Modular frame type high-efficiency vertical axis wind turbine

A frame type, wind turbine technology, applied in the field of modular frame type high-efficiency vertical axis wind turbines, can solve the problems of low utilization rate of wind energy, narrow application range, poor startability, etc., to solve technical and cost problems, reduce Manufacturing cost, effect of improving starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

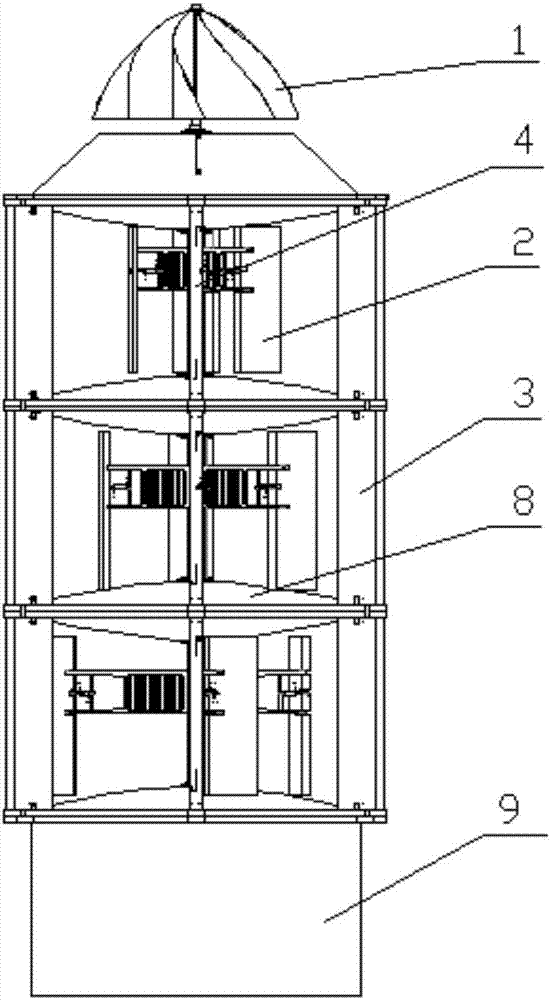

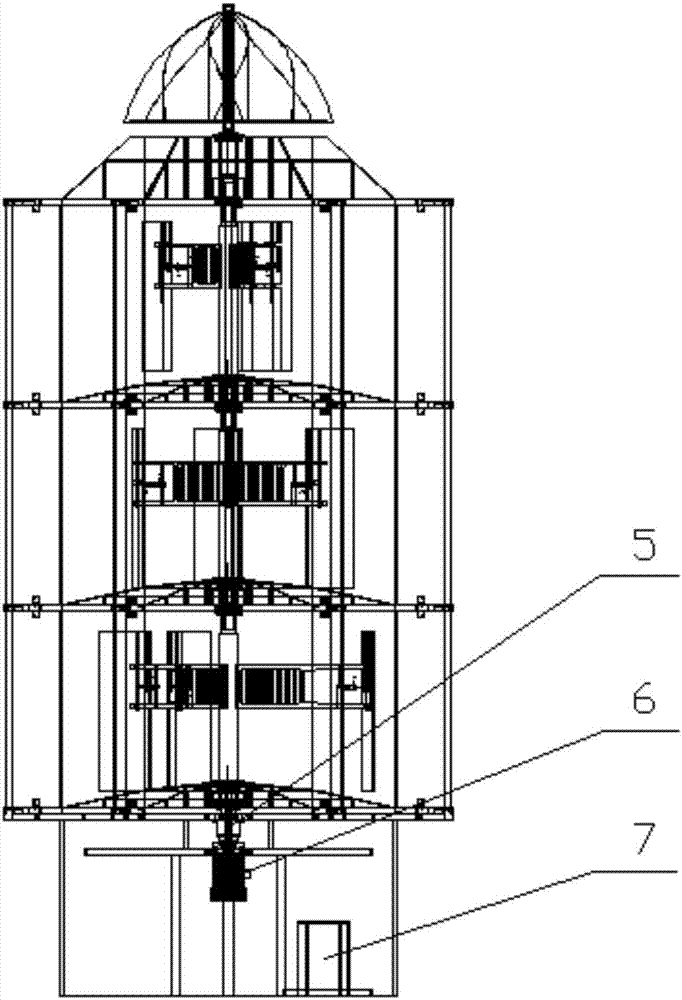

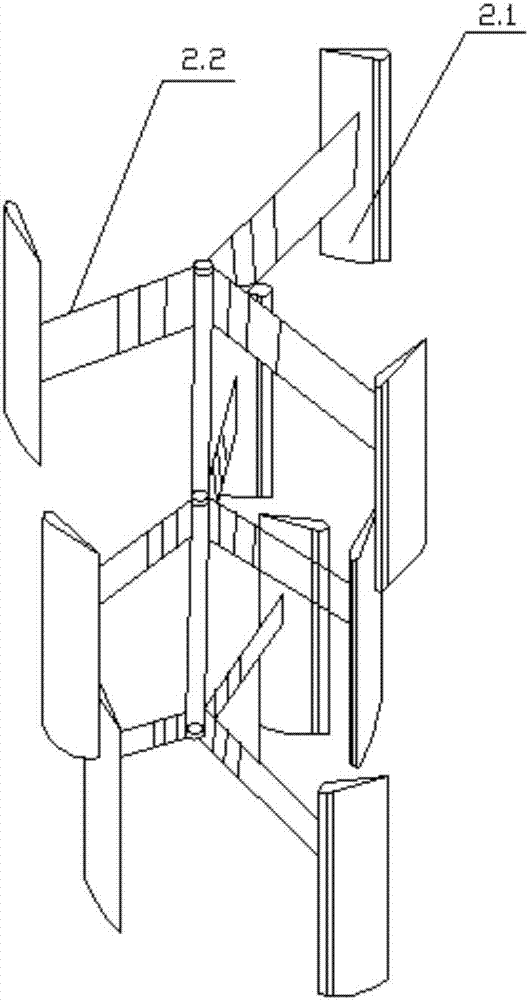

[0035] The modular frame-type high-efficiency vertical axis wind turbine in this embodiment includes a wind rotor main shaft 4, a speed-increasing gearbox 5, a permanent magnet synchronous generator 6, a wind power control cabinet 7, a peripheral foundation 9, a resistance type wind wheel 1, and a lift type Wind wheel 2, wind deflector 3 and lateral support structure 8; the resistance type wind wheel 1 is installed on the top of the wind turbine, and the lower part of the resistance type wind wheel 1 is connected with the wind wheel main shaft 4; the lift type wind wheel 2 It is a three-layer laminated impeller structure, each layer is equipped with a section of wind rotor main shaft 4, and each layer includes a number of blades 2.1, each blade is connected to the corresponding wind rotor main shaft 4 through the wind wheel bracket 2.2, each The main shaft of the section wind rotor is flexibly connected through the shaft sleeve; all the blades on the three layers are arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com