Blade tip improvement or repairing method of wind turbine blade and blade tip lengthened section structure

The technology of a wind turbine and a repair method, which is applied in the field of wind power generation, can solve the problems of damaged blade tip, scrapped blade, high renovation cost, etc., and achieves the effects of improving power generation efficiency, increasing swept area, and low cost of renovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

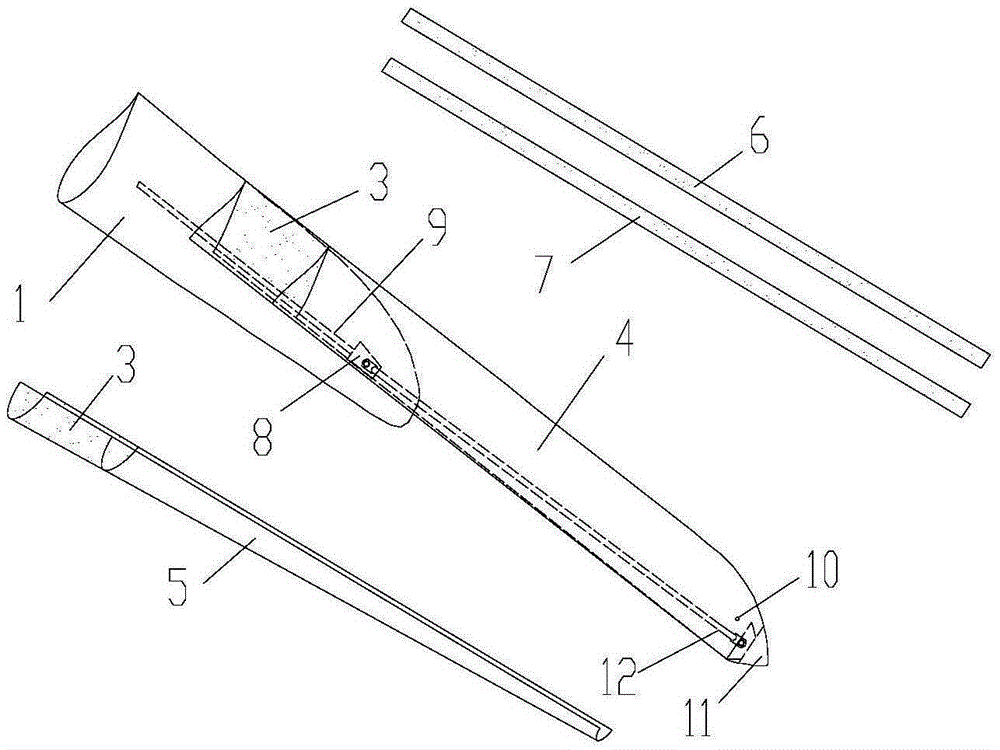

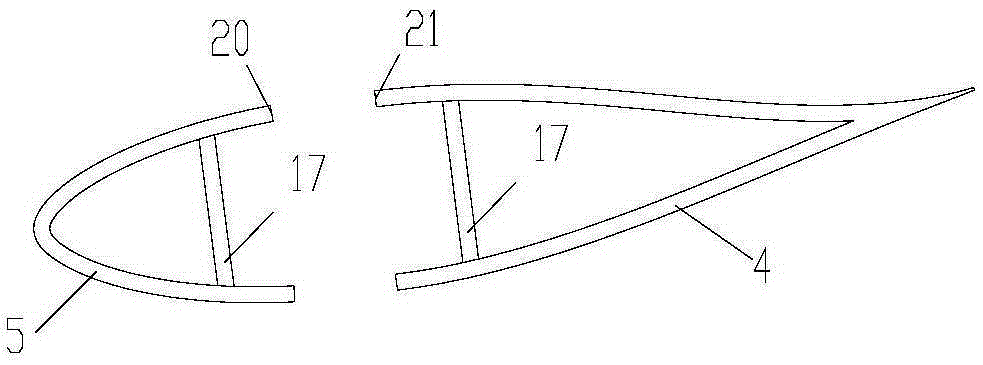

[0035] In order to describe the technical features and effects of the present invention in detail, and to implement according to the content of this specification, the embodiments of the present invention are further described below with reference to the accompanying drawings.

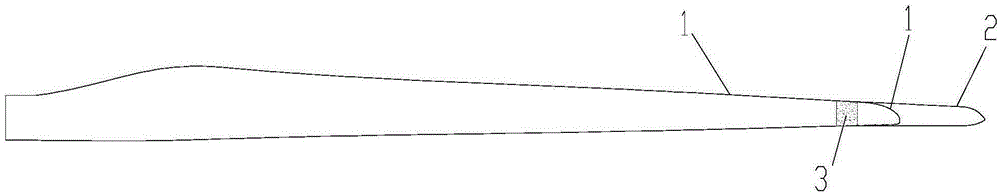

[0036] figure 1 A schematic diagram of forming a new blade after lengthening, reconstructing or repairing the blade tip of a wind turbine blade by using the method for reconstructing or repairing a blade tip of a wind turbine according to the present invention is schematically shown. Since the technical solution of the present invention does not involve other parts or components and shape structures of the wind turbine blade (hereinafter referred to as the original blade), therefore figure 1 Only the general structure of the wind turbine blade is schematically shown in the figure, and it is obvious that the shape and structure of the actual wind turbine blade are relatively complex.

[0037] The steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com