Patents

Literature

169results about How to "Increase starting torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

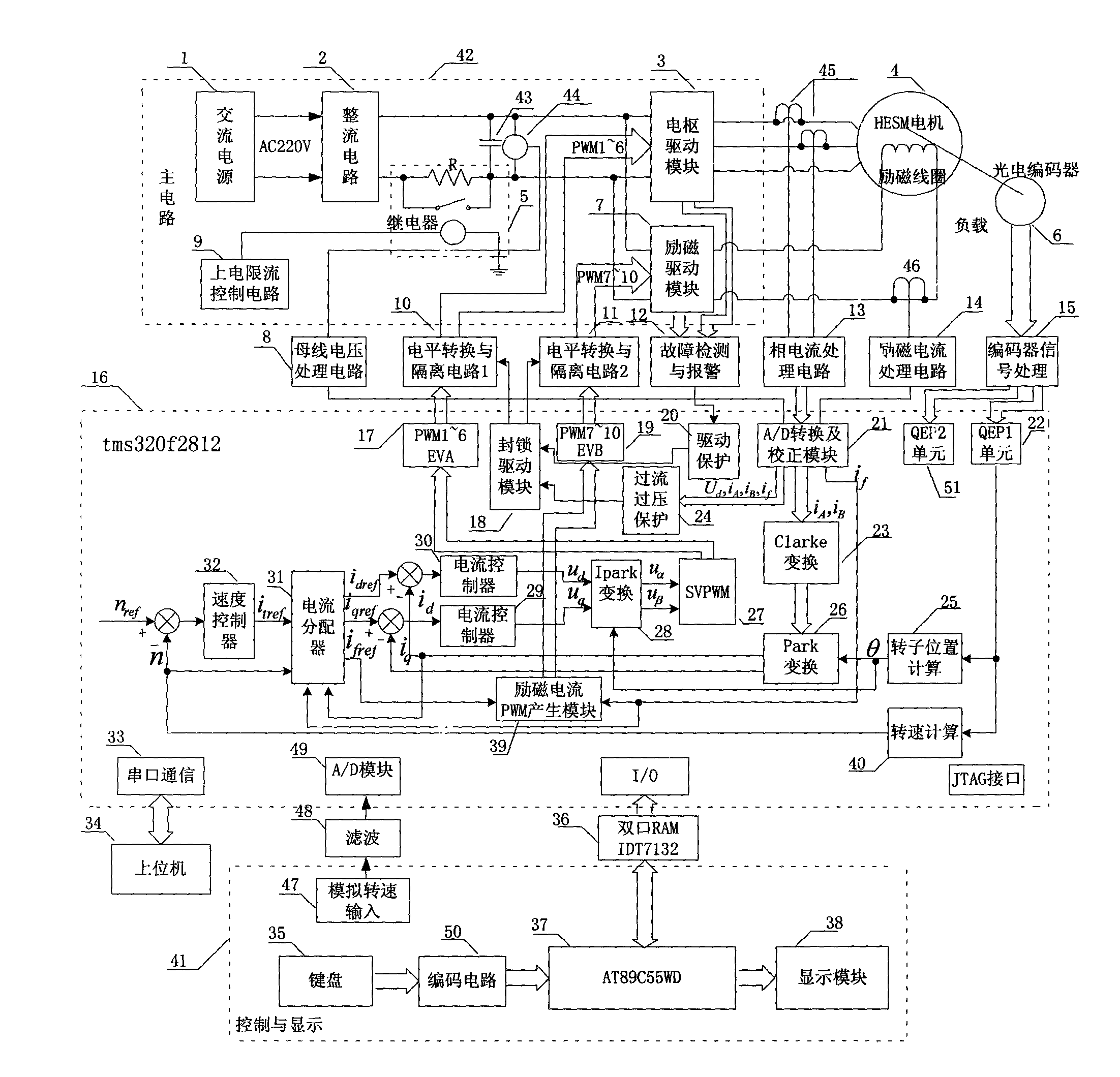

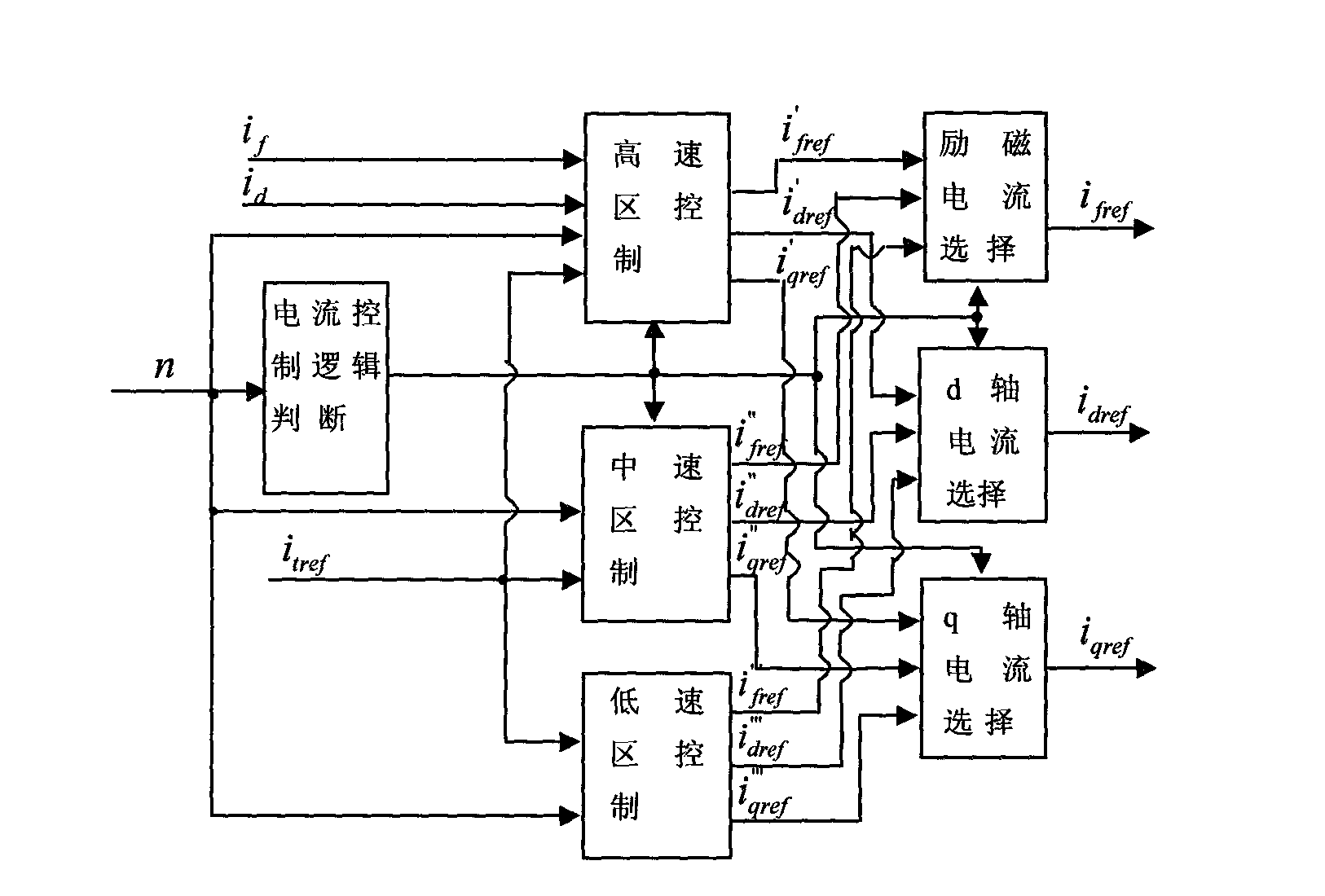

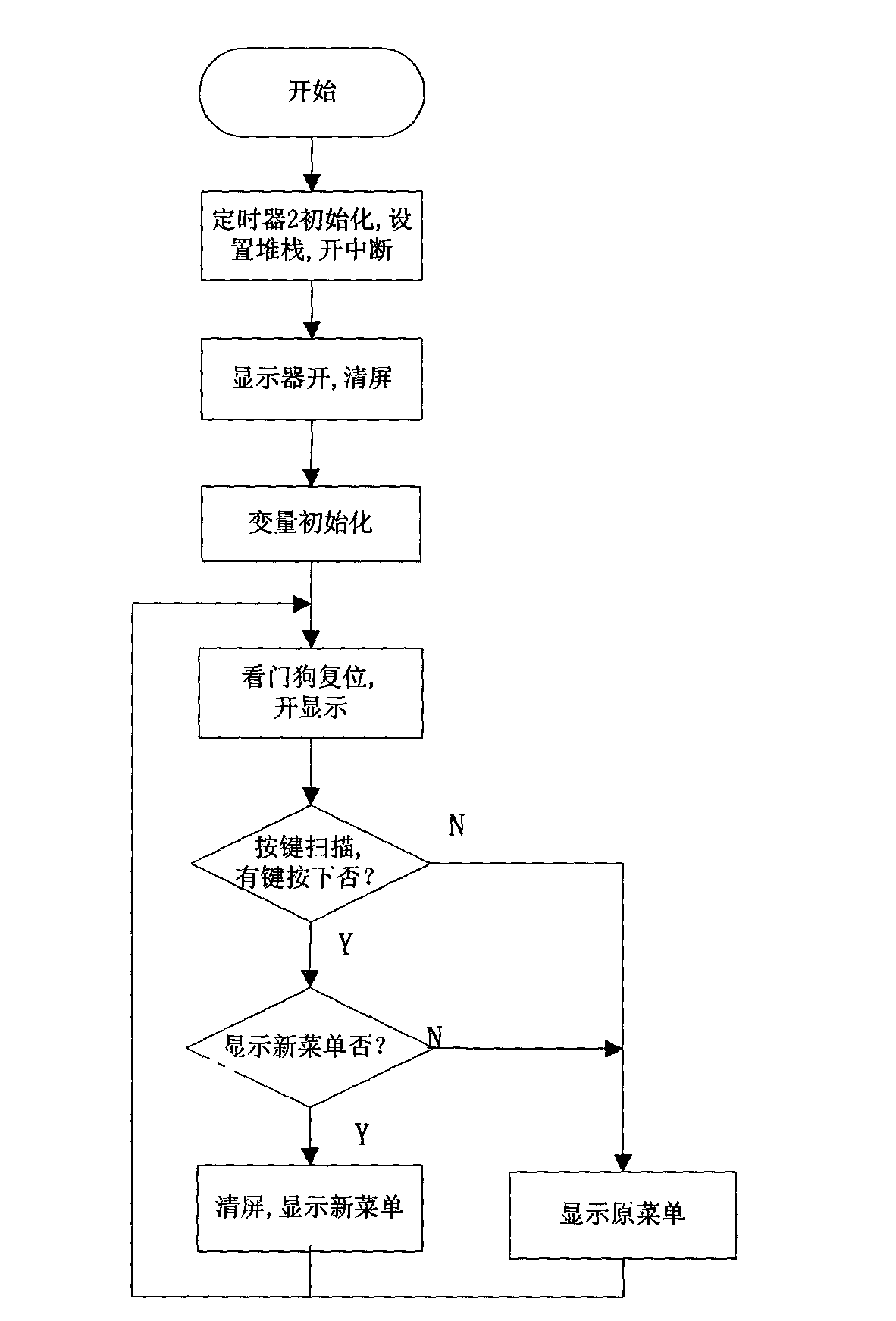

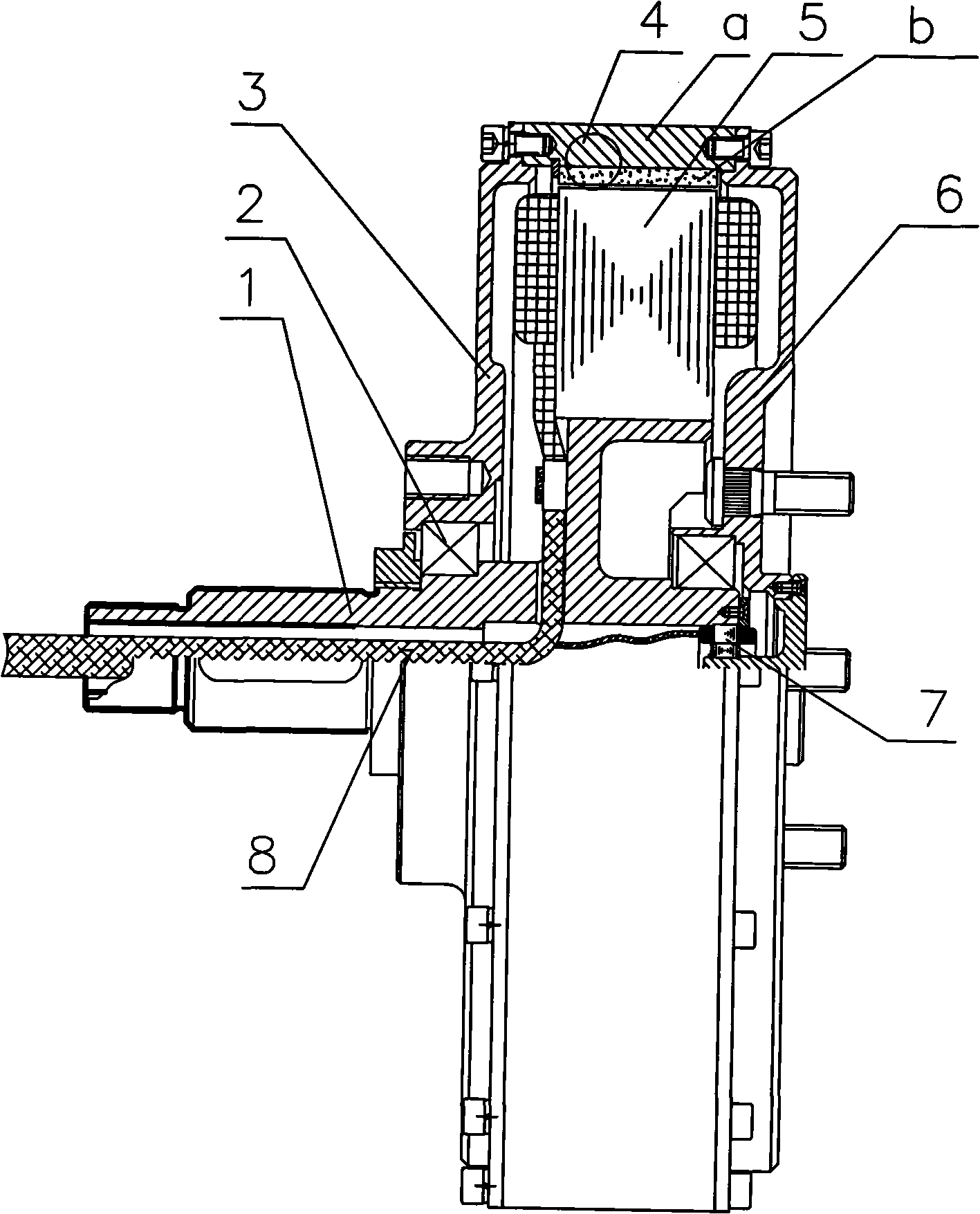

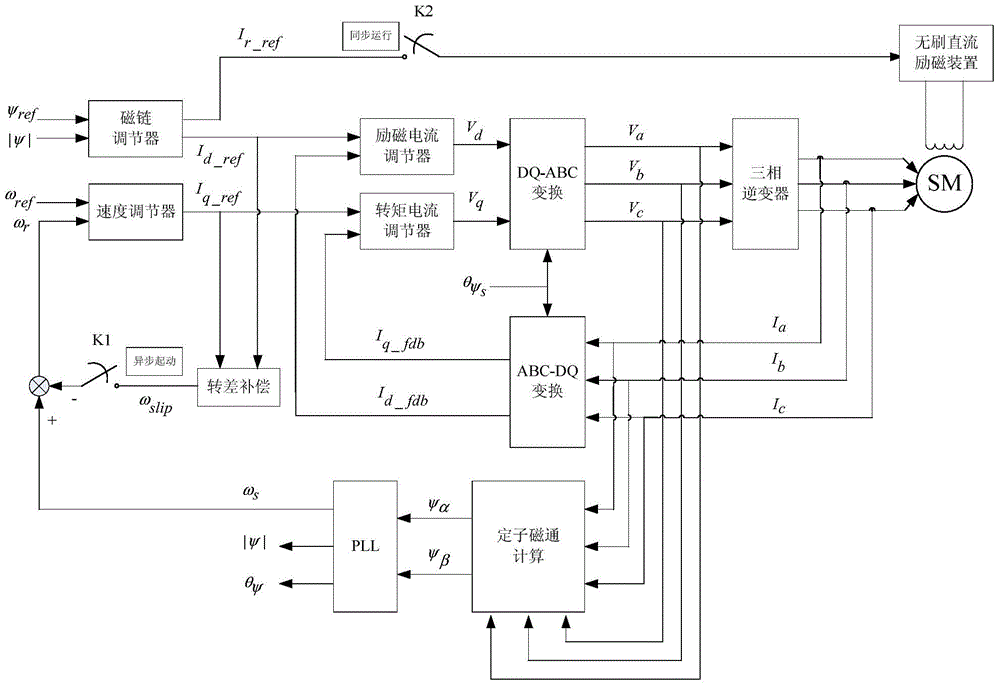

Wide range speed control system and current distribution method for hybrid excitation synchronous machine

InactiveCN102324882AIncrease starting torqueShort transition timeVector control systemsEmergency protective circuit arrangementsLow speedConstant power

The invention discloses a wide range speed control system and current distribution method for a hybrid excitation synchronous machine. A control policy is applied to armature drive and excitation drive simultaneously. When the motor is in the starting period, a rated forward magnetism strengthening current is applied to the exciting winding to increase the starting torque of the motor, so that the motor obtains electromagnetic torque exceeding the rated torque under the condition of no overcurrent, and the transition time of motor starting is shortened. When the motor is in the low speed operating interval, if the motor load exceeds the rated load, the electromagnetic torque of the motor is increased by applied the forward magnetism strengthening current, so that the motor obtains excessive loading capacity under the condition of no overcurrent and no overheat. When the motor operates at high speed, a constant power operating interval far above the rated rotating speed can be obtainedby applying an appropriate reverse exciting current to HESM (Hybrid Excitation Synchronous Machine) and performing weak magnetic regulation on the d-axis armature current.

Owner:HENAN INST OF ENG

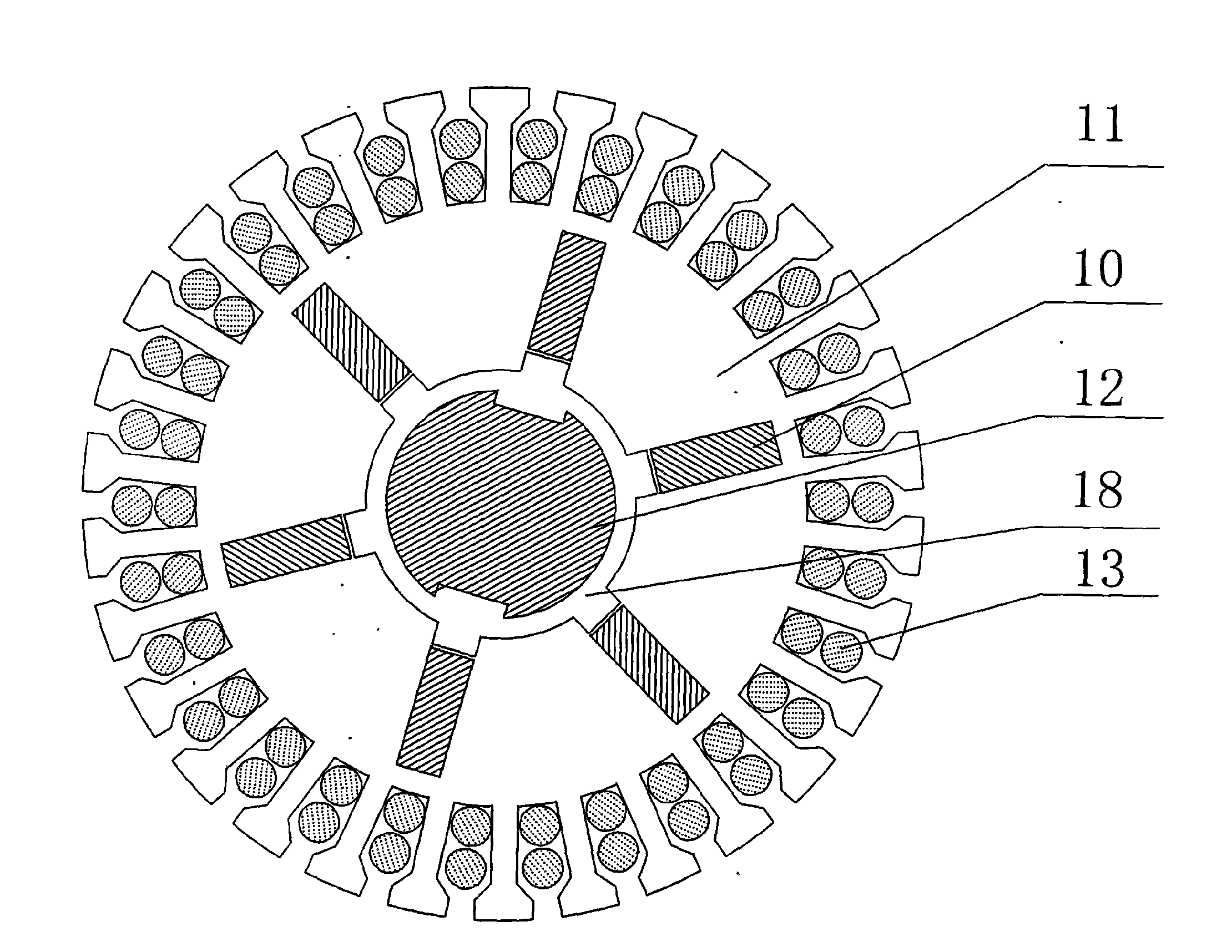

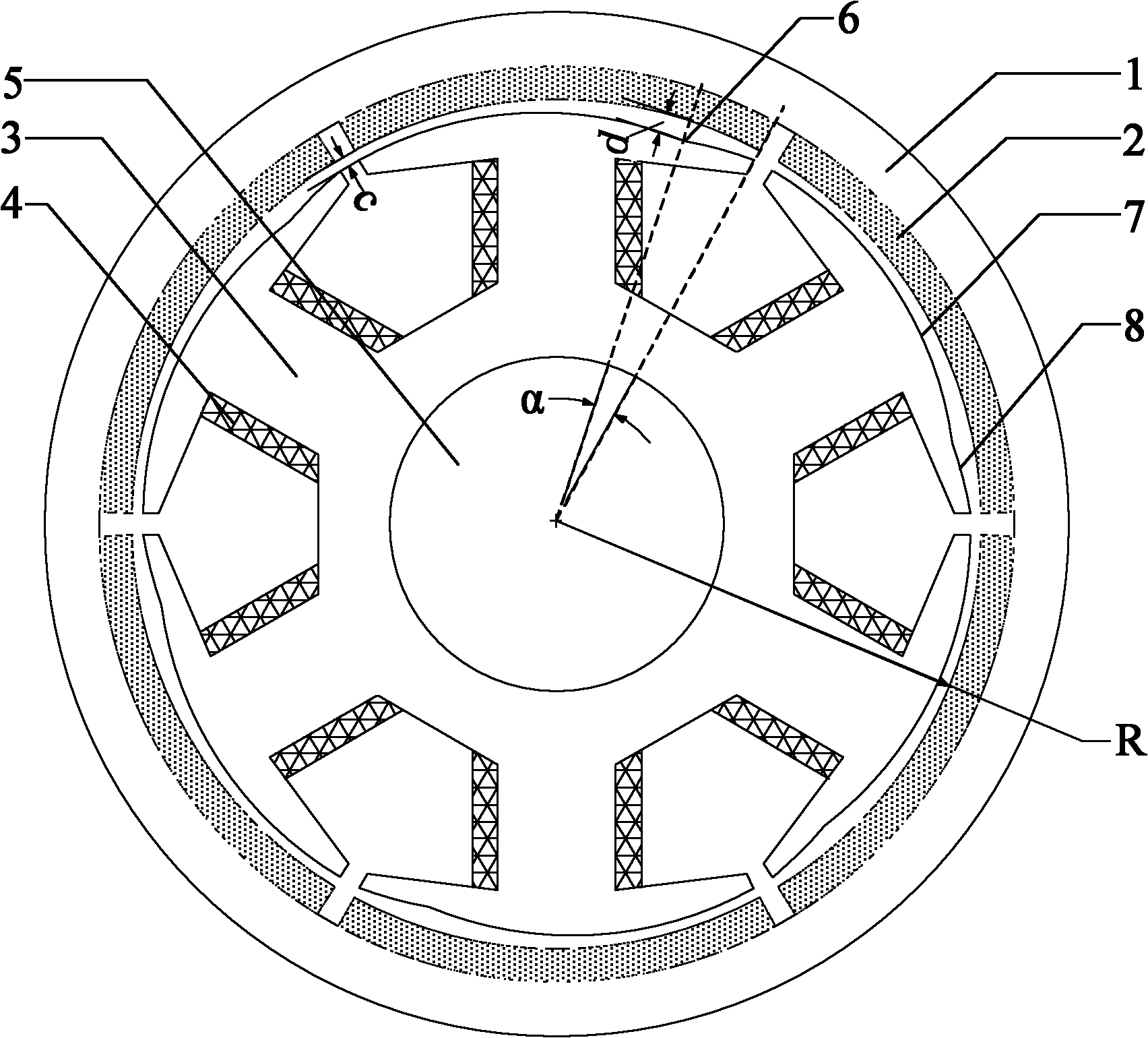

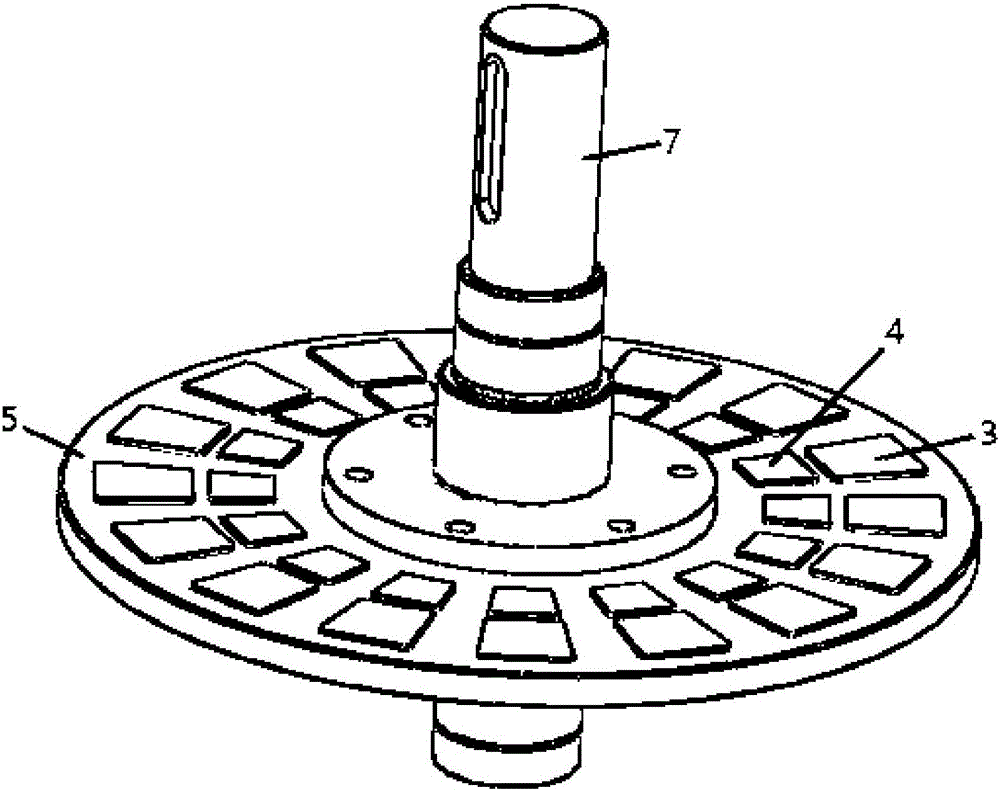

Permanent magnetism synchronous wheel hub motor for directly driving electric vehicle wheel

InactiveCN101282071AOptimize layoutSimple structureMagnetic circuit rotating partsSynchronous machine detailsInterference fitGear wheel

A permanent magnetism synchronous hub motor for electrically driven vehicle direct drive comprises shafts, a left end cover, rotors, stators, a right end cover, a rotating transformer, bearings are arranged on the shafts, inner rings of the left end cover and the right end cover are connected with the bearings in interference fit, stators are hot sleeved on the support of the shaft, the left end cover, the right end cover and the rotors are jointed together by bolts, the rotors are composed of rare earth magnet steels at interval adhering in the inner wall of the support by the magnet steel glue. The invention can be mounted in the vehicle wheel hub for directly driving the vehicle wheel and save traditional drive devices, thereby simplifying the whole vehicle structure, improving the drive efficiency and using the space effectively; the invention is an outer rotor motor without reduction gear mechanism, has small volume, large power, large starting moment, good control performance and low energy consumption, can reduce the whole vehicle weight and the maintenance cost and improve continued mileage and battery life.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

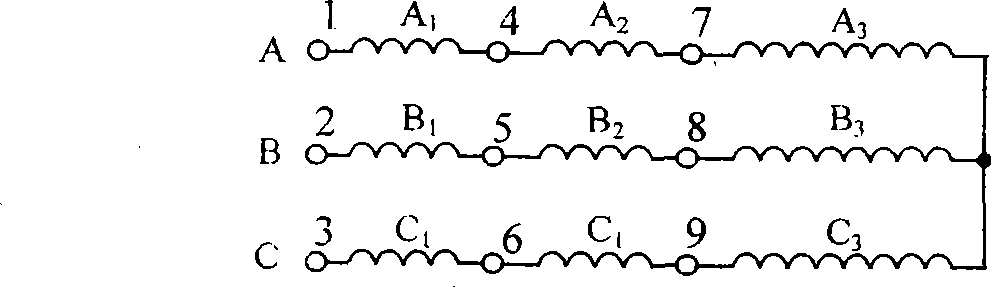

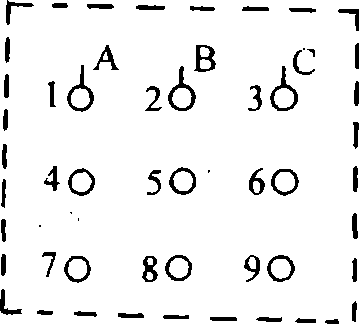

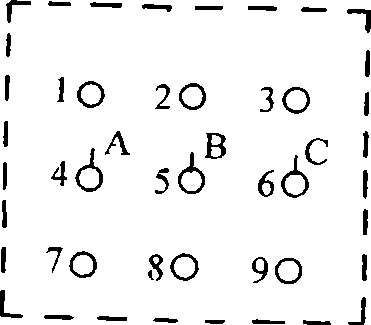

Micro-size single-phase permanent-magnet synchronous motor

ActiveCN102938626ASimple structural designIncrease starting torqueVector control systemsSingle motor speed/torque controlPermanent magnet rotorSynchronous motor

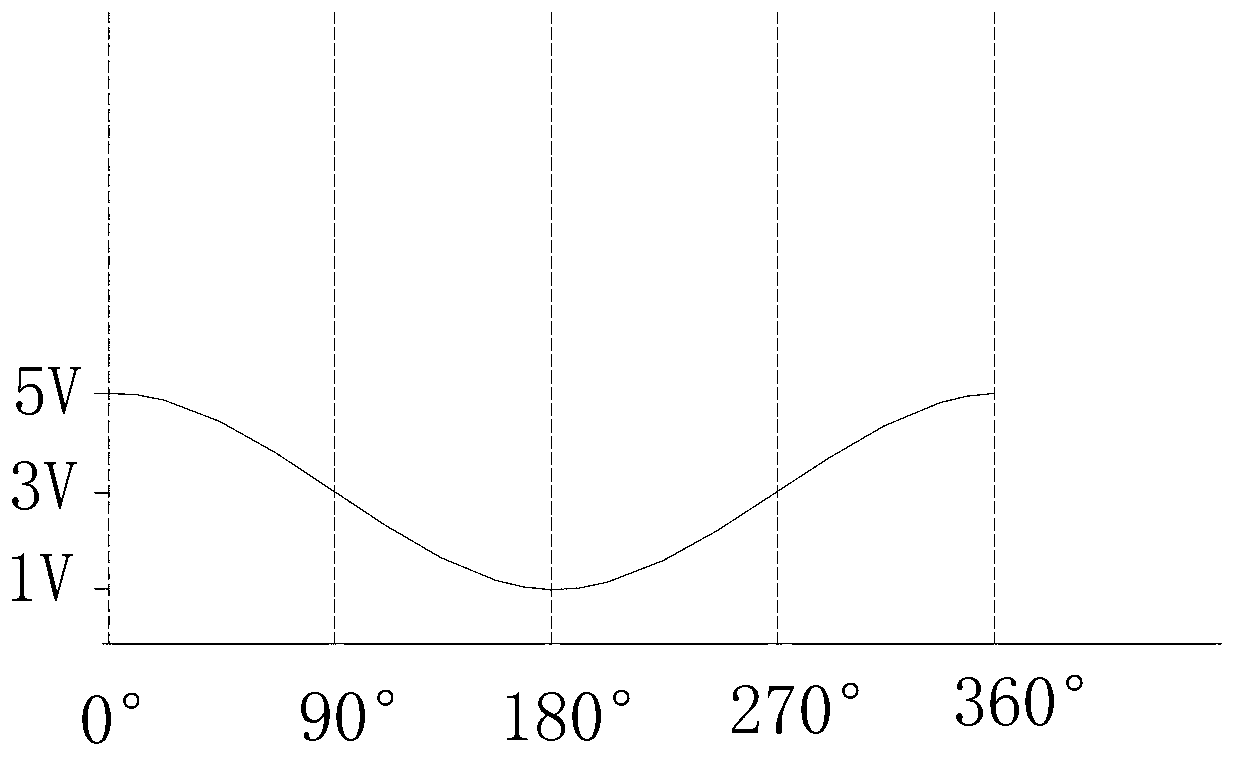

The invention relates to a micro-size permanent-magnet single-phase synchronous motor which comprises a stator and a permanent-magnet rotor which are same in pole number, wherein an AC (Alternating Current) power supply supplies electricity to the stator through the switch of a control circuit; an air gap is narrowed along a same peripheral direction under each pole so that the axial lines of the poles of the permanent-magnet rotor deflect an acute angle in a free state by taking the axial line of one closest pole of the stator as a reference; a linear magnetic position sensor is arranged on the peripheral preset position of the permanent-magnet rotor to detect the polarity and the position of the permanent-magnet rotor; the control circuit determines the axial direction of the permanent-magnet flux of various poles of the permanent-magnet rotor through the output of the linear magnetic position sensor by taking the peripheral preset position as the reference; and the control circuit detects the polarity of voltage which is supplied by the AC power supply to the stator to determine the axial directions of main fluxes generated at all the poles and control the half-waves of the AC power supply one by one according to a rotation direction set for the permanent-magnet rotor. The micro-size permanent-magnet single-phase synchronous motor disclosed by the invention can start and operate according to the preset rotation direction and is good in property and simple and reliable in control structure.

Owner:HANYU GRP CO LTD

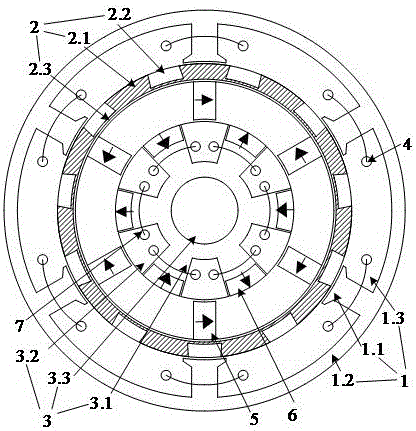

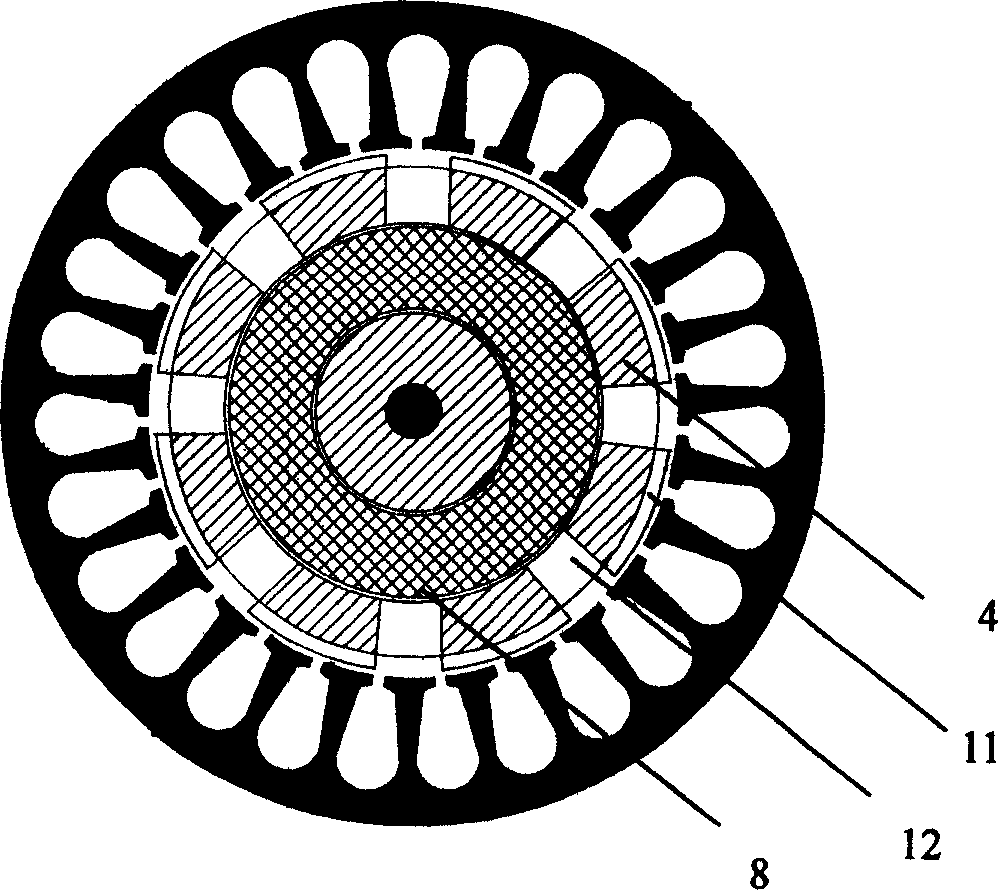

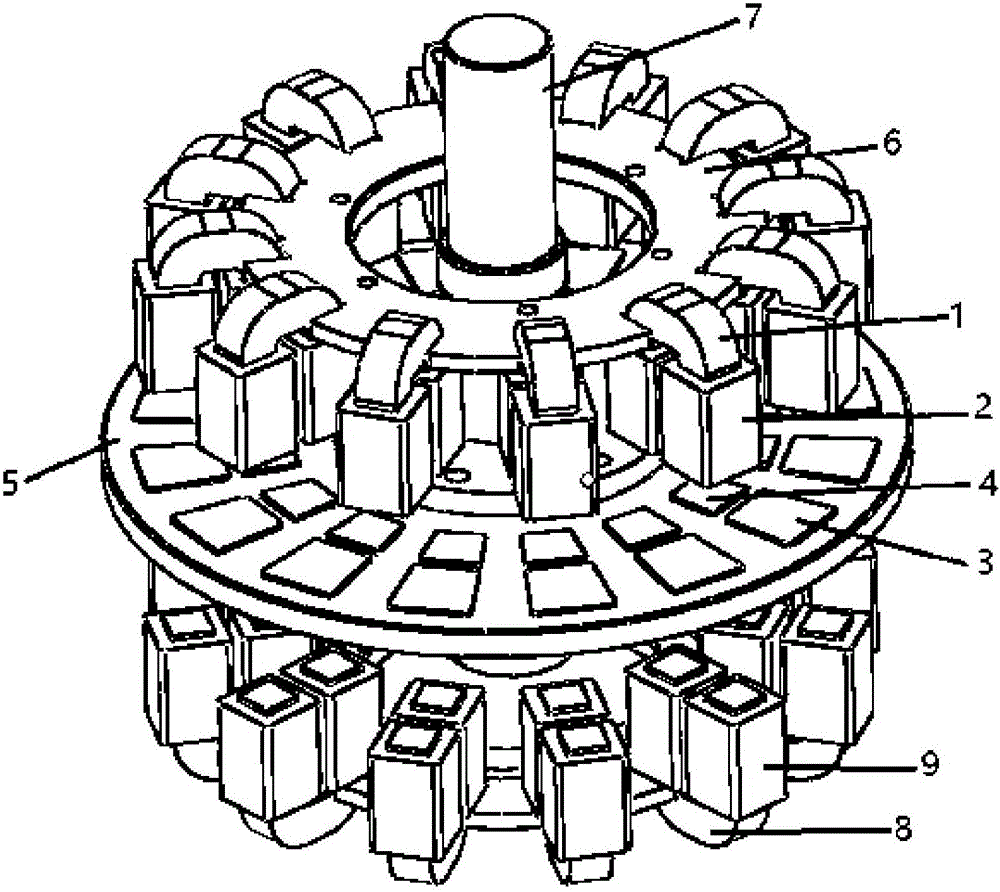

Magnetic gear type double-stator hybrid permanent magnet memory motor

InactiveCN105141092ASimple structureImprove space utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsEpoxyElectric machine

The invention discloses a magnetic gear type double-stator hybrid permanent magnet memory motor. The motor comprises an external stator, a rotor and an internal stator which are coaxially arranged and sleeved from outside to inside in turn. The external stator comprises armature iron core teeth, stator yokes and armature windings which are arranged on the armature iron core teeth. The internal stator comprises an internal stator iron core provided with internal slots, neodymium iron boron permanent magnets, aluminum nickel cobalt permanent magnets and pulse magnetic regulating windings which are arranged in the internal slots of the internal stator. The two types of co-excitation permanent magnets are arranged in a "U" shape. The number of single permanent magnets on the internal stator is equal to that of external stator armature teeth. The whole rotor has an annular cup-shaped structure. Rotor iron blocks are fixed in a non-magnetic-conductive epoxy resin sleeve. The rotor iron blocks are connected via magnetic conductive bridges. Disadvantages that a conventional single stator has multiple internal excitation sources which are mutually hindered in space and torque density is relatively low can be solved. Besides, high power density is realized by arrangement of double-stator hybrid permanent magnets, and residual magnetization intensity and magnetization direction of the permanent magnets are regulated by applying pulse current so that motor magnetic field high-efficiency regulation is realized, and rotating speed operation range is enhanced.

Owner:SOUTHEAST UNIV

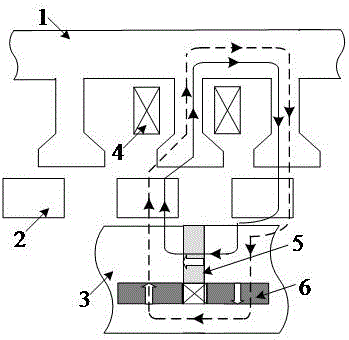

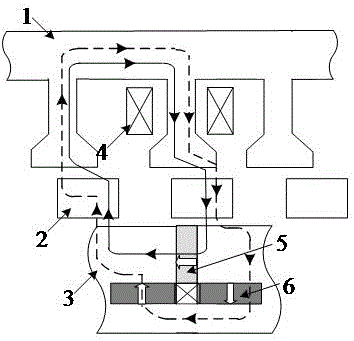

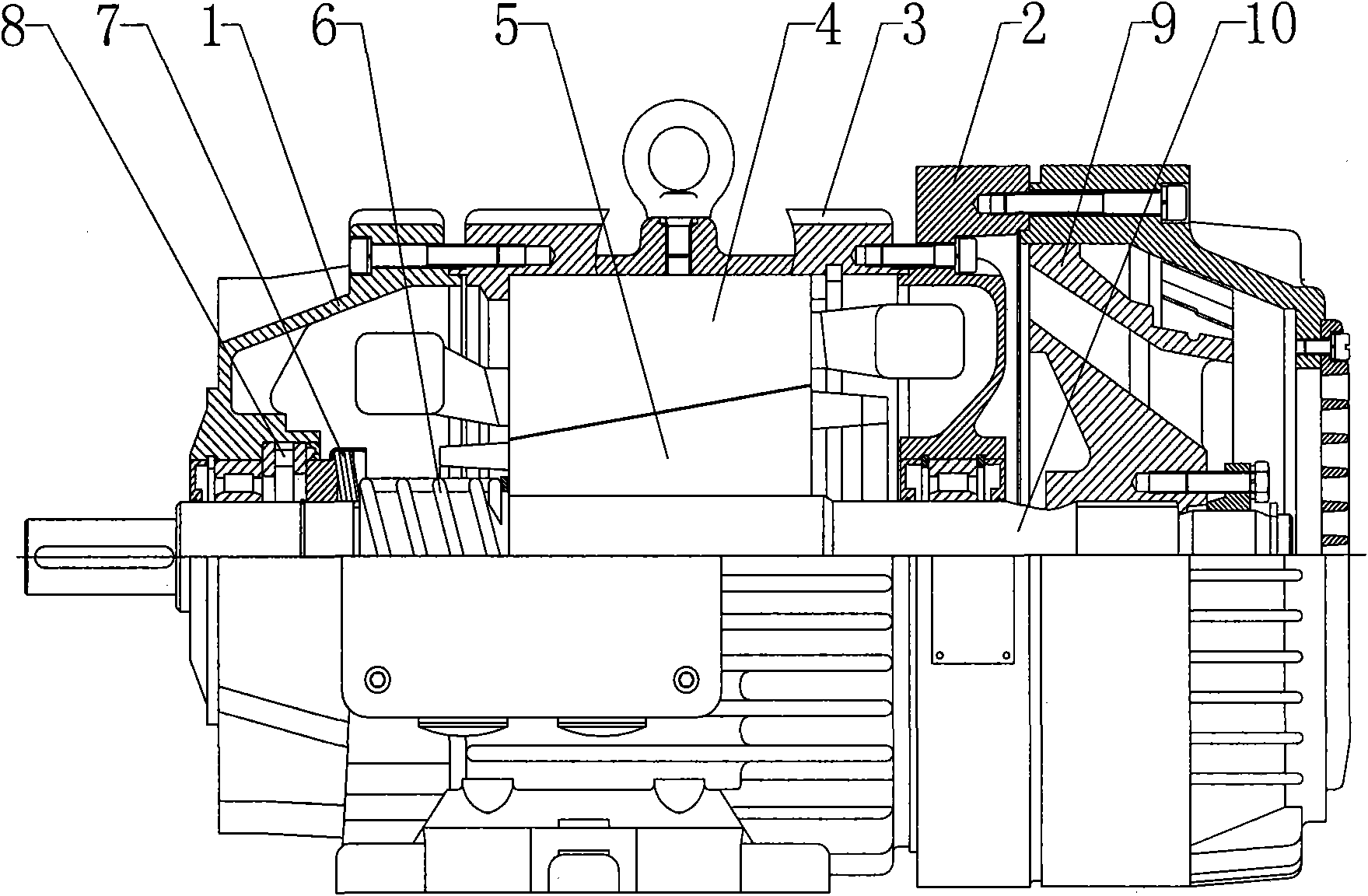

Wound rotor self-starting permasyn motor

InactiveCN101594036AImprove starting performanceImproved pull-in synchronizationSynchronous machine detailsMagnetic circuit rotating partsLow speedPermanent magnet synchronous motor

The invention relates to a wound rotor self-starting permasyn motor, which belongs to the technical field of permanent magnet motors. The wound rotor self-starting permasyn motor comprises a fan housing, a fan, a front bearing end cover, a front bearing, a front motor end cover, a rear bearing end cover, a stator winding, a shell, a stator core, a permanent magnet, a rotor core, a rotating shaft, a rotor winding, an electric brush, a slip ring, a rear motor end cover, a rear bearing and a magnetic shielding bridge. The wound rotor self-starting permasyn motor has the following advantages: a wound rotor structure can improve the starting performance of the permasyn motor, namely the starting torque, reduce the starting current, improve the force-energy index, and simultaneously reduce the motor slip ratio by removing the rotor resistance gradually, improve the capability of pulling into synchronism to adapt to the operating condition requirement on low speed and large torque of overload starting, prevent impact to an electric network due to overlarge starting current or the incapability of starting the motor due to undersize starting torque, and ensure the smooth pulling into synchronism of the motor at the same time.

Owner:SHENYANG POLYTECHNIC UNIV

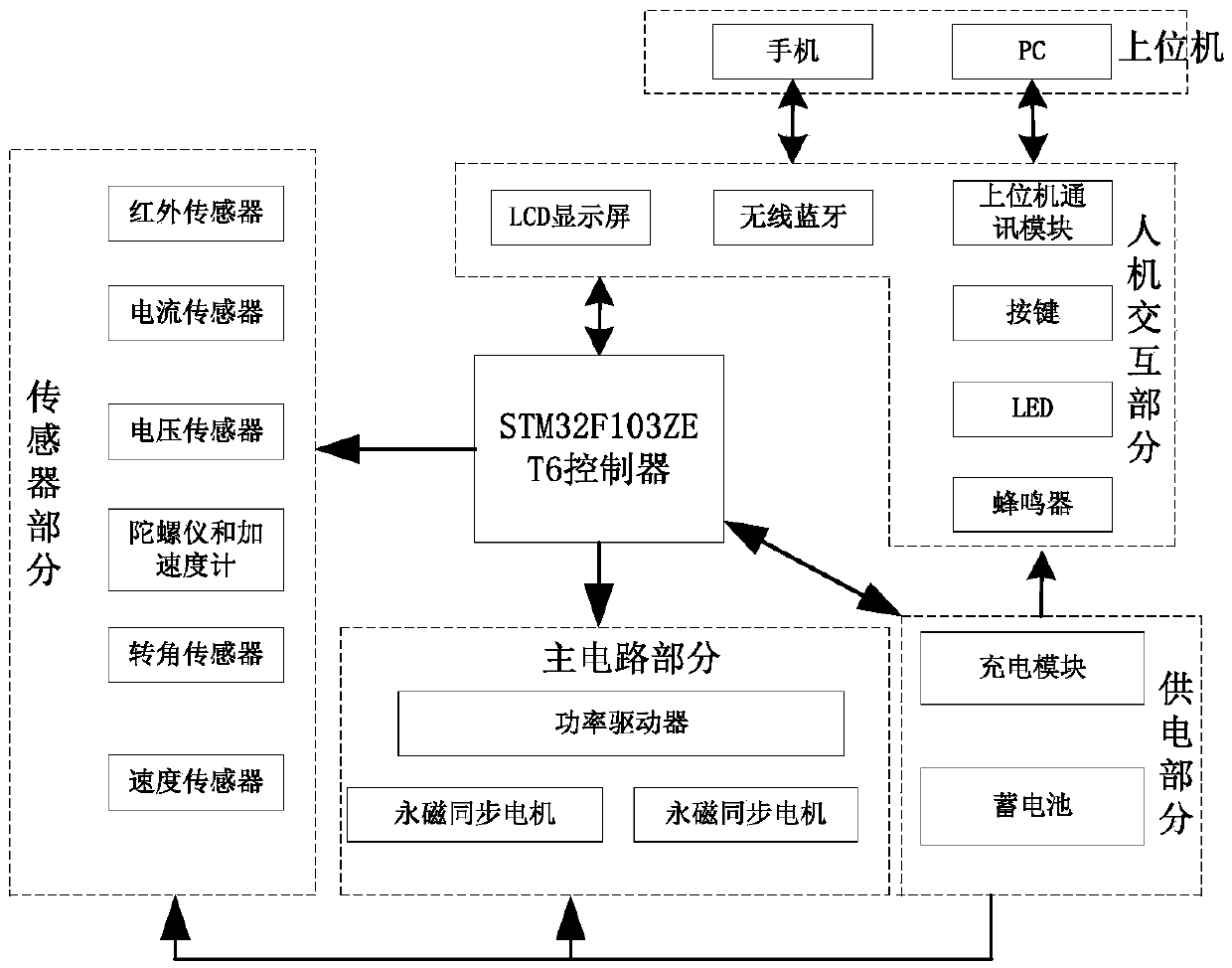

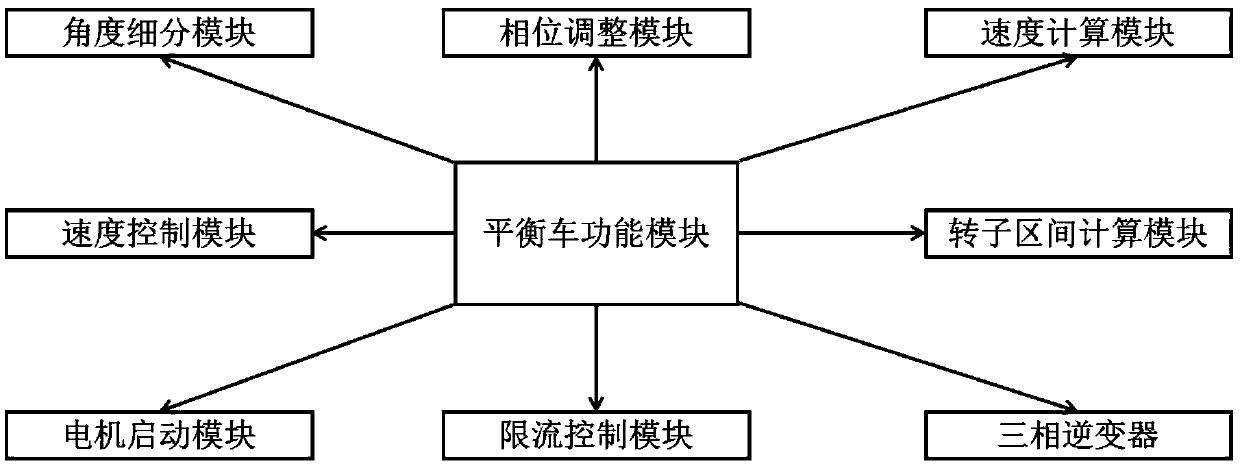

A system for balancing a vehicle and a control method thereof

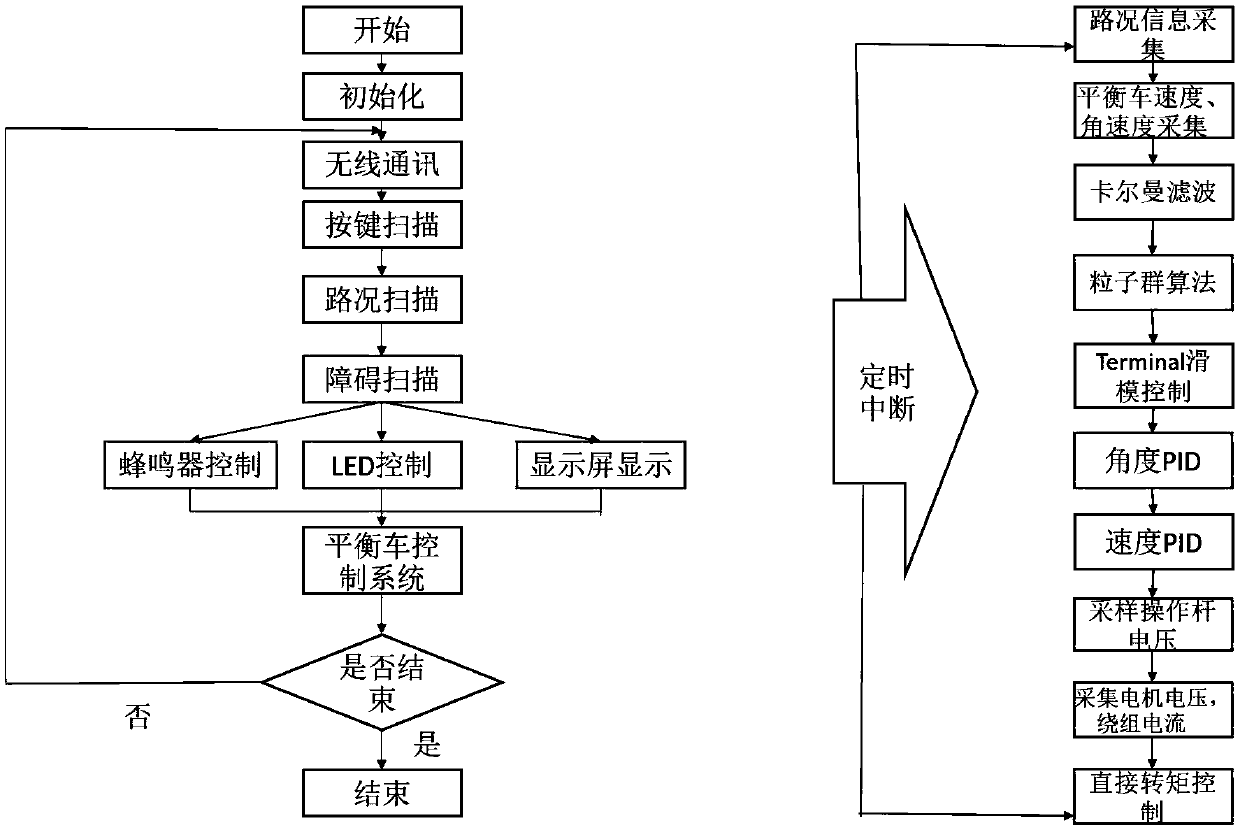

ActiveCN109067264AStrong battery lifeReduce loss rateTorque ripple controlMultiple motor speed/torque controlMathematical modelParticle swarm algorithm

The invention discloses a balancing vehicle system and a control method thereof. According to a difference equation model and a drift error model of attitude signals of the balancing vehicle system, astate equation of an extended Kalman filter and a mathematical model of a permanent magnet linear motor are established. A second-order dynamic Terminal sliding film is used to drive permanent magnetsynchronous motor. Particle Swarm Optimization (PSO) is used to optimize the parameters of tracking controller, synchronization controller, clearance elimination controller and switching function ina two-motor system. The invention realizes that the signal collected by the sensor of the balancing vehicle has large noise and zero drift error, and solves the problem of poor robustness and the problem that the Brush motor structure is complex, fault, maintenance workload, short life, commutation spark easy to produce electromagnetic interference, as well as in the balance of the car in the process of running jitter, deviation is too large, and low security.

Owner:汇佳网(天津)科技有限公司

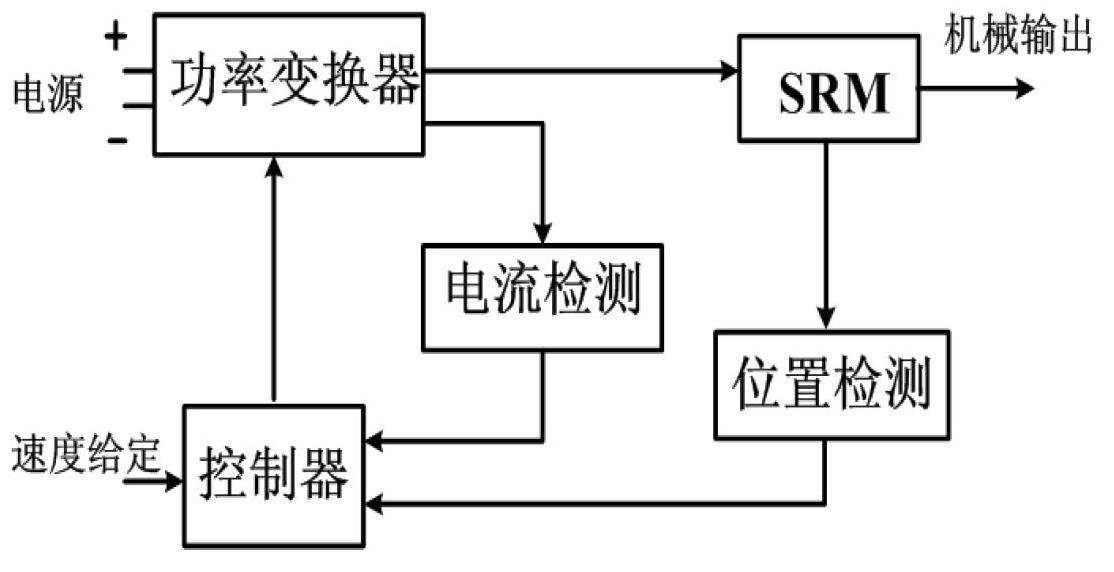

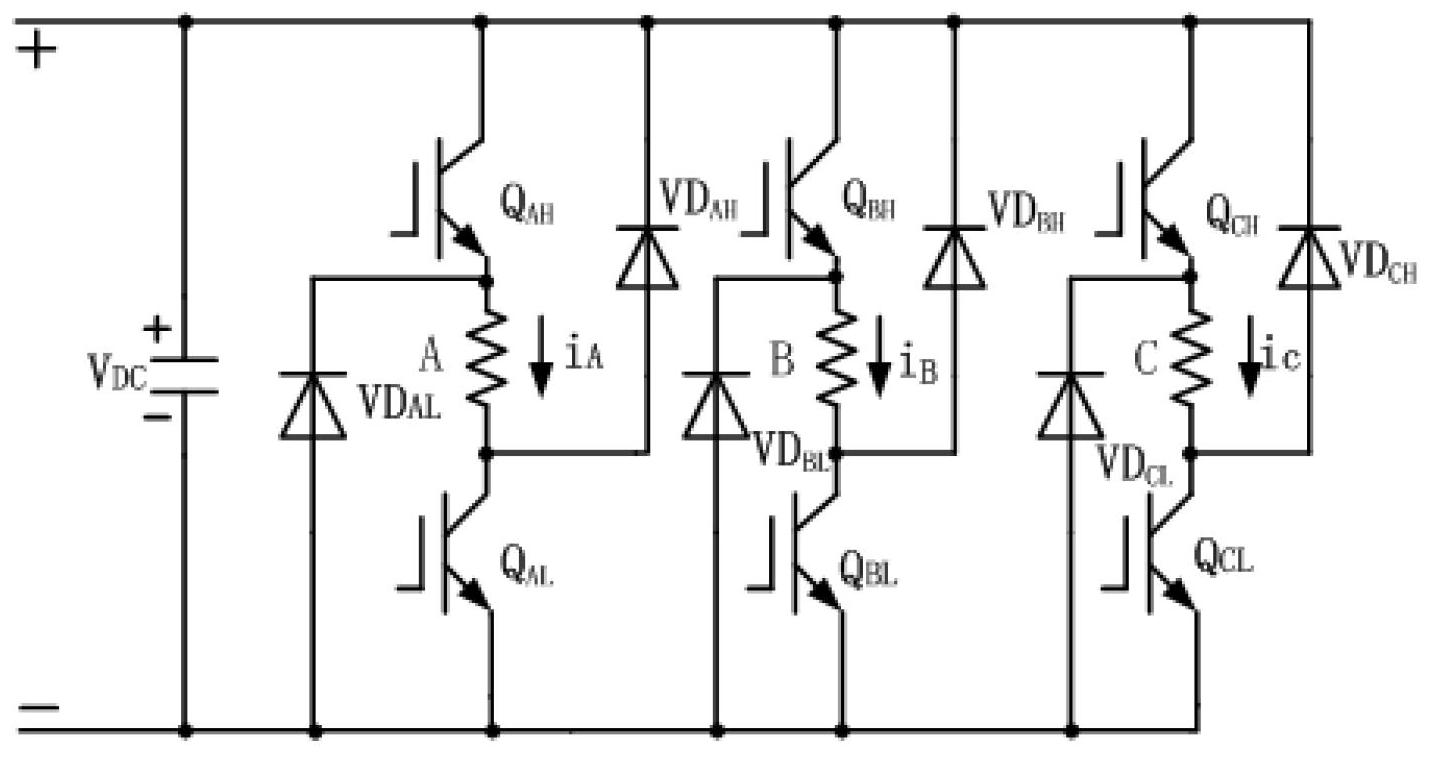

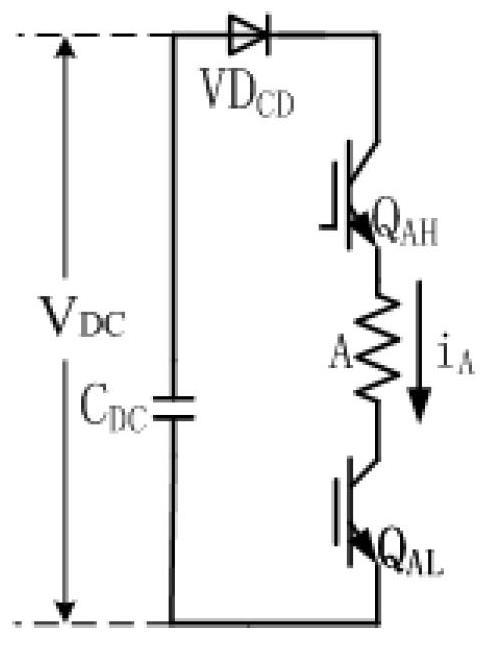

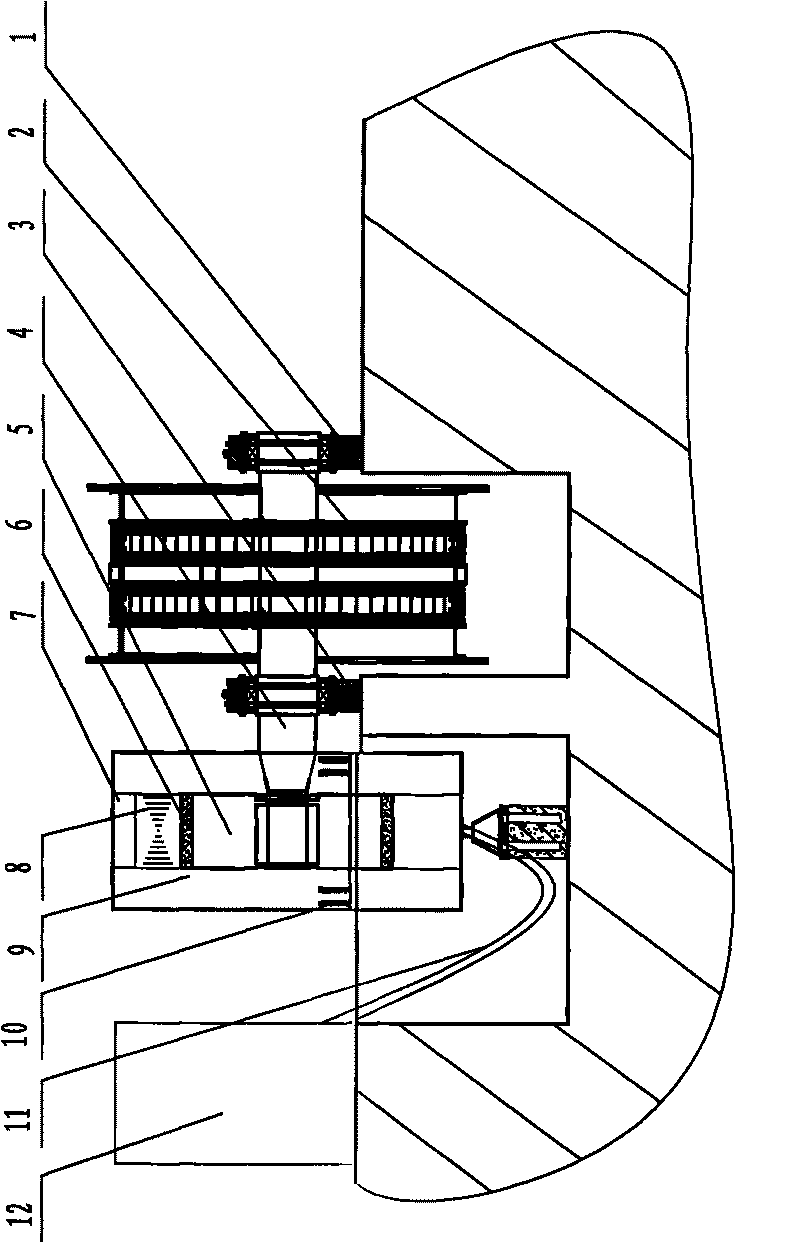

Motor drive system for direct main drive of weaving machine

InactiveCN102684579AIncrease starting torqueMeet the Quick Start RequirementsAC motor controlSingle motor speed/torque controlEngineeringControl theory

The invention discloses a motor drive system for direct main drive of a weaving machine. The motor drive system comprises a switched reluctance motor, a power converter, a controller and a position detector, wherein the motor is a three-phase switched reluctance motor; the power converter is a four-level power converter; the position detector is an absolute-type encoder; the instantaneous current flowing through a power device and a motor winding is detected by adopting the current sensor; the controller regards the instantaneous current as the foundation for current chopping control and over-current protection; and the direct current side voltage is detected by adopting a voltage sensor for voltage protection. The motor drive system for the direct main drive of the weaving machine disclosed by the invention has the characteristics of simple structure, small starting current and large starting torque. Heavier current passes through the motor winding by exerting the voltage higher than that of an asymmetric bridge power converter on the motor winding when the weaving machine is started, so that the starting torque of the motor is improved, so as to meet the requirement of fast start of the direct main drive of the weaving machine, thereby rated work rotating speed is achieved while beating-up is carried out for the first time by the weaving machine achieves, and generation of start-up marks of fabric is avoided.

Owner:TIANJIN POLYTECHNIC UNIV

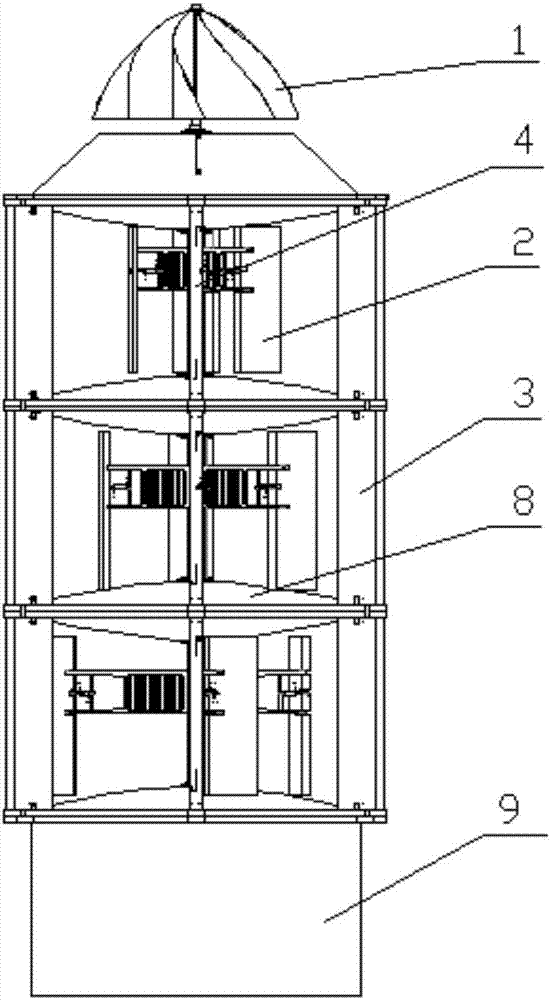

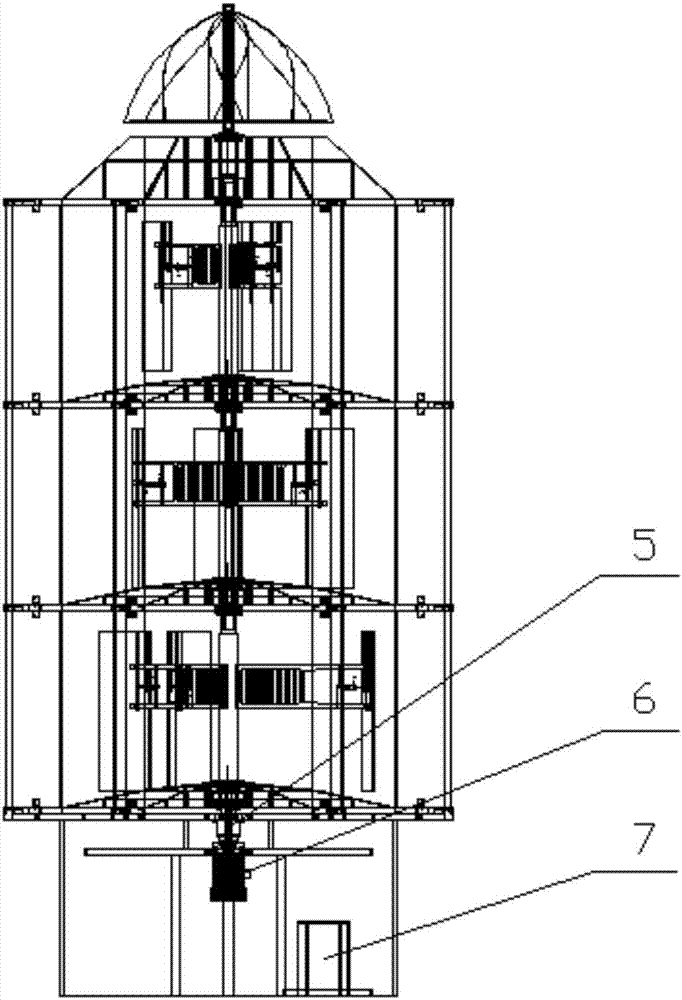

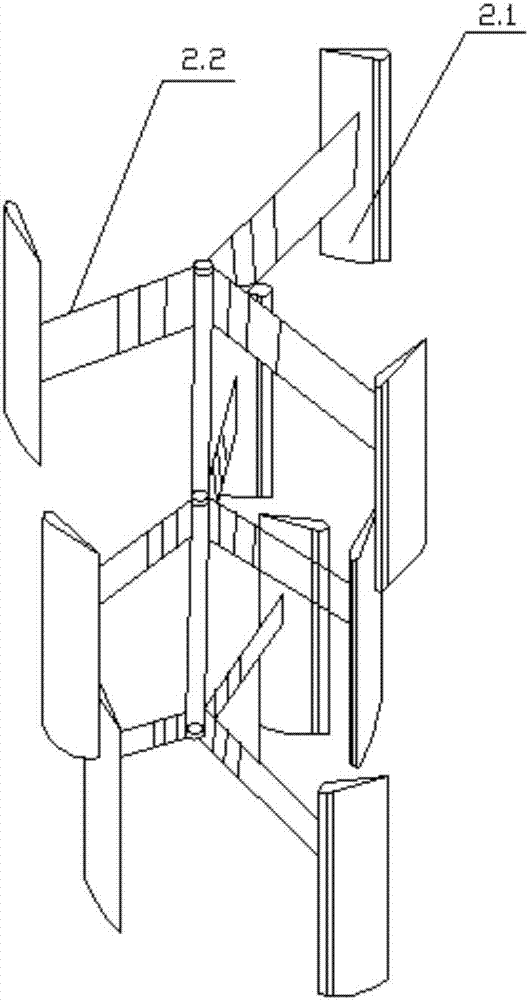

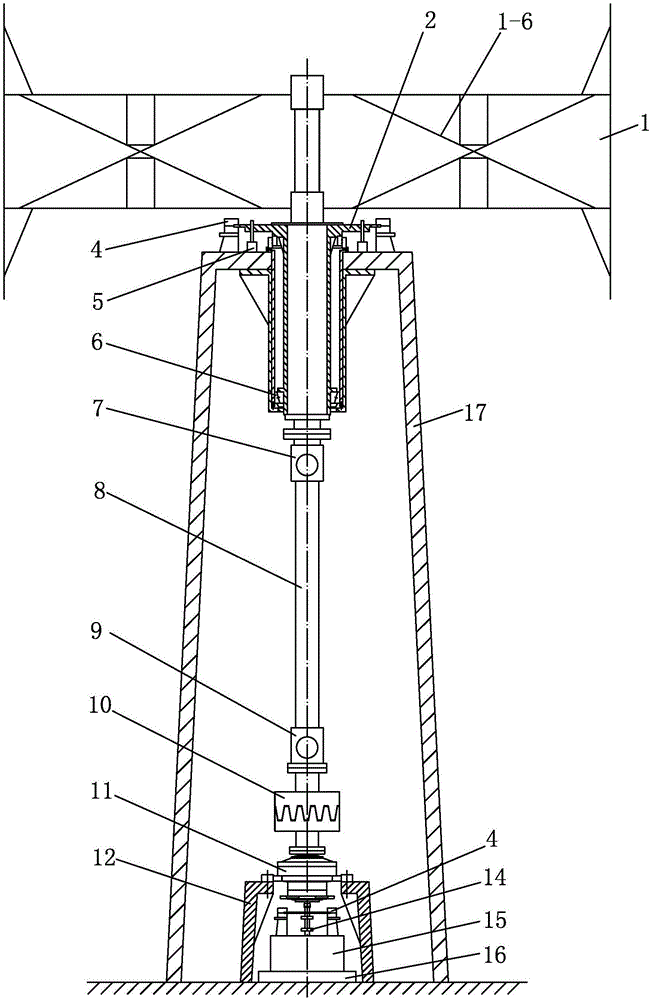

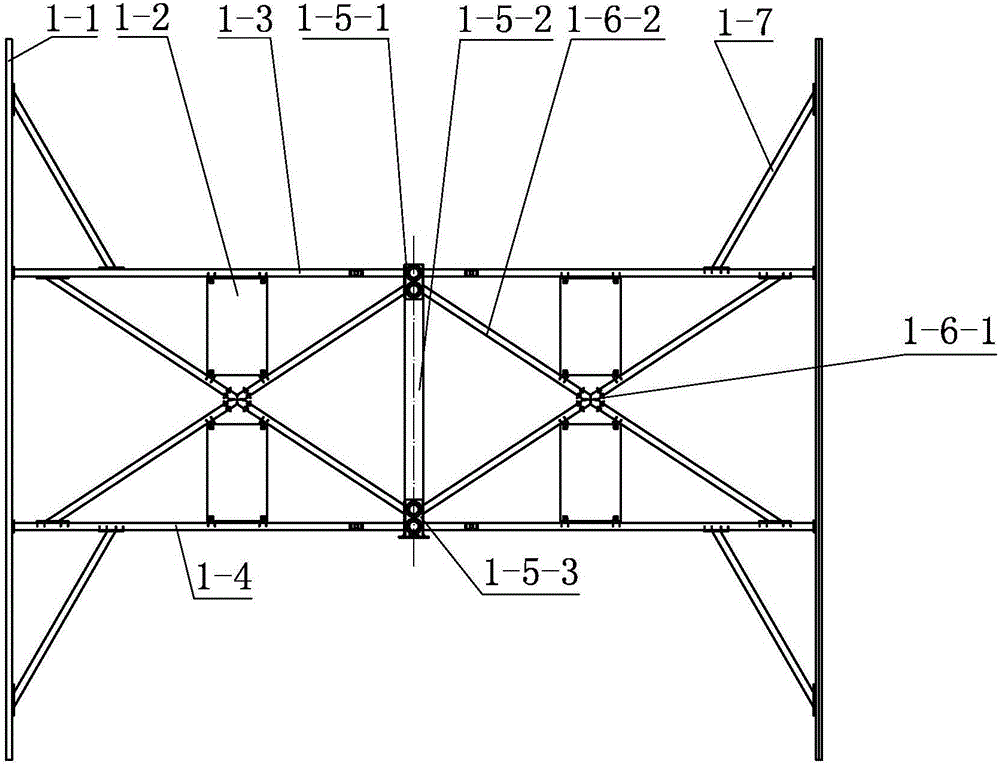

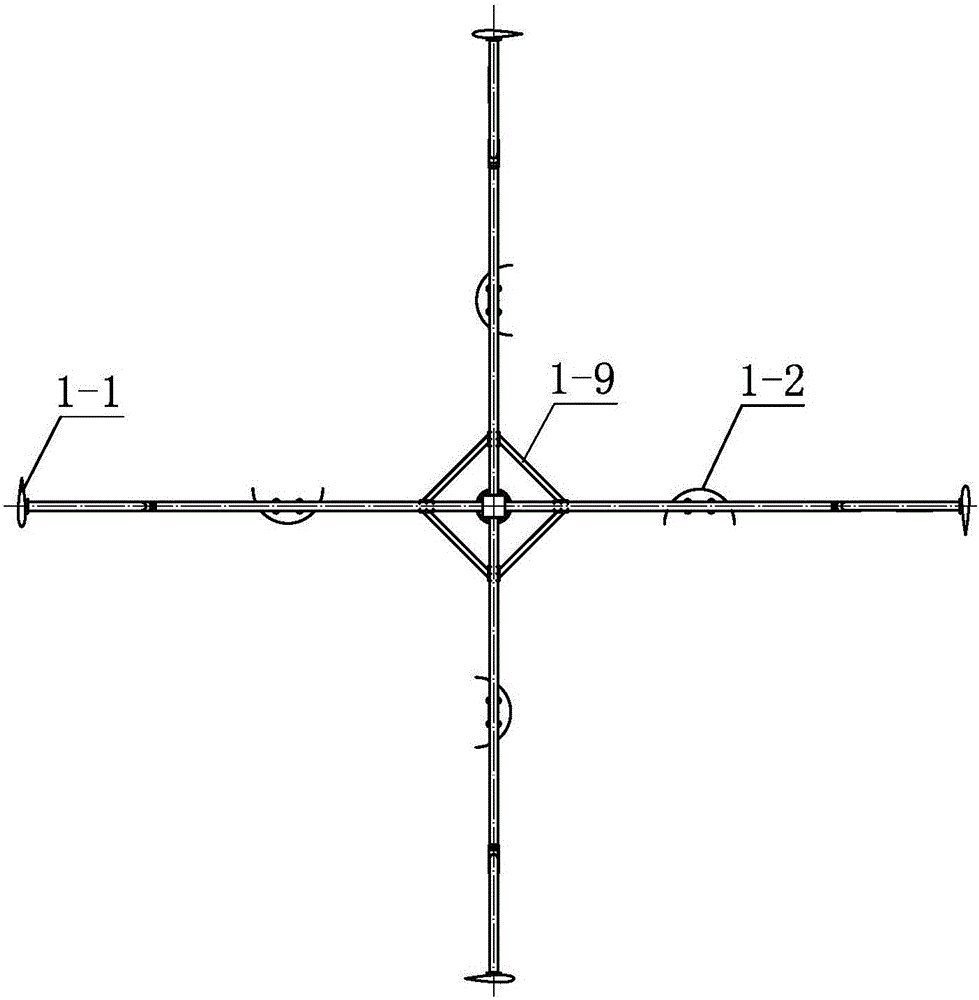

Modular frame type high-efficiency vertical axis wind turbine

ActiveCN107061151ASave design costSave installation costsMachines/enginesWind motor with perpendicular air flowImpellerEngineering

The invention relates to a modular frame type high-efficiency vertical axis wind turbine. The modular frame type high-efficiency vertical axis wind turbine comprises a wind wheel spindle, a step-up gear box, a permanent magnet synchronous generator, a wind power control cabinet and a peripheral foundation, and is characterized by further comprising a resistance type wind wheel, a force lifting type wind wheel, wind direction flow guide plates and transverse supporting structures; the resistance type wind wheel is mounted on the top of the wind turbine, and the lower part of the resistance type wind wheel is connected with the wind wheel spindle; the force lifting type wind wheel has a three-layer stacked impeller structure, a corresponding section of the wind wheel spindle is arranged in the center of each layer of the force lifting type wind wheel, each layer comprises a plurality of blades, each blade is connected with the corresponding section of the wind wheel spindle through a wind wheel support, and the different sections of the wind wheel spindle are flexibly connected through shaft sleeves; all the blades on the three layers are arranged in a staggered manner, projections of all the blades on the horizontal plane are distributed in a circular area, and the number of the blades in each layer is an odd number; and each wind wheel support comprises a rectangular frame, and one end of each rectangular frame is connected with the wind wheel spindle.

Owner:HEBEI UNIV OF TECH

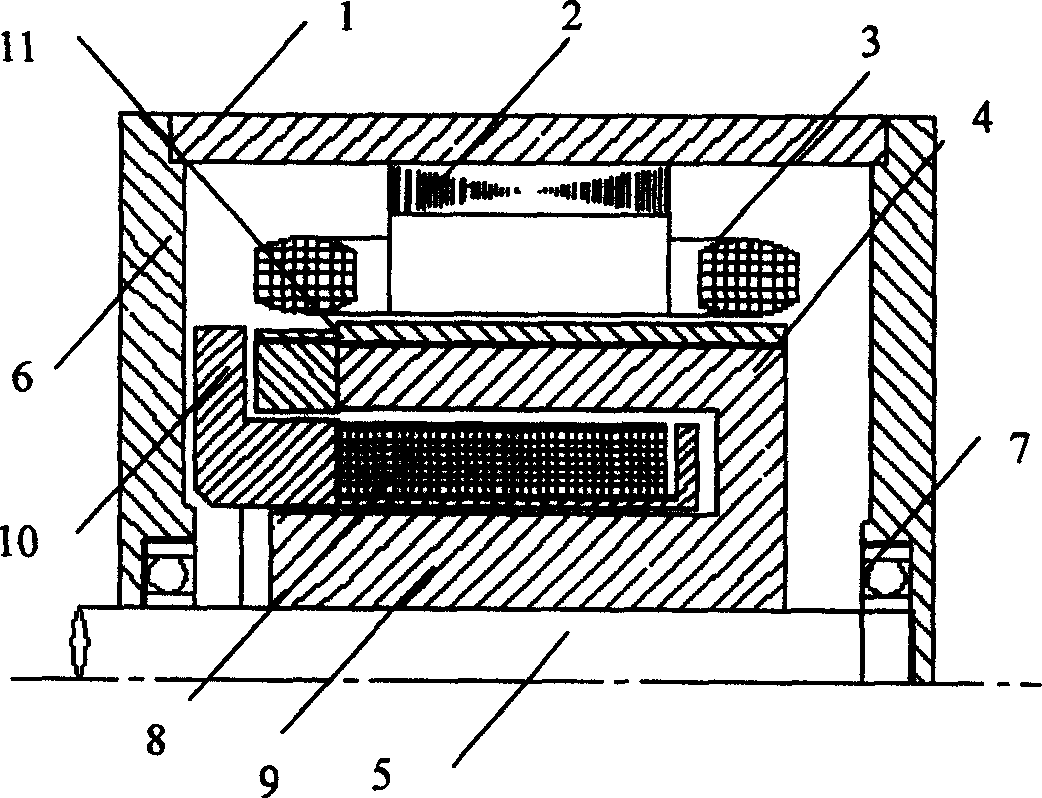

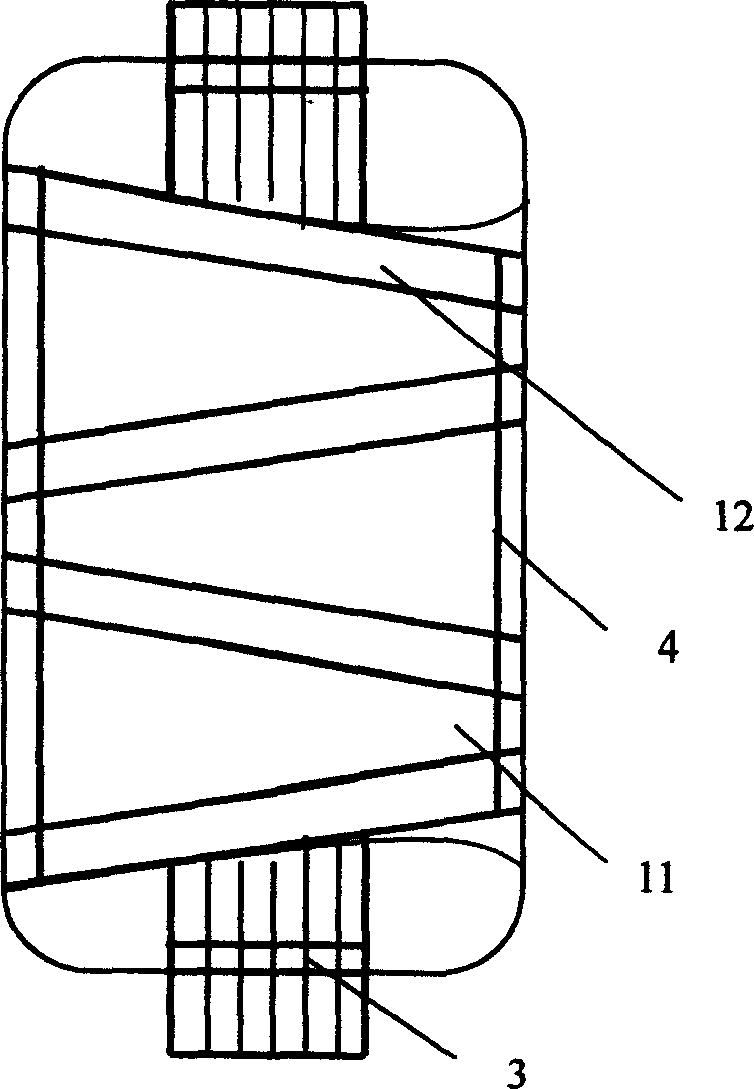

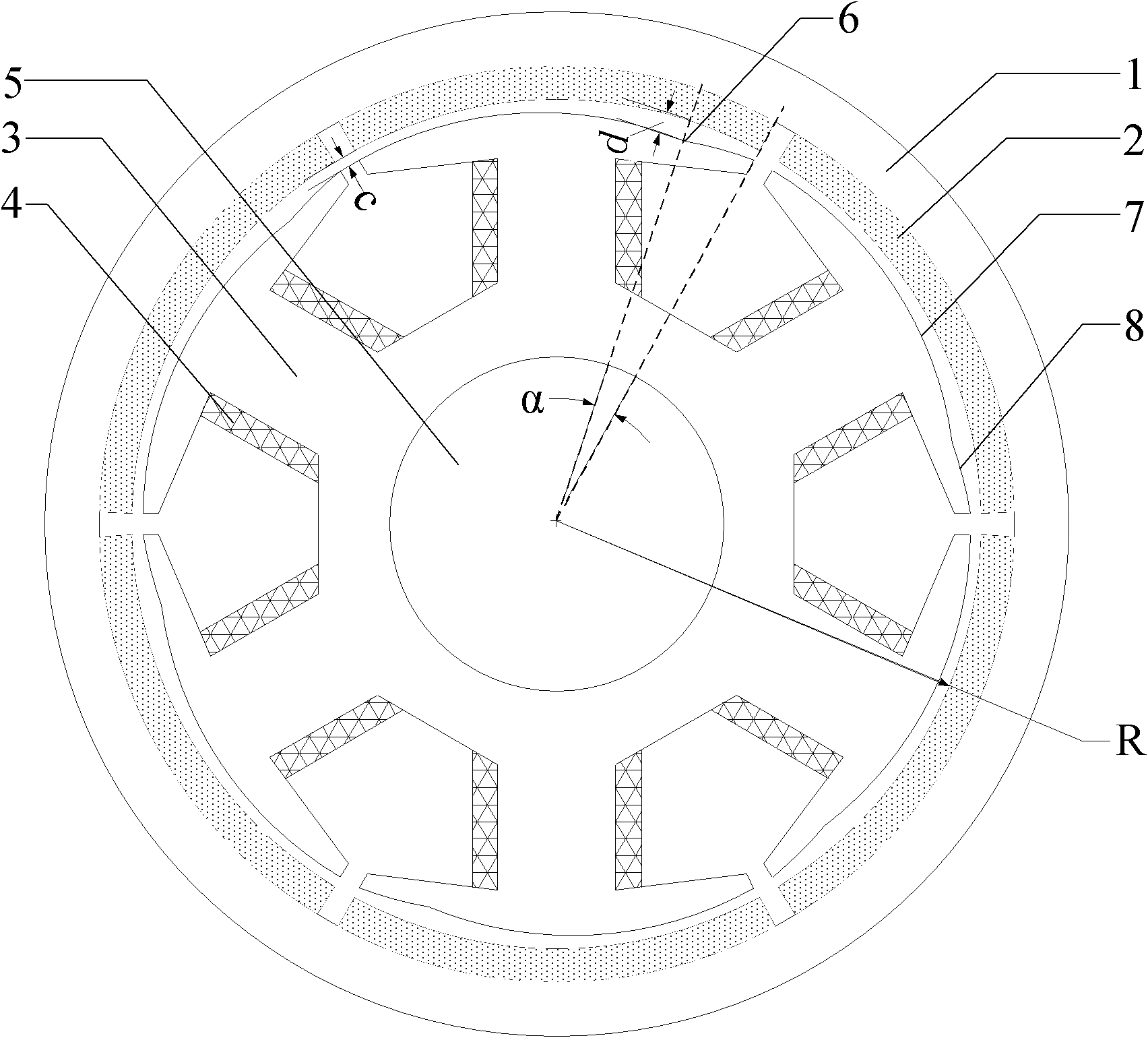

High-efficiency energy-saving double-salient-pole synchronous reluctance motor

ActiveCN101409471ASimple structureLow costMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous reluctance motorMotor control

The invention provides an efficient energy-saving dual salient pole synchronous reluctance motor, comprising a motor mechanical body and a motor control part; wherein, the motor mechanical body comprises a motor shell, a stator which is arranged on the internal wall of the motor shell and a rotor which is arranged at the center in the motor shell; the rotor is arranged on a motor shaft; the motor mechanical body also comprises a motor end cover which is arranged at the two ends of the motor shell; the motor shaft is connected with the motor end cover by a bearing; a shaft sleeve and an oil seal are arranged between the internal end surface of the bearing and the rotor; wherein, the rotor is provided with 8 salient poles; the stator is provided with 12 salient poles and 12 winding coils which are corresponding to the 12 salient poles.

Owner:黑龙江三众科技有限公司

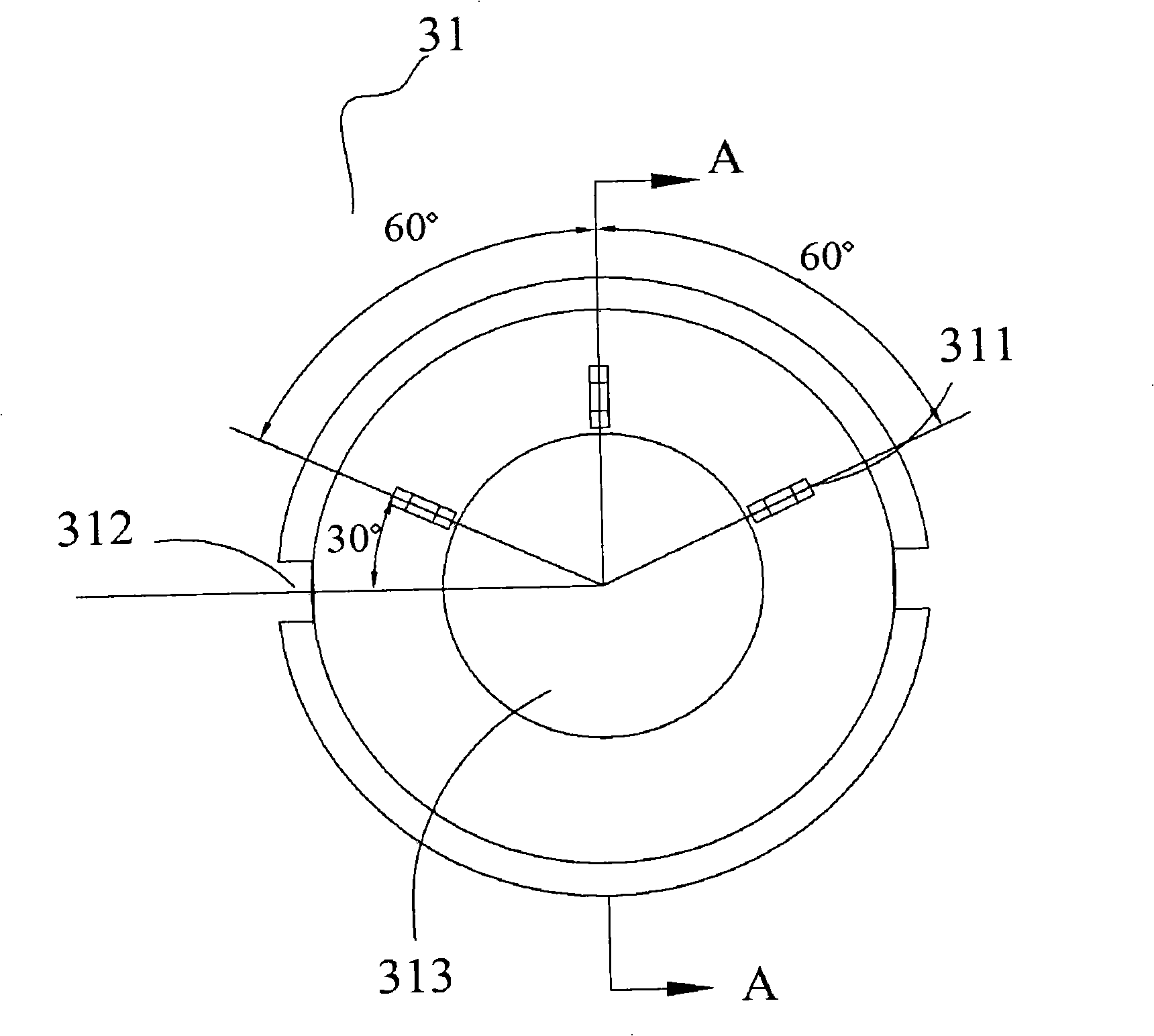

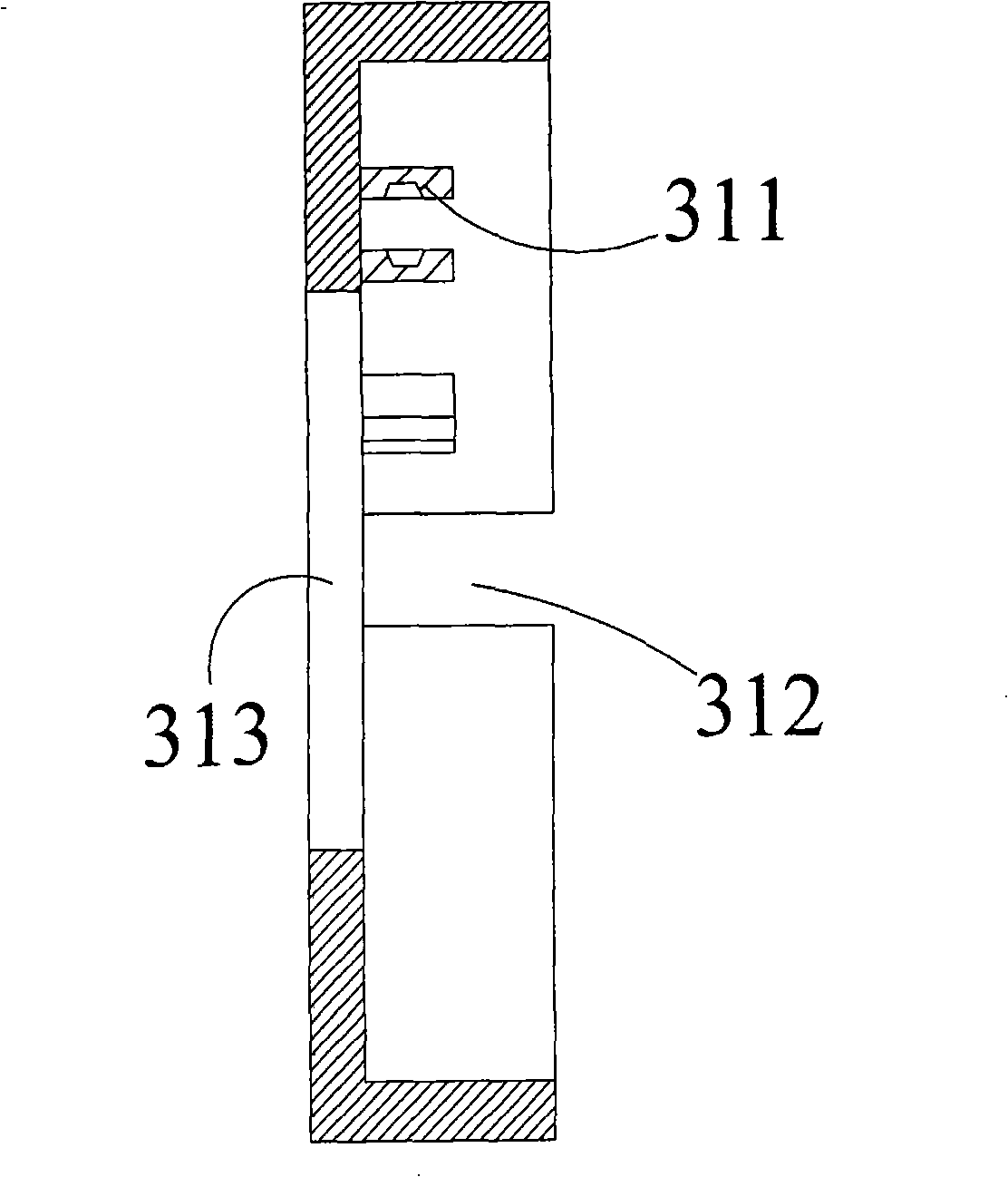

Vertical-axis clutch type wind power generation device

ActiveCN106321359AReduce design difficultyReduce design weightWind motor controlEngine fuctionsDrive shaftCoupling

The invention relates to a power generation device, in particular to a vertical-axis clutch type wind power generation device so as to solve the problems that an existing large-power vertical-axis wind power generator is difficult in self-starting and braking and low in power generation efficiency. The vertical-axis clutch type wind power generation device comprises a wind wheel, a first transmission shaft, a wind wheel locking device, a first coupler, a second transmission shaft, a third coupler, a clutch, a speed increasing gear, a support, a second coupler, a power generator, a tower and two brake devices. The vertically-arranged first transmission shaft is rotationally arranged on the top of the tower, one brake device is arranged on the top of the tower, and the wind wheel locking device is arranged on the top of the part, below a flange plate, of the tower. The upper end of the first transmission shaft is connected with the wind wheel, the lower end of the first transmission shaft is connected with the first coupler, and the speed increasing gear is fixed to the support. The clutch is connected between the second transmission shaft and an input shaft of the speed increasing gear, an output shaft of the speed increasing gear is connected with an input shaft of the power generator through the second coupler, and the other brake device is arranged on a power generator shell. The vertical-axis clutch type wind power generation device is used for wind power generation.

Owner:HARBIN INST OF TECH

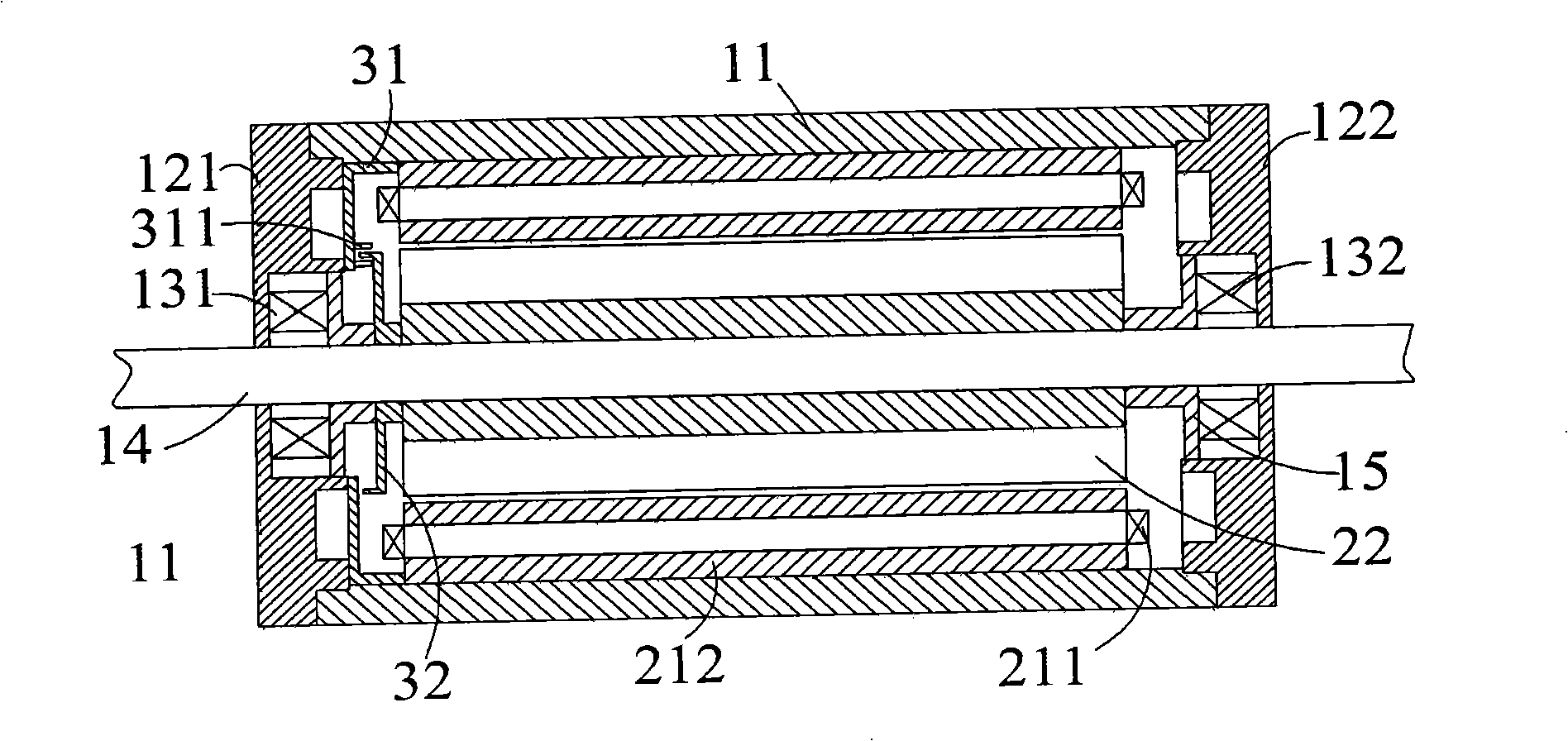

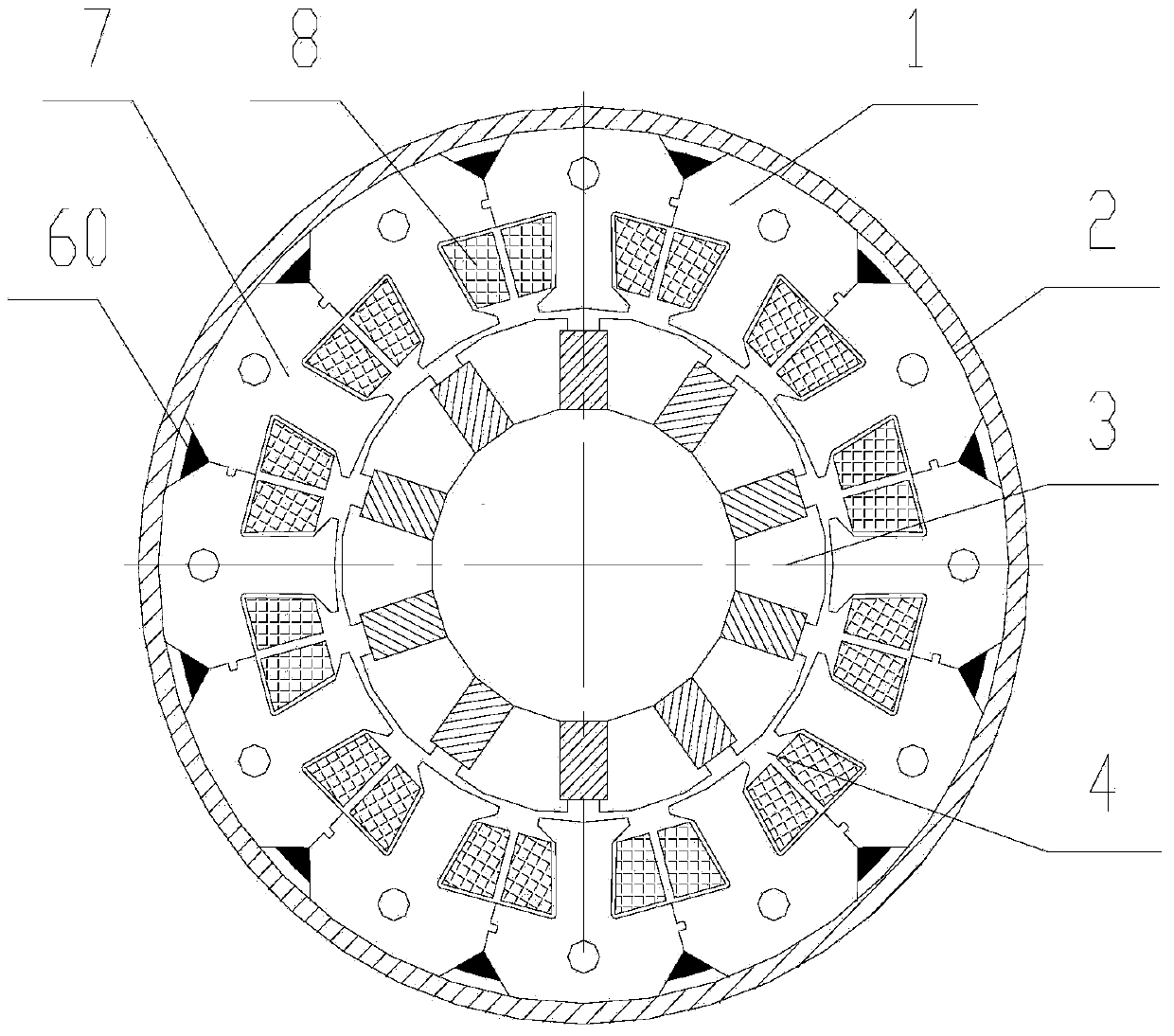

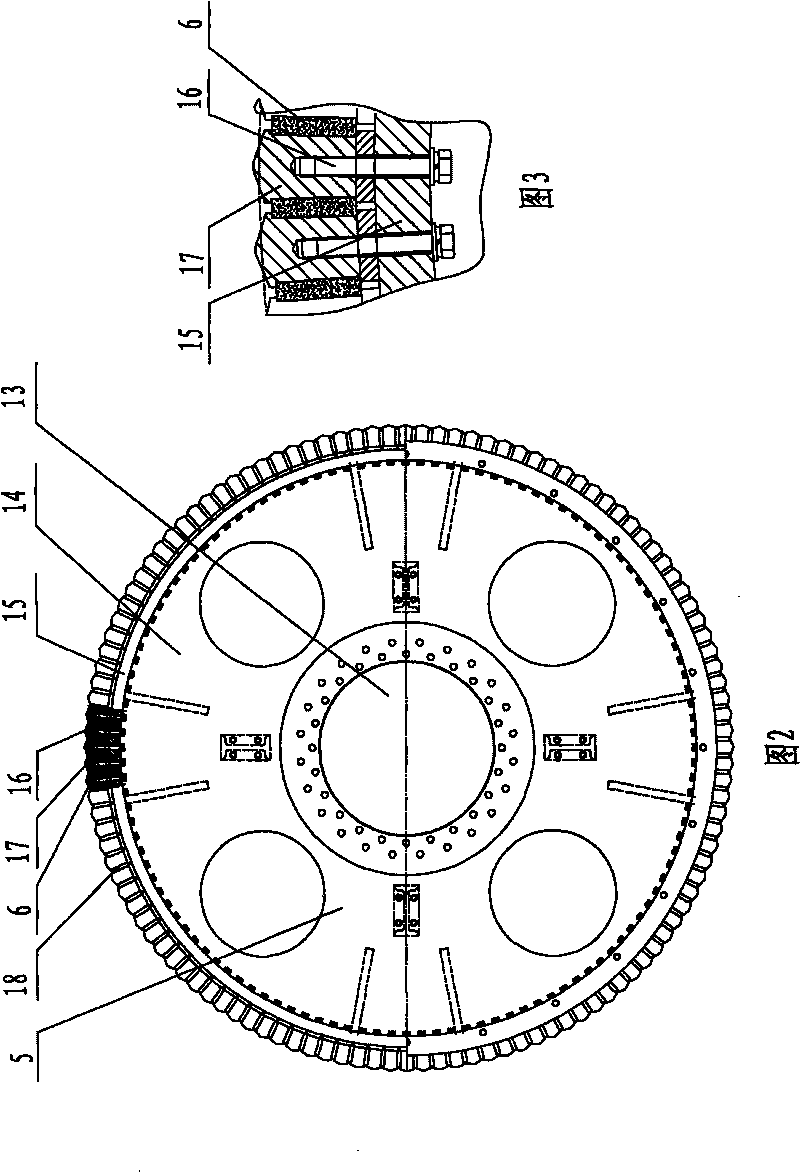

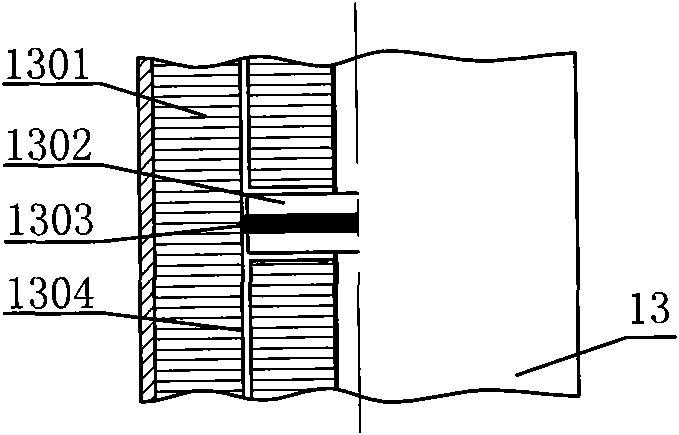

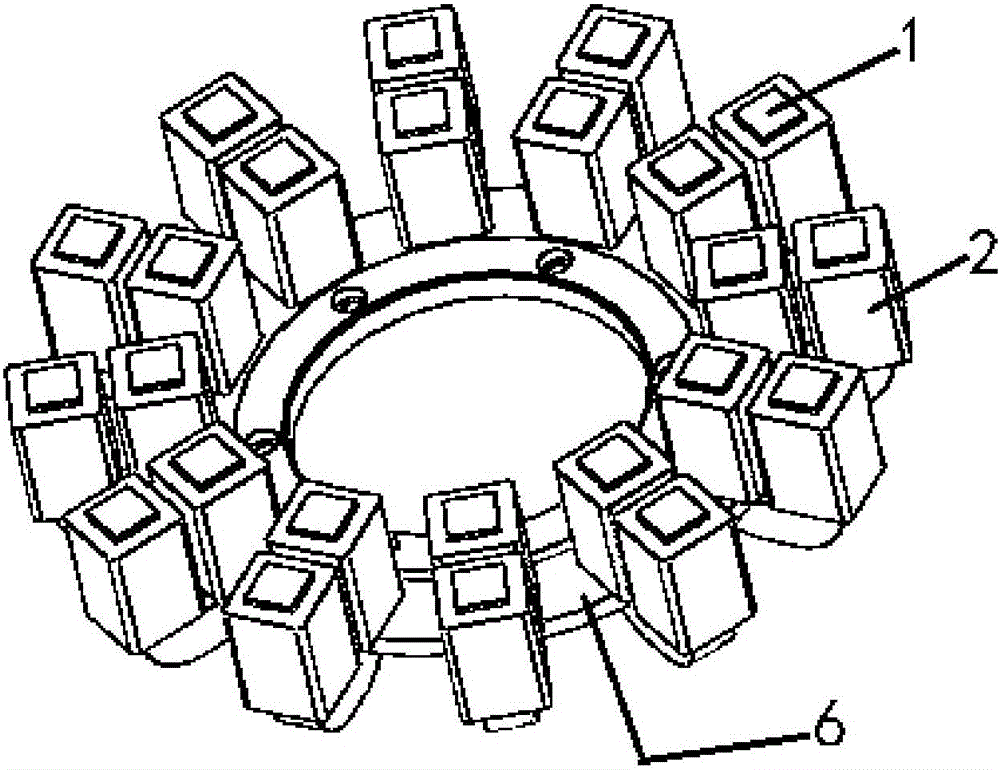

Oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and manufacture method

InactiveCN103633755AImprove the winding methodIncrease the winding spaceMagnetic circuit stationary partsManufacturing stator/rotor bodiesCopper wirePermanent magnet motor

The invention provides an oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and a manufacture method. The oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor comprises a motor unit, wherein the motor unit comprises a stator core of a split type structure, the stator core is assembled into an annular shape by multiple core blocks with windings, each core block with one winding comprises a slender core block and a winding copper wire, each slender core block is formed by overlaying T-shaped punched pieces and is provided with a stator tooth, and the winding copper wires are wound on the stator teeth. The manufacture method of the permanent magnet motor comprises the steps of overlaying the T-shaped punched pieces to form the slender core blocks, and winding the winding copper wires on the stator teeth to form the core blocks with the windings; connecting the multiple core blocks with the windings in sequence along the peripheral direction and assembling to form the annular stator core; arranging the annular stator core into an enclosure by press-fitting. The winding process of the core blocks with the windings is easy to realize, and the manufacturing is simple.

Owner:PETROCHINA CO LTD

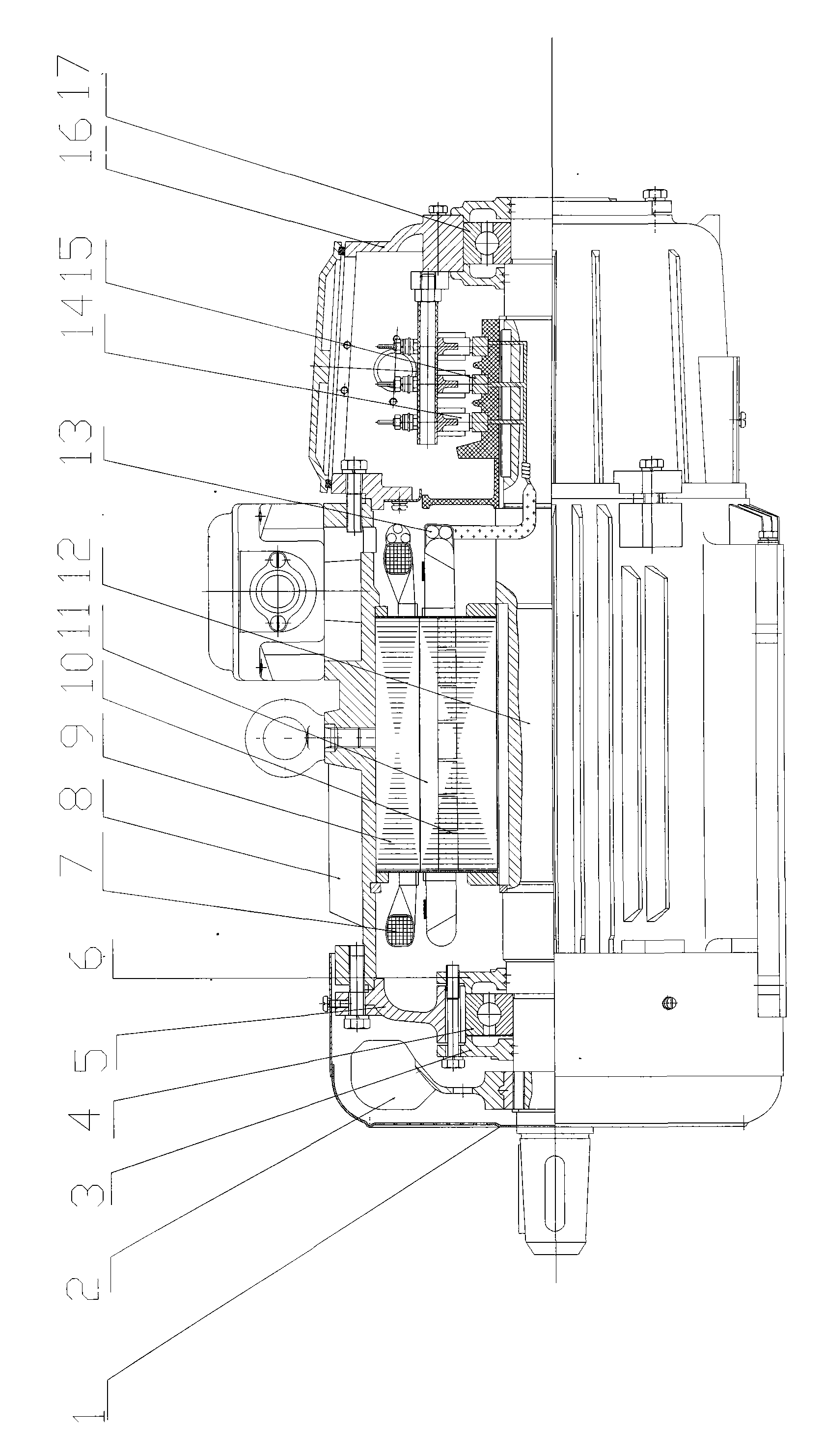

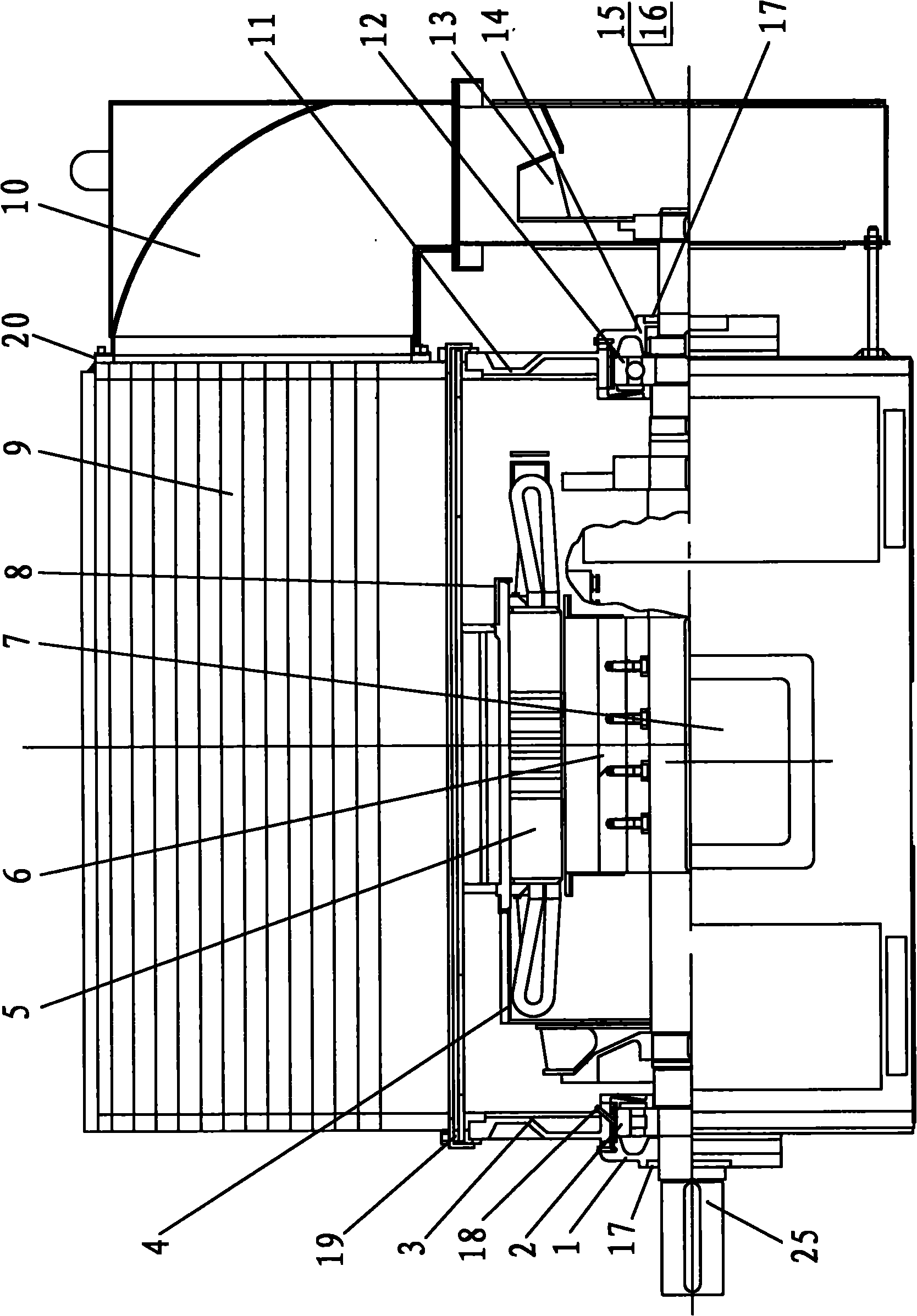

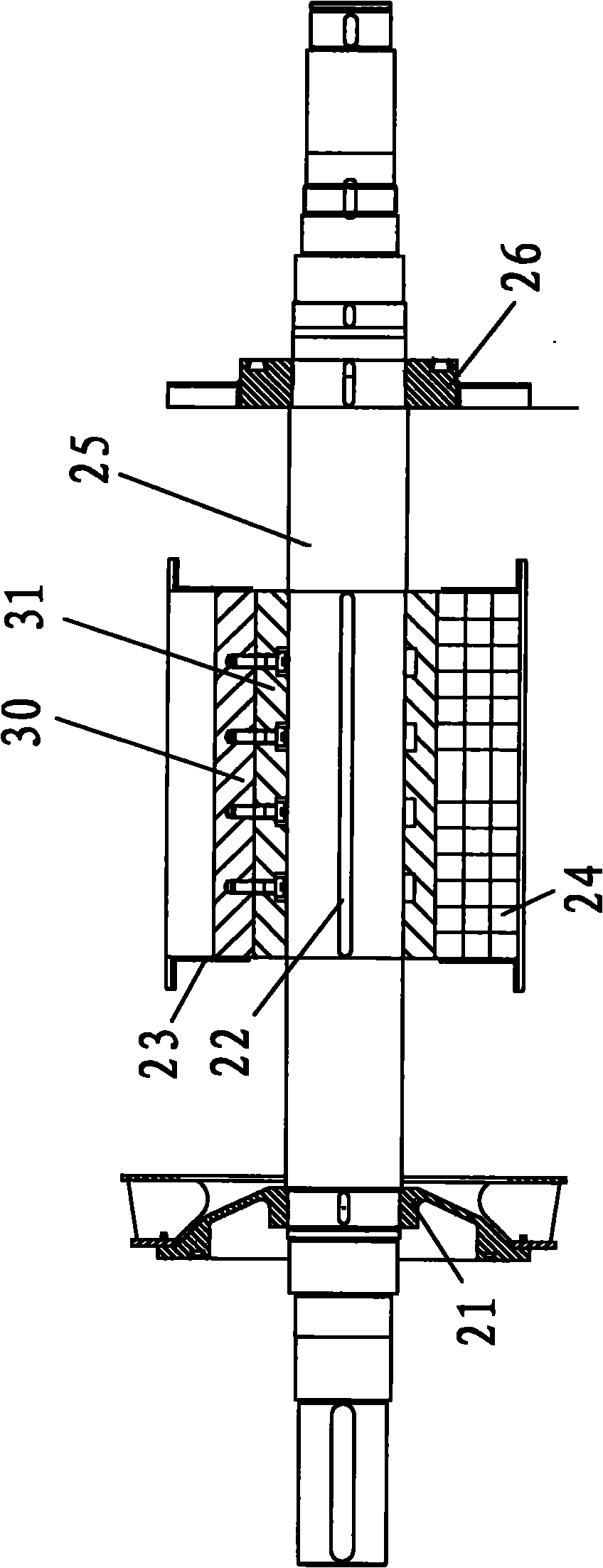

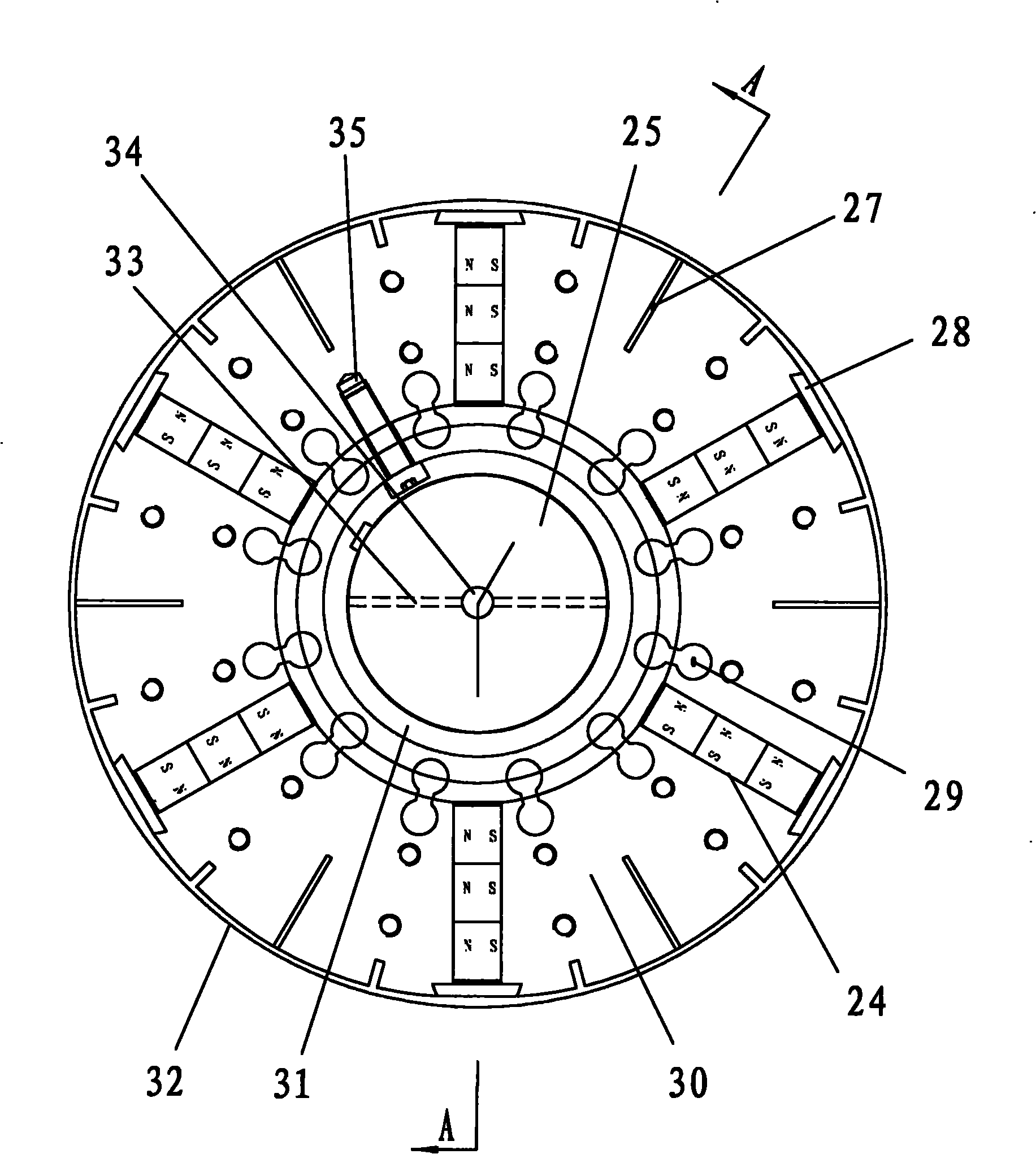

Direct-drive type permanent magnet synchronous motor dedicated to mine hoister

InactiveCN101707414ASimple structureImprove system efficiencyMagnetic circuit rotating partsStructural associationPhysicsMagnetic core

The invention relates to a direct-drive type permanent magnet synchronous motor dedicated to mine hoister, which is a driver motor dedicated to large machinery equipment, belonging to the technical field of electromotor. The direct-drive type permanent magnet synchronous motor dedicated to mine hoister provided by the invention can improve driving efficiency of the mine hoisting system, reinforce reliability of system running, reduce maintenance difficulty and dispense with reduction gears. The direct-drive type permanent magnet synchronous motor dedicated to mine hoister comprises a motor shell, a rotor embedded with a permanent magnet is arranged at the center in the motor shell, a stator magnetic core winded with stator winding is arranged at the outside of the rotor, and the stator magnetic core is fixed on the motor shell. The invention is characterized in that the stator winding is connected with a frequency converter by leads.

Owner:大连伯顿冠力电机有限公司

Novel permanent magnetic synchronous motor

ActiveCN101860100AImprove overload capacityImprove power densityWindingsMagnetic circuit rotating partsSynchronous motorPower factor

The invention relates to a novel permanent magnetic synchronous motor, which is mainly applied to high-energy-consumption industries such as iron and steel, electrical power, petrochemical engineering, machinery and the like. The novel permanent magnetic synchronous motor mainly comprises a stator and a rotor assembly, wherein the rotor assembly comprises a rotating shaft, an inner lining sleeve is fixedly connected in the middle part of the rotating shaft through a flat key, the outer side of the inner lining sleeve is fixedly connected with permanent magnet steel and a shaft sleeve, the shaft sleeve is divided into a plurality of blocks which are fixedly connected with the inner lining sleeve through fastening connecting elements, gaps are arranged between the shaft sleeve cutting blocks divided by the shaft sleeve, permanent magnetic steel is fixedly embedded in the gaps, the permanent magnetic steel can be set into four blocks, six blocks or eight blocks according to the step number of the motor, and the fastening connecting elements can adopt screw bolts and splayed pins. The novel permanent magnetic synchronous motor uses permanent magnets for replacing electric magnetic excitation magnetic poles, realizes the brushless structure, reduces the size of a rotor, omits a magnetic excitation DC power supply, and greatly improves the efficiency of the motor, and the power factor of the novel permanent magnetic synchronous motor is greatly higher than the power factor of an asynchronous motor.

Owner:唐杰

Hybrid-exciting brush-free claw-pole motor

InactiveCN1710781AIncrease the effective pole areaIncrease air gap flux densityMagnetic circuit rotating partsNon magneticHigh power density

Iron core and armature winding constitute outer stator of the motor. Annular exciting winding and magnetic yoke bracket of the exciting winding constitute inner stator. Rotor is composed of claw pole, magnetic yoke of rotor, and shaft. A layer of thin permanent magnetism piece is inlaid on pole faces of each claw pole in rotor. Thickness of each claw pole is identical. Shape of pole face of claw pole is trapezoid. Through soldered points, each adjacent and staggered claw poles are fixed on inner circle of non-magnetic thin circular plate of stainless steel so as to form a whole. Rotor is encapsulated by cylinder prepared by non-magnetic stainless steel. Features of the motor are: high power density, high efficiency, high starting up torque and wide speed adjustable range.

Owner:SOUTHEAST UNIV

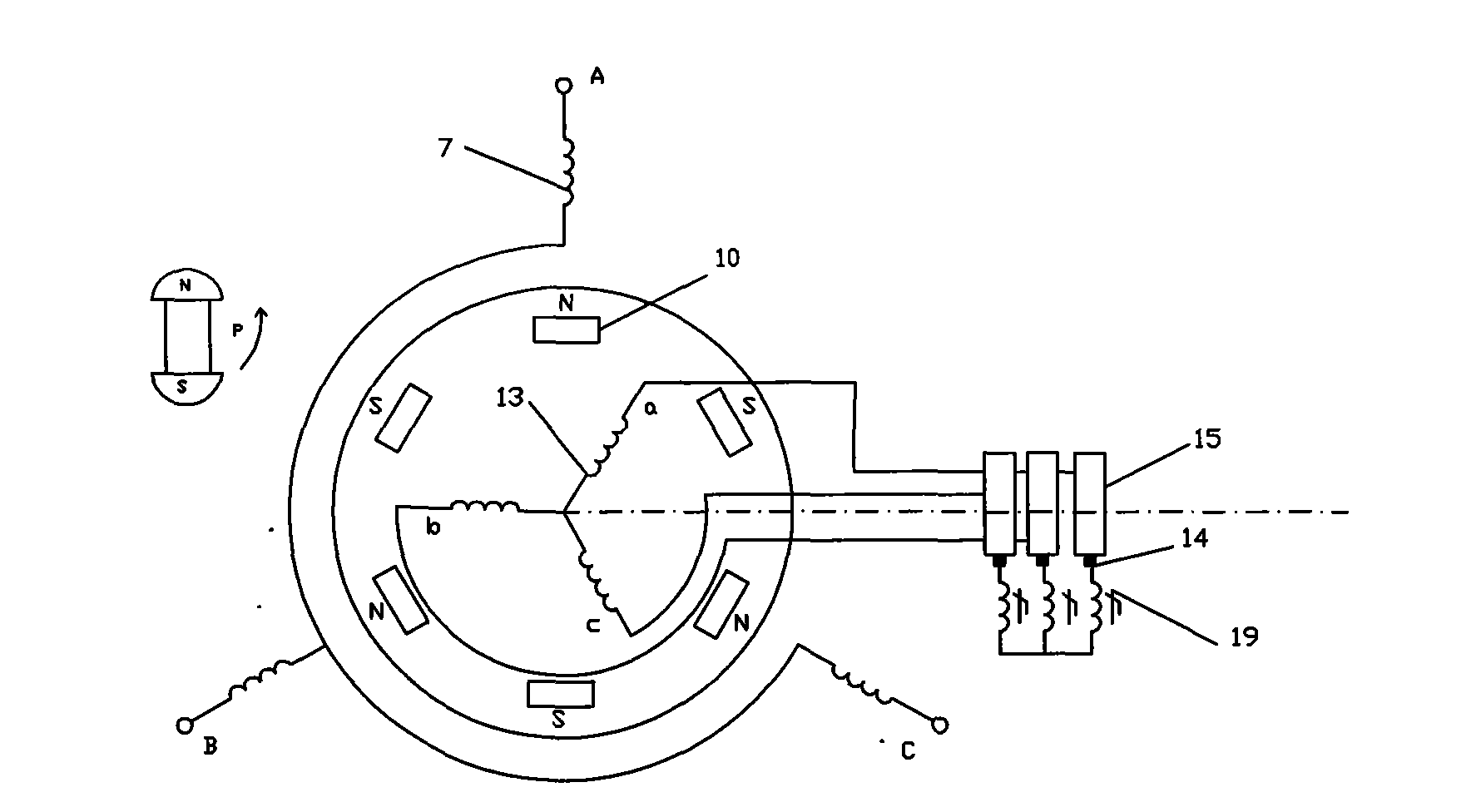

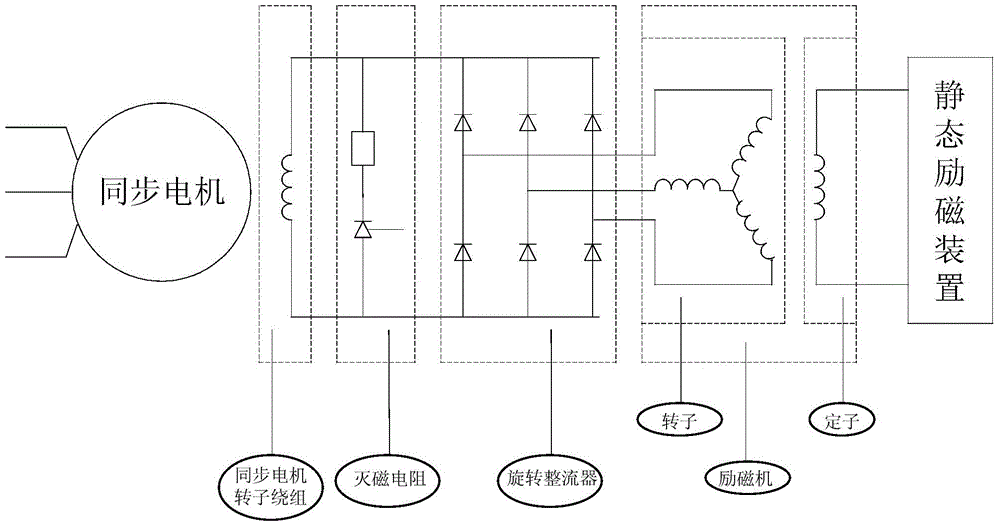

Starting method for brushless direct-current excitation synchronous motor

ActiveCN104901597AAchieve smooth switchingEliminate current shockElectronic commutation motor controlAC motor controlControl vectorSynchronous motor

The invention discloses a starting method for a brushless direct-current excitation synchronous motor. The method includes the following steps of: S1, asynchronous starting closed-loop vector control process: three-phase reference voltage Va, Vb and Vc can be obtained according to three-phase stator current Ia, Ib and Ic of the synchronous motor, and the three-phase reference voltage Va, Vb and Vc c are subjected to pulse-width modulation and are outputted to stator windings of the synchronous motor so as to perform excitation; S2: transition closed-loop vector control process: when the rotation speed of the synchronous motor achieves preset rotation speed, excitation provided by the stator windings is gradually switched to excitation provided by a brushless direct-current excitation device; and S3: synchronous closed-loop control process: when all excitation is switched to excitation provided by the brushless direct-current excitation device, the synchronous motor enters a synchronous operation process. The starting method for the brushless direct-current excitation synchronous motor of the invention has the advantages of simple control, low starting current, excellent speed adjusting performance and high starting torque.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

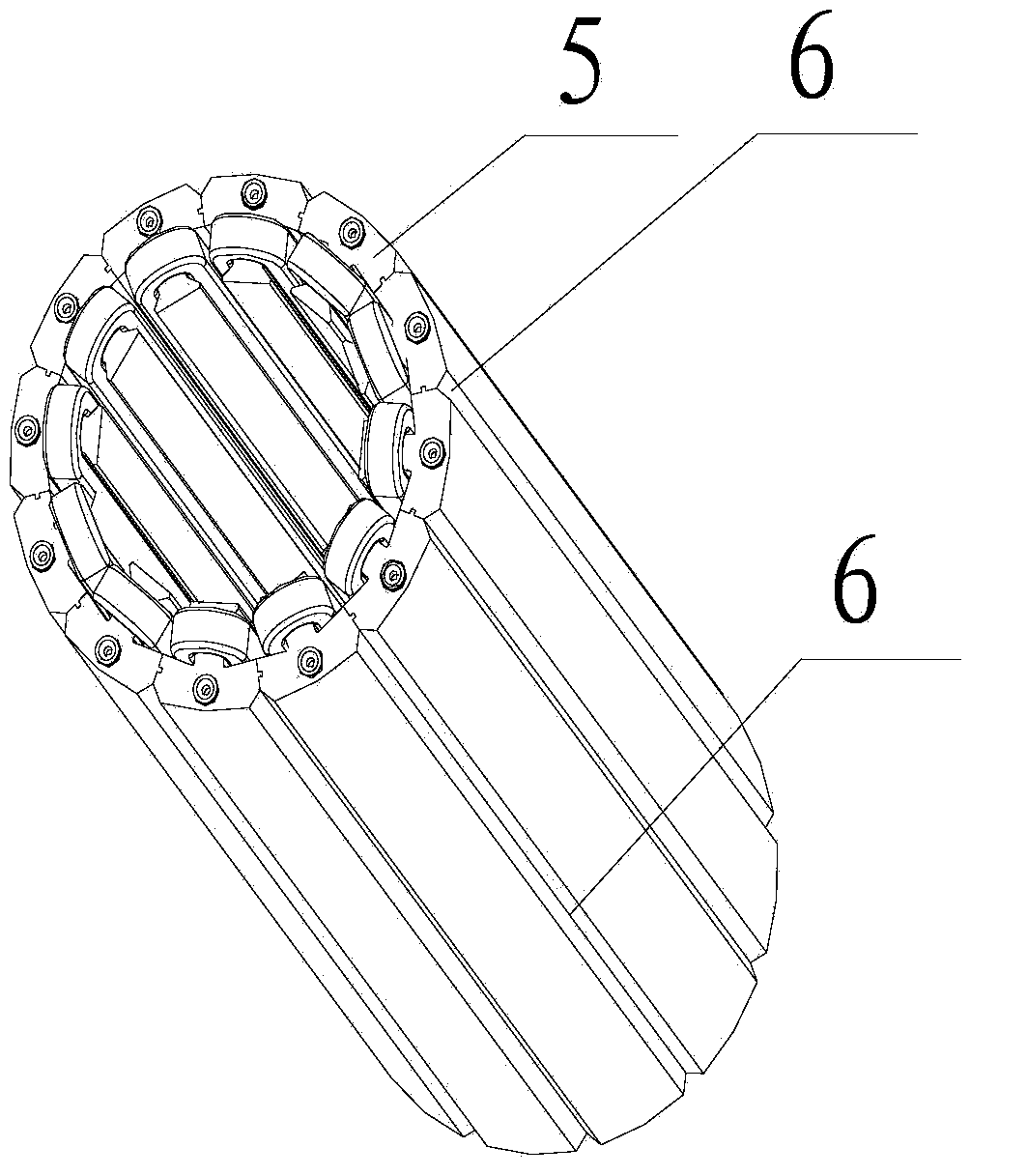

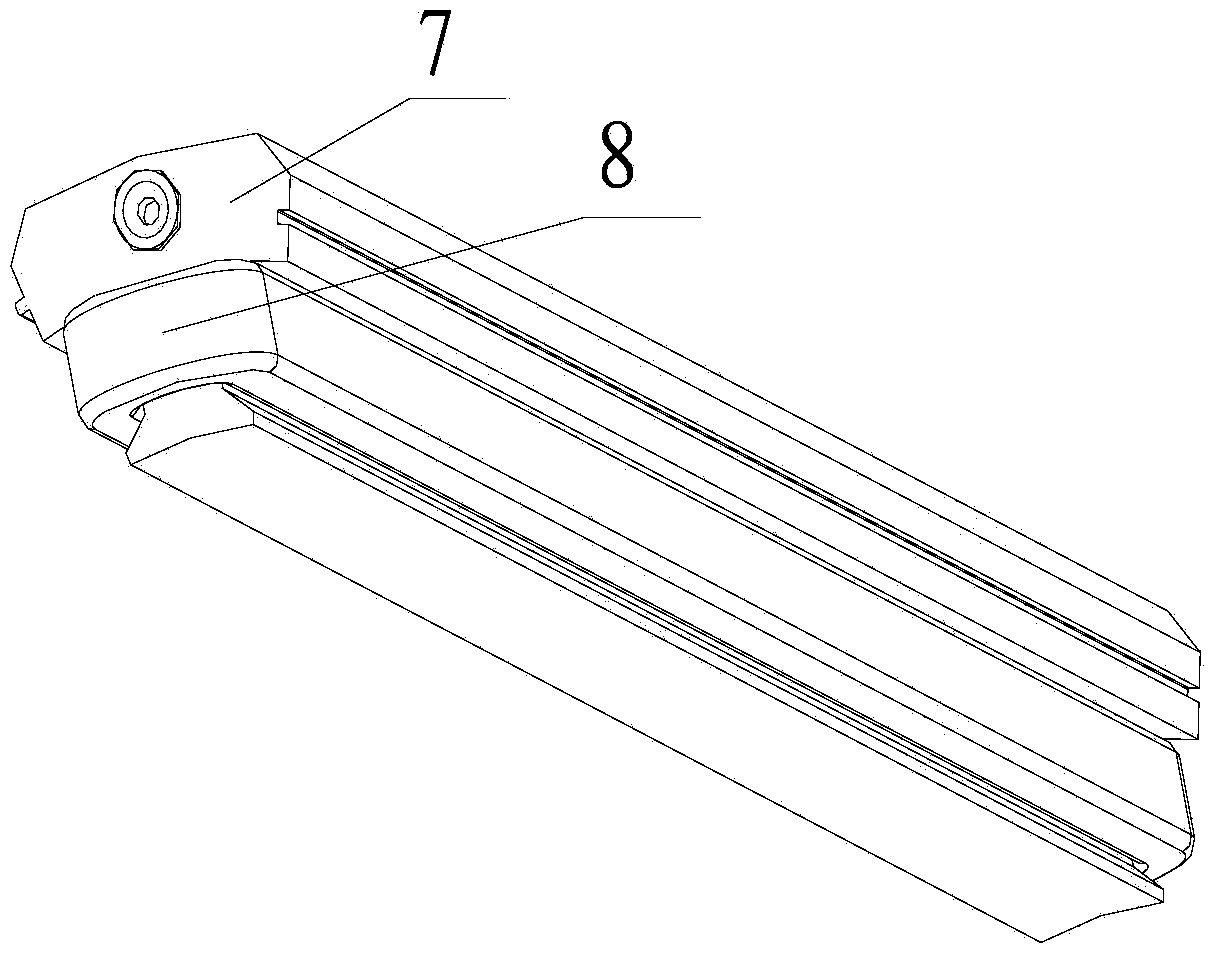

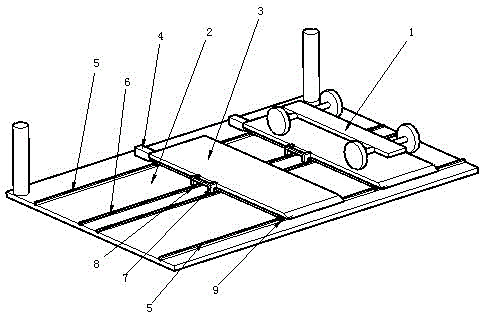

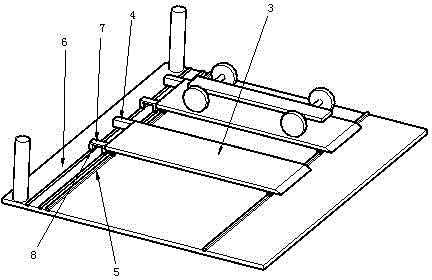

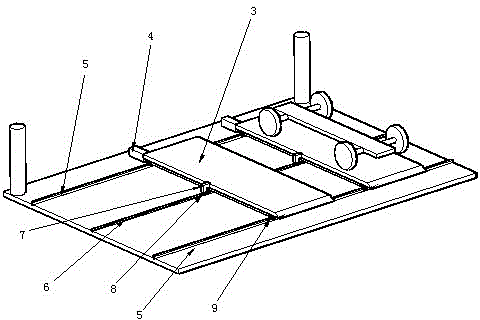

Tool arrangement

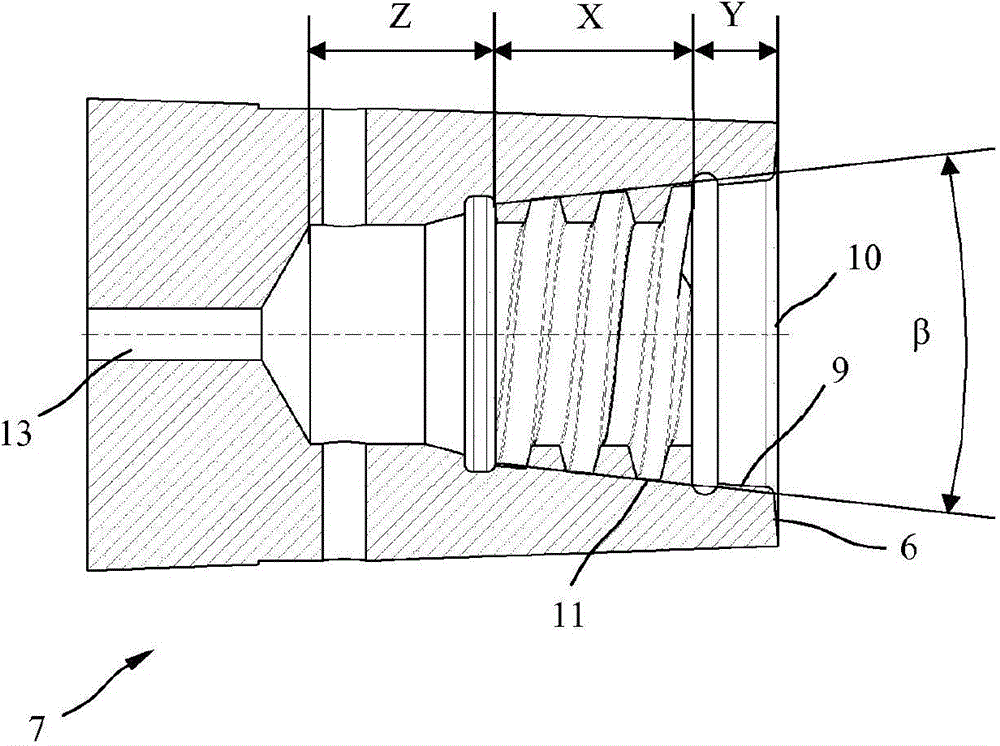

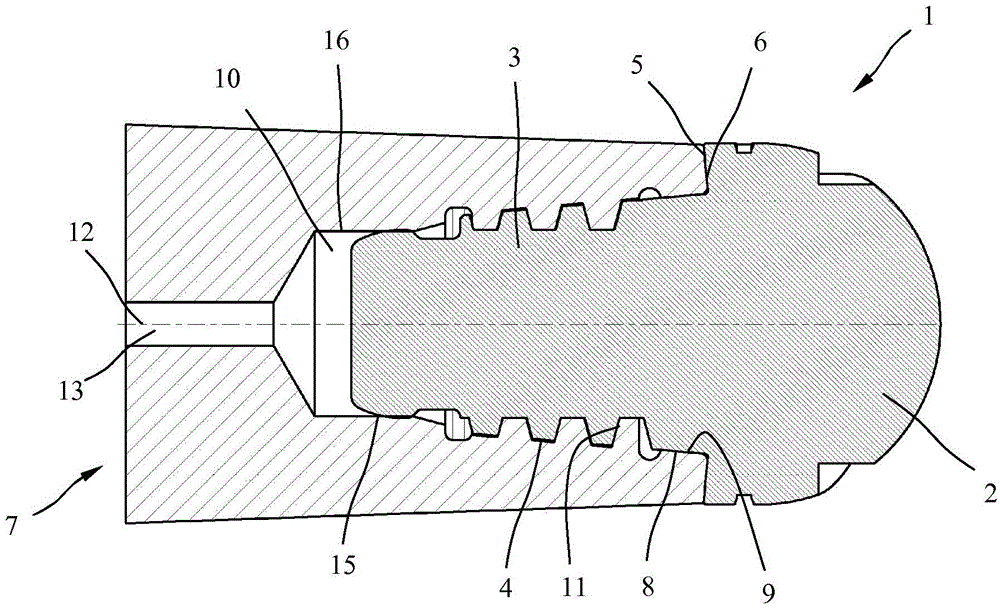

ActiveCN104582882AUniform loadUniform Loading DiagramSleeve/socket jointsTool workpiece connectionEngineeringMechanical engineering

The invention relates to a tool arrangement with a screw-in tool (1) and a tool receiver (7), the screw-in tool (1) having a thread (4) for engagement in a counter thread (11) on the tool receiver (7). According to the invention, the counter thread (11) and the thread (4) have different thread contours and therefore, in the screwed condition, these adapt to one another by elastic deformation.

Owner:FRANZ HAIMER MASCHINENBAU KG

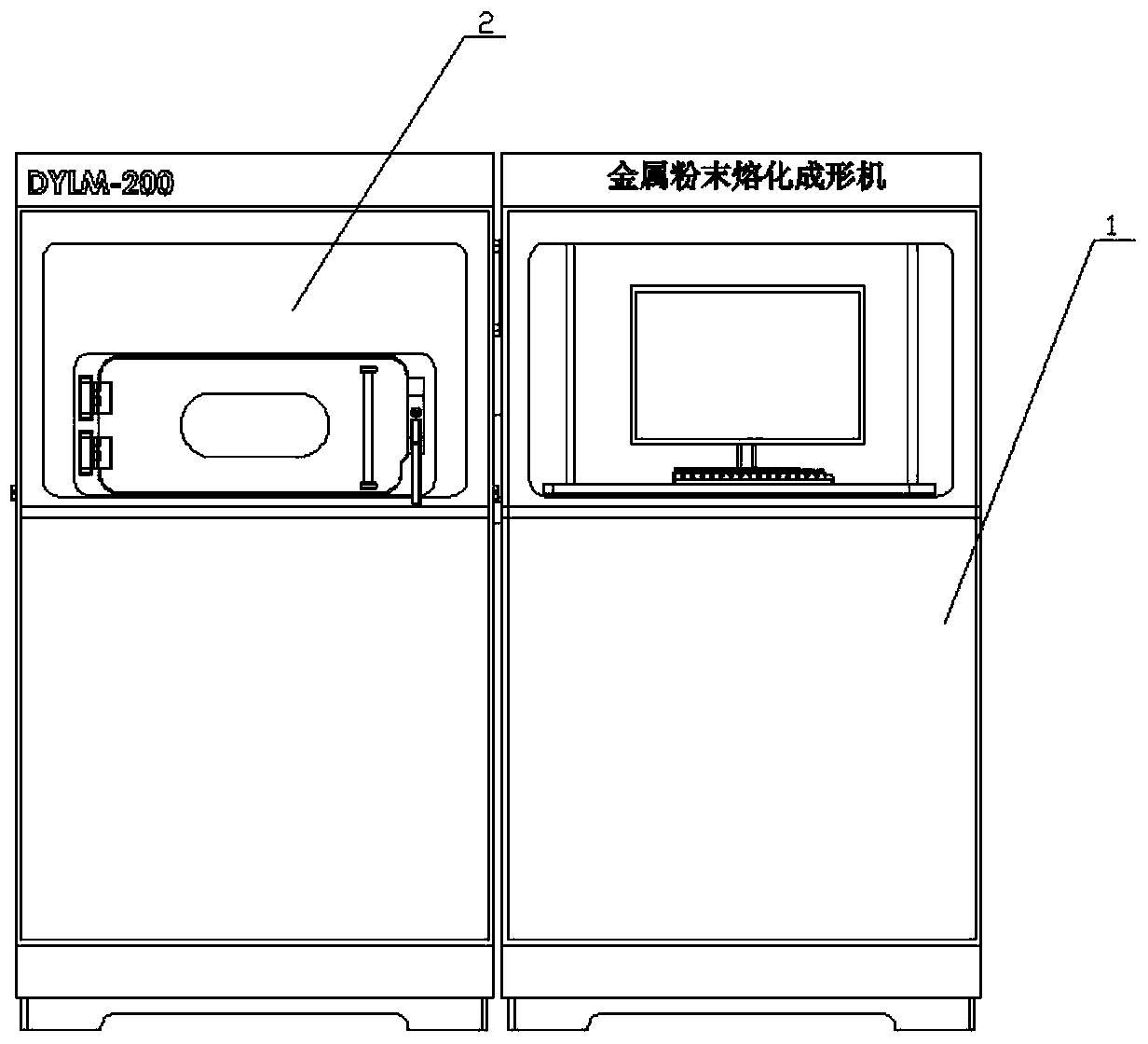

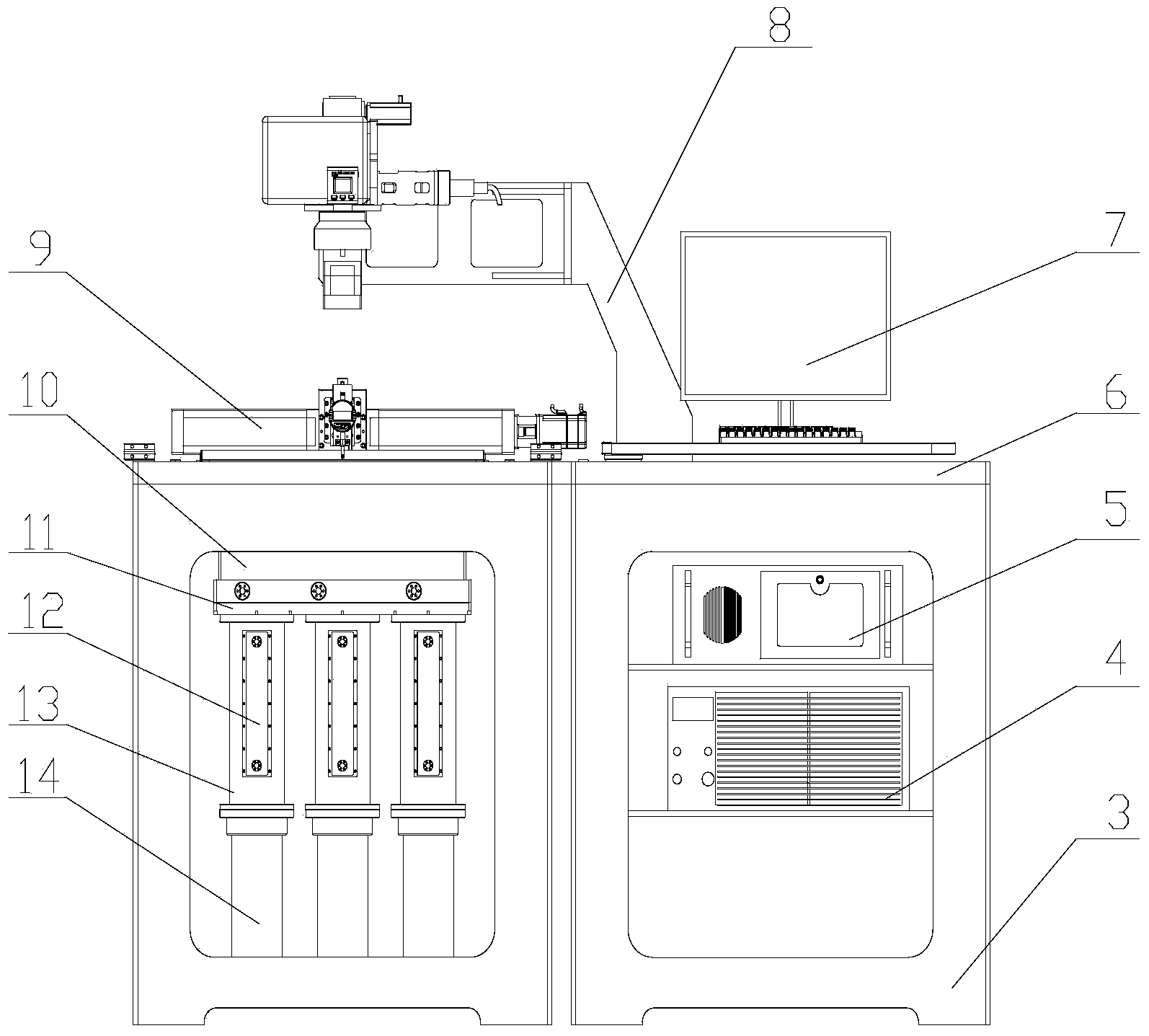

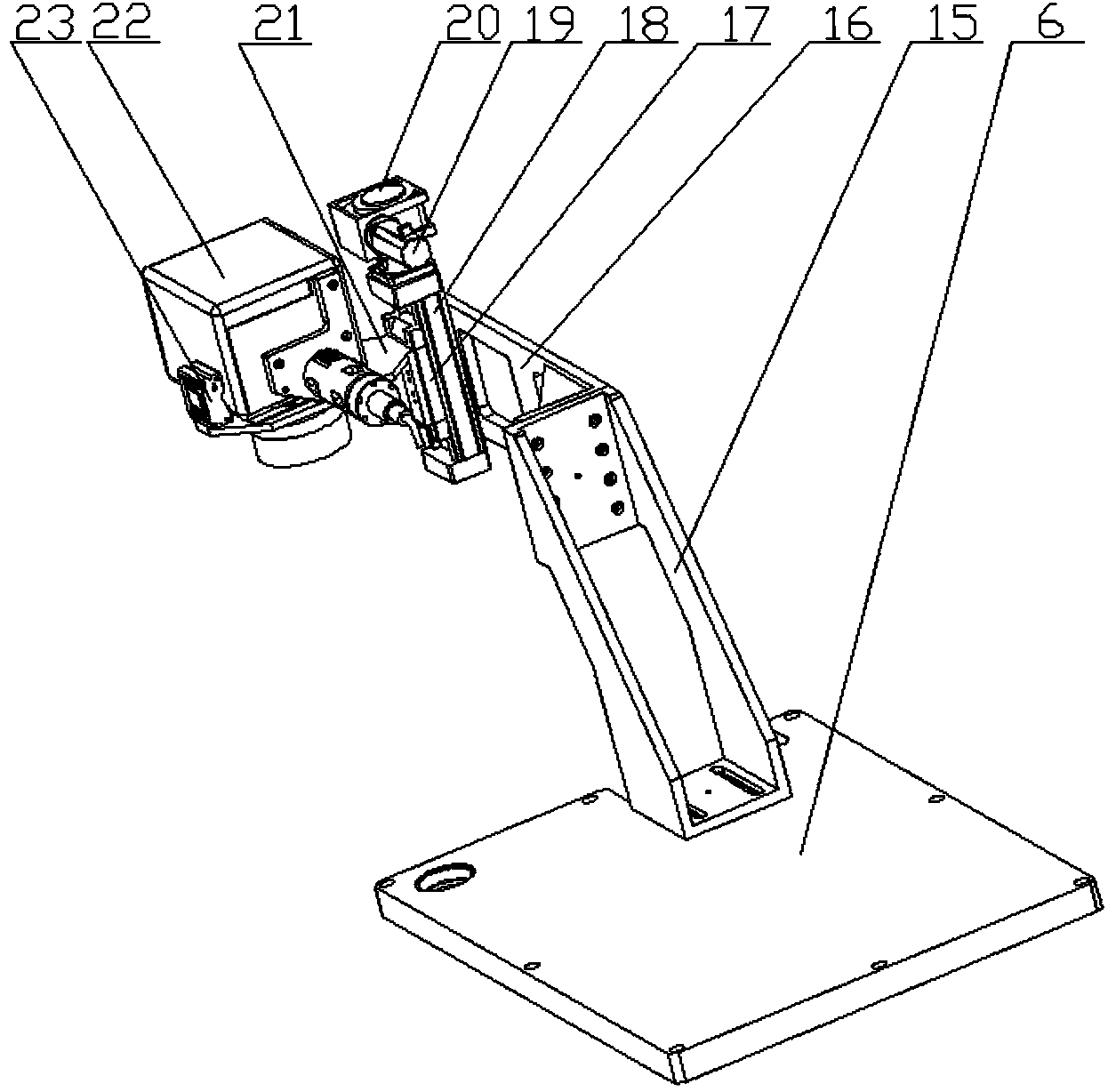

Novel metal powder melting and quick-molding machine

The invention relates to a novel metal powder melting and quick forming machine which comprises a frame, a control system, a laser galvanometer scanning device, a powder laying device, a three-cylinder body and a laser, wherein the control system, the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all arranged on the frame, the laser galvanometer scanning device is in optical connection with the laser, and the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all connected to the control system. The novel metal powder melting and quick forming machine has the advantages that a nonequilibrium supersaturated solid solution and uniform and fine metallographic structures can be obtained, the density of a formed part is close to 100%, the mechanical performance is equivalent to that of a forging part, the processing time and cost can be obviously reduced, and the development cycle of a new product is shortened. The novel metal powder melting and quick forming machine greatly adapts to the requirements of quick, individuated and flexible development of the modem manufacturing industry and has a broad application prospect in the manufacturing fields of aviation, aerospace, medicine, molds, weaponry and the like.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

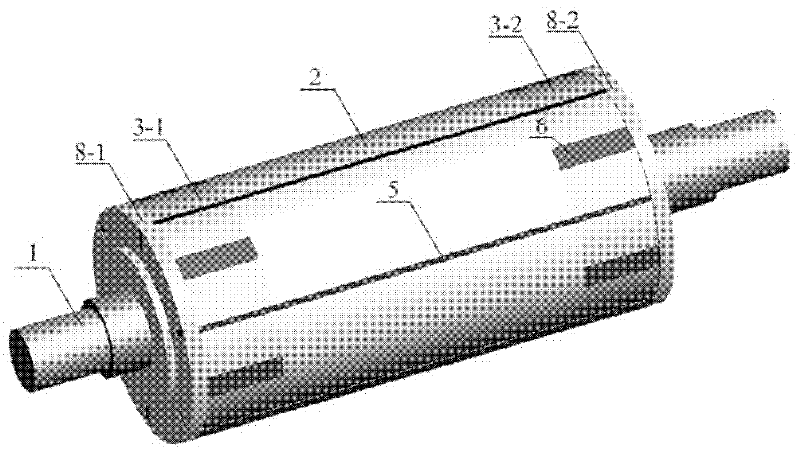

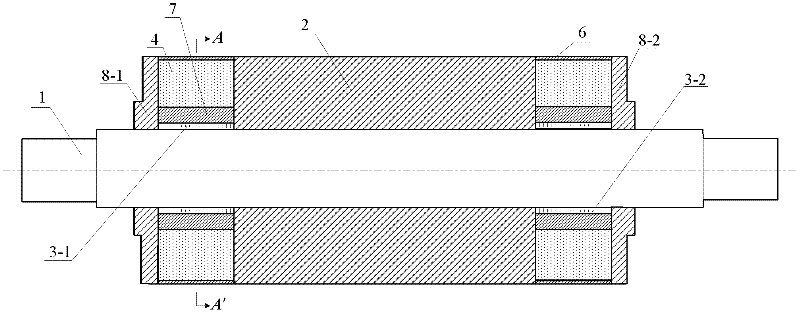

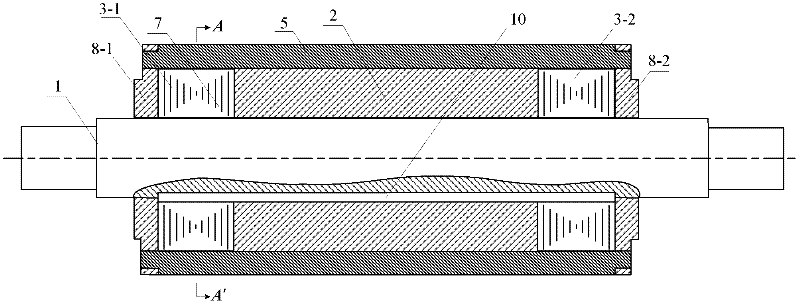

Sandwich permanent magnet synchronous motor rotor structure with solid-lamination axial direction compound

InactiveCN102522841AWith self-starting abilityImprove starting performanceMagnetic circuit rotating partsRectangular apertureInduction motor

The invention provides a sandwich permanent magnet synchronous motor rotor structure with solid-lamination axial direction compound, belonging to the motor technology field. Problems that starting performance of a cage type induction motor is poor, operation efficiency of a solid rotor induction motor is low, and a price of a permanent magnet synchronous motor is expensive are solved. A left lamination rotor part, a solid rotor part and a right lamination rotor part of the rotor structure are sleeved on a rotor shaft in order and are installed on the rotor shaft through key iron. An aluminum magnetic isolation body and a permanent magnet pole are respectively placed in radial slots of the two lamination rotor parts. Aluminum bronze slot wedges are embedded in dovetail slots at openings of the radial slots of the two lamination rotor parts. Iron copper alloy starting cages are embedded in an axially through groove which is formed after installation of the left lamination rotor part, the solid rotor part and the right lamination rotor part. A left end protecting cover and a right end protecting cover are installed at outer side surfaces of the left lamination rotor part and the right lamination rotor part and are in cooperation fixation with rectangular terminals at two ends of the iron copper alloy starting cages through a respective rectangular aperture.

Owner:BEIJING JIAOTONG UNIV

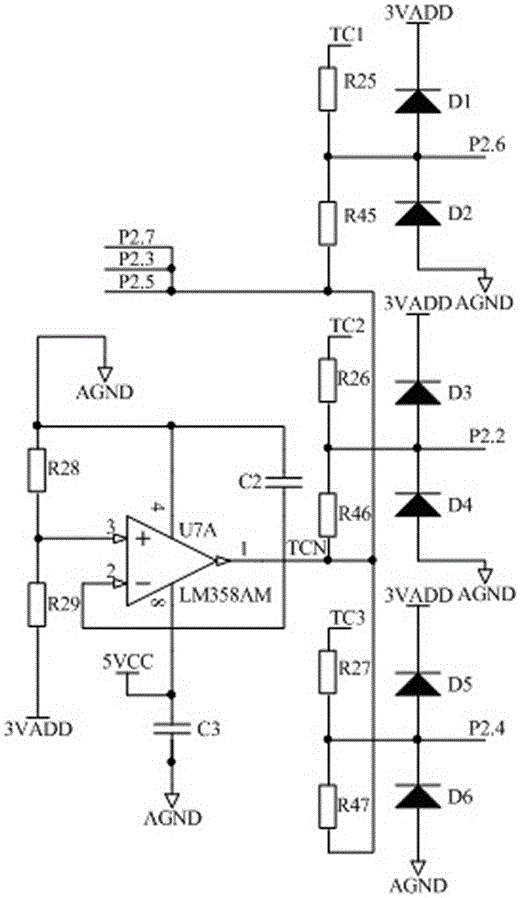

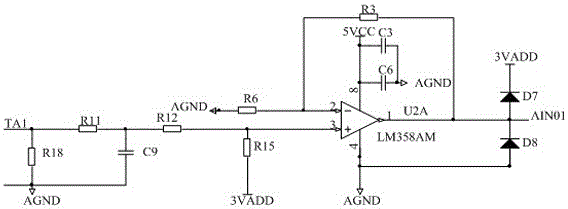

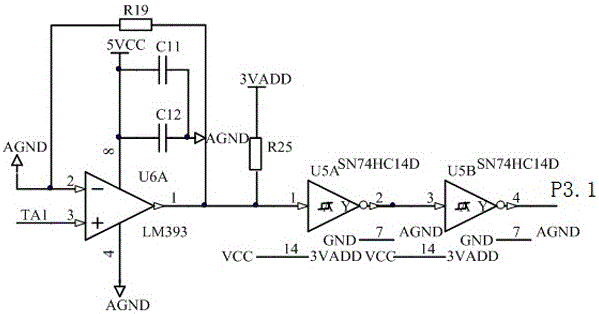

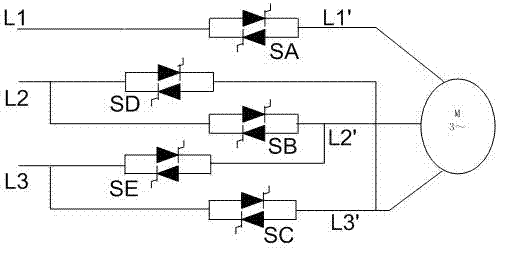

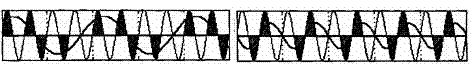

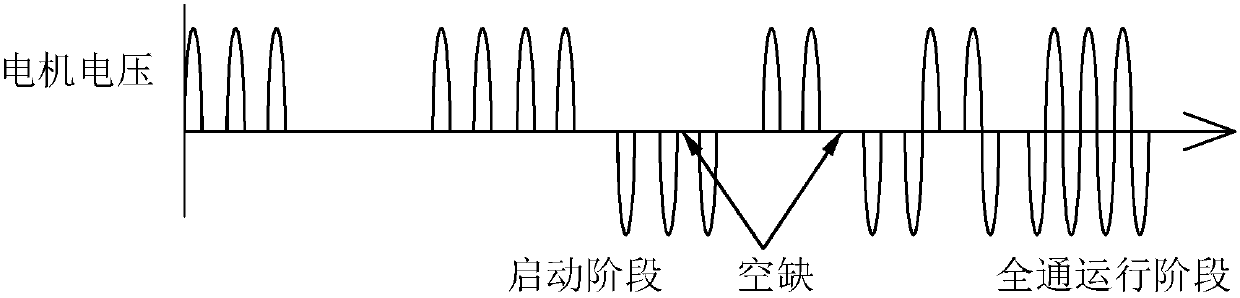

Five-stage discrete frequency-conversion soft-start device based on power factor angle closed-loop control

InactiveCN106026787AConstant voltageReduce torque ripplePolyphase induction motor starterMicrocontrollerLoop control

The name of the invention is a 5-stage discrete frequency conversion soft starter based on power factor angle closed-loop control, which is applied in the motor starting process. The main circuit adopts the traditional thyristor soft starter main circuit, including the main circuit three-phase AC contactor K1, bypass One-way three-phase AC contactor K2, three-phase six-way anti-parallel thyristor, motor. The synchronous signal acquisition circuit and the current detection circuit collect the voltage and current signals in the main circuit and output them to the single-chip microcomputer, and the single-chip microcomputer sends instructions to the trigger circuit after calculation, and the trigger circuit receives the single-chip microcomputer signal and sends a trigger pulse to the thyristor. The control method of this device adopts the 5-stage discrete frequency conversion soft-start control method. During the process of voltage rise, the frequency is discretely increased in 5 stages. f / 7→ f / 4 → f / 3→ f / 2→ f (50Hz). The device can reduce the starting current of the motor and increase the starting torque of the motor, and is especially suitable for the occasion of heavy-load starting of the motor.

Owner:TAIYUAN UNIV OF TECH

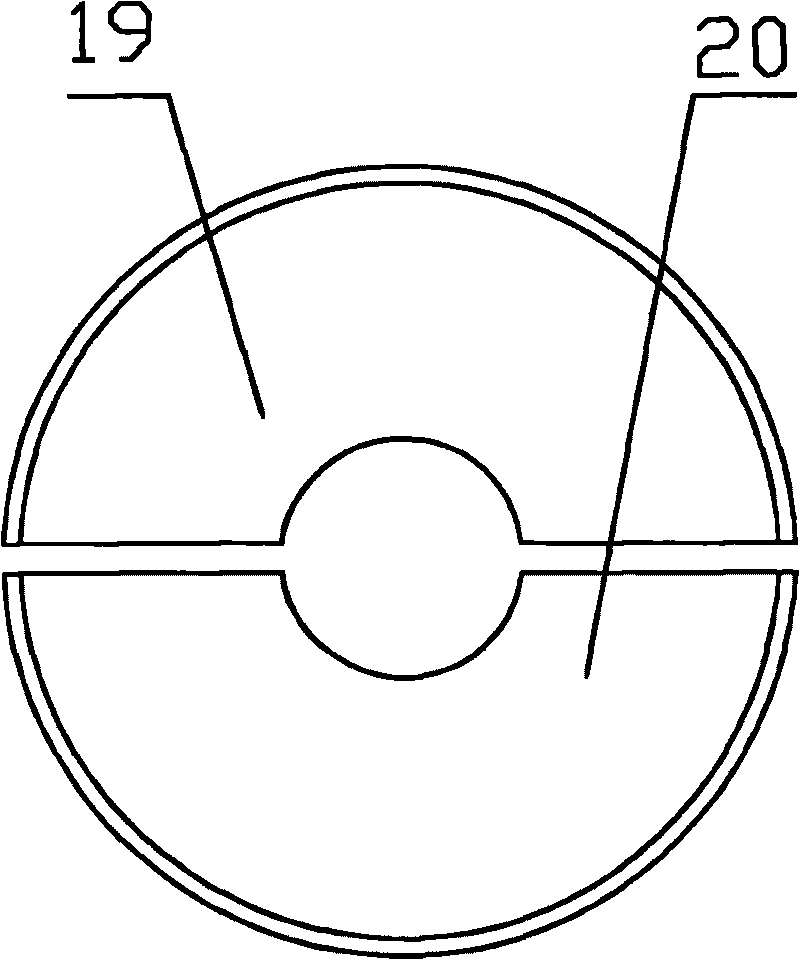

Single-phase self-start permanent magnet synchronous motor

ActiveCN102044946AEasy to startIncrease starting torqueSynchronous machine detailsSynchronous machines with stationary armatures and rotating magnetsNoise levelPermanent magnet synchronous motor

The invention discloses a single-phase self-start permanent magnet synchronous motor, which comprises a rotor yoke, a permanent magnet and a stator. The permanent magnet is attached to an inner surface of the rotor yoke, and an N pole and an S pole are distributed alternately; the stator is arranged on the inner side of the permanent magnet and comprises a stator core and a single-phase stator winding; a tooth part surface of the stator core is a curve formed by connecting a first arc section and a second arc section; an air gap is formed between the curve and the inner surface of the permanent magnet; the centre of a circle of the first arc section and the second arc section is not the rotation centre of the motor; and the air gap is non-uniform two-section air gap. As the two-section air gap is different from a one-section air gap structure of which the air gap gradually grows from the smallest part to the biggest part, the air gap of the two-section air gap gradually grows from thesmallest part to the biggest part and then to the smallest part, the starting performance of the self-start permanent magnet synchronous motor can be improved, the torque ripple is weakened, the vibration and noise level is reduced, and the operation stability is increased.

Owner:SOUTHEAST UNIV

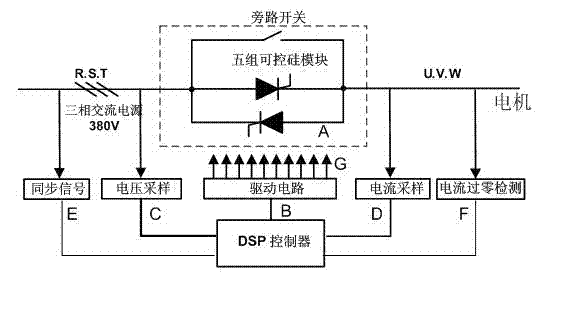

Graded frequency conversion stepless voltage regulating soft starting device based on non-speed sensor

InactiveCN102904492ASmall starting currentIncrease starting torquePolyphase induction motor starterLoop controlThree phase asynchronous motor

The invention discloses a graded frequency conversion stepless voltage regulating soft starting device based on a non-speed sensor, and belongs to the technical field of starting of motors, and the device is mainly used for solving the problems that the existing soft starting device has reduced starting voltage, consequently the starting torque is seriously reduced, and the heavy-duty starting is hard. The graded frequency conversion stepless voltage regulating soft starting device is mainly characterized by being composed of a main loop which is composed of five groups of sequentially-connected antiparallel controllable silicon groups, and a main loop control circuit, wherein the main loop control circuit comprises a DSP (digital signal processor) controller, a current signal zero cross detection circuit, a voltage sampling circuit, a current sampling circuit, a synchronous signal collection circuit and a driving circuit; and the voltage sampling circuit and the synchronous signal collection circuit are connected between the main loop and a DSP, the current sampling circuit and the current signal zero cross detection circuit are connected between the main loop and the DSP, and the driving circuit is connected between each silicon controlled end and the DSP. The graded frequency conversion stepless voltage regulating soft starting device provided by the invention has the characteristics that the starting current is small, the starting torque is high, the frequency division section switching is smooth, and the graded frequency conversion stepless voltage regulating soft starting device is mainly used for a three-phase asynchronous motor belt heavy-duty starting occasion.

Owner:万洲电气股份有限公司

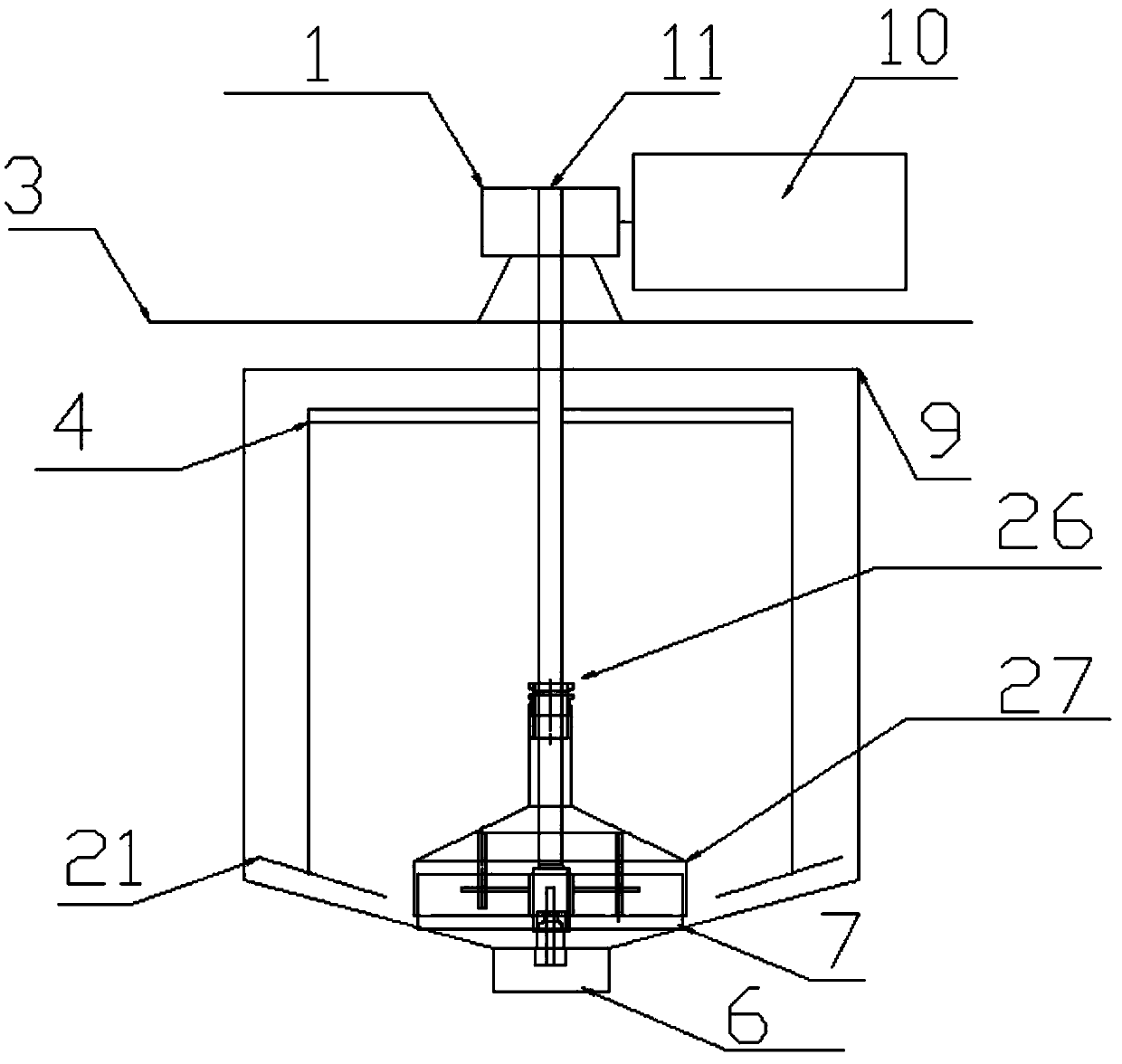

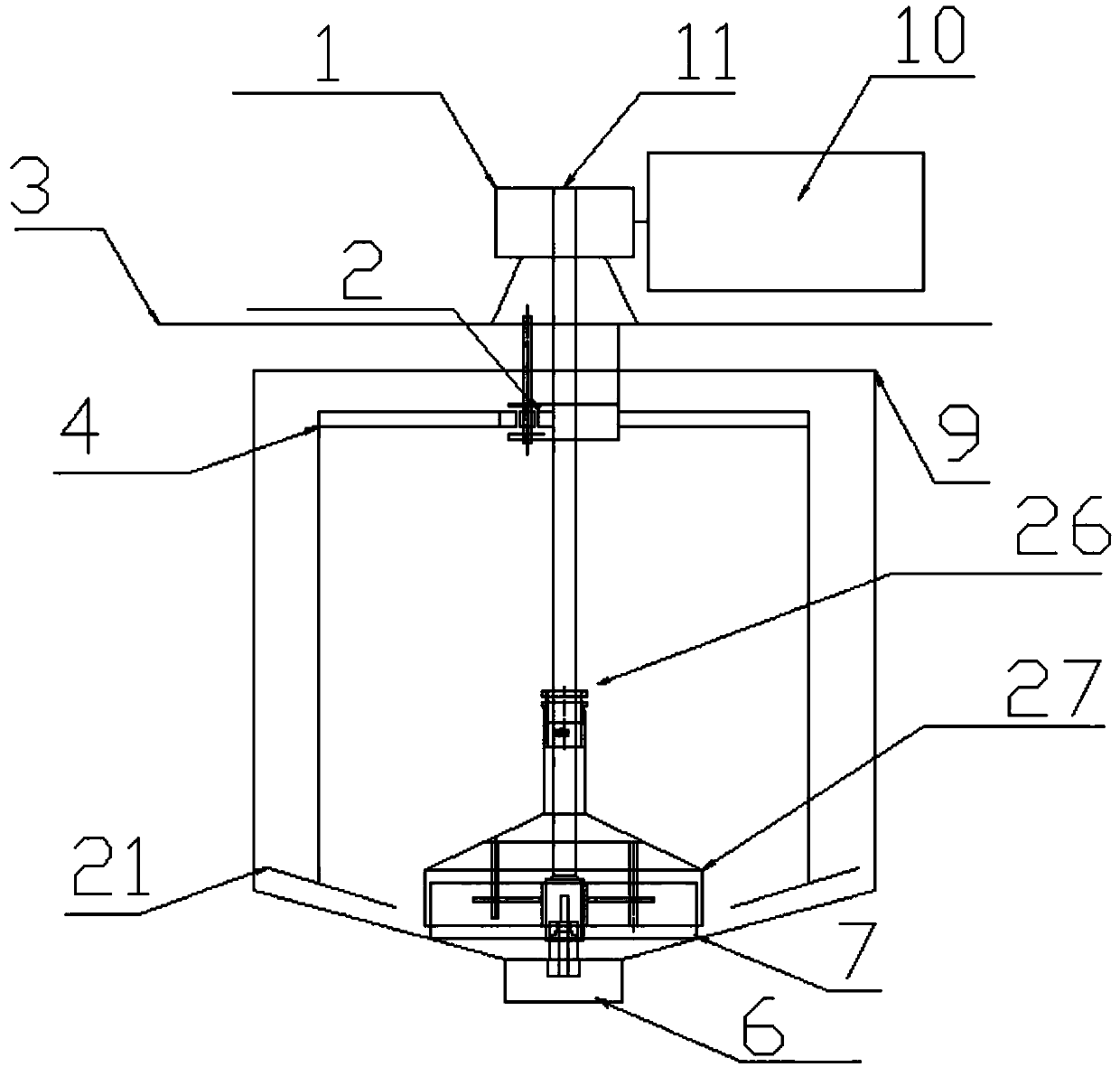

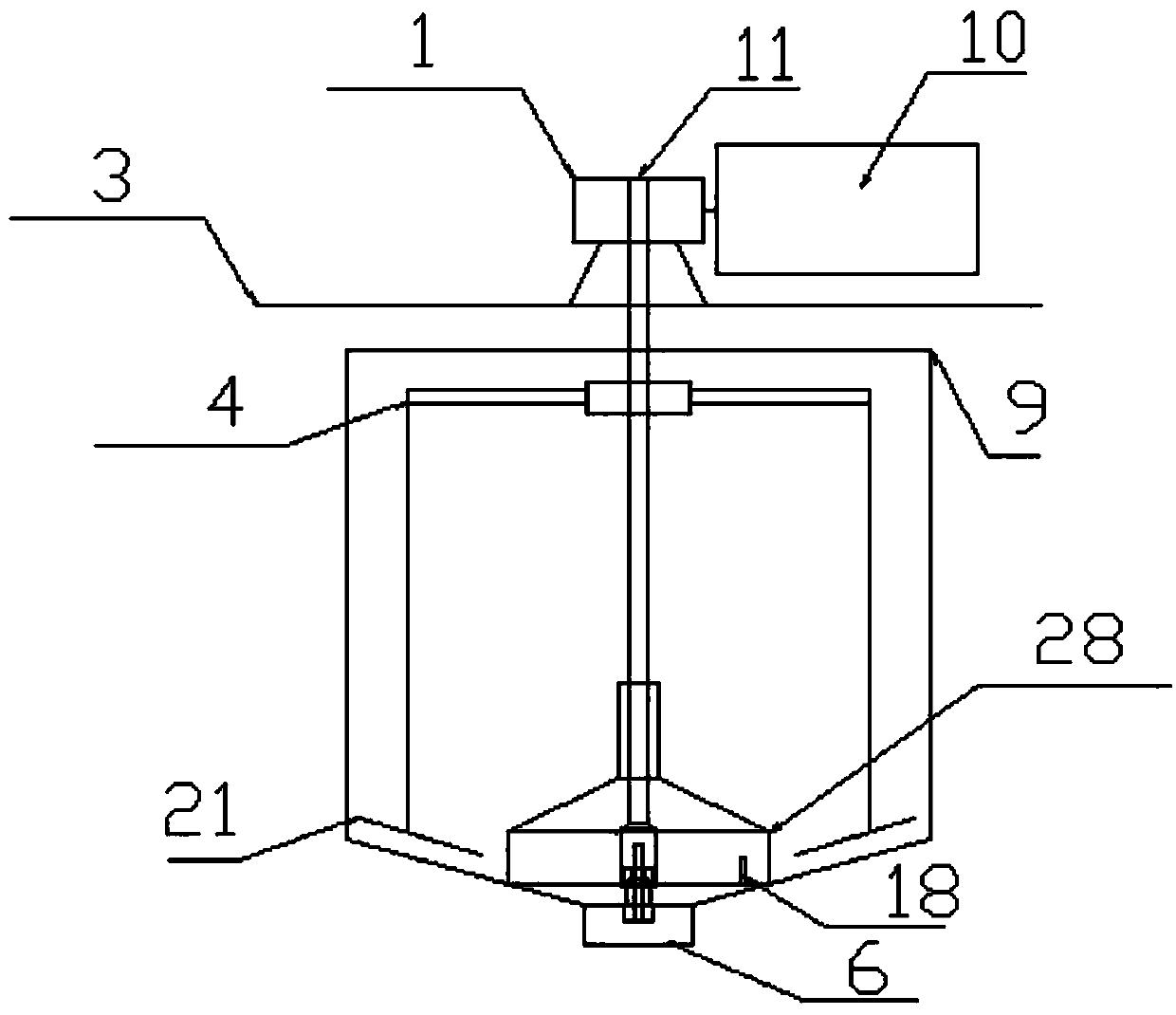

Uniform powdery material feeding device

InactiveCN104210856AIncrease starting torqueNot easy to stallLarge containersLoading/unloadingPowderControl engineering

The invention relates to a uniform powdery material feeding device which comprises a tank body, wherein the top of the tank body is provided with a stepping motor and a speed reducer, wherein the stepping motor is connected with the speed reducer; the speed reducer is used for transferring power to a transmission shaft; the middle upper part of the transmission shaft positioned in the tank body is connected with a material overturning tool fixing rack which is connected with a material overturning tool used for overturning materials in the tank body; the lower end of the transmission shaft is connected with a uniform feeding control component. According to the scheme, the powder material feeding precision can be precisely controlled, and the uniform powdery material feeding device is high in popularization value.

Owner:张永利

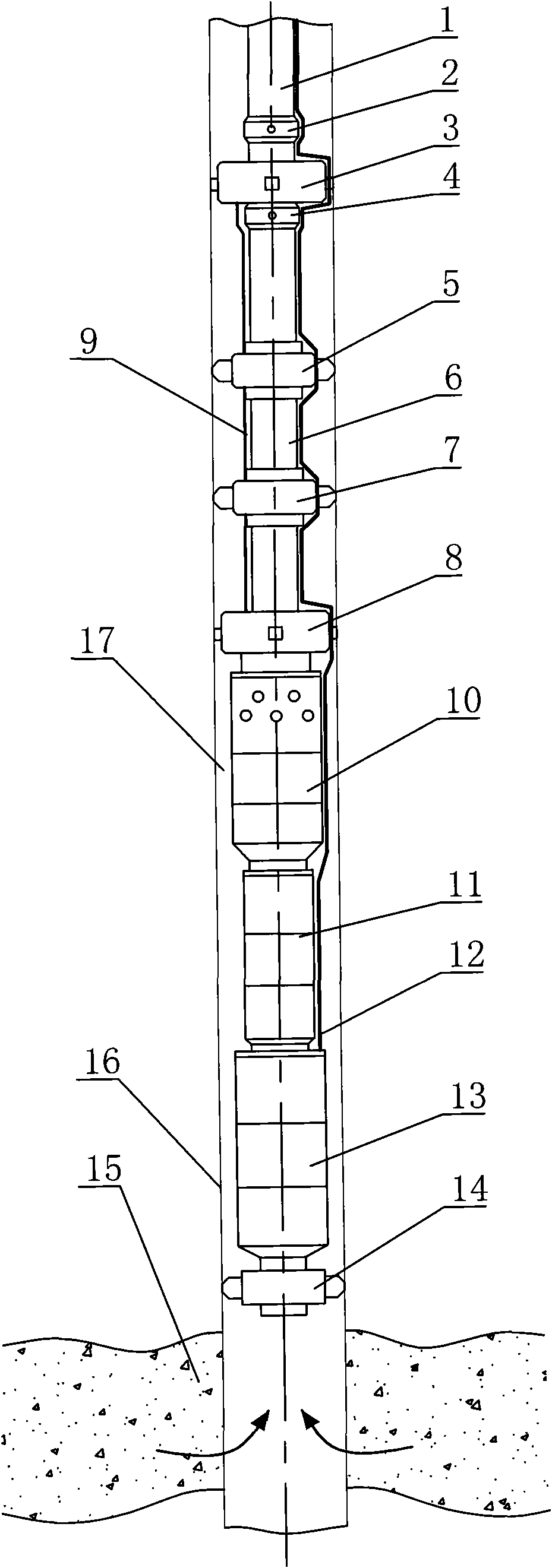

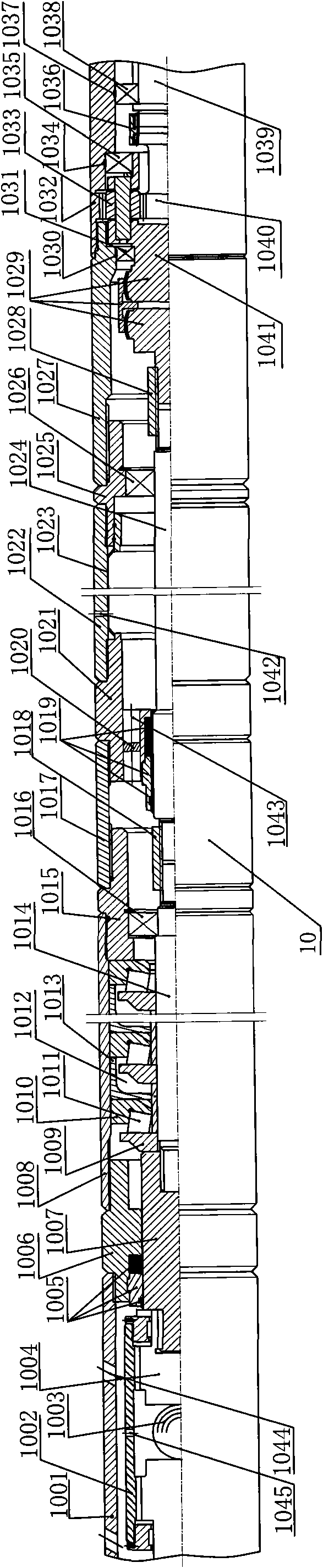

Large-discharge electric submerged screw pump oil extracting equipment

ActiveCN101864932AWith anti-vibration effectAspect ratio heightFluid removalElectric machineCoupling

The invention relates to large-discharge electric submerged screw pump oil extracting equipment. Compared with the traditional electric submerged screw pump oil extracting equipment which belongs to a large-discharge series and also mainly comprises an underground motor, an underground rotating type mechanical drive device, an underground screw pump, and the like, the large-discharge electric submerged screw pump oil extracting equipment has the technical scheme key that the underground screw pump is connected with an underground multistage motor by the underground rotating type mechanical drive device; the screw pump is rigidly fixed on the sleeve pipe wall of an oil well by adopting the underground multistage motor with high torque output and vibration resistance, a drum-gear coupling with high torque output, vibration resistance and an opening type structure, a series combined stopping type bear joint and an underground rotating type mechanical drive device of a compensating type lubricating oil tank through an anchoring device; the problem of oil leakage of an oil pipe of a large-gradient well or a horizontal well is solved by adopting a hydraulic type oil pipe oil drainer; and the large discharge of the electric submerged screw pump is realized by the technical measures, and thus the invention can be used for the oil well with large-discharge (more than 200m<3> / d) on the electric submerged screw pump.

Owner:盘锦三阳石油科技发展有限公司

Axial structured permanent-magnet motor

ActiveCN105680656AImprove power densityExcellent mechanical propertiesMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet motorHardness

The invention provides an axial structured permanent-magnet motor which is applicable for fields of a motor and a power generator. The axial structured permanent-magnet motor comprises two stators and a rotor, wherein the rotor is arranged between the two stators, and a gap exists between the stators and the rotor. In the axial structured permanent-magnet motor, the stators and the rotor are matched, the power density and the mechanical characteristic of the motor can be improved, and the fabrication cost of the motor is reduced; and the motor efficiency can be remarkably improved with the low loss characteristics of the stators made of amorphous and nanocrystalline material, the starting torque of the motor also can be increased with the high-permeability characteristics, and the output hardness of mechanical characteristic of the motor under a high rotational speed also can be improved with the wideband characteristics.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Parking pallet transverse moving drive device

InactiveCN104563564AIncrease starting torqueGood safety and reliabilityParkingsFailure rateMotor drive

Disclosed is a parking pallet transverse moving drive device. Rails are arranged on a ground parking space, parking pallets are arranged on the rails, rollers are arranged on the parking pallets, and each parking pallet is driven by a motor to bilaterally move on the rails. The parking pallet transverse moving drive device is characterized in that a direct-current motor is arranged on each parking pallet, a power supply brush carrier is arranged on the back surface of each parking pallet, a positive power supply brush and a negative power supply brush are arranged on each power supply brush carrier, a positive conducting rail and a negative conducting rail are bilaterally arranged on the ground parking space below the parking pallets, the positive power supply brush and the negative power supply brush slide on the two conducting rails to acquire direct-current voltage, each direct-current motor drives the corresponding parking pallet to bilaterally move on the rails, the device is used on the parking pallets needing transverse moving, the direct-current motors on the parking pallets acquire power from the positive conducting rail and the negative conducting rail on the ground parking space, the parking pallets do not need power wires, the failure rate of the parking drive device can be effectively decreased, and the running condition of the device is improved.

Owner:梁晓军

Novel tri-power, efficient, energy-saving three-phase asynchronous motor used for oil extractor

InactiveCN101447720ALarge starting torqueImprove operating efficiency and power factorAsynchronous induction motorsWindings conductor shape/form/constructionContactorOil well

The invention discloses a novel tri-power, efficient, energy-saving three-phase asynchronous motor used for an oil extractor, which comprises a rotor and a stator winding; the stator winding adopts the unique 3Y composite series connection method and the novel technology of turn removal; the stator winding corresponds to a low power grade, a medium power grade and a high power grade, and the number of turns of serial coils in each phase reduces with the power grade, with the low grade power corresponding to a maximum number of turns and the high grade power corresponding to a minimum number of turns; and the switch among the three power grades is achieved by three contactors. As the invention has the high, the medium and the low power grades which are all available for option, and the high power grade has a high start-up torque and is applied to starting the oil extractor, the motor can automatically operate at the low or medium power grade on the completion of the start-up process, and can realize two-way automatic switch of operating power according to the change in the working condition of an oil well. As the motor has the advantages of great start-up torque, high operating efficiency and power factor, convenient control, good reliability and remarkably reduced no load current, the motor can achieve better energy-saving effect.

Owner:南阳华晟辰电机工程有限责任公司

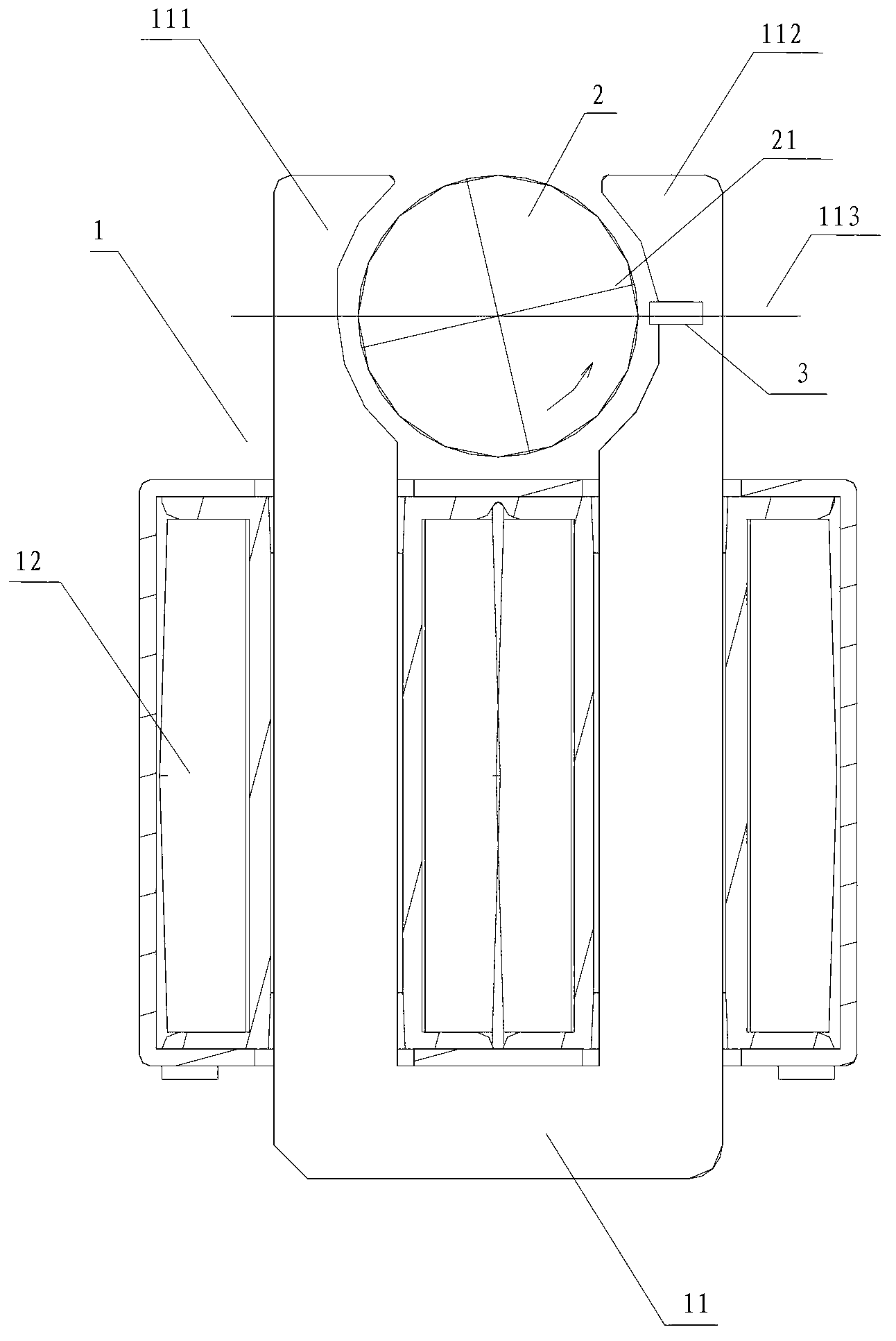

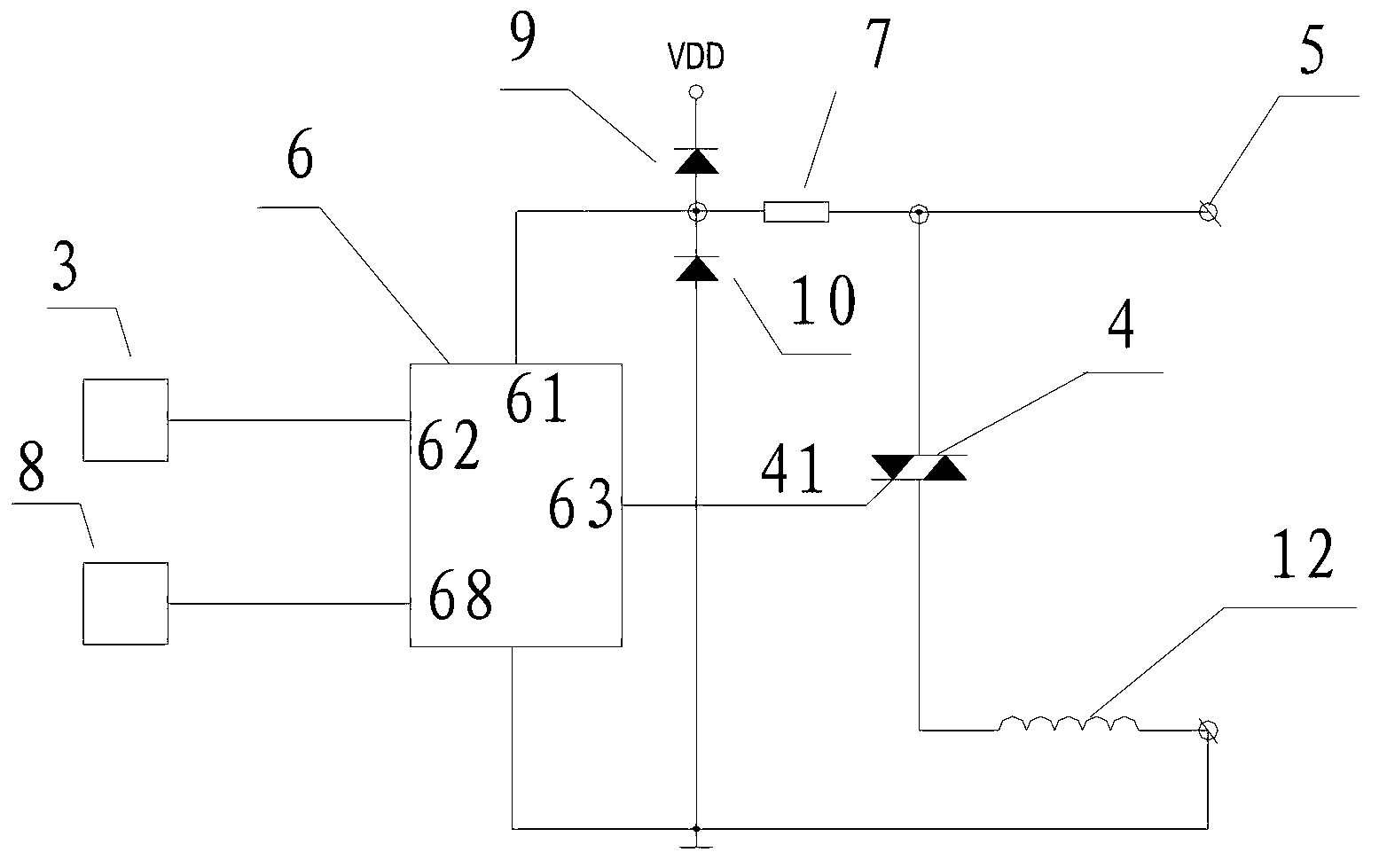

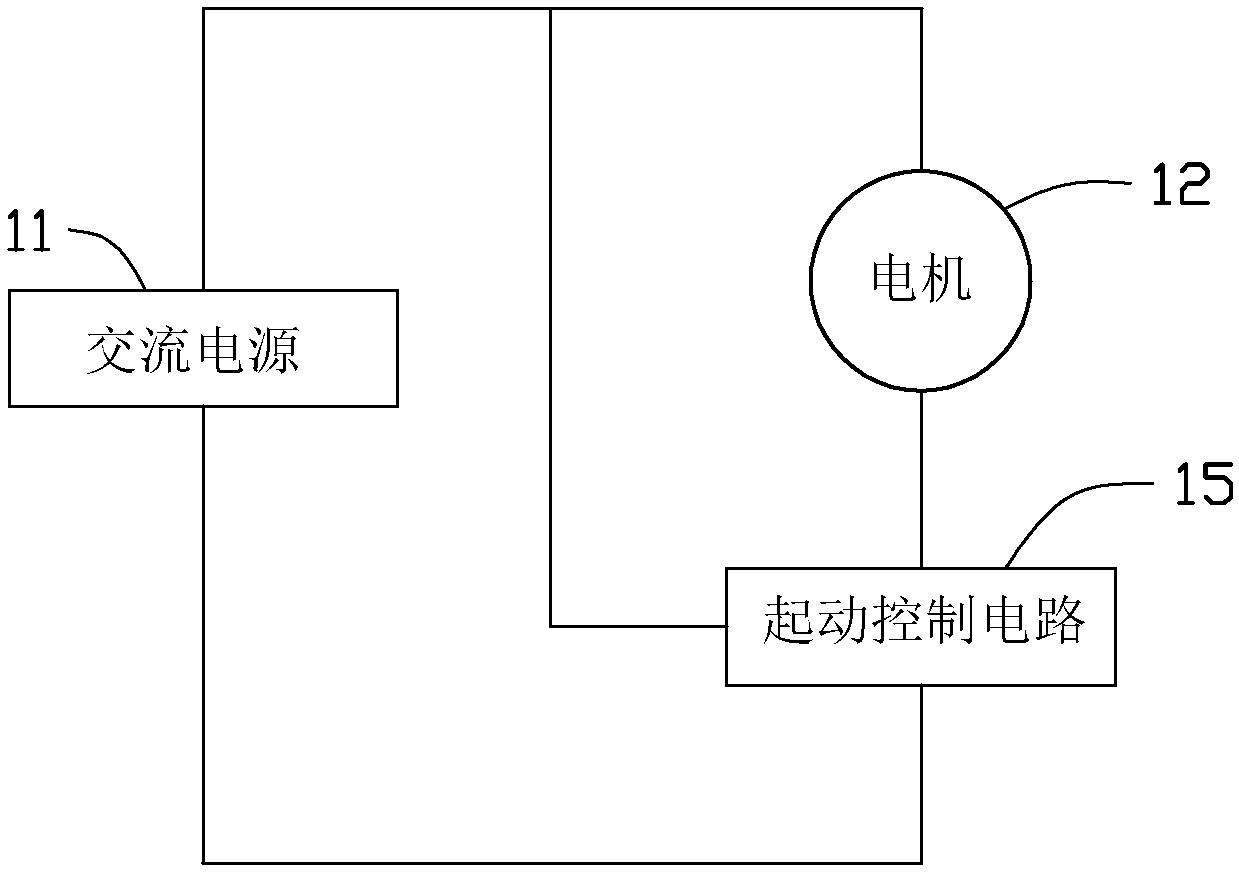

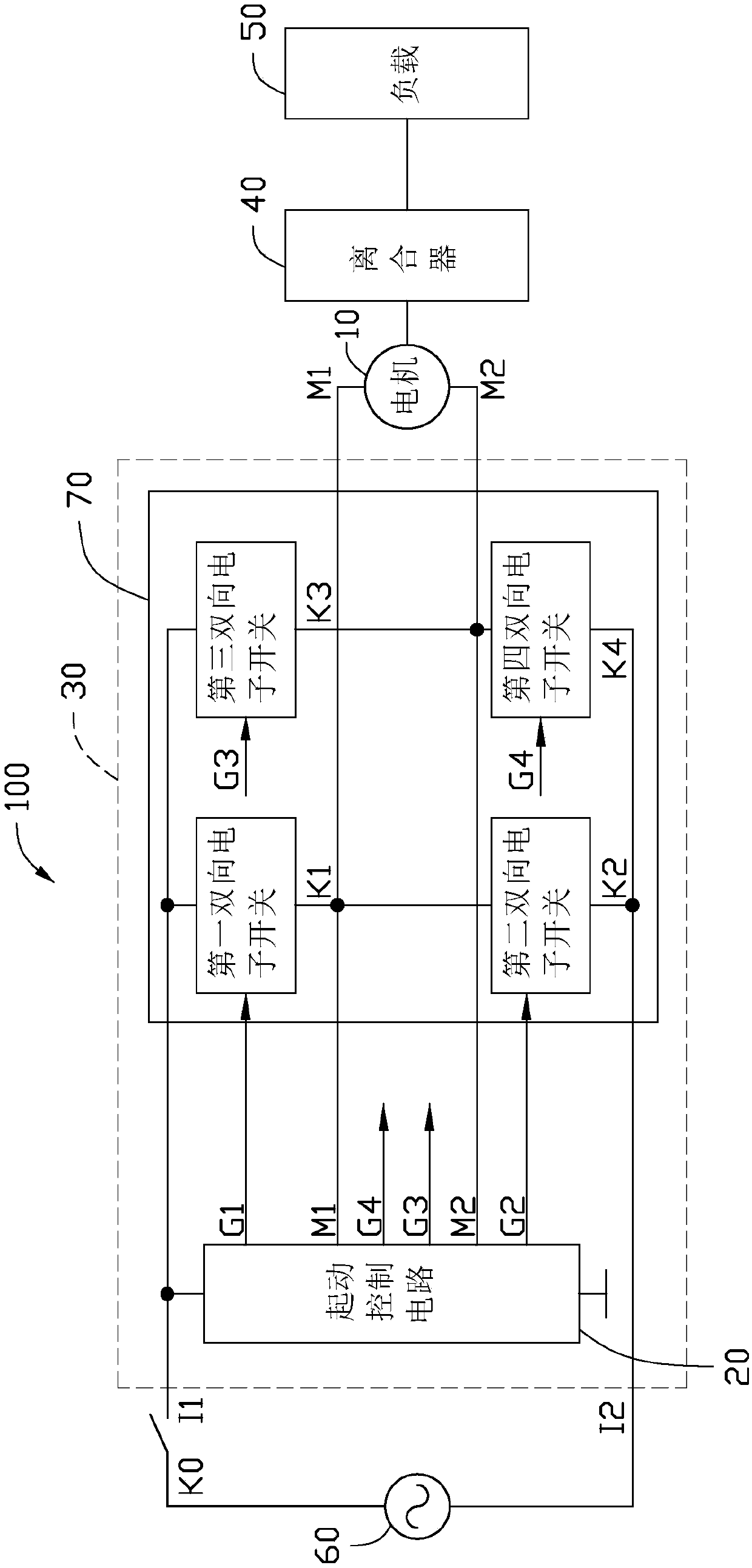

Motor drive device, motor assembly and load drive device

The invention provides a motor drive device, a motor assembly employing the same and a load drive device. The motor drive device includes a start control circuit and a bridge-type circuit. The bridge-type circuit includes a first bridge arm and a second bridge arm. The first bridge arm includes a first and a second bidirectional electronic switch connected in series. The second bridge arm includesa third and a fourth bidirectional electronic switch connected in series. The first bridge arm and the second bridge arm are connected between a first terminal and a second terminal of an AC power source in parallel. The synchronous motor is connected between a connection point of the first and the second bidirectional electronic switch and a connection point of the third and the fourth bidirectional electronic switch. The start control circuit controls the first and the fourth bidirectional electronic switch and a second and a third bidirectional electronic switch to connect in an alternating manner in a state stage of the motor and provides continuous drive force for the synchronous motor in each cycle of the AC power source.

Owner:JOHNSON ELECTRIC SHENZHEN

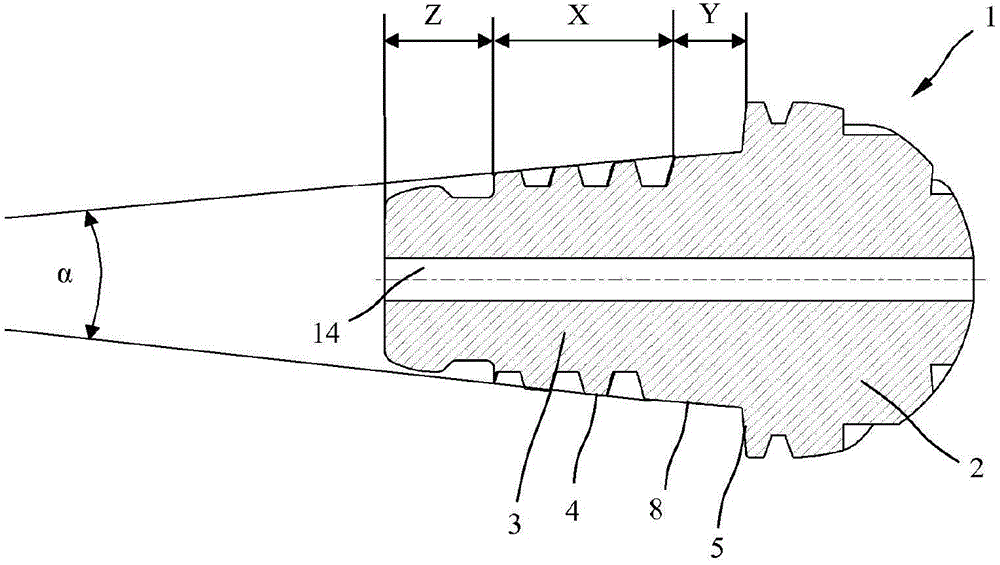

Mouse-cage type tapered rotor electromotor

InactiveCN101577463AIncrease starting torqueLarge temperature rise marginMechanical energy handlingStatorPull force

The invention relates to a mouse-cage type tapered rotor electromotor, and the main design of the electromotor comprises that: an inner cavity of a stator and the surface of a rotor of the electromotor are tapered; the tapered rotor is simultaneously used as a brake. After a triphase winding of the stator is connected with a power supply, an axial magnetic pull force is generated to allow the rotor to generate axial movement; an axial braking spring is drawn; and the tapered rotor is pushed to enable the normal operation of the electromotor; when the electromotor is needed to be stopped, the power supply of the electromotor is powered off; and then the axial magnetic pull force disappears; under the action of resilience of the spring, the tapered rotor rapidly brakes to allow the rotor to stop rotating immediately, thereby realizing the function of rapid braking.

Owner:无锡市宏泰电机股份有限公司

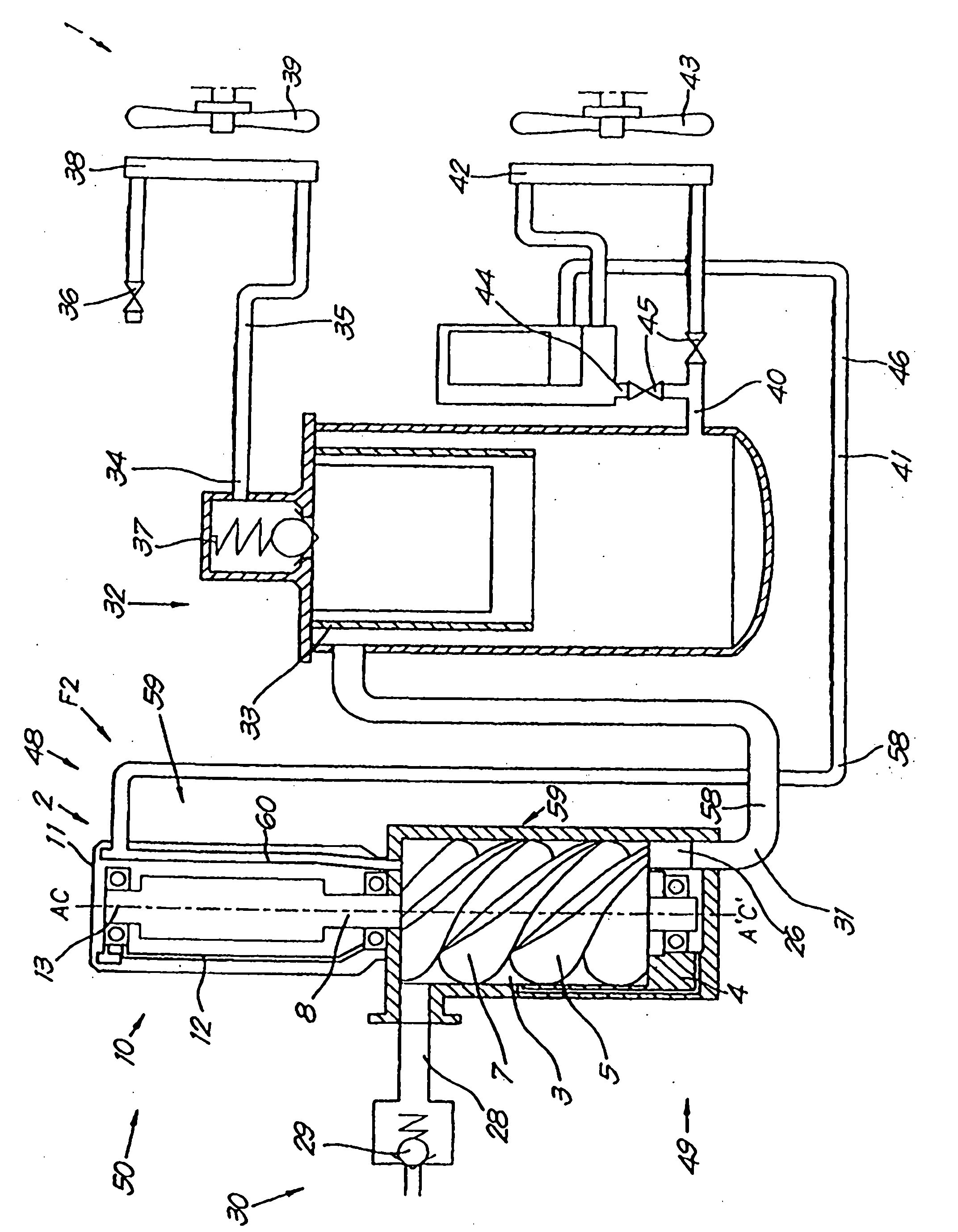

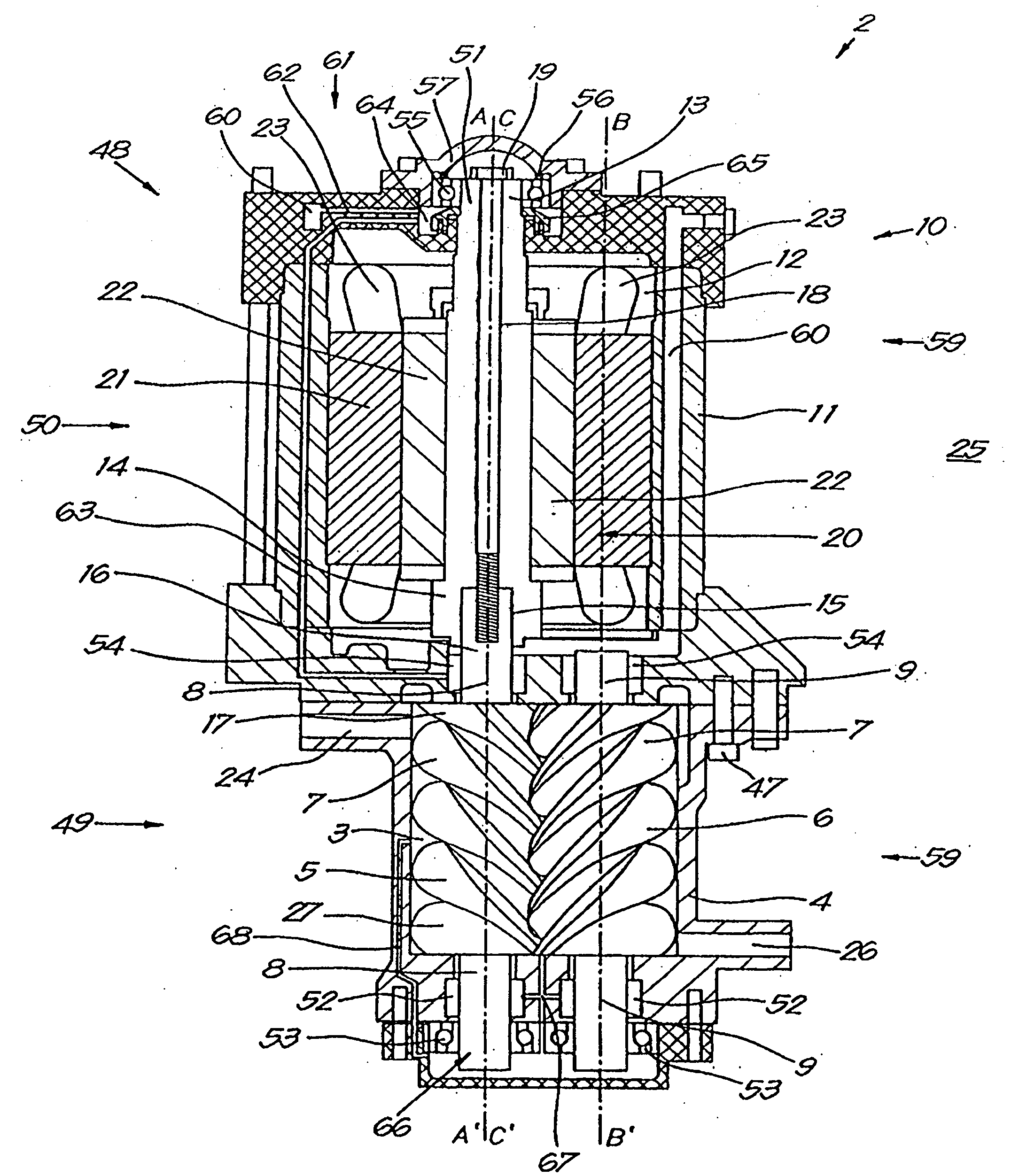

Compressor device, as well as the use of such an assembly

ActiveCN104220757AImprove energy efficiencyPrevent leakageRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsDrive motorEngineering

Compressor device that is at least provided with a screw compressor (2) with a compression chamber (3) that is formed by a compression housing (4), with a drive motor (10) that is provided with a motor chamber (12) formed by a motor housing (11) and with an outlet (26) for the discharge of compressed air that is connected to a pressure vessel (32) via an outlet pipe (31), whereby the compression housing (4) and the motor housing (11) are connected directly to one another to form a compressor housing (48), whereby the motor chamber (12) and the compression chamber (3) are not sealed off from one another and whereby the outlet pipe (31) between the pressure vessel (32) and the screw compressor (2) is free of closing means.

Owner:ATLAS COPCO AIRPOWER NV

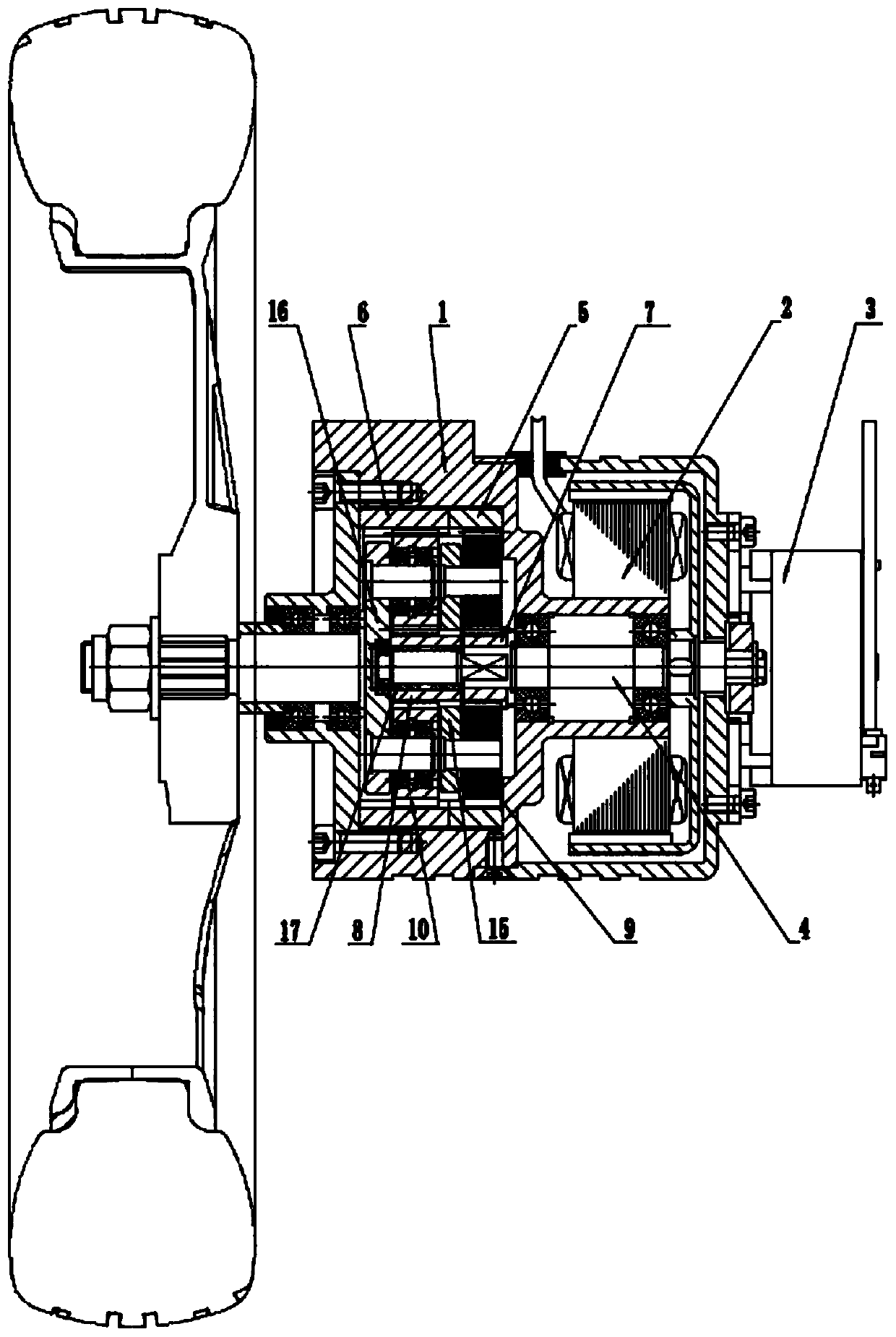

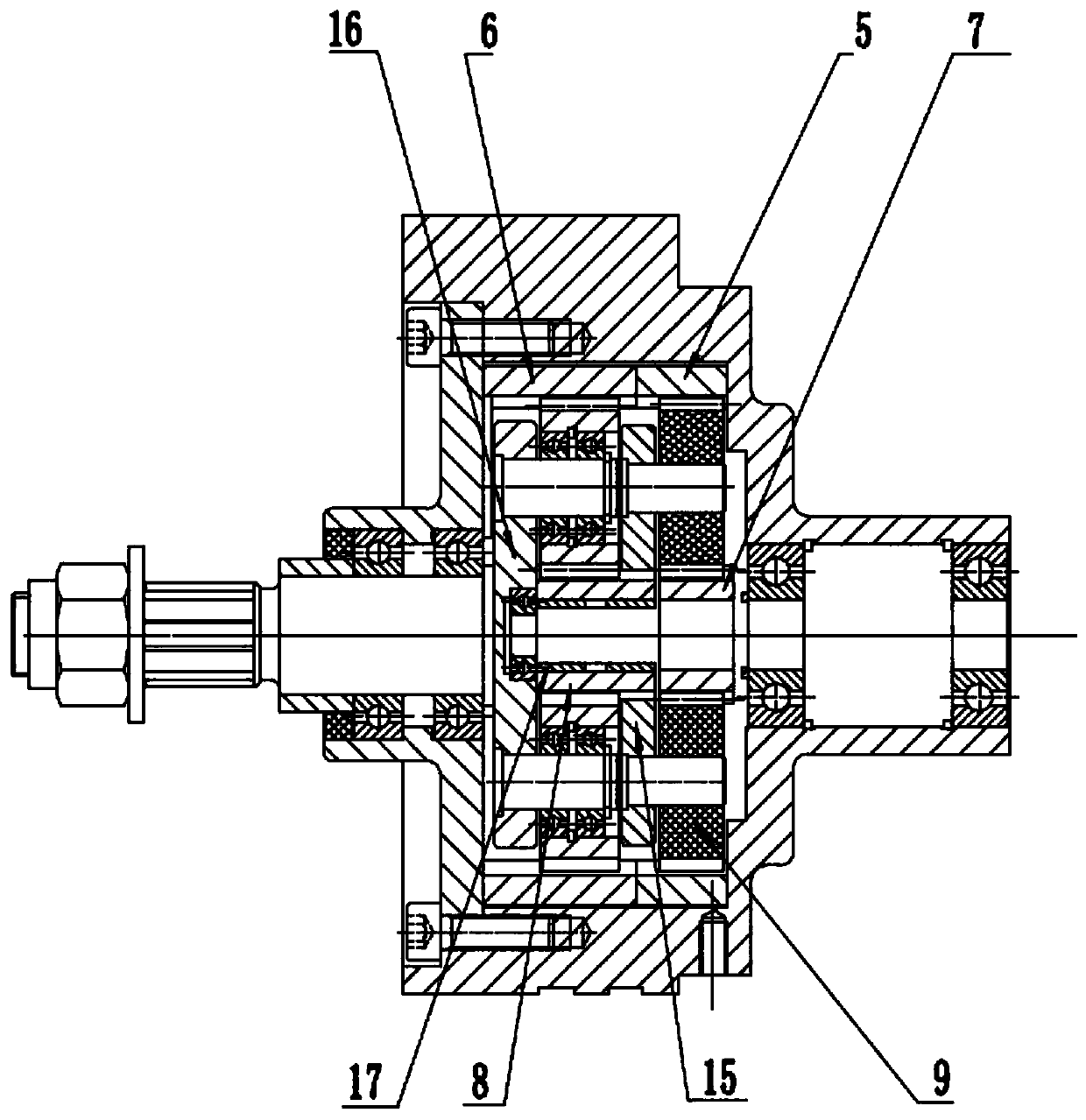

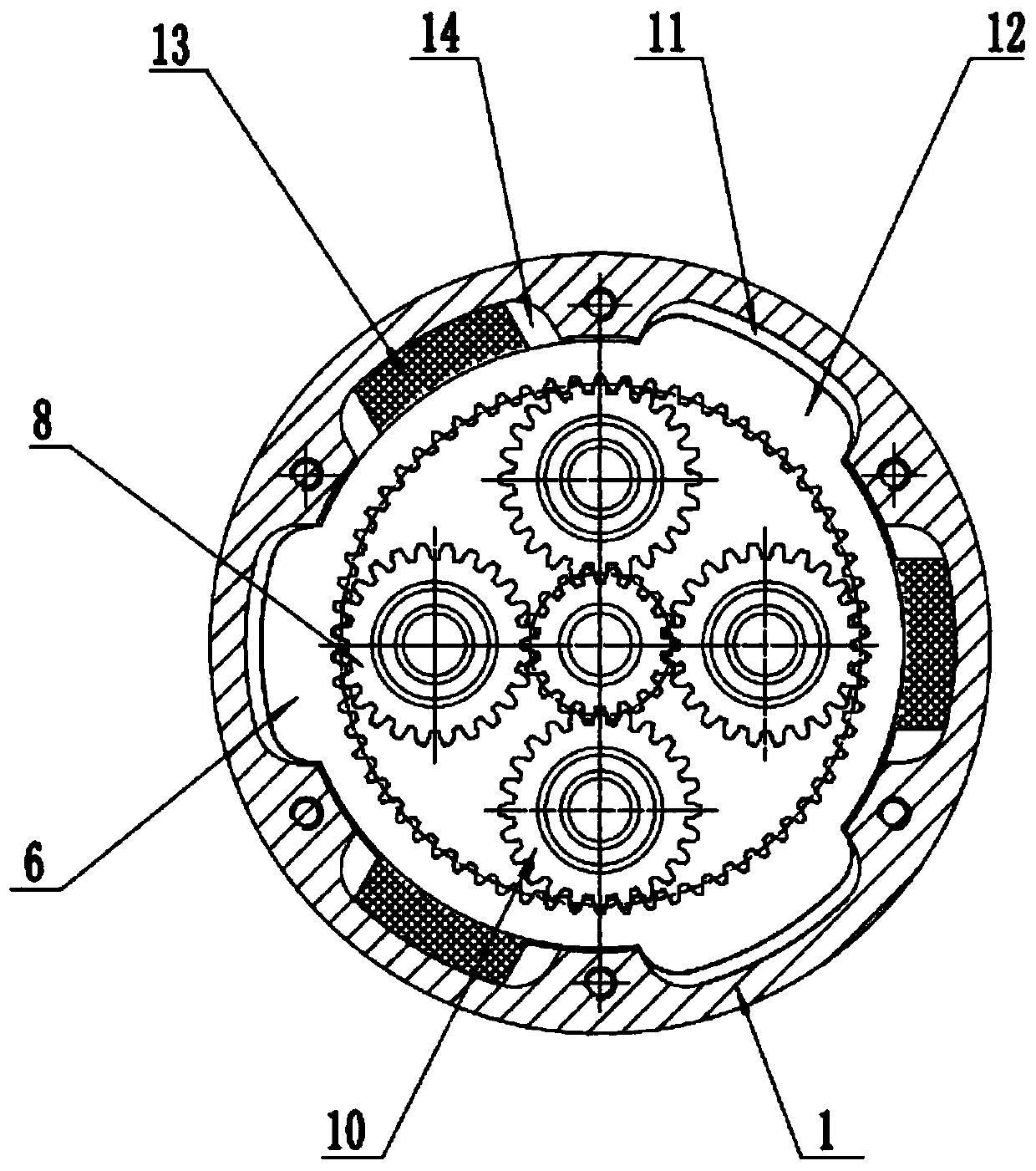

Driving motor assembly for electric vehicle

PendingCN110385979AReduce volumeReduce running noiseMotor depositionControl devicesMotor shaftDrive motor

The invention discloses a driving motor assembly for an electric vehicle. The driving motor assembly comprises a machine casing, a motor housing, an outer rotor brushless permanent magnet motor, a speed reducer and a brake, wherein the outer rotor brushless permanent magnet motor is arranged in the motor housing, the speed reducer is arranged in the machine casing, the brake is connected with themotor housing, the outer rotor brushless permanent magnet motor comprises a motor shaft, and the brake is connected with the motor shaft; the speed reducer comprises a first floating inner gear ring and a second floating inner gear ring, an inner gear of the speed reducer is in a split type, and comprises the first floating inner gear ring and the second floating inner gear ring, different modulican be set for planetary gears which achieve different stages of speed reduction, and the size of the speed reducer is reduced; the outer rotor brushless permanent magnet motor is adopted for the motor, and has large rotor rotation inertia, a small axial size, a steady rotation speed, high efficiency and large starting torque; besides, the machine casing is slidably connected with the first floating inner gear ring and the second floating inner gear ring through sliding keys and key grooves, and reduction of running noise of the speed reducer is facilitated.

Owner:ZHONGSHAN CITY ROTONTEC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com