Patents

Literature

62results about How to "Increase the swept area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

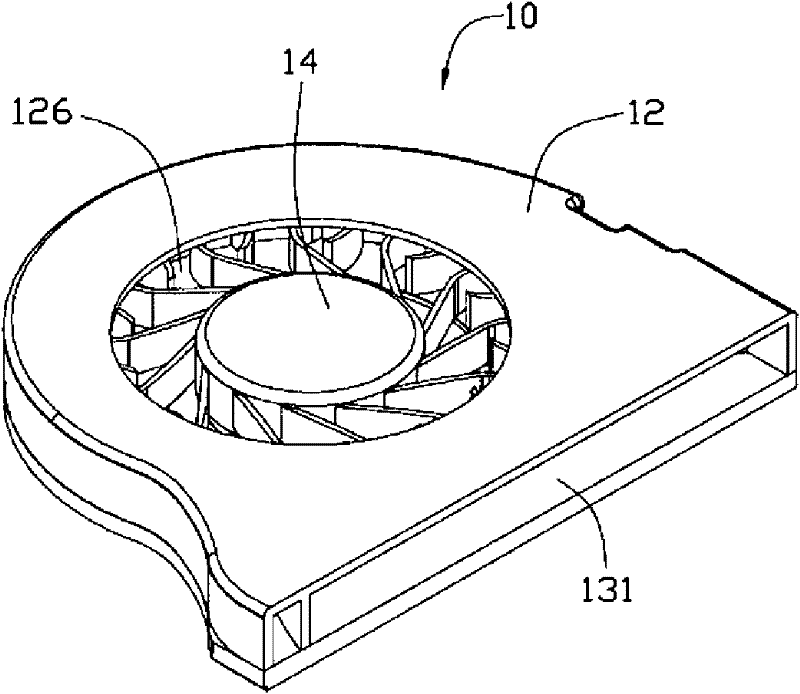

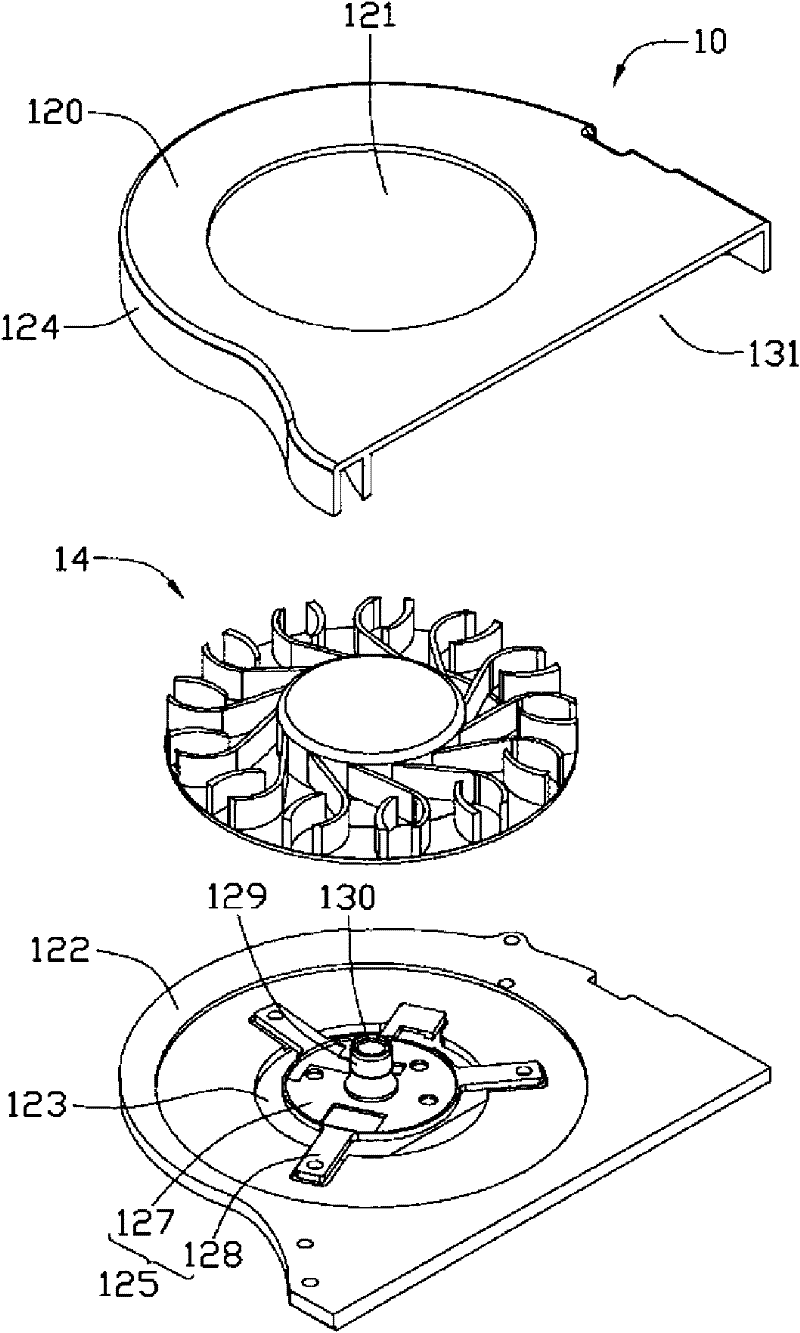

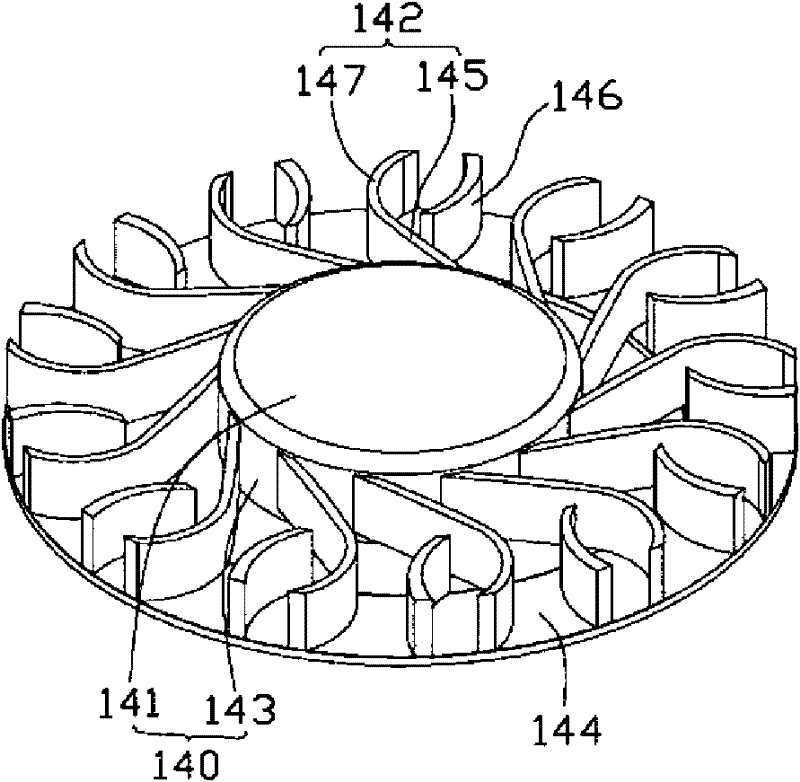

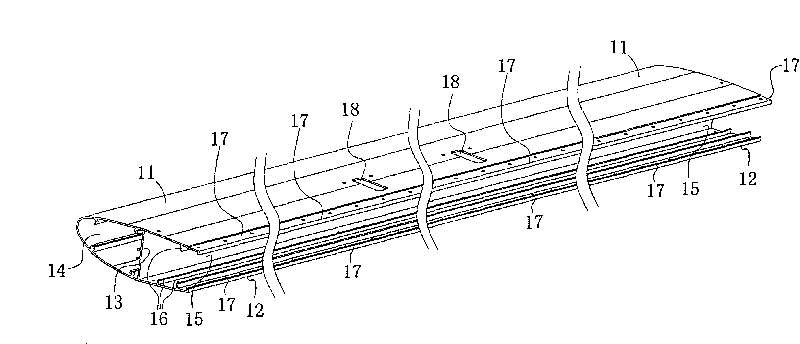

Fan blade structure and centrifugal fan with same

InactiveCN102128178AImprove cooling effectHigh speedPump componentsDigital data processing detailsCentrifugal forceFan blade

The invention relates to a fan blade structure and a centrifugal fan with the same. The fan blade structure comprises a hub and a plurality of first blades extending outwards along the outer edge of the hub, a blade disc which is arranged at ends of the first blades and is mutually connected with the first blades and a plurality of second blades which are arranged on the blade disc and are positioned among the first blades, wherein the ends of the first blades bend and extends outwards to form an arc-shaped part; the second blades are in an arc shape of which the direction is opposite to the bending direction of the arc-shaped part of each first blade; and the speed of air flow can be increased to allow more air flow on the inner side of the arc-shaped parts of the first blades to flow towards the outer periphery and fan frames of the fan blade structure, so that more air flow is discharged from an air outlet of the centrifugal fan to enhance the heat dispersion performance of the centrifugal fan.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

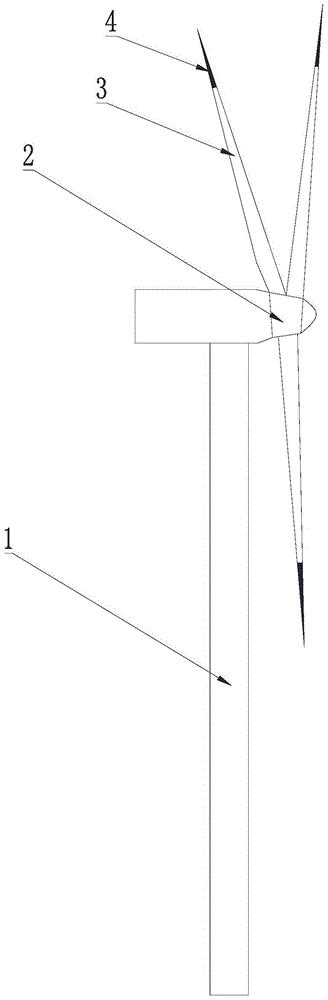

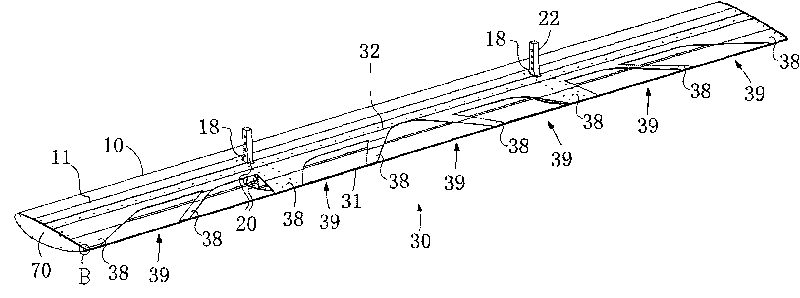

Method for lengthening wind power blade

The invention relates to a method for lengthening a wind power blade, in particular to a method for connecting a new tip to the tip of the wind wheel blade of the conventional wind driven generator. The invention comprises a blade tip lengthened connecting structure and a process scheme. According to the wind wheel blade tip lengthening scheme for the wind driven generator, the lengthened blade has a safe structure, and the method is simple in process, low in cost and high in implementation feasibility.

Owner:苏州可汗极米科技有限公司 +1

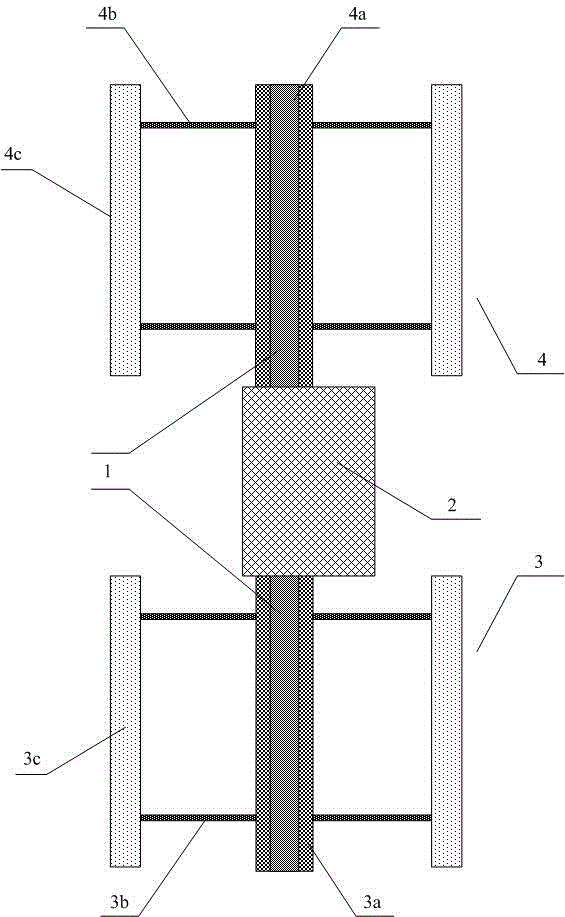

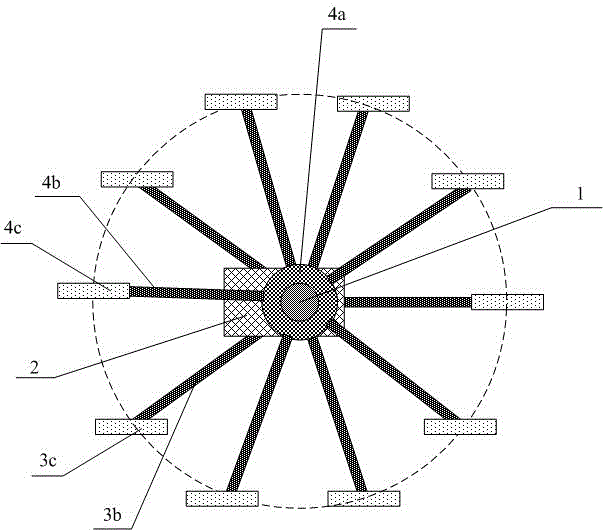

Vertical-axis clutch type wind power generation device

ActiveCN106321359AReduce design difficultyReduce design weightWind motor controlEngine fuctionsDrive shaftCoupling

The invention relates to a power generation device, in particular to a vertical-axis clutch type wind power generation device so as to solve the problems that an existing large-power vertical-axis wind power generator is difficult in self-starting and braking and low in power generation efficiency. The vertical-axis clutch type wind power generation device comprises a wind wheel, a first transmission shaft, a wind wheel locking device, a first coupler, a second transmission shaft, a third coupler, a clutch, a speed increasing gear, a support, a second coupler, a power generator, a tower and two brake devices. The vertically-arranged first transmission shaft is rotationally arranged on the top of the tower, one brake device is arranged on the top of the tower, and the wind wheel locking device is arranged on the top of the part, below a flange plate, of the tower. The upper end of the first transmission shaft is connected with the wind wheel, the lower end of the first transmission shaft is connected with the first coupler, and the speed increasing gear is fixed to the support. The clutch is connected between the second transmission shaft and an input shaft of the speed increasing gear, an output shaft of the speed increasing gear is connected with an input shaft of the power generator through the second coupler, and the other brake device is arranged on a power generator shell. The vertical-axis clutch type wind power generation device is used for wind power generation.

Owner:HARBIN INST OF TECH

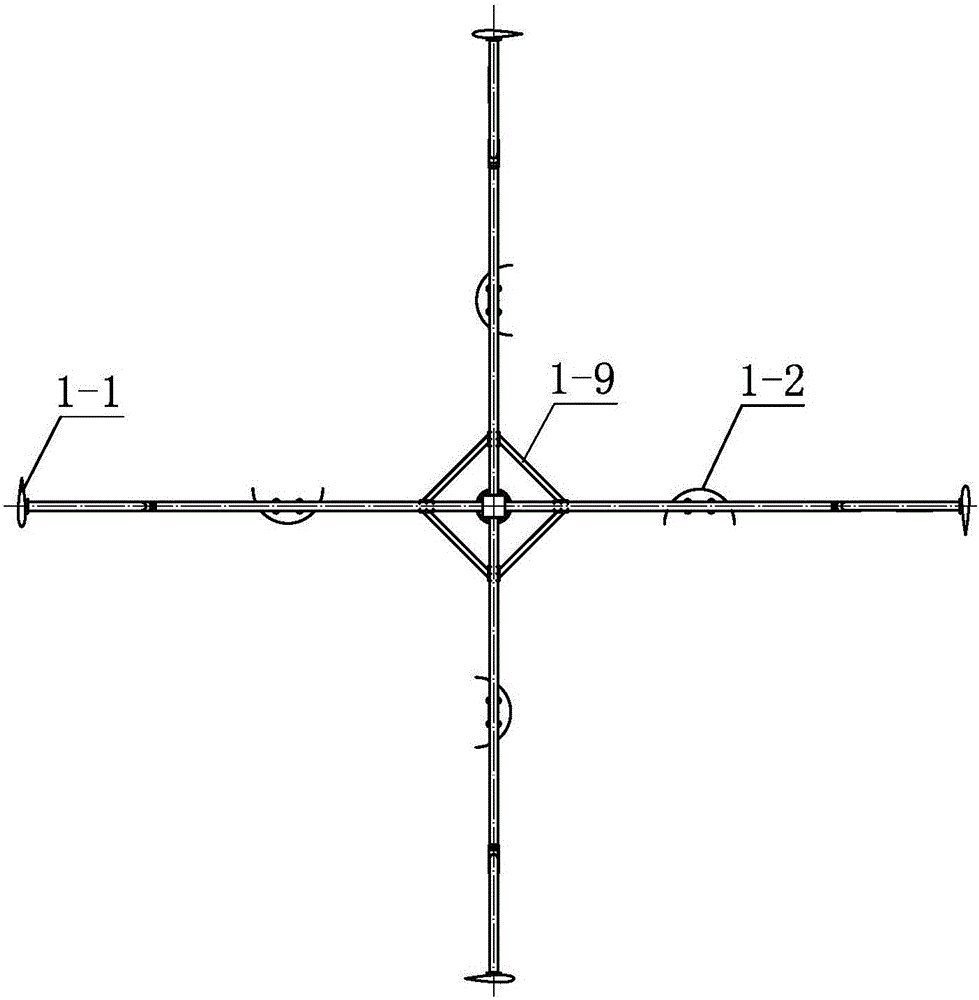

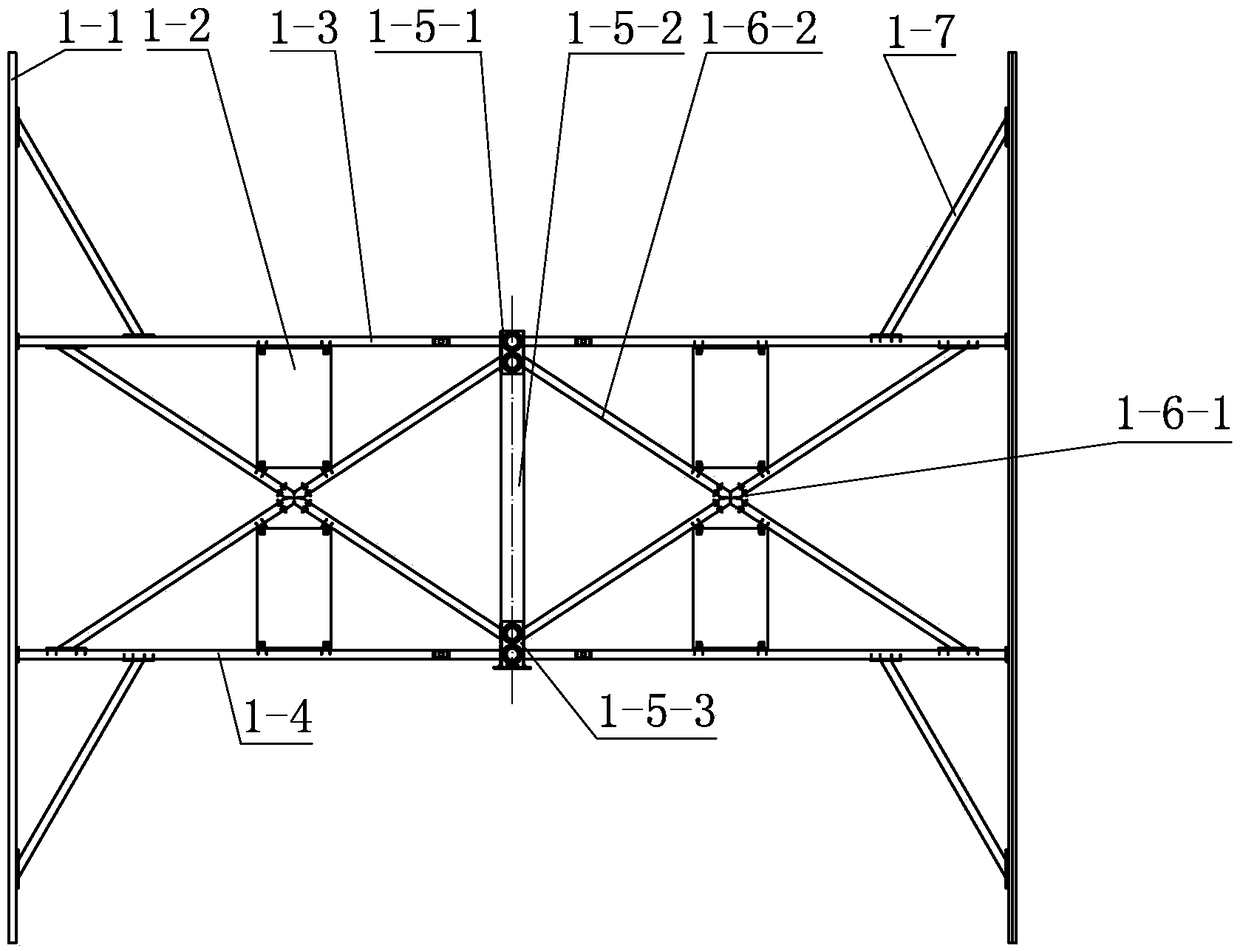

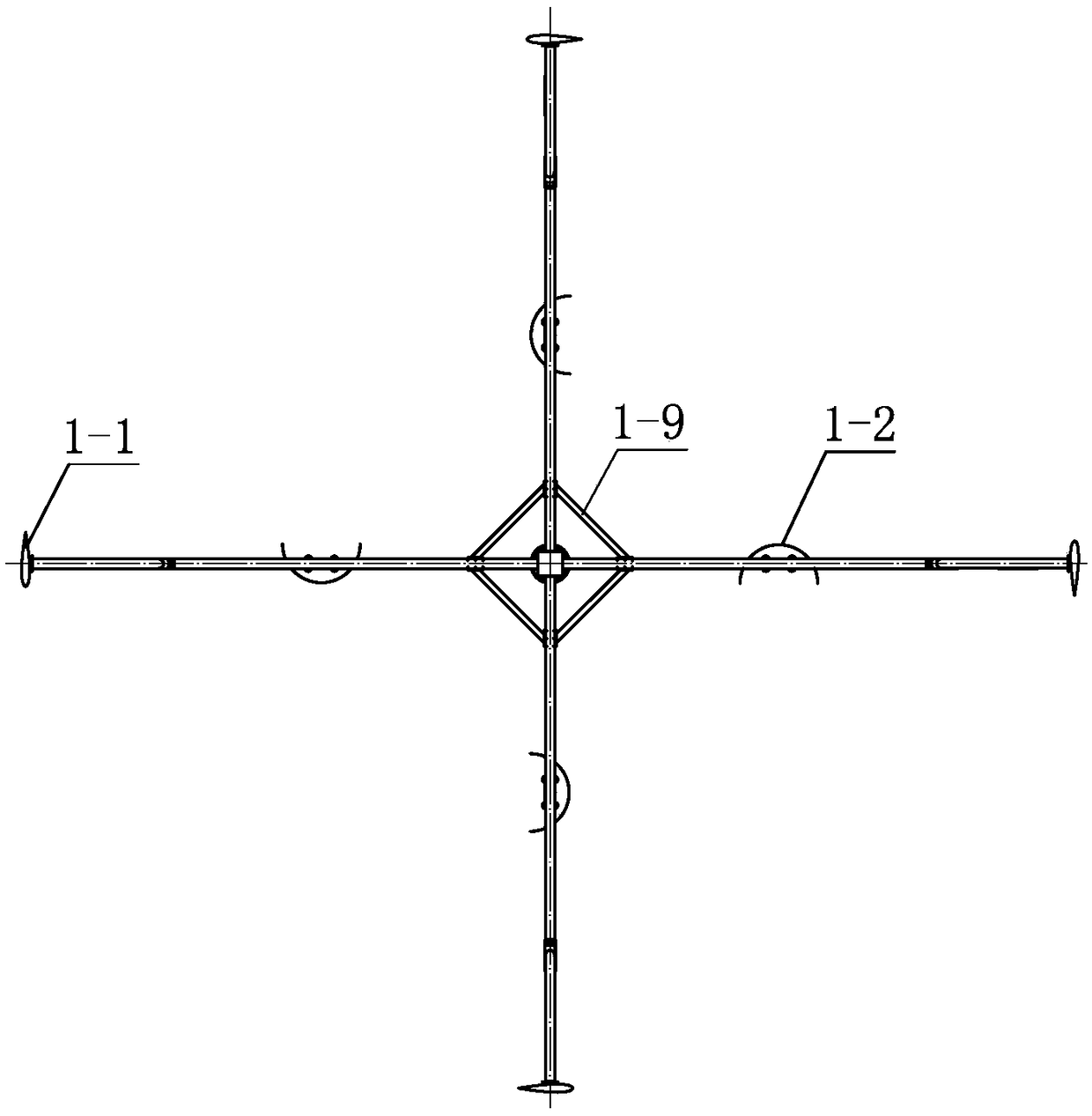

Detachable H-shaped vertical axis wind power generation device and work method thereof

PendingCN110173393AEfficient captureEasy to installWind motor controlWind motor assemblyImpellerPower usage

The invention discloses a detachable H-shaped vertical axis wind power generation device and a work method thereof, and belongs to the wind power generation technology field. The detachable H-shaped vertical axis wind power generation device comprises a vane, a vane wheel rotation shaft, a connection rod, an electric generator and a bottom seat. The vane, the vane rotation shaft and the connectionrod which are of multi-segment telescopic structure are used, and the telescopic length of the vane, the vane rotation shaft and the connection rod is controlled according to actual air conditions, and therefore efficient capturing of wind energy in a large wind speed range is achieved. Furthermore, all the components adopt the detachable structure, and therefore the detachable H-shaped verticalaxis wind power generation device is simple and rapid to assemble and disassemble, and convenient to store and carry, can be rapidly structured in any place, and meets urgent power usage demands.

Owner:CHINA HUANENG GRP CO LTD +1

Improvement method for fan

InactiveCN105065197AEasy to operateLow costMachines/enginesWind energy generationHanging basketWind speed

The invention relates to an improvement method for a fan. The appropriate length L of a blade of the fan is determined according to the load of the blades of existing fans and the wind speeds of the places where the existing fans are located, and the blades of the existing fans are lengthened to the appropriate length L without disassembling the blades of the existing fans. With the improvement method for the fan, it is not needed that the blades of a fan are dissembled for the improvement, an operator rises to the tail ends of the blades through an elevator or a hanging basket to carry out the improvement at the tail ends of the blades of the fan, the operation sequence is simplified, time and labor are saved, and cost is reduced.

Owner:CHINA DATANG CORP RENEWABLE POWER

Air conditioner with four air outlets

InactiveCN105003960AIncrease the swept areaDucting arrangementsLighting and heating apparatusEngineeringEvaporator

Owner:ZHONGSHAN YAXI ENVIRONMENTAL PROTECTION TECH

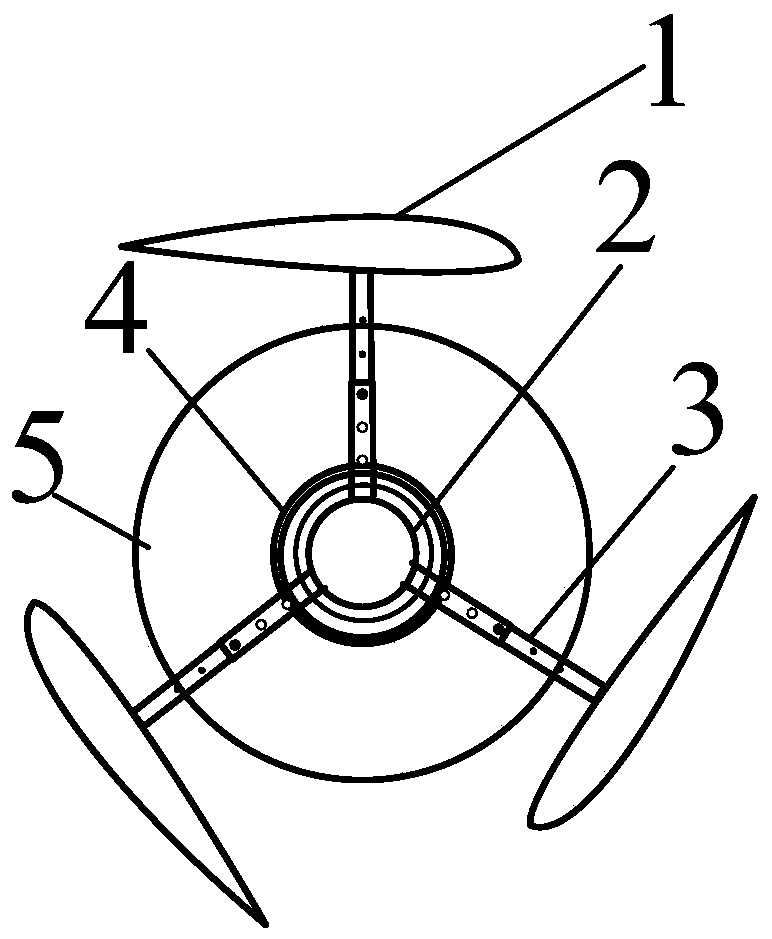

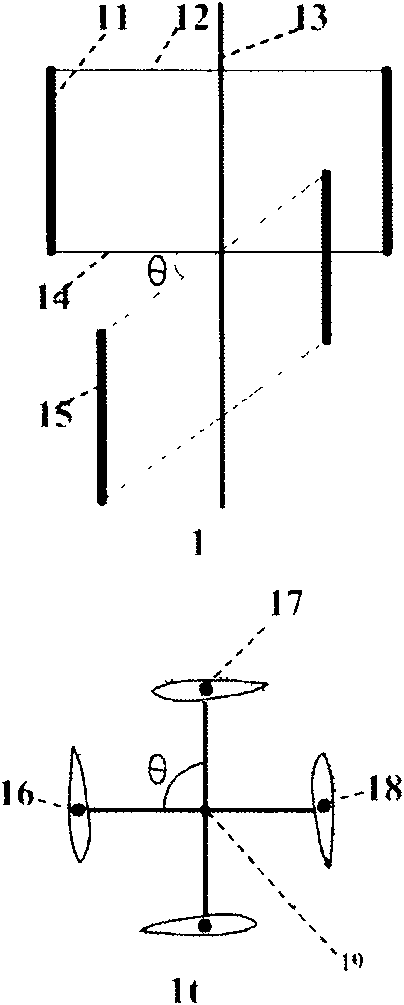

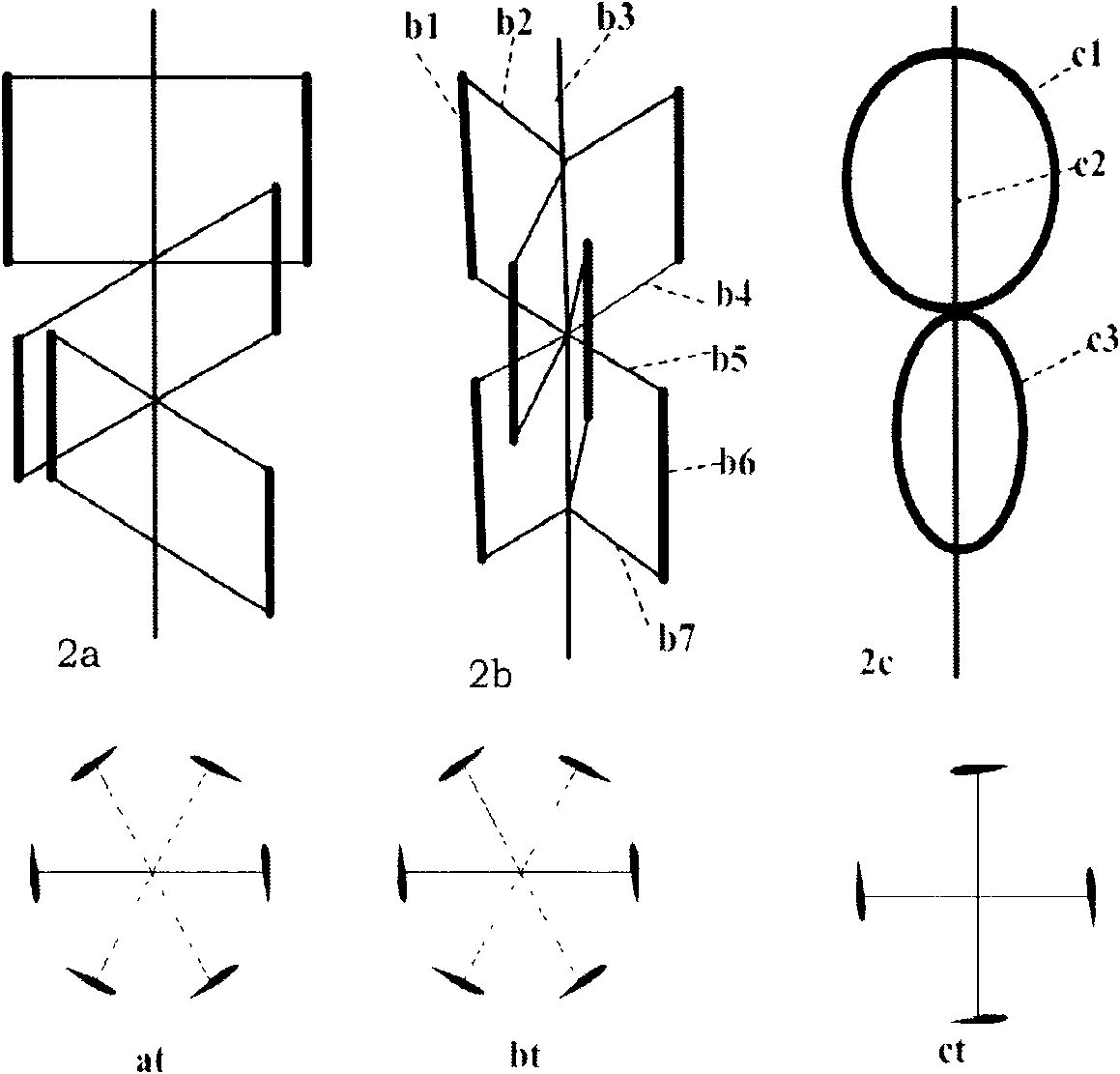

String-type wind wheels and magnetic levitation string-type windmill

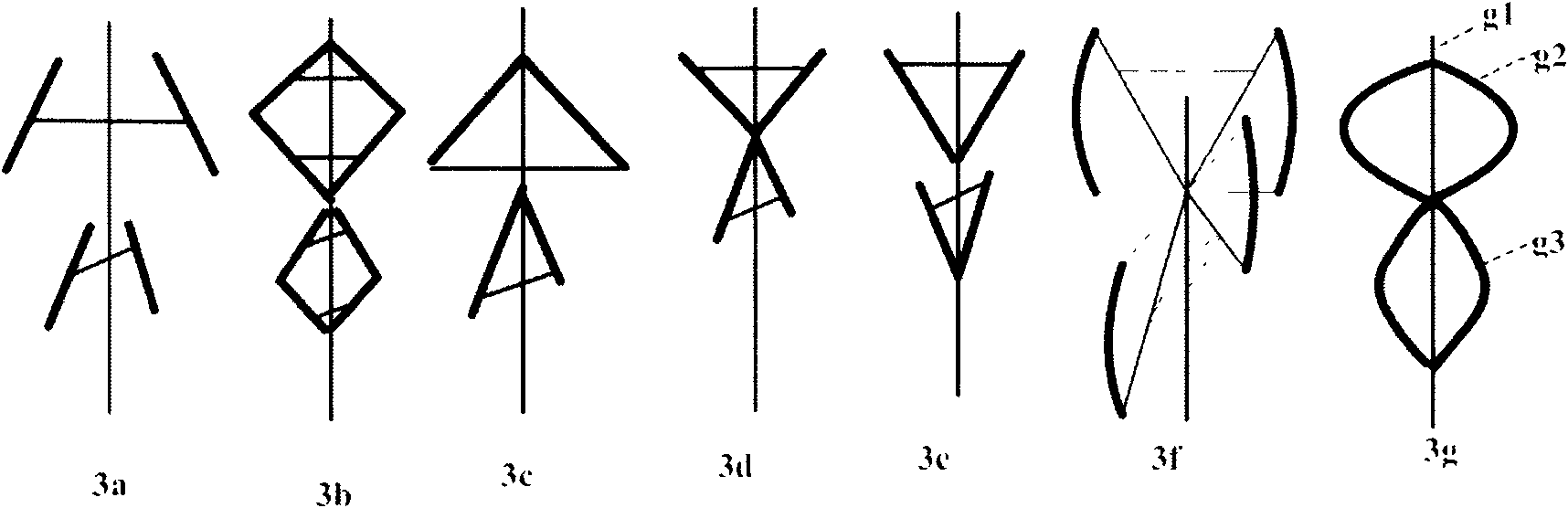

InactiveCN102062047ASolve the problem of smooth self-startingImprove efficiencyMachines/enginesWind motor combinationsMaximum diameterAcute angle

The invention relates to a method for constructing a string-type wind wheels and a corresponding magnetic levitation string-type windmill. Two or more Darrieus-type wind wheels with two to three blades respectively are connected in series and mounted in the vertical direction to form a new wind wheel which has the characteristics and the key points for generating the self-starting capability: (1) an included angle theta of the connecting lines between the geometric center points of the cross sections of any two adjacent blades and the rotating center of the wind wheels in the whole projection of the wind wheels in the vertical direction meets the following conditions that: the sum of all acute angles theta is larger than 120 degrees, and preferably, theta=360 / sigma y, wherein y is the blade number of wind wheels; (2) the axial crossed part of the blades of the upper layer and the lower layer is not larger than 25 percent of the height sum of the wind wheels of the upper layer and the lower layer; (3) the maximum diameter difference of the wind wheels of all the layers is not larger than 1 / 3; and (4) the height difference of the wind wheels of all the layers is not larger than 50 percent. The string-type wind wheels are constructed according to the conditions, and the magnetic levitation string-type windmill is constructed by further adopting the magnetic levitation technology so that the string-type windmill can be started more easily start and has high efficiency.

Owner:李永平

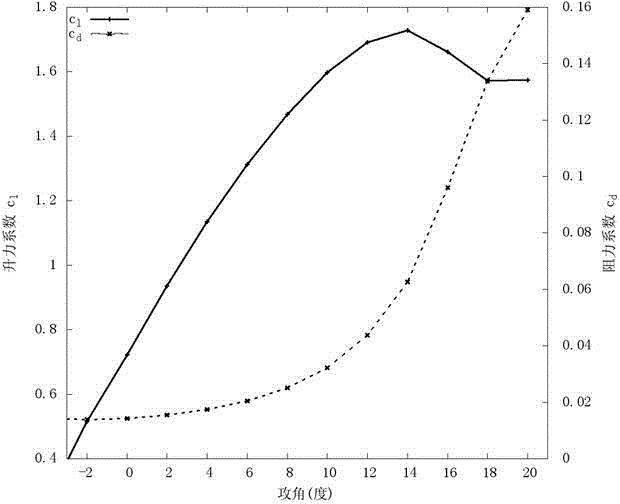

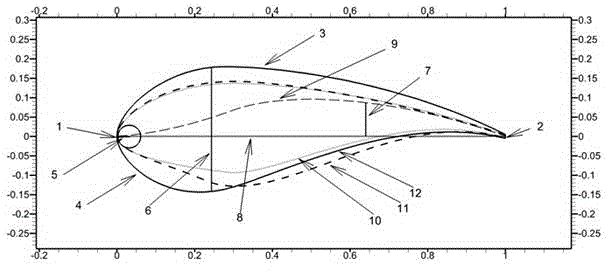

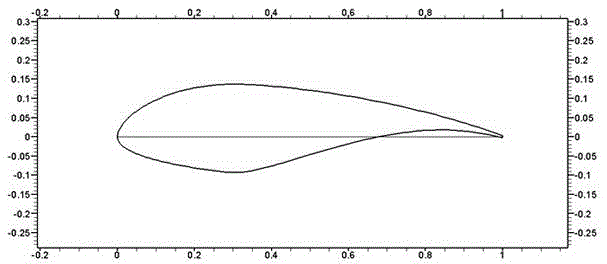

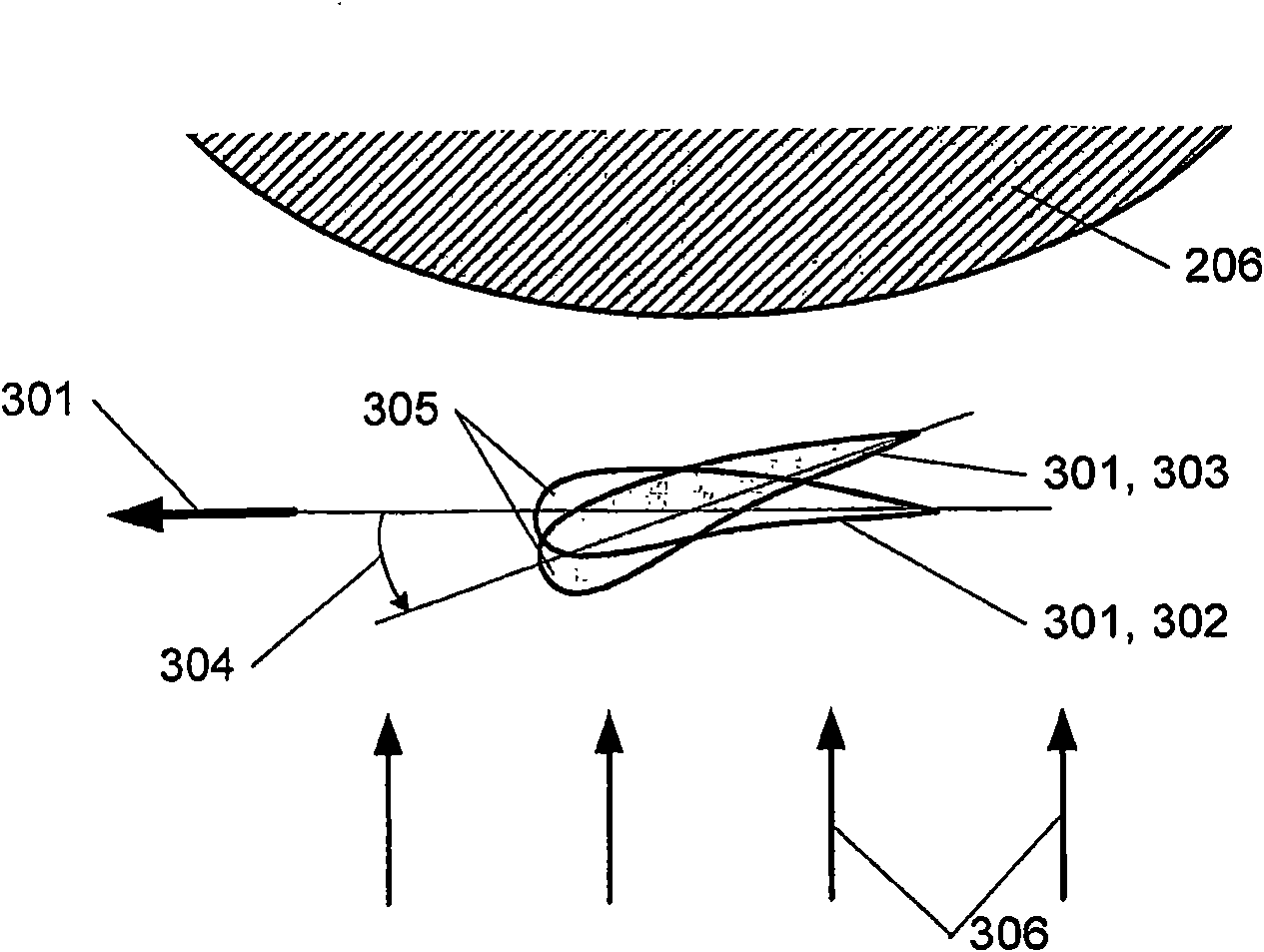

Wind turbine blade wing section group

InactiveCN104819106AImprove structural performanceIncrease the swept areaMachines/enginesEngine componentsSuction forceTurbine blade

The invention discloses a wind turbine blade wing section group which comprises a first wing section, a second wing section and a third wing section. The outlines of the first wing section, the second wing section and the third wing section are formed by smoothly connecting non-dimensional two-dimensional coordinates, the non-dimensional two-dimensional coordinates are obtained by using horizontal coordinates and longitudinal coordinates of all points on the pressure faces and suction force faces of the first wing section, the second wing section and the third wing section to divide the chord lengths of the wing sections. The relative thicknesses of the first wing section, the second wing section and the third wing section are respectively 23%, 27% and 32%, and the maximum camber positions are respectively located at the positions of the chord lengths of 67.6%, 74.1% and 64.4% of the front edges of the wing sections. The demands for thick wing sections of large wind turbine blades applied to a low-wind-speed wind field are met, the aerodynamic characteristics of the thick wing sections are effectively improved, the maximum lift coefficient and maximum lift-drag ratio of the thick wing sections are improved, and front edge roughness sensibility of the wing sections is reduced. Compared with existing thick wing sections, the structural performance of the blades is obviously improved, and static load under the limiting condition is reduced, so that the blades are lengthened, wind diffusion area is increased, and more wind energy is captured.

Owner:NANJING BEIDA GONGDAO INNOVATION +1

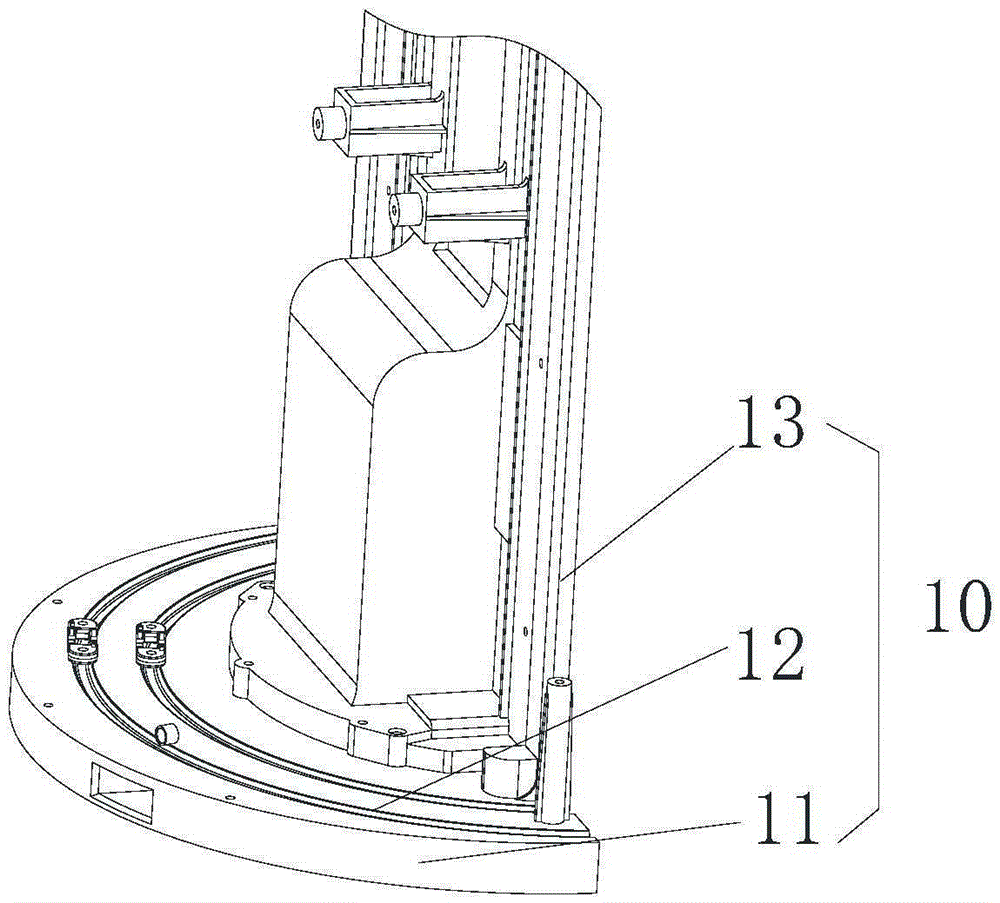

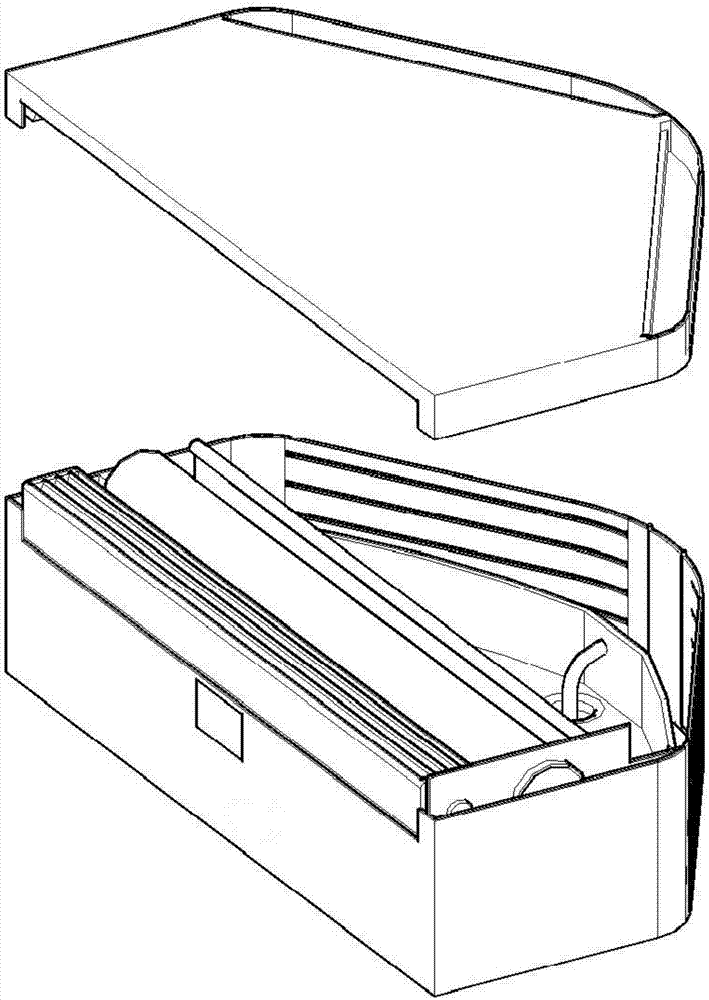

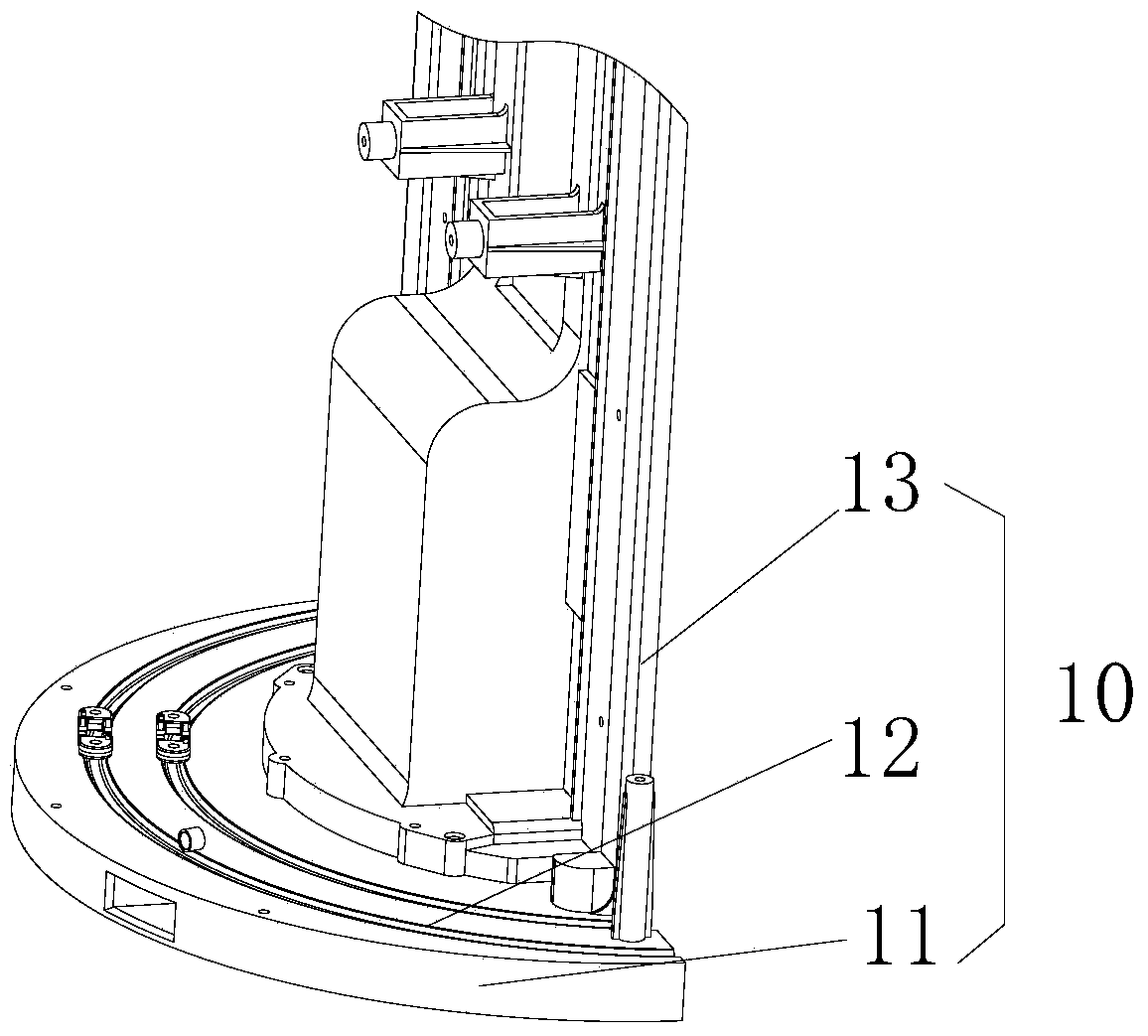

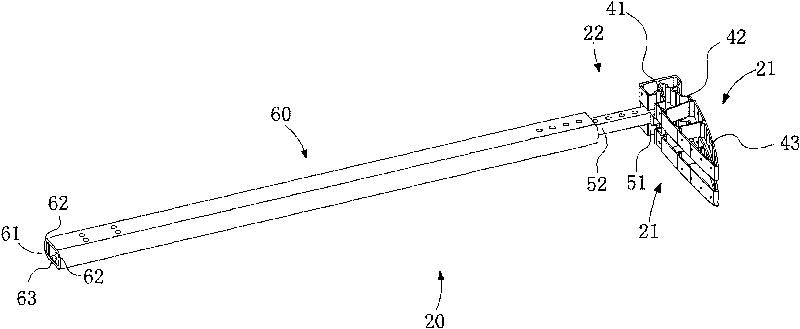

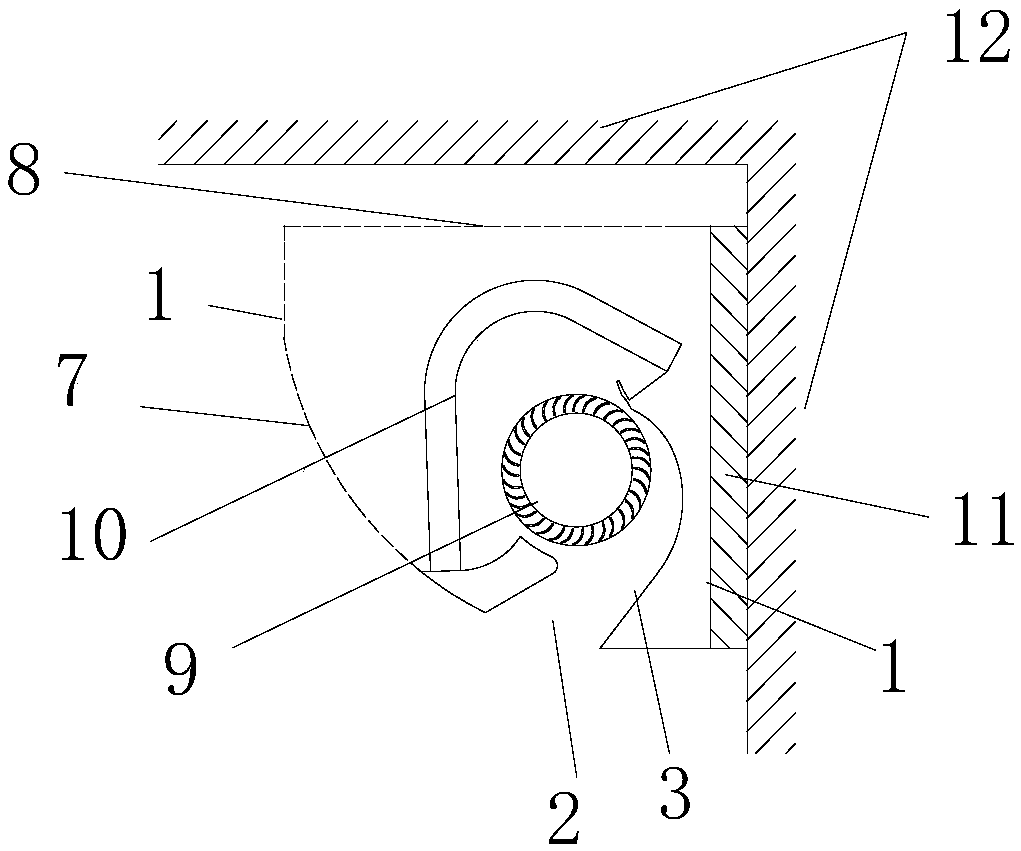

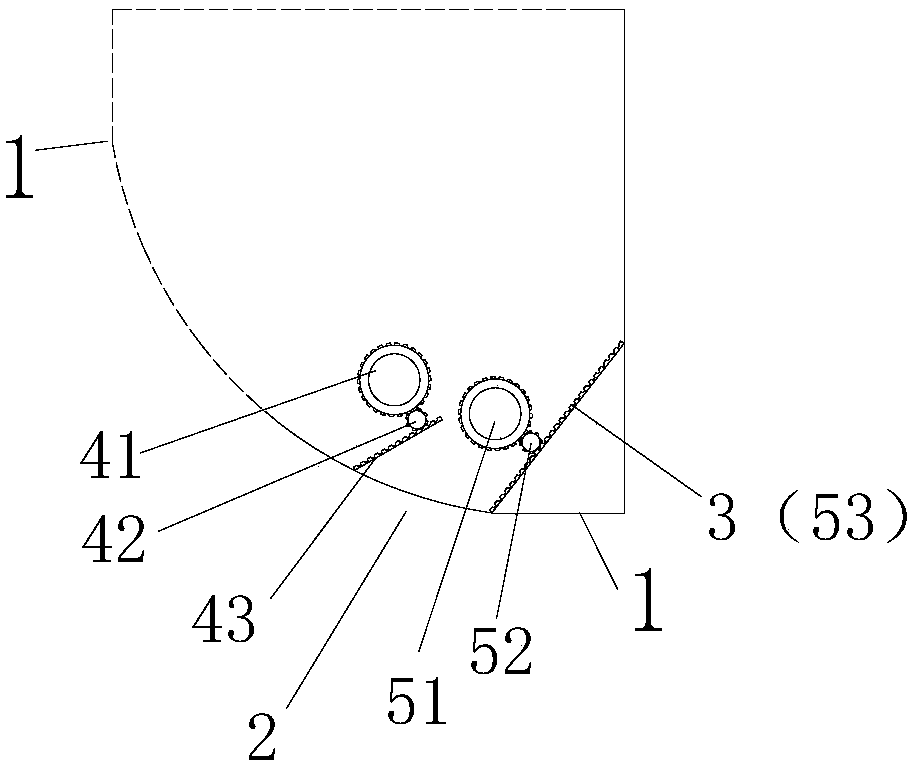

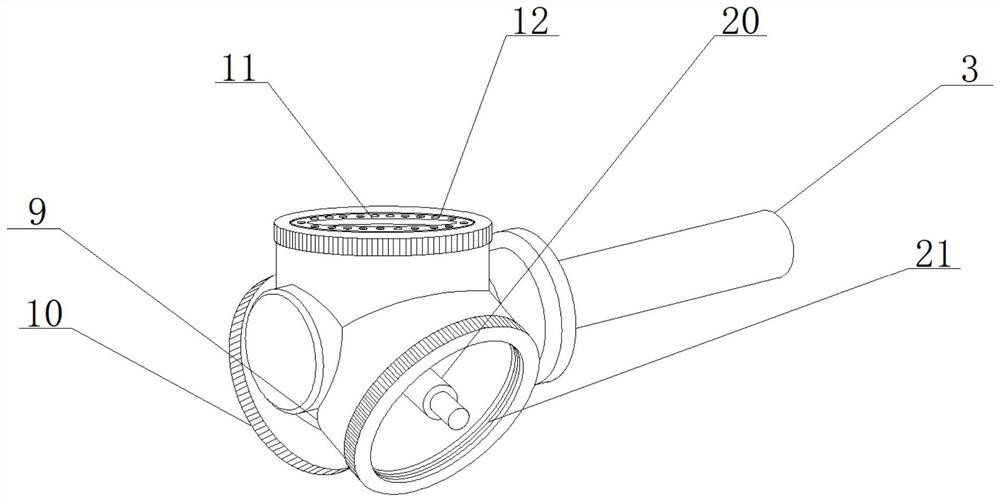

Air output assembly and air conditioner with same

ActiveCN105387601AIncrease the swept areaLighting and heating apparatusAir-flow control membersIndustrial engineering

The invention provides an air output assembly and an air conditioner with the same. The air output assembly comprises a supporting part, a guide rail part, a rotating driving part and an air output part, wherein the supporting part is provided with a first arc-shaped guiding groove, and the guide rail part is connected with the supporting part and provided with a second arc-shaped guiding groove corresponding to the first arc-shaped guiding groove; the rotating driving part comprises a driving assembly which is provided with at least two oppositely-arranged driving rollers, one driving roller is located in the first arc-shaped guiding groove, and the other driving roller is located in the second arc-shaped guiding groove; the air output part is provided with an air outlet, is connected with the rotating driving part and synchronously rotates with the rotating driving part. By means of the air output assembly and the air conditioner with the same, the problem that the air sweeping range is small in the prior art is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

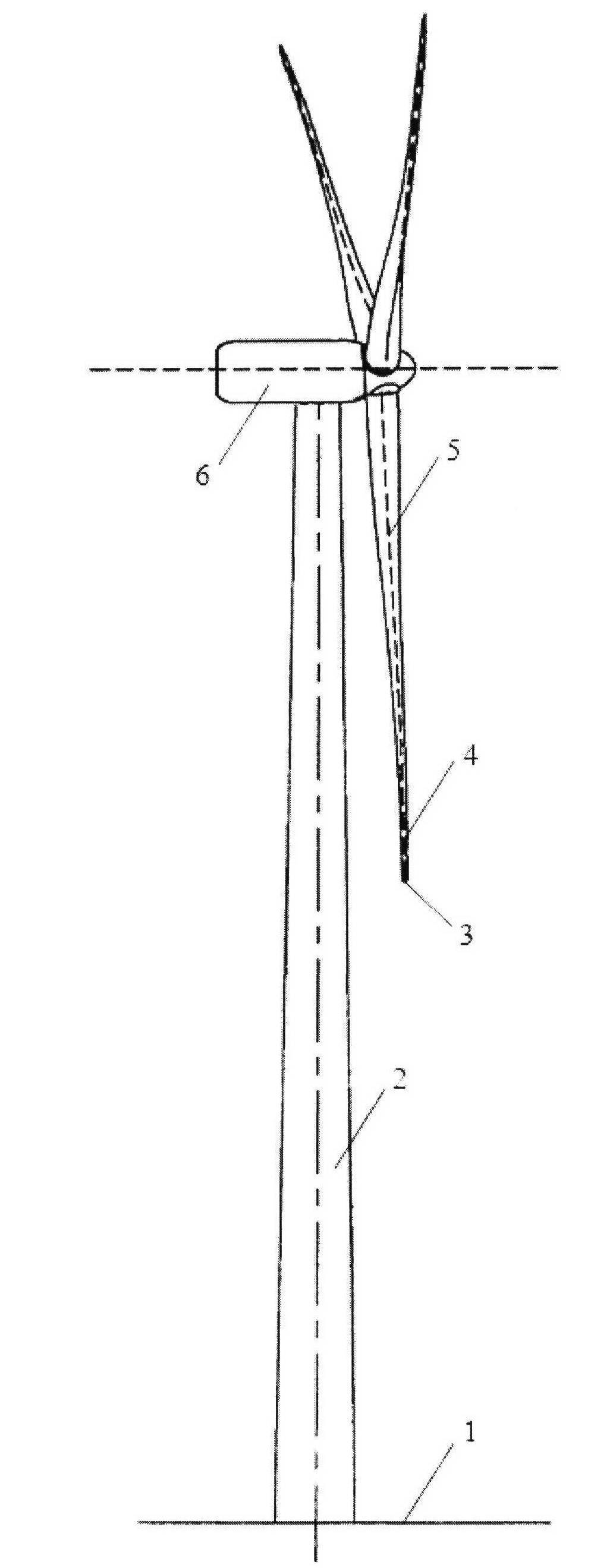

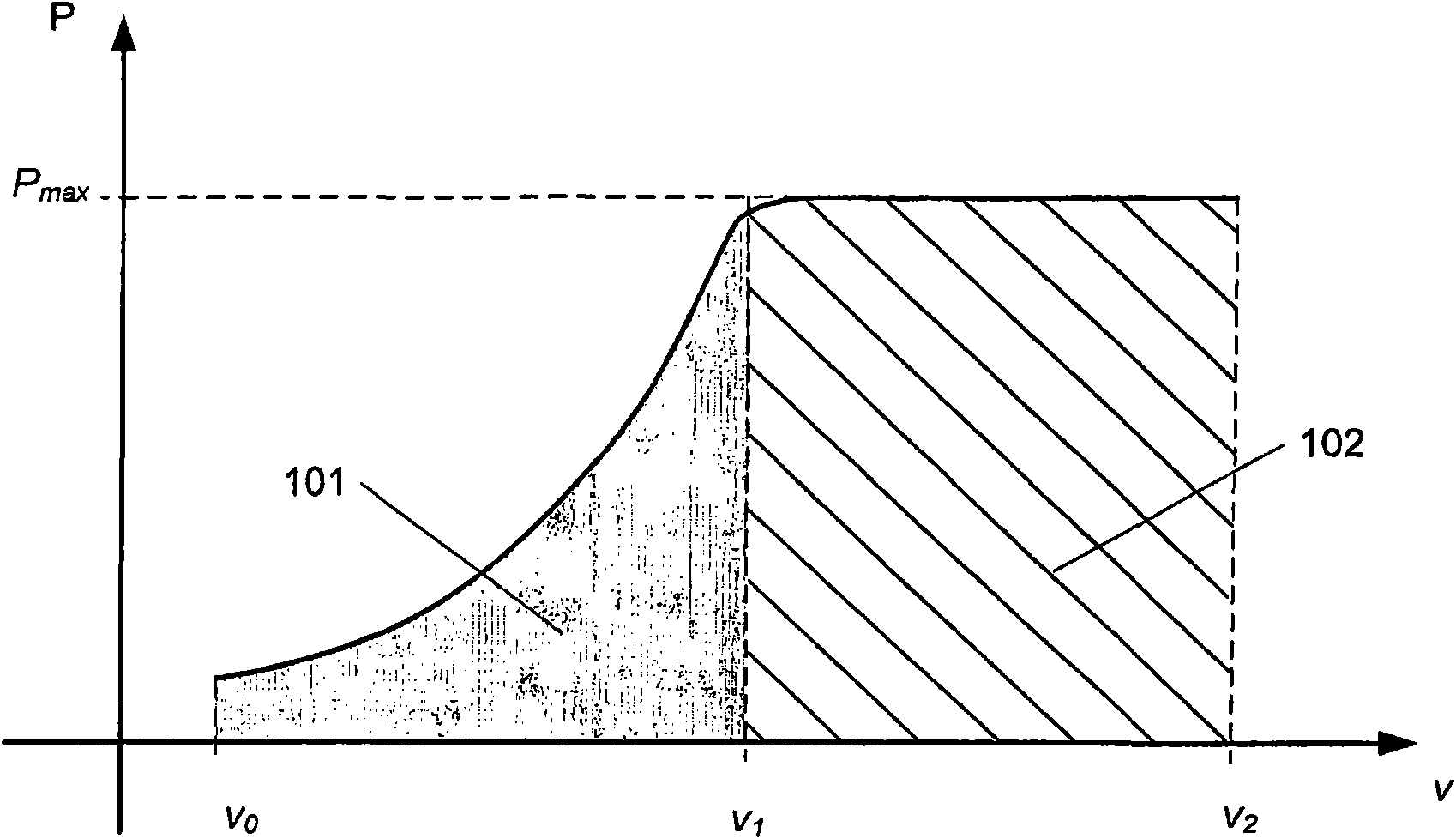

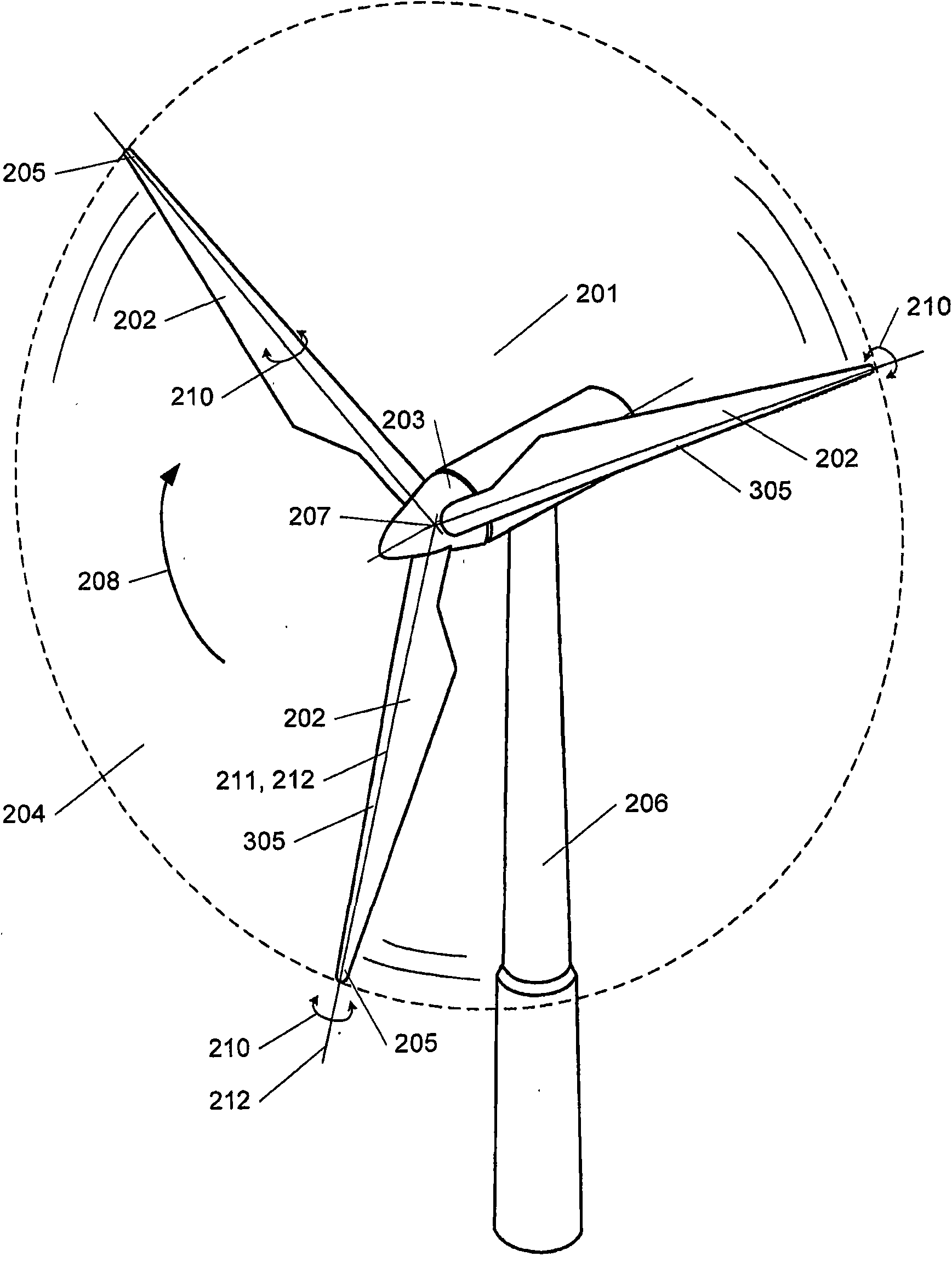

Pitch of blades on a wind power plant

ActiveCN101600879ASwept area optimizationIncrease distanceAvoid excessive blade deflectionWind motor controlLeading edgeEngineering

The present invention relates to a blade for a wind power plant with an assembly face for mounting in a circular pitch bearing, whose pitch axis is angled relative to the longitudinal axis of the blade, and wherein the blade comprises a root part with an approximately elliptic cross-section, in which root part the assembly face is arranged. The invention further relates to a wind power plant in general having a pitch- adjustable blade mounted in a pitch bearing such that the distance between the outermost part of the blade and the tower is increased when the leading edge of the blade is pitched up in the wind. This is accomplished in that the longitudinal axis of the blade is angled in a particular way compared to its pitch axis. The invention also relates to a method of controlling a wind power plant, including to increase the rotor area and / or increasing the distance between the outermost part of at least one blade and the tower by regulating, during operation, the pitch of a blade about a pitch axis which is angled relative to the longitudinal axis of the blade.

Owner:LM GLASSFIBER

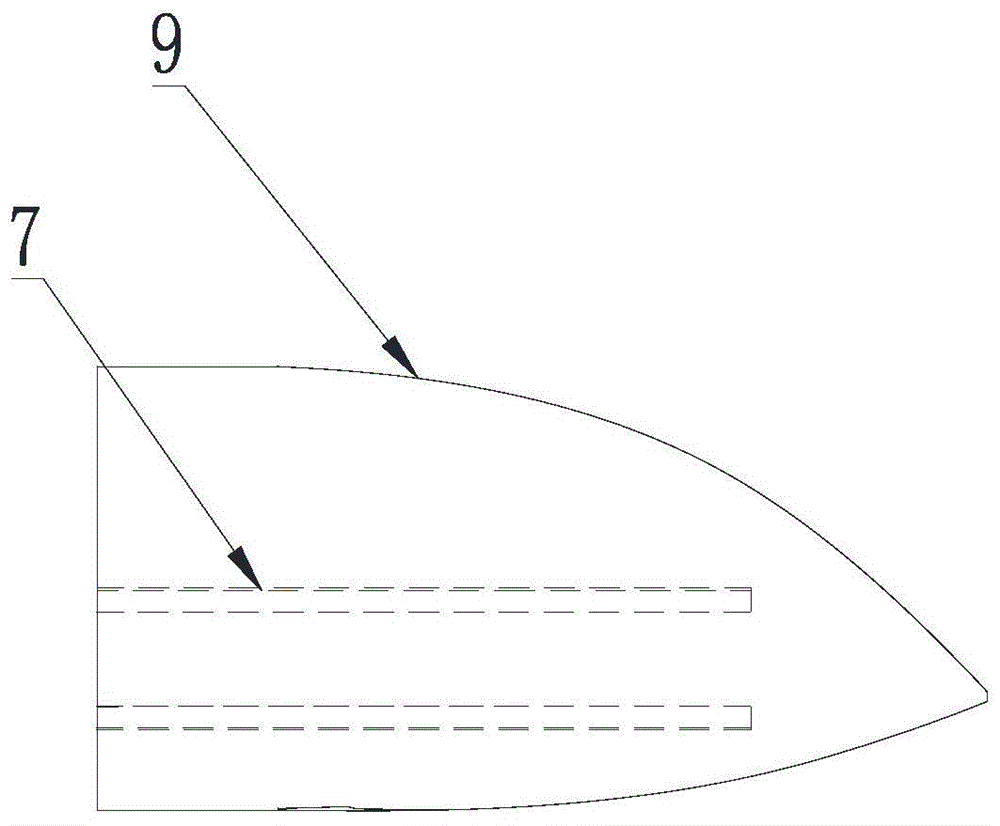

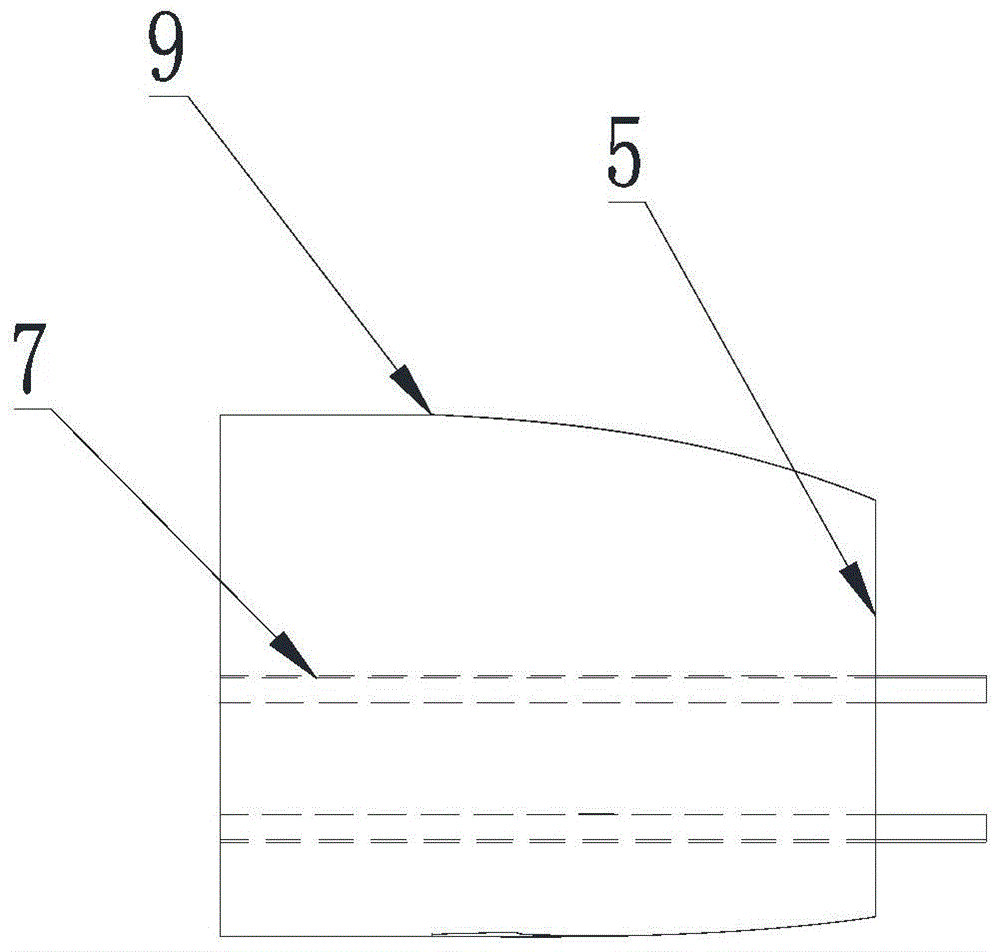

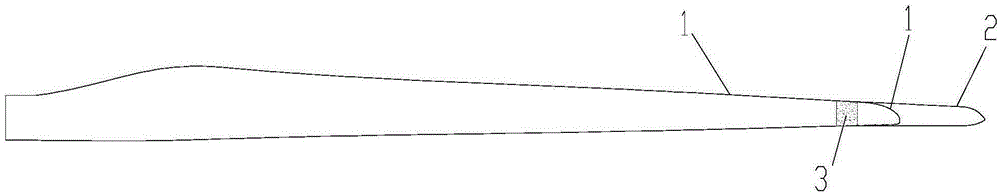

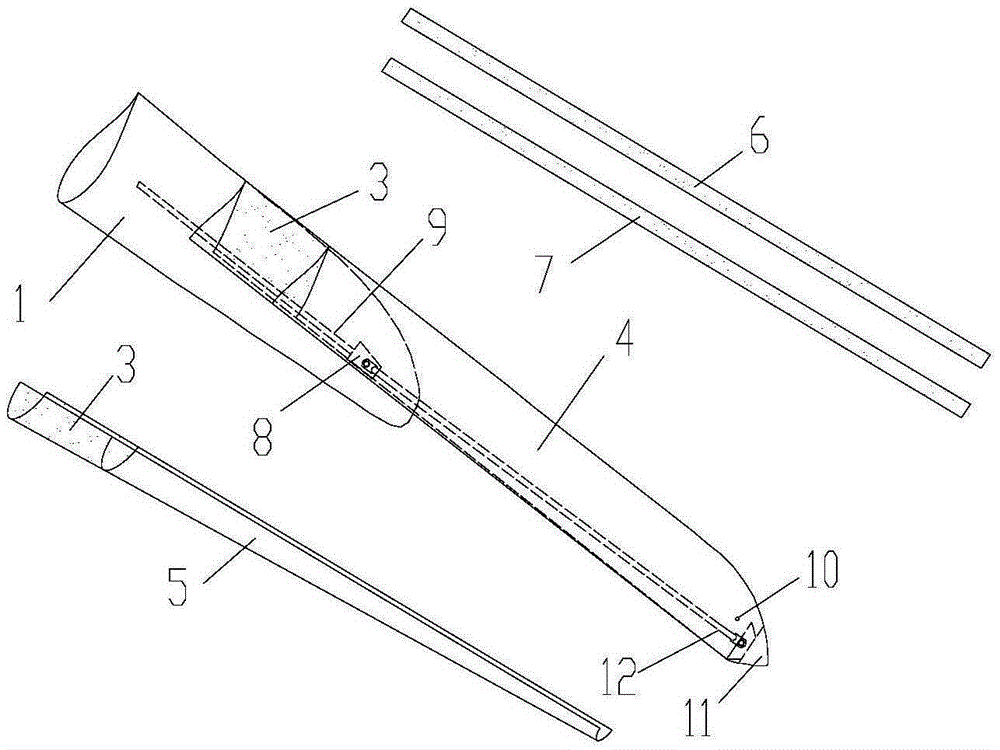

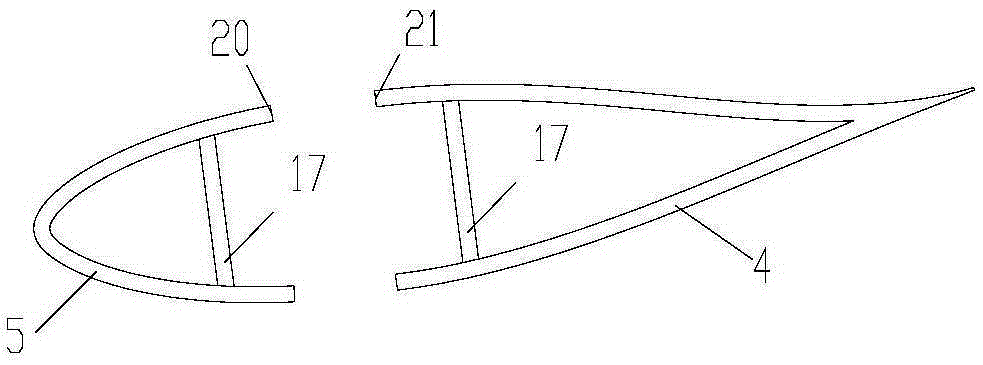

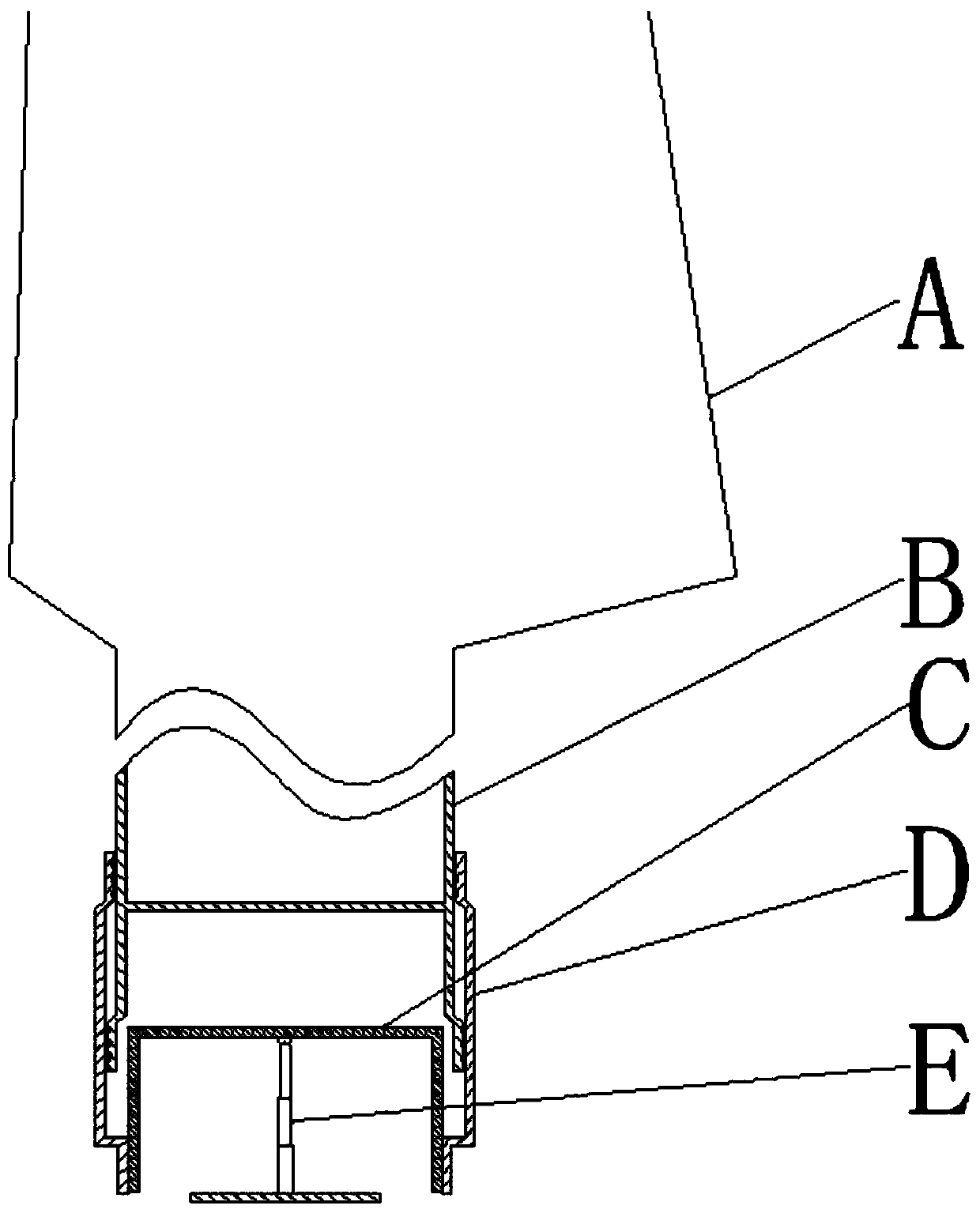

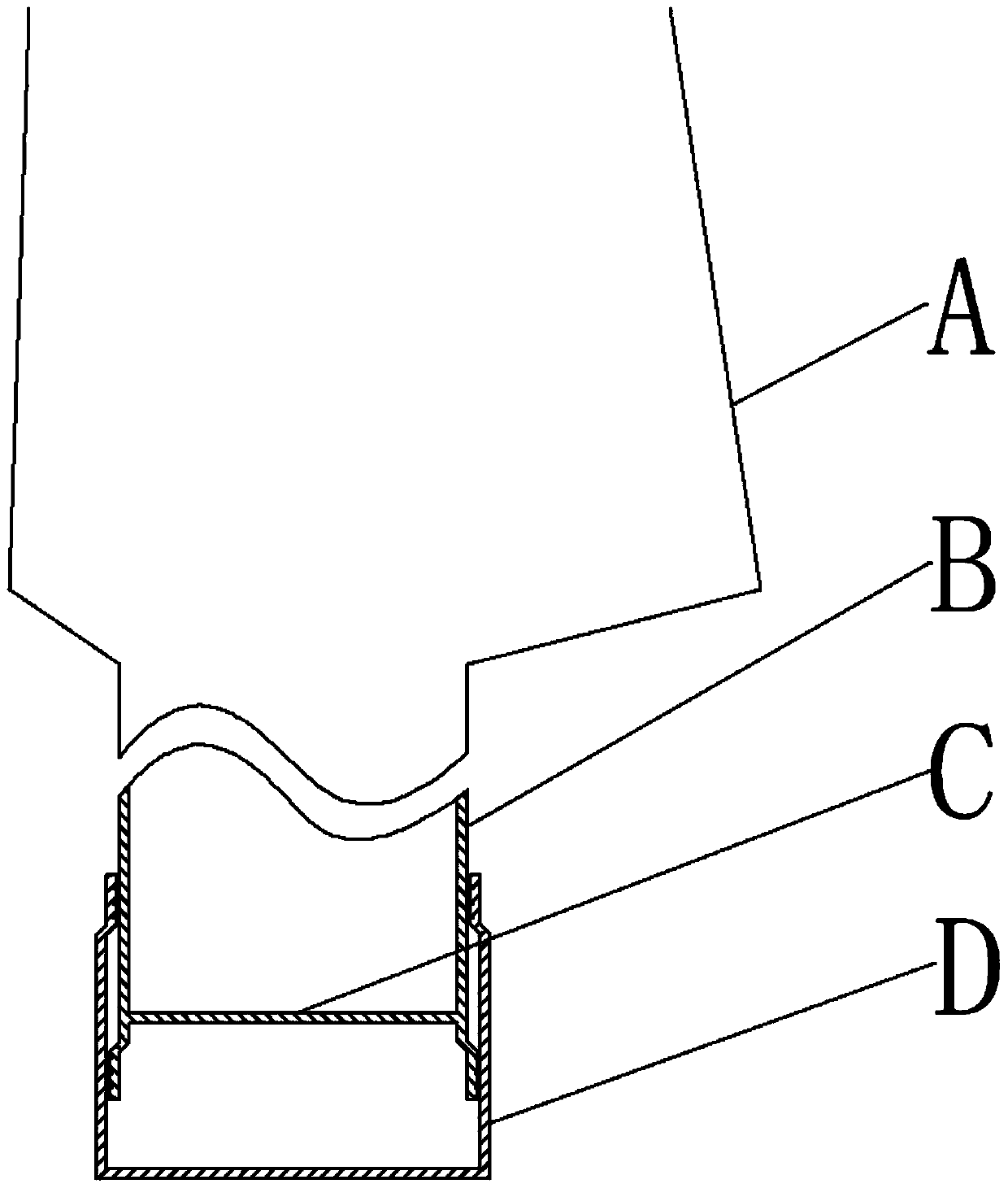

Blade tip improvement or repairing method of wind turbine blade and blade tip lengthened section structure

InactiveCN105415717AIncrease the swept areaImprove power generation efficiencyTurbine bladeEconomic benefits

The invention discloses a blade tip improvement or repairing method of a wind turbine blade. The blade tip improvement or repairing method includes the following steps that a blade tip lengthened section divided into two parts of shell bodies in the axial direction is fixed to the blade; additional reinforcement is carried out on the splicing area of the two parts of shell bodies, so that a new blade tip is formed. The blade tip of the original blade is lengthened or the damaged blade tip of the original blade is repaired, so that the sweeping area of the blade is increased, the generation efficiency of a wind turbine is improved, the economic benefits are obvious, the implementation is simple, and the improvement cost is low. The invention further discloses a blade tip lengthened section structure of the wind turbine blade for improving or repairing the original blade tip. The blade tip lengthened section structure comprises two parts of shell bodies divided in the axial direction. The two parts of shell bodies include the front edge shell body and the rear edge shell body which are spliced and bonded into a whole, and a new blade tip is formed. Or the two parts of shell bodies include the windward side shell body and the leeward side shell body which are spliced and bonded into a whole, and a new blade tip is formed.

Owner:东方电气风电股份有限公司

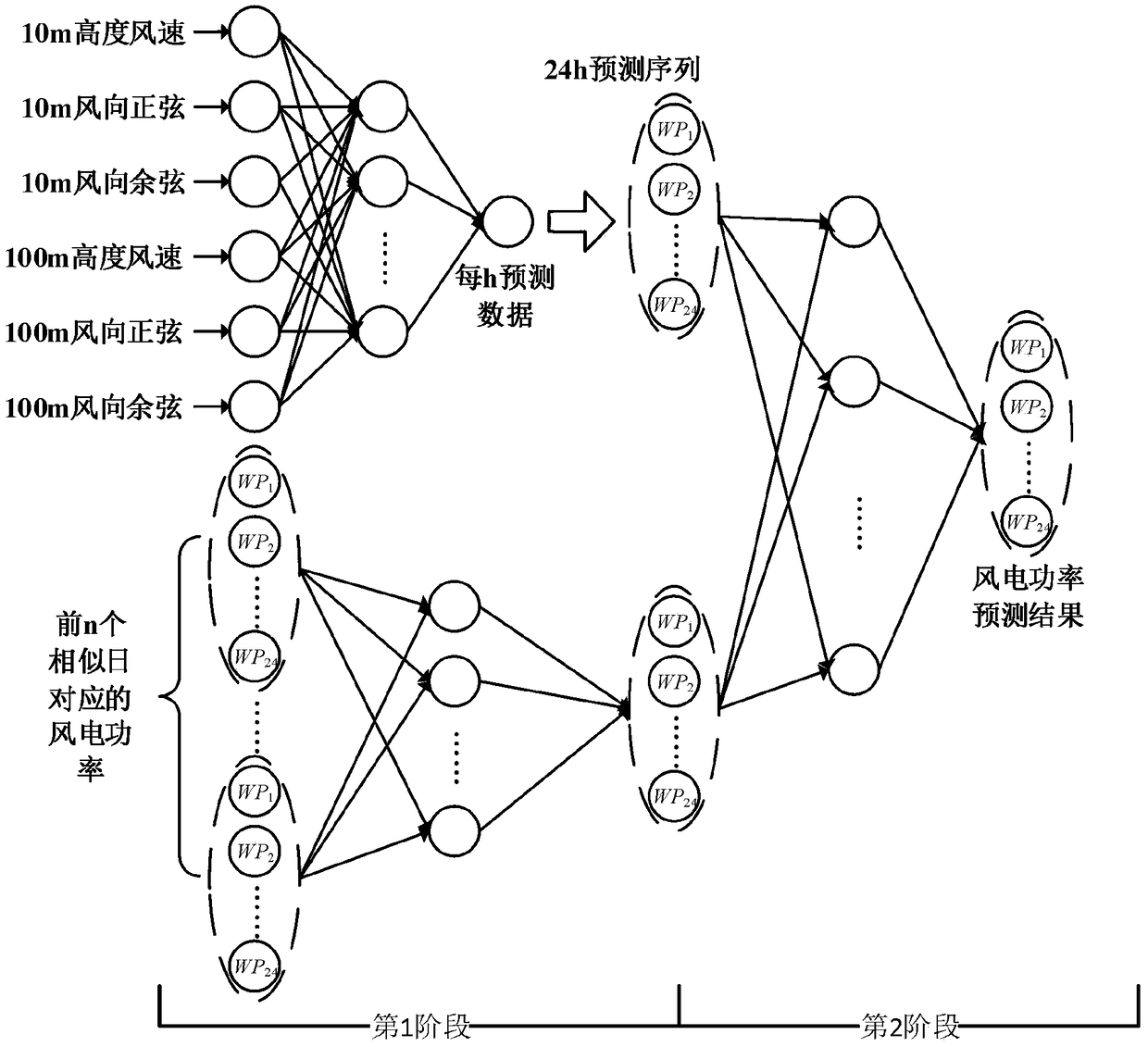

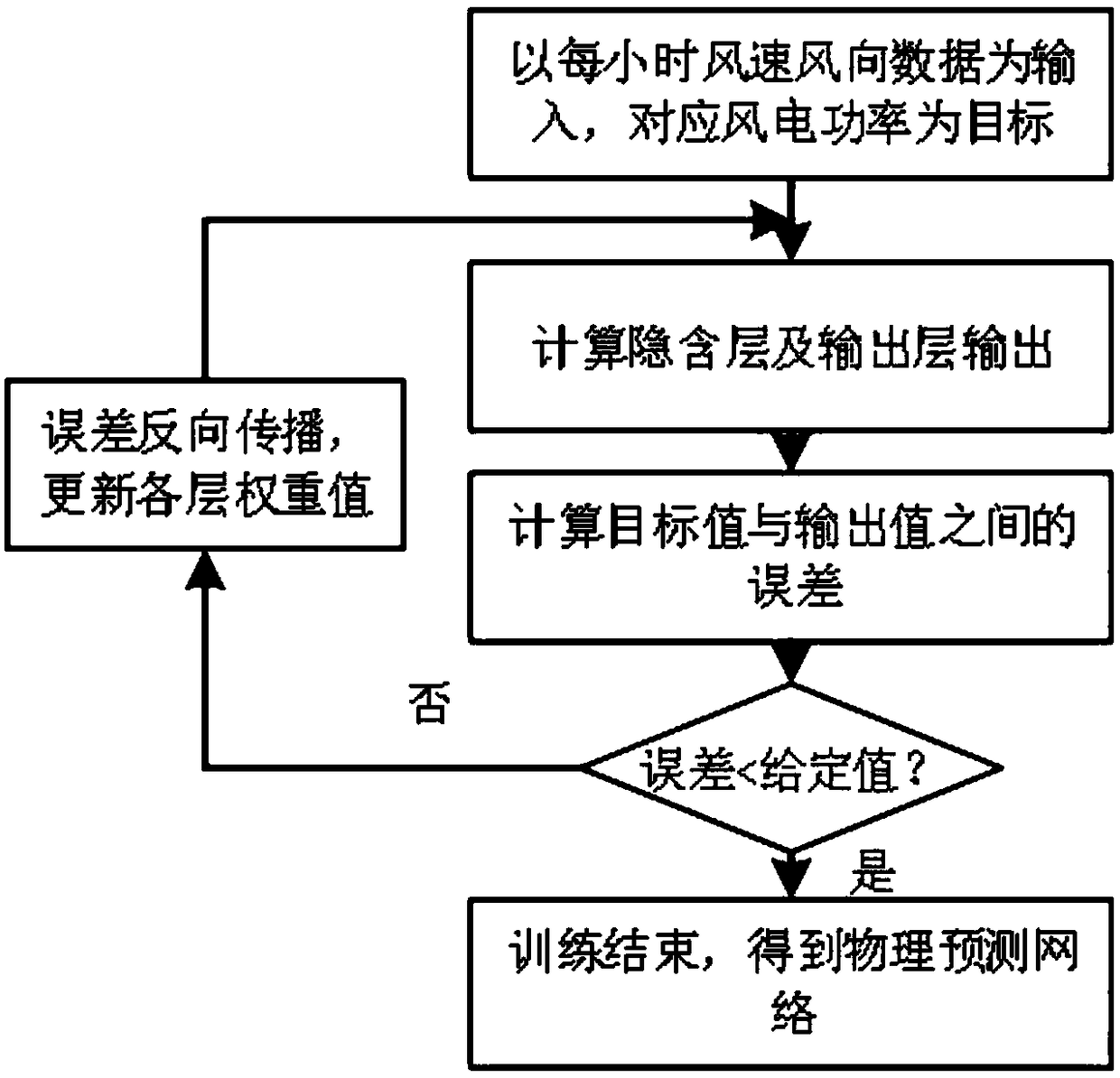

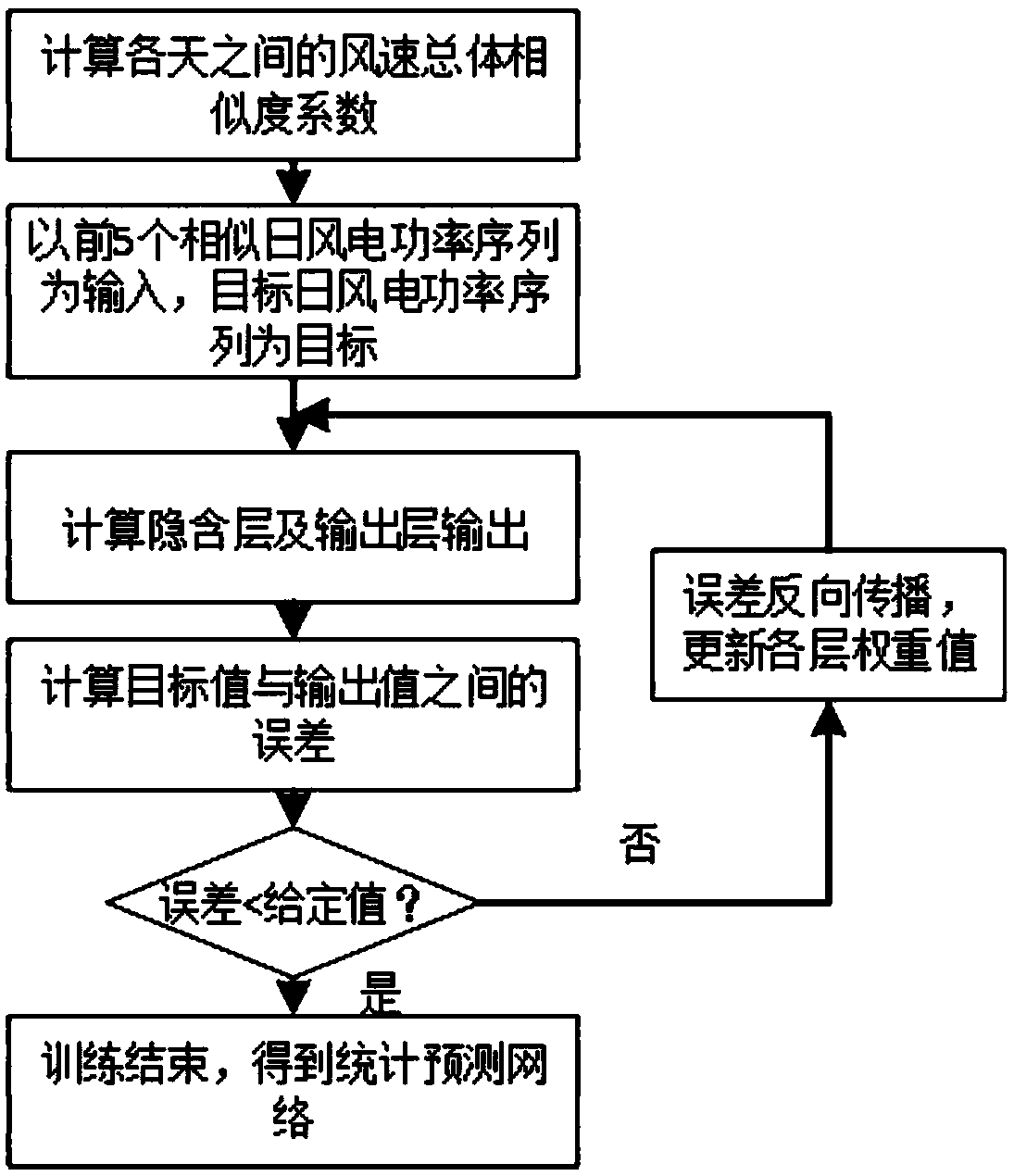

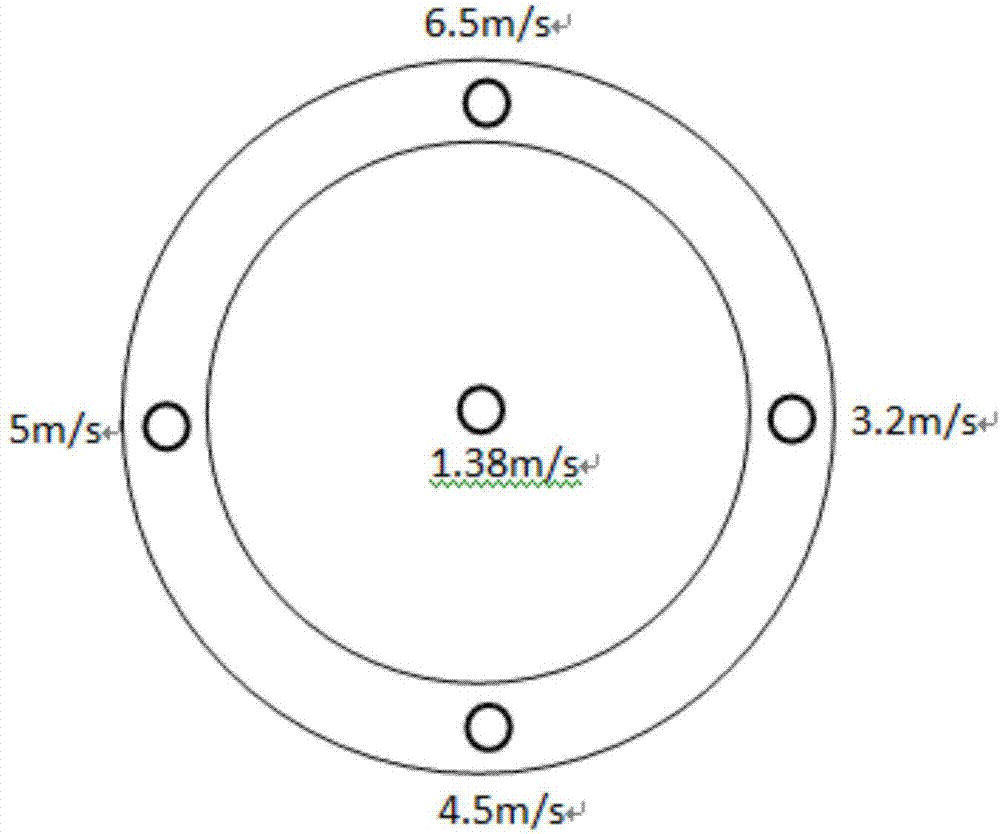

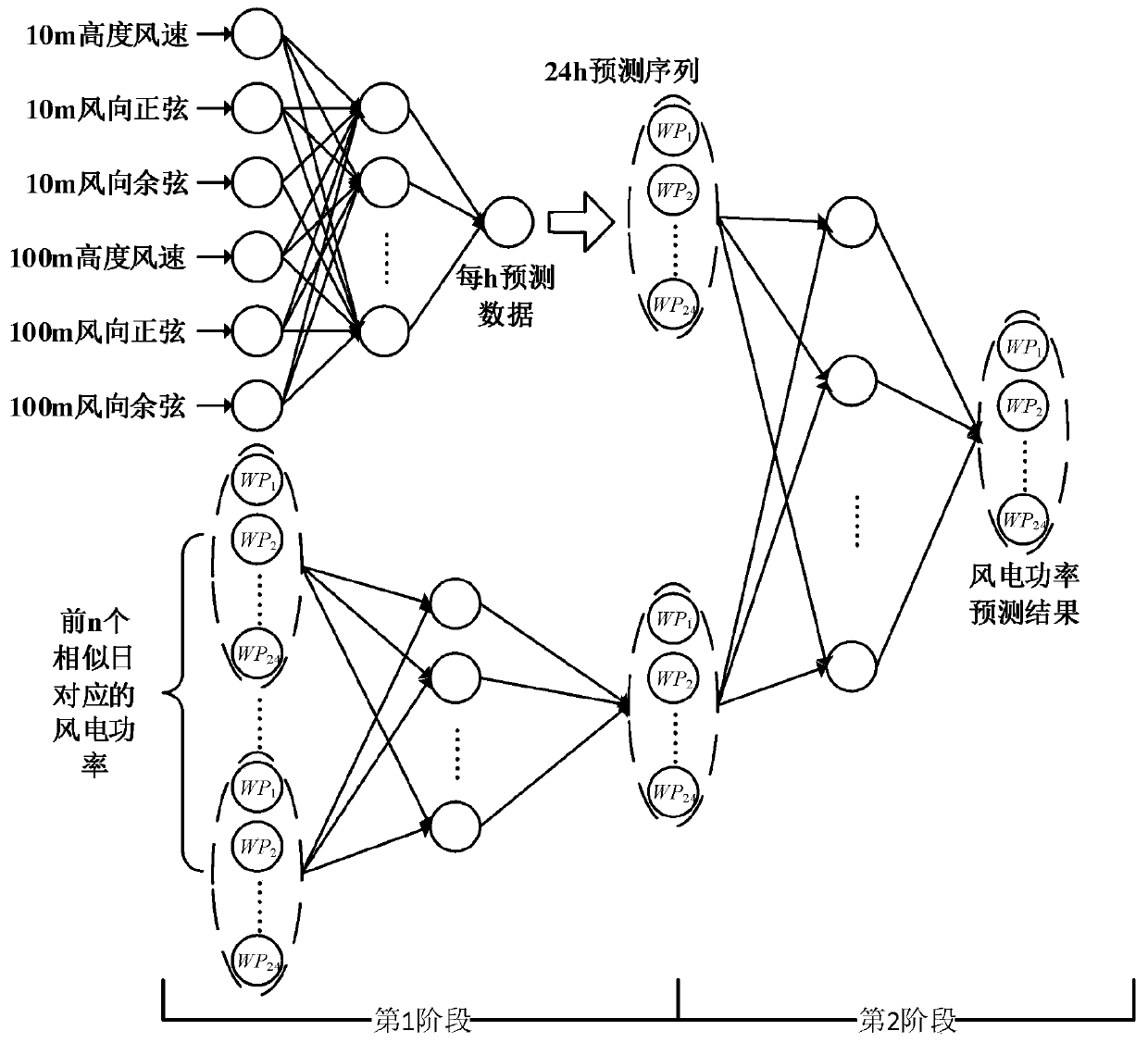

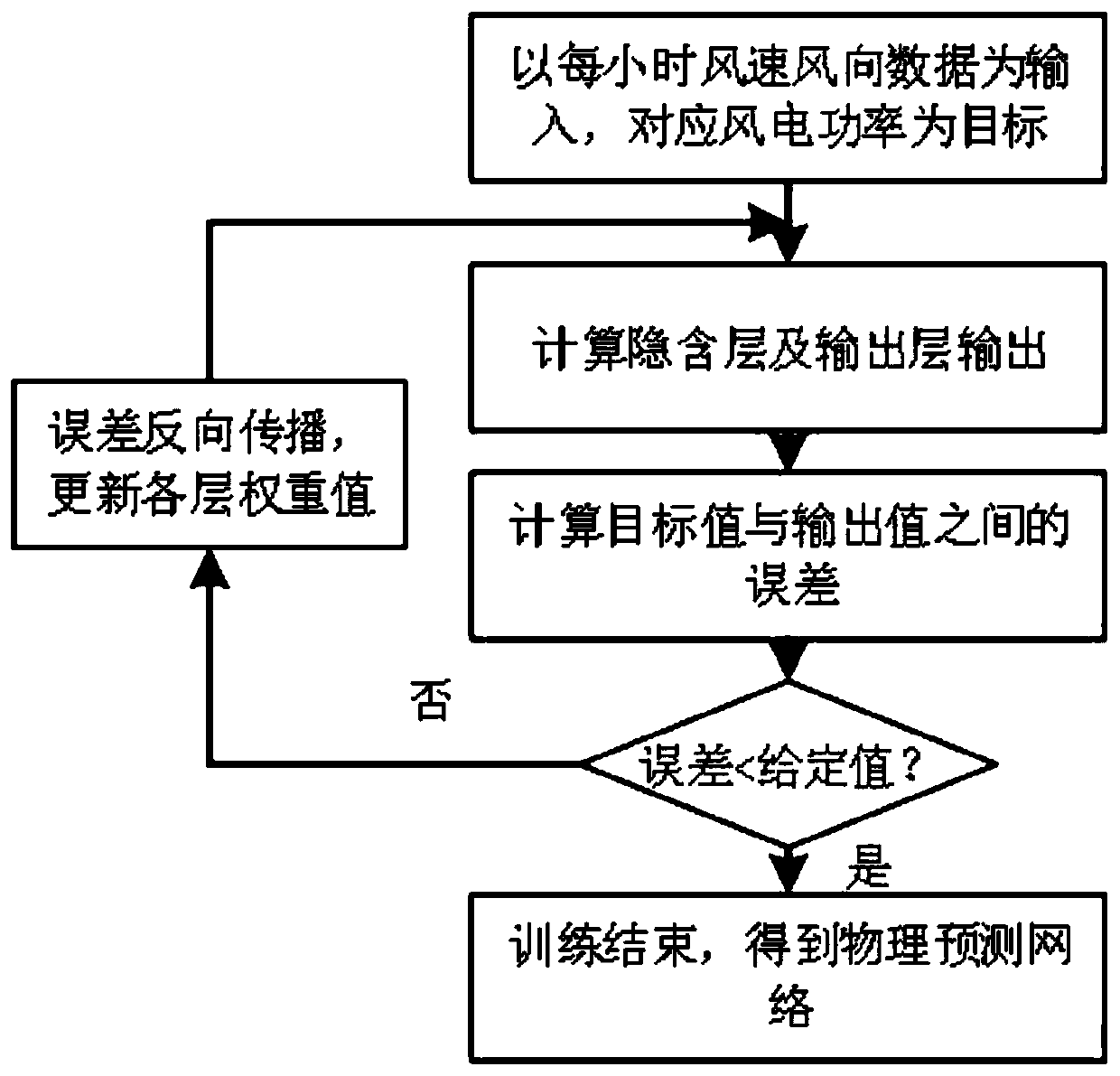

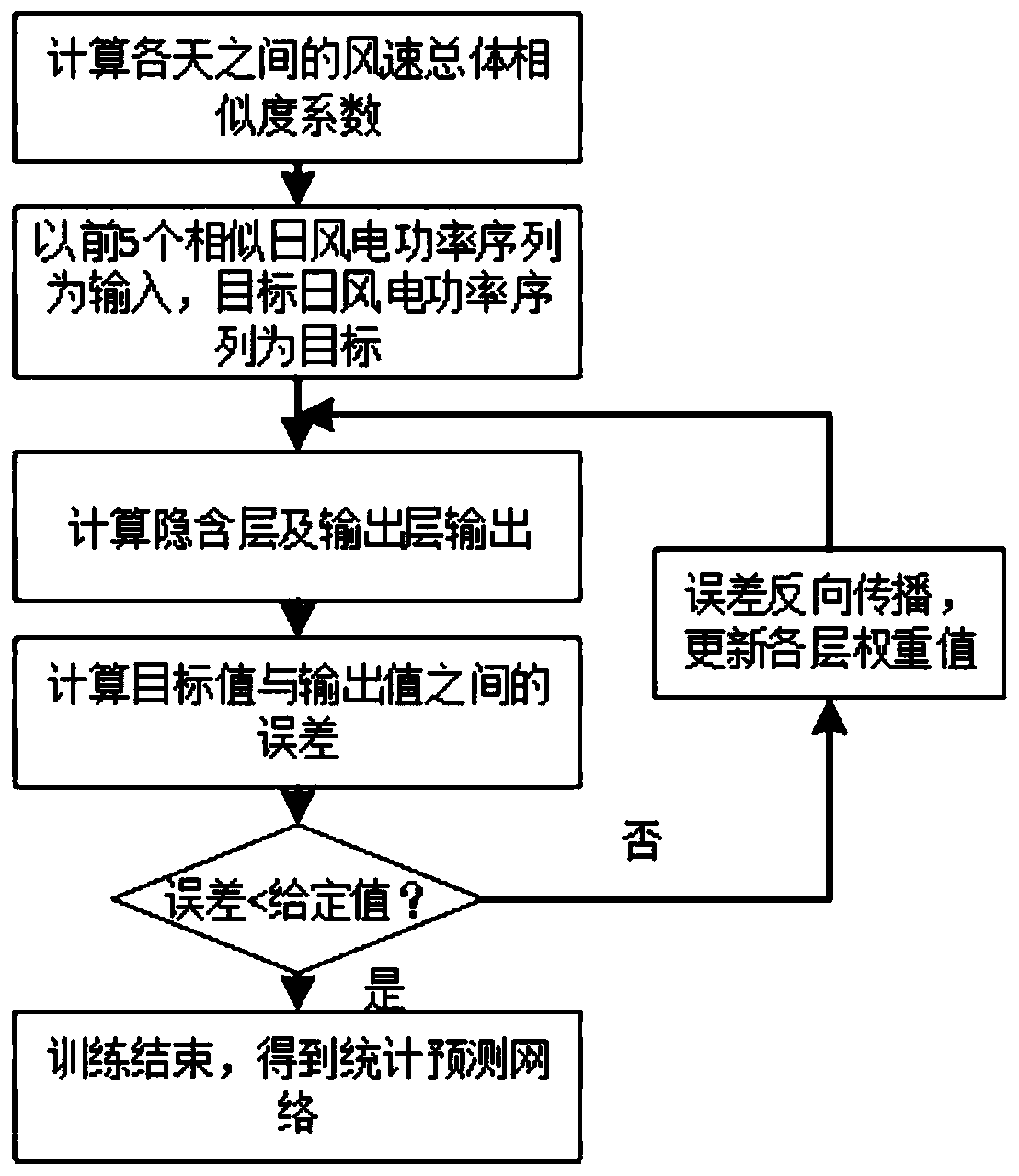

Physical-statistical hybrid two-stage wind power prediction method

ActiveCN108832623AImprove forecast accuracyConducive to scheduling decision optimizationForecastingAc network circuit arrangementsElectricityAlgorithm

The invention discloses a physical-statistical hybrid two-stage wind power prediction method. Wind power prediction obtained by a physical prediction method and a statistical prediction method is usedas input of a second stage, and through a BP neural network, a wind power sequence on a target day is predicted. The method comprises the following specific steps: a physical prediction neural network model is built and trained; with each day as the target day, wind speed general similarity coefficients of other days relative to the target day are calculated respectively; a statistical predictionneural network model is built and trained; with wind speed and wind direction data of 24 h per day as input, a wind power physical prediction sequence for each day in former 180 days is sorted; withwind power sequences corresponding to former five similar days of each day as input, a wind power statistical prediction sequence for each day in former 180 days is obtained; and a BP neural network prediction model in a second stage is built and trained until a training error is smaller than a given value, and a two-stage prediction model is obtained finally.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

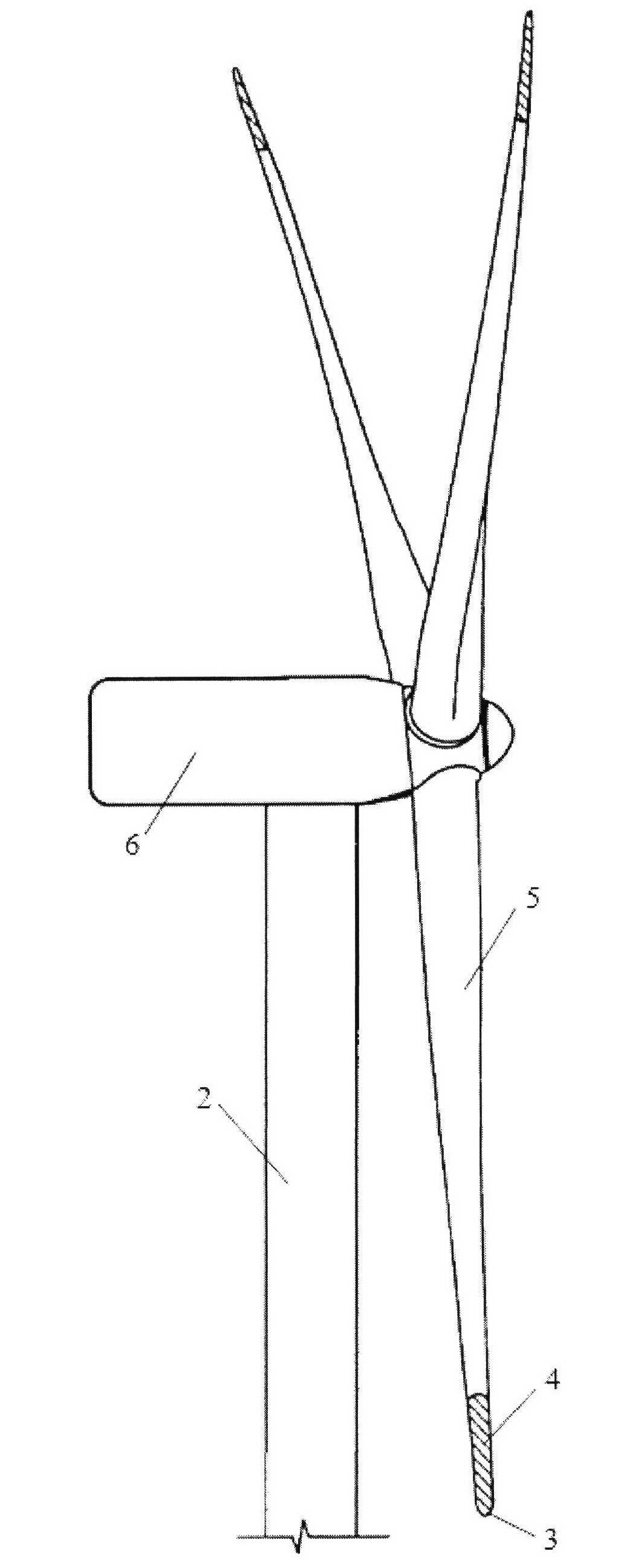

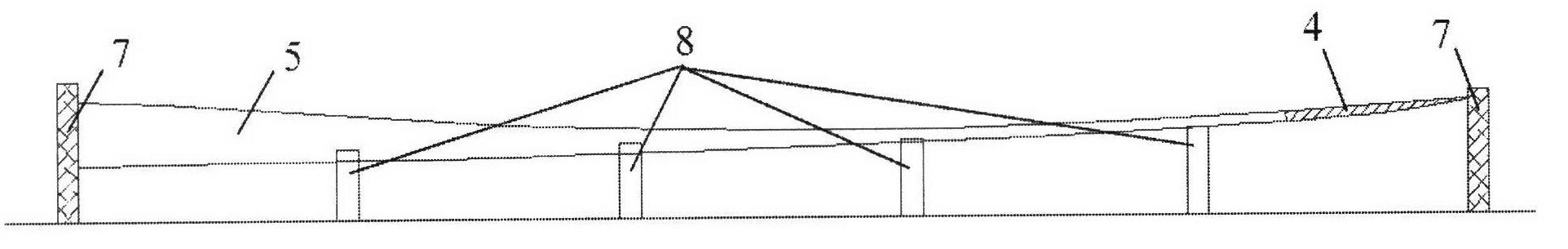

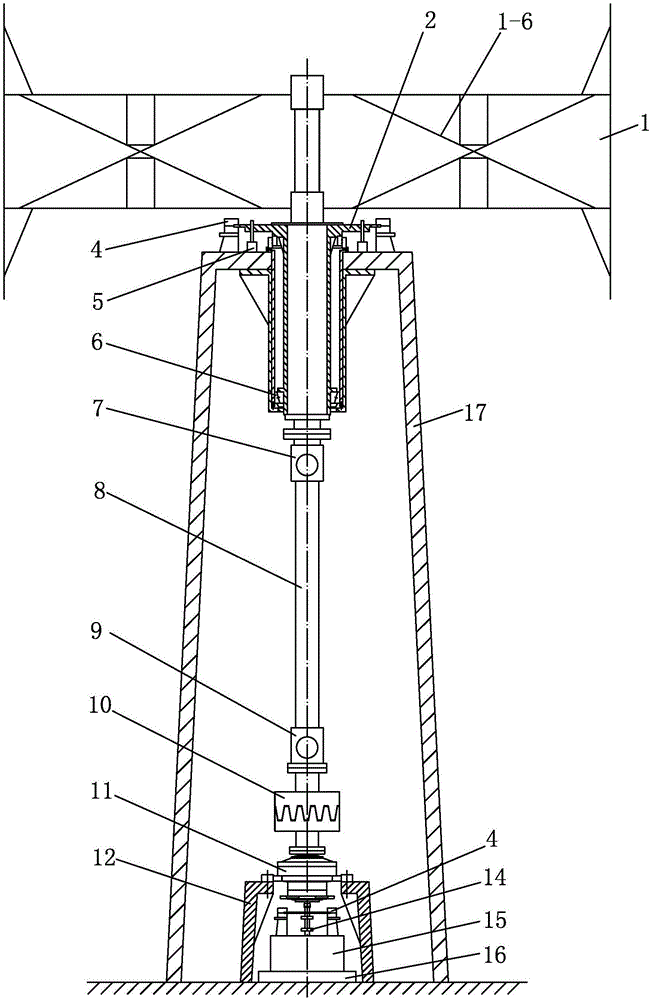

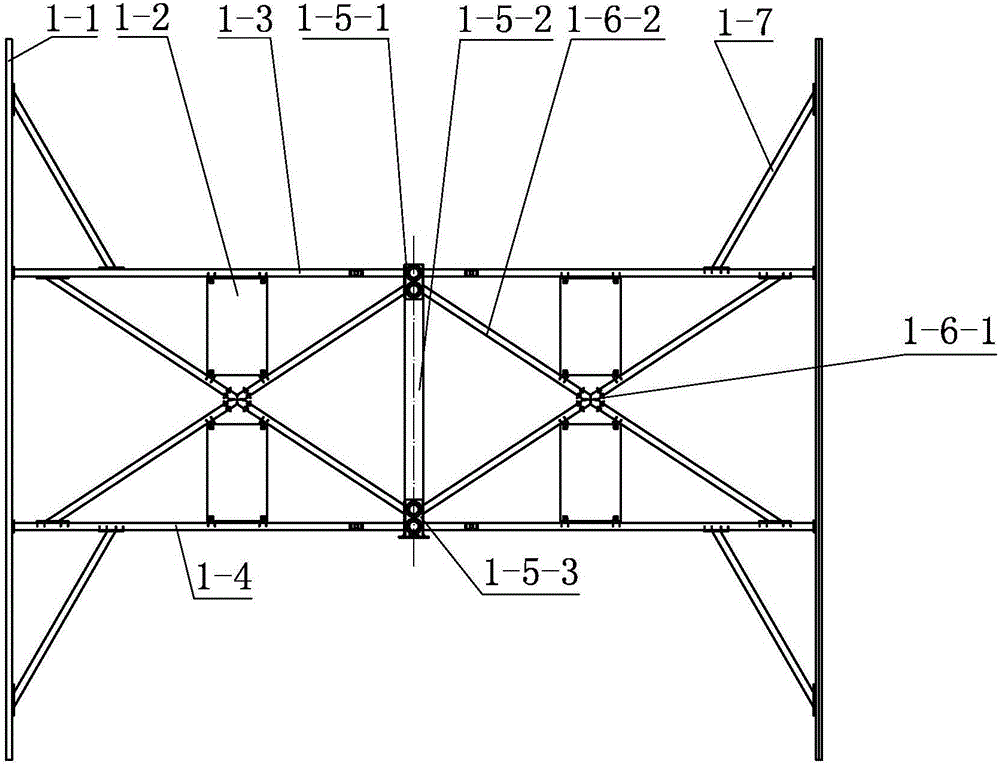

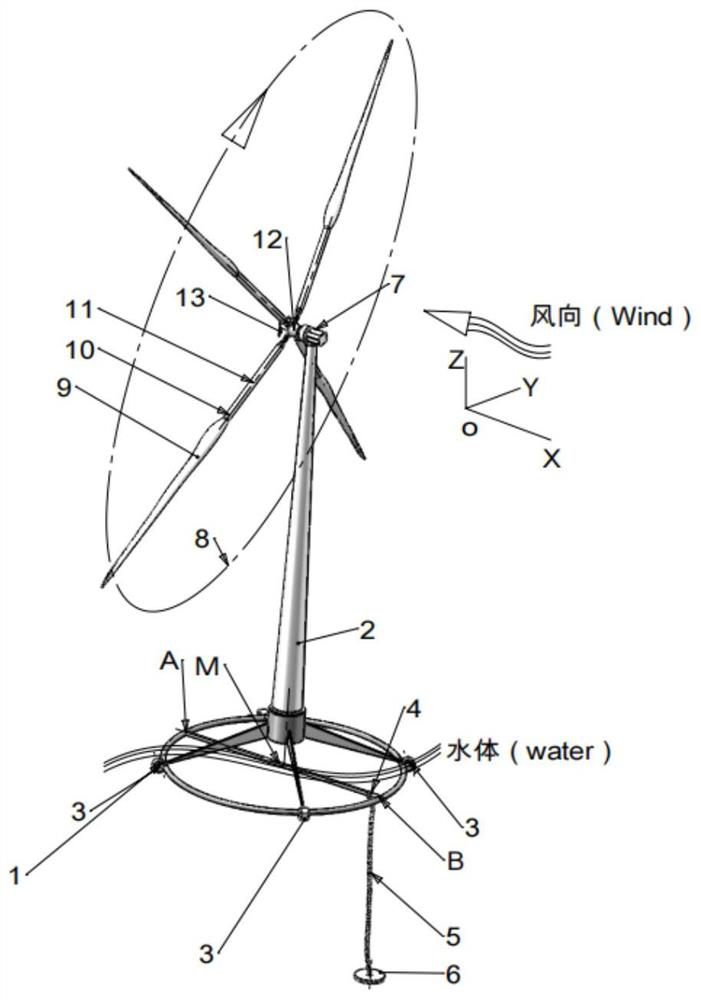

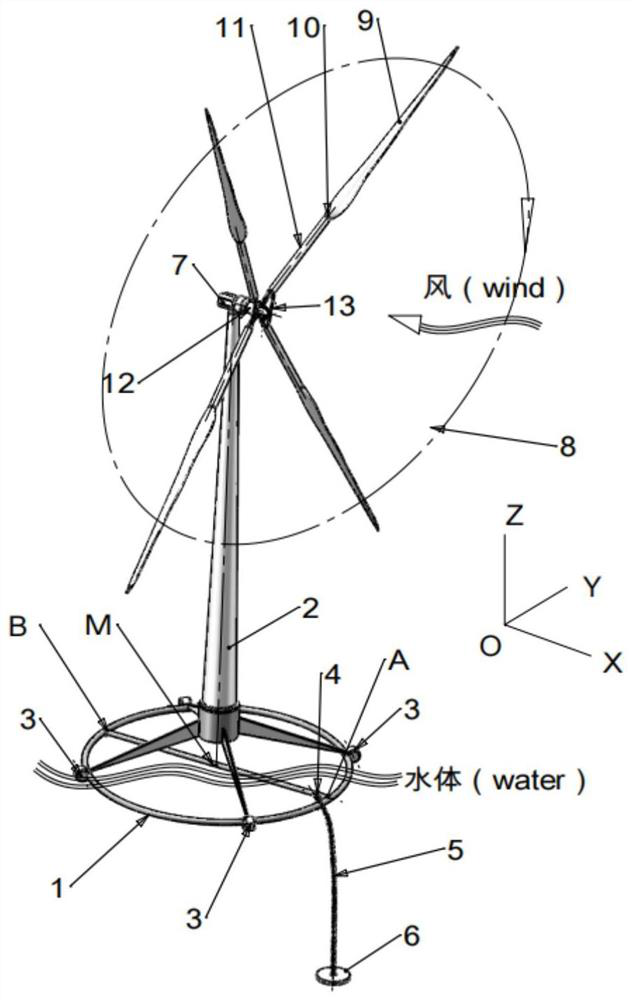

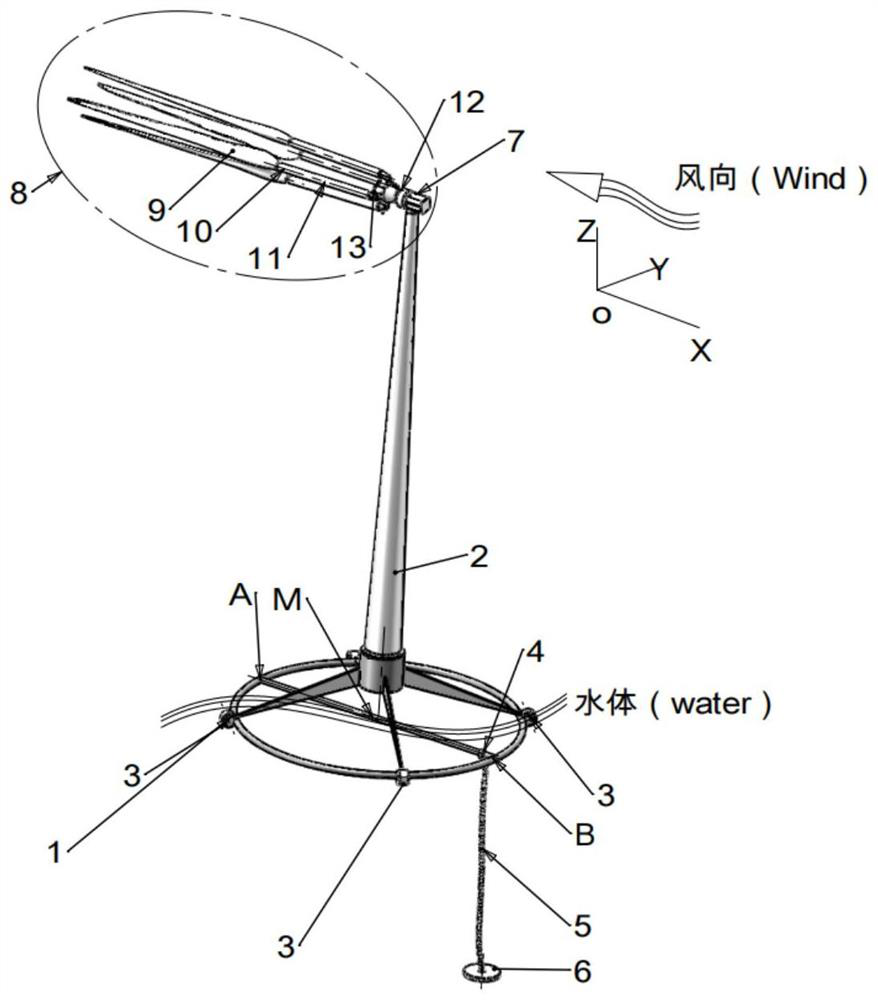

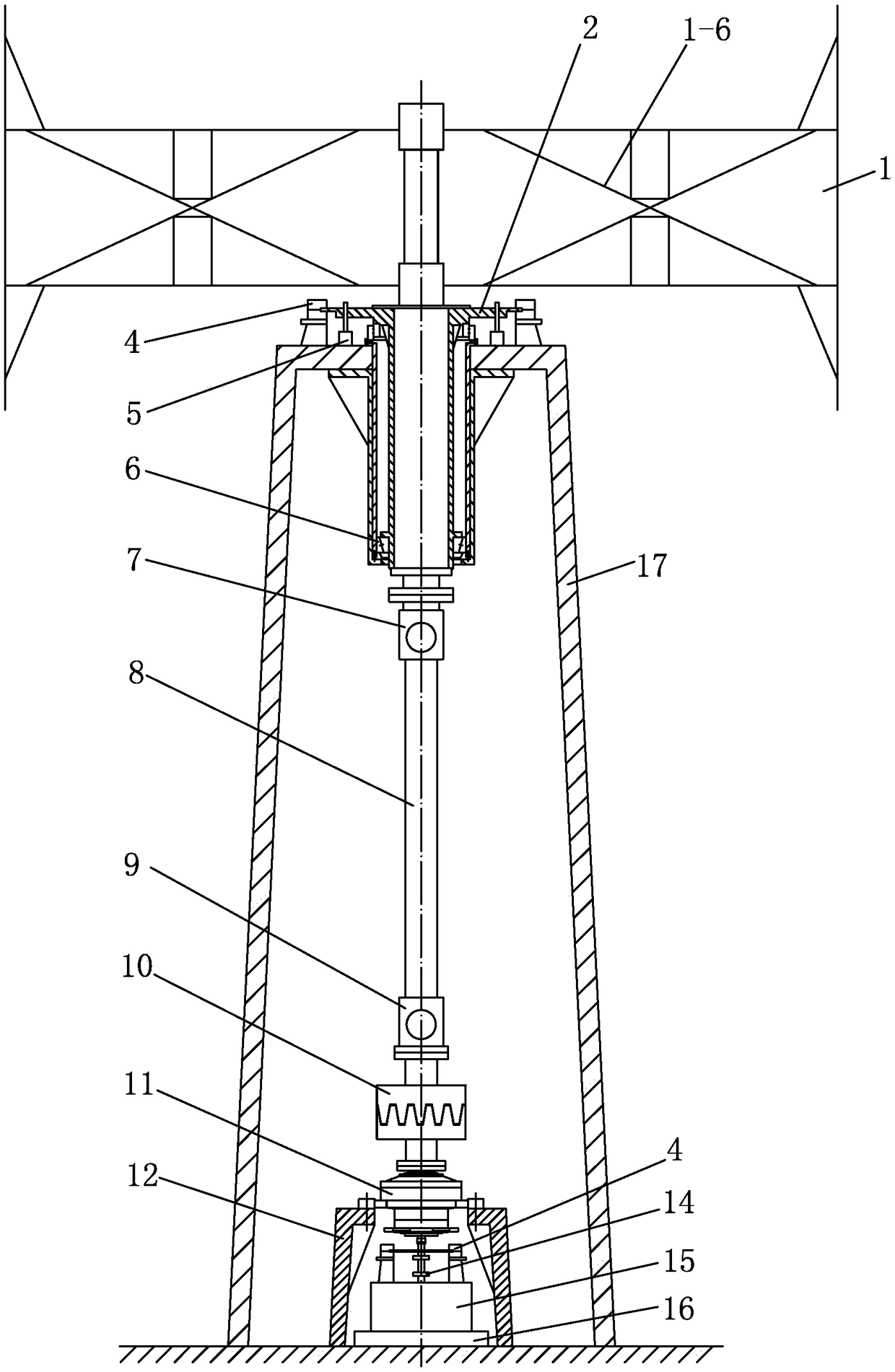

Floating yaw type anti-typhoon wind power generation device and typhoon defense method

PendingCN114576091AObvious adaptive operation advantageRaise the upper limit of wind speedWind motor controlWind motor supports/mountsMarine engineeringControl system

The invention discloses a low-cost floating yaw type anti-typhoon wind power generation device and a typhoon resisting method, and provides a low-cost structure configuration and control strategy for improving the anti-typhoon capacity and reducing the degree of typhoon, and the characteristic that a floating system can freely rotate on a water body without a bearing and a rail is utilized. A set of expensive yaw bearing and control system of a traditional fan is omitted, the cost of a tower drum and a transmission chain structure can be further optimized through the self-adaptive directional stress state, and a structure that blades of a wind wheel can be put down and folded together under the typhoon condition is constructed. And in combination with control of the yaw system and the downwind blowing effect of wind power, all the blades point to the downwind direction in the typhoon environment, the upsetting moment of the wind power device is balanced, and therefore the typhoon disaster resisting capacity is greatly improved, and the safe operation capacity of a large fan within the 30-year service life is guaranteed.

Owner:张长增

A vertical shaft clutch type wind power generation device

ActiveCN106321359BReduce design difficultyReduce design weightWind motor controlWind motor assemblyDrive shaftCoupling

Owner:HARBIN INST OF TECH

Air conditioner with water absorption curtain

ActiveCN107270405AReduce energy consumptionLow costSpace heating and ventilation safety systemsCondensate preventionRegulation temperatureEngineering

Owner:湖南展鸿环保科技有限公司

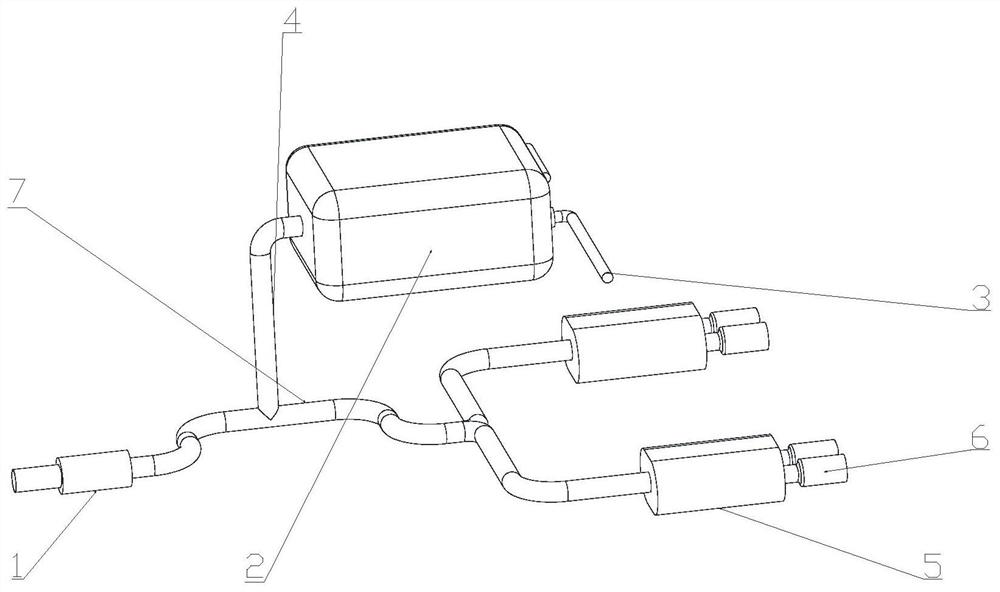

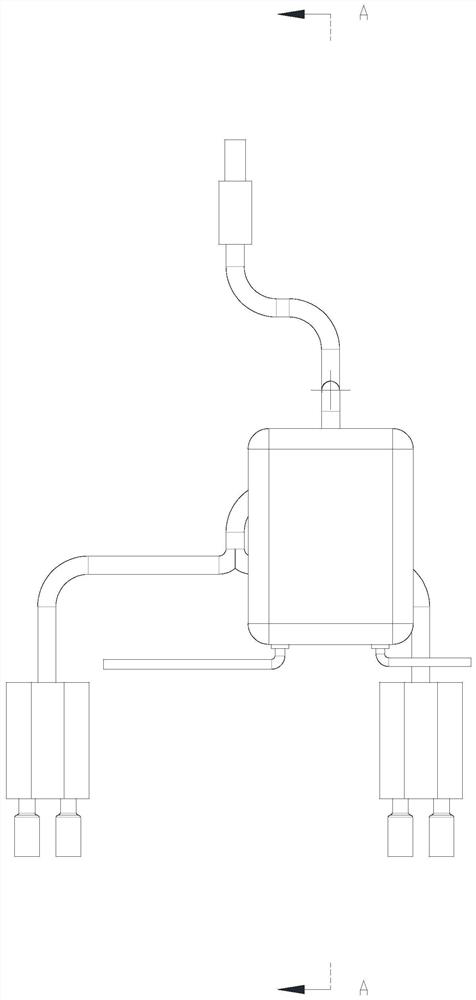

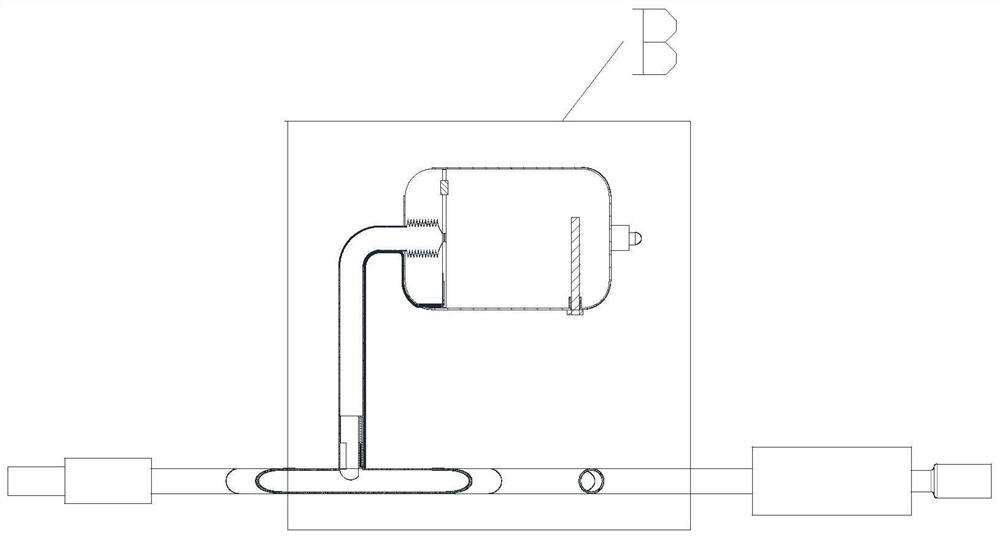

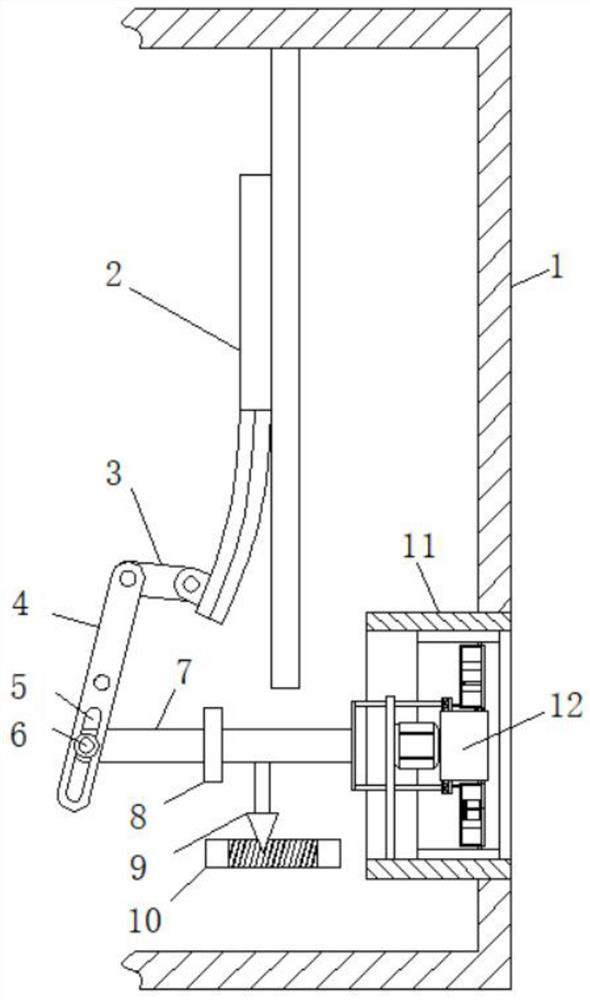

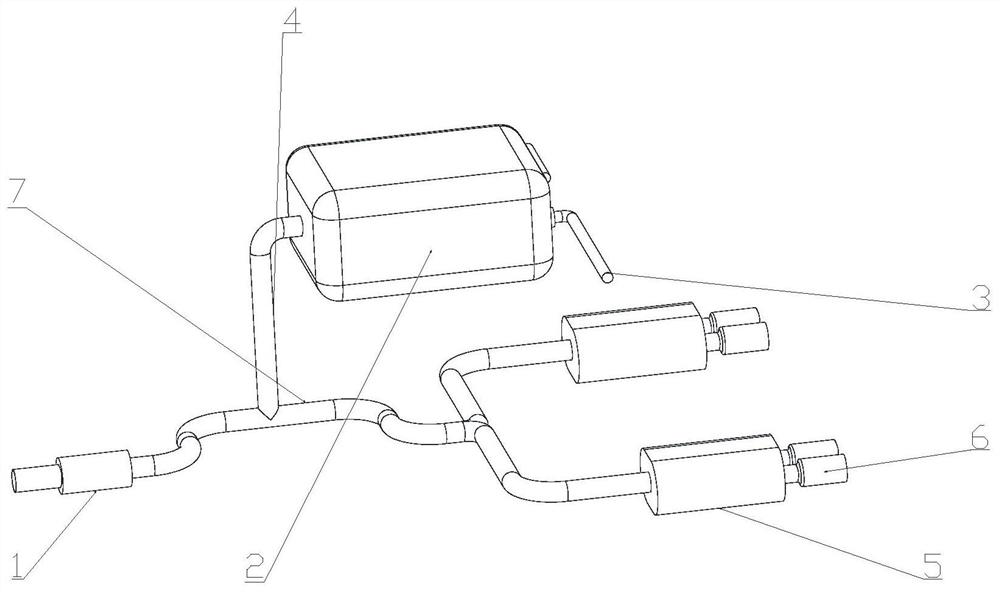

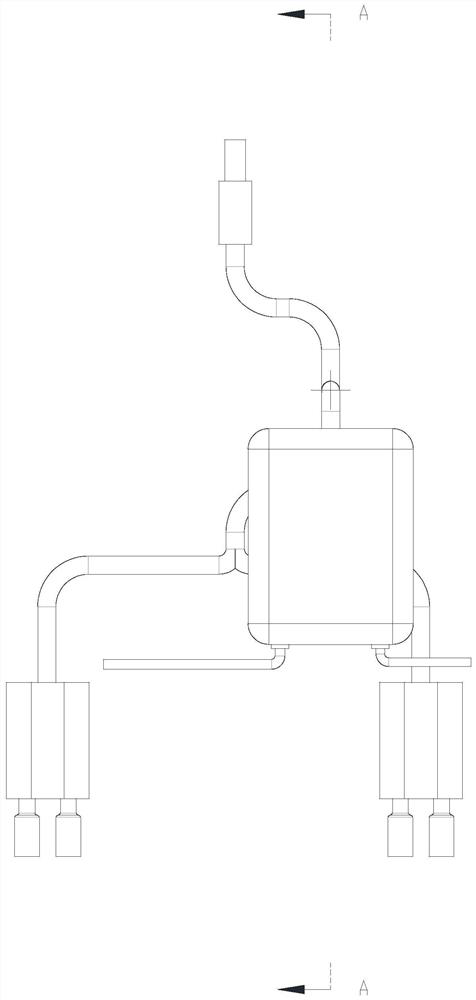

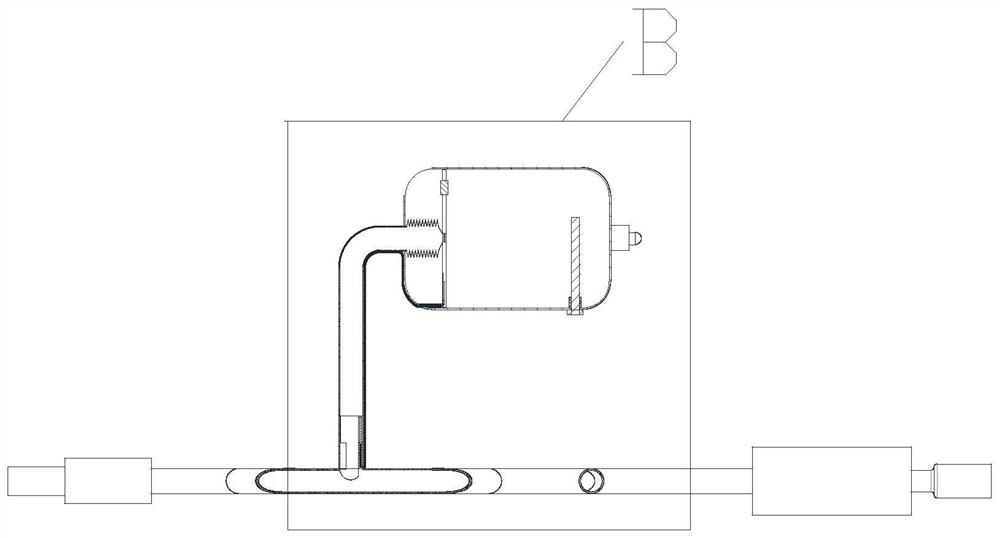

Device for cleaning rainwater on rearview mirror by using automobile exhaust waste heat

ActiveCN111976658AIncrease the swept areaClear allInternal combustion piston enginesVehicle cleaningEnvironmental engineeringMechanical engineering

The invention discloses a device for cleaning rainwater on a rearview mirror by using automobile exhaust waste heat. The device comprises a first ventilation pipe, a gas storage box body and an air port swing control device; the first ventilation pipe is fixedly arranged above the middle of an exhaust conveying pipe, and an automatic air interchanger is arranged in the first ventilation pipe; thegas storage space and a temperature adjusting device are arranged inside the gas storage box body; the gas storage box body is in ventilation connection with the first ventilation pipe; a gas outlet device is arranged at the front end of the gas storage box body; and the air port swing control device is arranged on the rearview mirror and is in ventilation connection with the air outlet device. Automatic collection of tail gas can be achieved, and the treated tail gas is used for cleaning rainwater on the automobile rearview mirror.

Owner:HANGZHOU HUOXI AUTO PARTS CO LTD

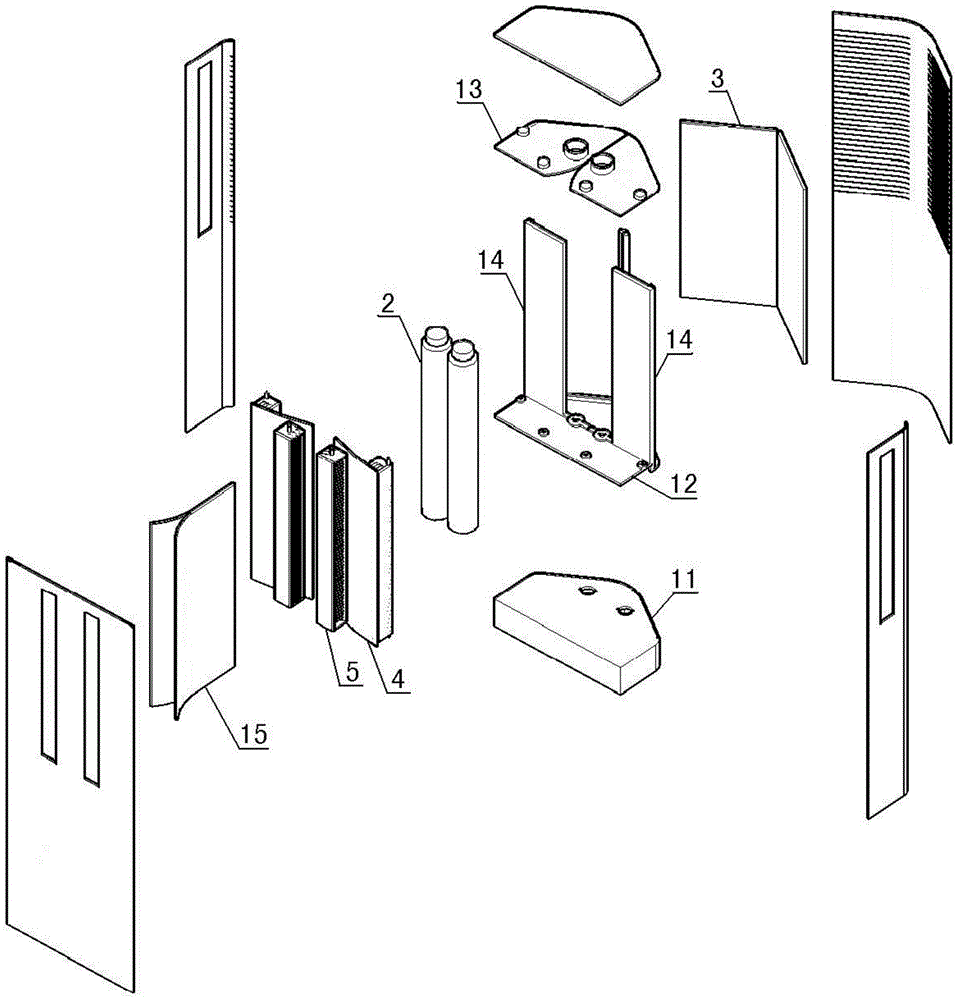

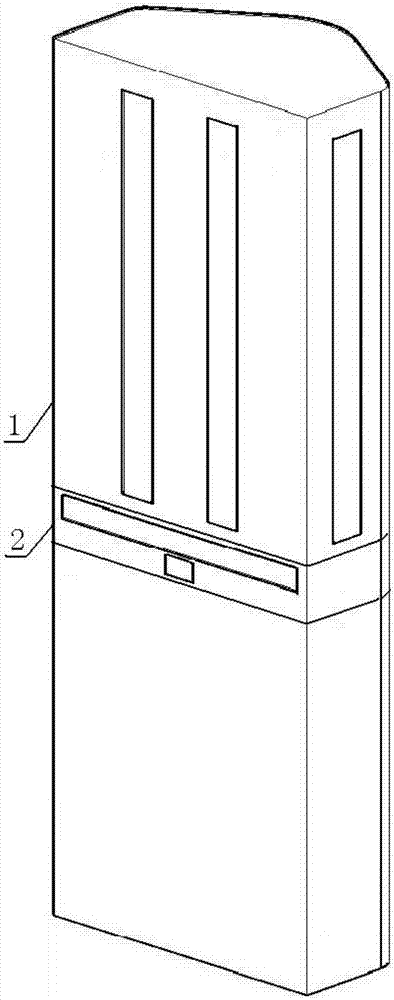

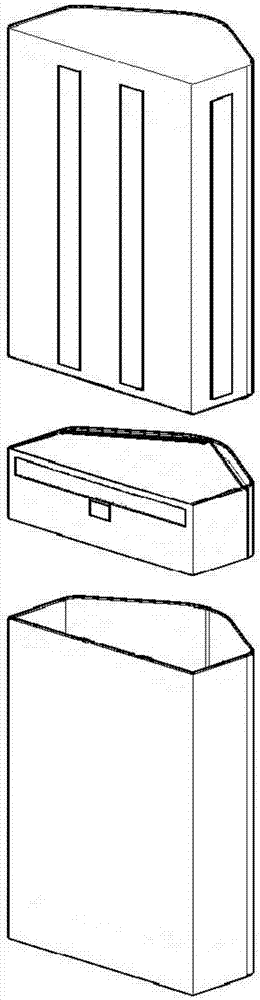

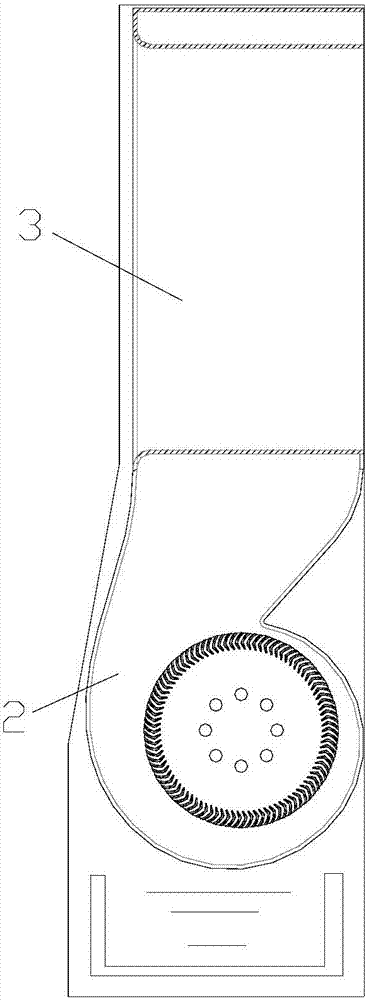

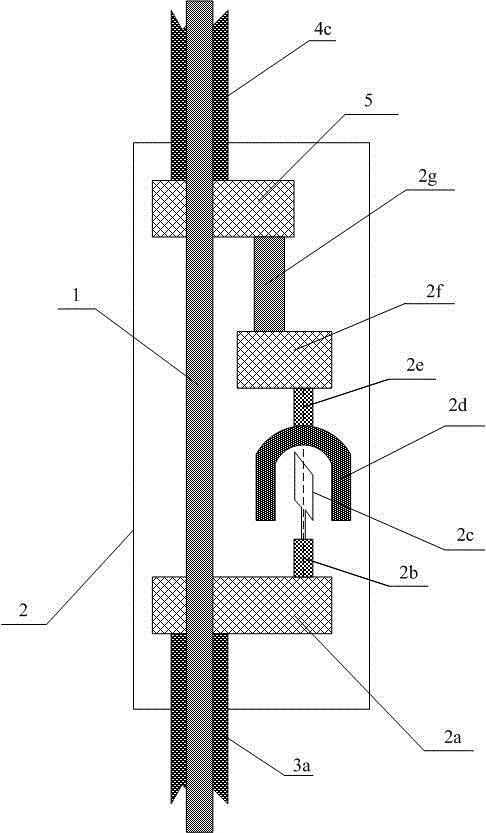

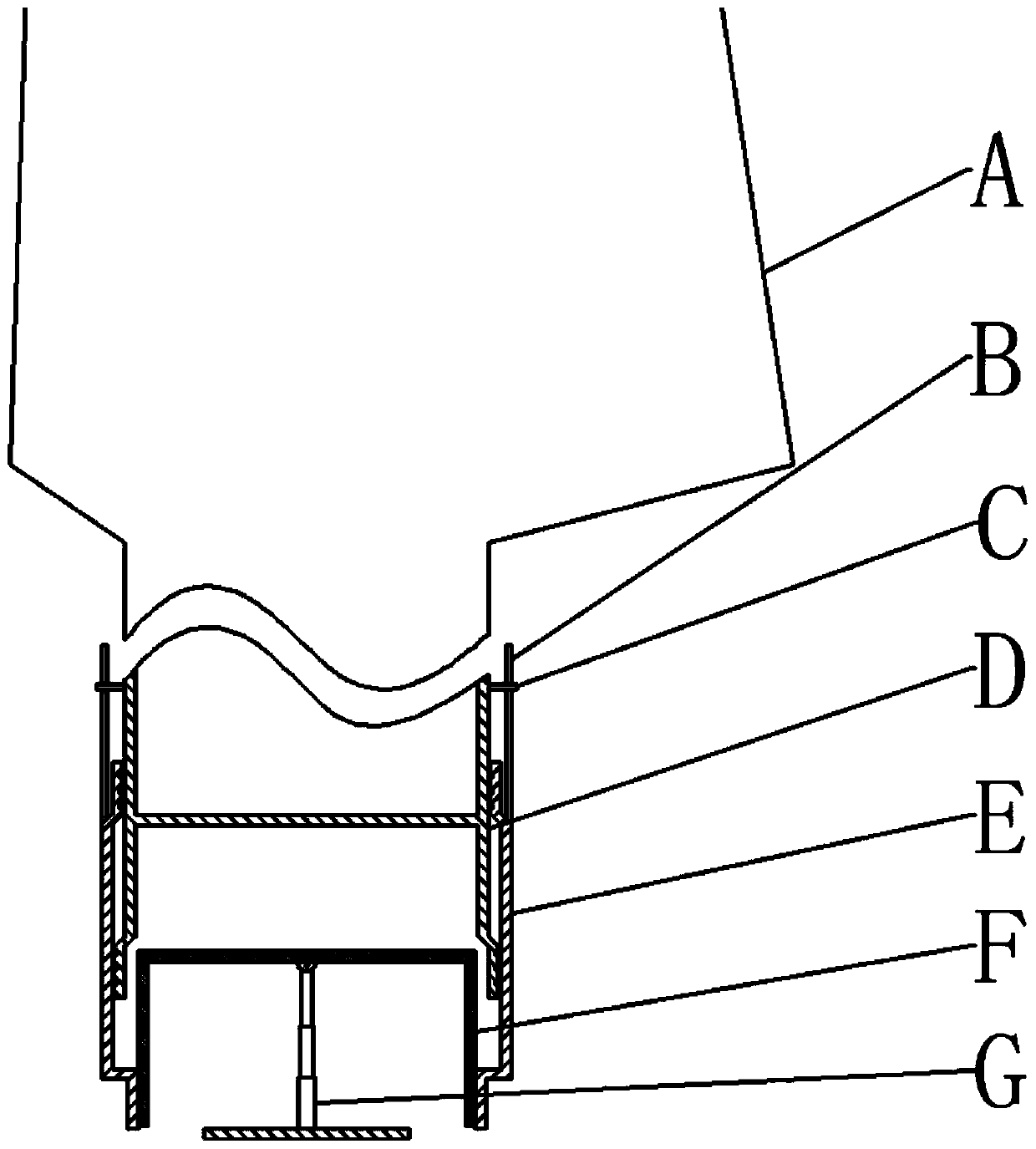

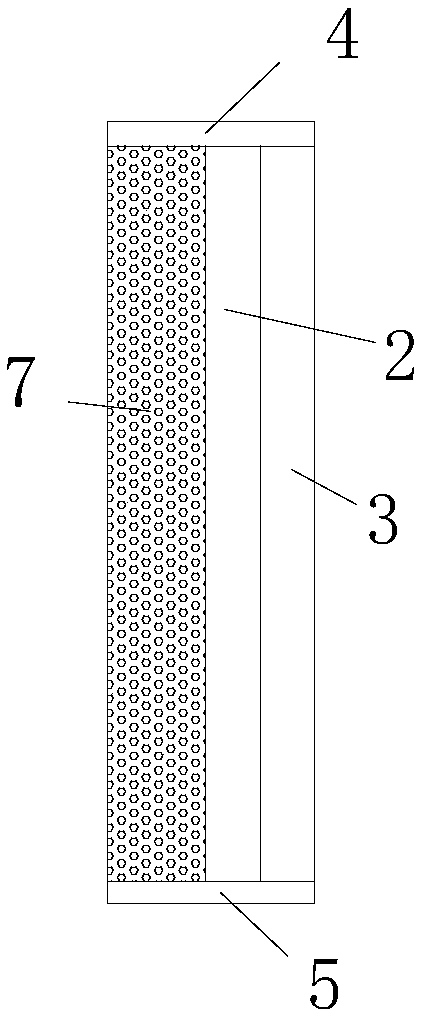

Two-side intake bladeless fan

InactiveCN107543272APromote circulationSpeed up the flowLighting and heating apparatusAir humidification systemsAir volumeOlder people

The invention provides a two-side intake bladeless fan. The two-side intake bladeless fan comprises a shell (1), and a volute part (2) and an exhaust part (3) arranged in the shell (1); the exhaust part (3) is an annular structure form; the volute part (2) comprises a first intake port (21) formed in one side, and a second intake port (22) formed in the other side opposite to the side; and an exhaust port (31) is formed in the exhaust part (3). The two-side intake bladeless fan is higher in air volume output and air amplifying times and more uniform in exhausting, prevents powerful impact on persons by a conventional fan, enables the persons to feel comfortable through exhausting, is suitable for cooldown of old people and children, is tireless after long-time blowing, and is safe and reliable.

Owner:GREE ELECTRIC APPLIANCES INC

Vertical axis wind power generation structure capable of achieving high power

InactiveCN104533707ARealize magnetic pole counter-rotating power generationRealize counter-rotating power generationMachines/enginesRenewable energy generationMagnetic polesTurbine

The invention relates to the field of wind power generation, and discloses a vertical axis wind power generation structure capable of achieving high power. The vertical axis wind power generation structure comprises an upper-layer wind turbine structure, a lower-layer wind turbine structure, and a double-rotor structure. The reverse action of a reverse box device is adopted to finally allow a rotor coil and a rotor magnetic pole in the double-rotor structure to counter rotate and generate power. Compared with the single wind turbine structure, the double-layer wind turbine structure can double the wind sweeping area, the output power of the wind power generation structure can be increased, the available lowest wind speed can be reduced, and the vertical axis wind power generation structure has the wider application scenes.

Owner:CHENGDU FENGDA TECH

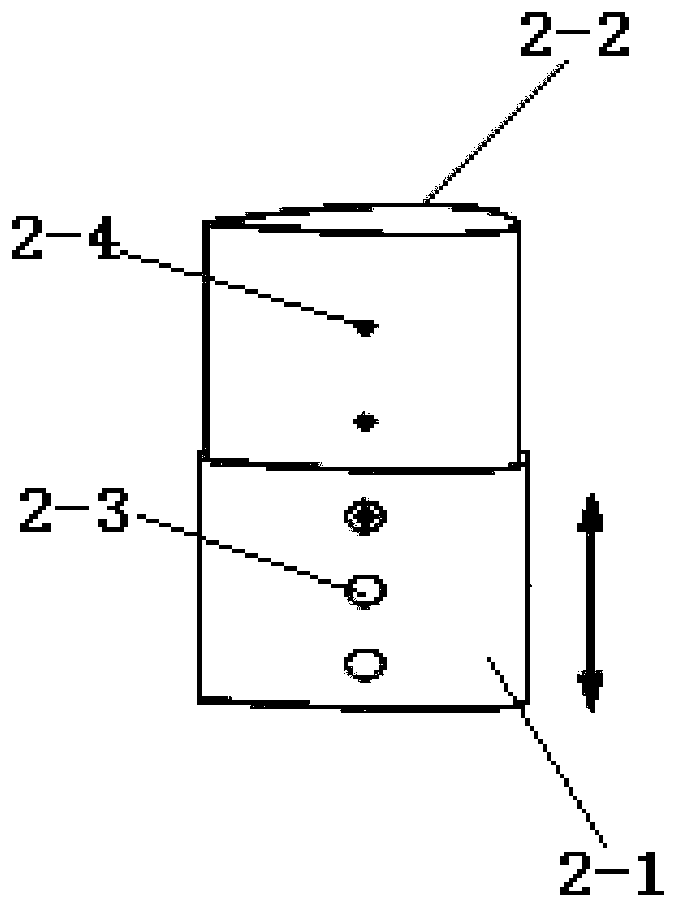

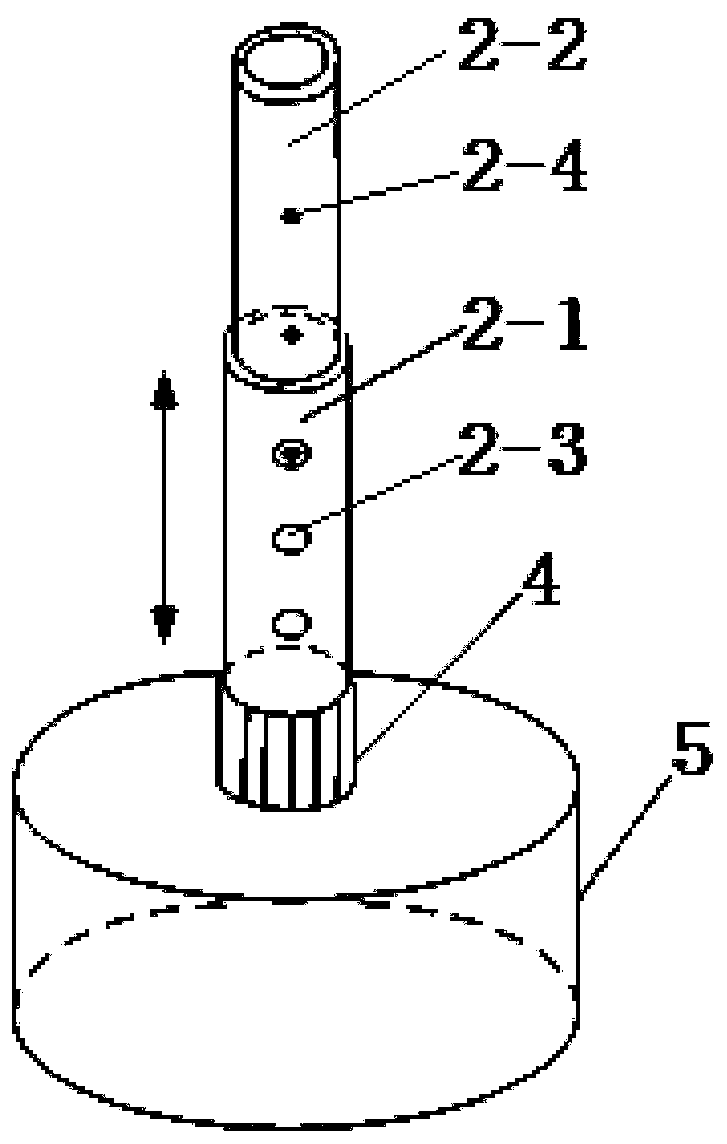

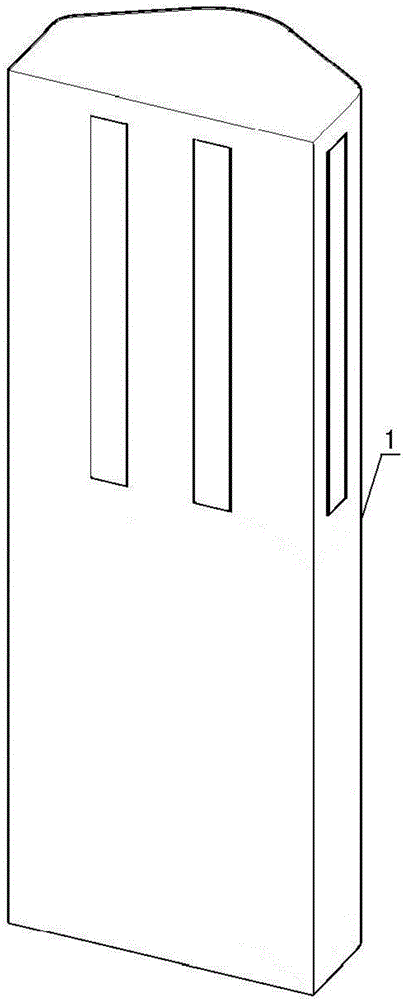

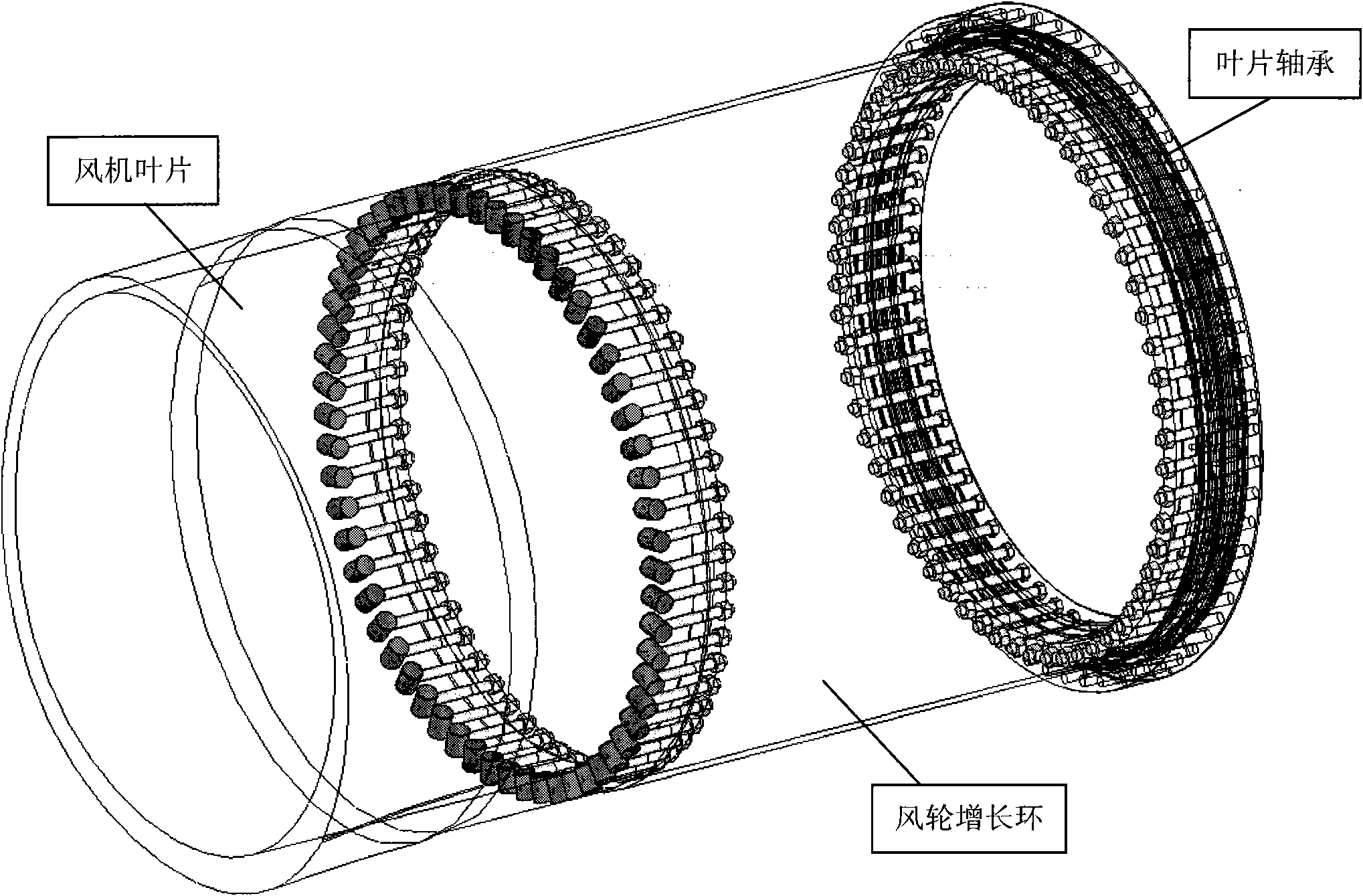

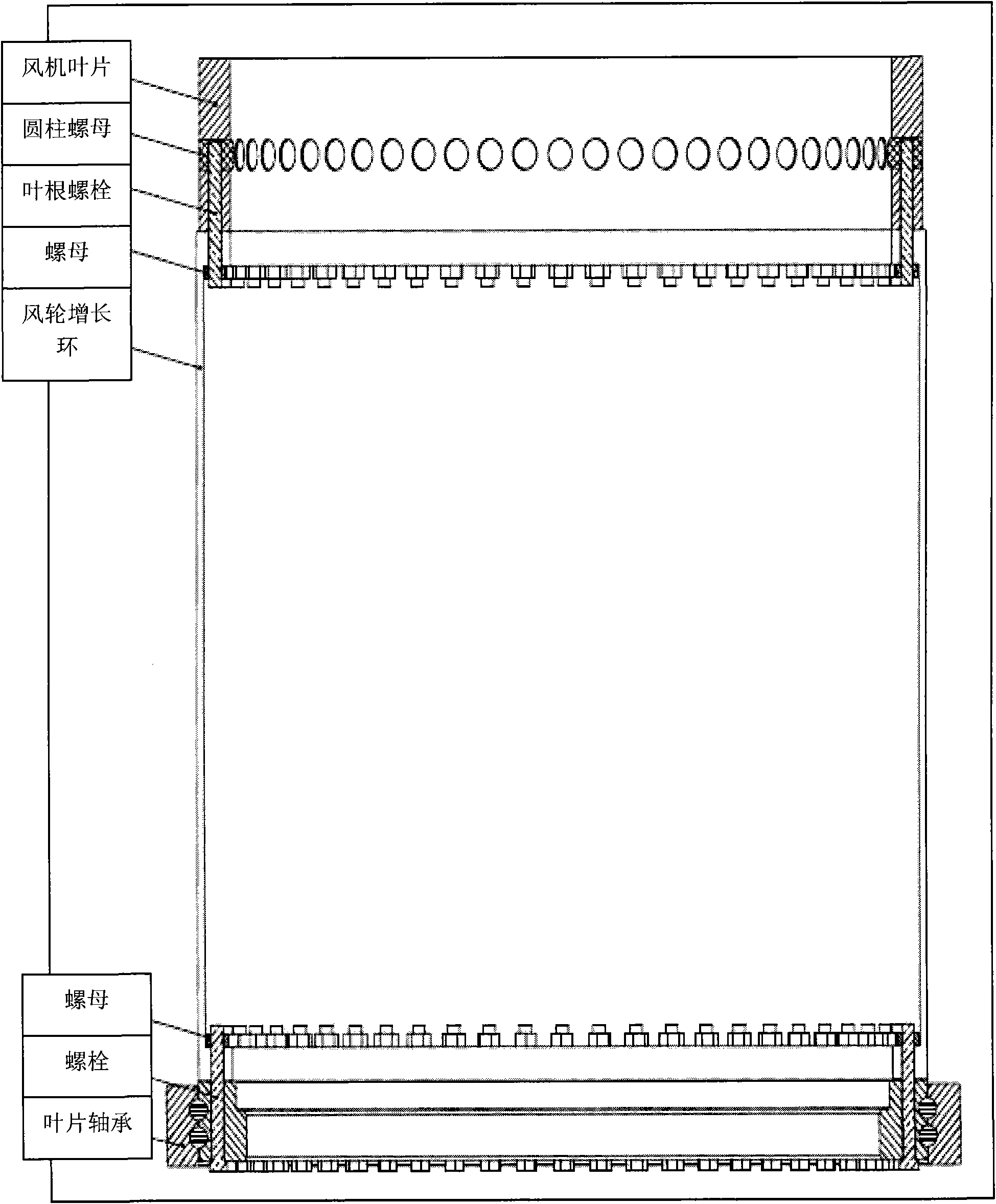

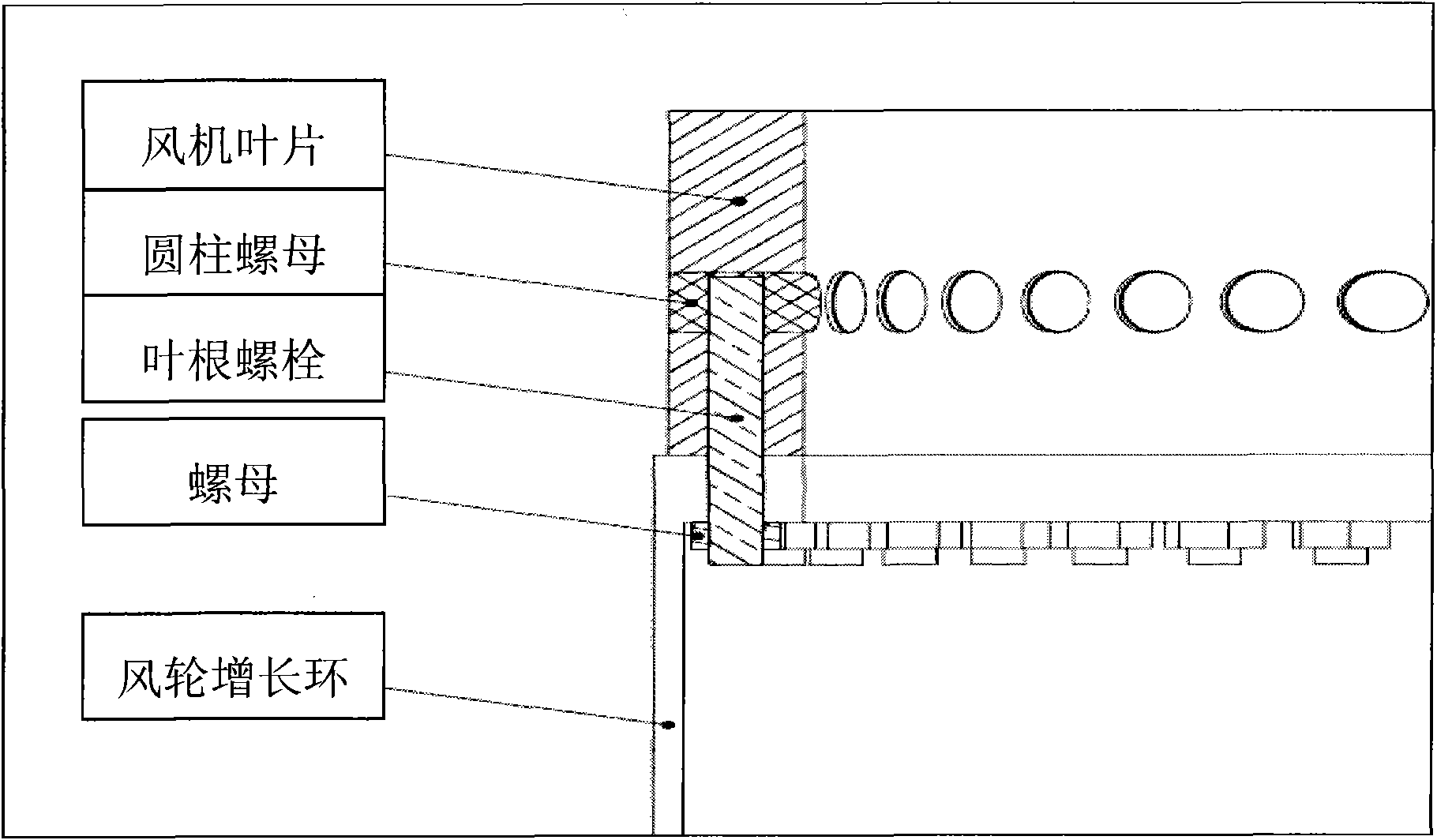

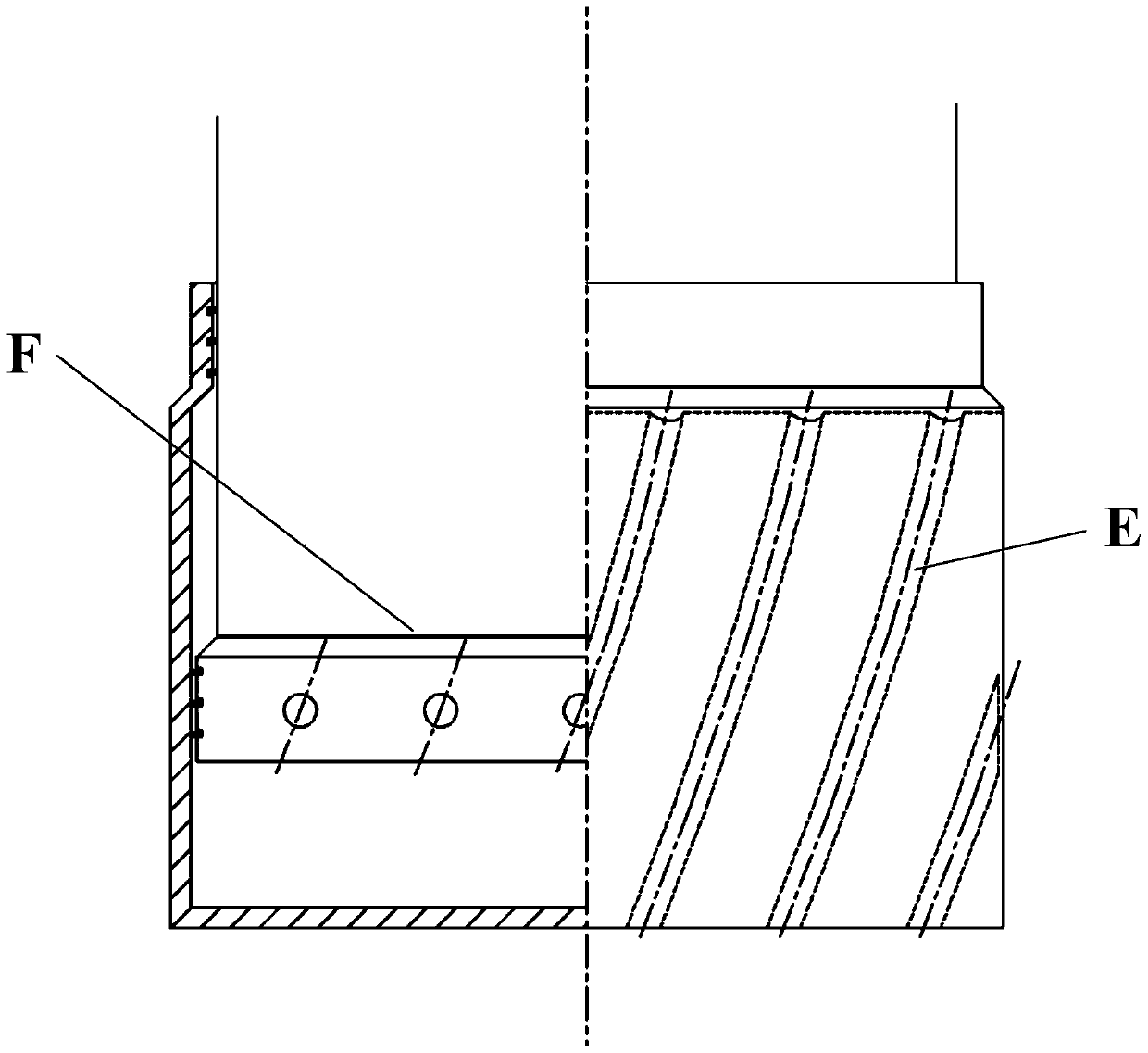

Wind wheel lengthening ring

InactiveCN102338045AIncrease the swept areaReduce development costsFinal product manufactureMachines/enginesElectricityEngineering

The invention discloses a wind wheel lengthening ring for a blade of a wind generating set. Along with the continuous enlargement of a wind wheel of the generating set, the length of the blade is necessary to lengthen; the traditional method is as follows: the blade is designed again; but the development period of the bade is shortened because of the rapid development of wind power industry, therefore, a lot of blade moulds and support equipment are wasted; furthermore, the transportation difficulty and the transportation cost of the fan blade which is ultra-long originally are also further increased. According to the wind wheel lengthening ring disclosed by the invention, a columnar cylinder is used as a main body; the blade and a blade bearing are respectively connected to the two ends of the columnar cylinder; on the basis of using the original blade, the blade is lengthened; the wind sweeping area of the wind wheel is increased; by means of the application of the wind wheel lengthening ring, the blade development cost is saved, therefore, a lot of blade moulds and the support equipment are not wasted; the manufacture cost and the transportation cost resulted from the lengthening of the blade are reduced; meanwhile, the standardization degree and the batch production of the blades are also facilitated.

Owner:SHANGHAI ELECTRIC WIND ENERGY CO LTD

Telescopic wind turbine blade

PendingCN110374795AIncrease wind capacityUniform loadWind motor controlMachines/enginesPistonCavity wall

The invention relates to a telescopic wind turbine blade. The telescopic wind turbine blade comprises a blade root telescopic part, a sealing partition plate, an air cylinder barrel, a pressure regulating piston and a driving mechanism, wherein the blade root telescopic part is a root cylinder section of wind turbine blade; the sealing partition plate is used for sealing the bottom end of the blade root expansion part so as to enable the blade root telescopic part to form a piston form; the two ends of the air cylinder barrel are opened, the air cylinder barrel is fixed on a hub of the wind turbine, and the blade root telescopic part is assembled in one end of the air cylinder barrel; the pressure regulating piston is arranged at the other end of the inner cavity wall of the air cylinder barrel, so that the sealing end part of the blade root telescopic part and the pressure regulating piston define a sealing space in the interior of the air cylinder barrel; and the driving mechanism isused for driving the pressure regulating piston to extend and contract in the other end of the air cylinder barrel so as to adjust the pressure in the air cylinder barrel, and the blades of the windturbine realize the expansion and contraction in the rotating process. By adopting the structure, the blades can be stretched and retracted for a limited stroke along with the rotation period, so thatthe wind catching load is limited, and the load of the blades is balanced, thereby reducing the alternating load.

Owner:中国大唐集团新能源科学技术研究院有限公司

Air outlet component and air conditioner with same

ActiveCN105387601BIncrease the swept areaLighting and heating apparatusAir-flow control membersIndustrial engineering

The invention provides an air output assembly and an air conditioner with the same. The air output assembly comprises a supporting part, a guide rail part, a rotating driving part and an air output part, wherein the supporting part is provided with a first arc-shaped guiding groove, and the guide rail part is connected with the supporting part and provided with a second arc-shaped guiding groove corresponding to the first arc-shaped guiding groove; the rotating driving part comprises a driving assembly which is provided with at least two oppositely-arranged driving rollers, one driving roller is located in the first arc-shaped guiding groove, and the other driving roller is located in the second arc-shaped guiding groove; the air output part is provided with an air outlet, is connected with the rotating driving part and synchronously rotates with the rotating driving part. By means of the air output assembly and the air conditioner with the same, the problem that the air sweeping range is small in the prior art is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

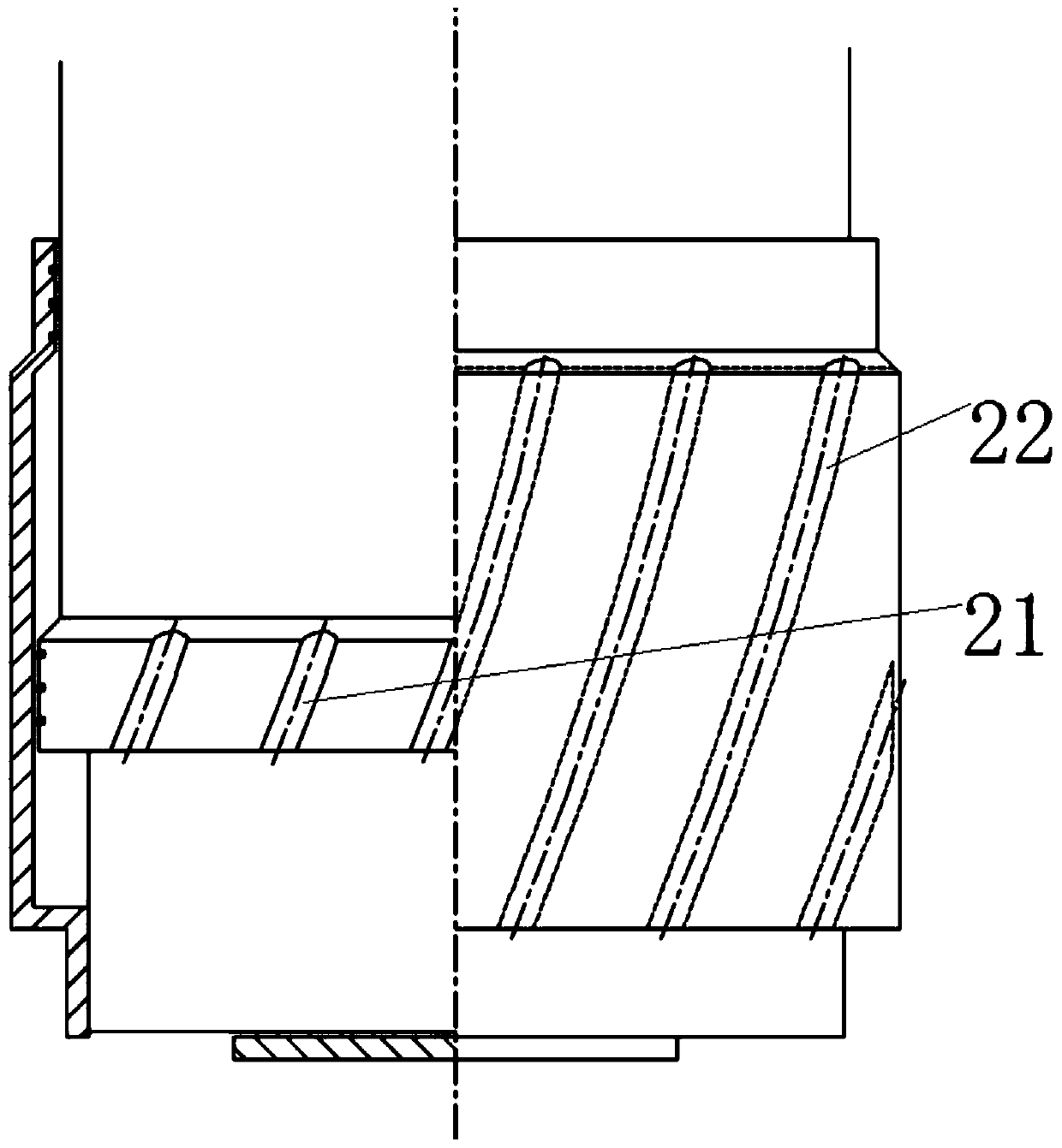

Passive independent variable-pitch blade

PendingCN110374794AIncrease the swept areaIncrease wind capacityWind motor controlMachines/enginesEngineeringCavity wall

The invention discloses a passive independent variable-pitch blade. The passive independent variable-pitch blade comprises a blade root part, an air cylinder barrel and a variable-pitch mechanism, wherein the blade root part is a column-shaped body, and an end part opening of the blade root part is sealed in the form of a piston; the air cylinder barrel is used for being fixed on a hub of a wind turbine, one end of the air cylinder barrel is opened, and the column-shaped body at the blade root part is in sealed sliding fit with an inner cavity wall of the air cylinder barrel, the variable-pitch mechanism comprises a spiral guide rail and a sliding block, the spiral guide rail is arranged on the inner wall side of the air cylinder barrel, the sliding block is fixed at the position, corresponding to the spiral guide rail, of the blade root part or the spiral guide rail is arranged on the outer side of the blade root part, the sliding block is fixed on the inner wall of the cylinder barrel, the sliding block is in sliding fit with the spiral guide rail, the blade of the wind turbine drive the blade root part to extend and retract in the inner cavity of the air cylinder barrel under the gravity of the blade in the rotating process, and the variable-pitch mechanism is used for automatically driving the blade to twist during the blade is extended and retracted. The passive independent variable-pitch blade can be used for restraining alternating load by means of low cost.

Owner:中国大唐集团新能源科学技术研究院有限公司

Blade of vertical axis wind turbine

InactiveCN101709688AIncrease the swept areaImprove efficiencyMachines/enginesRenewable energy generationVertical axis wind turbineEngineering

The invention relates to a blade of a vertical axis wind turbine, which comprises a blade housing unit, a blade supporting unit and a blade wind catching unit, wherein the blade wind catching unit is fixedly connected with the blade supporting unit and the blade housing unit; with the help of a plurality of wind catching ports of the wind catching unit, wind can enter into a cavity of the blade from a plurality of wind catching ports under the action of the wind, thereby leading the wind to be simultaneously acted on the outer surface of the wind catching unit and on the inner surface of the wind catching unit and further increasing the wind sweeping area of the blade; furthermore, when in existence of the transverse sweeping wind, the wind carries out the turbulent motion on the blade, thereby further increasing the rotational speed of the blade, improving the energy conversion efficiency of a wind turbine and improving the efficiency of the wind turbine under the premise of not changing the original external shape of the blade.

Owner:深圳风光新能源有限公司

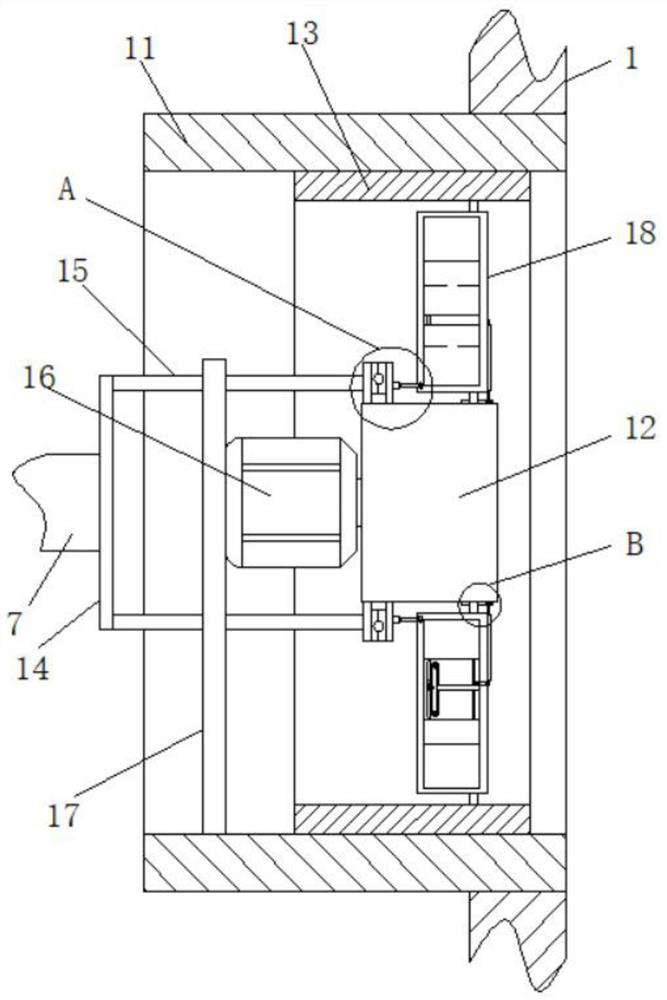

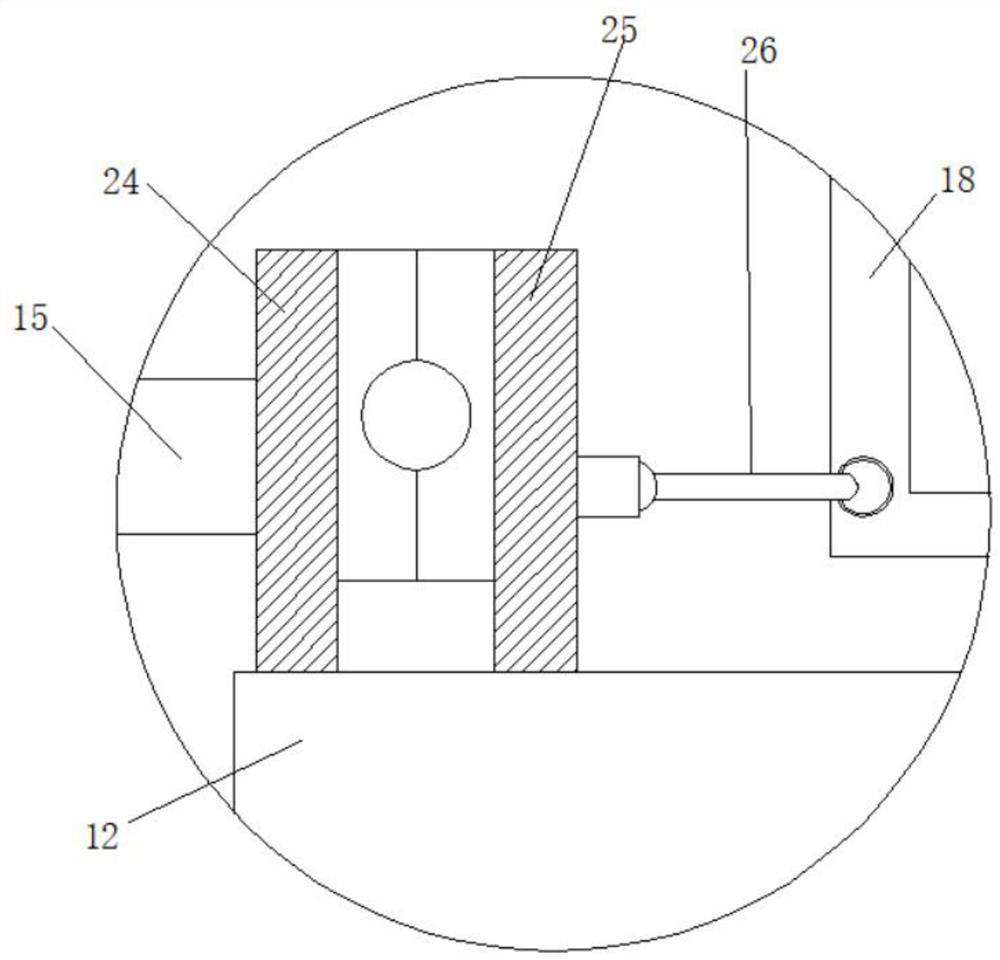

Individual pitch control device for vane

PendingCN110230571AIncrease the swept areaIncrease wind capacityWind motor controlMachines/enginesEngineeringCavity wall

The invention discloses an individual pitch control device for a vane. The individual pitch control device comprises a vane root, an air cylinder barrel, a pressure regulating piston, a driving mechanism and a pitch control mechanism, wherein the vane root is cylindrical and an opening in the end part of the vane root is sealed in a piston form; the air cylinder barrel is fixed to a wheel hub of awind turbine, two ends of the air cylinder barrel are opened, and the vane root and the air cylinder barrel are in hermetical sliding fit; the pressure regulating piston is arranged at the other endof an inner cavity wall of the air cylinder barrel; the driving mechanism is used for driving the pressure regulating piston to adjust the pressure in the air cylinder barrel; and the pitch control mechanism comprises a spiral driving part connecting the vane root and the air cylinder barrel, and when the vane root shrinks in an inner cavity of the air cylinder barrel, the spiral driving part automatically drives the vane to reverse relative to the air cylinder barrel. The individual pitch control device can inhibit an alternating load reliably with a low cost.

Owner:中国大唐集团新能源科学技术研究院有限公司

A physical-statistical hybrid two-stage wind power prediction method

ActiveCN108832623BImprove forecast accuracyConducive to scheduling decision optimizationForecastingAc network circuit arrangementsWind runNetwork model

The invention discloses a physical-statistical hybrid two-stage wind power prediction method. Wind power prediction obtained by a physical prediction method and a statistical prediction method is usedas input of a second stage, and through a BP neural network, a wind power sequence on a target day is predicted. The method comprises the following specific steps: a physical prediction neural network model is built and trained; with each day as the target day, wind speed general similarity coefficients of other days relative to the target day are calculated respectively; a statistical predictionneural network model is built and trained; with wind speed and wind direction data of 24 h per day as input, a wind power physical prediction sequence for each day in former 180 days is sorted; withwind power sequences corresponding to former five similar days of each day as input, a wind power statistical prediction sequence for each day in former 180 days is obtained; and a BP neural network prediction model in a second stage is built and trained until a training error is smaller than a given value, and a two-stage prediction model is obtained finally.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

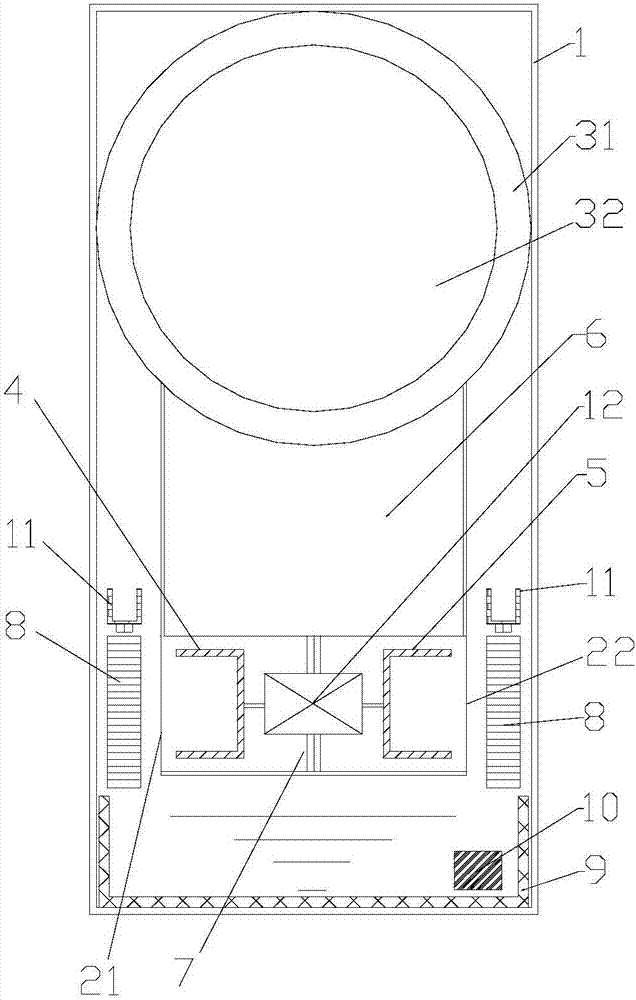

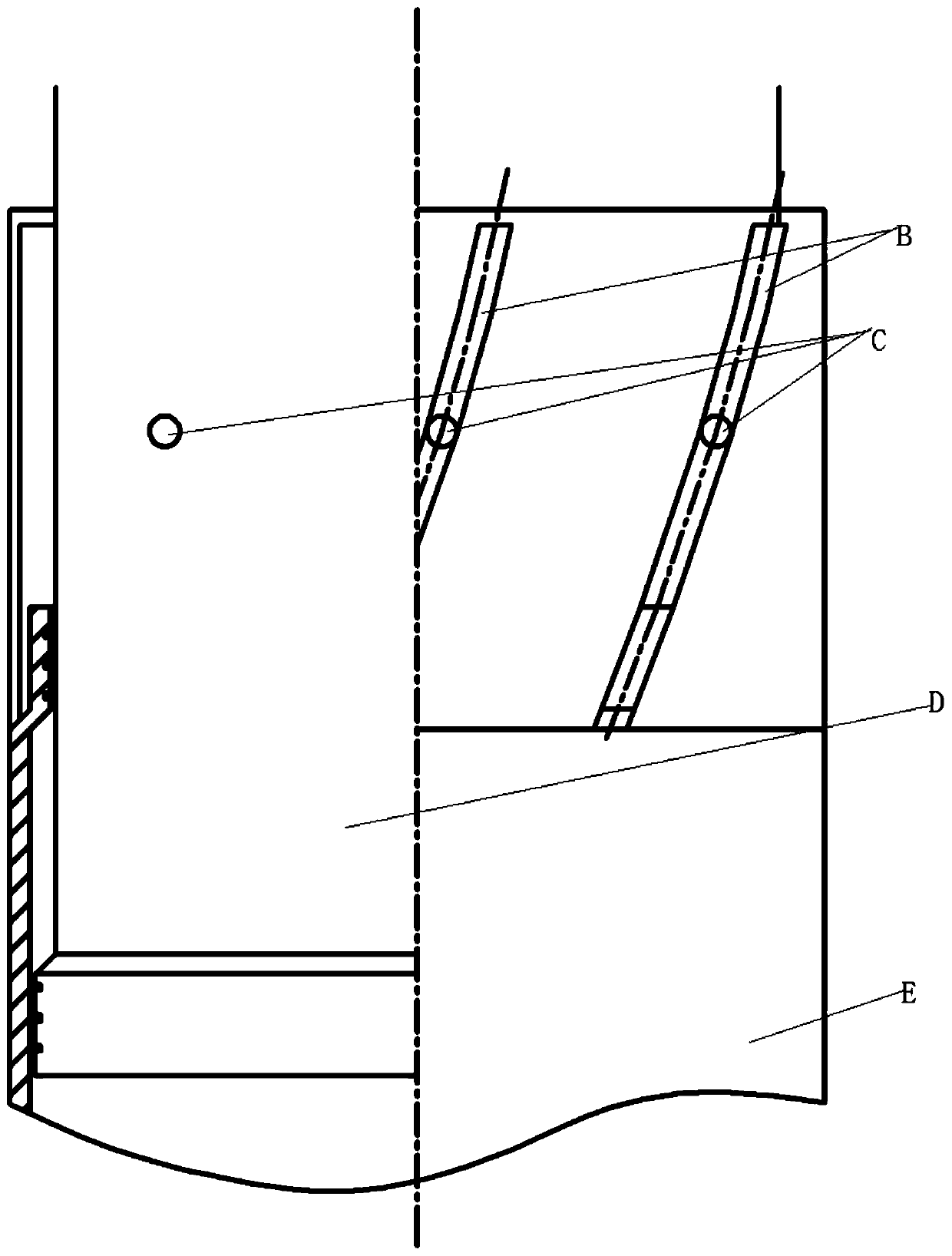

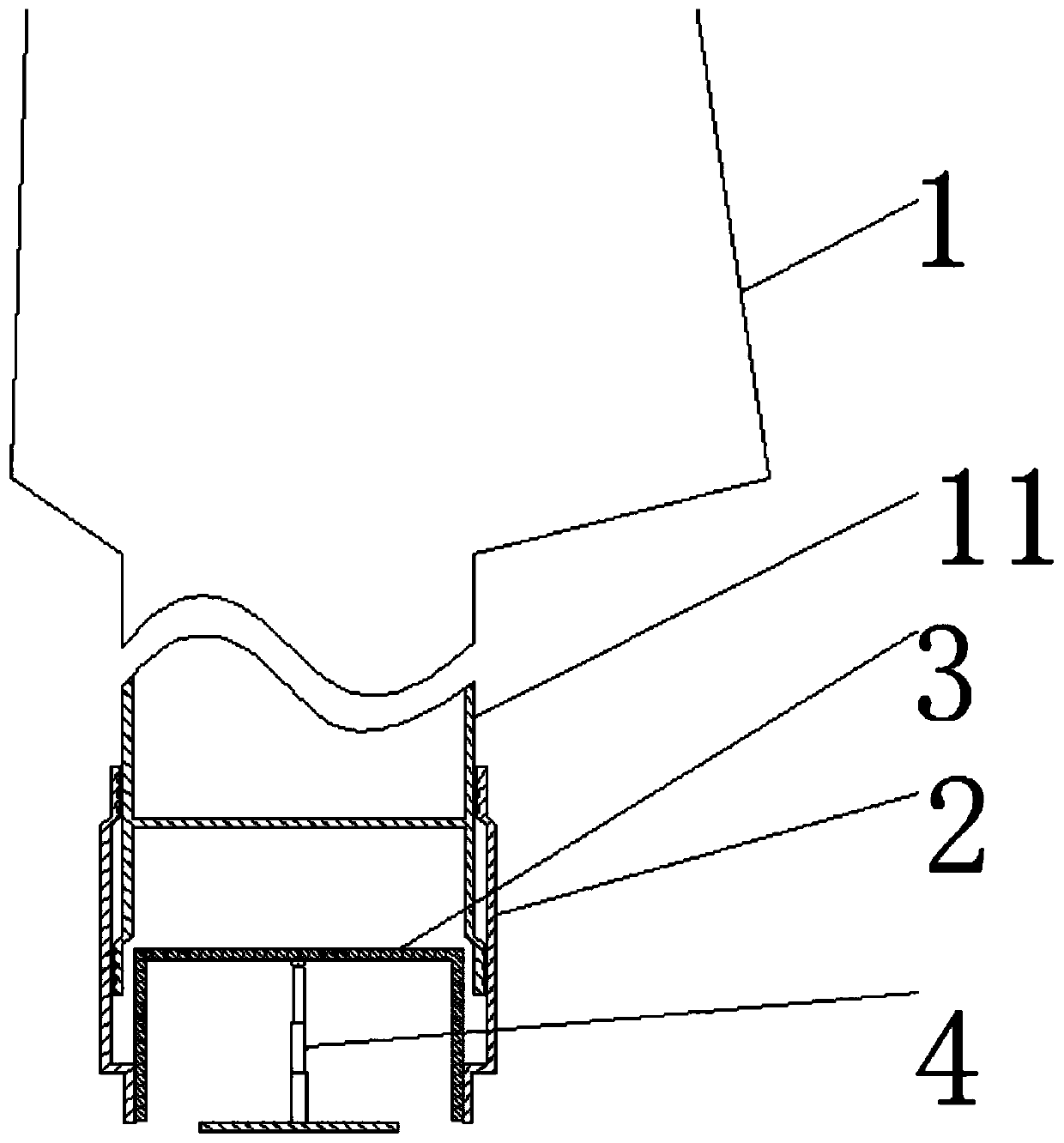

Indoor unit of air conditioner and air conditioner

PendingCN108571777AImprove comfortFix the angle problemLighting and heating apparatusAir conditioning systemsPower conditionerEngineering

The invention provides an indoor unit of an air conditioner and the air conditioner. The indoor unit of the air conditioner comprises an air conditioner bottom shell (1) and a spiral casing (3), wherein the air conditioner bottom shell is provided with an air conditioner vent hole (2); the spiral casing (3) is positioned in the air conditioner bottom shell (1) and forms an air duct of the indoor unit of the air conditioner; furthermore, the spiral casing (3) can move so as to extend out of the air conditioner bottom shell (1) at the air conditioner vent hole (2). The air conditioner provided by the invention can effectively enlarge a wind sweeping angle and a wind sweeping area, thus improving the indoor comfort degree; the technical problems that the existing air conditioner is small in air supply angle, short in air supply distance and poor in complete machine comfort are effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Safety protection device of communication management machine for integrated automation system and its use method

ActiveCN112566463BRapid heat dissipation and coolingAvoid damageEnergy efficient computingModifications using gaseous coolantsCommunications managementControl engineering

Owner:SHANDONG HEYUAN INTELLIGENT TECH CO LTD

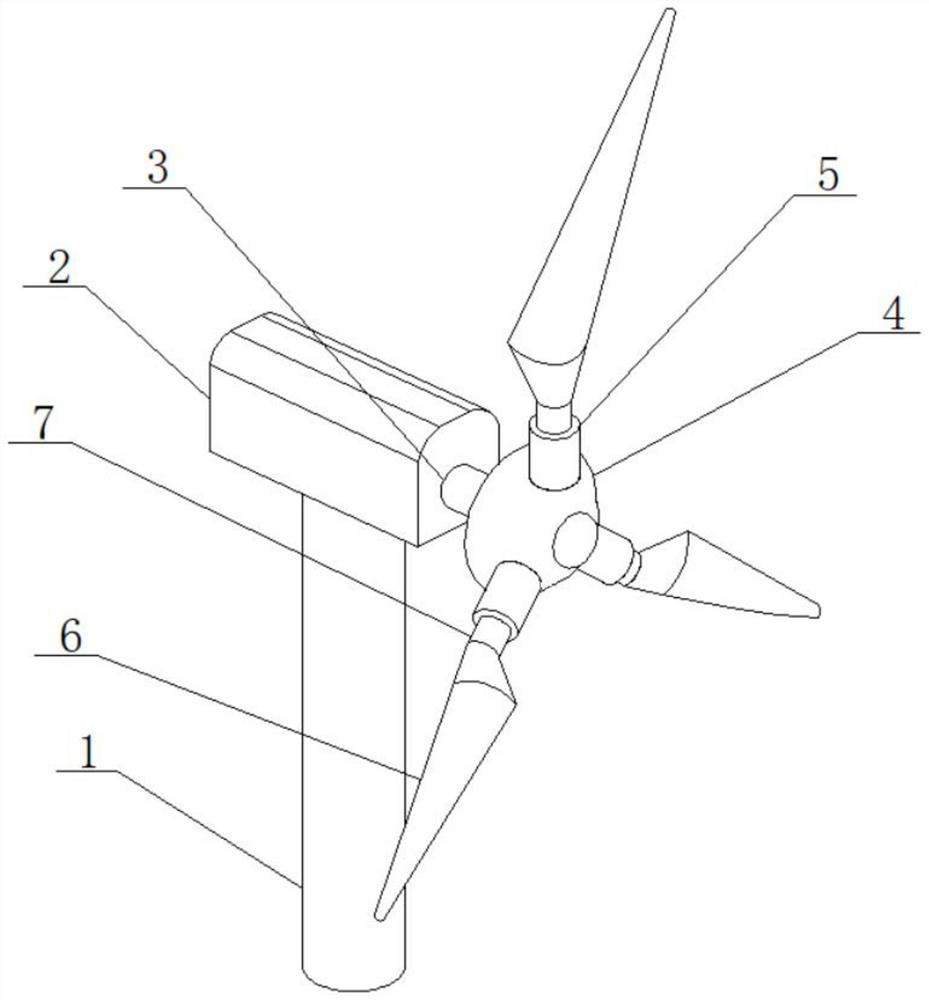

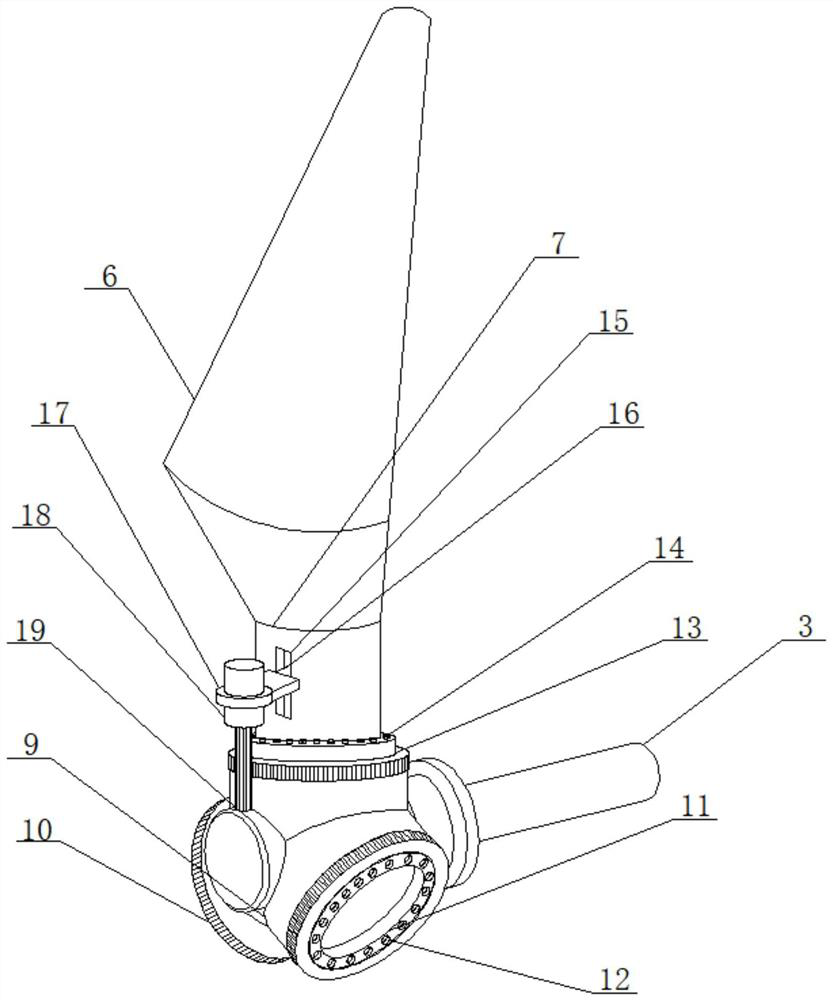

A wind turbine wind wheel variable pre-cone angle device and using method

ActiveCN113217269BSmall cone angleAvoid damageWind motor controlMachines/enginesElectric machineGear wheel

The invention provides a variable pre-cone angle device for a wind turbine wheel of a wind turbine and a method for using it, including a connecting seat, a hub, a blade root and a blade; The blade root is connected to the blade root, and the blade is connected to the blade root; there are three bosses evenly distributed on the connecting seat; the top of the boss is provided with a gear ring, and a fixing groove is opened on the inner wall of the gear ring, and the pitch bearing is installed on the gear through the fixing groove. the blade root is fixed on the pitch bearing; the blade root has a slot, and a fixing plate is installed inside the slot, and the fixing plate is connected to the motor base located outside the slot, and the motor A motor is installed on the seat; the output shaft of the motor is connected with a toothed roller, and the toothed roller meshes with the gear ring. The invention can reduce the blade cone angle when the wind speed is small, increase the sweeping area, and improve the production efficiency; when the wind speed is high or the blade deformation is large, the blade cone angle can be increased to avoid the deformation of the blade and the tower hit and damage the device.

Owner:HUANENG CLEAN ENERGY RES INST

Variable pitch device for wind turbine

PendingCN110242500AIncrease wind capacityUniform loadWind motor controlMachines/enginesPistonPneumatic pressure

The invention discloses a variable pitch device for a wind turbine. The variable pitch device comprises a blade root, an air cylinder barrel, a pressure adjusting piston and a driving mechanism, wherein the blade root is a column-shaped body; an opening in the end of the blade root is sealed; the air cylinder barrel is used for fixing a hub of the wind turbine; two ends of the air cylinder barrel are opened; one end of the wall of an inner cavity of the air cylinder barrel is matched with the column-shaped body of the blade root by a spiral groove and a spiral guide rail structure; the pressure regulating piston is arranged at the other end of the wall of the inner cavity of the air cylinder barrel, and a sealing space is defined by a sealing end of the blade root and the pressure adjusting piston in the air cylinder barrel; and the driving mechanism is used for driving the pressure adjusting piston to expand and retract in the other end of the air cylinder barrel to further adjust the pressure in the air cylinder barrel; a blade of the wind turbine drives the blade root to expand and retract in the inner cavity of the air cylinder barrel under the self gravity and the air pressure action in the air cylinder barrel in the rotating process, and when the blade root expands and retracts, the spiral groove and the spiral guide rail structure automatically drive the blade to twist. The variable pitch device can reliably inhibit alternating load.

Owner:中国大唐集团新能源科学技术研究院有限公司

A device for cleaning rainwater from rearview mirrors by using waste heat from automobile exhaust

ActiveCN111976658BIncrease the swept areaClear allInternal combustion piston enginesVehicle cleaningEnvironmental engineeringMechanical engineering

A device for cleaning rainwater in rearview mirrors by using the residual heat of automobile exhaust gas, comprising a first ventilation pipe fixedly arranged above the middle part of the tail gas conveying pipe, and an automatic ventilation device is arranged in the first ventilation pipe; gas storage The box body is equipped with a gas storage space and a temperature adjustment device inside the gas storage box; the gas storage box is ventilated and connected with the first ventilation pipe; the front end of the gas storage box is provided with an air outlet device; the tuyere swing control device, the The tuyere swing control device is arranged on the rearview mirror, and is ventilatedly connected with the air outlet device. It can realize the automatic collection of exhaust gas, and after processing, it can be used to clean up the rainwater on the rearview mirror of the car.

Owner:FUYANG BAINUO PIPE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com