Patents

Literature

279results about How to "Fix the angle problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

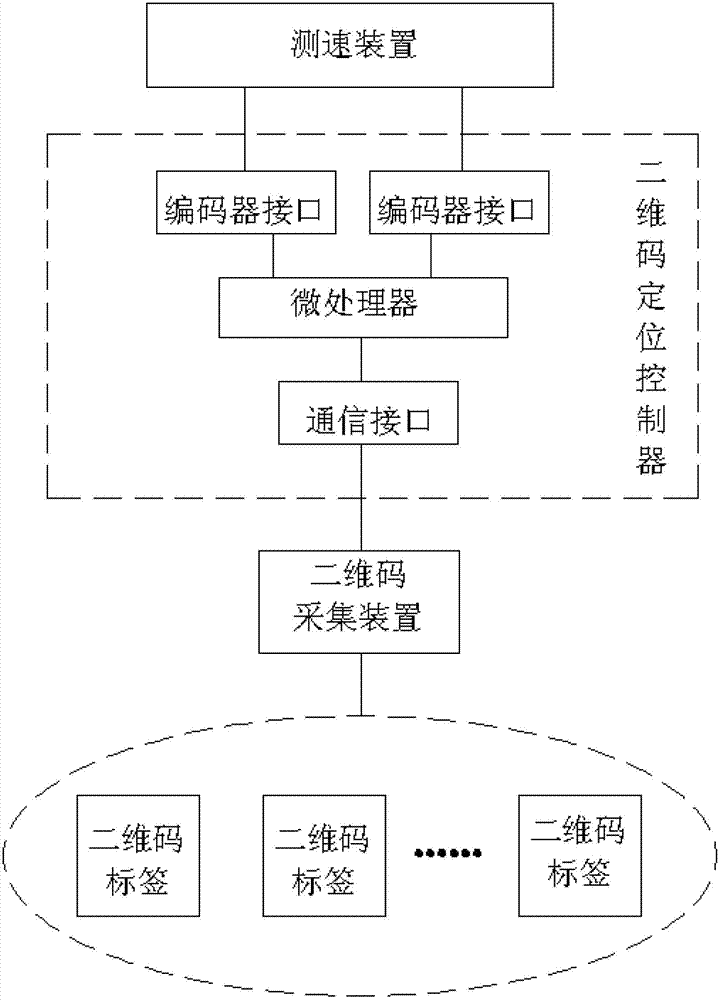

Indoor mobile robot positioning system and method based on two-dimensional code

ActiveCN102735235ASolve the speed problemFix the angle problemNavigation instrumentsCommunication interfaceImaging processing

The present invention relates to an indoor mobile robot positioning system and method based on two-dimensional code. The system includes a two-dimensional code positioning controller mounted on a mobile robot, a two-dimensional code acquisition device and a two-dimensional code label distributed in the indoor environment. The two-dimensional code positioning controller is composed of a microprocessor and a communication interface that are connected together. The microprocessor is connected with the two-dimensional code acquisition device through the communication interface and is used for controlling the two-dimensional code acquisition device to acquire two-dimensional code images, receive the two-dimensional code images acquired by the two-dimensional code image acquisition device and realize precise positioning function. The method acquires an actual position of the mobile robot through photographing the indoor two-dimensional code labels, transforming coordinates and mapping code values. The method of the invention organically combines visual positioning technique, two-dimensional code positioning technology and two degree of freedom measuring technology to realize the function of precise positioning of the mobile robot and solve problems of complex image processing and inaccurate positioning of a traditional vision positioning system.

Owner:爱泊科技(海南)有限公司

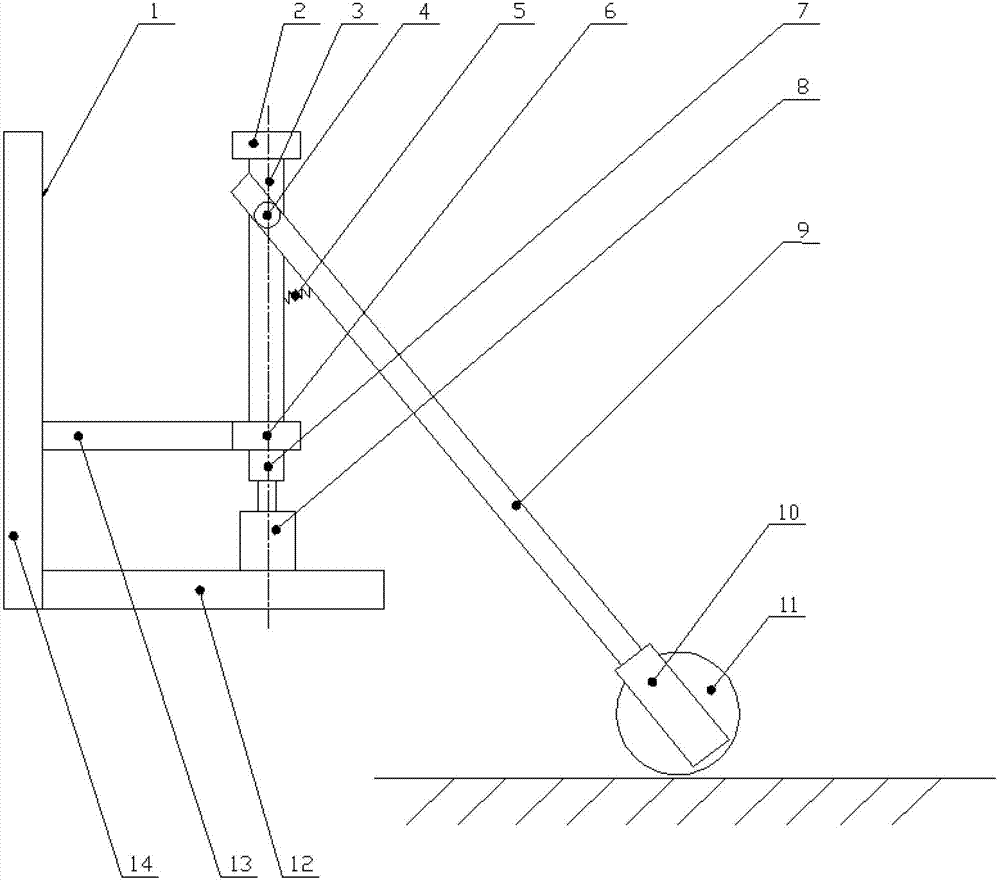

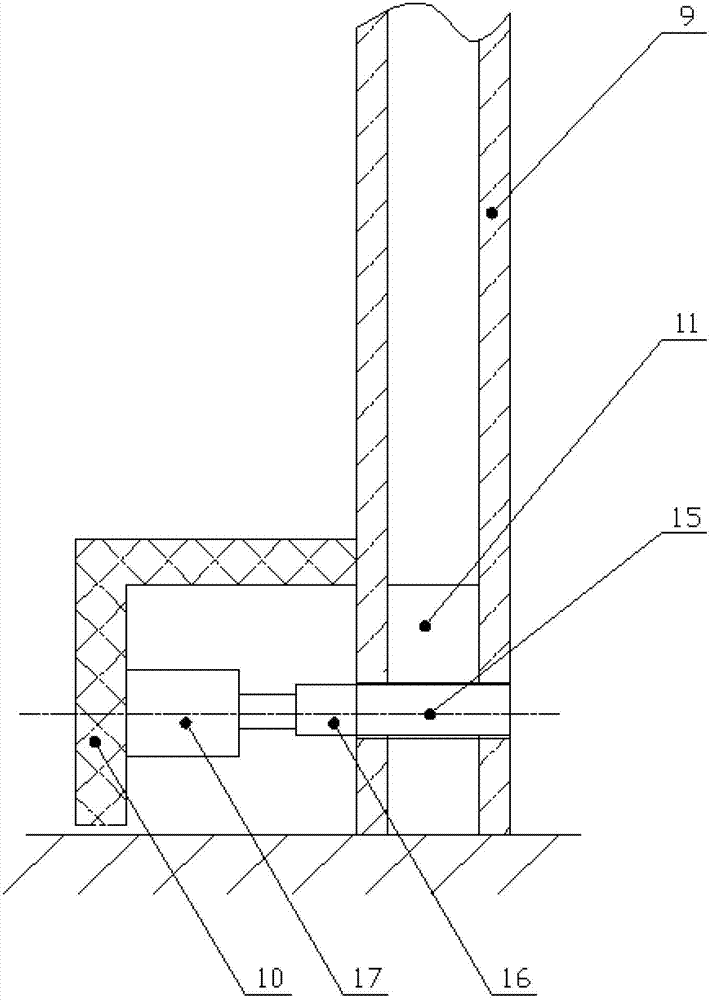

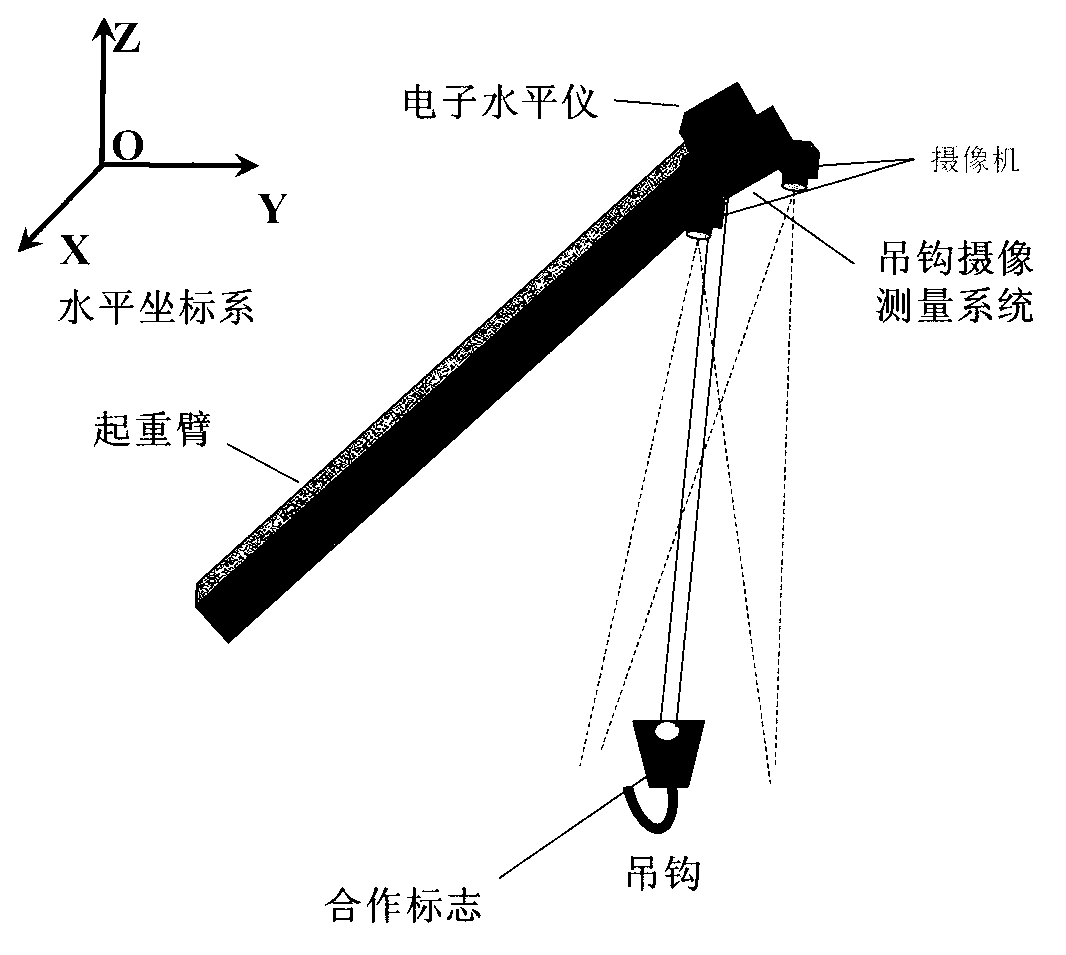

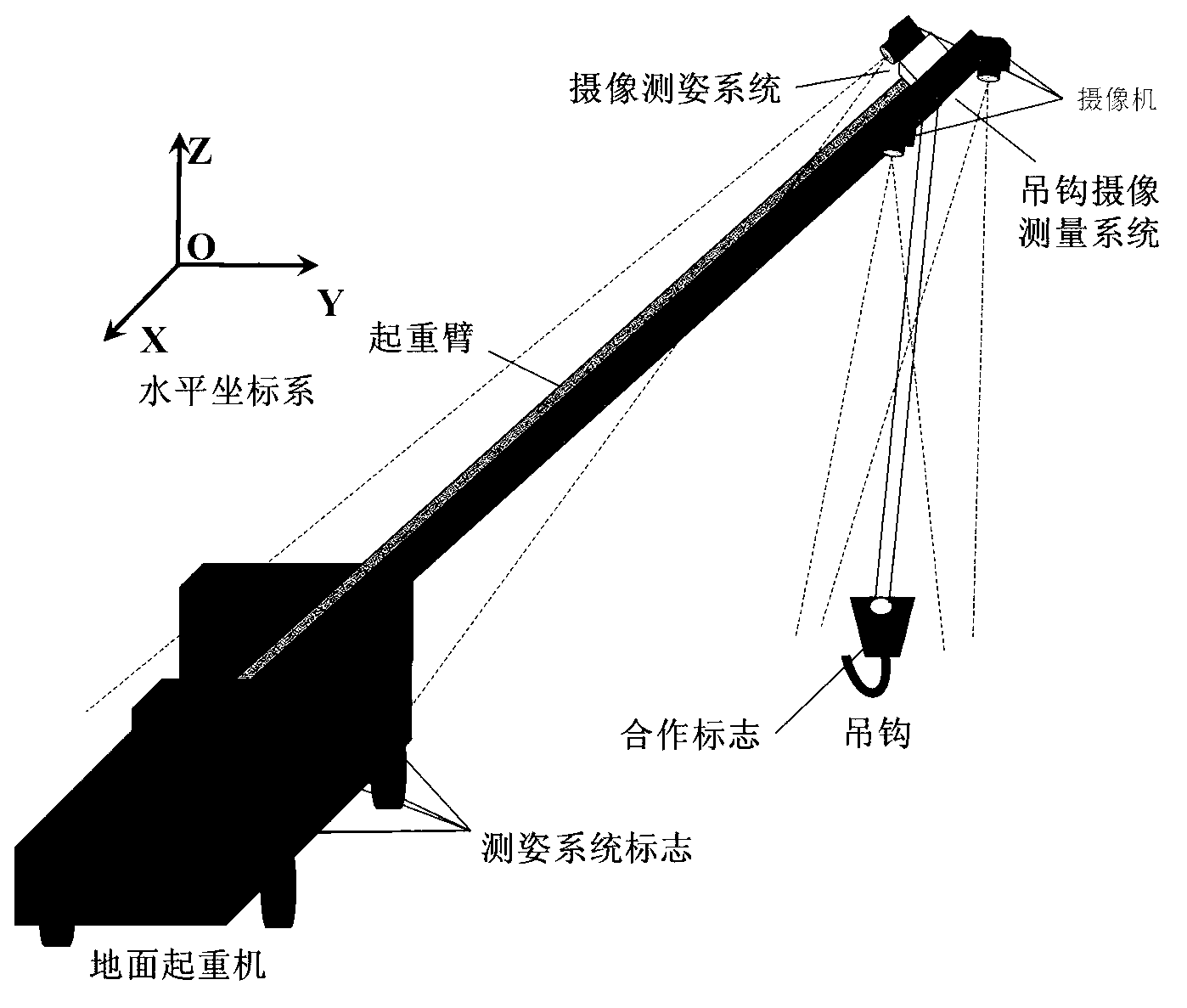

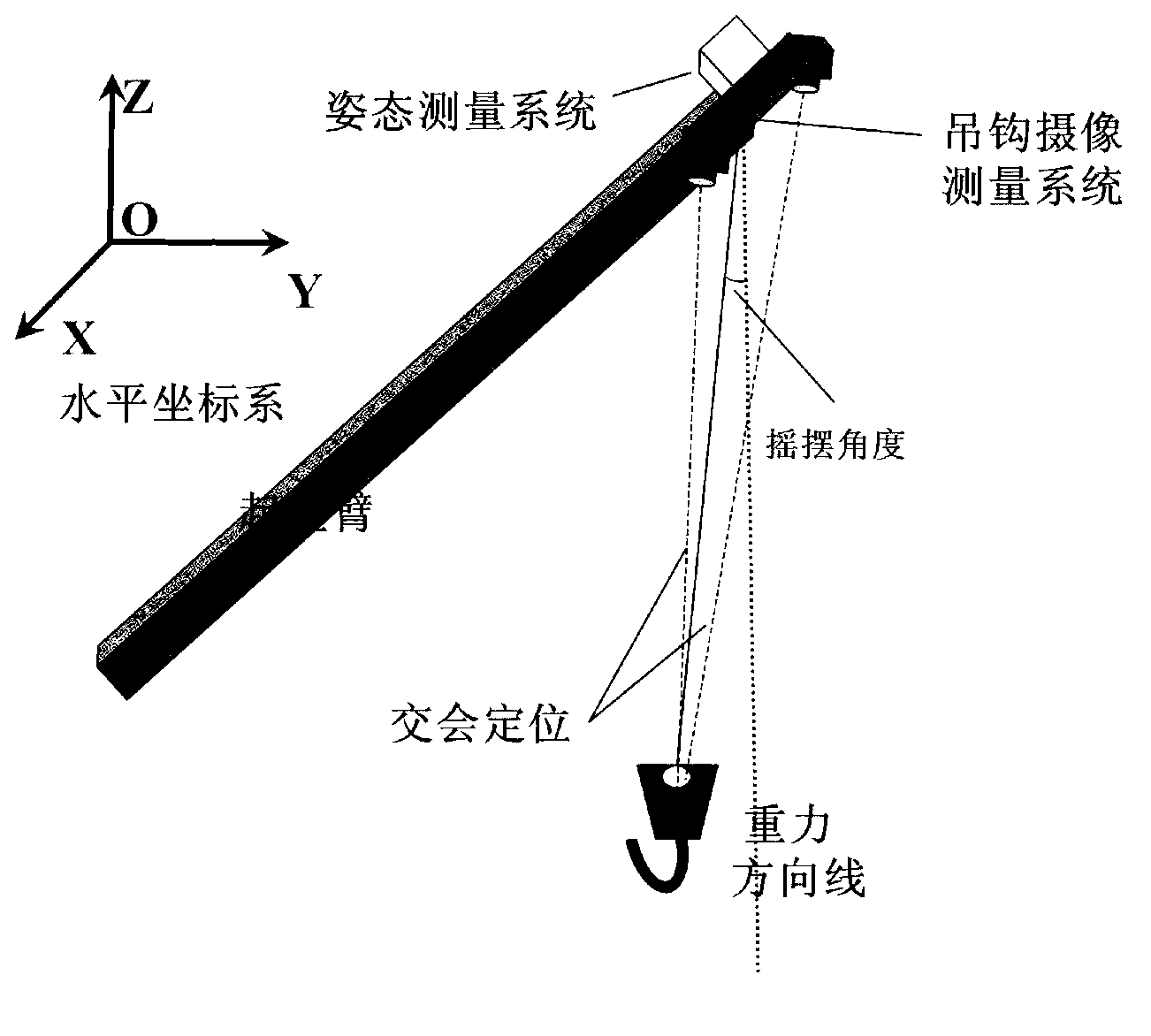

Real-time photographic measuring method of position and swing angle of lifting hook of crane

InactiveCN102795547AFix the angle problemProcessing calculations are easy to implementLoad-engaging elementsEngineeringHorizontal coordinate system

The invention relates to a photographic measuring method of a position and a swing angle of a lifting hook of a crane. The method comprises the steps of: mounting a set of gesture measuring system and a set of lifting hook photographic measuring system at the top end of an arm rest of a crane, which is close to a lifting rope rolling wheel; mounting a cooperation mark on the lifting hook; measuring inclination gesture of the lifting hook photographic measuring system in real time through a gesture measuring system; measuring the position of the cooperation mark on the lifting hook, with respect to the lifting hook photographic measuring system in real time and in an intersecting manner through double cameras of the lifting hook photographic measuring system; representing the position of the lifting hook by using a horizontal coordinate system based on the inclination gesture; and calculating a swing angle of the lifting hook in real time by utilizing the position of the lifting hook represented by the horizontal coordinate system. As the photographic measuring method is utilized to solve the measurement problem of the position and swing angle of the lifting hook of the crane, the photographic measuring method of the position and the swing angle of the lifting hook of the crane, disclosed by the invention, has the advantages of easy implementation of relevant treatment and calculation and high real-time capability, and can be applied to measurement of positions and swing angles of lifting hooks of multiple cranes.

Owner:NAT UNIV OF DEFENSE TECH

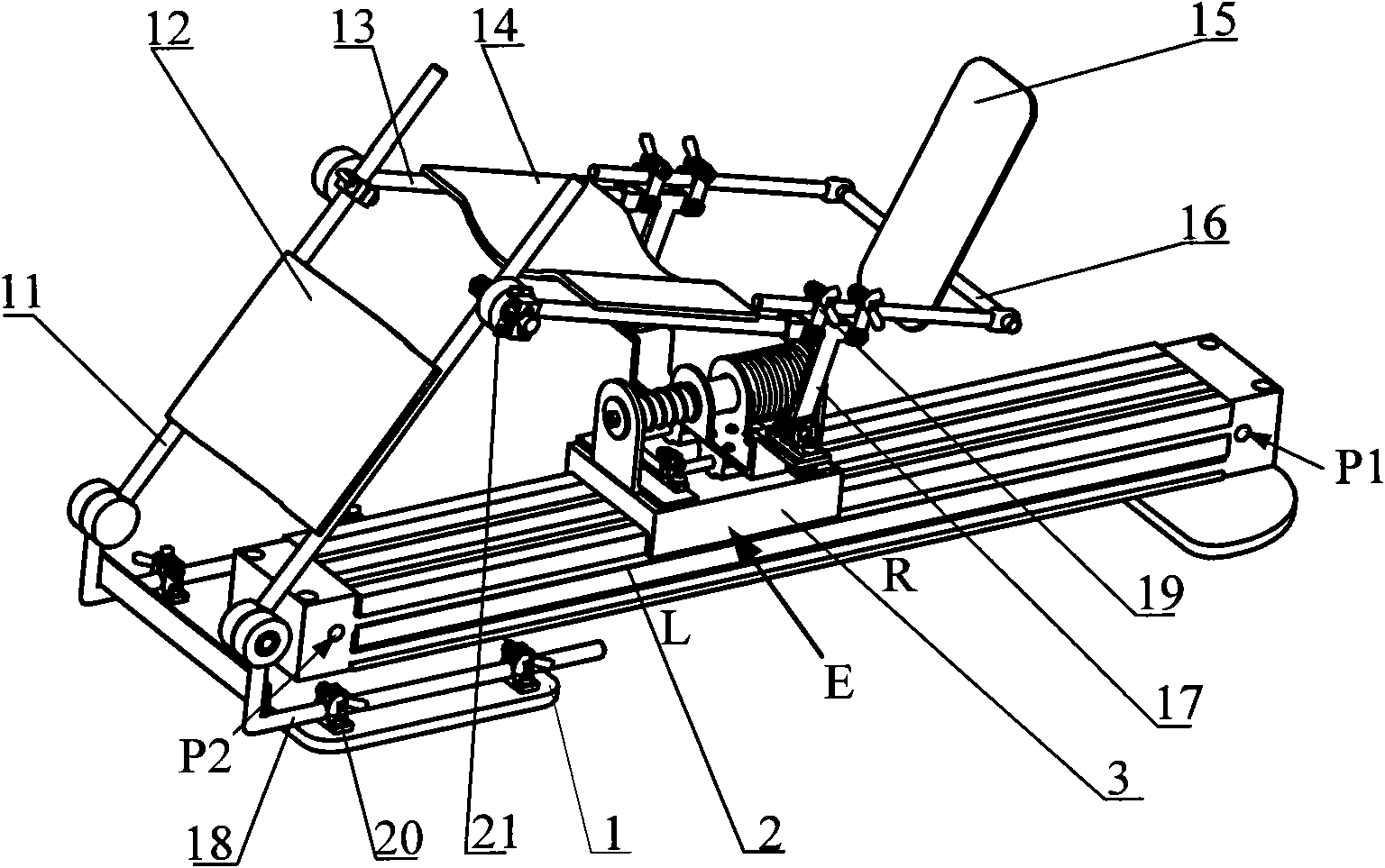

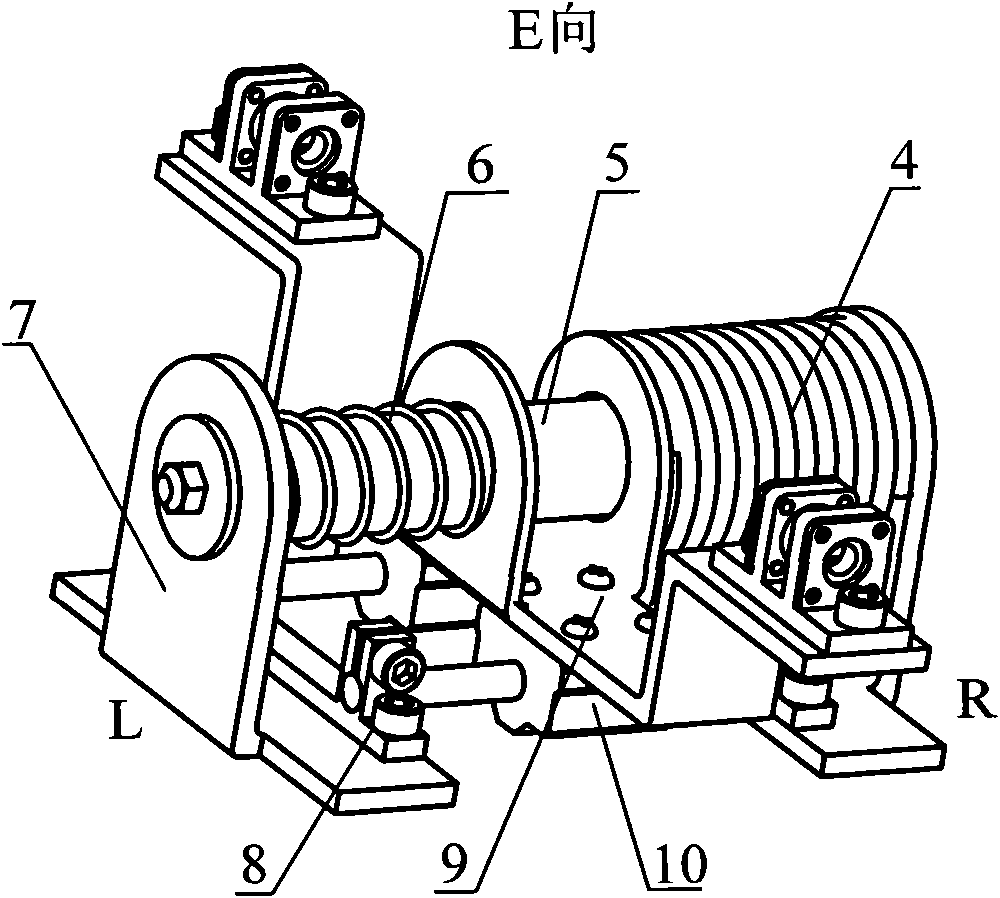

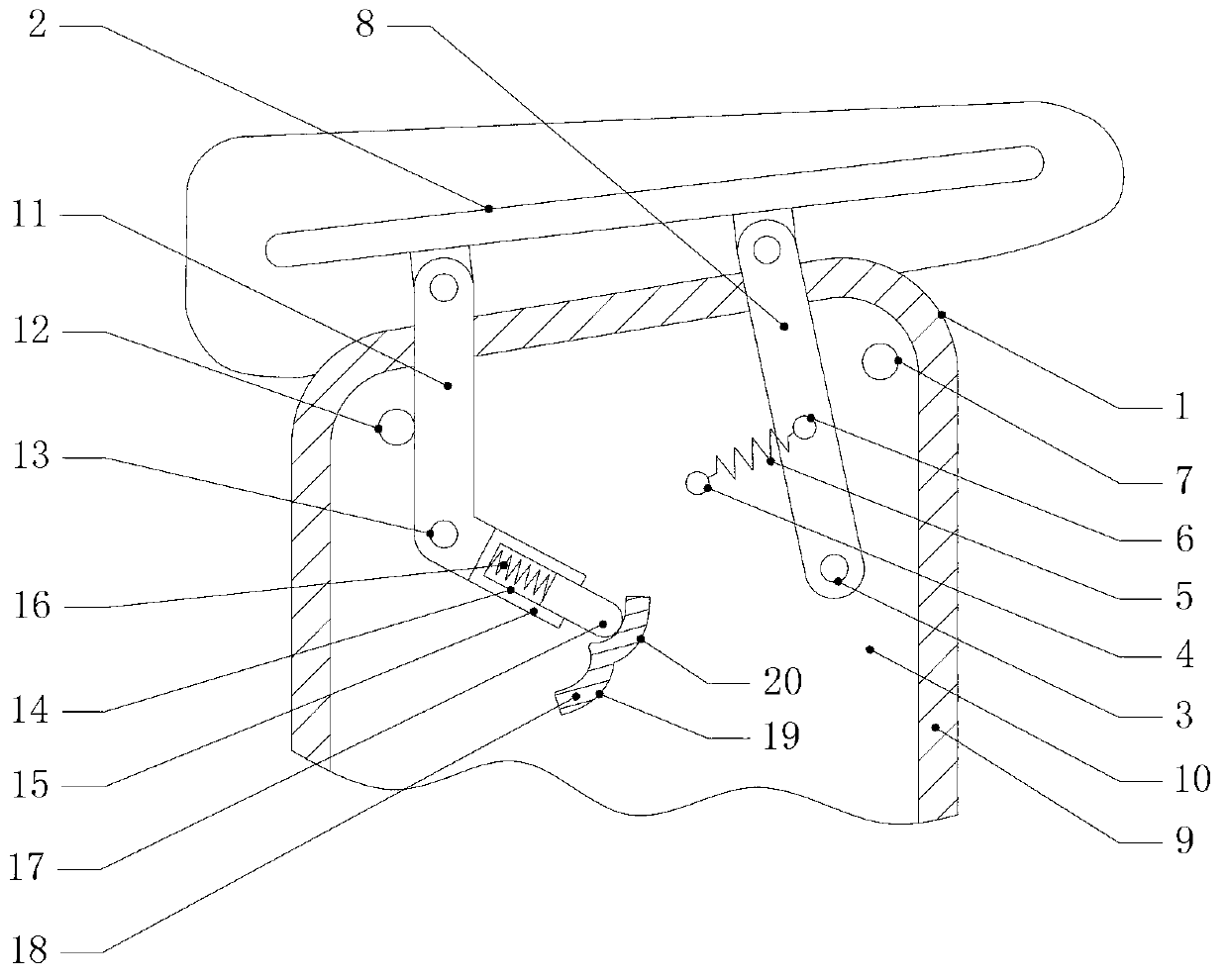

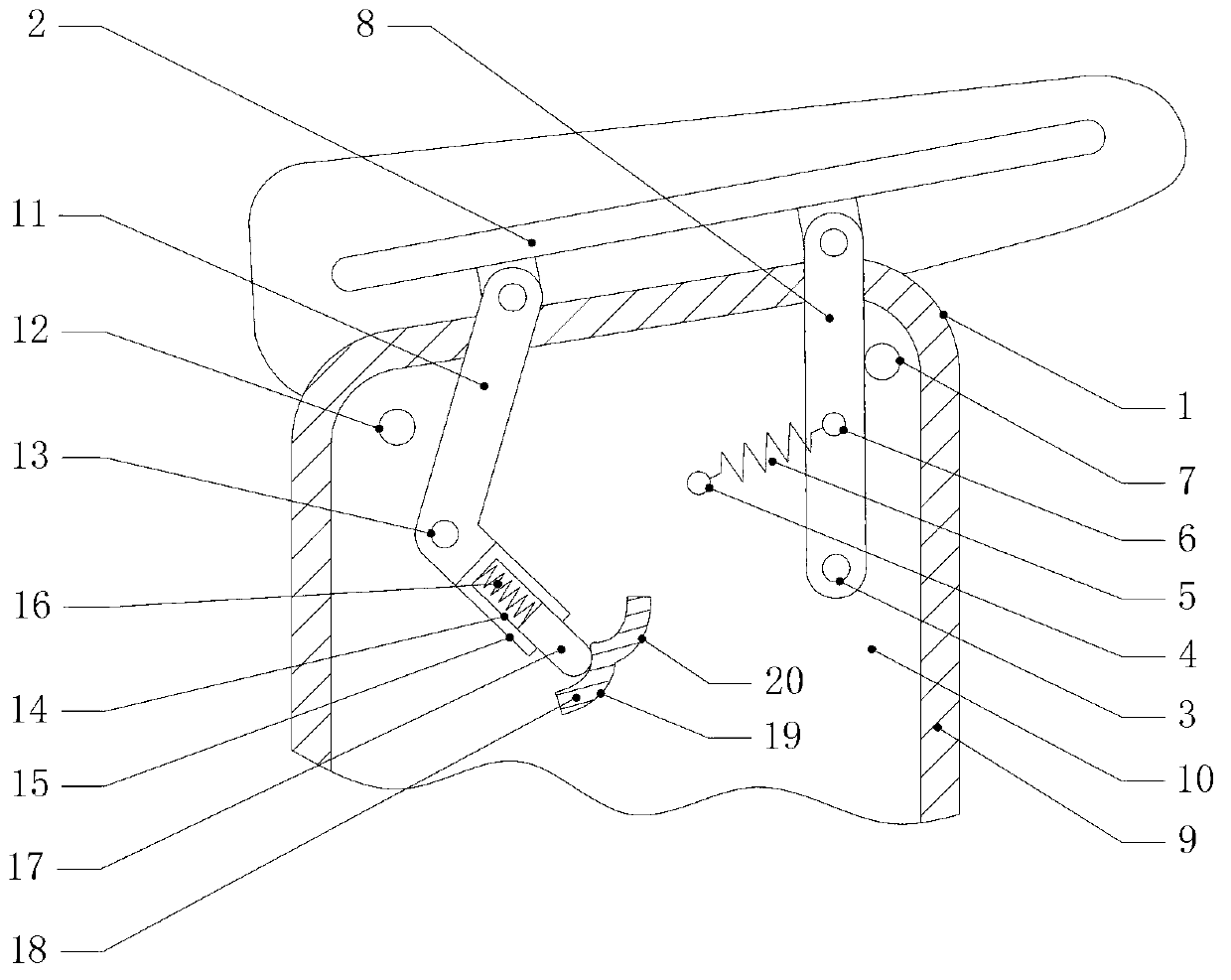

Flexible active and passive knee-joint rehabilitation training device

ActiveCN101836930AAvoid secondary damageImprove flexibilityGymnastic exercisingChiropractic devicesThighBaseboard

The invention discloses a flexible active and passive knee-joint rehabilitation training device, comprising a linear drive unit, a leg bracket unit and a control unit, wherein, the linear drive unit comprises a baseboard, a rodless cylinder, a sliding table for the rodless cylinder, an inflatable extendible flexible driver, a guide rod, a spring, a fixed support, a connecting piece, a removable bracket and a sliding pair; the leg bracket unit comprises a thigh rod, a thigh supporting board, a shank rod, a shank supporting board, a feet bracket, a connecting rod, a T-type connecting piece, a L-type rod, a first regulating device and a second regulating device; and the control unit comprises an angular displacement sensor, a force sensor, a displacement sensor and a controller. The training device can conveniently achieve a plurality of rehabilitation training modes such as knee-joint passive training, active training and the like according to the rehabilitation degree of a patient, and an applying force (including a driving force in the passive training and a damping force in the active training) is regulated in a stepless manner.

Owner:TECH TRANSFER CENT CO LTD NANJING UNIV OF SCI & TECH

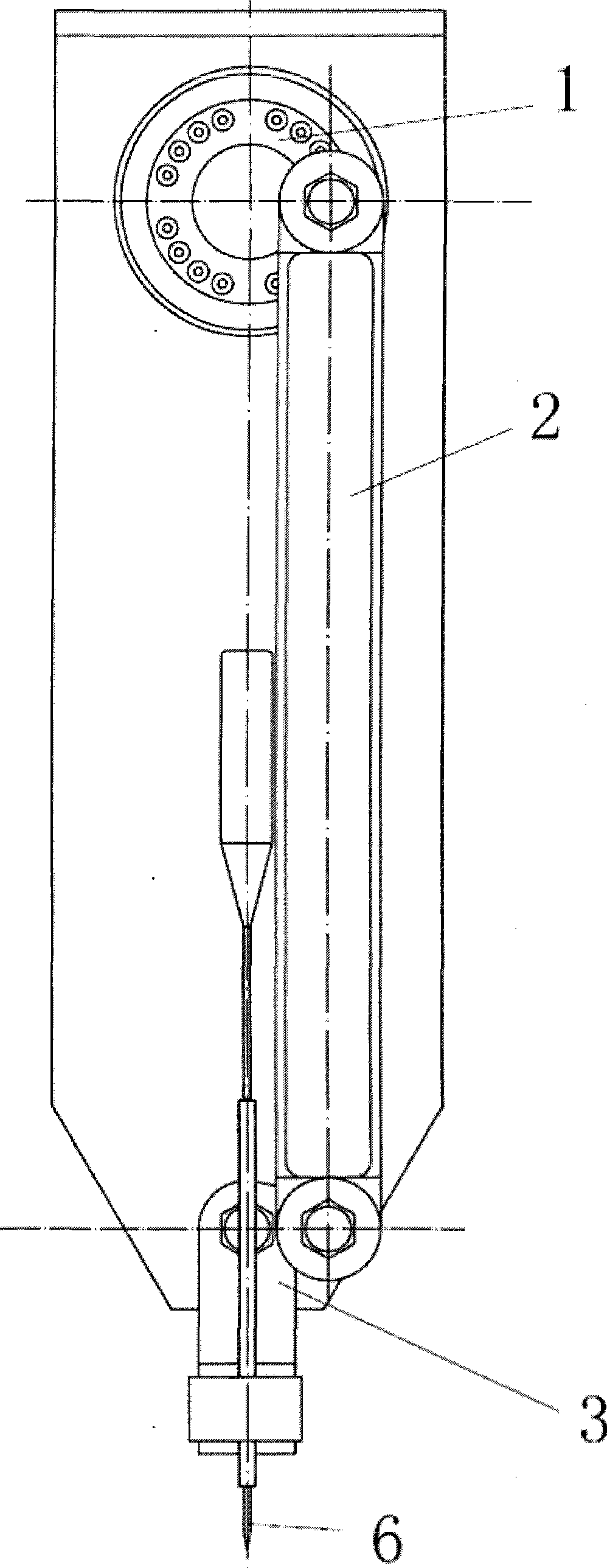

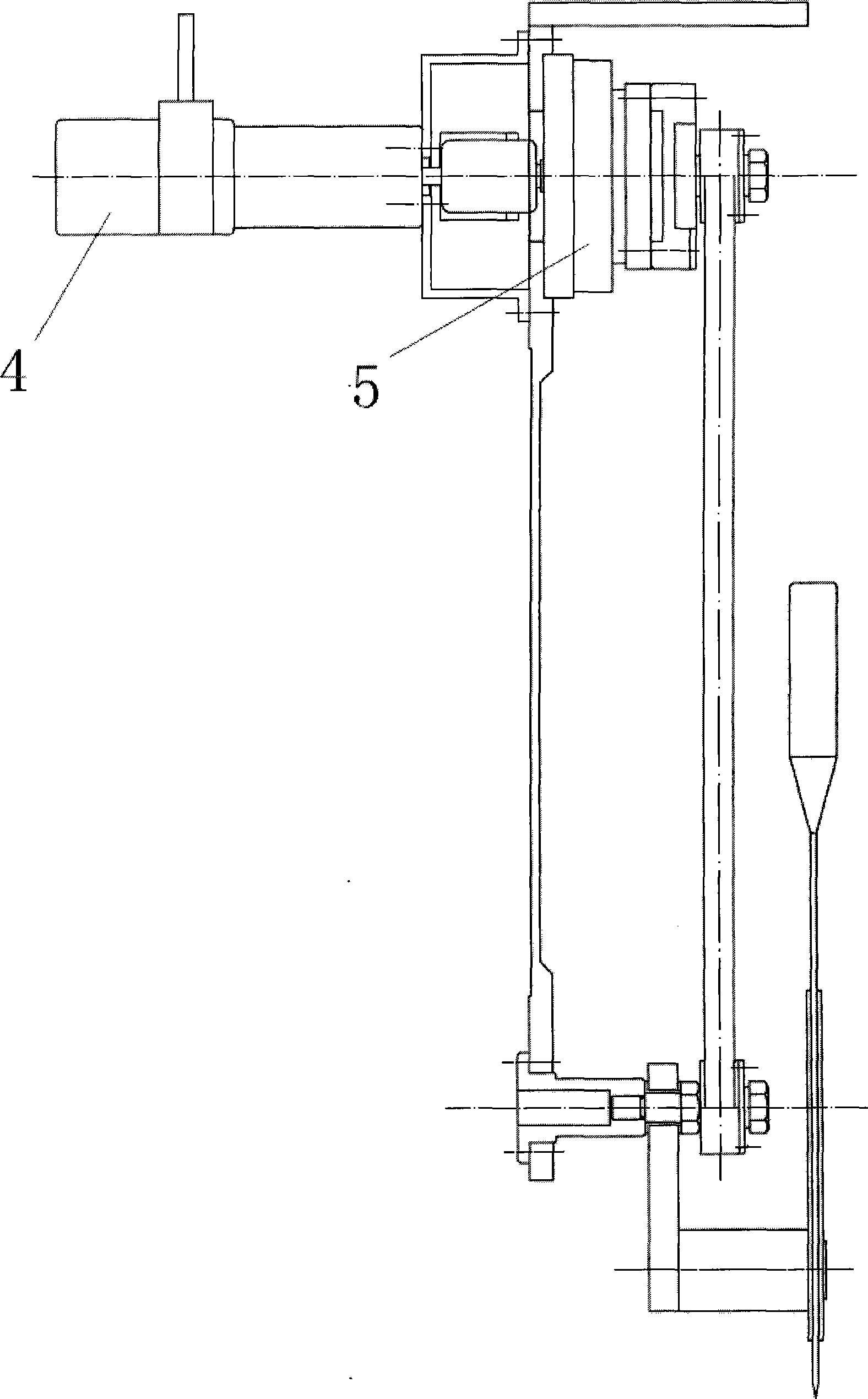

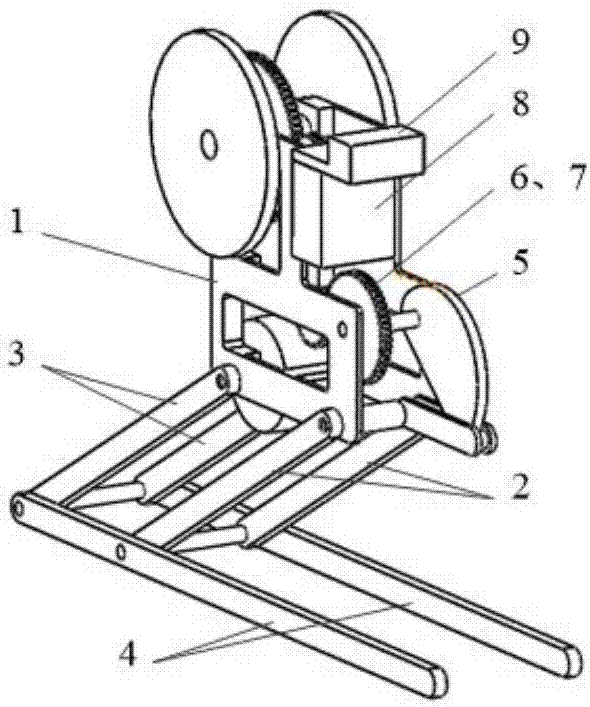

Operation robot needle-insertion positioning device under magnetic sensor environment

InactiveCN101416894ANormal work impactFix the angle problemMicromanipulatorSurgical needlesSurgical operationSurgical robot

The invention discloses a positioning device for needle insertion by a surgical robot under a magnetic sensor environment, which pertains to the technical field of accessories for minimally invasive surgery. The positioning device adopts a connecting rod mechanism taking the shape of parallelogram to transmit motion and comprises a short rod and a long rod of an inputting terminal and a short rod of an outputting terminal, wherein, the short rod of the inputting terminal has a disc-shaped structure and is fixedly connected with a harmonic reducer; one end of the long rod is hinged with the short rod of the inputting terminal to transmit the motion to the outputting terminal; the short rod of the outputting terminal is designed to a straight-angle shape and has a long side and a short side, wherein, the end of the long side of the short rod of the outputting terminal is provided with a surgical needle parallel to the long side so that the surgical needle has a maximum positioning scope of + / -90 degrees vertically; the long rod is longer so that the distance between a revolving shaft of the short rod of the inputting terminal and the end of the long side of the short rod of the outputting terminal is more than or equal to 400mm when the long side of the short rod of the outputting terminal is vertical. The positioning device has compact structure, avoids the influence of magnetic interference sources such as a motor and the reducer of the inputting terminal on the normal operation of a magnetic locator, and also solves the problems of single angle and small scale in needle insertion in the traditional surgical operation.

Owner:TSINGHUA UNIV +1

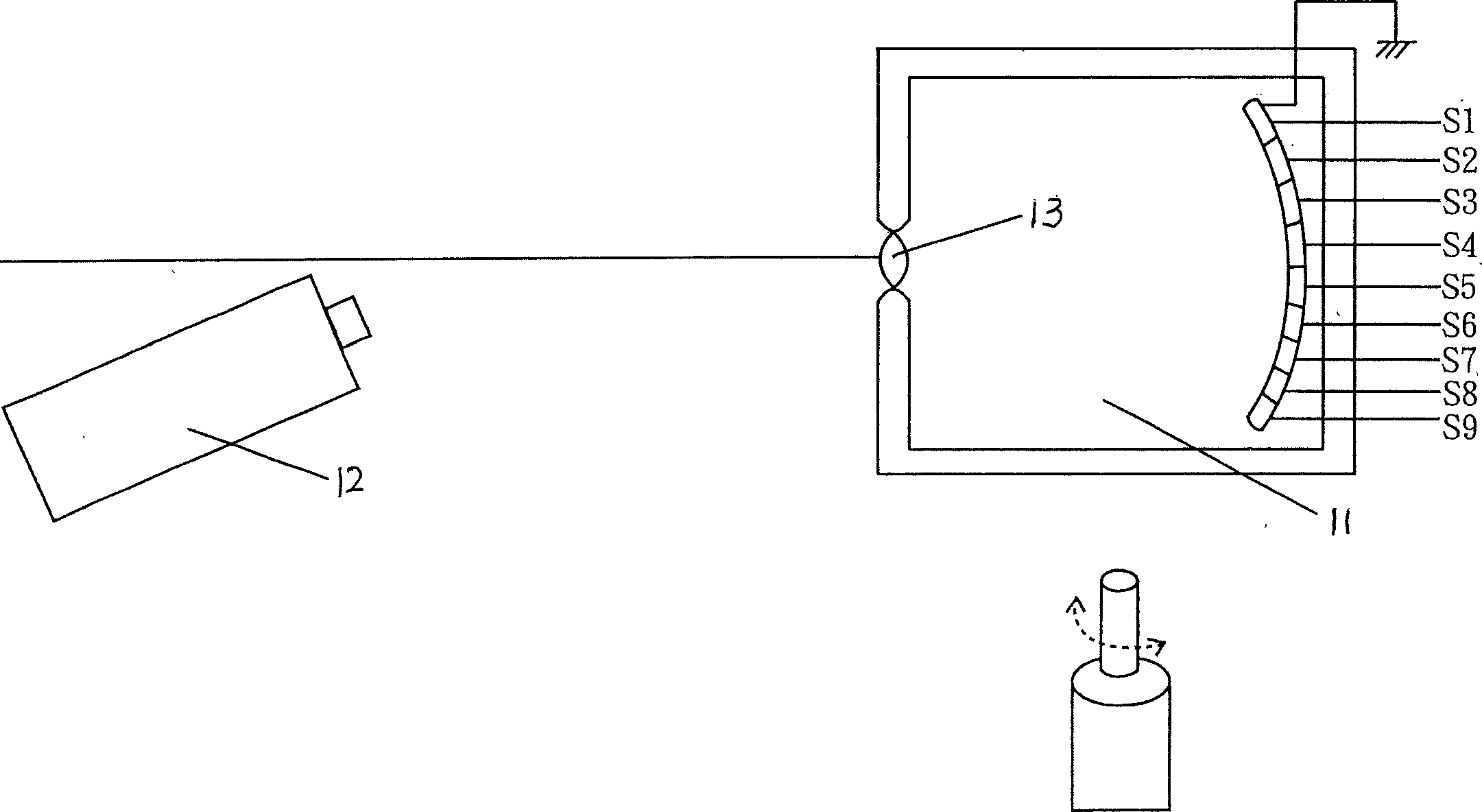

Display unit possessing automatic alignment function, and automatic alignment system

InactiveCN1760969ASolve the costFix the angle problemTelevision system detailsCathode-ray tube indicatorsControl signalTriangulation

The invention suitable to and aligns electronic equipment. The system includes following parts: a signal emission device in use for transmitting an alignment signal; being setup on the electronic equipment, signal receiving devices are in use for receiving alignment signal and generating a sensing signal; being connected to the signal receiving devices, a control device in use for receiving the sensed signal obtains position and direction between the electronic equipment and the signal emission device through triangulation method, as well as generates a control signal; being connected to the control device, an alignment mechanism adjusts the electronic equipment based on the control signal in order to align to the signal emission device.

Owner:ACER INC

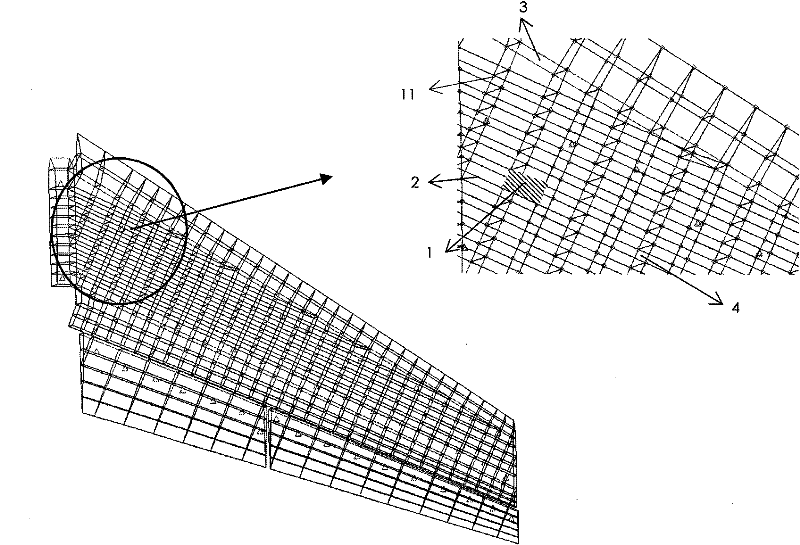

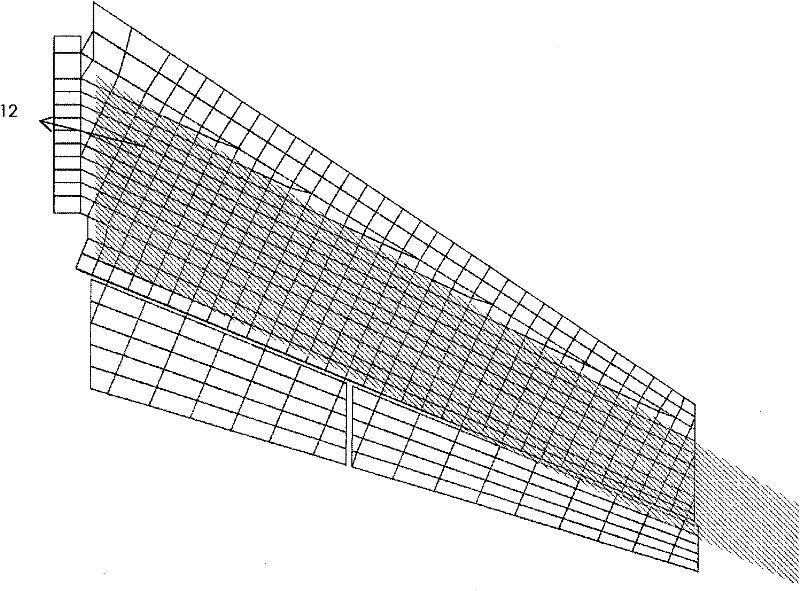

Optimization method for subsonic flutter of aircraft wing skin

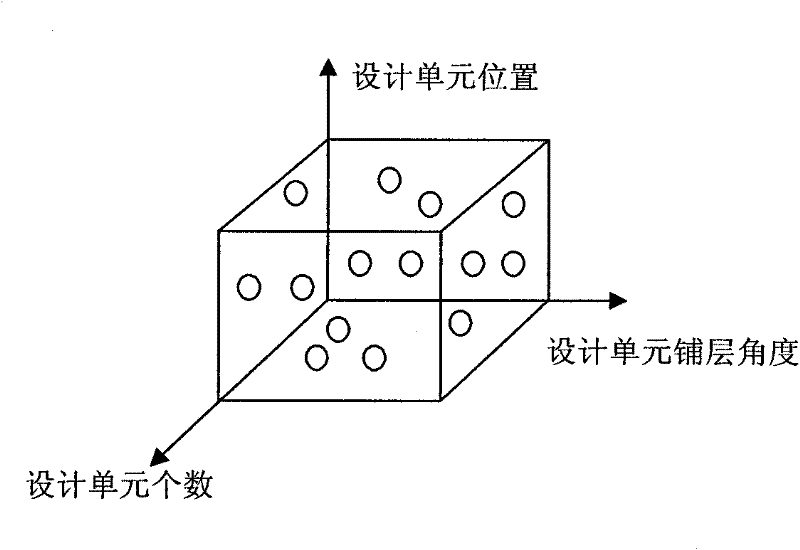

ActiveCN102262692ASolve the problem of excessive calculation timeHigh performance computingGenetic modelsSpecial data processing applicationsJet aeroplaneAlgorithm

The invention provides a method for optimizing skins of an airplane airfoil by a subsonic flutter based on a network computing platform. The method provided by the invention can take elements of each skin of the airfoil as objects to be optimized and also selects layering angles, layering thickness increment and layering positions as design variables; and a search which guarantees a genetic algorithm is processed in a space area comprising all possible solutions. The process of optimizing utilizes a double-circulation flow so that a decoupling problem of great design variables (more than 1000) is solved and also utilizes a 'small increment valley-filling method' to effectively avoid the oscillation of the algorithm so that a high repeatability of the algorithm is assured. The method provided by the invention is integrated into a gridding platform so that the method not only can solve the problem that the hardware-software resource is not enough, but also can solve the problem that thetime of the genetic algorithm is too long through a parallel computing.

Owner:中国航空工业集团公司科学技术委员会 +1

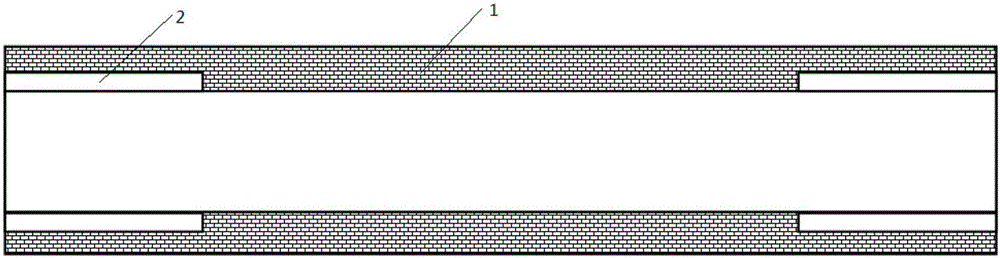

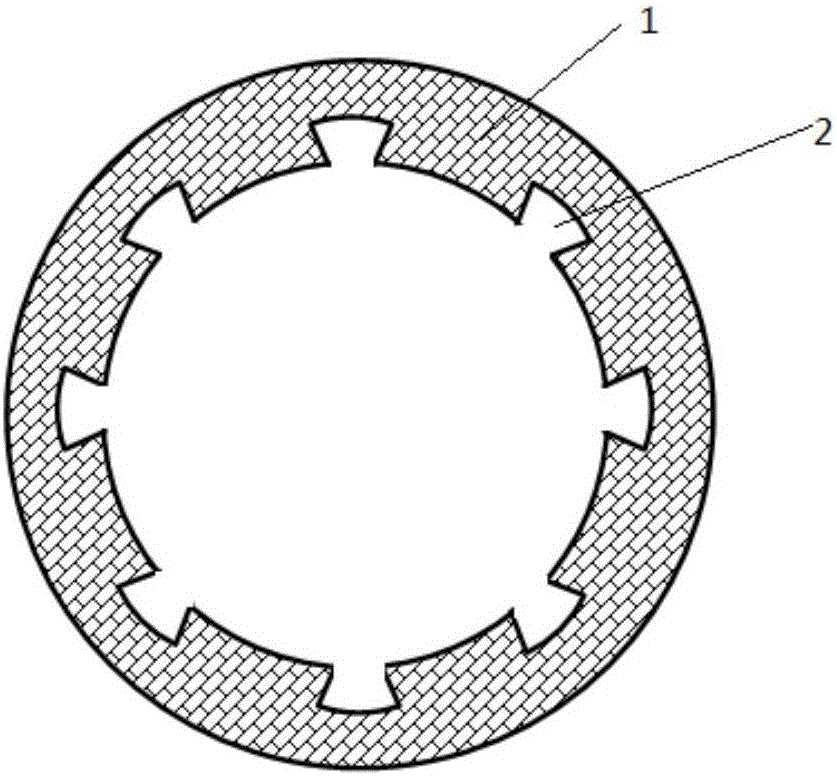

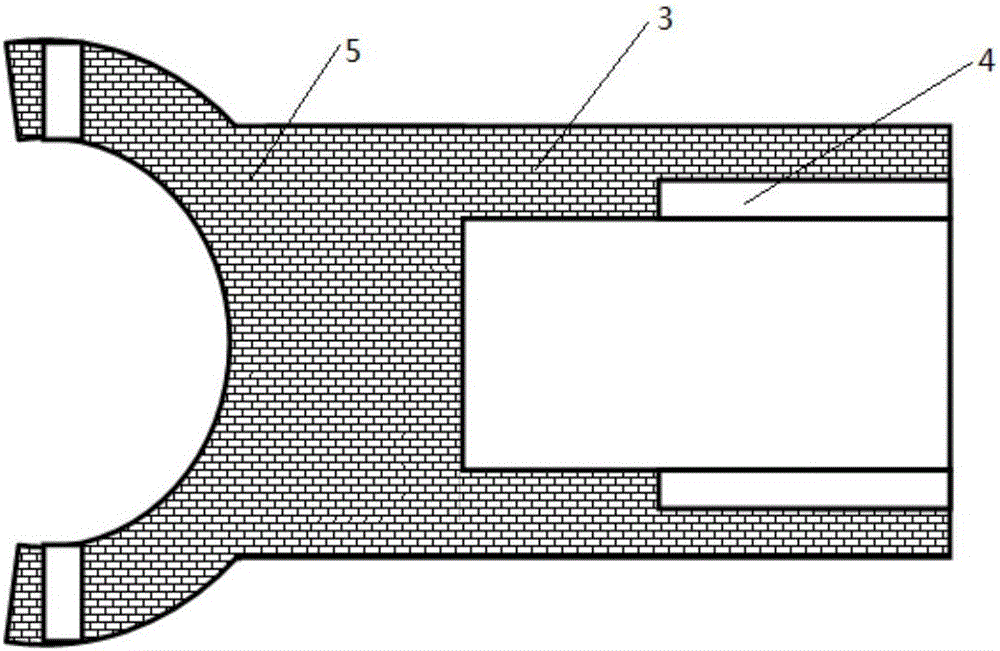

Three-dimensionally-woven composite automotive transmission shaft and manufacturing method of three-dimensionally-woven composite automotive transmission shaft

ActiveCN105690793ASmall running vibrationMeet the use requirementsYielding couplingShaftsFiberUniversal joint

The invention discloses a three-dimensionally-woven composite automotive transmission shaft and a manufacturing method of the three-dimensionally-woven composite automotive transmission shaft. A three-dimensionally-woven composite transmission shaft pipe and a universal joint are designed and the sleeve connection and combination manner of the three-dimensionally-woven composite transmission shaft pipe and the universal joint is designed according to the stress characteristic of the transmission process of the automotive transmission shaft. Three-dimensional multi-axial fabric structure combination is conducted through a hybrid fiber multi-direction weaving manner, the structural performance of the specific portion of the transmission shaft is strengthened, and finally integrated weaving of the three-dimensional prefabricated body structure is achieved. After a related three-dimensional fabric prefabricated body workpiece is manufactured, the specific fiber is selected to be subjected to thickness-direction seam laying secondary strengthening treatment so that the strength and rigidity in the thickness direction can be improved; and finally, a thermosetting resin glue solution serves as a base material, resin impregnation recombination and resin curing are conducted on the three-dimensionally-woven prefabricated body fabric by the adoption of continuous forming with vacuum infusion and quick thermocuring combined, and finally a three-dimensionally-woven composite automotive transmission shaft assembly made of the hybrid fiber fabric is formed.

Owner:SHANDONG ZHONGHENG CARBON FIBER TECH DEV CO LTD

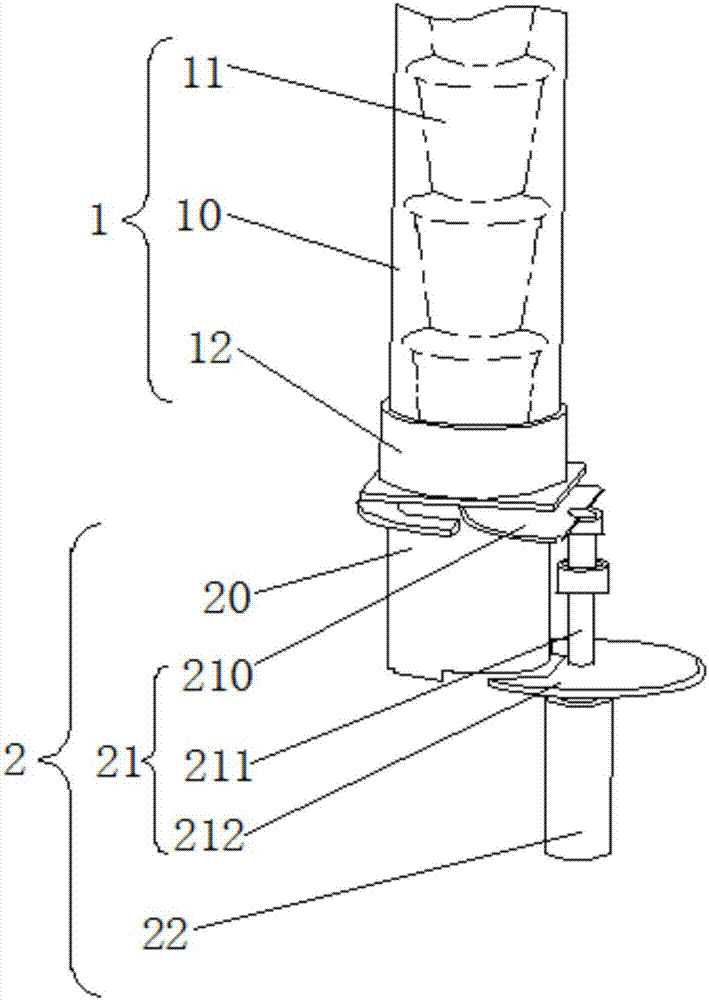

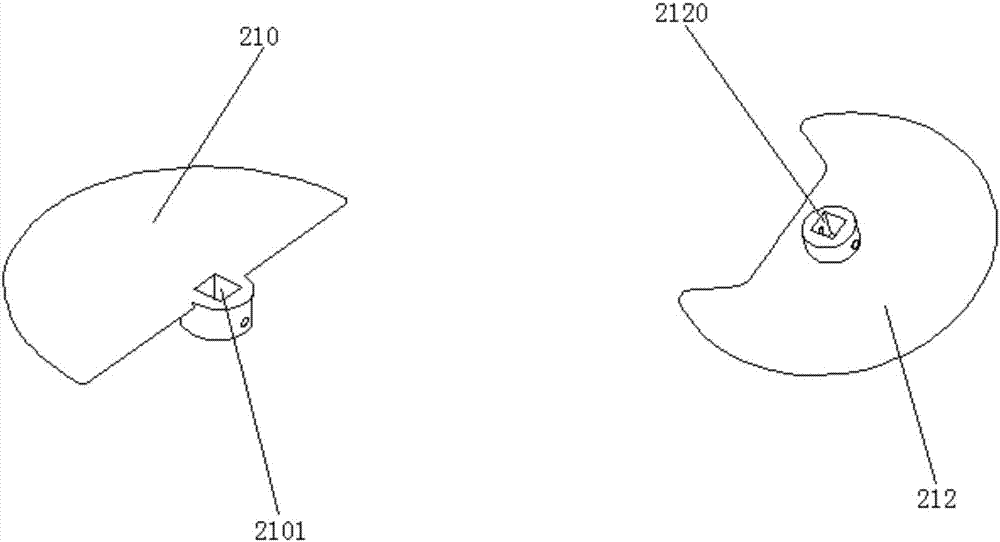

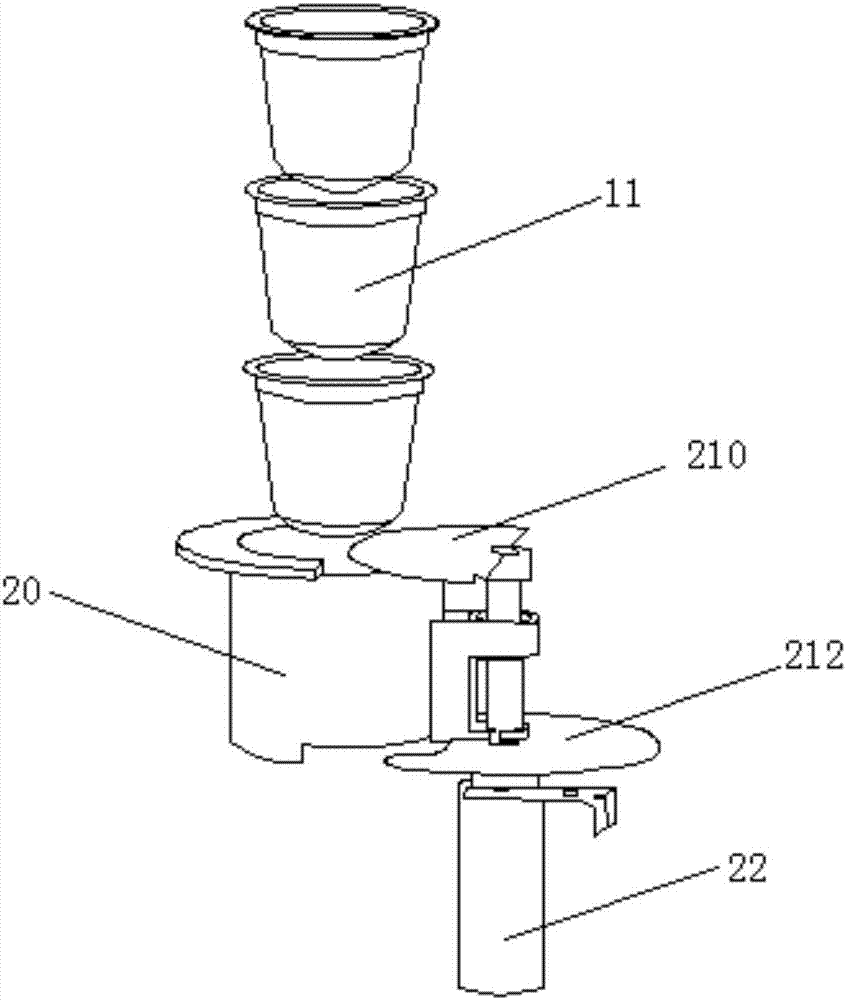

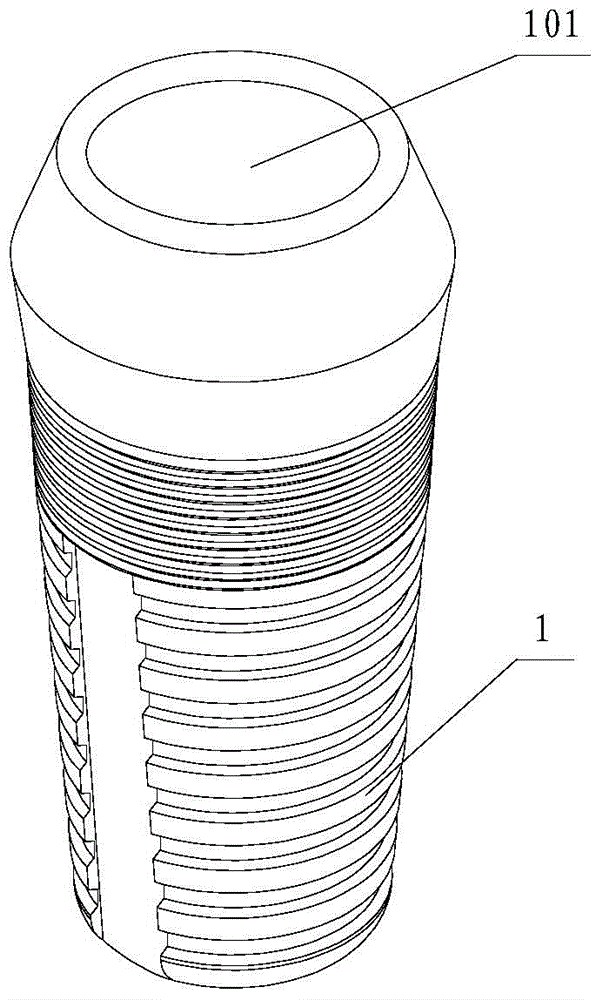

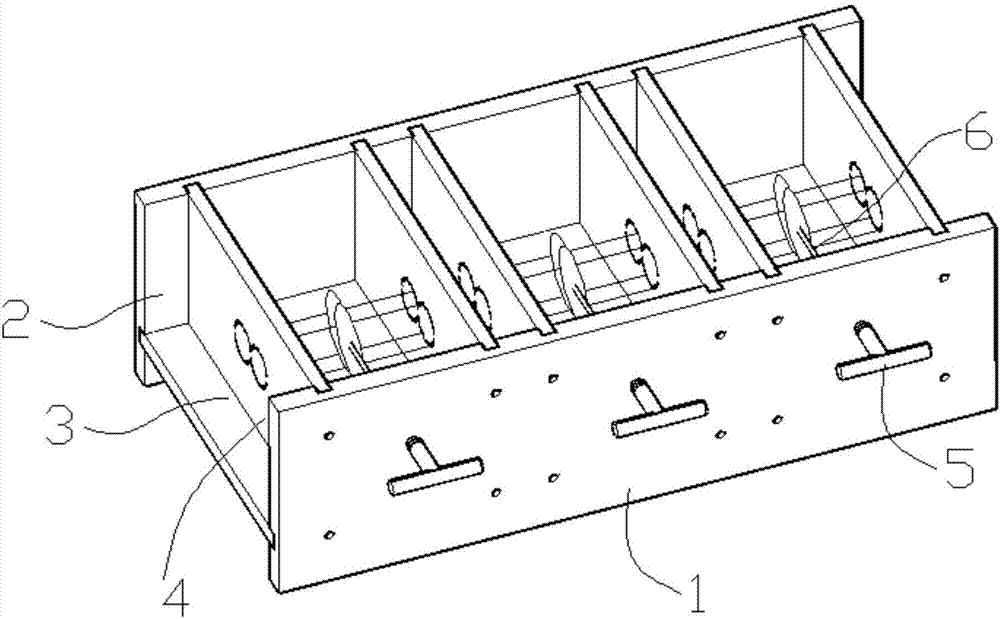

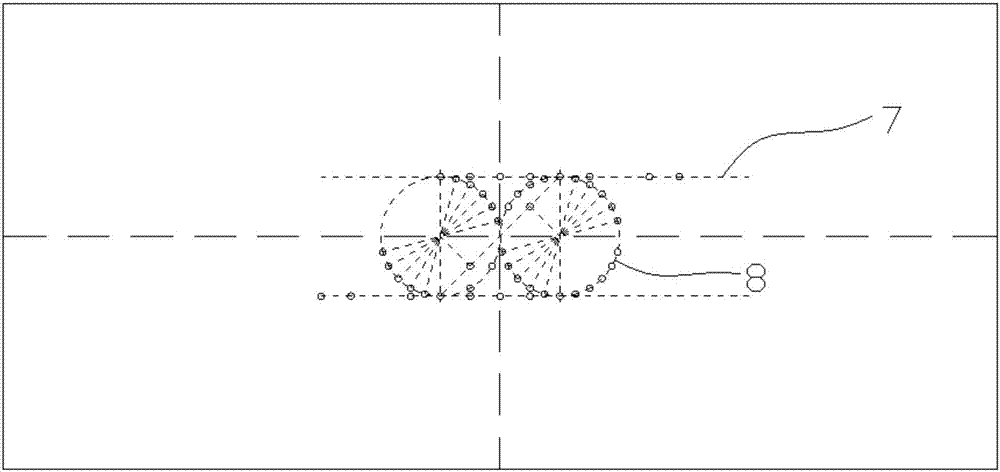

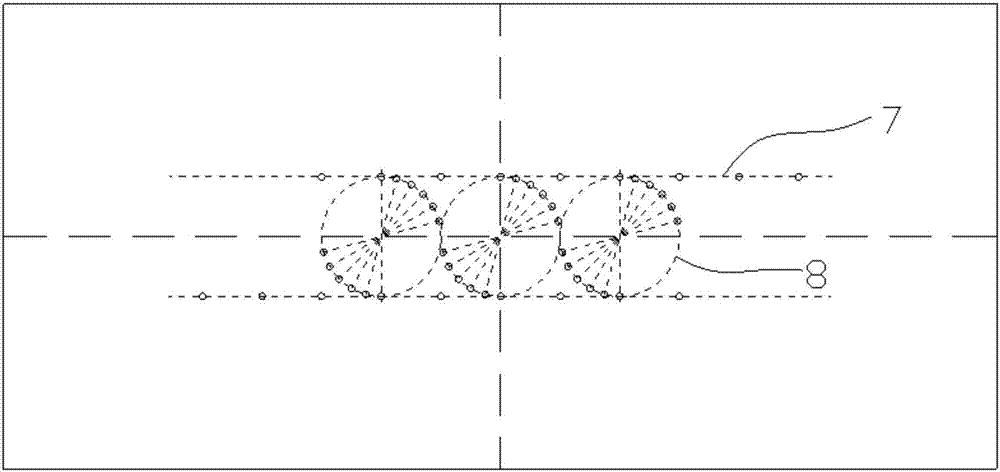

Rotary automatic blanking structure, blanking system and control method

PendingCN107265141ASolve the problem of easy jammingSolve the problem of inaccurate blanking quantityConveyorsLoading/unloadingEngineeringRotating disc

The invention discloses a rotary automatic blanking structure, a blanking system and a control method. The structure comprises a storage module, and a discharge module arranged under the storage module; the storage module comprises a storage barrel, and a storage barrel base arranged at the bottom of the storage barrel; the discharge module comprises a discharge fixed cylinder arranged rightly under the storage barrel base, and a turntable module arranged on one side of the discharge fixed cylinder; the turntable module comprises an upper rotating disc arranged between the storage barrel base and the discharge fixed cylinder; and the upper rotating disc is connected with a lower rotating disc arranged under the discharge fixed cylinder through a connecting piece. The structure solves the problems of higher use cost, more complicated and unstable structure, no design of a transmission structure for falling one commodity at each time and inconvenience in maintenance in drink capsule automatic selling equipment in the prior art.

Owner:SHENZHEN DINGJIA HONGSI BEVERAGE TECH CO LTD

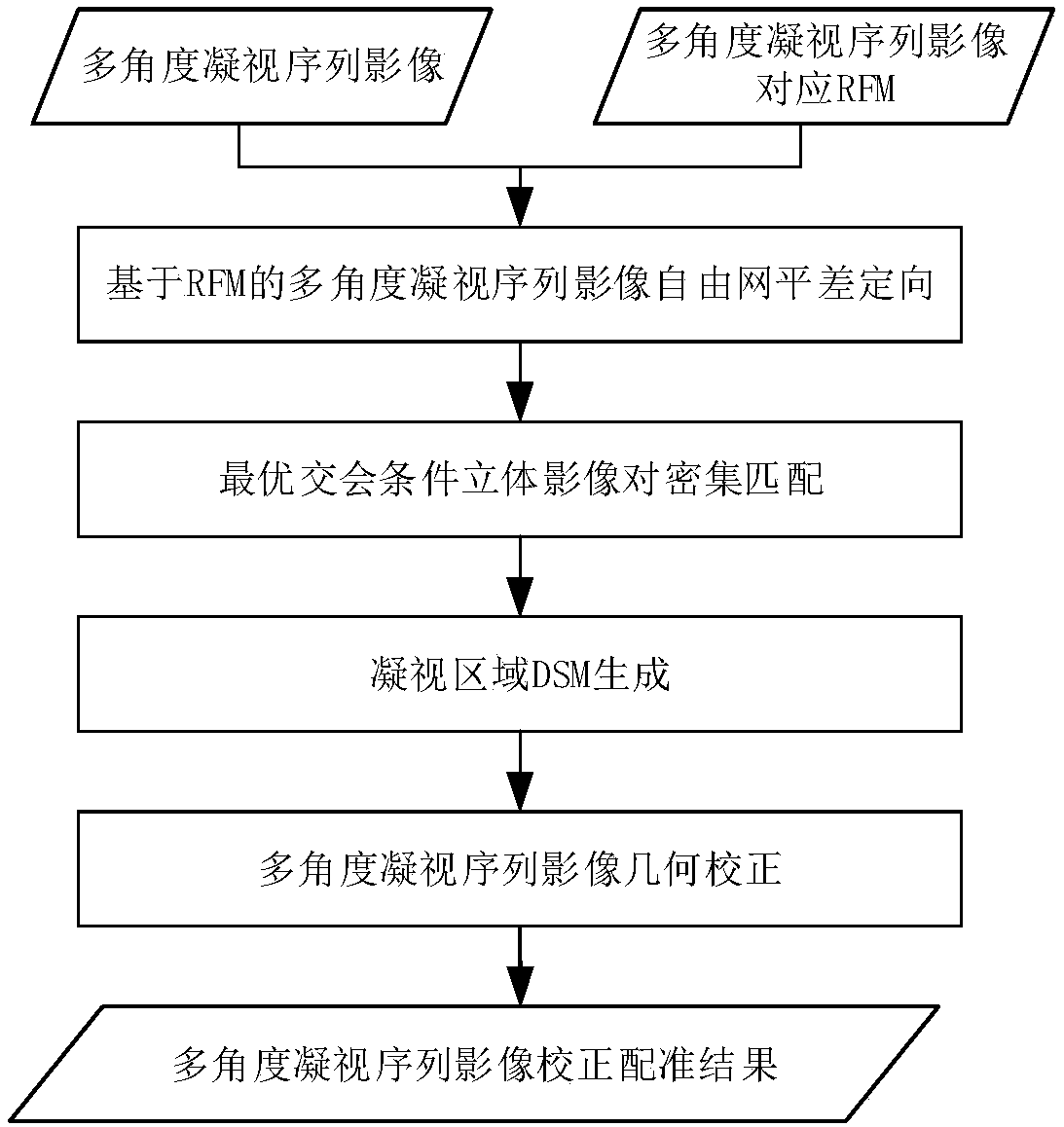

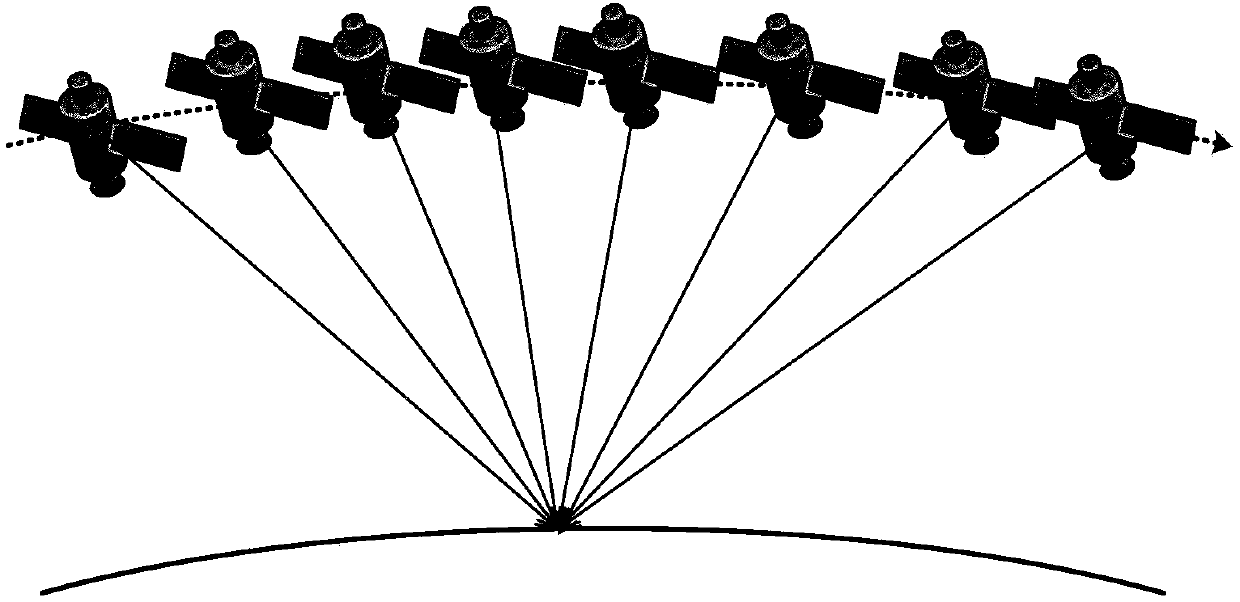

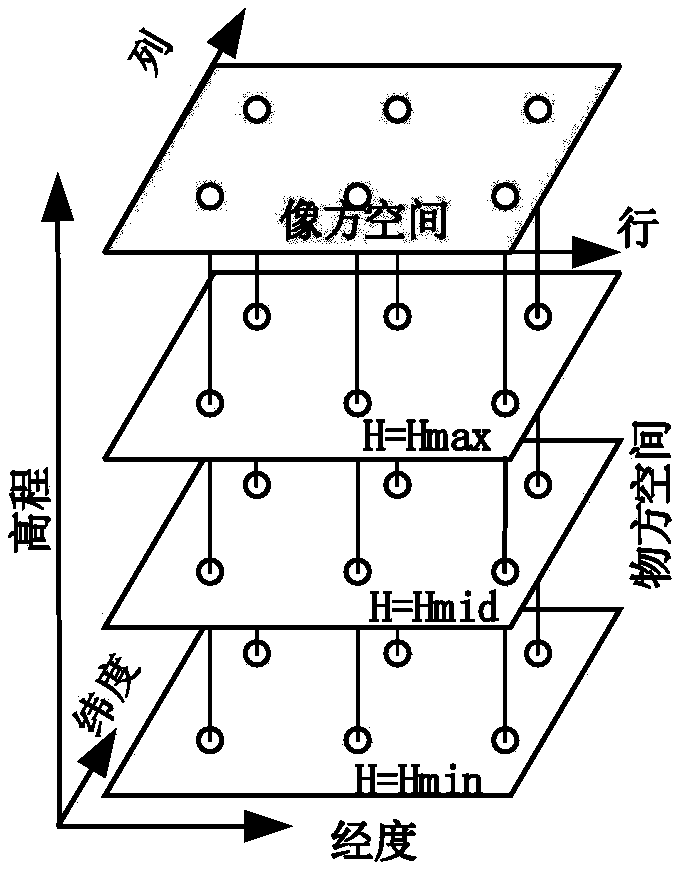

Geometric constraint-based high-resolution optical satellite staring image registration method

ActiveCN107705329AAchieve high-precision registrationHigh precision registrationImage enhancementImage analysisPoint cloudDigital surface

The invention discloses a geometric constraint-based high-resolution optical satellite staring image registration method. The method comprises the steps of S100, building a free network adjustment directional model of images by utilizing a rational function model of additional image space error compensation; S200, based on the free network adjustment directional model, performing dense matching ona stereoscopic image pair with an optimal rendezvous condition in the images to obtain coordinates of dense homonymy points; S300, generating dense point cloud data, performing gross error point deletion on the dense point cloud data, and generating digital surface model data; and S400, based on the free network adjustment directional model and DSM data, performing geometric correction on the images in sequence. By utilizing geometric locating consistency, high-precision registration of high-resolution optical satellite multi-angle staring sequence images is realized; the multi-angle staringsequence image registration problem caused by satellite platform control inaccuracy and attitude measurement inaccuracy is solved; and a high-precision data basis can be provided for subsequent application.

Owner:WUHAN UNIV

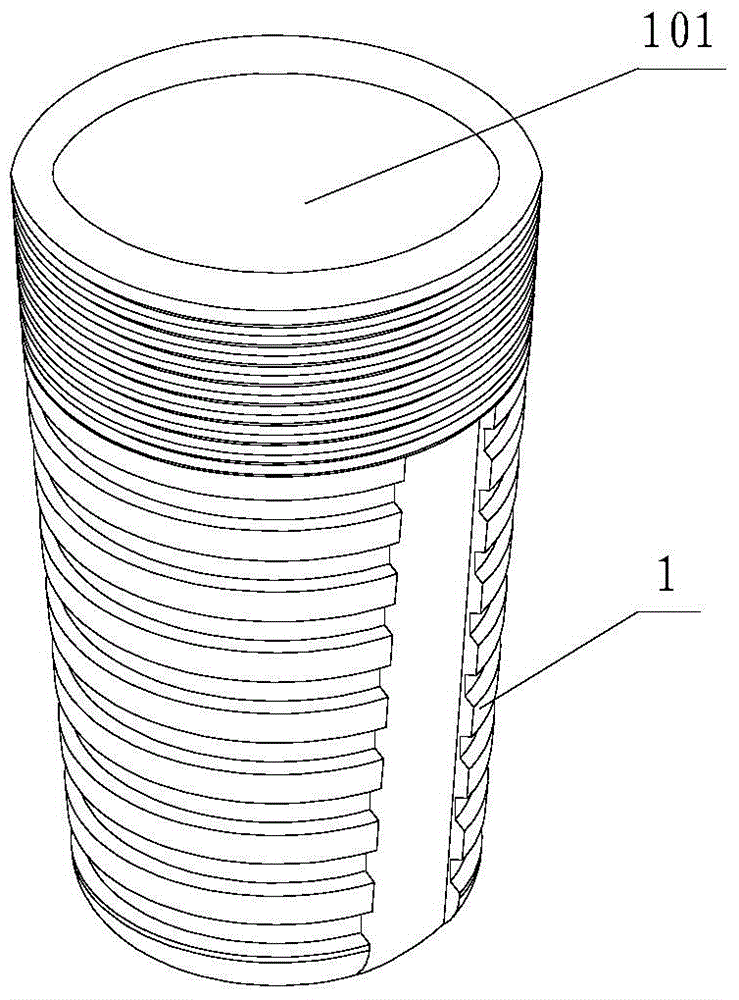

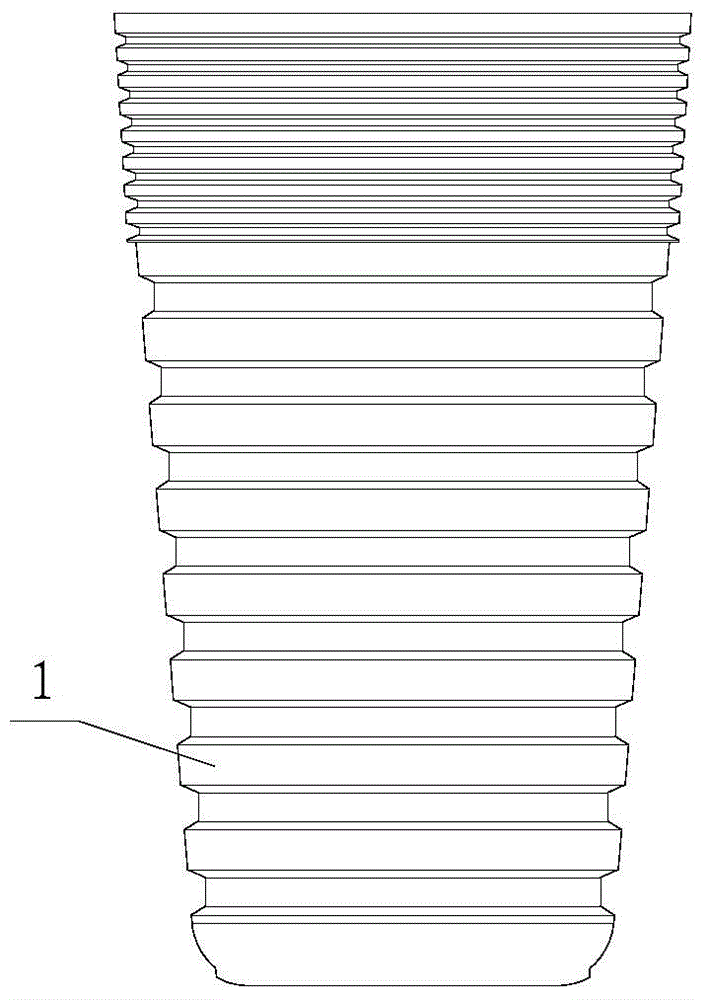

Oral implantation digital pontic restoration abutment and plantation method thereof

The invention belongs to the field of dentistry plantation restoration, and concretely relates to an oral implantation digital pontic restoration abutment and a plantation method thereof. The oral implantation digital pontic restoration abutment comprises implants, restoration abutments, a pontic and a digital abutment, the implants are respectively arranged between two adjacent teeth in the oral gum, each of the implants is provided with one restoration abutment, the digital abutment used for a scanner to scan as a reference is docked to the restoration abutments when the scanner scans, the implants, the restoration abutments and the digital abutment are respectively provided with a through hole, and the implants, the restoration abutments and the digital abutment are connected through screws inserted to through holes; and adjacent restoration abutments are connected through the pontic made according to the scanning result of the scanner, and the digital abutment dismounted restoration abutments and the pontic are respectively fixedly connected with a false tooth. The oral implantation digital pontic restoration abutment solves a problem that implantation pontics of different manufacturers, models, specifications and systems cannot be restored in a unified manner, and well overcomes disadvantages of clinic restoration.

Owner:朴永浩

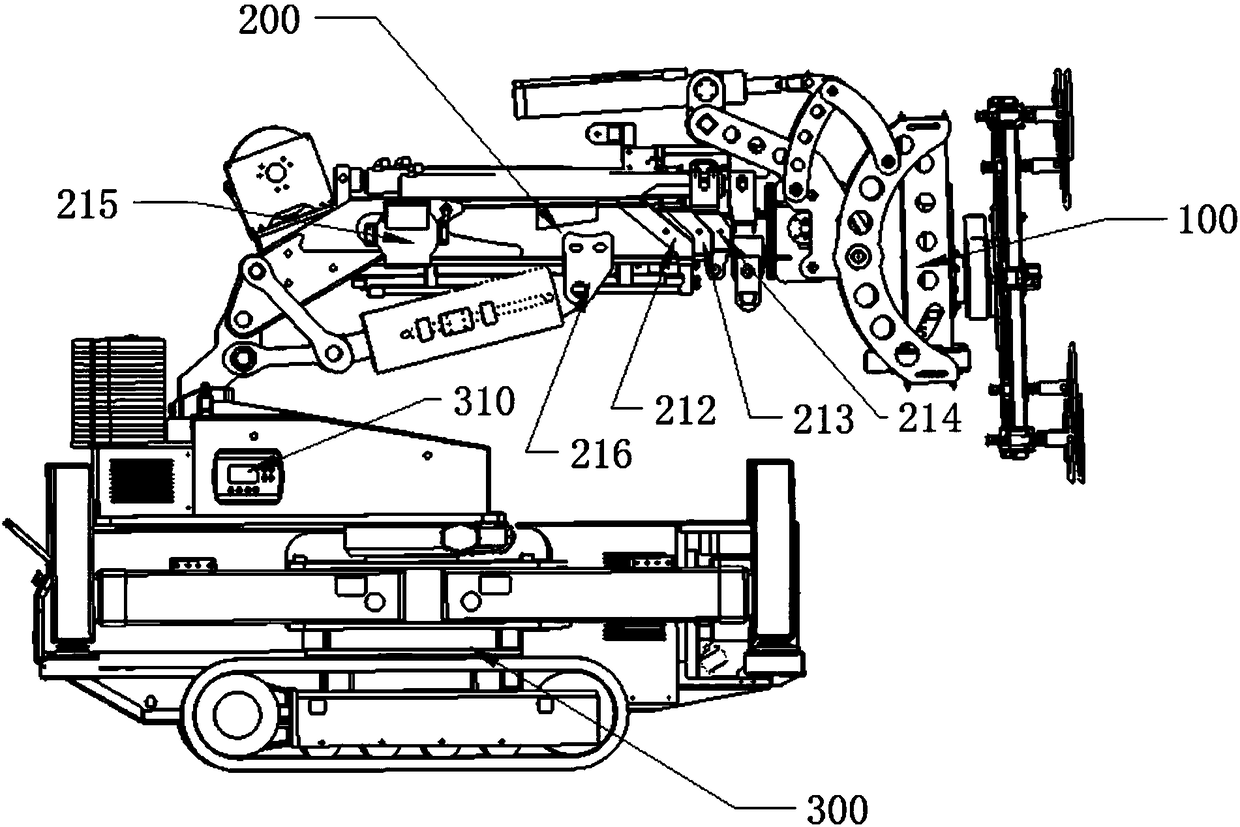

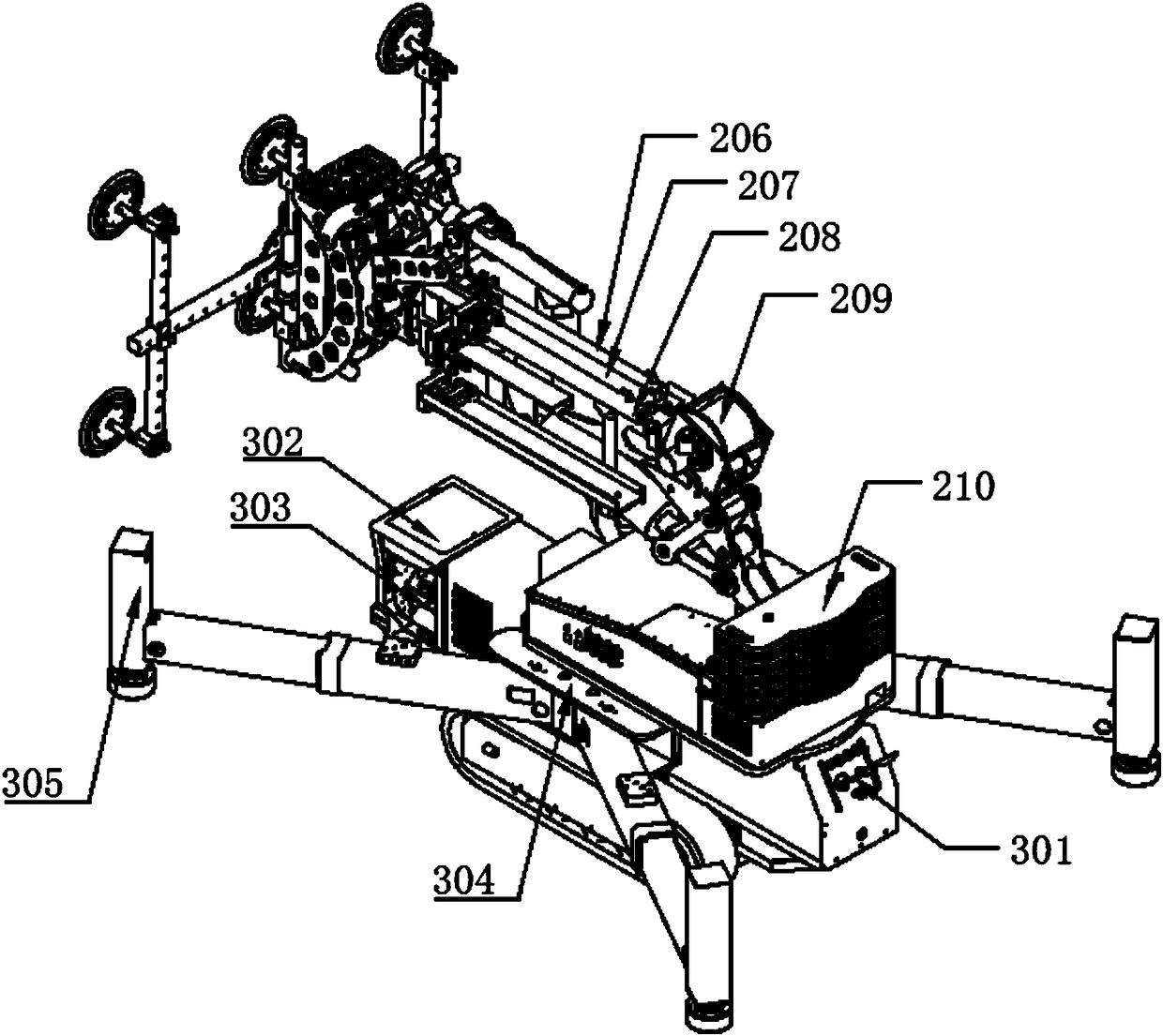

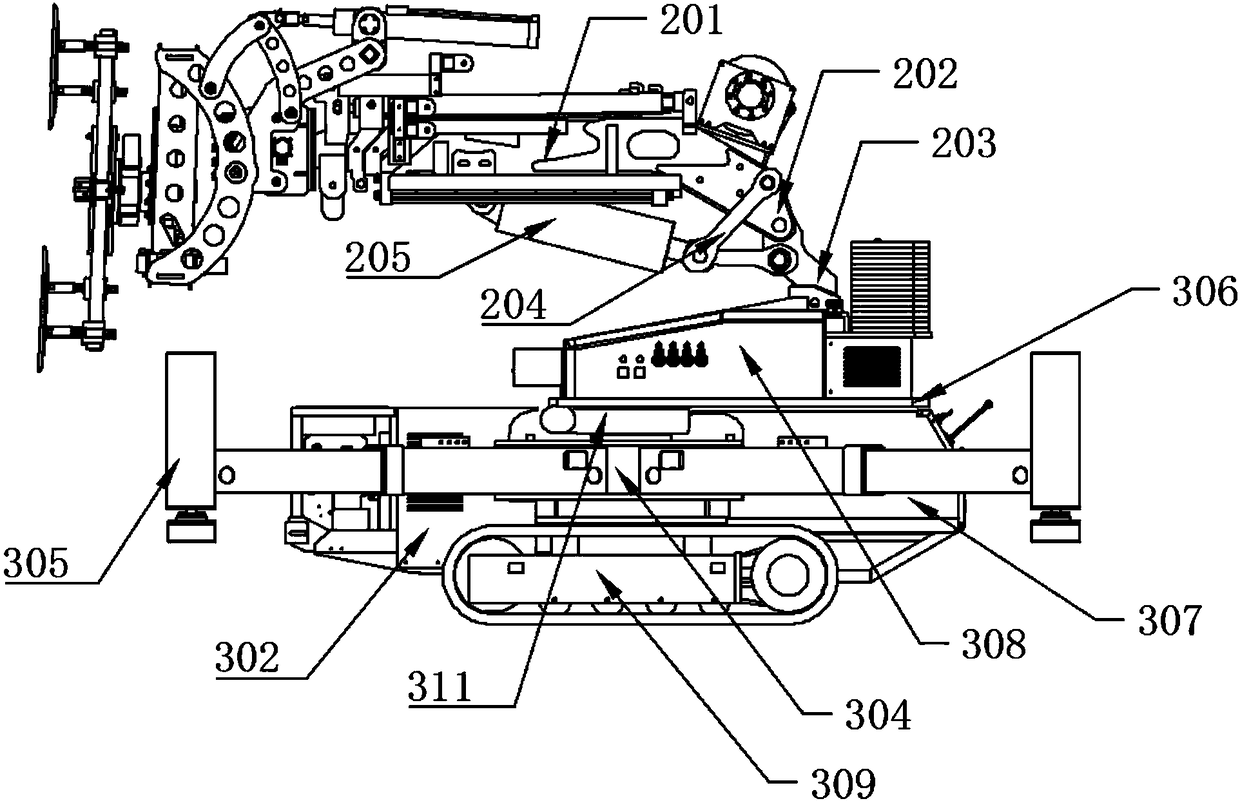

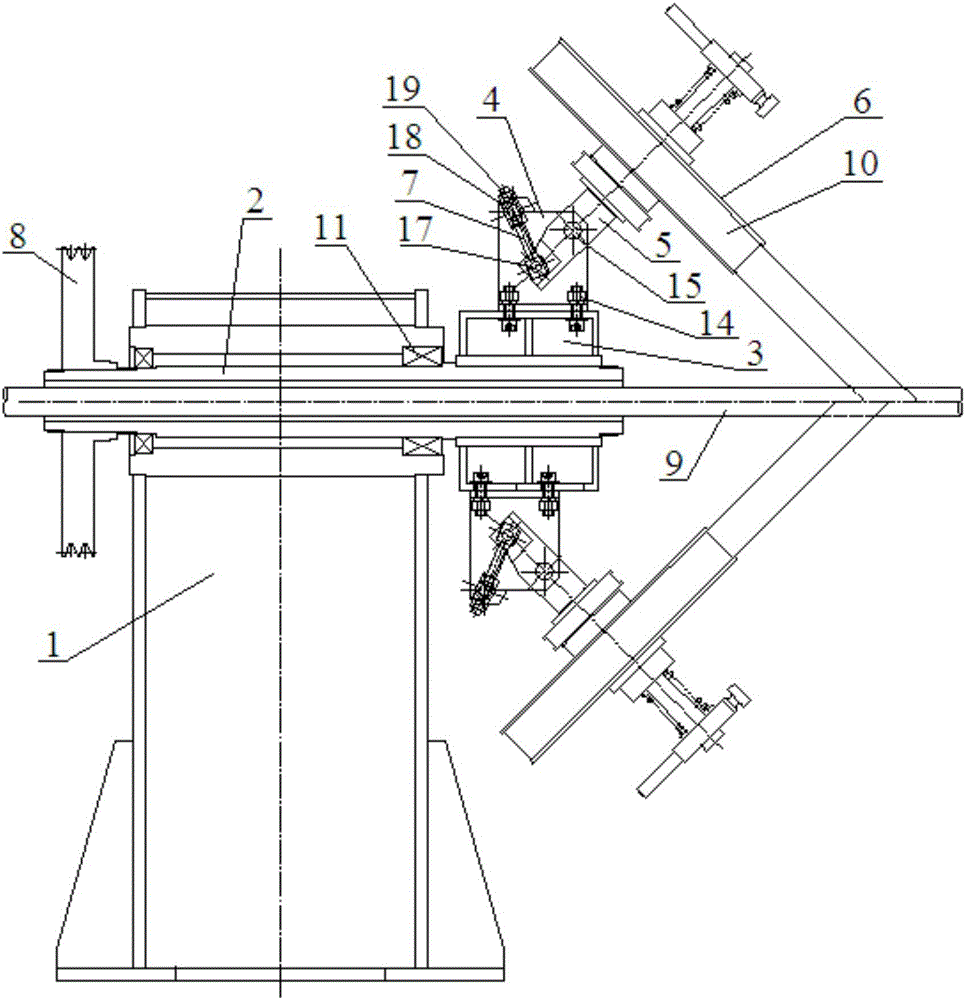

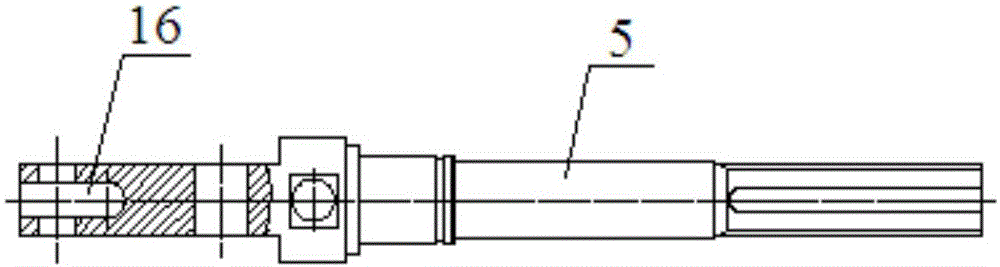

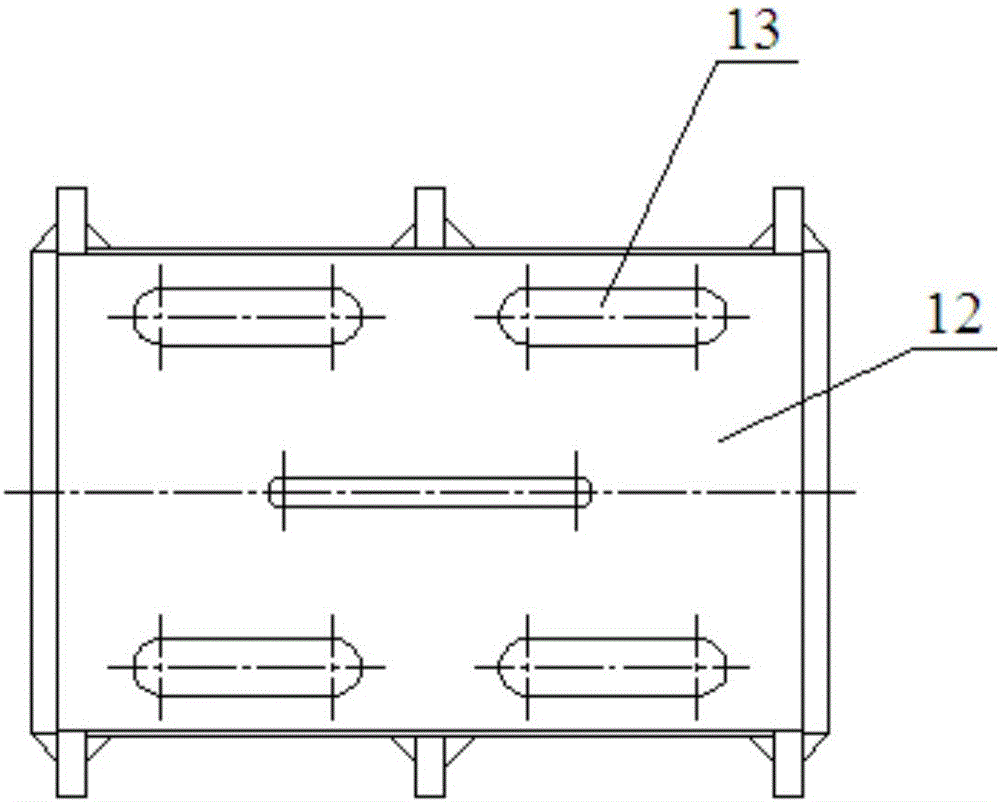

Multi-dimensional glass mounting robot

PendingCN108453697AIncrease productivityImprove production efficiencyProgramme-controlled manipulatorGripping headsEngineeringMulti dimensional

The invention discloses a multi-dimensional glass mounting robot which comprises a multi-dimensional mounting head, a telescopic mechanical arm and a rotary walking chassis, wherein the multi-dimensional mounting head is mounted on the telescopic mechanical arm; the telescopic mechanical arm is mounted on the rotary walking chassis; the multi-dimensional mounting head comprises an up-down slidingunit, a left-right rotating unit, an overturning unit, a rotary unit and a translation unit. The multi-dimensional glass mounting robot is scientific and reasonable in design and compact in structure,at least can achieve movement in eight directions, solves the problems of multi-dimensional and multi-angle mounting and carrying, and achieves the effects of efficiently and flexibly mounting and carrying by coarse and fine adjustment. The multi-dimensional glass mounting robot disclosed by the invention achieves mechanical and auxiliary automatic operations of grabbing, carrying and mounting large glass panels, so that the large panel mounting quality, the production efficiency and the benefit are improved, a lot of labor forces are saved, the labor intensity is reduced, and the construction cost is lowered.

Owner:GUANGZHOU COWEST MACHINERY EQUIP CO LTD

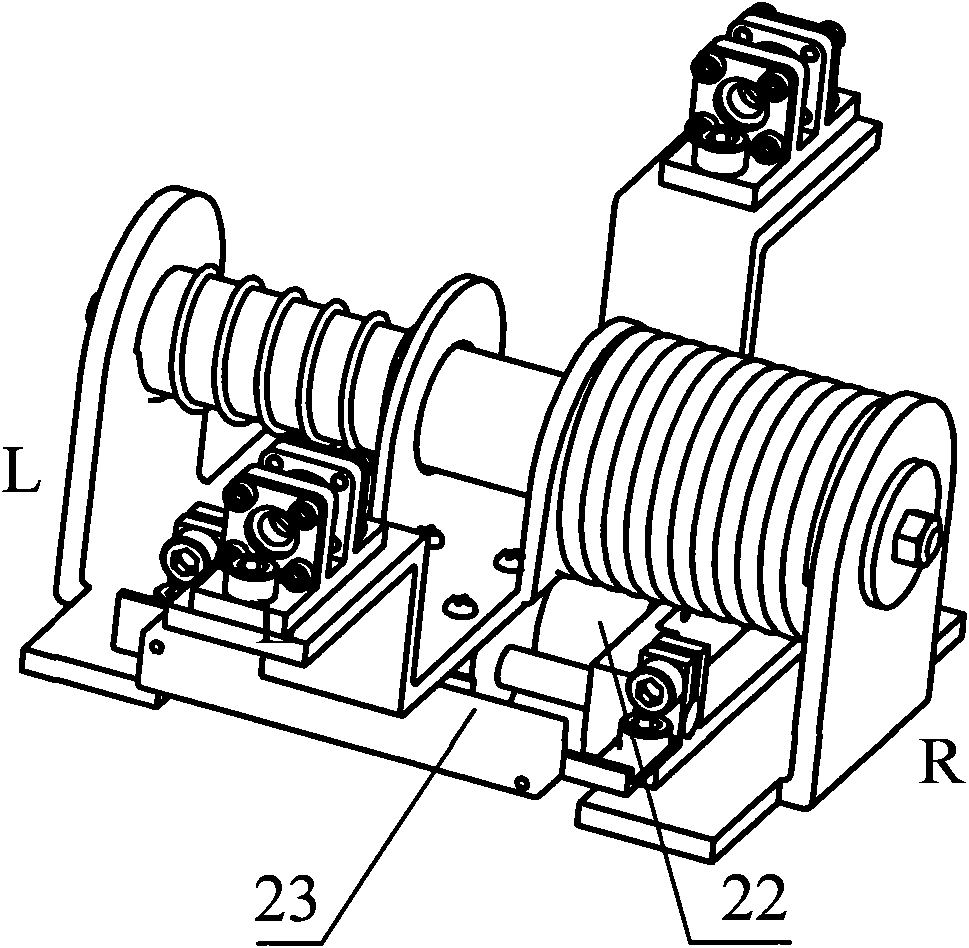

High-speed wrapping machine

InactiveCN106024211AGood performanceEasy to adjustInsulating conductors/cablesEngineeringSupport plane

The invention discloses a high-speed wrapping machine. The high-speed wrapping machine comprises a wrapping support and a hollow main shaft, the right end of the hollow main shaft is provided with a rotation support, multiple installation planes are respectively arranged around the rotation support, and multiple support frames are respectively installed on the installation planes; and the high-speed wrapping machine comprises multiple aslant arranged reel shafts, the central portions of the multiple reel shafts are each provided with a reel, the rear portions of the multiple rear shafts are respectively correspondingly rotationally installed on the multiple support frames, the multiple support frames are each provided with an adjustment screw rod, and the rear ends of the adjustment screw rods are respectively in rotational connection with the rear ends of the reel shafts rotationally installed on the support frames. The application performance is good, the adjustment is simple, the locking is reliable, the safety is high, the rigidity of the rotation support is high, during high-speed rotation, loosening is not easily generated, the problem of adjustment of the angle of a wrapping band in a wire and cable production process and the pitch problem of coverage of multiple wrapping bands are solved, the production efficiency is improved, and the high-speed wrapping machine is suitable for a wrapping machine rotating at a high speed.

Owner:WUHU ELECTROTECHN MACHINERY

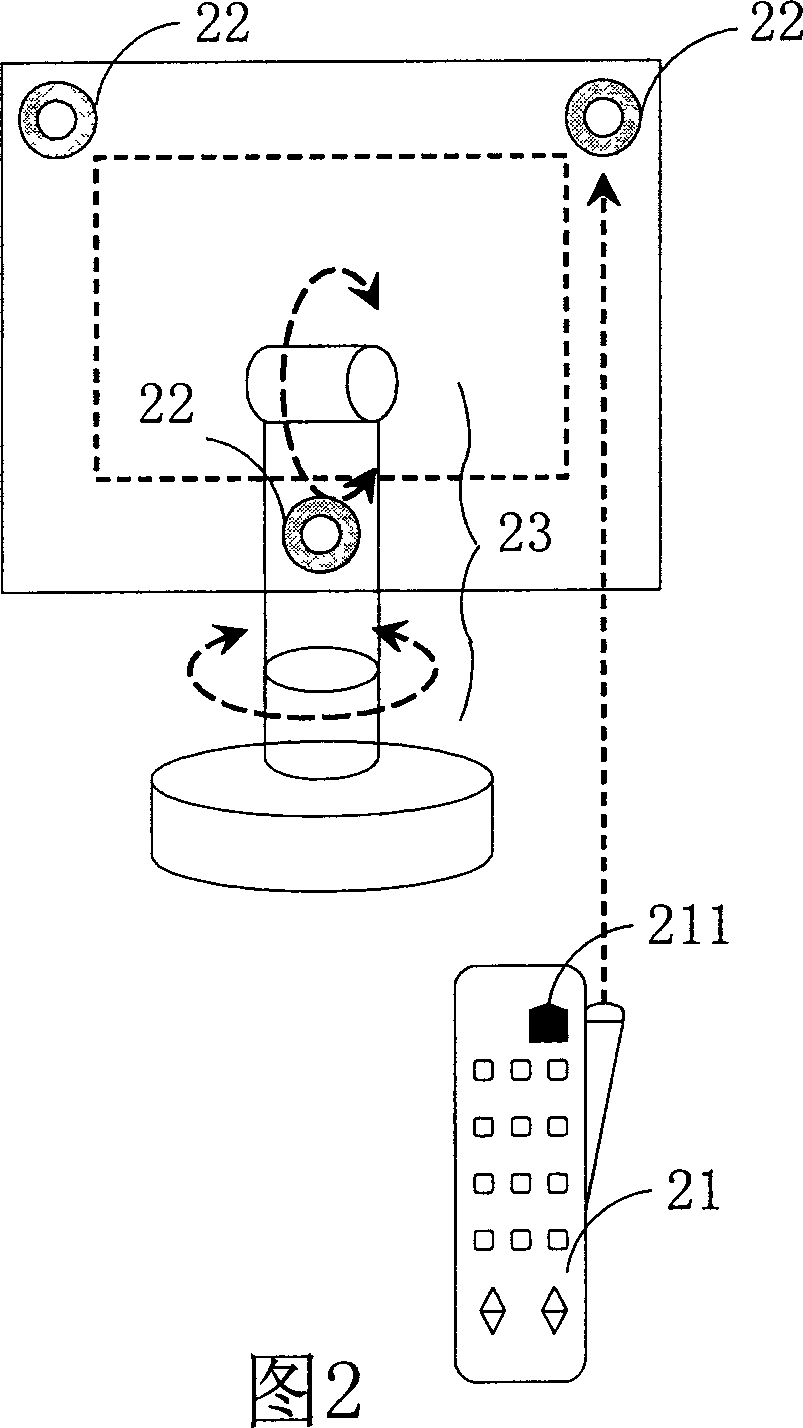

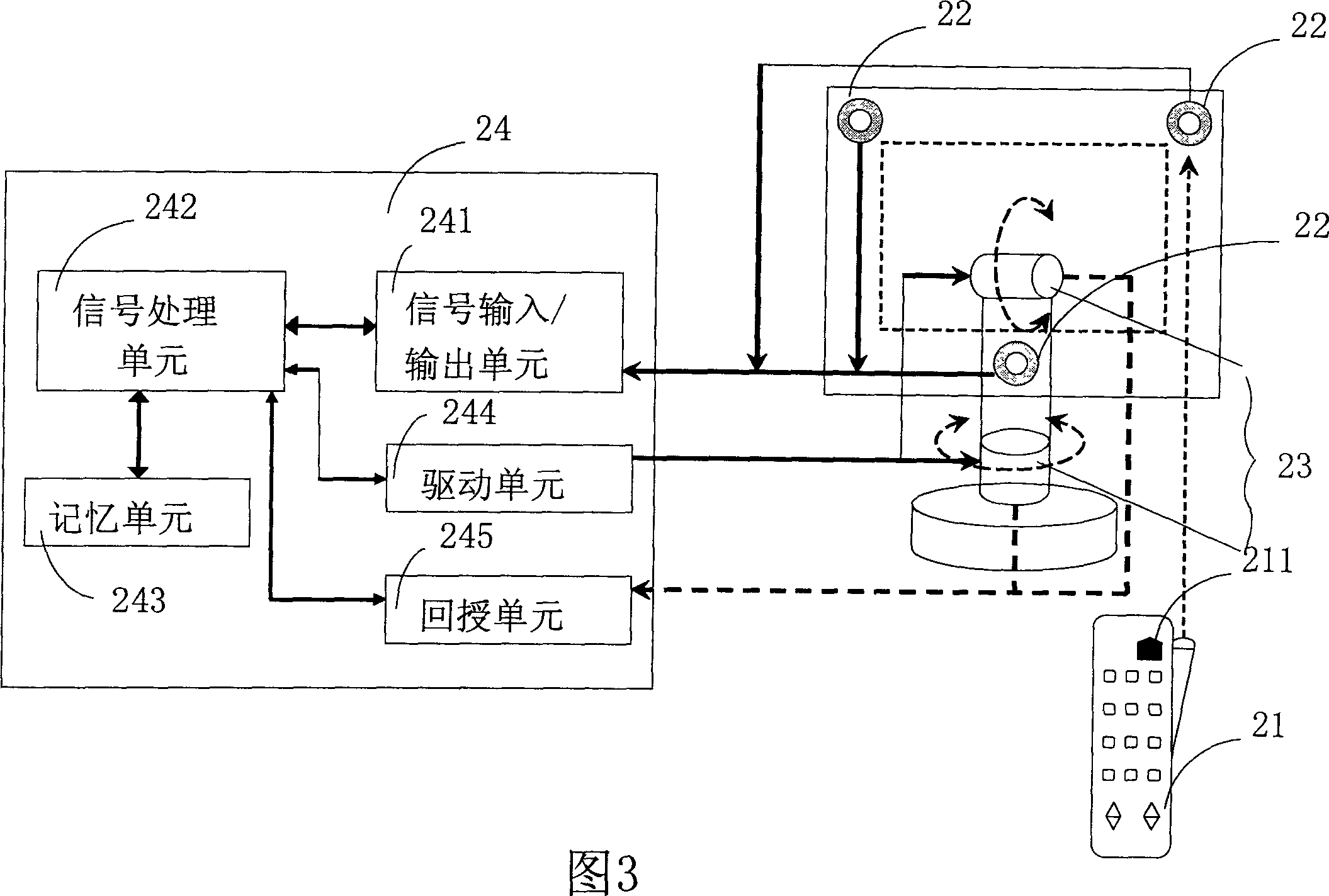

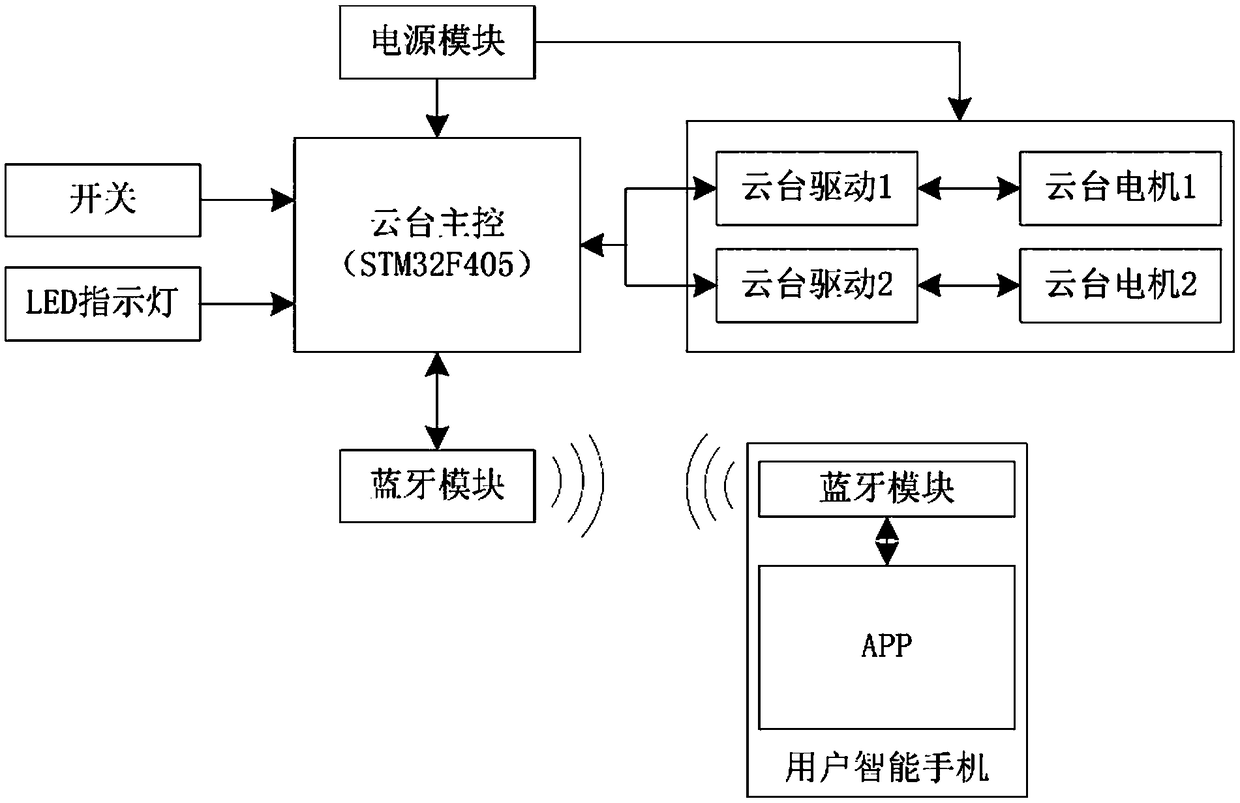

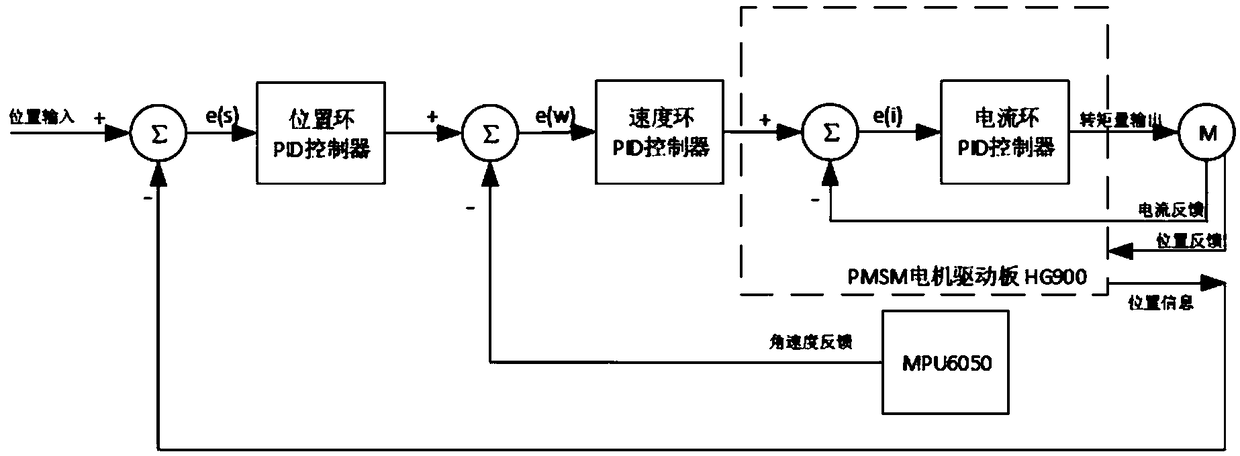

Intelligent shooting holder control method based on face recognition

InactiveCN109391775ASolve appearanceFix the angle problemTelevision system detailsColor television detailsFace detectionAutomatic control

The invention provides an intelligent shooting holder control method based on face recognition, which comprises the following steps: S1, performing starting ; S2, performing initialization operation;S3, extracting a video frame and preprocessing the same; S4, performing face detection; S5, judging whether a face exists or not, if not, returning to step S3, and if yes, proceeding to the next step;S6, waiting for a user to select a target face; S7, determining a target face; S8, extracting a video frame and preprocessing the same; S9, performing face detection. The invention also provides an intelligent shooting holder control system based on face recognition. The method and the system have the advantages that a two-axis holder is controlled based on the face recognition, the two-axis holder can be automatically controlled so that the camera is always aimed at the target face, and the shooting problems of framing-out, inconvenient control and difficult angle control in self-shooting are solved, and the operation is convenient and the cost is low.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

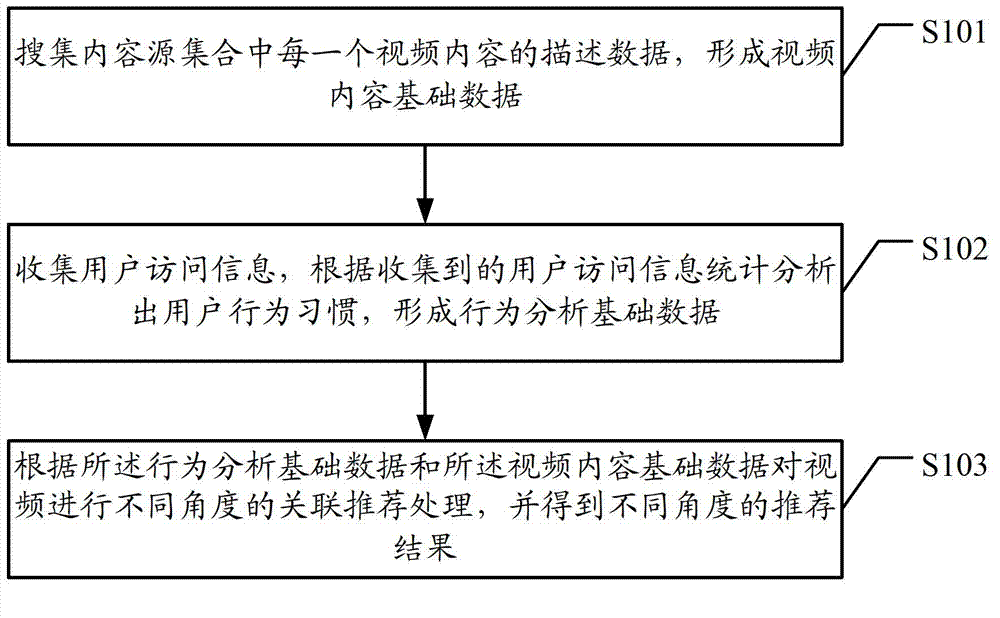

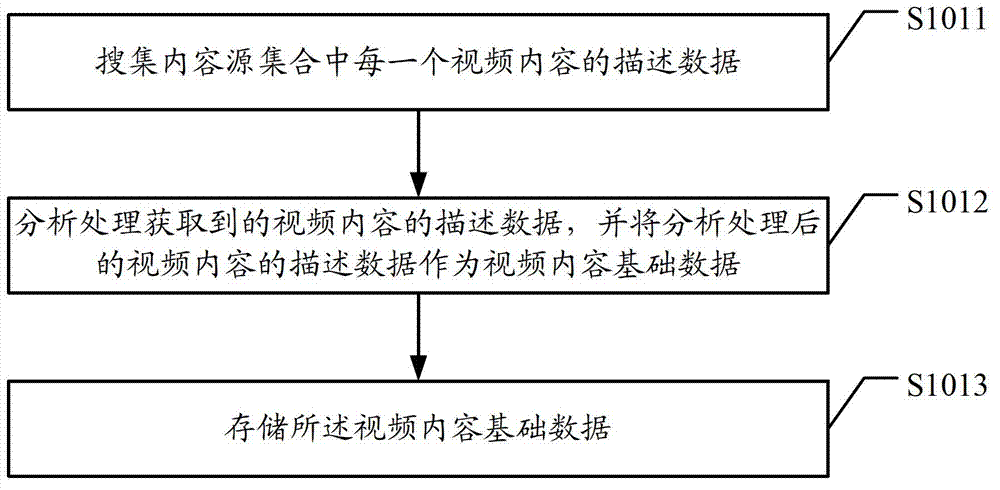

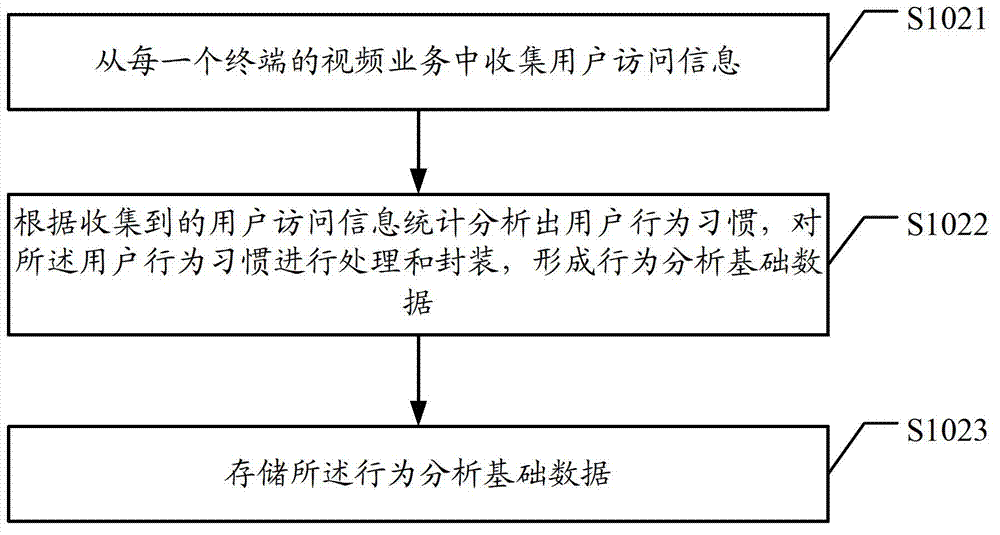

Video relevant recommendation method and server

InactiveCN103096139ASolve efficiency problemsFix the angle problemSelective content distributionForm analysisBehavioral analytics

The invention discloses a video relevant recommendation method and a server. The video relevant recommendation method includes the steps: collecting description data of contents of each video in a content source set to form video content essential data, collecting visit information of users, statistically analyzing behavioral habits of the users according to the collected visit information of the users to form analysis essential data, and carrying out relevant recommendation processing from different angles on videos according to the video content essential data and the analysis essential data to acquire recommendation results from the different angles. The video relevant recommendation method and the server are applied, and carrying out intelligent relevant recommendation on huge amounts of videos can be achieved.

Owner:SHENZHEN LONG VISION

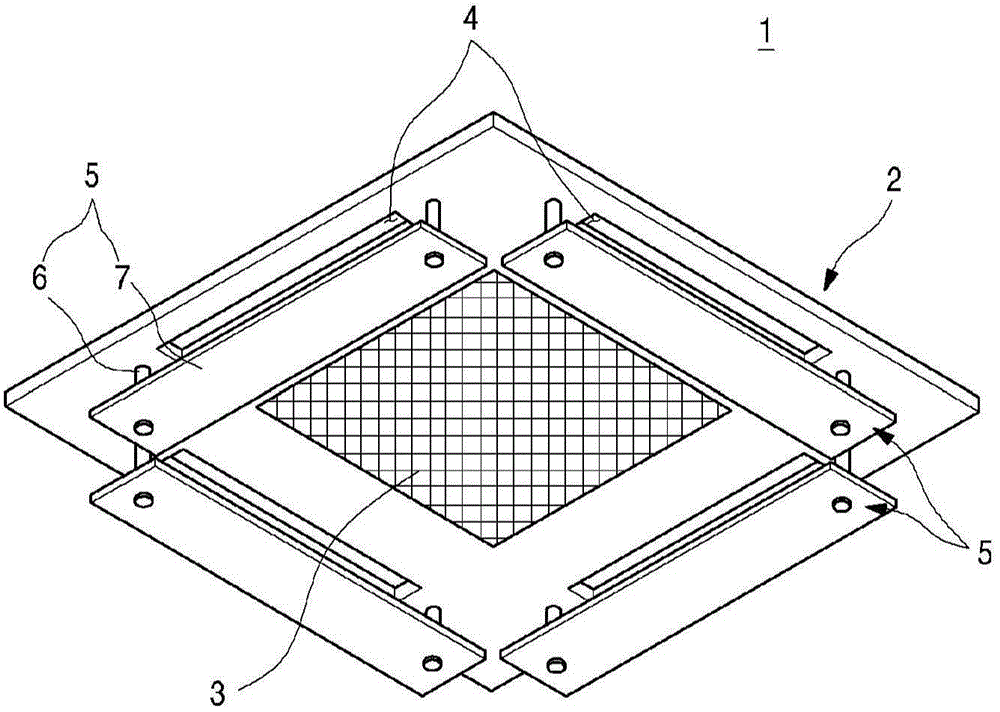

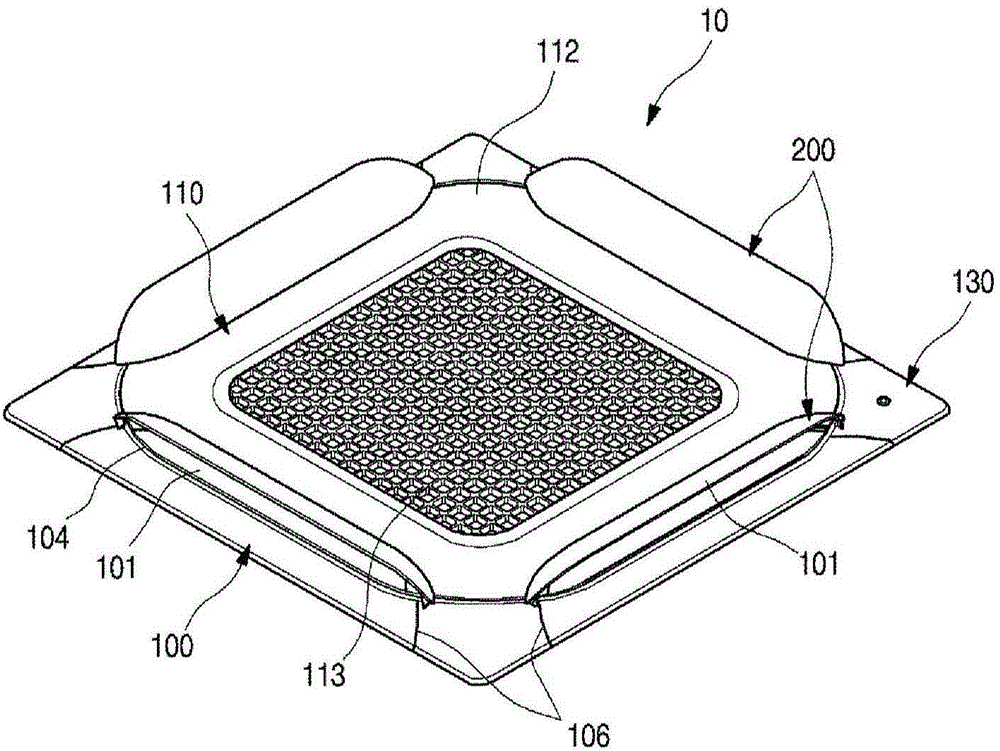

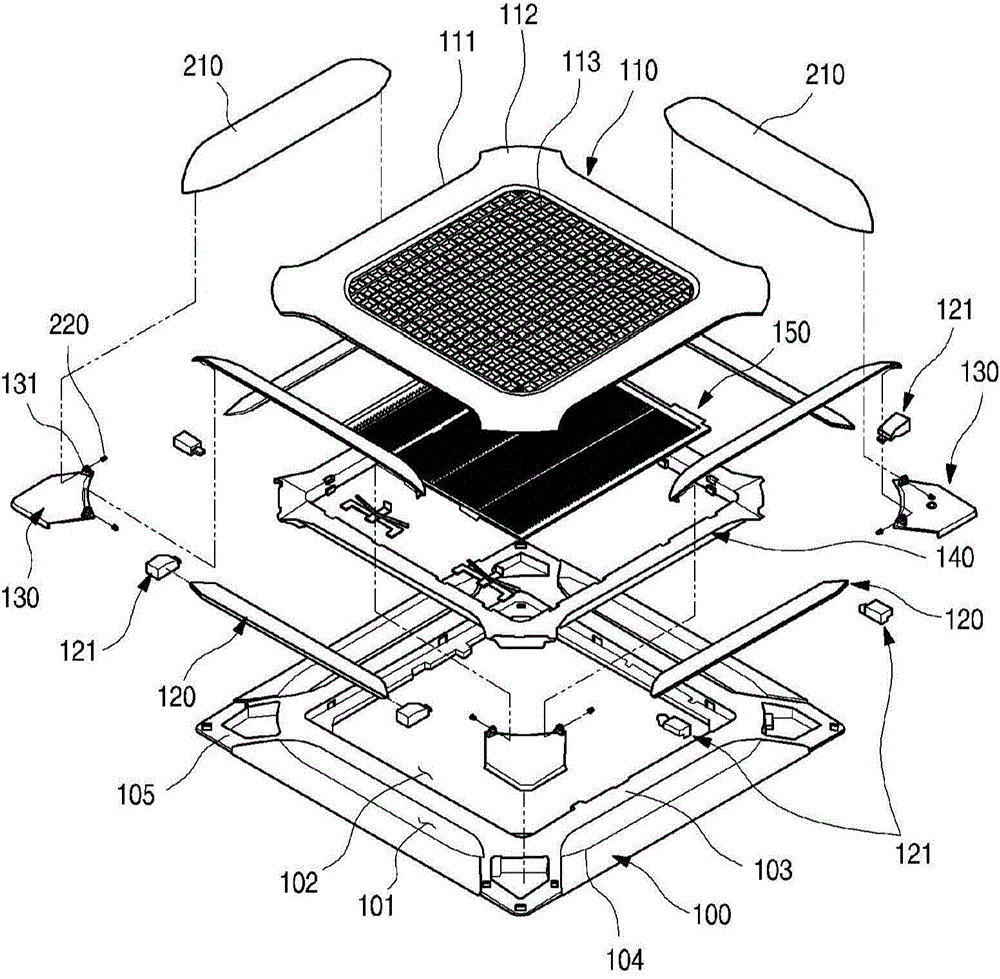

Indoor device for air conditioner having wind visors

ActiveCN104807081AFix the angle problemSolve liquidity problemsDucting arrangementsLighting and heating apparatusEngineeringAir conditioning

Provided are a wind visor and an indoor unit for an air conditioner having the wind visor. The wind visor has a shape corresponding to that of a discharge hole and is directly rotatably mounted on a bottom surface of the indoor unit to guide discharged air, thereby providing a more simplified structure. A fixing part on which the wind visor is installed is provided in the indoor unit, and the wind visor is rotatably coupled to the fixing part through the simplified structure.

Owner:LG ELECTRONICS INC

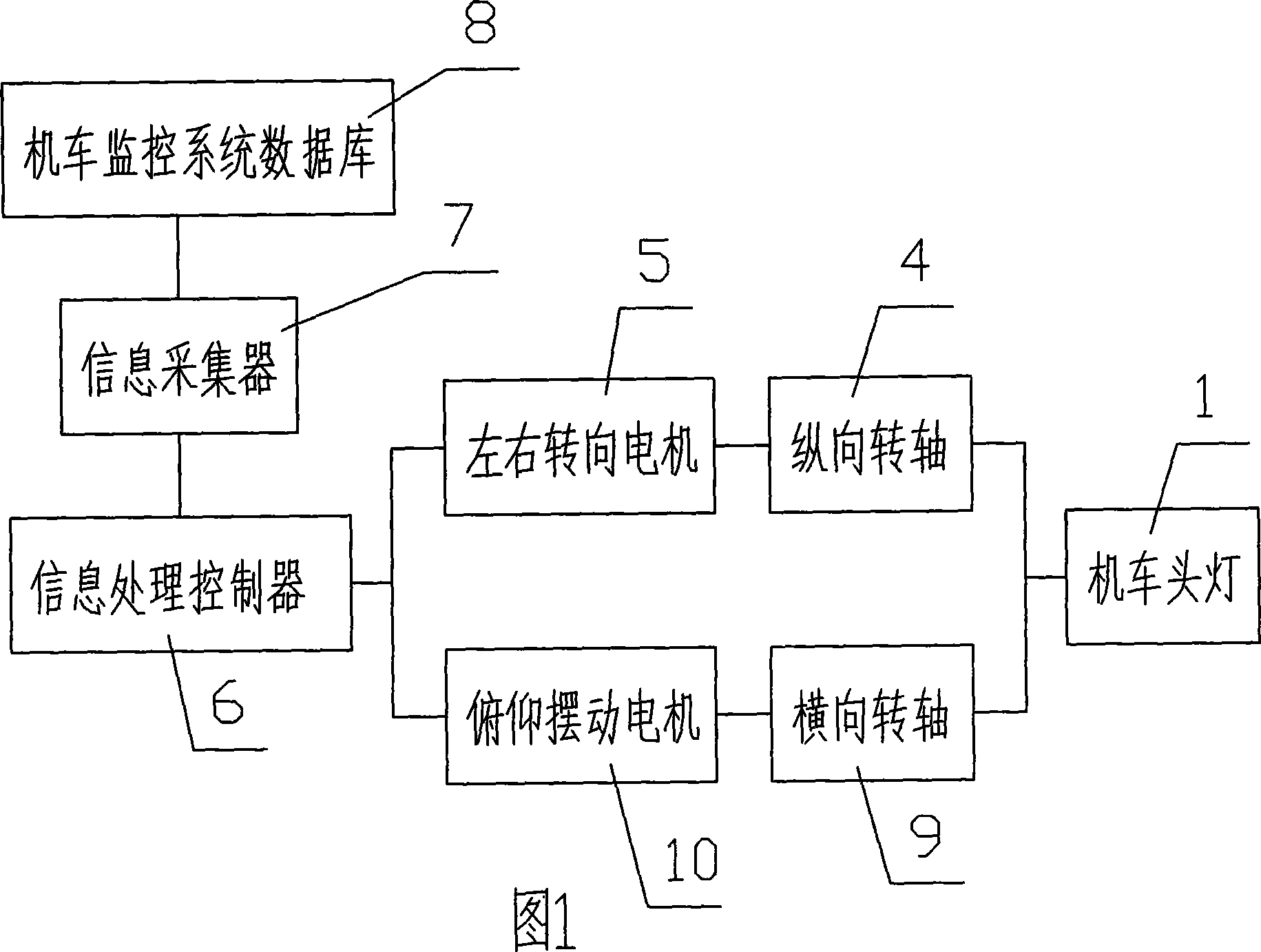

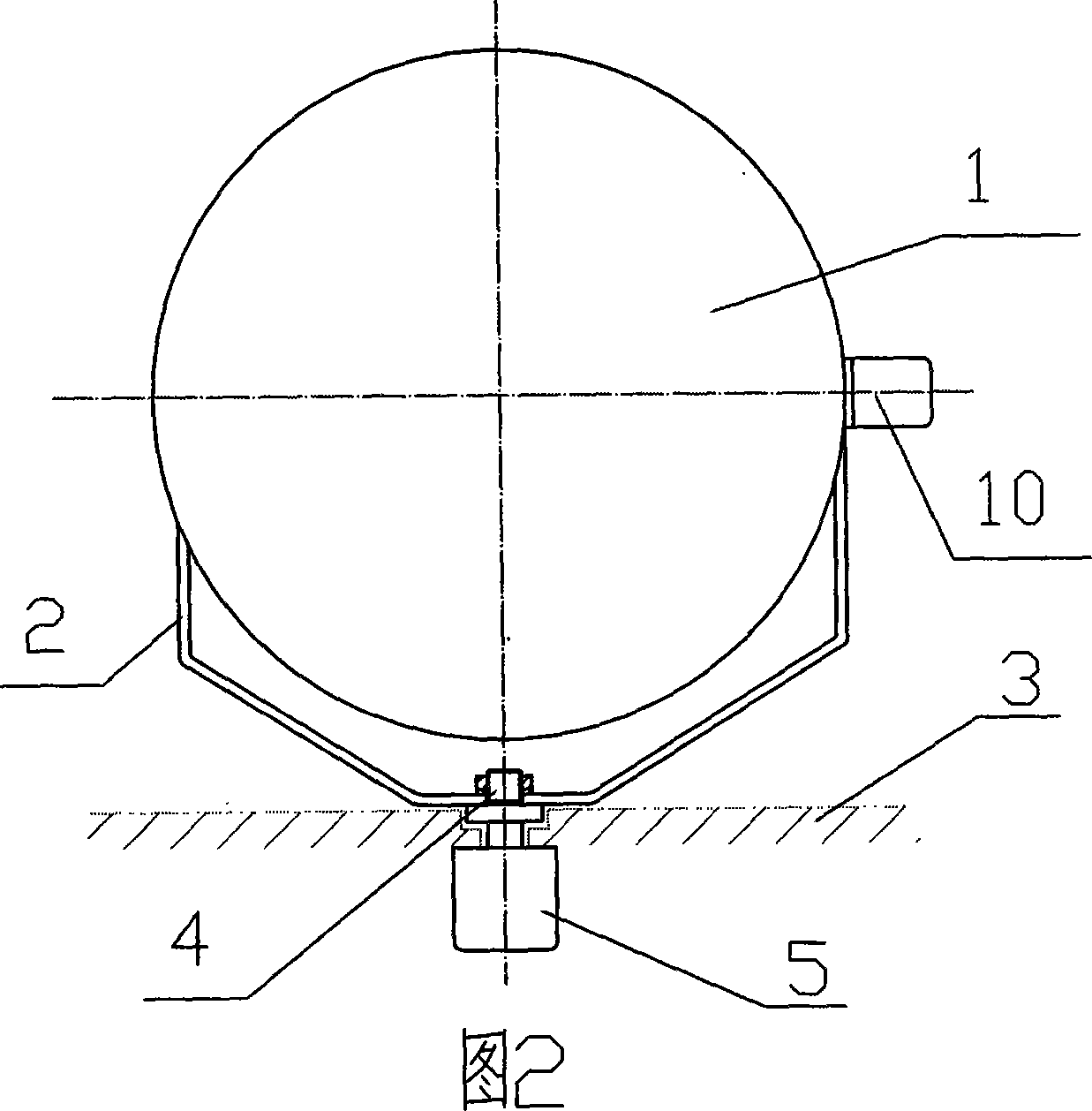

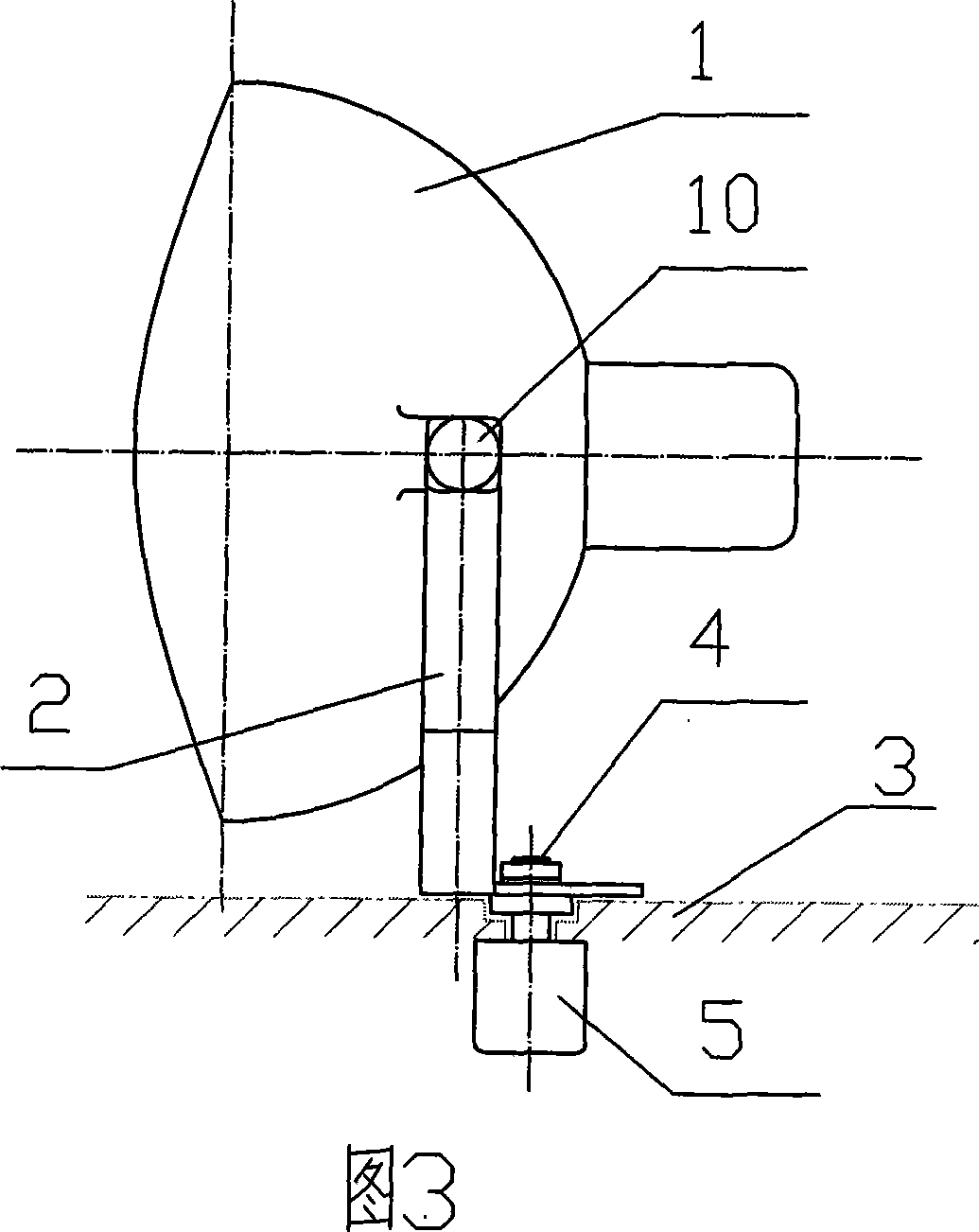

Rail facility engine hatch lamp device capable of automatic regulatiing irradiation angle followed by topographic form

InactiveCN101077711AFix the angle problemSolve needsSignalling indicators on vehicleOptical signallingMotor driveMonitoring system

The railroad locomotive headlamp unit capable of regulating the illuminating angle of the lamp automatically with the landform includes a head lamp, a steering stand for mounting the head lamp, a longitudinal rotation shaft for connecting the steering stand to the locomotive, a steering motor with output shaft connected to the longitudinal rotation shaft, and an information processor, which has a signal output connected to the motor driving controller, a signal input connected through an information acquirer to the locomotive monitoring system database to obtain the real-time landform parameters and a headlamp steering program. The present invention can steering the headlamp automatically according to the landform parameter, so as to regulate the illuminating angle and reach good illuminating effect.

Owner:北京汇梦沃德高新科技有限公司

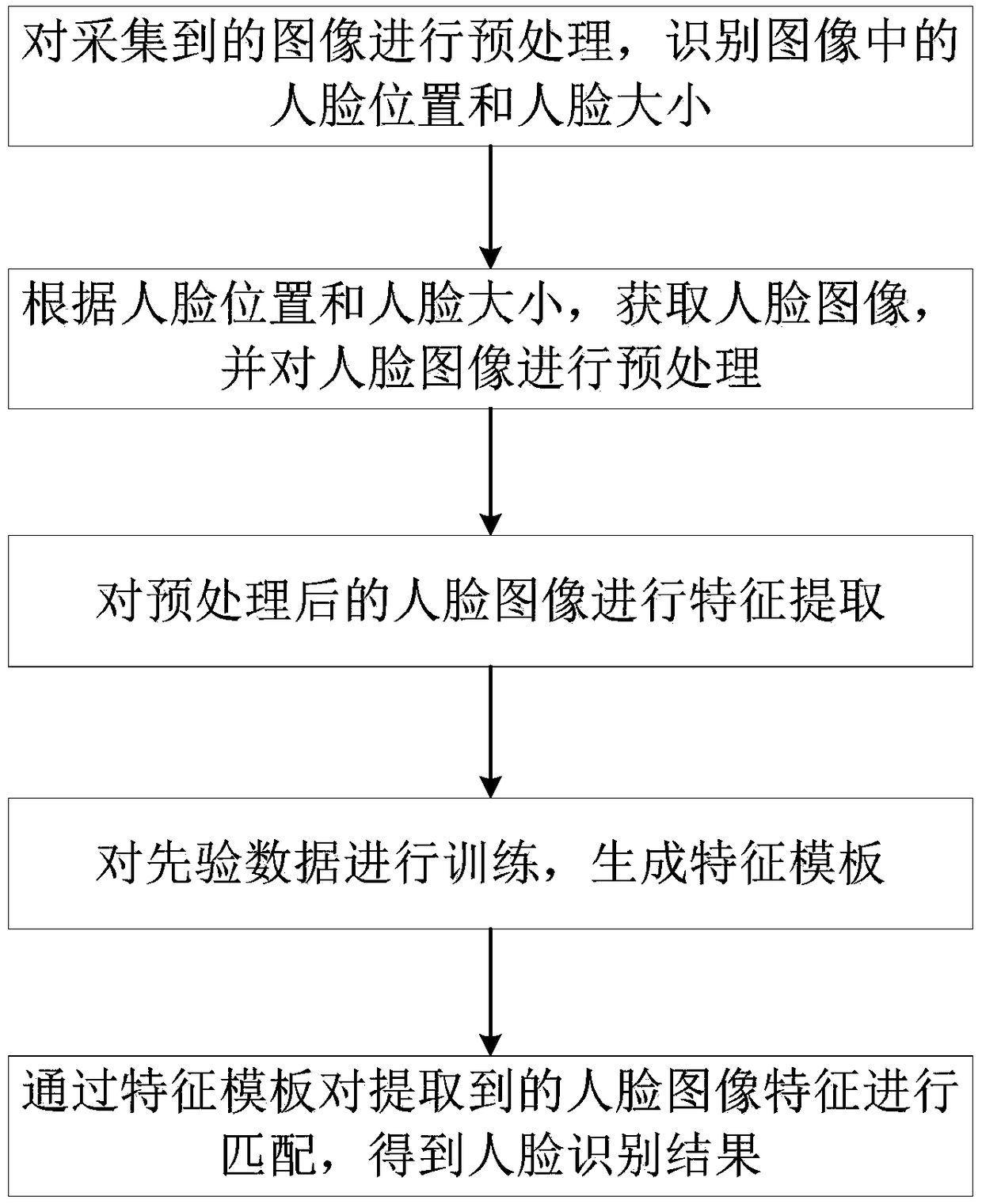

Face recognition method, system and storage medium

InactiveCN109508700AImprove accuracyFix the angle problemCharacter and pattern recognitionTemplate matchingFeature extraction

The invention discloses a face recognition method, system and a storage medium. According to the position and size of human face, obtaining the human face image, and preprocessing the human face image; extracting features of the preprocessed face image; Training the prior data to generate a feature template; taking The feature template to match the extracted face image features, and obtaining theface recognition results. The invention adopts a face recognition method based on feature template matching, a stereo-adjustable shape vector training sample is established based on the characteristics of human face, After locating the human face position, the human face image is matched through the feature template, which solves the problem that the prior art is easily affected by the observation angle, occlusion and expression change in the process of face recognition, improves the accuracy of face recognition, and can be widely used in the field of depth learning technology.

Owner:GUANGZHOU YUEJIAN SANHE SOFTWARE

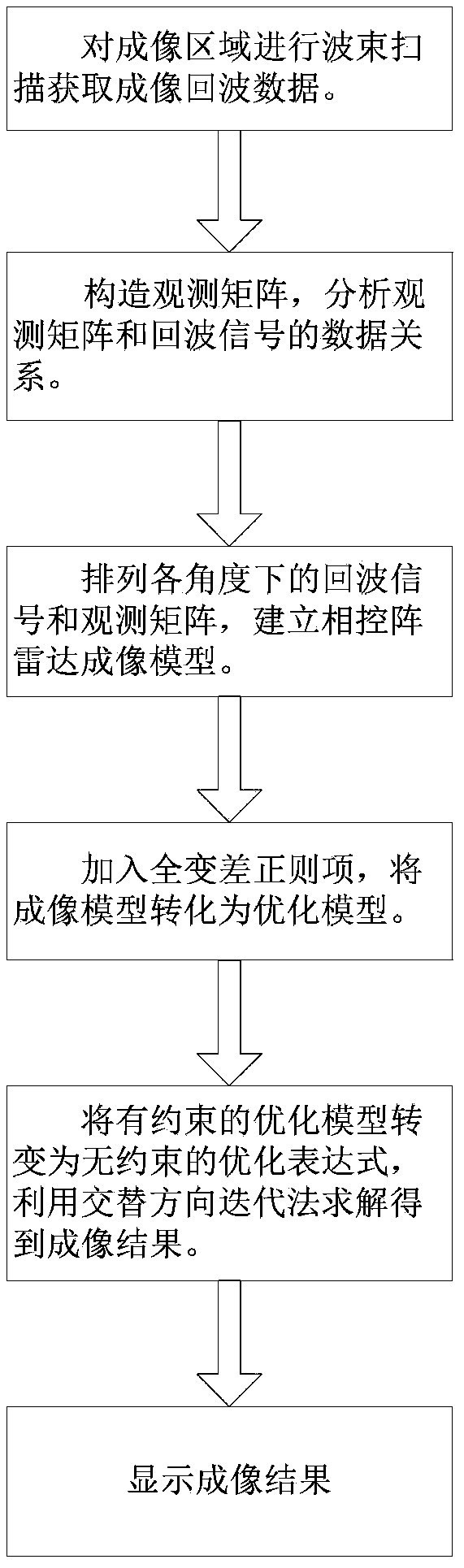

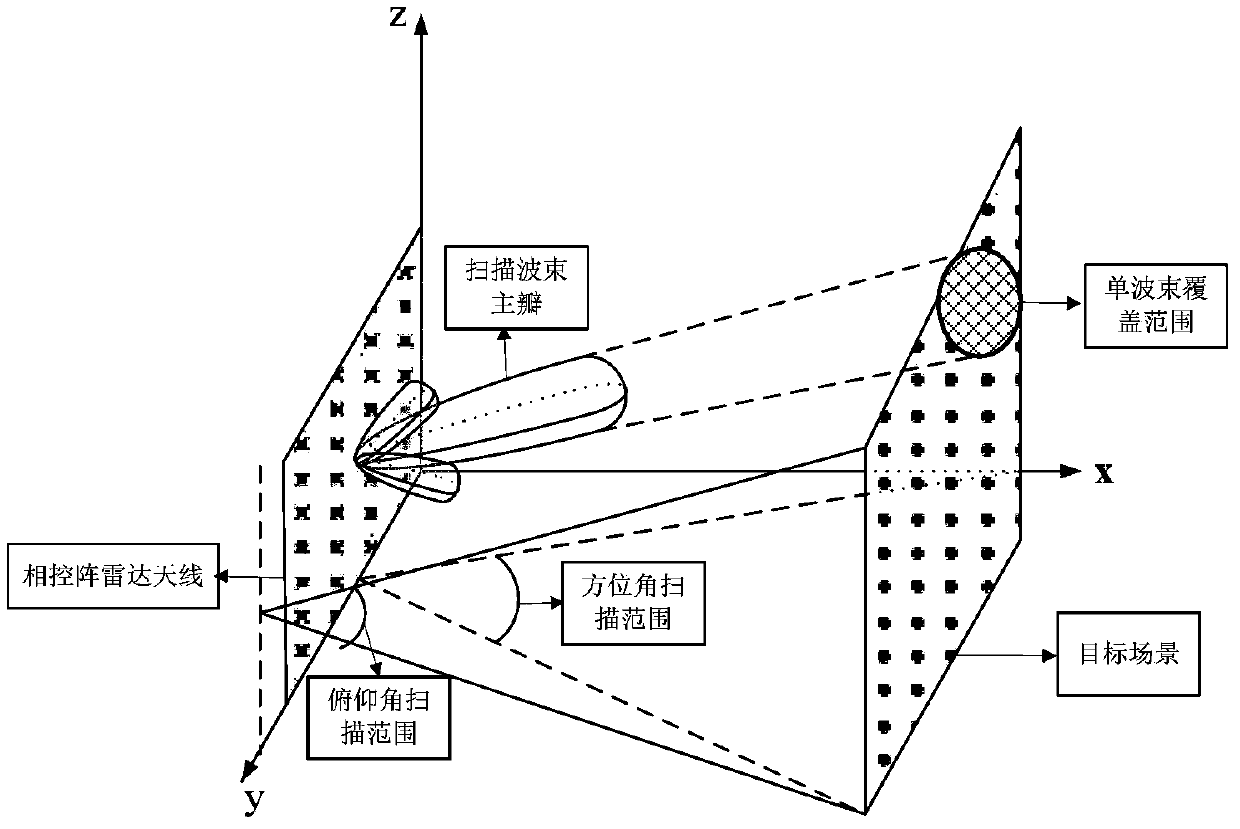

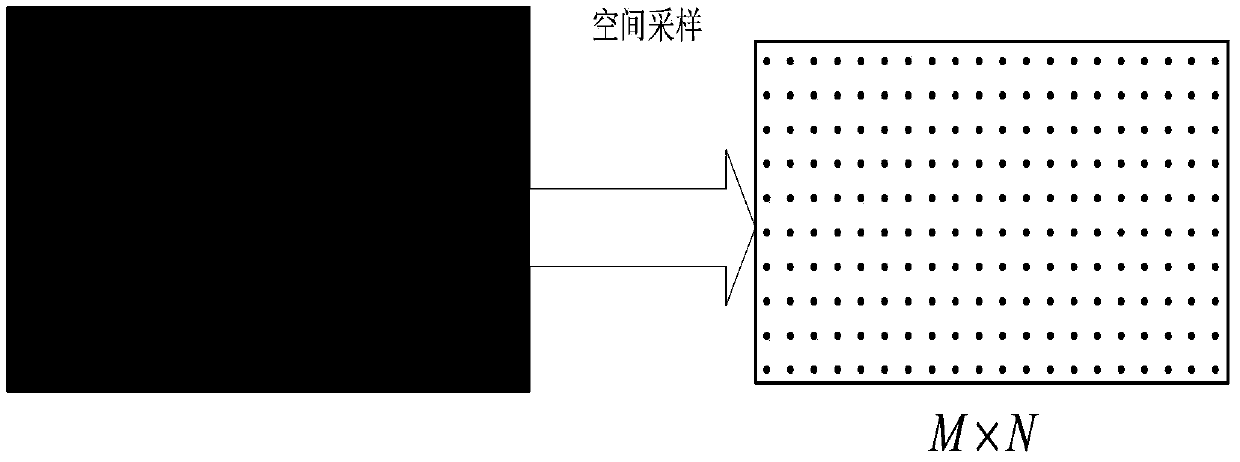

High-resolution detecting and imaging method for real-aperture phased array radar

InactiveCN103399315ARealize high-resolution imagingFix the angle problemRadio wave reradiation/reflectionPhysicsImage resolution

The invention discloses a high-resolution detecting and imaging method for a real-aperture phased array radar, and mainly solves the problem that the conventional phased array radar imaging system cannot image a target region with high resolution due to lower angle resolution. The high-resolution detecting and imaging method comprises the following implementation steps of (1) acquiring an echo signal according to a working mode of the phased array radar; (2) constructing an observation matrix in an ideal form of the echo signal; (3) constructing a phased array radar imaging model according to a relation between the echo signal and the observation matrix; (4) converting the radar imaging model into an optimization model by a regularization method according to prior information of the sparseness of a contour of a target scene; and (5) converting the restraint optimization model into a non-restraint optimization expression and obtaining a final imaging result by an alternating direction iteration method. According to the high-resolution detecting and imaging method, the detecting and imaging times and the detection data can be reduced, and high-resolution imaging for the target region with an obvious contour characteristic can be realized; and the high-resolution detecting and imaging method can be used for target identification.

Owner:XIDIAN UNIV

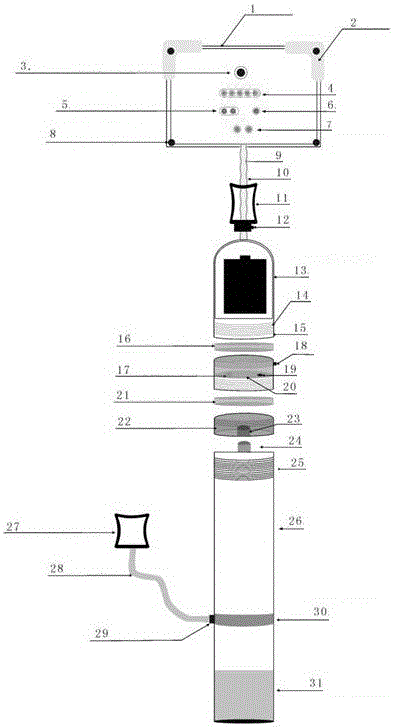

Retractable infrared image acquisition instrument

ActiveCN106713863AEasy to watchAvoid unexpected situationsNon-electrical signal transmission systemsClosed circuit television systemsUniversal jointComputer science

The present invention provides a retractable infrared image acquisition instrument. The retractable infrared image acquisition instrument comprises an image acquisition device, a retractable supporting device and a terminal fixing support; the image acquisition device is fixed at the top end of the retractable supporting device through a universal tube; the terminal fixing support is fixed to the lower end of the retractable supporting device through a universal joint; the image acquisition device includes a shell, a camera mounted within the shell, an LED light compensating lamp, an infrared emitter and an infrared receiver, wherein the LED light compensating lamp, the infrared emitter and the infrared receiver are mounted below the camera; the retractable supporting device comprises a retractable insulating rod and an insulating battery cabin; the top of the insulating battery cabin is connected with the bottom of the shell through the universal tube; the lower end of the retractable insulating rod is provided with a fixing ring; the fixing ring is provided with a fixing clamping position; and the terminal fixing support is fixed onto the fixing clamping position through the universal joint. The retractable infrared image acquisition instrument of the invention is convenient to carry and is simple to operate. With the retractable infrared image acquisition instrument of the invention adopted, power outage is not required, a user does not need to carry a heavy ladder and can read a meter and take pictures without climbing to a high place. According to the retractable infrared image acquisition instrument, data are transmitted wirelessly, so that work efficiency can be improved.

Owner:广州市华蓝佳声计算机科技有限公司

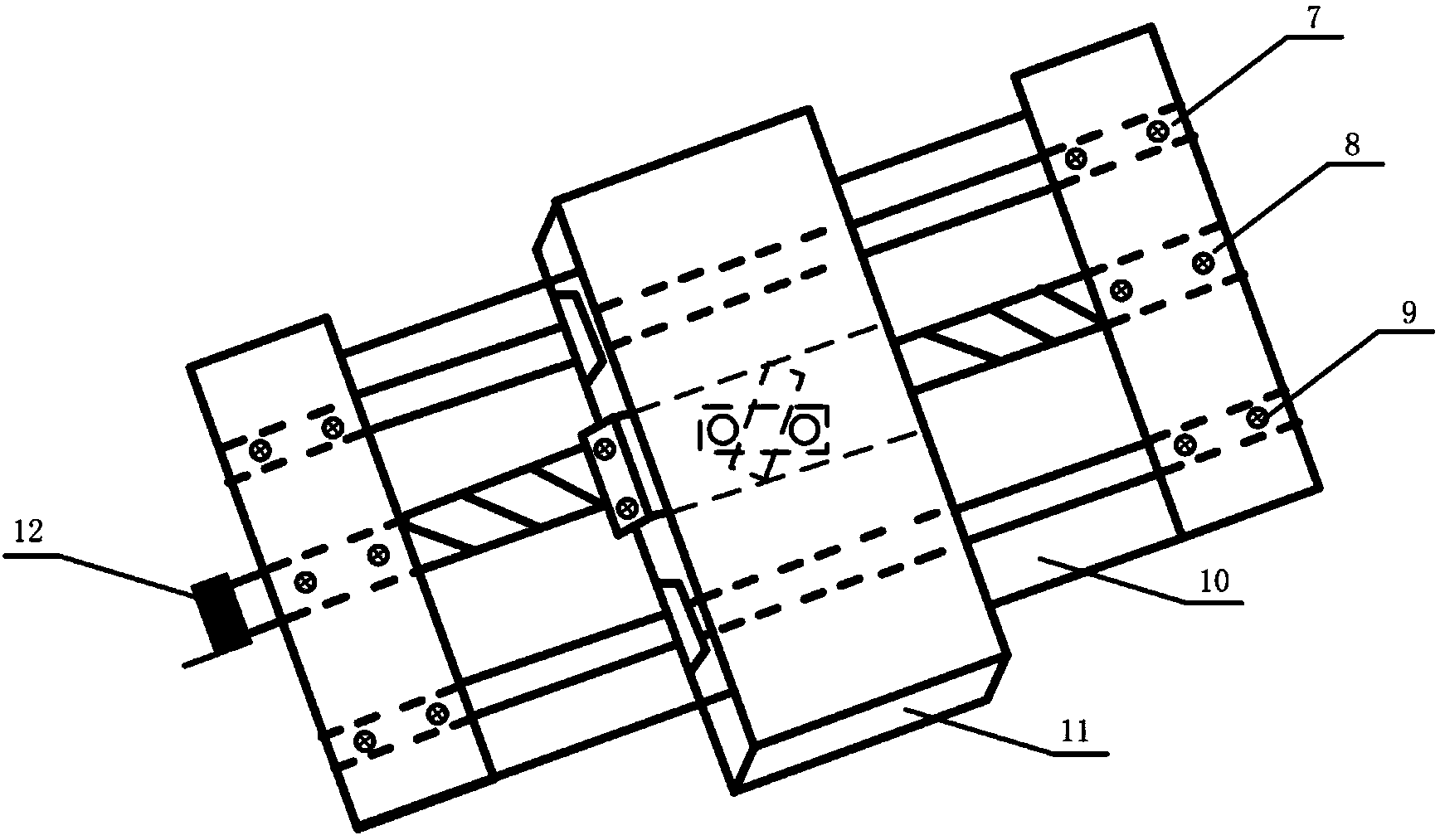

Manufacture device and method of hydrological coupling test three-dimensional fracture rock sample

ActiveCN106989968AAchieve positioningCrack localization achievedPreparing sample for investigationPolyesterGeomorphology

The invention relates to a manufacture device and method of a hydrological coupling test three-dimensional fracture rock sample; the manufacture method comprises a three-dimensional fracture precision positioning sample mold and a high-pressure injection fracture preforming device; the three-dimensional fracture precision positioning sample mold comprises side plate I, side plate II, a bottom plate and positioning porous plates and can provide precision positioning for multiple three-dimensional fractures and forming of a sample. The high-pressure injection fracture preforming device comprises polyester film boxes, cotton threads, rubber water pipes, mandrels and manual screws, and can preform high-pressure injection three-dimensional fractures and form an injection passage. By combining annularly distributed holes and transversely distributed holes, the positioning porous plates are used to allow precision positioning for the angle, spacing and spatial positions of the multiple three-dimensional fractures; the small-diameter rubber water pipes and mandrels to preform hydraulic passages in the sample and communicate the open fractures, high-pressure injection of water is achieved for the open fractures. The manufacture device and method are simple in structure, convenient to operate and good positioning precision and are widely applicable to the hydraulic coupling test for three-dimensional fracture rock materials.

Owner:SHANDONG UNIV

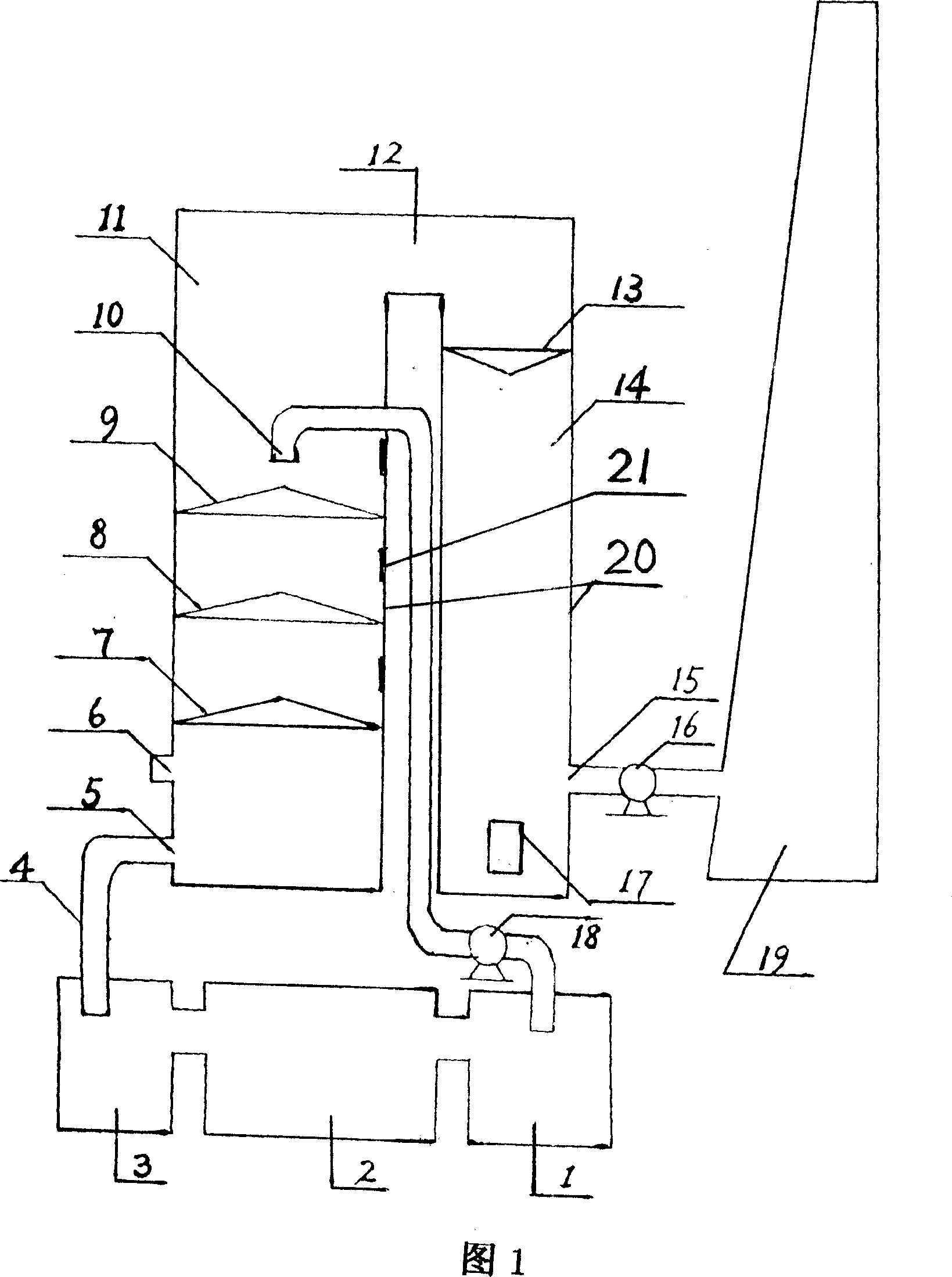

Highly effective wet-process desulfurizing, denitrifying and dedusting process and integration device thereof

InactiveCN1994532ANo pollution in the processIncrease phase flow rateCombination devicesCycloneSulfur

The invention relates to a method for removing sulfur, nitrogen and dust and relative device, wherein the method comprises that: preparing absorber, feeding smoke into main tower, using absorber to remove sulfur, nitrogen and dust, clearing smoke slag, recycling the absorber, dehumidifying the smoke and discharging. And the device comprises that: 1, sulfur-nitrogen-dust removing system formed by cyclone plate tower, tubular liquid feeder, liquid outlet, and smoke inlet; 2, the defroster formed by assist tower and defrost plate tower; 3, and absorber circulate system formed by circuit deposit pool, alkali pool, pump pool and water pump. The invention has low cost and non-second pollution, with long service life.

Owner:江苏溧竹环境工程有限公司

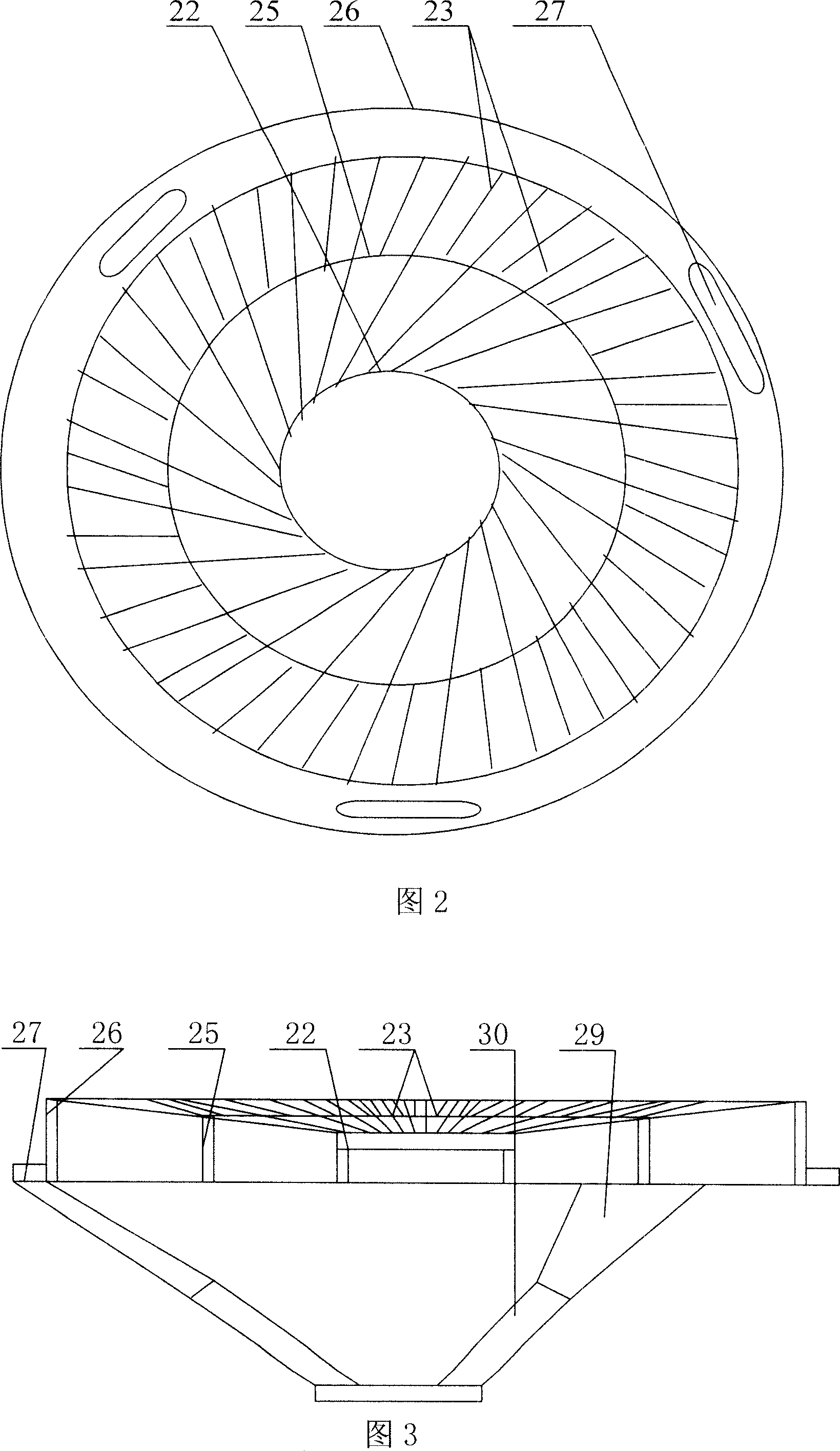

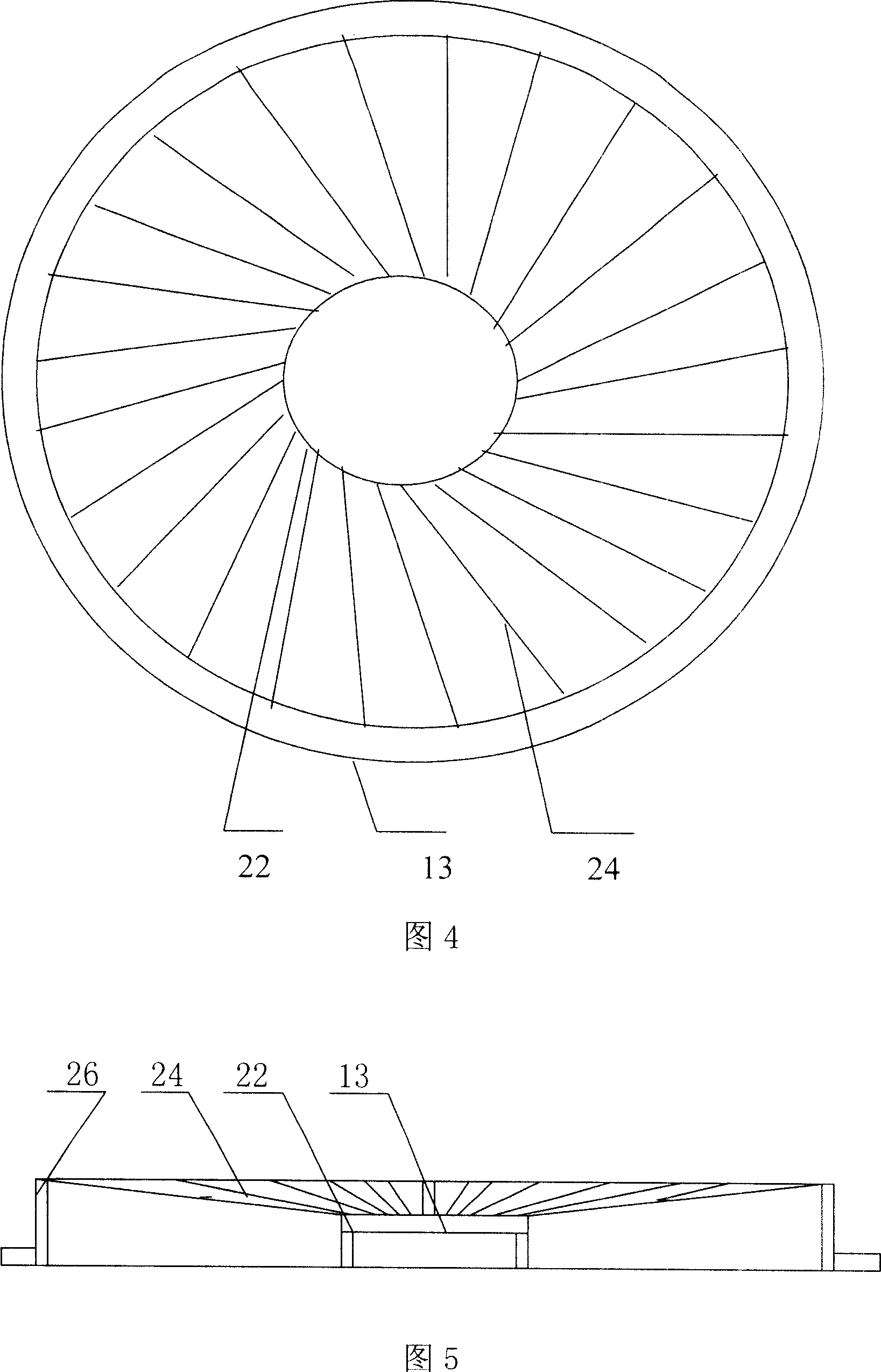

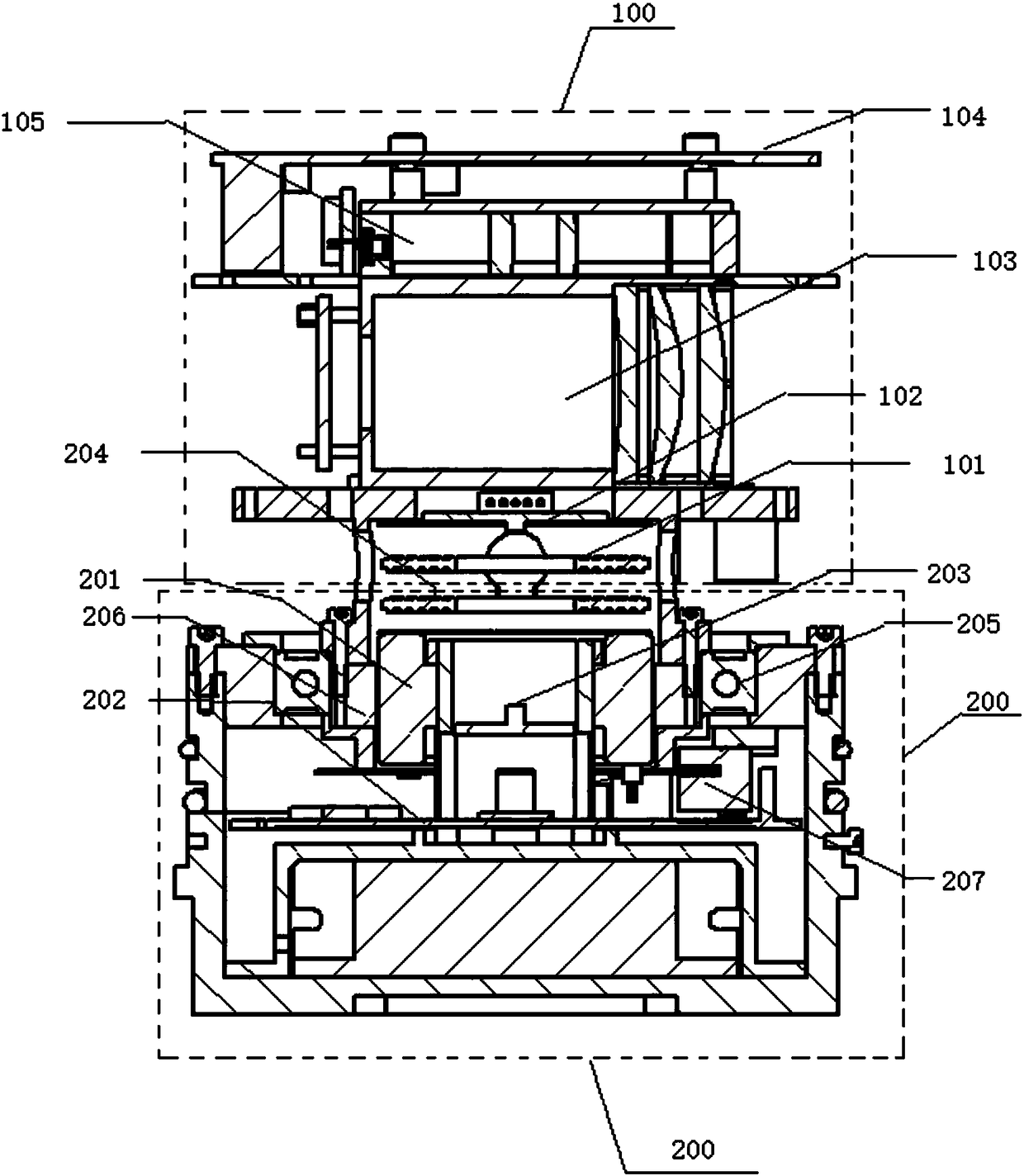

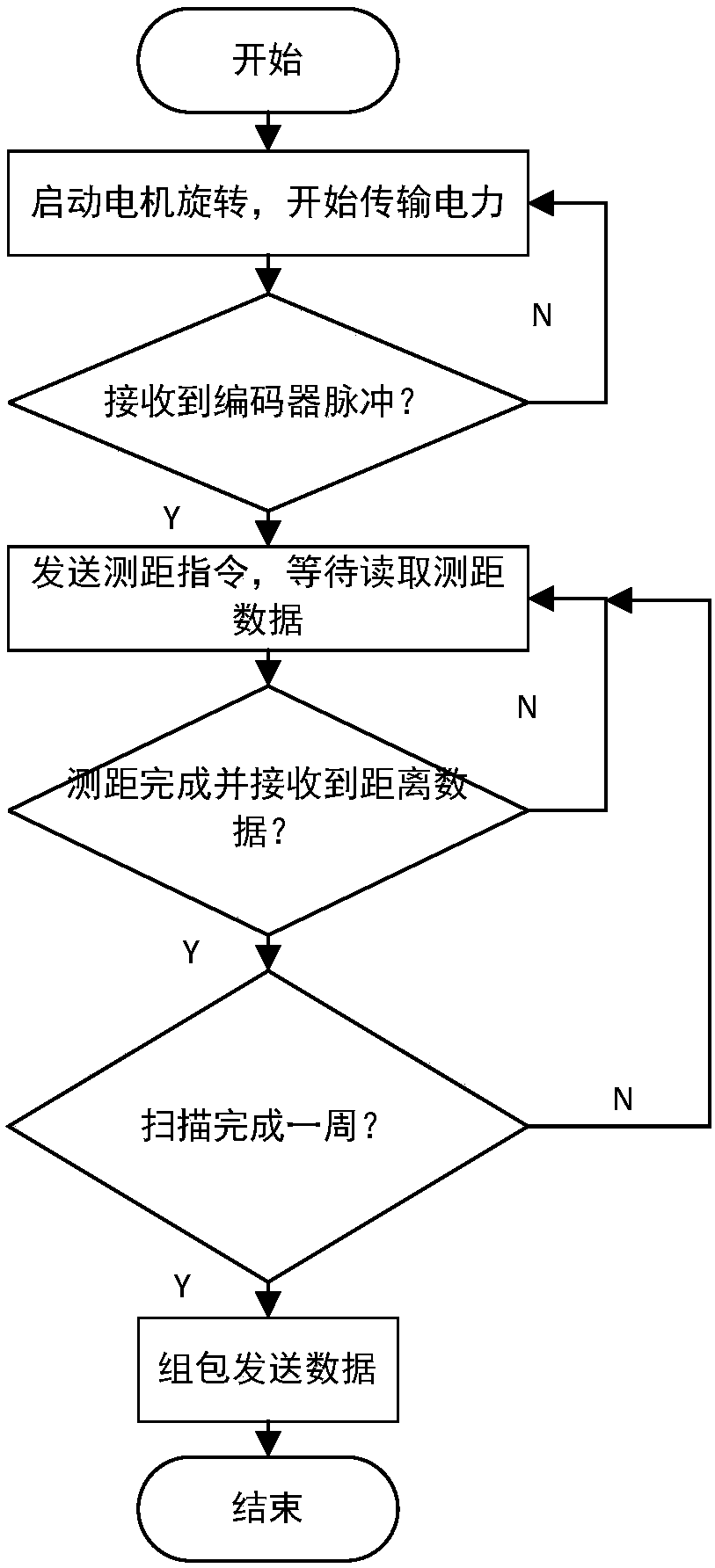

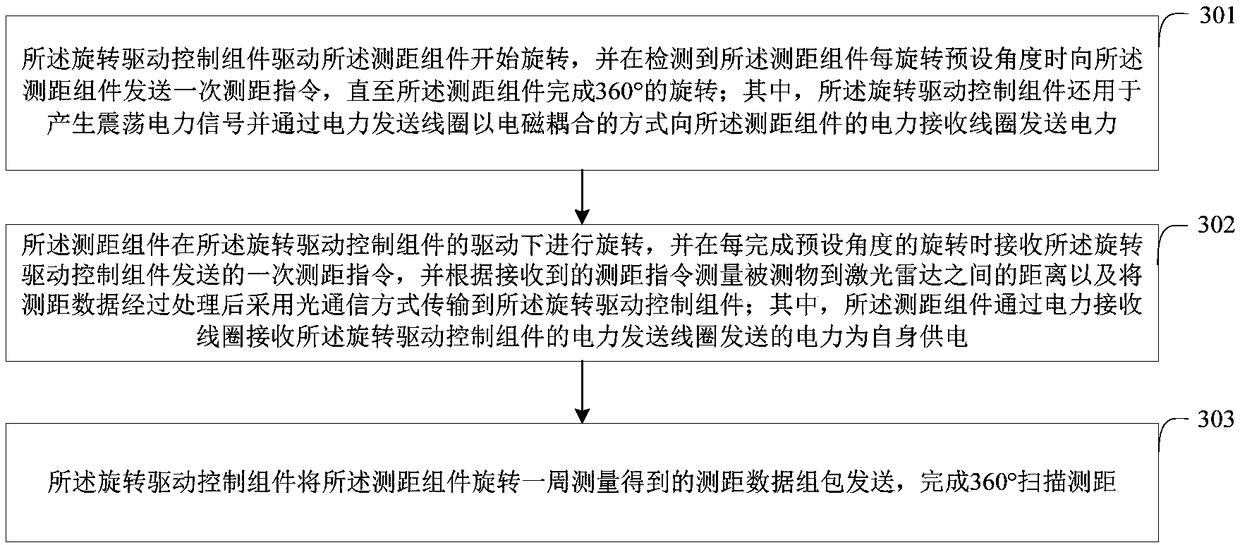

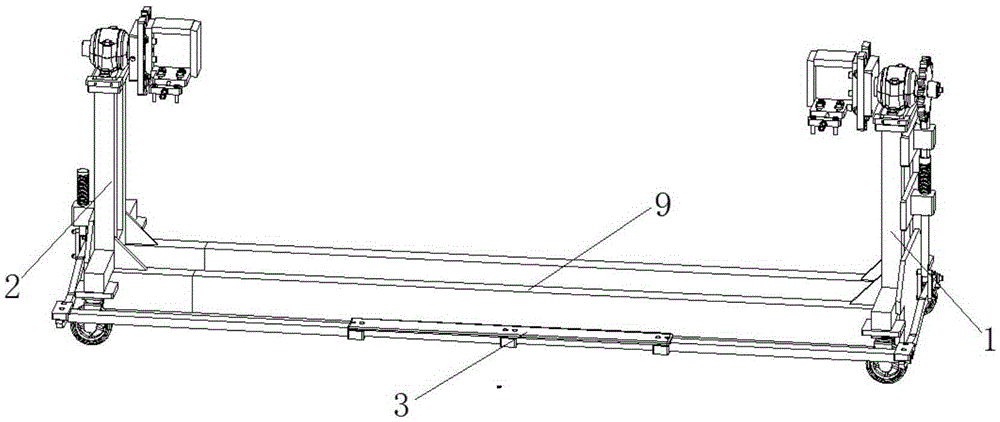

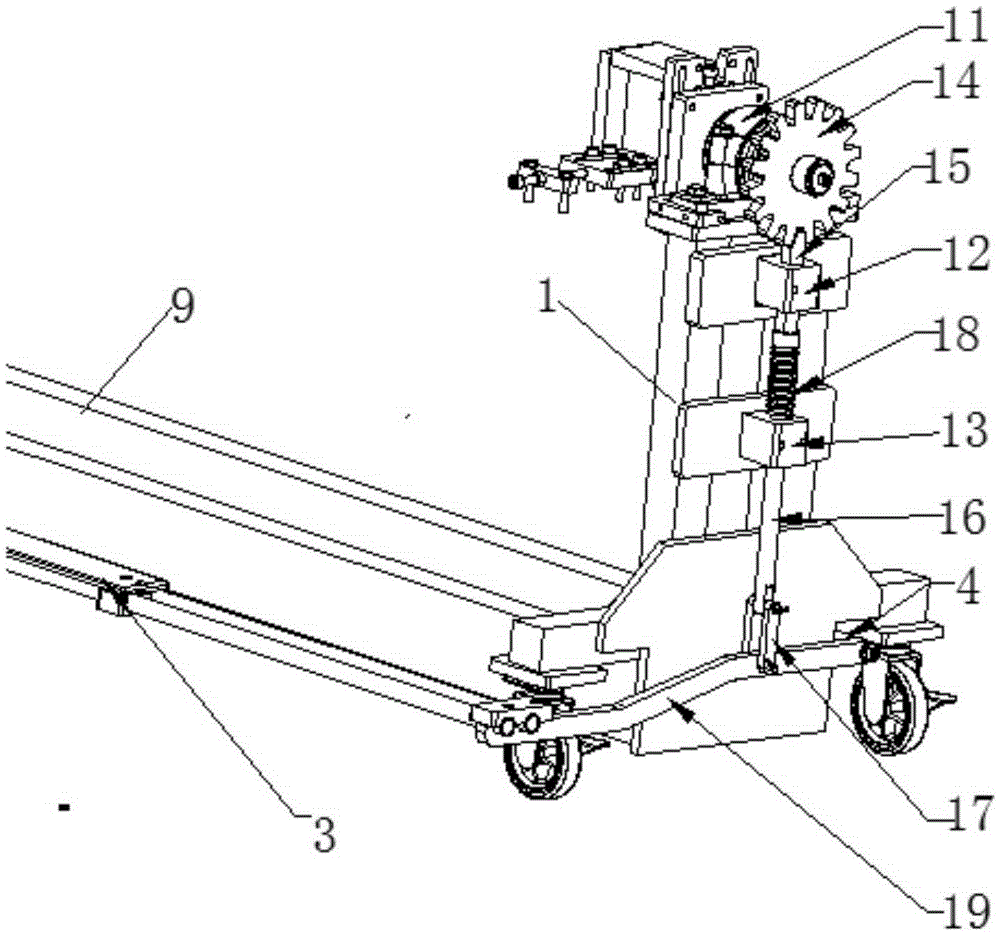

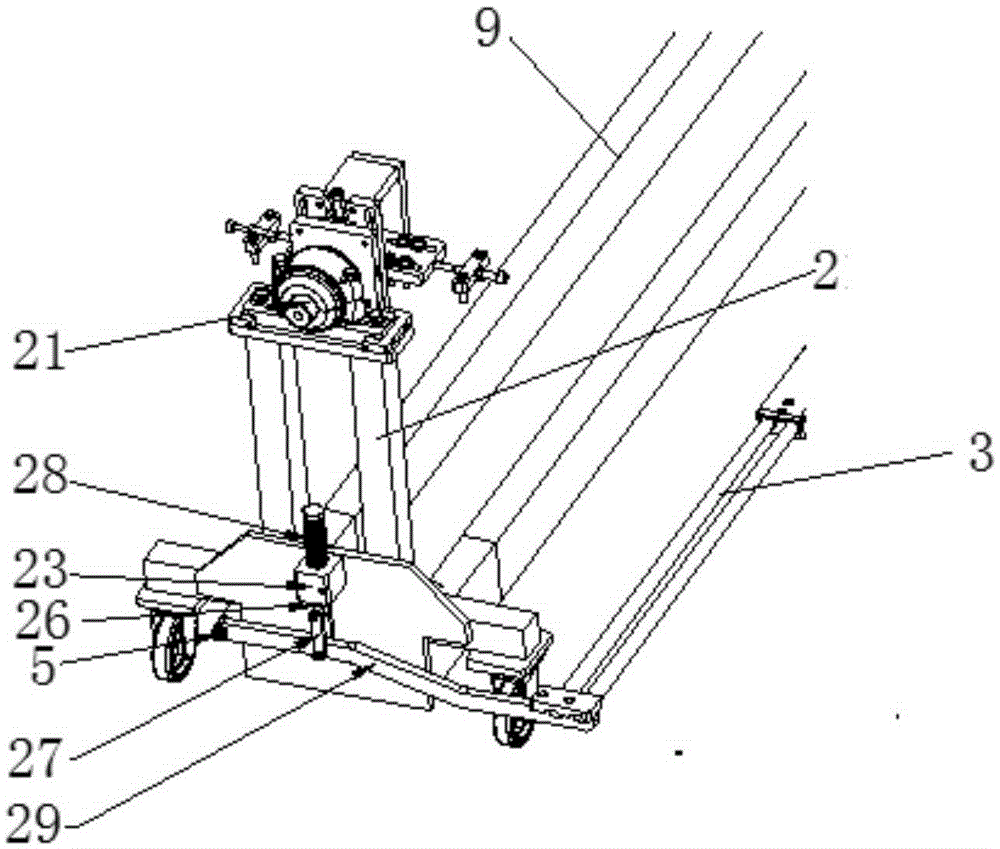

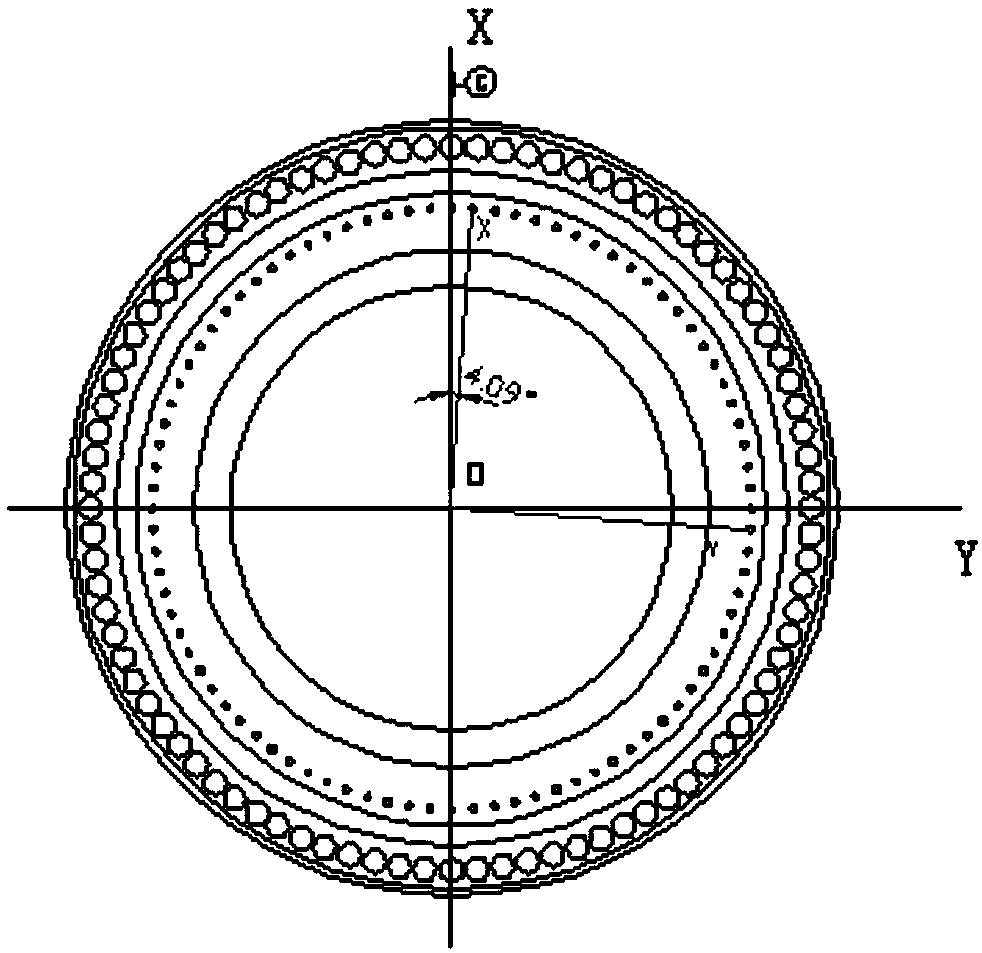

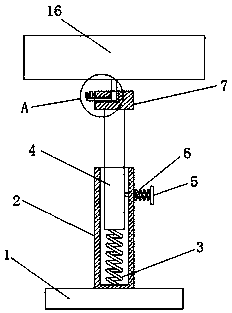

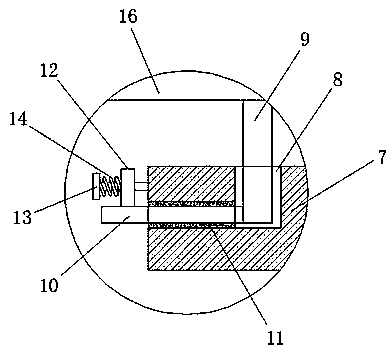

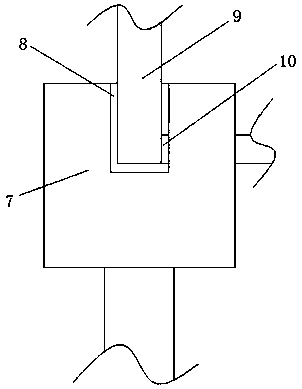

360-degree scanning laser distance measuring system and distance measuring method

InactiveCN108107442ASolve energy lossFix the angle problemOptical rangefindersElectromagnetic wave reradiationLaser rangingProcess Measures

The invention provides a 360-degree scanning laser distance measuring system and distance measuring method. The distance measuring system includes a distance measuring component and a rotation drivingcontrol component; the distance measuring component rotates on the whole under the driving of the rotation driving control component, measures a distance between a measured object and a laser radar after receiving a distance measuring instruction sent by the rotation driving control component, processes measured distance data and transmits the processed distance data to the rotation driving control component through an optical communication mode; and the rotation driving control component is used for driving the distance measuring component to perform 360-degree rotation, sends a distance measuring instruction to the distance measuring component through an optical communication mode and receives distance measuring data sent by the distance measuring component. With the 360-degree scanninglaser distance measuring system and distance measuring method of the invention adopted, limitations such as energy loss and low possibility of realizing 360-degree scanning angles which are caused bya condition that a traditional scanning laser distance measuring system uses a reflector to performing scanning can be eliminated. The 360-degree scanning laser distance measuring system of the invention has the advantages of easiness in realizing miniaturization, long service life and extended application range.

Owner:WUHAN WANJI INFORMATION TECH

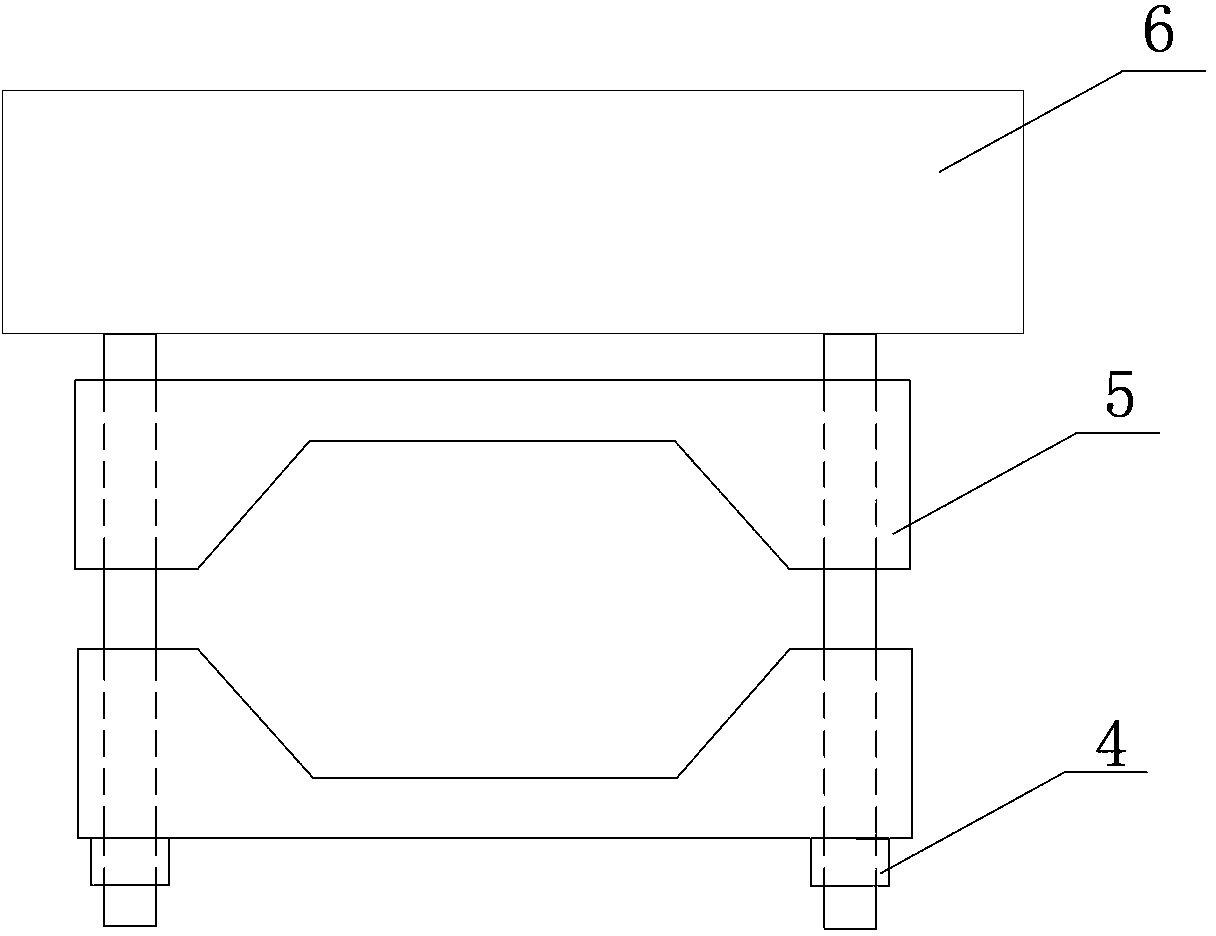

Welding fixture turnover bracket

InactiveCN105328393AImprove welding efficiencyFix the angle problemWelding/cutting auxillary devicesAuxillary welding devicesElastic componentEngineering

The invention discloses a welding fixture turnover bracket which comprises a horizontal bottom cross beam and a pedal parallel to the bottom cross beam, wherein a vertical first bracket and a vertical second bracket are correspondingly arranged at a first end part and a second end part of the bottom cross beam; a first horizontal connecting rod is arranged at the bottom of the outer end face of the first bracket; one end of the first horizontal connecting rod is connected with a first end part of the pedal; the other end of the first horizontal connecting rod is in pivot connection with the first end part of the bottom cross beam; a second horizontal connecting rod is arranged at the bottom of the outer end face of the second bracket; one end of the second horizontal connecting rod is connected with a second end part of the pedal; the other end of the second horizontal connecting rod is in pivot connection with the second end part of the bottom cross beam; a first bearing penetrating through the first bracket along the direction parallel to the bottom cross beam is arranged at the top of the first bracket; the first bearing is in sleeving connection with a gear positioned on the outer end face of the first bracket; an elastic component capable of expanding and contracting in the vertical direction is fixed to the outer end face of the first bracket; the top of the elastic component can be connected with the gear in a clamping manner; and the bottom of the elastic component is in pivot connection with the first horizontal connecting rod.

Owner:SHANGHAI HEDA AUTOMOBILE FITTINGS

Control method for moving mechanism of all-wheel-drive combined attracting-type wall-climbing robot

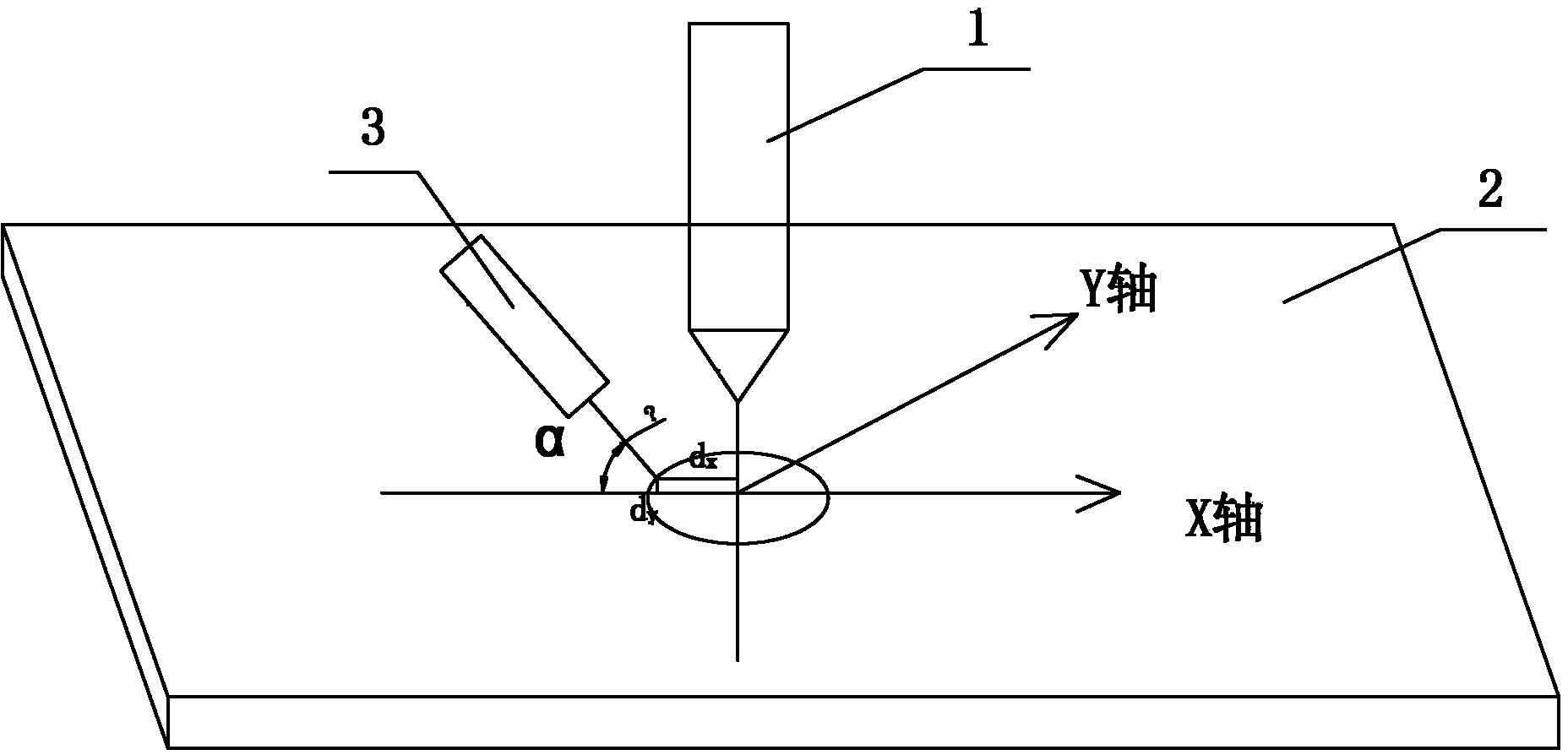

ActiveCN102699921AQuick checkDoes not affect motion controlWelding/cutting auxillary devicesArc welding apparatusHorizontal axisEngineering

The invention belongs to the technical field of specialized robots, and particularly relates to a control method for the moving mechanism of an all-wheel-drive combined attracting-type wall-climbing robot. The control method comprises the following steps: A, acquiring two-dimensional welded joint position information provided by a welded joint tracking sensor, and carrying out filter processing; B, sending a speed command to the motor driver of a crosshead shoe according to the processed information, so as to fulfill the horizontal axis movement and the longitudinal axis movement of the crosshead shoe, and realize the fast accurate movement of a welding gun; C, calculating the distance between a movable platform and a welded joint according to the welded joint position information provided by the welded joint tracking sensor and crosshead shoe motor code disc information; D, calculating the movement parameter of the movable platform according to the information; and E, sending a command to a platform motor driver, so as to fulfill multi-wheel matching movement. The control method has the advantages that the filter processing method can detect error data fast, so as not to impact movement control; the real-time tracking performance on continuous variation of a welded joint is favorable, so as to avoid additional latency; and the responding capability on the wide range step variation of a real welded joint position is better.

Owner:DONGFANG ELECTRIC CORP LTD

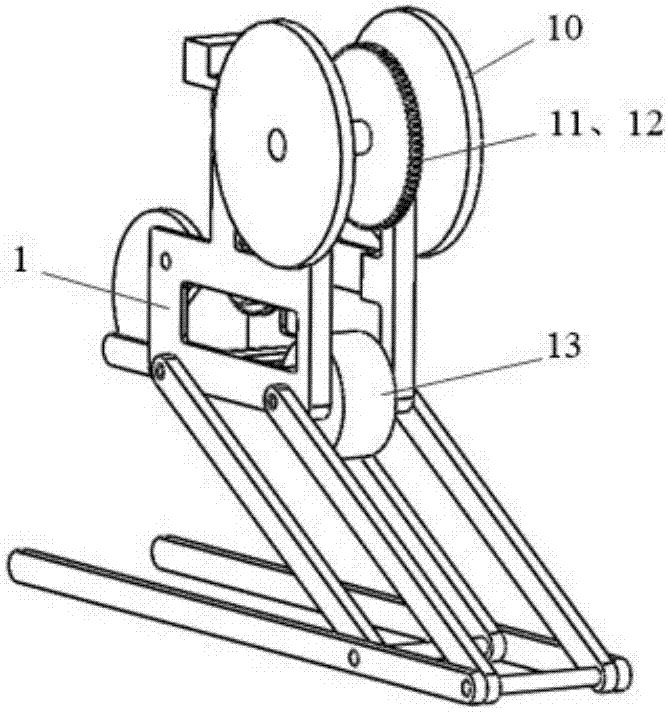

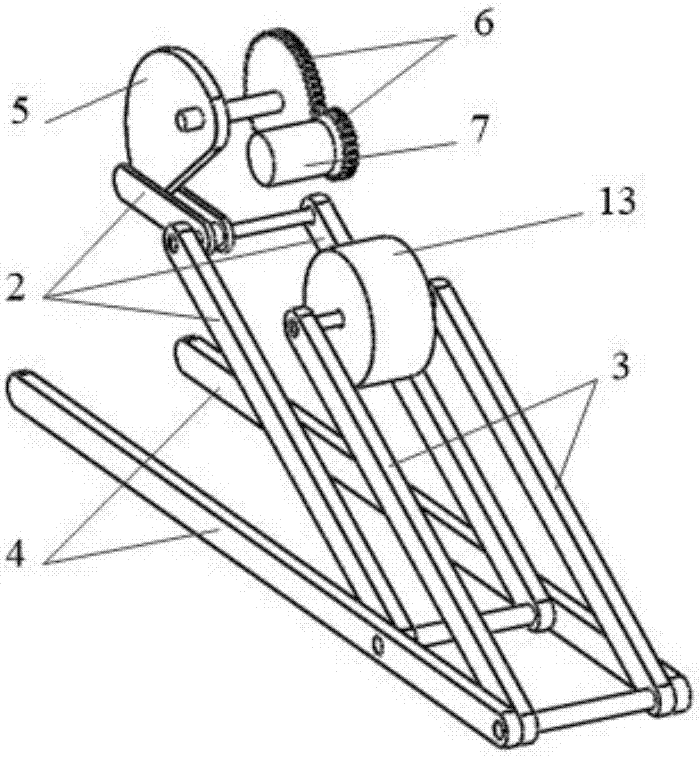

Hopping robot capable of actively adjusting attitude before falling to ground

The invention discloses a hopping robot capable of actively adjusting the attitude before falling to the ground. The hopping robot capable of actively adjusting the attitude before falling to the ground comprises a rack, thighs, auxiliary legs, shanks, a cam, a cam deceleration gear, a cam driving motor, a battery pack module, an induction control module, flywheels, flywheel deceleration gears, a flywheel driving motor and a variable stiffness elastic joint. The lower ends of the thighs and the auxiliary legs are hinged to the shanks, and the middles of the thighs are hinged to the rack. The rack, the thighs, the auxiliary legs and the shanks form a parallelogram structure, the upper ends of the thighs are in tight contact with the cam, the variable stiffness elastic joint is hinged to the upper ends of the auxiliary legs, and the upper ends of the auxiliary legs are connected to the rack. The cam is connected with the cam driving motor through the cam deceleration gear. The flywheels are arranged on the rack, and the flywheels are connected with the flywheel driving motor through the flywheel deceleration gears. The problems that an existing hopping robot is prone to turning over and laterally falling down after hopping, and has no effective attitude adjusting device, and the landing attitude angle cannot be set are solved.

Owner:UNIV OF SCI & TECH OF CHINA

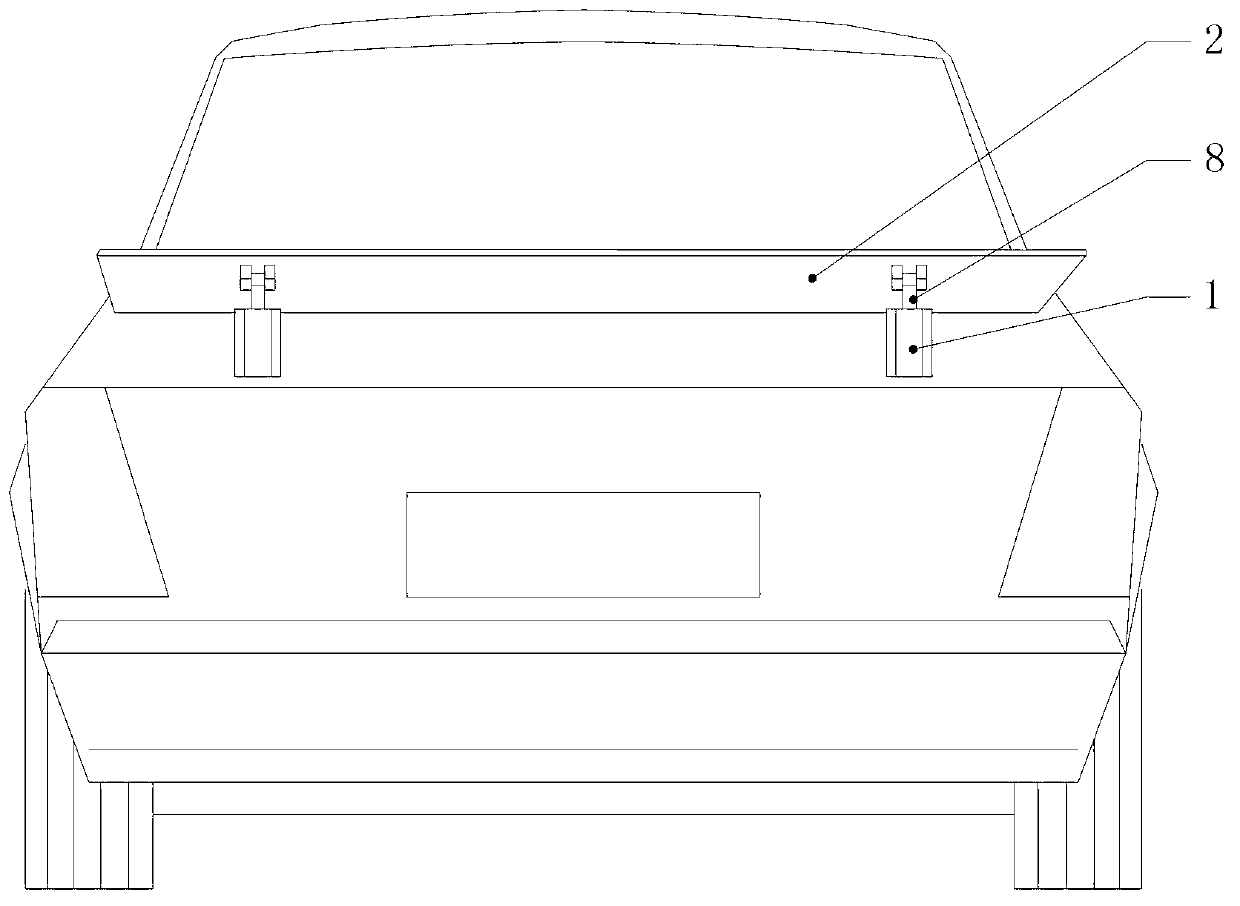

Air flow adjustment type car tail spoiler

InactiveCN103342137AImprove stabilityReduce consumption rateVehicle body stabilisationAirflowEngineering

The invention provides an air flow adjustment type car tail spoiler, and relates the technology of automatic displacement of the car tail spoiler. The air flow adjustment type car tail spoiler is composed of a spoiler sheet and two spoiler sheet supporting frames, and is characterized in that the two spoiler sheet supporting frames are symmetrically arranged at the two ends of the upper portion of a car tail box, and the spoiler sheet is hinged to the spoiler sheet supporting frames through a front connecting rod and a rear connecting rod, and is capable of moving front and back along the upper end surfaces of the spoiler sheet supporting frames under the support of the front connecting rod and the rear connecting rod. The air flow adjustment type car tail spoiler has the advantages of being novel in structure, low in cost, safe, reliable, and good in economy, aesthetics and safety and the like, thereby integrating economy and practicability.

Owner:DALIAN UNIV OF TECH

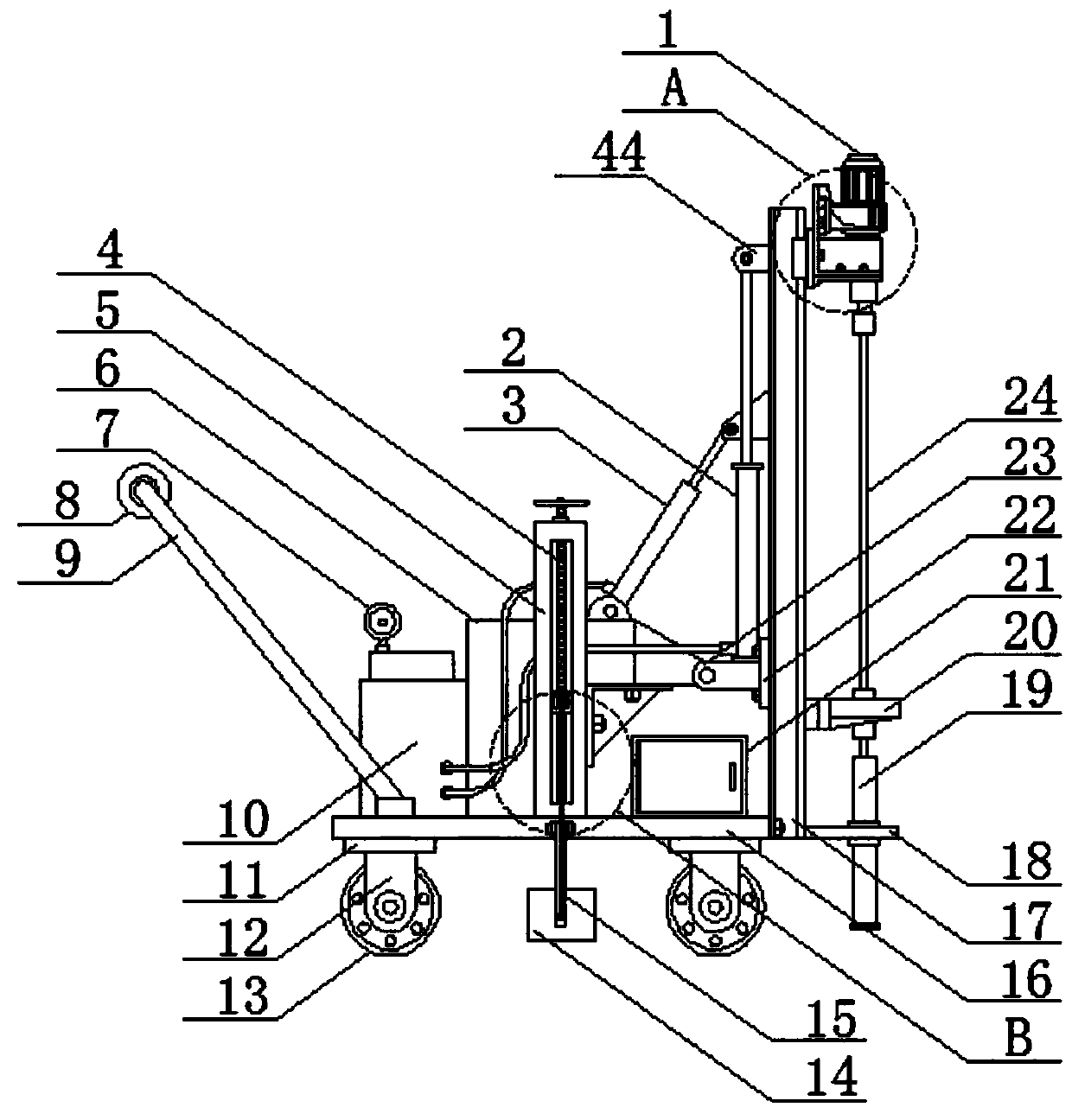

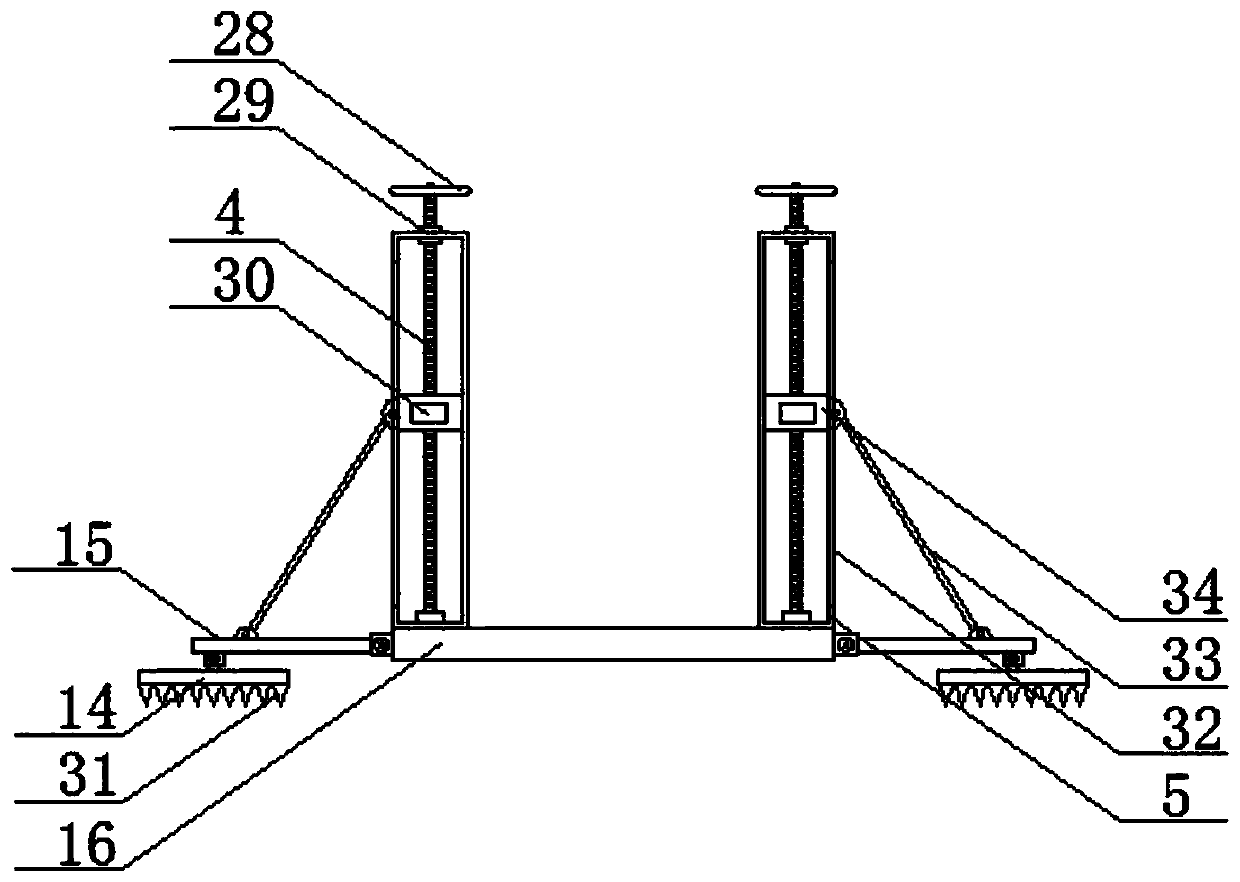

Coal seam gas sampling and collecting device for coal mine

ActiveCN110376028AImprove stabilityRealize the function of stable supportWithdrawing sample devicesGas removalEngineeringUltimate tensile strength

The invention discloses a coal seam gas sampling and collecting device for a coal mine. The device comprises a vehicle body, an oil transmission device, a control cabinet and a collecting box are fixed on the vehicle body successively from left to right, an auxiliary support device is arranged in the upper end of the vehicle body, a supporting block is fixed in one side of the control cabinet, a second oil cylinder is rotationally connected to the upper end of the supporting block, an H-shaped plate is detachably connected to one side of the vehicle body, a connecting block is rotationally connected to one end of the supporting block, one end of the connecting block is detachably connected to one side of the H-shaped plate, a U-shaped block slidingly sleeves one side of the H-shaped plate,and the H-shaped plate is provided with a third opening. Thus, the problems that the sampling angle and height are inconvenient to adjust and a sampling device is low in stability are solved, the sampling efficiency is improved, the labor intensity is reduced, convenience is provided for movement, and the condition that the sample is collected incompletely due to incapability of adjusting the sampling device is avoided.

Owner:CCTEG SHENYANG RES INST

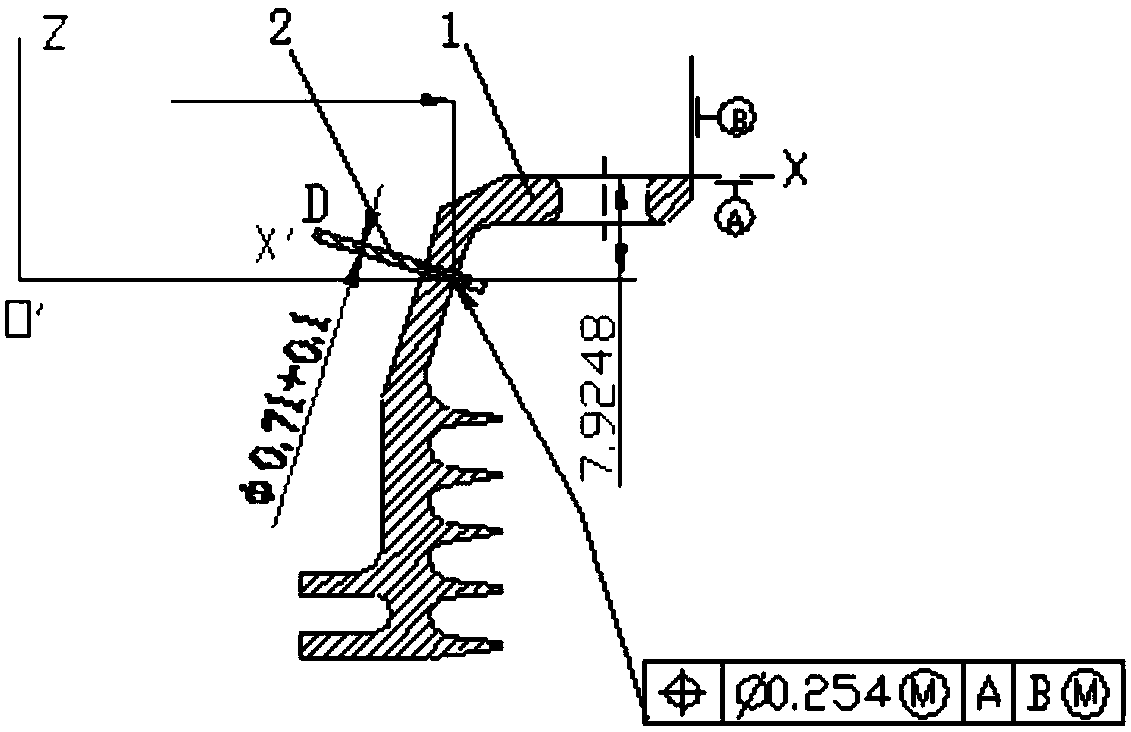

Wire side feeding clamping mechanism for welding

InactiveCN103521895AEasy to adjustFix the angle problemElectrode supporting devicesPlasma welding apparatusEngineeringGuide tube

The invention discloses a wire side feeding clamping mechanism for welding. The wire side feeding clamping mechanism comprises a wire feeding guide pipe, a welding gun clamping body, a cross-shaped sliding device and a wire feeding angle adjusting structure. The wire feeding angle adjusting structure is connected with the wire feeding guide pipe and the cross-shaped sliding device respectively. The cross-shaped sliding device is composed of a single-direction sliding mechanism A and a single-direction sliding mechanism B which are the same in structure. The wire feeding angle adjusting structure is fixed with a sliding table face in the single-direction sliding mechanism B. The wire feeding angle adjusting structure comprises a screw in the middle of a supporting frame, the screw is sleeved with a pressure spring, a T-shaped frame is arranged among the screw, the supporting frame and the wire feeding guide pipe, the two ends of a cross rod of the T-shaped frame are connected with the other end of the supporting frame and the other end of the screw respectively, and the end portion of a vertical rod of the T-shaped frame is connected with the wire feeding guide pipe. Large-angle wire feeding angle adjustment is conducted by adjusting a connecting bolt between the cross rod of the T-shaped frame and the vertical rod of the T-shaped frame, and small-angle fine adjustment is conducted by rotating the screw and adjusting the cross rod of the T-shaped frame up and down by the utilization of the pressure spring.

Owner:TIANJIN UNIV

Method for detecting hole location degree by three-coordinate measuring machine

InactiveCN109373946AResolve locationFix the angle problemMeasurement devicesSingle elementEngineering

The invention provides a method for detecting a hole location degree by a three-coordinate measuring machine. The method comprises the steps of (1) setting 88 small holes of a measured part to be 10 sets of core rods according to a tolerance of 0.01 mm, (2) steadily placing the measured part on a three-coordinate detection workbench, inserting the core rods into the small holes of the measured part to ensure that the core rods fit closely with the small holes of the measured part, (3) determining basic elements of measurement, (4) establishing a basic part coordinate system through PC-DMIS software on a three-coordinate measuring machine, and (5) selecting a measured object and completing the measurement. According to the method of the invention, the measurement of the location degrees ofthe small holes is converted into the measurement of the location degrees of the core rods through an indirect measurement method, the problem that the location degrees of the small holes cannot be measured and the normal angles of the centers of the small holes cannot be quantitatively judged is solved. The method of the present invention is applicable to a large number of repeated measurements of a single element, and the method of the invention has the advantages that the detection efficiency is improved greatly and the accuracy of detection is improved at the same time compared with a traditional detection method.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Projector capable of being lifted and lowered

InactiveCN108036168ASolve highFix the angle problemProjectorsStands/trestlesArchitectural engineeringProjector

The invention discloses a projector capable of being lifted and lowered. The projector includes a fixed base. The fixed base is of a rectangular parallelepiped structure. A telescopic sleeve is arranged at the center of the top of the fixed base, a vertically arranged elastic spring is arranged at the inner bottom of the telescopic sleeve, a telescopic column is connected on the top of the elasticspring, and positioning holes are formed in the outer wall of the telescopic column at equal distances along the length direction of the telescopic column. A first pull bolt horizontally penetrates through the outer wall of the telescopic sleeve, and one end of the first pull bolt penetrates through the outer wall of the telescopic sleeve and extends into the positioning holes in the telescopic column. A user can lift and lower the projector, and the height of the projector can be adjusted according to actual needs. Through a rotating shaft, a fixing plate, a second pull bolt, a second tension spring and limiting holes, the projector can be rotated to adjust the angle and fixed. The structure is simple, the problem of inconvenient adjustment of height and angle of conventional projectorsis solved, and the projector is convenient to use, has great practicability and is easy to popularize.

Owner:新昌县谷德机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com