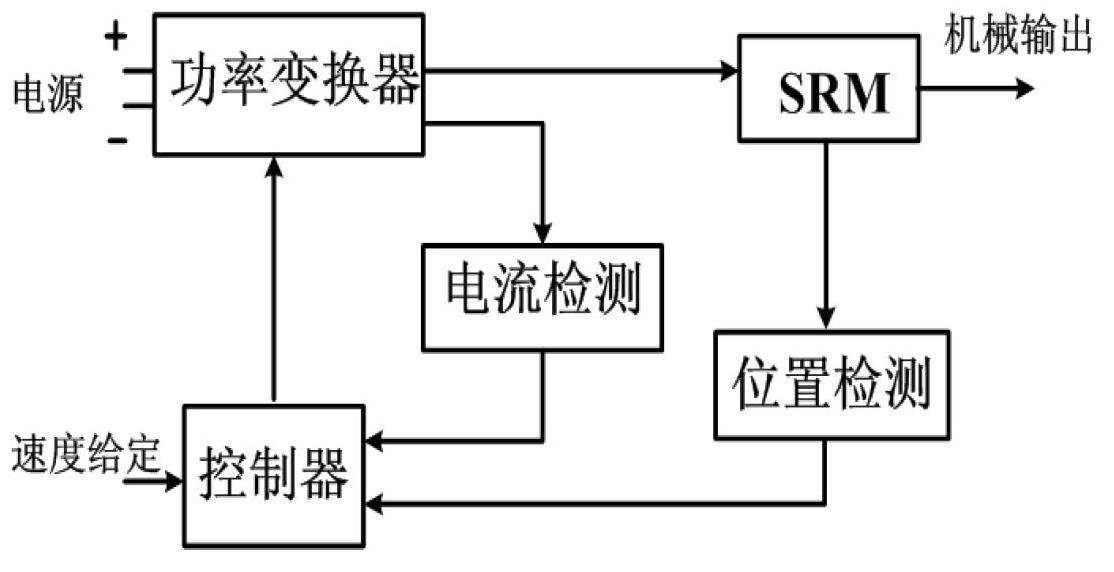

Motor drive system for direct main drive of weaving machine

A motor drive system and main drive technology, applied in looms, control systems, textiles, etc., can solve the problems of fabric drive marks, can not meet the requirements of quick start, output torque is limited, etc. Starting requirements, the effect of improving the starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

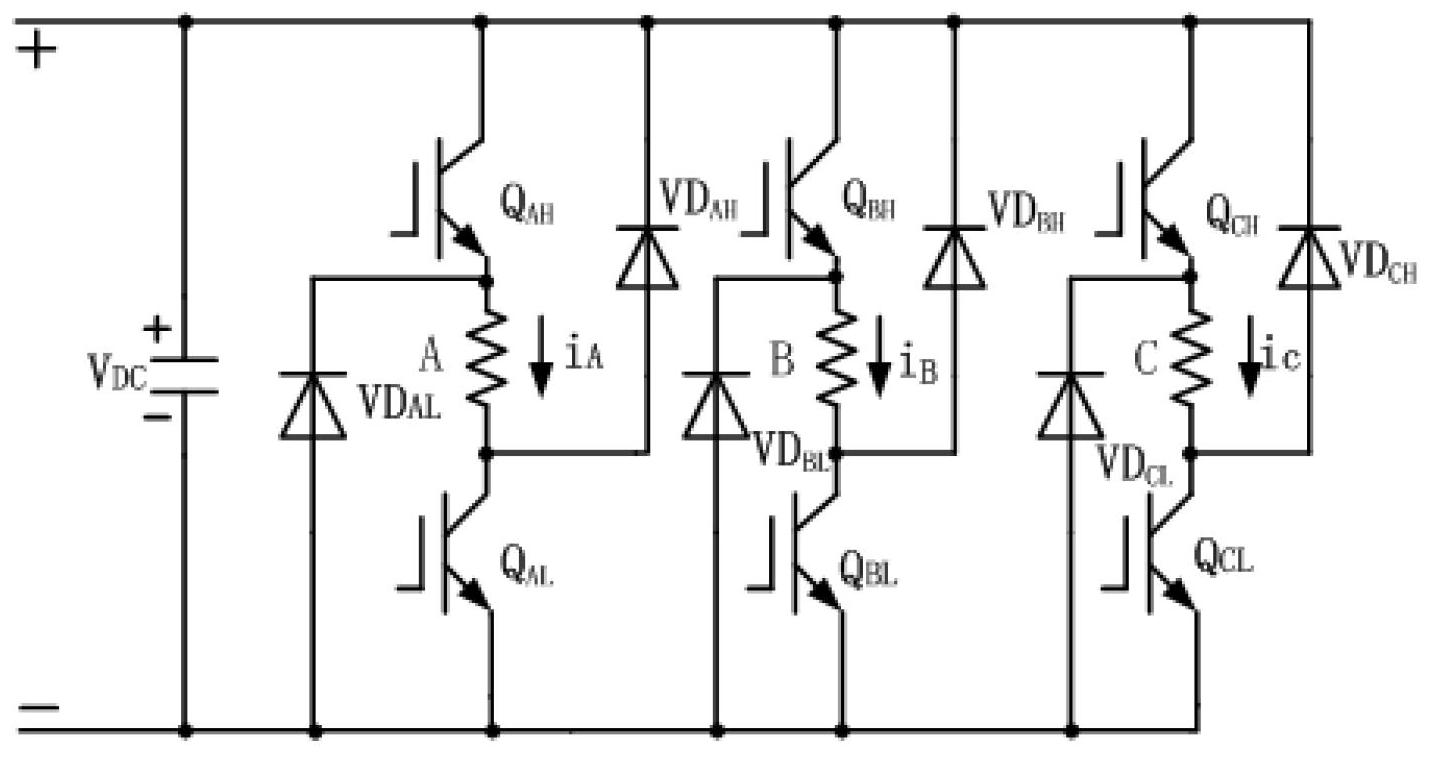

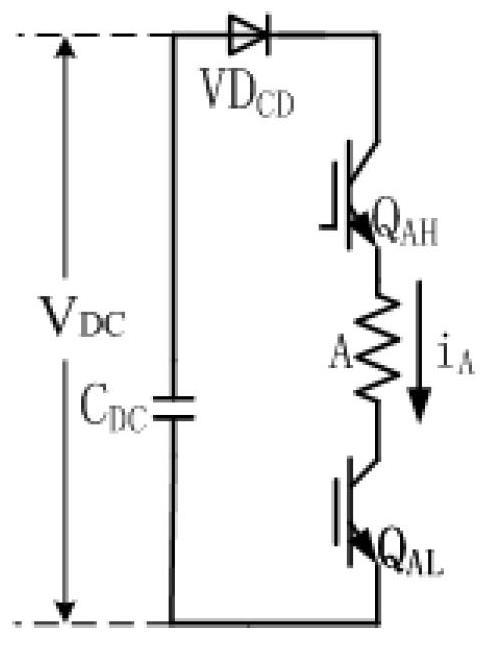

Method used

Image

Examples

Embodiment

[0033] Loom direct main transmission mechanism such as Figure 6-1 Or as shown in 6-2. Figure 6-1Schematic diagram of the transmission mechanism in which the main drive motor (SRM) directly drives the movement of the loom sley and the shedding mechanism. When the loom is running normally, the pinion 3 on the rotating shaft of the switched reluctance motor meshes with the large gear 2 that drives the sley and the gear 5 that drives the opening mechanism, and the main drive motor drives the sley and the opening; When weft, no special slow motor and weft-seeking clutch mechanism are needed, but the switched reluctance motor 4 with adjustable speed drives the slow motion of the loom to drive a series of mechanisms such as the heald frame to complete the weft-seeking action. Through the axial movement of the upper gear of the switched reluctance motor 4, the pinion 3 on the rotating shaft of the main transmission switched reluctance motor is no longer meshed with the large gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com