Vertical-axis clutch type wind power generation device

A wind power generation device, clutch-type technology, applied in the field of vertical axis wind power generation devices and power generation devices, can solve the problems of low power generation efficiency, self-starting and braking difficulties, etc., to achieve improved power generation efficiency, increased starting torque, and reliable braking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

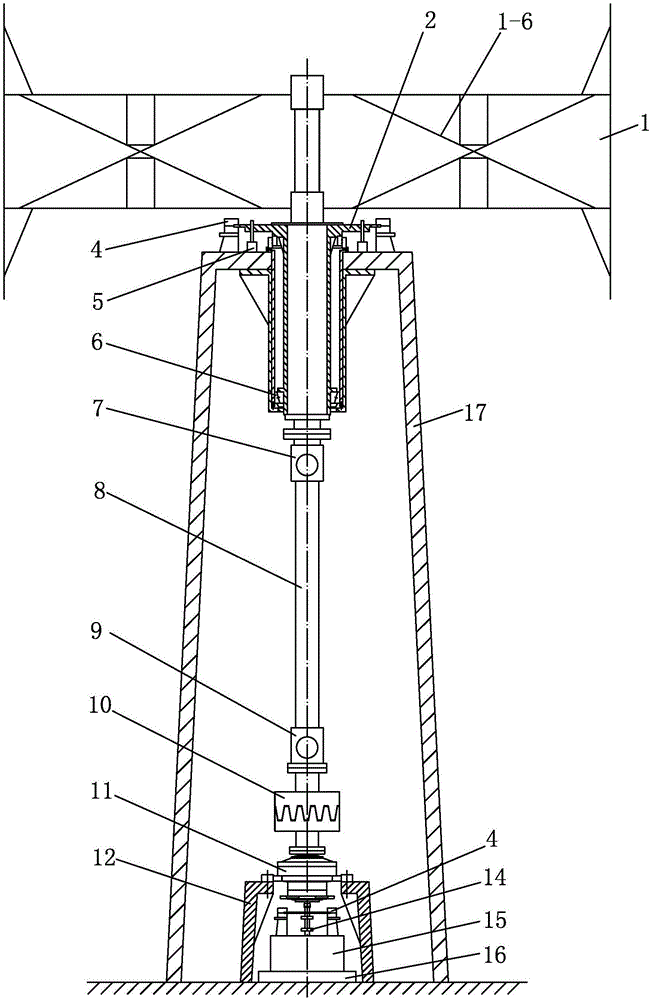

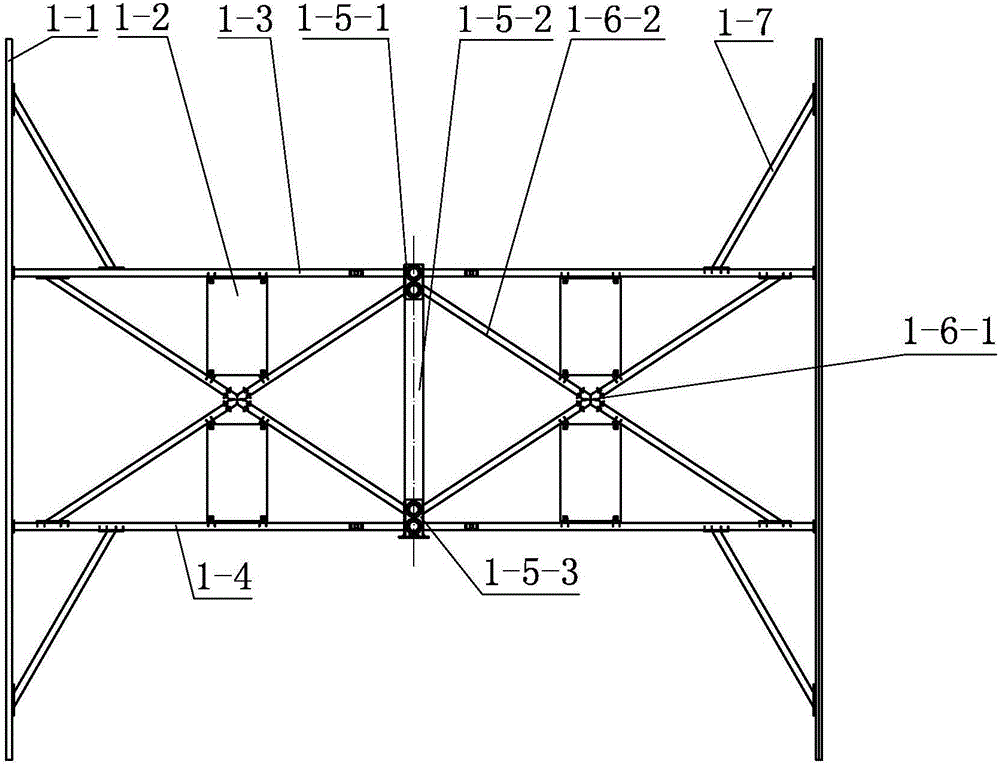

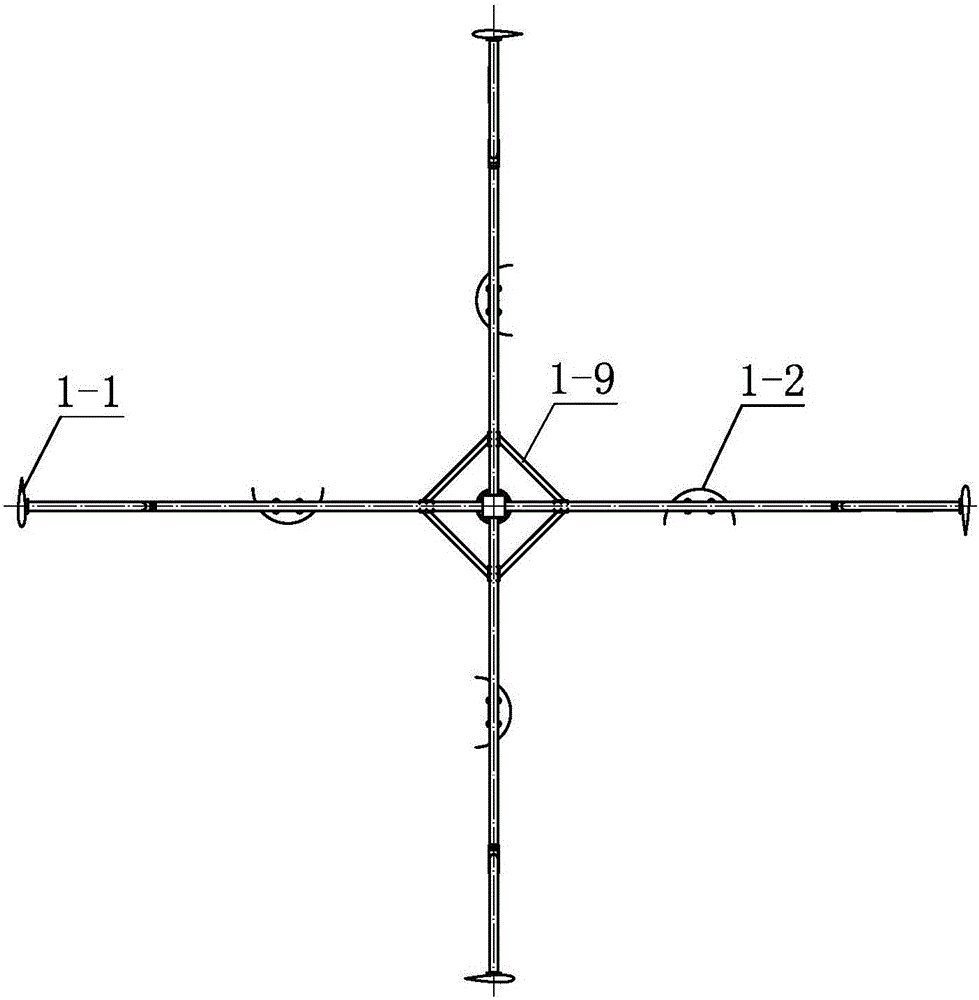

[0034] see Figure 1-Figure 12 As shown, a vertical shaft clutch type wind power generation device includes a wind wheel 1, a first transmission shaft 2, a wind wheel locking device 5, a first coupling 7, a second transmission shaft 8, a second coupling 9, a tooth insert Type clutch 10, speed increaser 11, support 12, No. 2 shaft coupling 14, generator 15, tower frame 17 and two brakes 4;

[0035] Each brake 4 is a disc brake, and the wind wheel 1 is a lift-drag composite wind wheel;

[0036]The top of the tower 17 is rotatably installed with the No. 1 transmission shaft 2 arranged vertically, and one of the brakes 4 is installed on the top of the tower 17, and the brake disc of one of the brakes 4 is connected to the flange 2 of the No. 1 transmission shaft 2- 1 is connected as a whole, the wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com