Furnace bottom anti-clogging boiling chloridizing furnace with chlorine uniform distribution

A boiling chlorination furnace, chlorine gas technology, applied in the direction of titanium halide, etc., can solve the problems of sieve plate blockage, air channel flow and dead zone, and achieve the effect of preventing channel flow, improving service life, and preventing channel flow and dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments are described below with reference to the drawings.

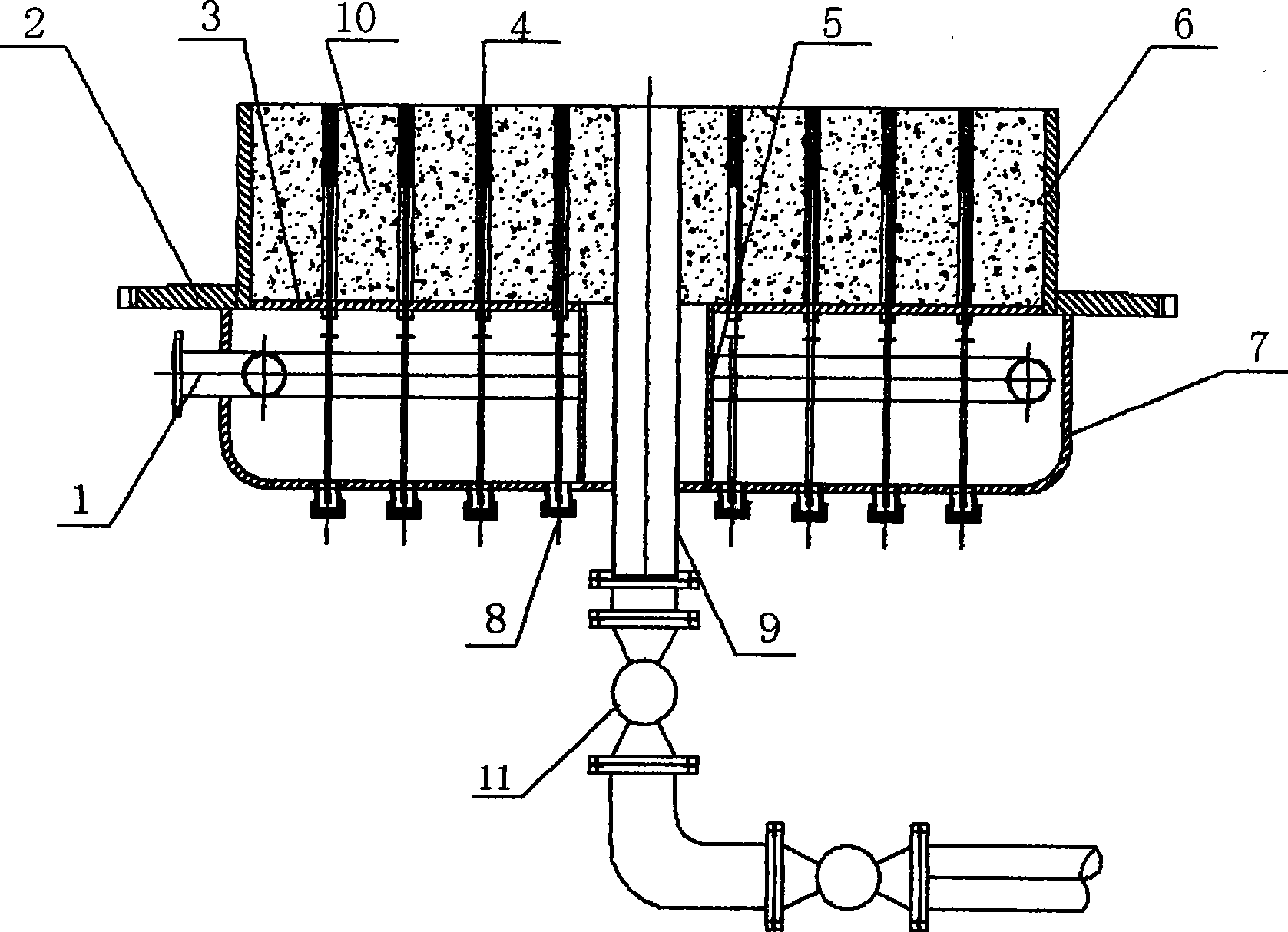

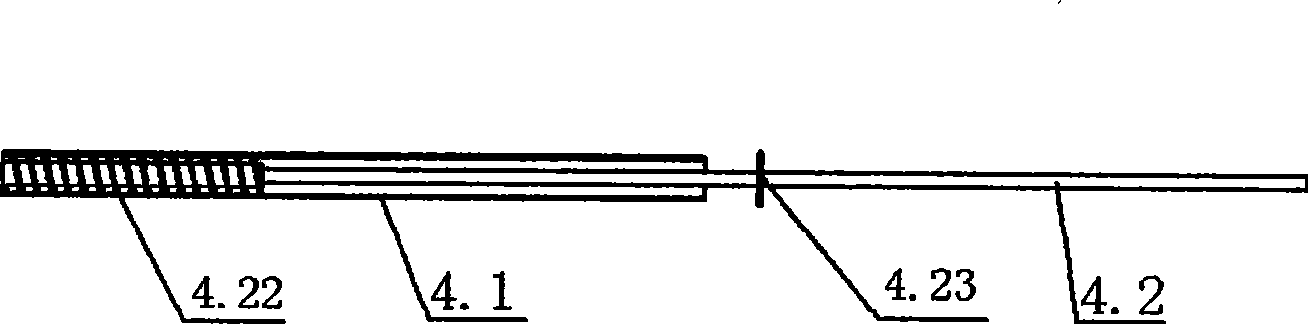

[0018] A kind of uniform distribution of chlorine gas to prevent clogging the bottom of boiling chlorination furnace. A support sleeve 5 is installed in the middle of the shallow cylindrical furnace bottom shell 7, and an isolation plate 3 is installed on the support sleeve 5. A number of pores are evenly distributed on the isolation plate 3, that is, pore distribution On concentric circles with the same spacing, the pore spacing on each circle is also the same. A chlorine gas distribution pipe 4 is installed in each air hole. The chlorine gas distribution pipe 4 is composed of a sleeve 4.1 and a swirl rod 4.2 that can be freely lifted and rotated in the sleeve 4.1. The casing 4.1 is fixed on the isolation plate 3 by welding or thermal expansion or welding combined thermal expansion. The upper surface of the swirl rod 4.2 has a spiral groove 4.22, the middle part of the swirl rod 4.2 has a baffle 4.23, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com