Highly effective wet-process desulfurizing, denitrifying and dedusting process and integration device thereof

A wet desulfurization and denitrification technology, which is applied to combined devices, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of corrosion of treatment equipment, complicated processes, secondary pollution, etc. Efficiency, the effect of reducing material wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

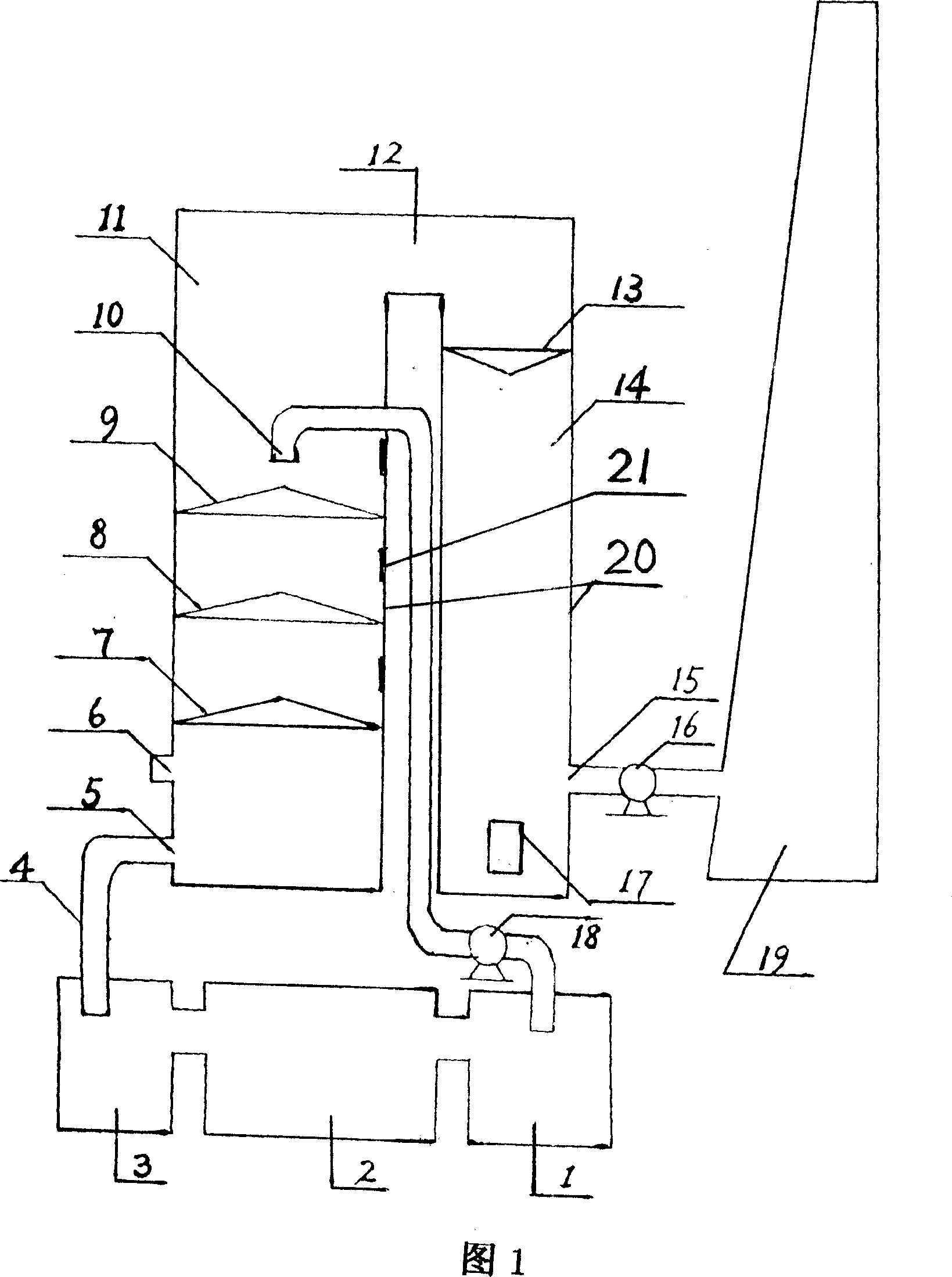

[0039] A high-efficiency wet desulfurization, denitrification and dust removal process is characterized in that it includes the following process steps:

[0040] a. Prepare the absorbent and send the absorbent to the main tower: prepare the absorbent in the alkaline pool 2 by adding calcium hydroxide and sodium hydroxide to the water and stirring and mixing. Sodium hydroxide neutralizes the calcium hydroxide in the water to make it into sodium hydroxide and sodium carbonate, and the double lye composed of sodium hydroxide and sodium carbonate is the absorbent. The composition ratio of sodium hydroxide, calcium hydroxide and water added to the double lye absorbent is 2:6:250-400. Adjust the pH of the absorbent to 11-12. The prepared absorbent is sent from the alkaline water tank 2 to the pump forebay 1 and then sent to the upper part of the main tower 11 by the water pump 18 through pipelines, and then flushed downwards from the central tube type liquid supply device 10 at the...

Embodiment 2

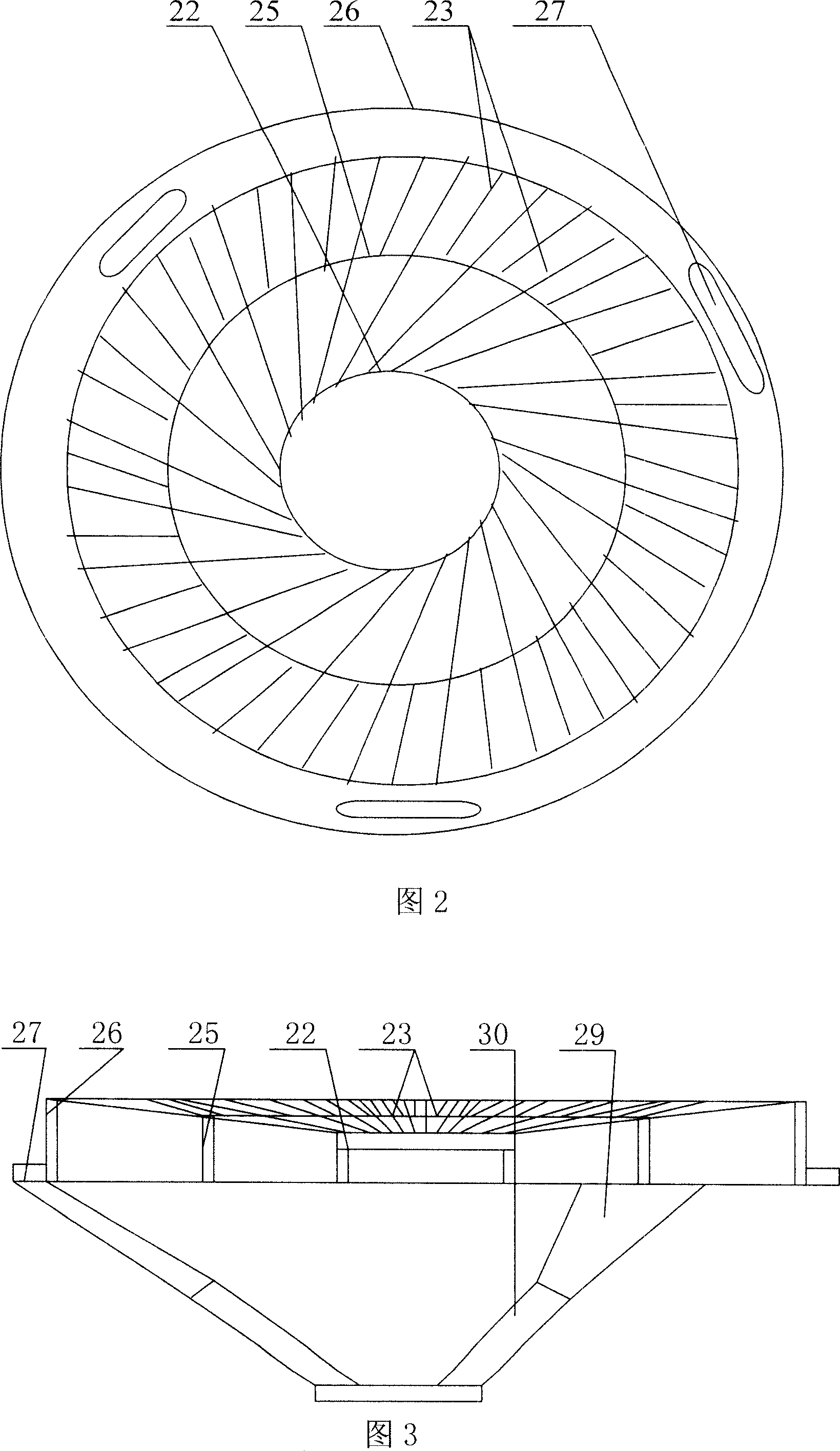

[0057]The spacing between each layer of swirl plate towers 9, 8, 7 is 110 centimeters. The diameter of the blind plate 22 in the middle of each swirl plate column is 90 centimeters. There are 100 swirl blades 23 on the upper swirl plate tower 9 and the middle swirl plate tower 8 , and 56 swirl blades 23 on the lower swirl plate tower 7 . There is an inclination angle between the swirl blades 23 of each swirl plate tower and the horizontal plane, and the inclination angle is 28 degrees.

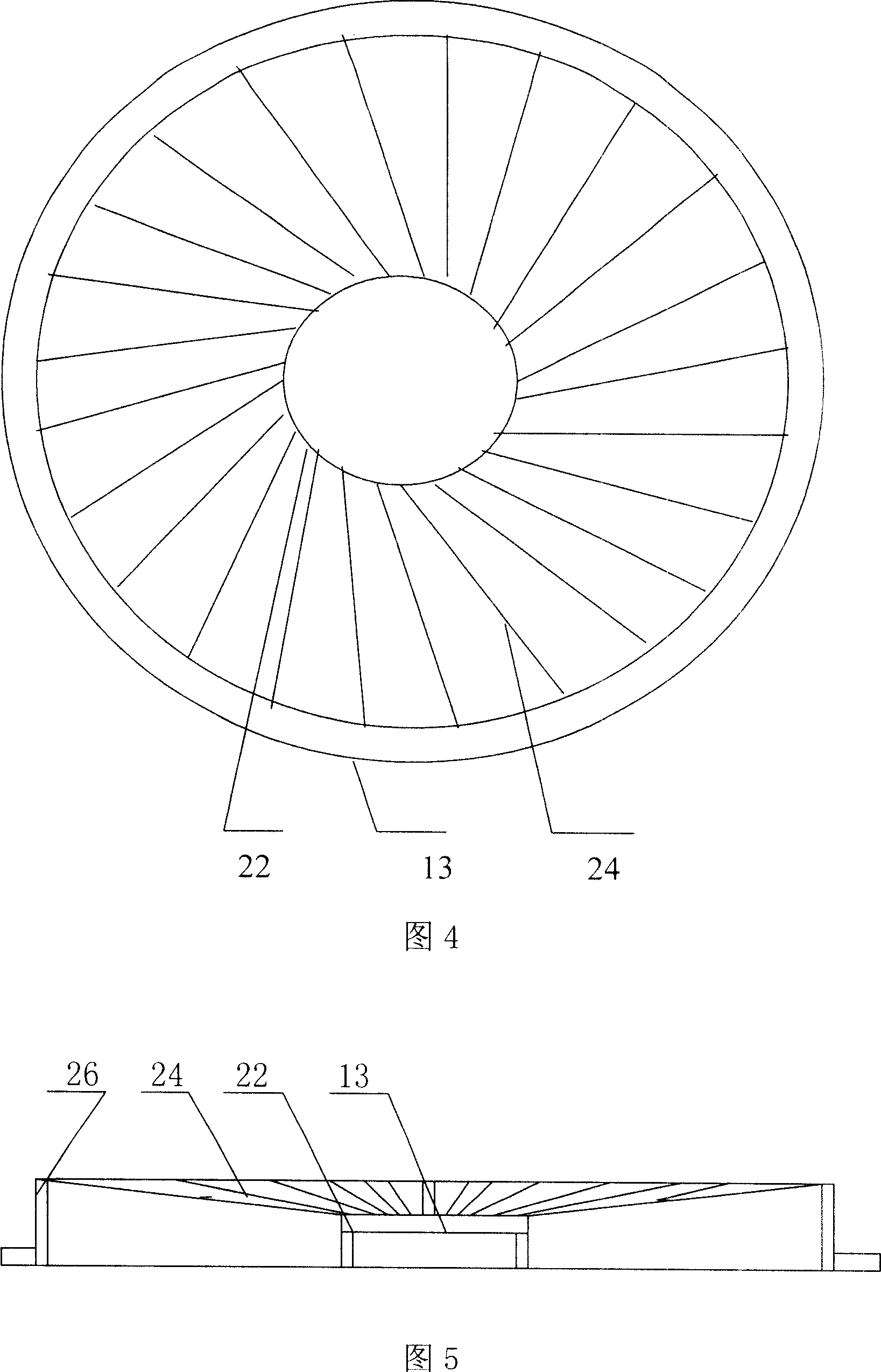

[0058] The diameter of the blind plate 22 in the middle of the defogging plate tower 13 is 27 centimeters. 28 defogging blades 24 are arranged on the defogging plate tower 13 . There is an inclination angle between the defogging blade 24 and the horizontal plane, and the inclination angle is 29 degrees.

[0059] The desulfurization, denitrification and dust removal process of this embodiment is the same as that of Embodiment 1. Other structures of this embodiment are the same as those of E...

Embodiment 3

[0061] The spacing between each layer of swirl plate towers 9, 8, 7 is 100 centimeters. The diameter of the blind plate 22 in the middle of each swirl plate tower is 80 centimeters. There are 90 swirl blades 23 on the upper swirl plate tower 9 and the middle swirl plate tower 8 , and 46 swirl blades 23 on the lower swirl plate tower 7 . There is an inclination angle between the swirl blades 23 of each swirl plate tower and the horizontal plane, and the inclination angle is 26 degrees.

[0062] The diameter of the blind plate 22 in the middle of the defogging plate tower 13 is 22 centimeters. 25 defogging blades 24 are arranged on the defogging plate tower 13 . There is an inclination angle between the defogging blade 24 and the horizontal plane, and the inclination angle is 26 degrees.

[0063] The desulfurization, denitrification and dust removal process of this embodiment is the same as that of Embodiment 1. Other structures of this embodiment are the same as those of Em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com