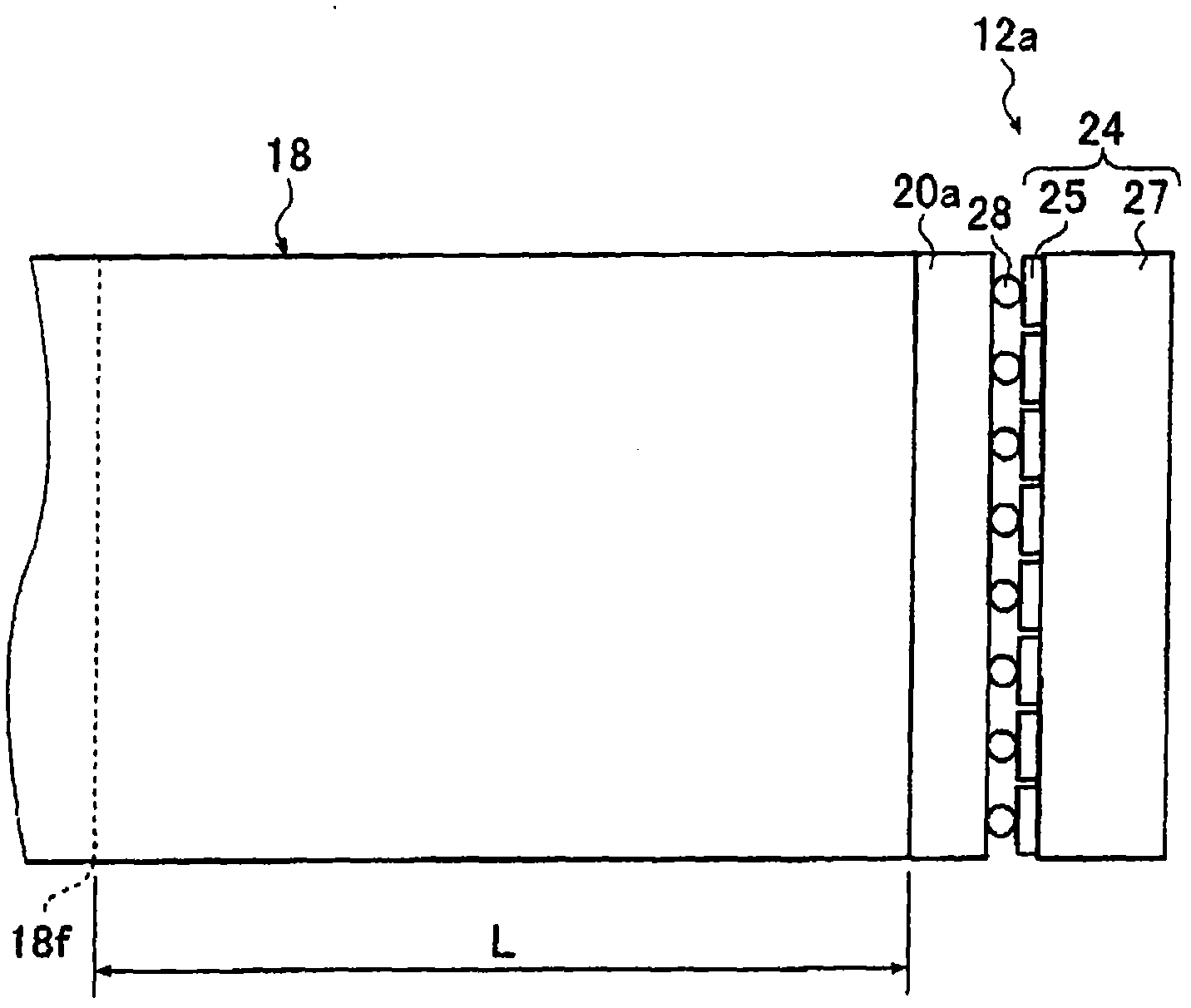

Lens driver and process for manufacturing the same

InactiveCN1890591ARealize large-scaleMiniaturizationDynamo-electric machinesMountingsOptical axisRepulsion force

A lens driver (1) comprising a moving lens body (10) consisting of a lens-barrel (10b) provided with a lens (14) and a lens-barrel holder (10a) for supporting the lens-barrel (10b) so as to be movable in the direction of the optical axis (11). The lens-barrel holder (10a) has a driving magnet (16) and a case body (24) for supporting the moving lens body (10) so as to be movable in the direction of the optical axis (11) encases first and second driving coils and has an end face (27) of an inner tubular section (26b) and a projecting edge (36) of an inner tubular section (42b) that regulate the moving range of the lens-barrel holder (10a) in the direction of the optical axis (11). The moving lens body (10) is moved by a magnetic attracting force or repelling force of the driving magnet (16) and the first and second driving coils.

Owner:SANKYO SEIKI MFG CO LTD

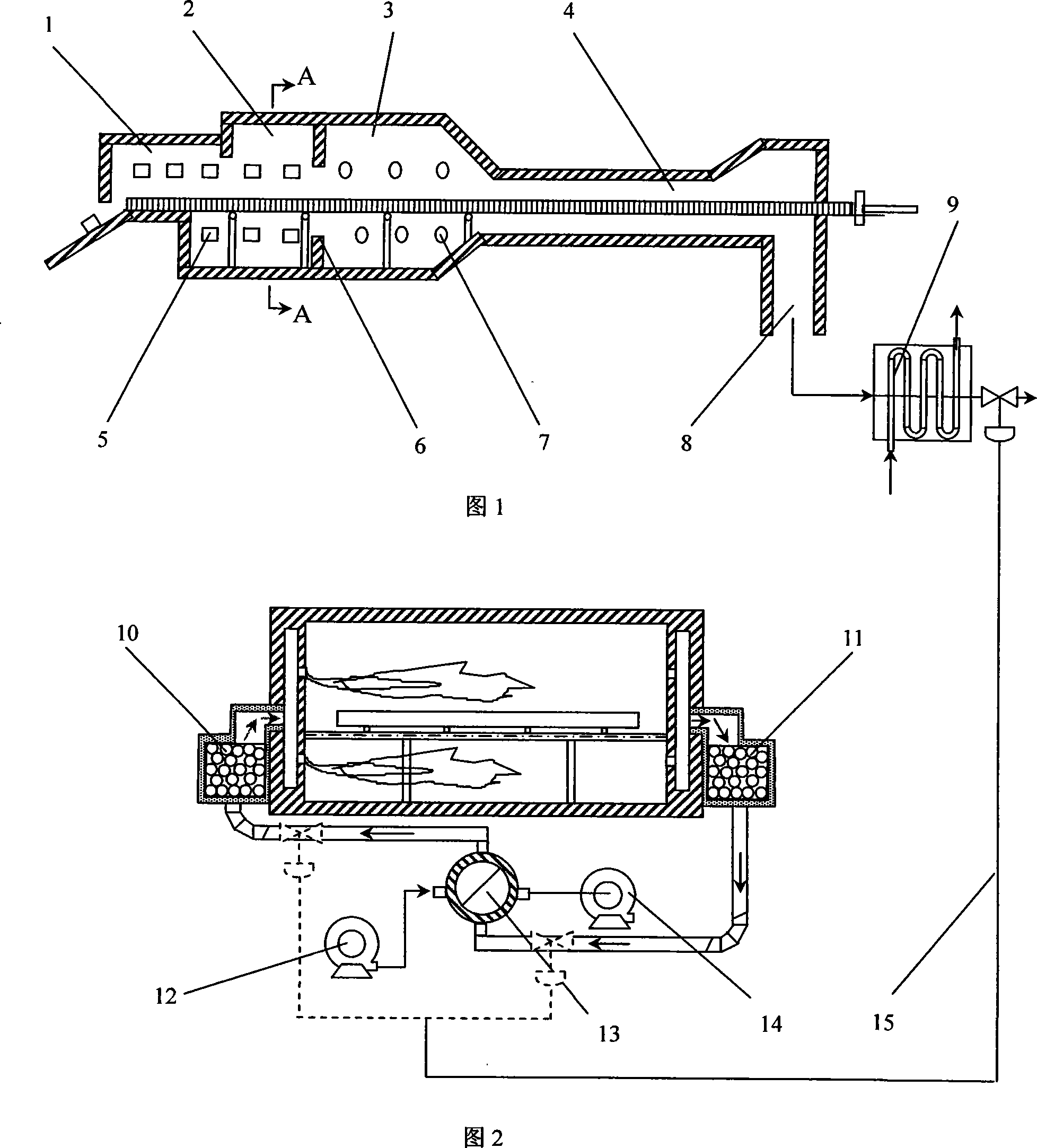

Microalgae half-dry solid state adherent cultivation device for alternate illumination of bright and dark light

ActiveCN103289886AReduce water consumptionAchieve ultra-high density cultureSolid phase fermentation bioreactorsCirculating pumpBiology

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

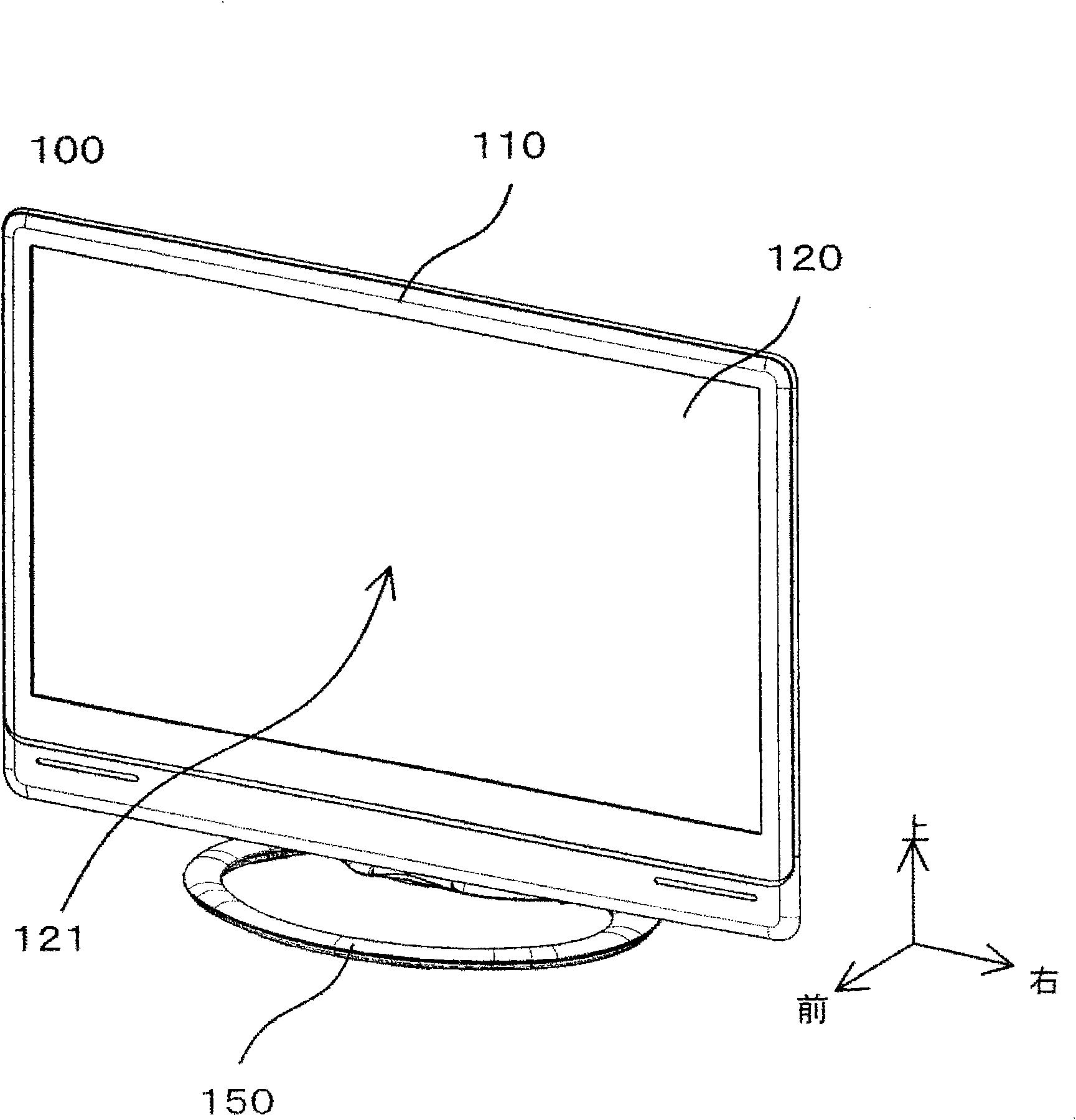

Infor mation apparatus and display controlling method

InactiveCN1487462APrevent leakageMiniaturizationImage analysisInternal/peripheral component protectionRadiologyInformation device

In an information device (10), a fingerprint image capture section (20) captures a fingerprint image of an operator. When a fingerprint image captured by the fingerprint image capture section (20) is referred to as a first fingerprint image and a fingerprint image captured at a given time interval after the first fingerprint image is captured is referred to as a second fingerprint image, a comparison section (30) compares minutiae points of the first and second fingerprint images extracted by a minutiae point extraction section (60). An image generation section (40) generates image information which is changed while reflecting the comparison results of the comparison section (30). A display section (50) displays an image based on the image information generated by the image generation section (40). The information device (10) may be provided with a check section (110), and display control by the display section (50) may be performed after a fingerprint image is checked by the check section.

Owner:SEIKO EPSON CORP

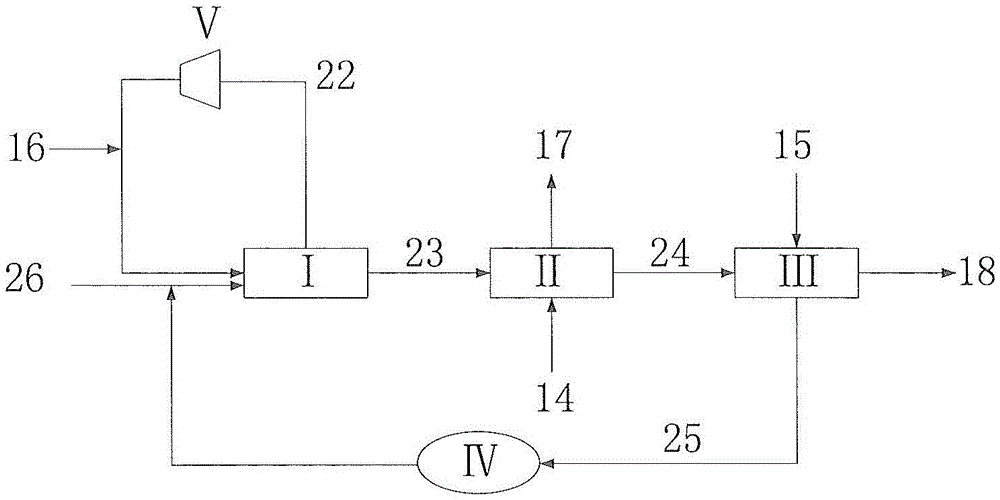

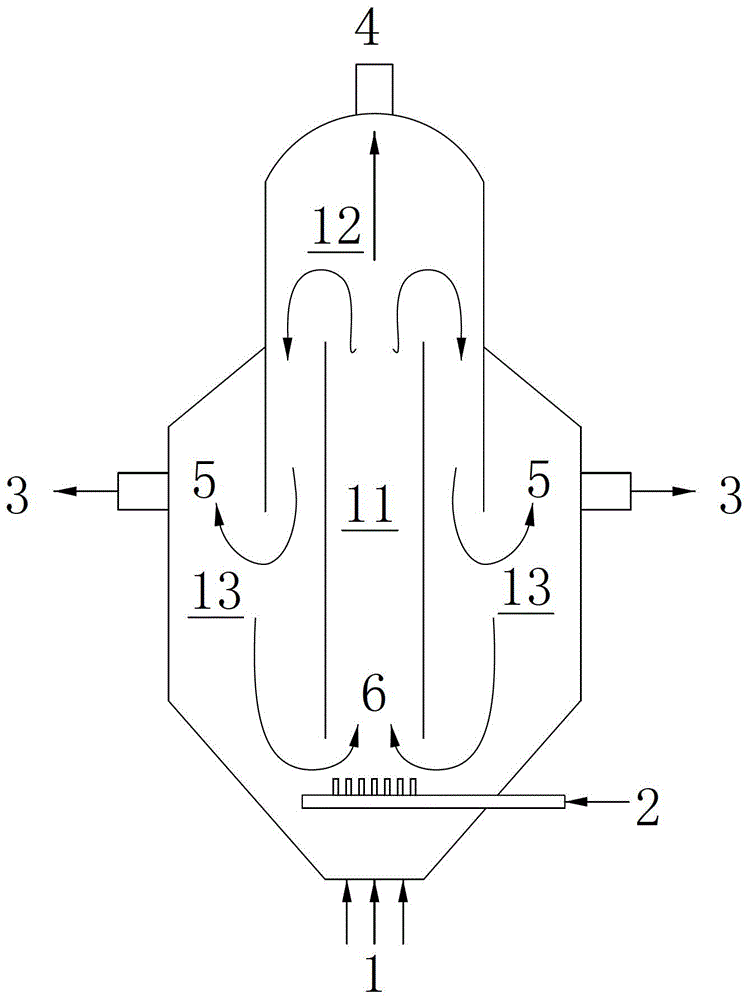

Method for preparing hydrogen peroxide

ActiveCN104418309AImprove hydrogen efficiencyAvoid air lockPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogen peroxide breakdownHydrogen

The invention discloses a method for preparing hydrogen peroxide. A working liquid and a hydrogen-containing gas are introduced into a slurry bed reactor; a hydrogenated liquid is obtained by reaction in the existence of a catalyst; the hydrogenated liquid reacts with oxygen to obtain the hydrogenated liquid containing hydrogen peroxide in an oxidation reactor; oxidized liquid is extracted and separated from an extraction tower to obtain a hydrogen peroxide solution and working liquid; the slurry bed reactor comprises a cap (12), an expanding section (13) and a draft tube (11); the expanding section (13) is positioned at the lower part of the cap (12); the pipe diameter of the expanding section (13) is greater than that of the cap; the draft tube (11) is arranged in the expanding section (13); the pipe diameter of the draft tube (11) is smaller than that of the cap (12); a bottom opening of the cap (12) extends into the expanding section (13); the outer wall of the cap (12) is connected with the top of the expanding section (13); an upper opening of the draft tube (11) extends into the cap (12); and an opening is formed in the lower part of the draft tube (11). The method disclosed by the invention is stable to operate, and easy for realization of industrial enlargement; no alkali is introduced in the process of preparing hydrogen peroxide; and the risk of explosion caused by hydrogen peroxide decomposition is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

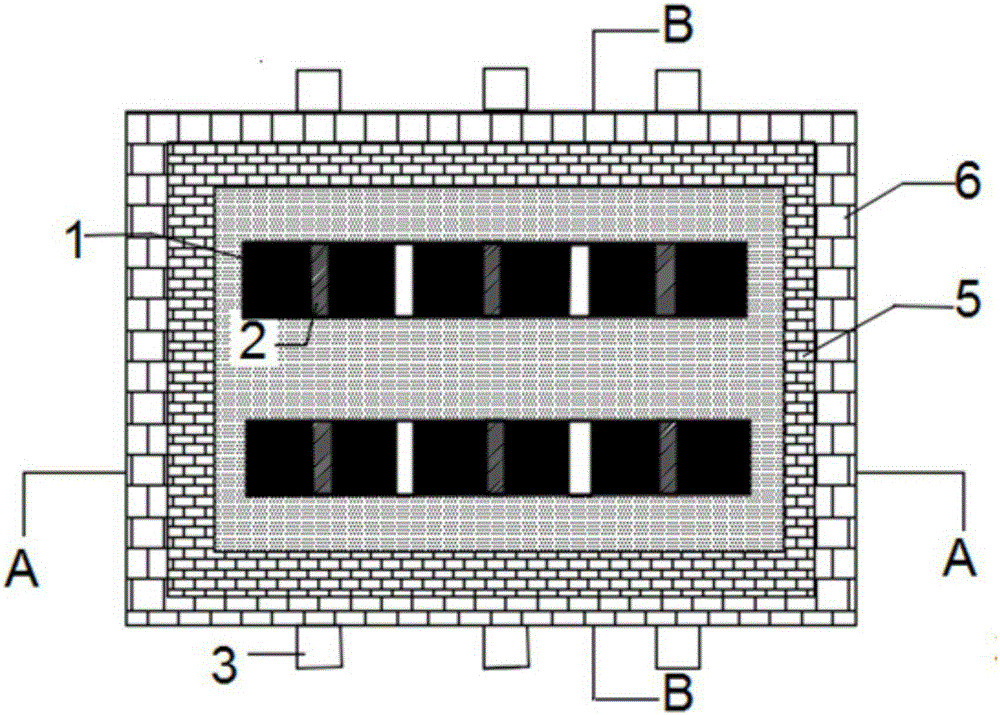

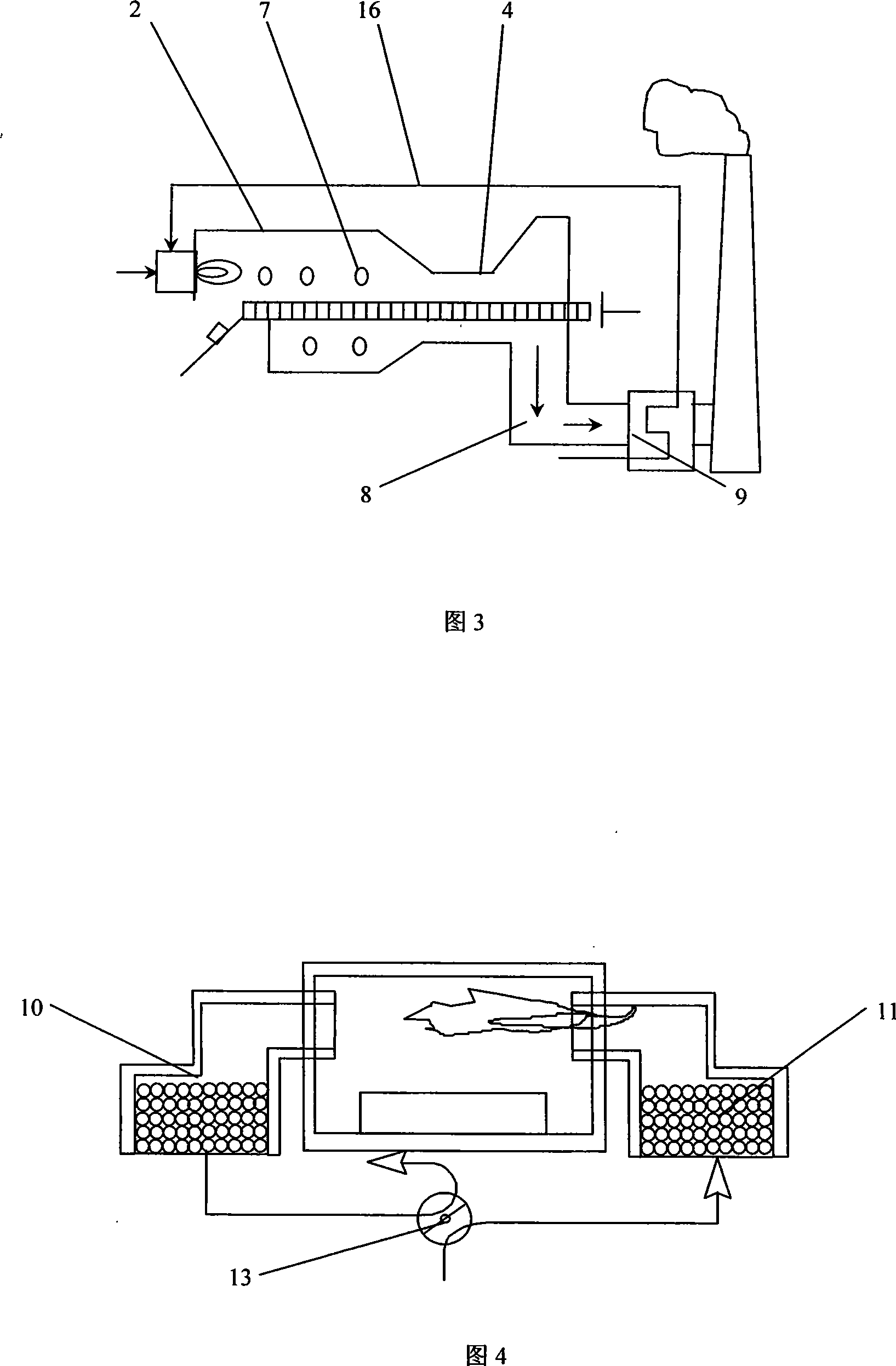

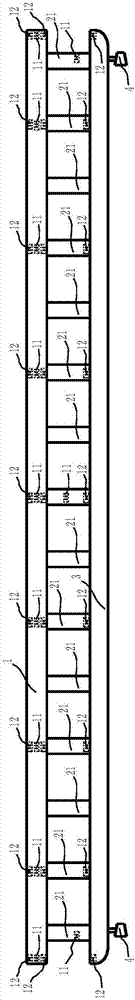

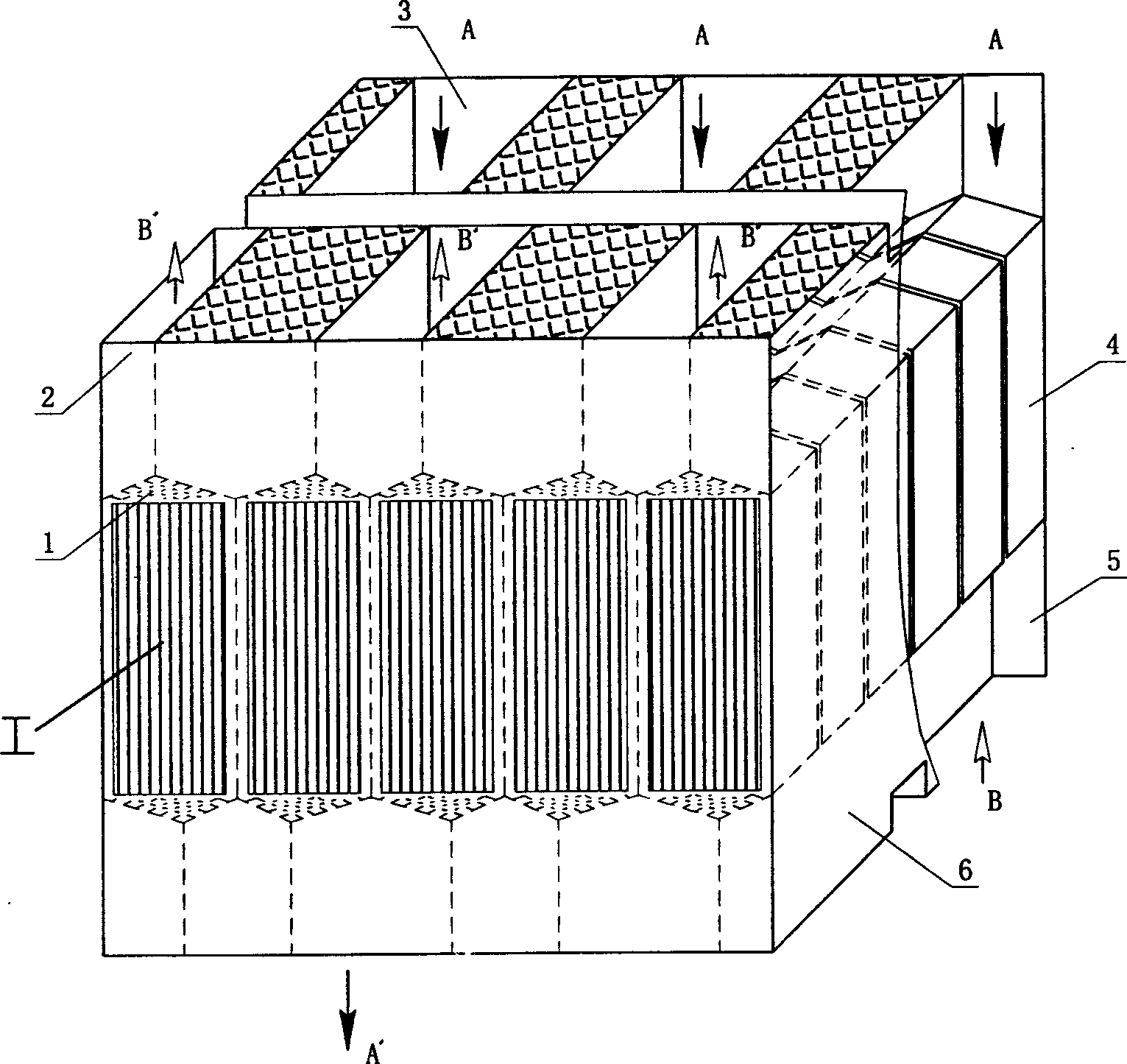

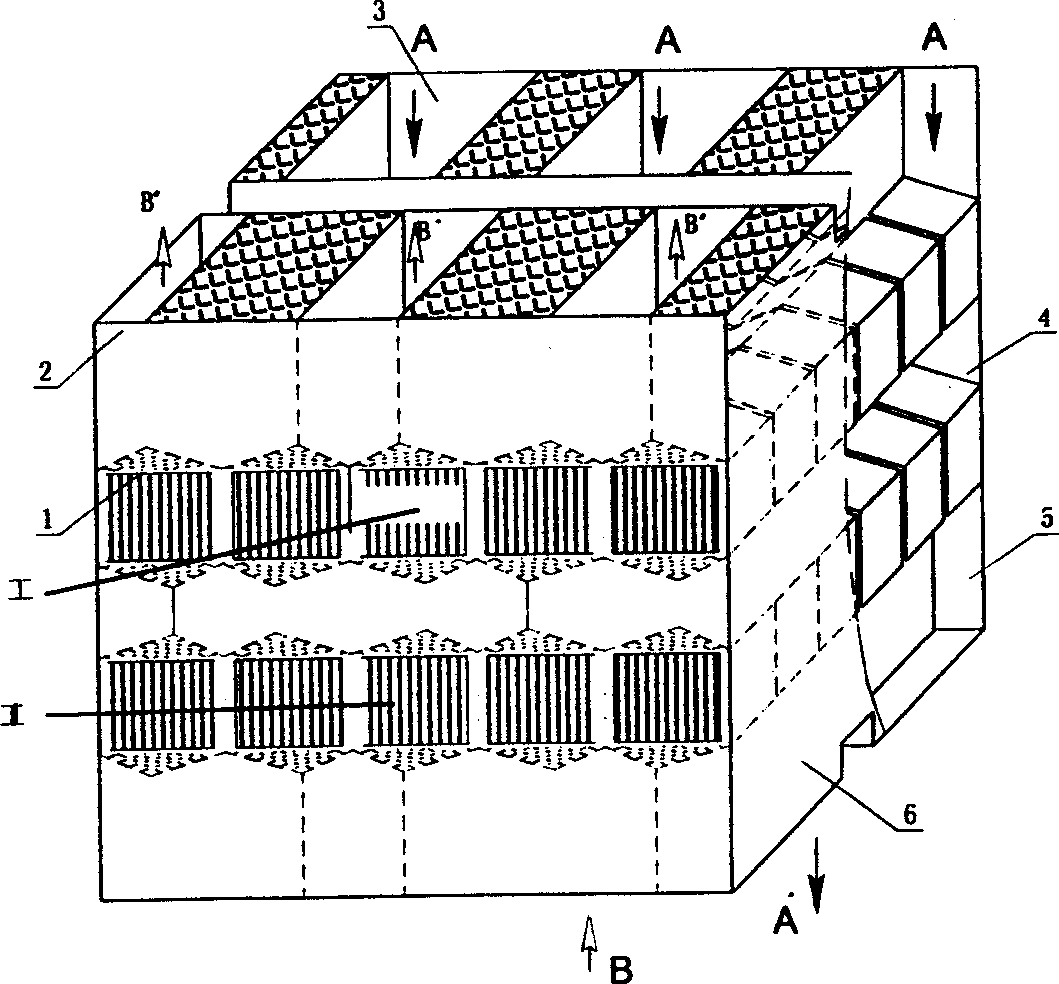

Arranging method of layered fluidization air distribution plate of fluidized bed boiler

ActiveCN1948831AImprove mixing conditionsRealize large-scaleFluidized bed combustionApparatus for fluidised bed combustionAir volumeCombustion

The invention adopts a multi-layer arrangement method of a fluidized-bed boiler bottom air-feeding plates and the integral hearth bottom consists of three independent air-feeding plates. One air-feeding plate is disposed in the lowerest part of the hearth and on the above air-feeding plate are overlaid the other air-feeding plates, so as to realize the step charging, the step air-supply and the fractional combustion of the recirculating fluidized-bed boiler. By regulating the blast volume and the fuel flow of each air-feeding plate, the uniform combustion and air-supply of the boiler can be realizer.

Owner:SHANGHAI BOILER WORKS

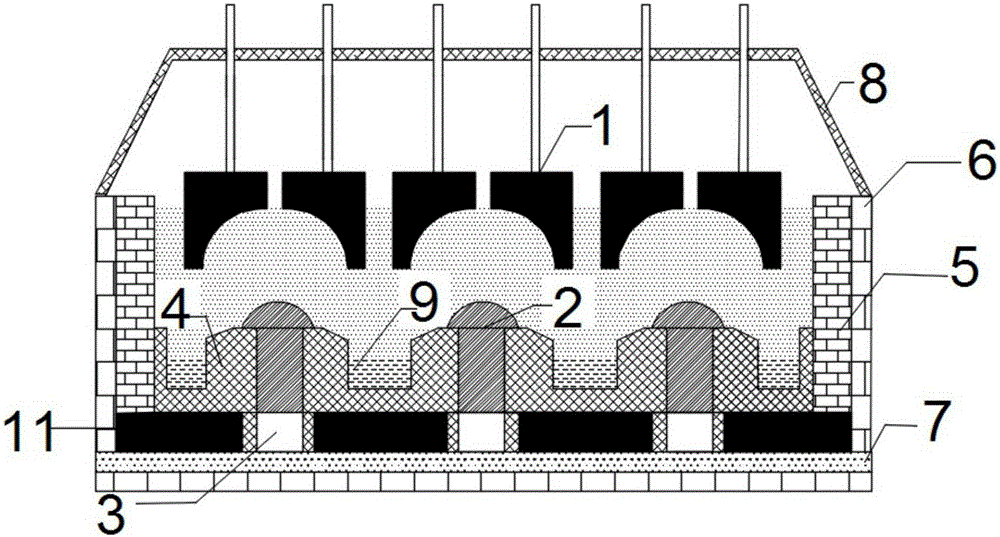

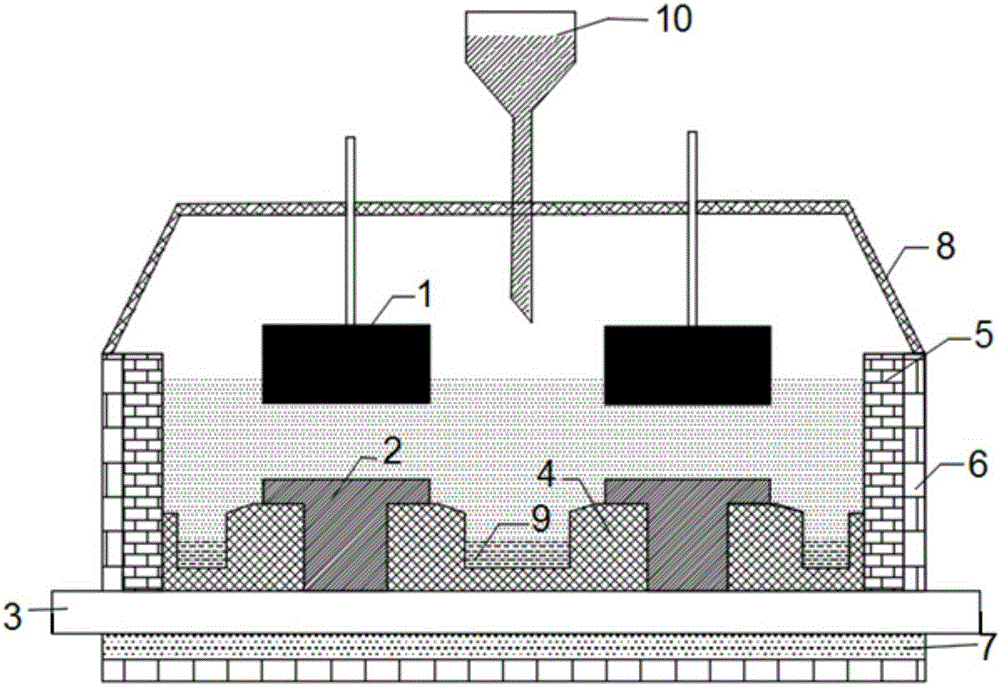

Novel rare-earth electrolytic bath

The invention relates to a novel rare-earth electrolytic bath. A gap is reserved in the center of each anode, and the bottom surface of each anode is a concave surface being concave from the periphery towards the center. A cathode is correspondingly arranged below each anode. The cathodes are buried in a protruding high-temperature-resisting material. The top of each cathode is an arc convex surface and protrudes out of the high-temperature insulating material. An electrical insulating layer is arranged between the high-temperature-resisting material and each cathode. A metal groove is formed between every two cathodes, and the high-temperature-resisting material is concave downwards to form the metal grooves. A cathode steel bar is located at the bottom of each cathode and connected with the cathode. The space between every two adjacent cathode steel bars is filled with a graphite block. An electrical insulating layer is arranged between each graphite block and the corresponding cathode steel bar. A feeder is arranged on the top of a bath body. According to the novel rare-earth electrolytic bath, the convex surfaces of the cathodes are higher than the high-temperature insulating layers, so that a high-temperature zone of the electrolytic bath is moved upwards. Through the metal grooves designed for the electrolytic bath, the contact area of metal and an electrolyte is reduced, re-dissolution of the metal is restrained, and the current efficiency is improved. The shapes of the anodes of the electrolytic bath are beneficial for discharging of anode bubbles.

Owner:CENT SOUTH UNIV

A vertical roller mill

InactiveCN102284322AImprove adaptabilityInorganic adjustment of grinding forceGrain treatmentsHydraulic cylinderSlag

The invention relates to a vertical roller mill, which comprises a vertical main rotating shaft arranged on a machine body, wherein a speed reducer and a motor are connected to the lower end of the main rotating shaft sequentially; a grinding bowl is arranged at the upper end of the main rotating shaft; the upper part of the inner side of the grinding bowl contacts a plurality of grinding rollers; the grinding rollers arranged on the grinding roller shaft by a bearing; the grinding roller shaft is connected to one end of a rocker arm; the middle part of the rocker arm is hinged to the machinebody; the other end of the rocker arm is hinged with the upper end of a hydraulic cylinder; the lower end of the hydraulic cylinder is arranged on the machine body; a central feed pipe which aligns with the grinding bowl downwards is arranged on the top of the machine body; and a discharge hole is formed below the grinding bowl on the machine body. The vertical roller mill has the advantages of convenience for oil injection, high yield, low energy consumption, large processing capacity, high efficiency and sealing performance, adjustable grinding force and the like, is easy to maintain and overhaul, and the technical problems of enrichment of steel slag and iron granules, high abrasion of the mill, difficulty of overhauling of equipment and the like are solved radically.

Owner:TIANJIN SUMEIR ENVIRONMENTAL PROTECTION INVESTMENT

Heat accumulation-exchange type heating stove and heating method thereof

InactiveCN101196369AExtend your lifeImprove work rateFurnace typesIncreasing energy efficiencyCombustionFlue gas

The invention provides a regenerative-recuperative combined heating furnace and the heating means, which relate to the technology field of industrial heating and recovery of waste heat. The invention is characterized in that: a regenerator and a heat exchanger are provided at the same time in the system; a soaking zone and a heating zone are arranged in front of the heating furnace; a preheating zone is provided on the tail of the heating furnace; multi-zone (point) heating system of the soaking zone, heating zone and preheating zone is adopted, the front of the heating furnace adopts regenerative combustion method and the back adopts recuperative combustion method; the preheating zone directly adopts flue gas waste heat to heat the materials. The objectives of the invention are to realize maximization of the heating furnace and smooth control of the furnace pressure, overcome the defects of the regenerative-recuperative heating furnaces and flue gas waste heat recovery technology and facilitate the low heat value fuels like pure blast furnace gas being applied in the heating furnace. The heating furnace has smooth pressure and long service life. The implementation of the invention realizes the maximization of the heating furnace, improves the flue gas waste heat utilization rate and reaches the aims of improving the pressure condition in the furnace, reducing air draft and sparking and energy conservation and emission reduction, etc.

Owner:蔡九菊

Light guide plate, planar illuminator using the same and liquid crystal display apparatus

InactiveCN102116892AImprove utilization efficiencyUniform injectionPrismsMechanical apparatusLiquid-crystal displayLight guide

The invention provides a light guide plate, a planar illuminator using the same and a liquid crystal display apparatus. The light guide plate made of a transparent resin is used for converting light of light sources into planar light. The light guide plate comprises a light exit plane having a rectangular outer shape; four light entrance planes which are connected to four sides of the light exit plane and are substantially orthogonal to the light exit plane; and a backside which is planes opposed to the light exit plane and includes four inclined planes inclined to be farther from the light exit plane toward a center from the four light entrance planes, wherein a minimum thickness is in the four light entrance planes and a maximum thickness is in the center from the four light entrance planes.

Owner:FUJIFILM CORP

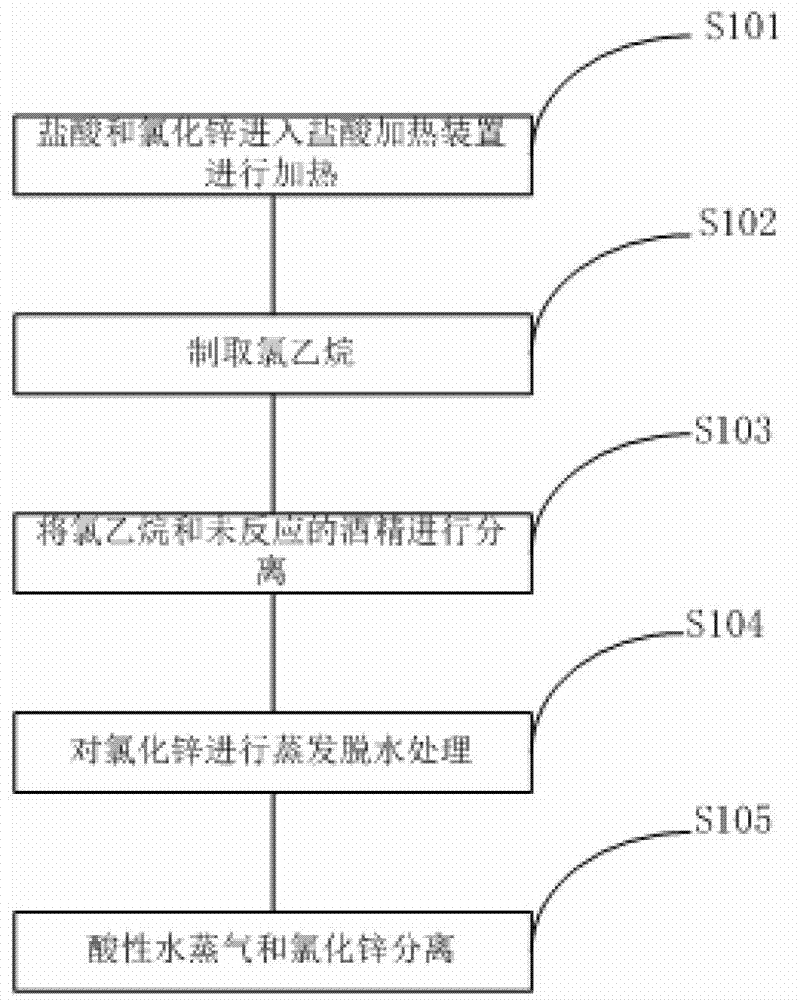

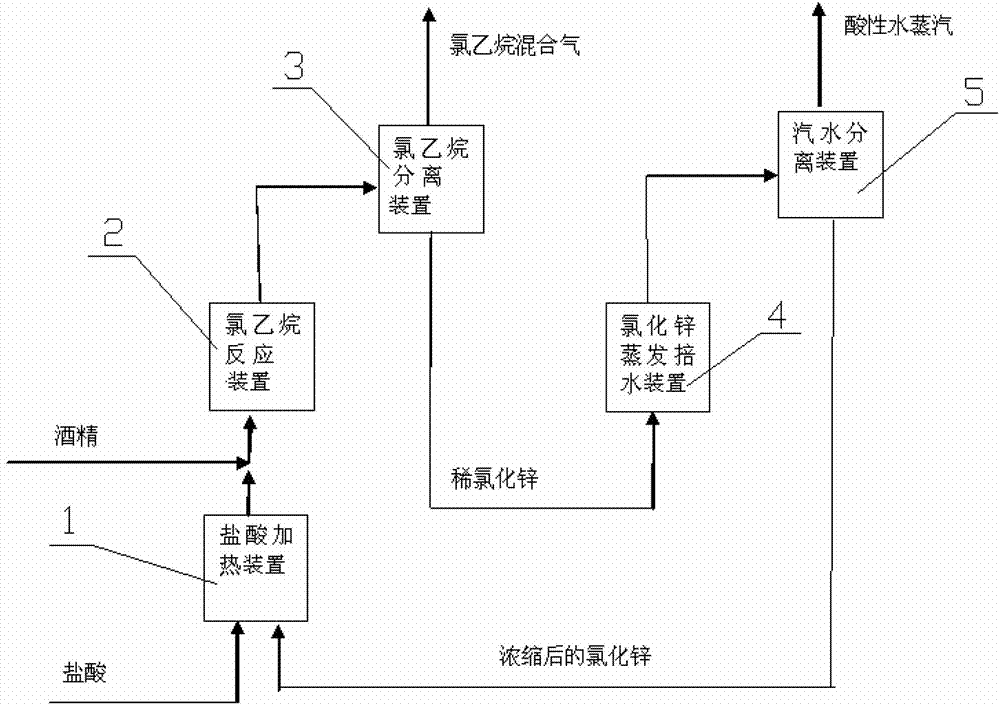

Method and system for producing ethyl chloride

InactiveCN103044187AIncrease productivityExpand the scope of operationChemical industryHalogenated hydrocarbon preparationHigh concentrationReaction rate

The invention discloses a method for producing ethyl chloride, which comprises steps as follows: hydrochloric acid and zinc chloride after concentration by evaporation enter a hydrochloric acid heating unit from the bottom to be heated, enter an ethyl chloride reactor, and are subjected to thermal separation of the ethyl chloride and mixed solution; the separated magnesium chloride enters an evaporation dehydrator to be heated; the zinc chloride solution is concentrated; and the high-concentration zinc chloride naturally flows to the lower part of a hydrochloric acid evaporator to be recycled. The invention can be matched with a climbing film graphite evaporator with larger heat transfer area to implement the large-size ethyl chloride reactor and enhance the level of the ethyl chloride industrialization device; the reaction rate and raw material conversion rate are enhanced; graphite is used as the distributor of the ethyl chloride reaction part, so the corrosion resistance is high; the steel liner polytetrafluoroethylene cylinder and pipeline are adopted, thereby resisting corrosion and enhancing the operating pressure and equipment utilization ratio; and in addition, the invention is convenient to operate, enhances the production efficiency of ethyl chloride, and has favorable application value.

Owner:JIANGSU YINZHU CHEM GROUP

Planar illumination device

InactiveCN101371074AUniform injectionAchieve thinningMechanical apparatusPoint-like light sourceLight guideMechanical engineering

A planar illumination device that is thin and lightweight, can emit illumination light uniform and having no irregularity in brightness, and can be increased in size. The planar illumination device has a light source and at least one light guide plate placed facing the light source. The light guide plate has a light entrance surface facing the light source and a light exit surface including one side of the light entrance surface. The light guide plate is shaped such that the farther from the light entrance surface, the greater the thickness of the plate in the direction normal to the light exit surface. The light guide plate contains scattering particles that scatter light entering from the entrance surface and propagating in the plate.

Owner:FUJIFILM CORP

Production method of rich-titanium material

ActiveCN103710551ASimple equipmentEasy to operateTitanium dioxideMagnetic separationProduct processingPelletizing

The invention relates to a production method of a rich-titanium material. The production method comprises the following steps: pre-oxidation, pre-reduction, multistage magnetic separation, airtight furnace smelting titanium slag granulation, and finished product processing and grading, wherein the pre-oxidation and the pre-reduction are carried in the same rotary kiln. According to the invention, the process of titanium concentrate-rotary kiln pre-reduction-airtight electric furnace smelting is adopted for the first time and the process of bonding and pelletizing of the titanium concentrate is omitted; besides, the production method of rich-titanium material is simple in used equipment, easy to operate, short in flow process and low in reduction temperature; high metallization ratio can be obtained; consequently, the energy consumption of the electric furnace during smelting is greatly reduced.

Owner:LOMON BILLIONS GRP CO LTD

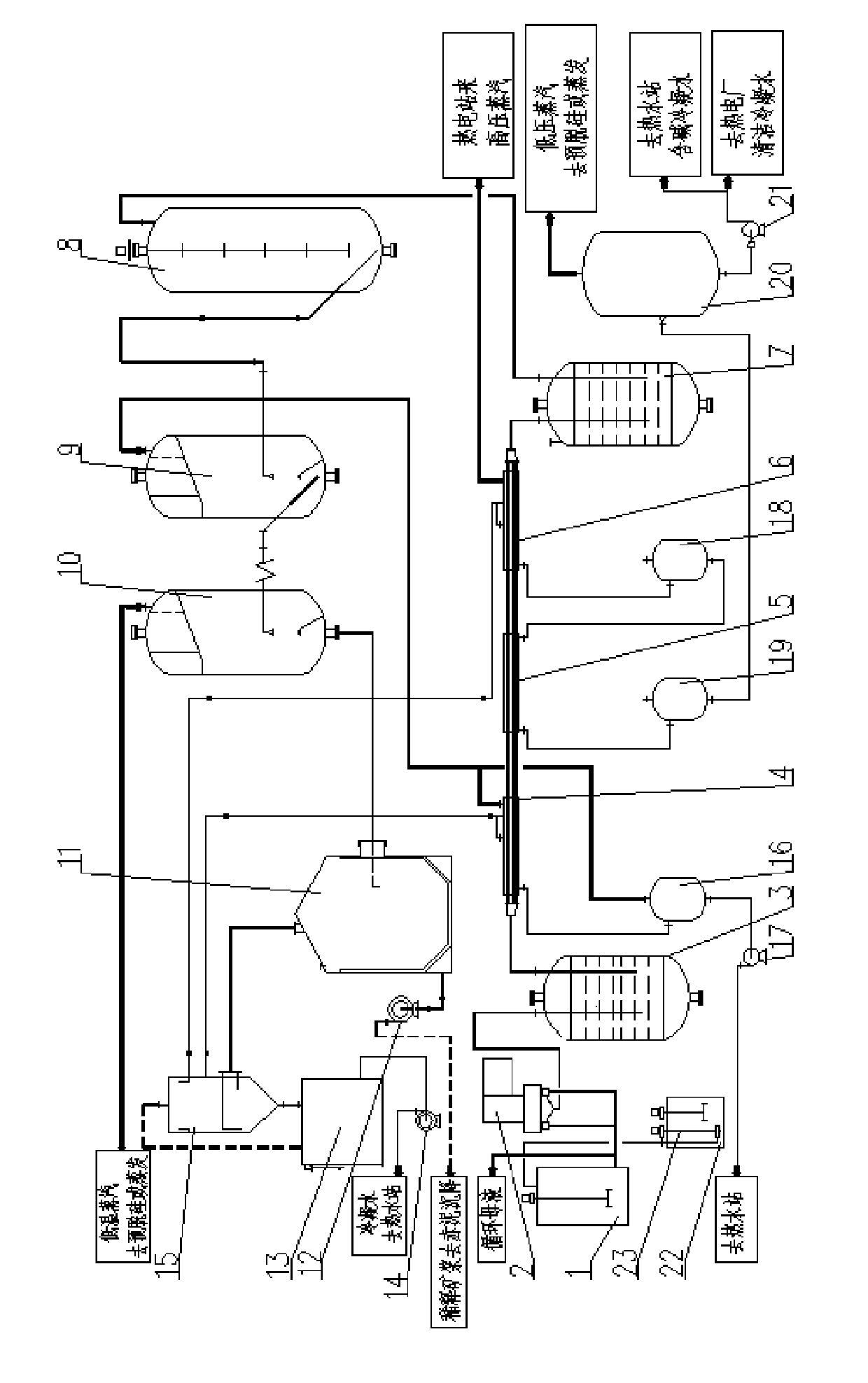

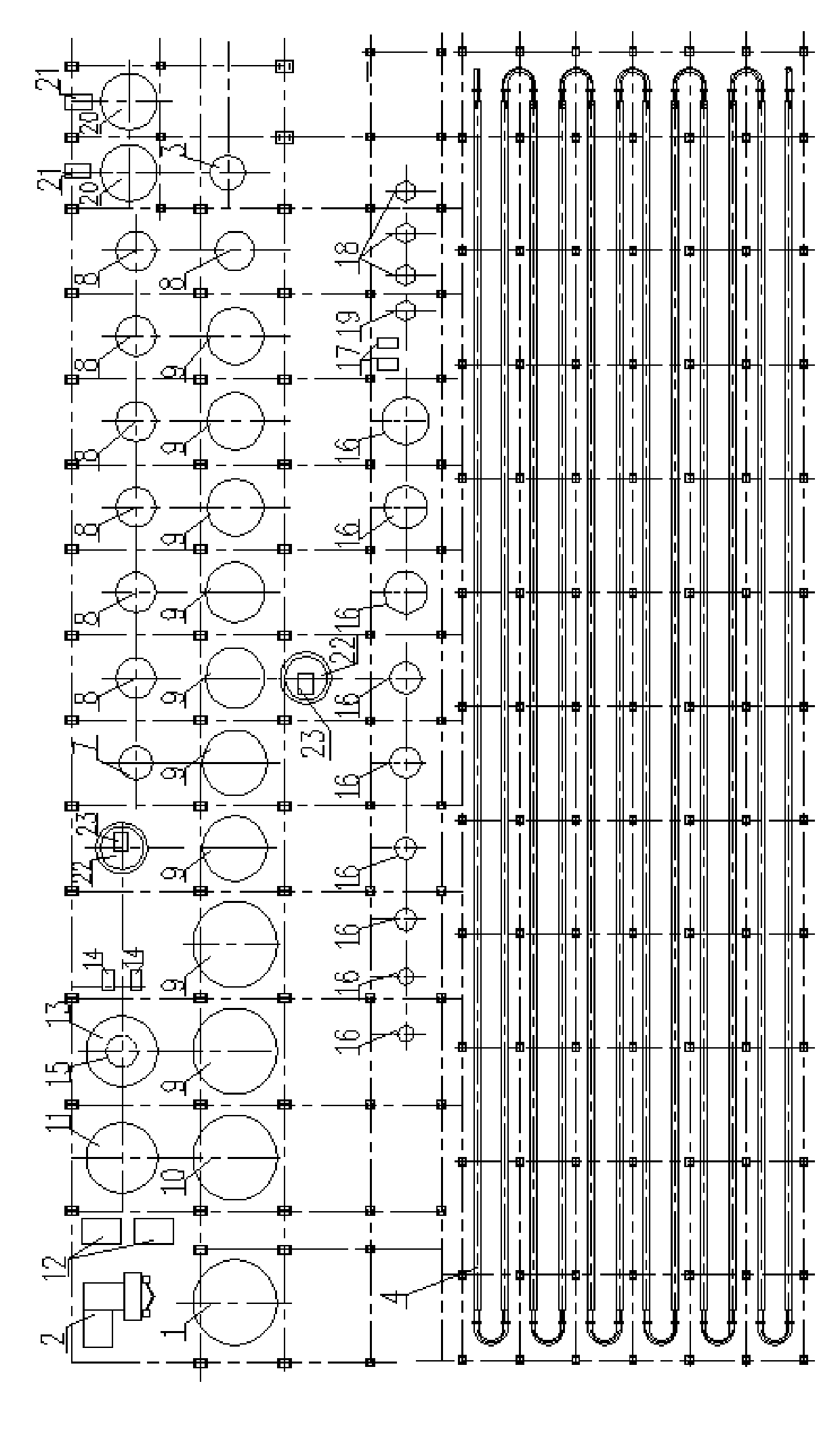

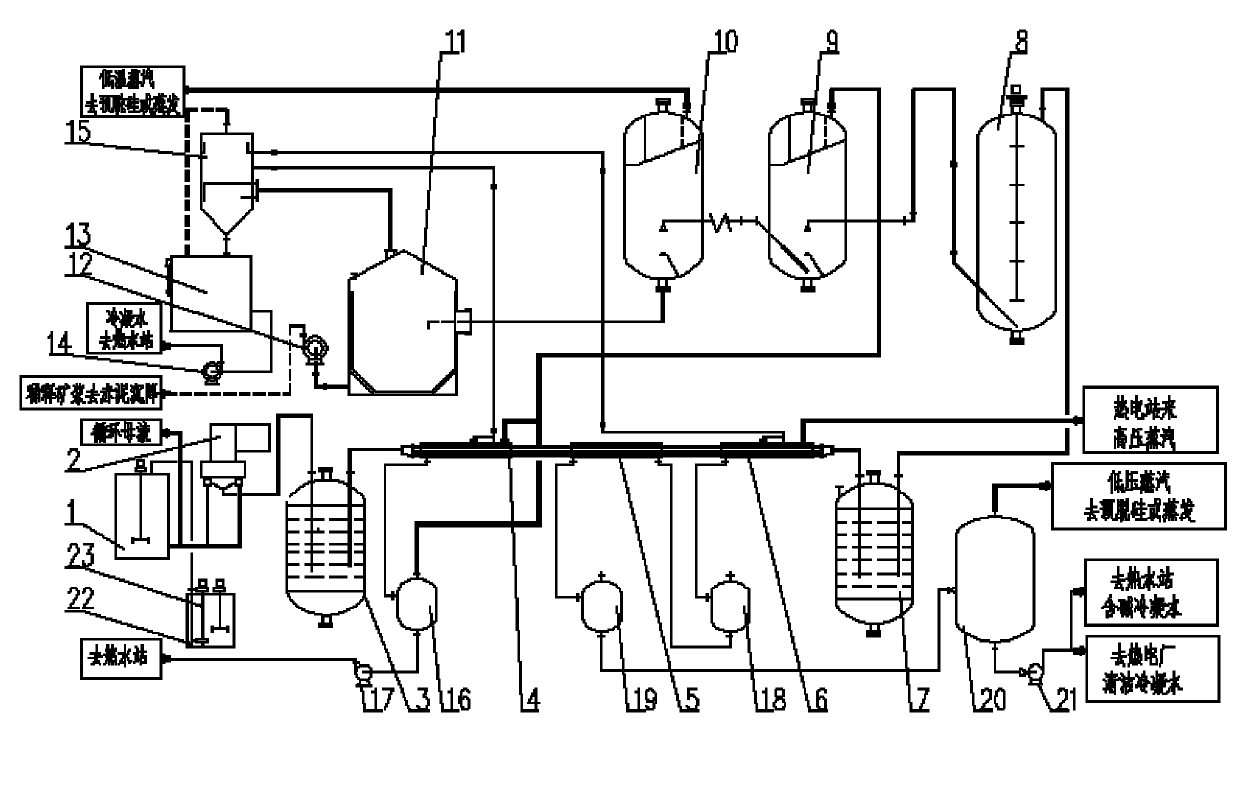

Dissolving-out process for large-sized pipeline remaining tank of diasporite bauxite ore

InactiveCN101767806ALarge pulp capacityImprove heat utilizationAluminium oxides/hydroxidesBoehmiteMother liquor

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Method for preparing light olefins from ethanol and methanol

InactiveCN101659587AIncreased level of controlReduce energy consumptionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveEnergy consumption

The invention relates to a method for preparing light olefins from ethanol and methanol. In the method, an ethanol raw material and a methanol raw material undergo a dehydration reaction in the presence of a molecular sieve catalyst. The method of the invention can produce a maximum amount of ethylene and propylene, reduce energy consumption and improve the control level of reaction conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Basic module of extra-large marine floating structure

PendingCN107097913AStrong ability to resist wave-induced movementStrong anti-sway stabilityClimate change adaptationVessel safetyWater volumeLoad resistance

The invention discloses a basic module of an extra-large marine floating structure. The basic module is composed of a lower-portion floating body structure, an upper-portion structure and middle connecting structures. The lower-portion floating body structure comprises multiple dispersedly arranged floating bodies and is wholly in an extra-large water plane area form, the sum of the water discharging areas of the floating bodies is greater than the equivalent-quantity water volume of the whole weight of the floating structure, the upper-portion structure is a frame structure or a box body structure, the middle connecting structures are dispersedly arranged in space, and the lower-portion floating body structure is connected with the upper-portion structure through the middle connecting structures to form a hyperstatic combined space structure. Two basic modules can form the kilometer-level extra-large marine floating structure through one-time splicing. The basic module has very strong wave exciting load resistance and load change capability, has very strong sway-resistant stabilizing rigidity and can remarkably decrease relative motion during basic module splicing and connector load after splicing.

Owner:TANGSHAN REMOVABLE ISLAND MARINE HEAVY IND CO LTD

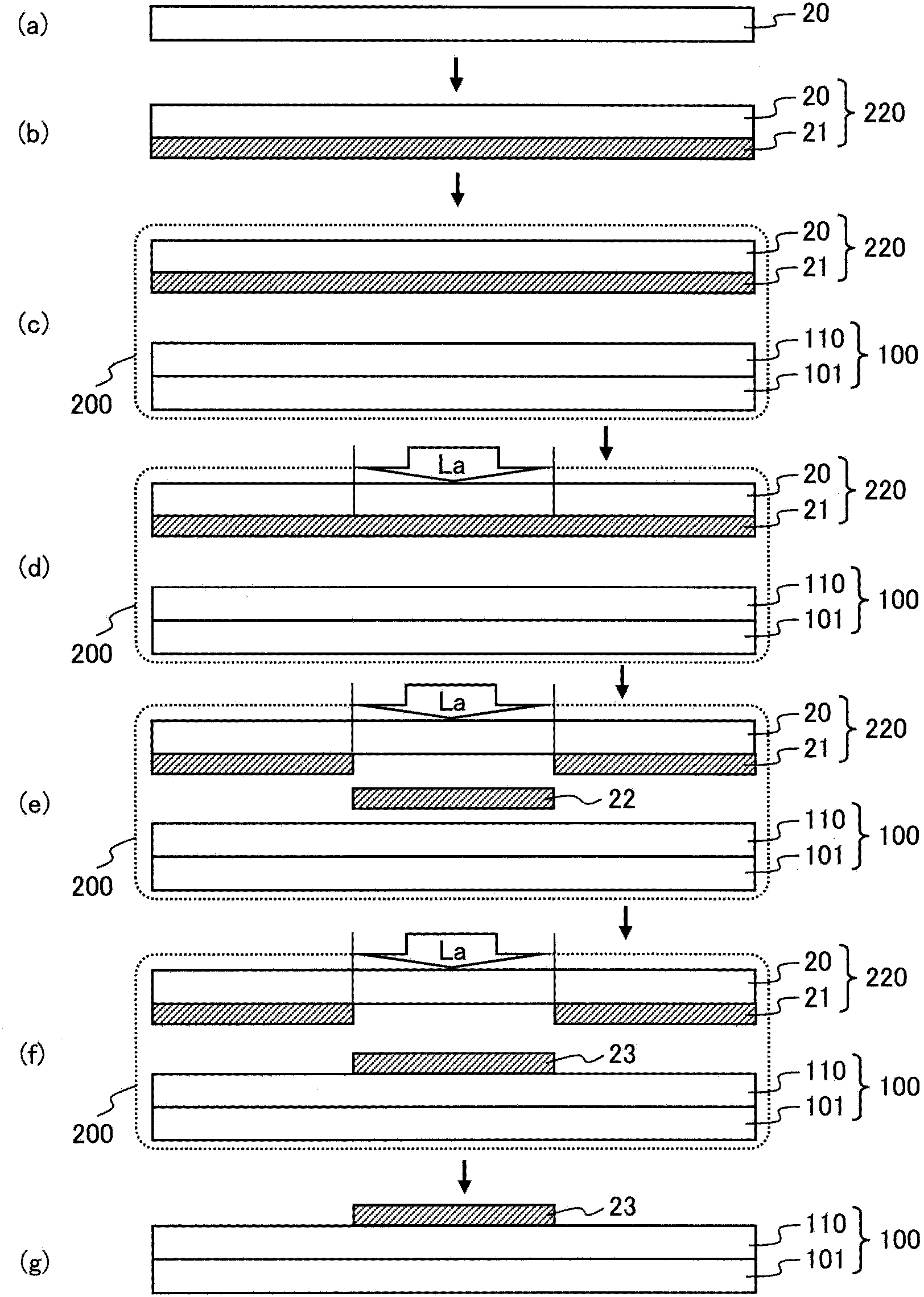

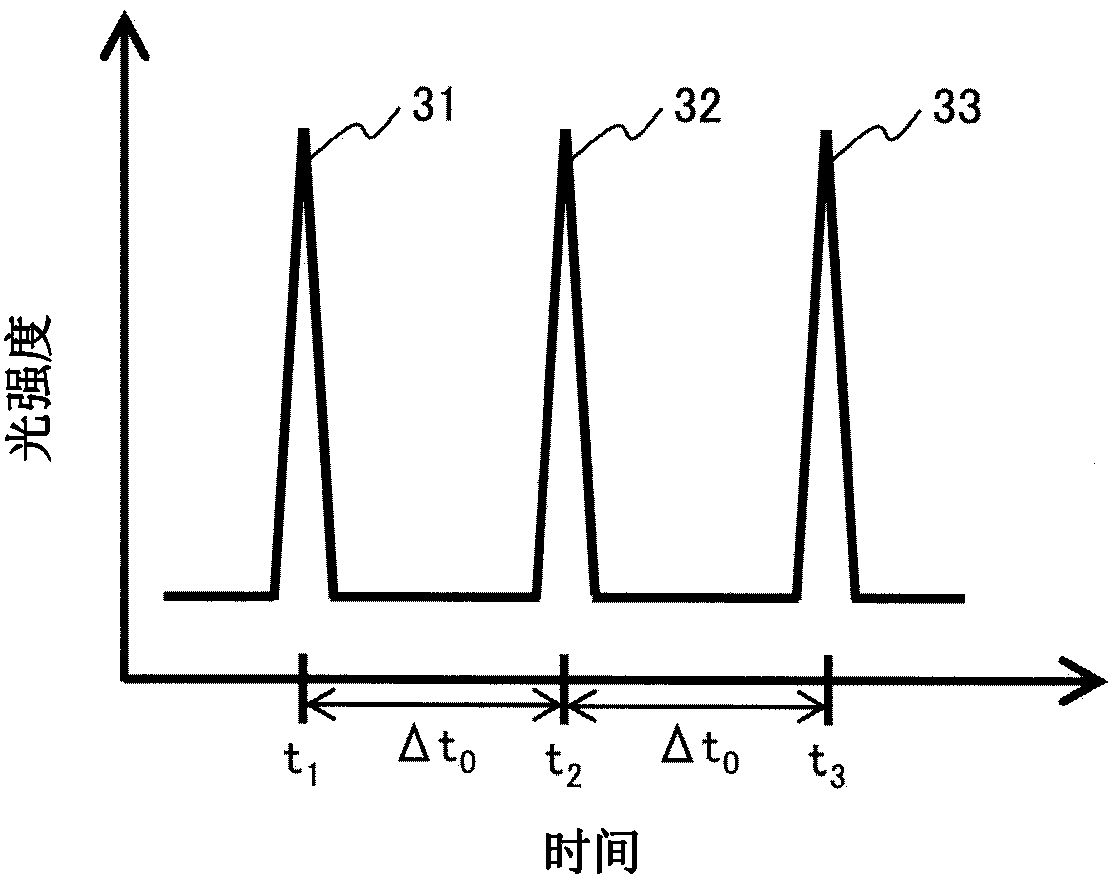

Laser transfer method and apparatus therefor

InactiveCN103568614ARealize large-scaleAchieve high precisionDuplicating/marking methodsSolid-state devicesEvaporationOptoelectronics

The invention relates to a laser transfer method and apparatus therefor, and to an organic EL panel, and an organic EL layer for forming lighting layer of the organic EL panel without using an evaporation mask. A circuit substrate (101) with an organic EL component forming portion is arranged opposite to an organic EL film (21) and on a supporting substrate (20), and a metallic subject substrate (220) is subjected to laser to generate chock wave in the supporting substrate (20). An organic EL layer is formed on the circuit substrate (101) side. In this way, organic EL panels can be manufactured in high precision and large frame and at a low cost.

Owner:HITACHI HIGH-TECH CORP

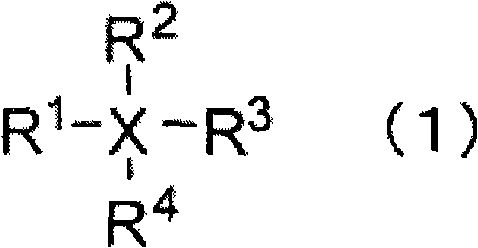

Plate type air preheater

ActiveCN1884915AEasy to blow sootSolve the problem of equipment dust accumulationCombustion processIndirect carbon-dioxide mitigationHeat transfer efficiencyEngineering

The invention relates to a sheet air preheating device, which comprises: a box, a heat exchange element, and an air-smoke entrance tubular box, wherein said box is arranged with sheet heat exchange element formed by sheet beam with at least one layer of one sheet beam module; the upper end of sheet beam is through to the smoke inlet tubular box and the air outlet tubular box, while the lower end is through to the smoke outlet tubular box and the air inlet tubular box; the sheet beam module is formed by layered ripple sheets; the air-smoke channels of sheet beam module are sealed channels with reversed direction. The invention uses reverse flow to exchange heat, with high efficiency, small volume, light weight and low cost.

Owner:GANSU LANPEC TECH +2

Furnace bottom anti-clogging boiling chloridizing furnace with chlorine uniform distribution

The invention relates to an evenly distributed chlorine anti-blockage boiling chlorination furnace bottom which can solve the problems of blockage of a sieve plate of the existing boiling chlorination furnace and channeling and dead zones of airflow, a support sleeve is arranged at the middle part of an outer shell of the furnace bottom, an isolation plate is arranged on the support sleeve, a plurality of chlorine distribution pipes are evenly distributed on the isolation plate, whirlpool rods which can ascend, descend and rotate freely are arranged in the chlorine distribution pipes, and an annular chlorine pipe is arranged in the outer shell of the furnace bottom. A fixed sleeve is arranged at the periphery of the isolation plate, and refractory fillers which consist of fireclay refractory materials containing 45 percent-70 percent silicon oxide are filled among the chlorine distribution pipes in the fixed sleeve. A slag discharge pipe is penetrated in the refractory fillers, the isolation plate and the middle part of the furnace bottom. The adoption of the boiling chlorination furnace bottom can lead chlorine to enter the chlorination furnace in the whirlpool form, form a stable flow layer in the furnace, realize the large-scale chlorination furnace and the stable operation, solve the problems of material leakage and blockage of the sieve plate and prevent the occurrence of channeling and dead zones.

Owner:锦州金业化冶技术有限公司

Video display apparatus

InactiveCN101685209AHigh strengthImprove rigidityStatic indicating devicesNon-linear opticsDisplay deviceEngineering

The present invention provides a simply usable shield cover capable of enhancing the mechanical strength of a set even if a display device is decreased in thickness. In a video display apparatus including a base chassis on a front surface of which a displaying member is arranged and on a back surface of which a unit for driving and controlling the display device is arranged, and a plurality of frames arranged on the back surface of the base chassis in parallel with each other, a shield cover is attached to the plurality of frames to extend over those to form a crosslink structure.

Owner:HITACHI LTD

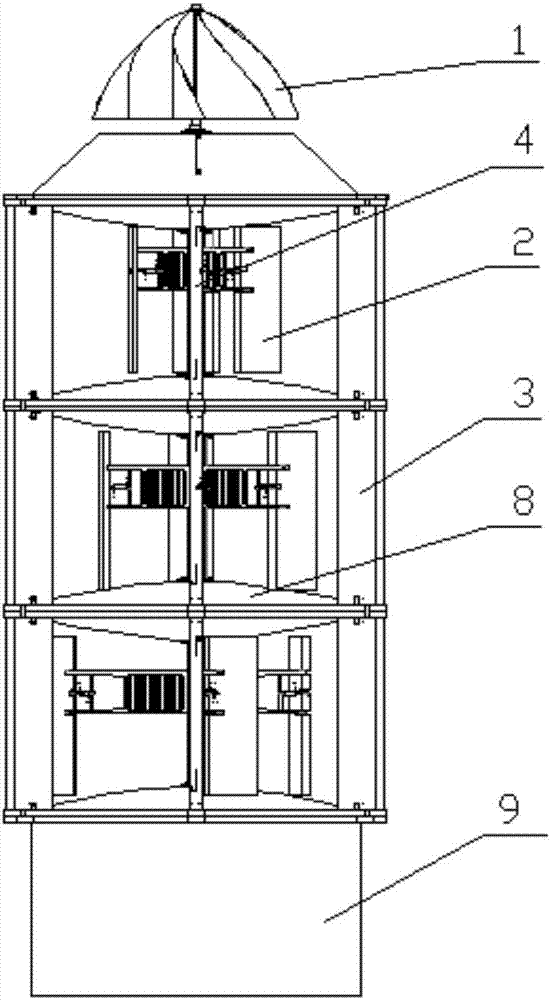

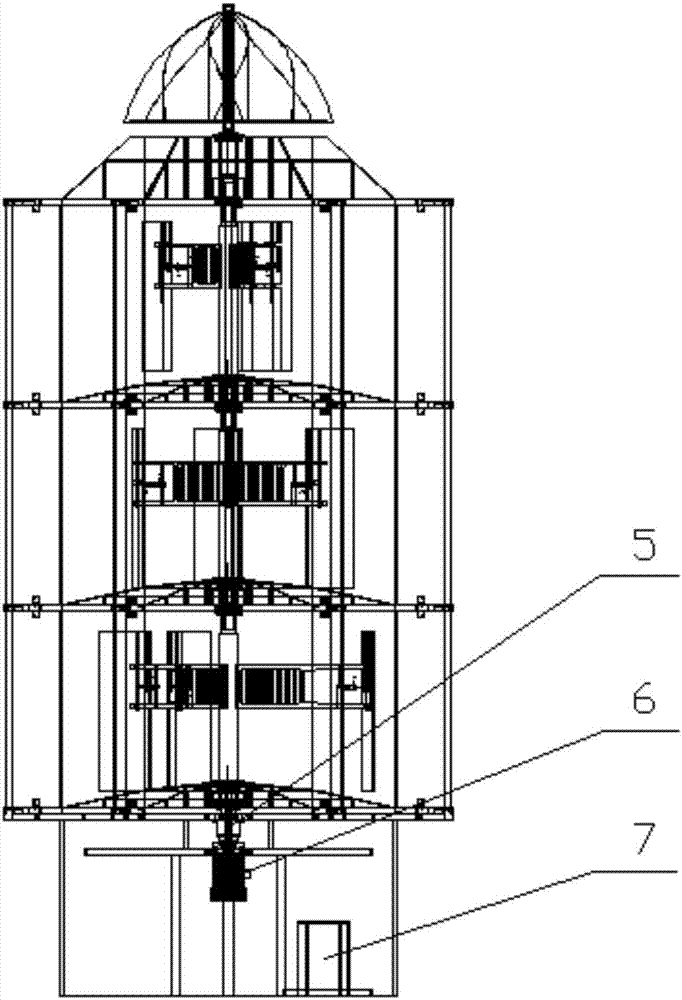

Modular frame type high-efficiency vertical axis wind turbine

ActiveCN107061151ASave design costSave installation costsMachines/enginesWind motor with perpendicular air flowImpellerEngineering

The invention relates to a modular frame type high-efficiency vertical axis wind turbine. The modular frame type high-efficiency vertical axis wind turbine comprises a wind wheel spindle, a step-up gear box, a permanent magnet synchronous generator, a wind power control cabinet and a peripheral foundation, and is characterized by further comprising a resistance type wind wheel, a force lifting type wind wheel, wind direction flow guide plates and transverse supporting structures; the resistance type wind wheel is mounted on the top of the wind turbine, and the lower part of the resistance type wind wheel is connected with the wind wheel spindle; the force lifting type wind wheel has a three-layer stacked impeller structure, a corresponding section of the wind wheel spindle is arranged in the center of each layer of the force lifting type wind wheel, each layer comprises a plurality of blades, each blade is connected with the corresponding section of the wind wheel spindle through a wind wheel support, and the different sections of the wind wheel spindle are flexibly connected through shaft sleeves; all the blades on the three layers are arranged in a staggered manner, projections of all the blades on the horizontal plane are distributed in a circular area, and the number of the blades in each layer is an odd number; and each wind wheel support comprises a rectangular frame, and one end of each rectangular frame is connected with the wind wheel spindle.

Owner:HEBEI UNIV OF TECH

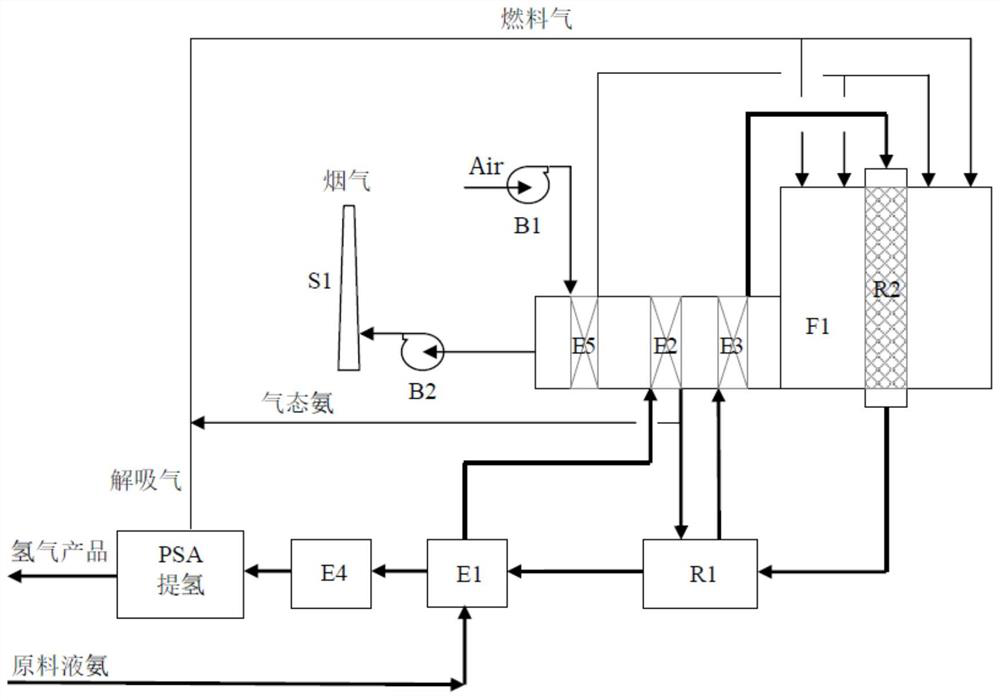

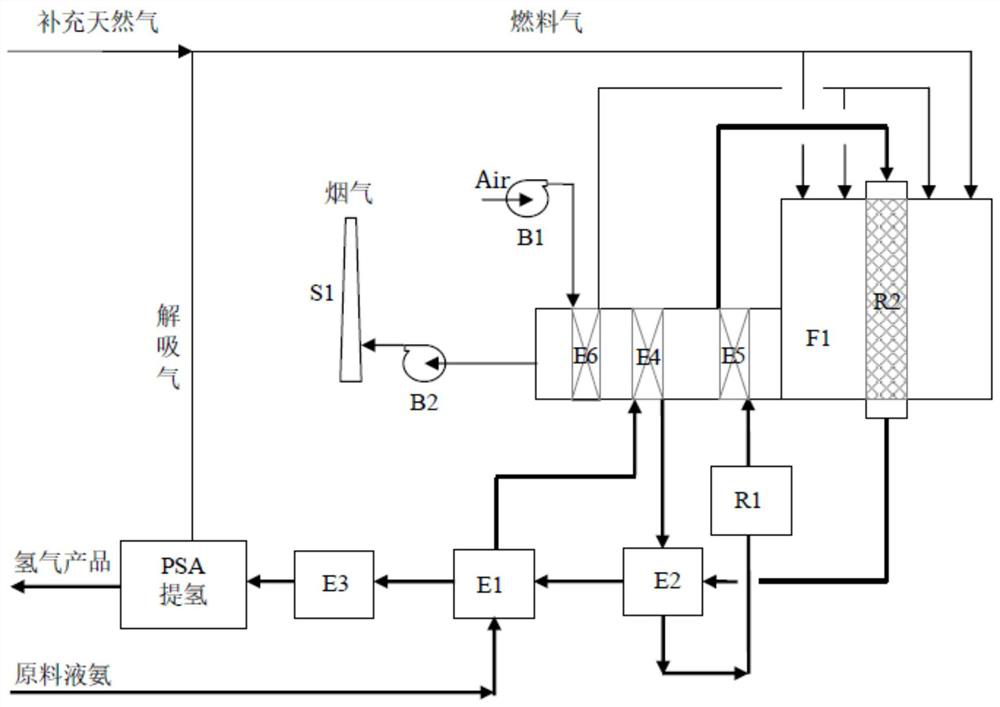

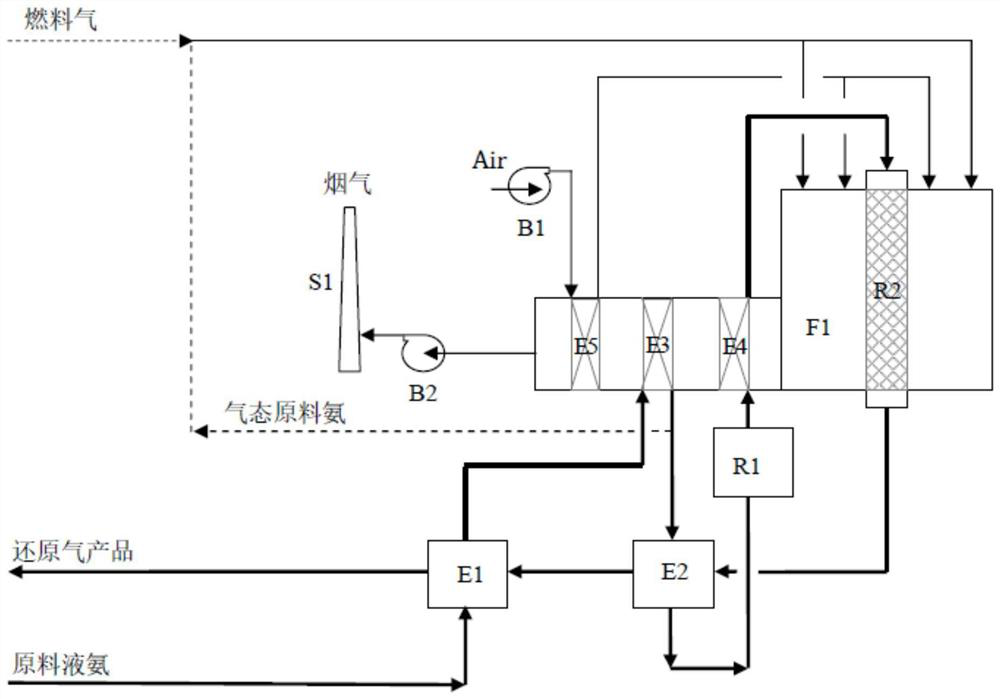

Method for preparing hydrogen or reducing gas by ammonia cracking through two-stage process

ActiveCN113896168AReduce pyrolysis reactionSave heatHydrogen productionHydrogen/synthetic gas productionThermodynamicsProcess engineering

The invention particularly relates to a method for preparing hydrogen or reducing gas by ammonia cracking through a two-stage process, which comprises the following steps that firstly, raw material liquid ammonia iscompletely gasified and heated through a heat exchange gasification system, then enters a first-stage heat exchange ammonia cracking reaction system, and a partial ammonia cracking reaction is conducted, the reaction gas discharged from the first-stage heat exchange ammonia cracking reaction system enters the second-stage high-temperature ammonia cracking reaction system to carry out a residual ammonia cracking reaction, and the second-stage high-temperature ammonia cracking reaction gas sequentially enters the first-stage heat exchange ammonia cracking reaction system and the heat exchange gasification system to obtain the reducing gas after heat is recovered step by step. And when the reducing gas needs to be subsequently prepared into hydrogen, the reaction gas is cooled to normal temperature after heat recovery, and then enters a PSA hydrogen extraction system to prepare the product hydrogen. The two-stage ammonia cracking method is adopted, the gas heat of a second-stage high-temperature ammonia cracking reaction outlet is fully utilized, the external heat supply amount is saved, and meanwhile, the investment of a second-stage high-temperature ammonia cracking reaction system is reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com