High-speed wrapping machine

A wrapping machine, high-speed technology, applied in the direction of electrical components, circuits, conductor/cable insulation, etc., to achieve the effect of good performance, not easy to loosen, and simple adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

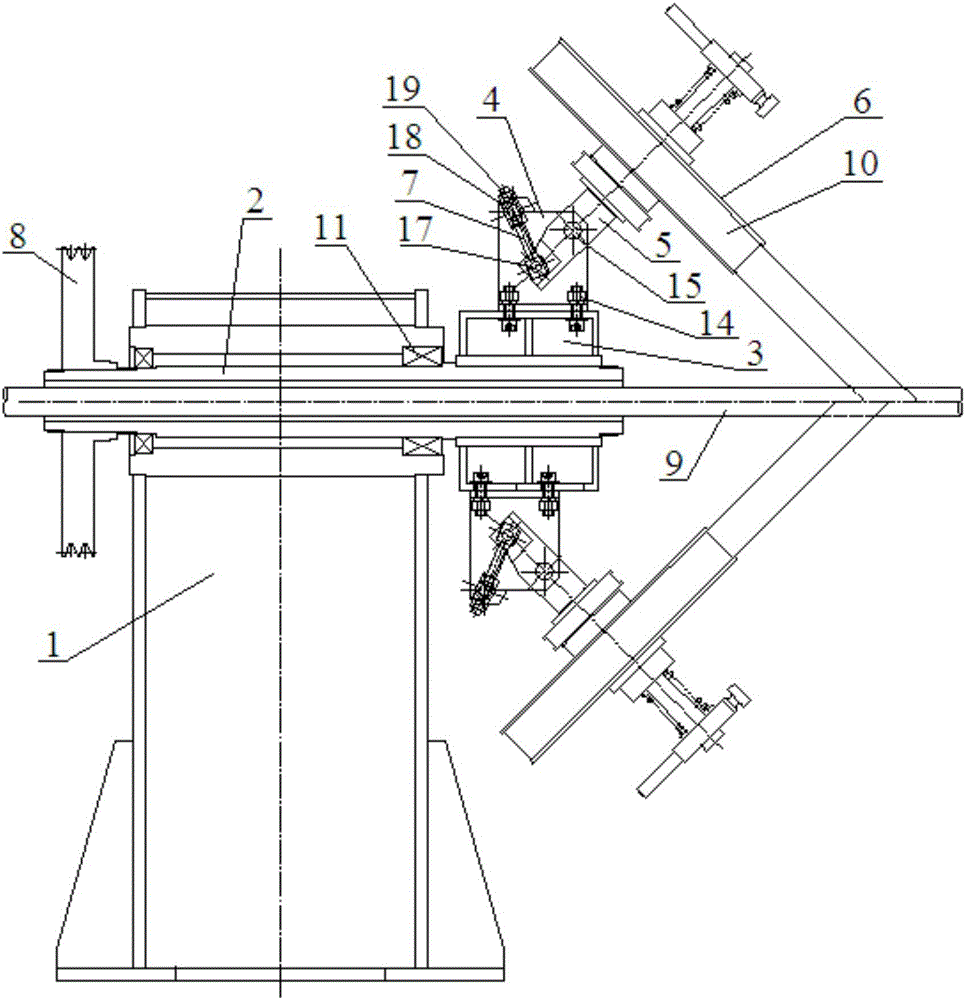

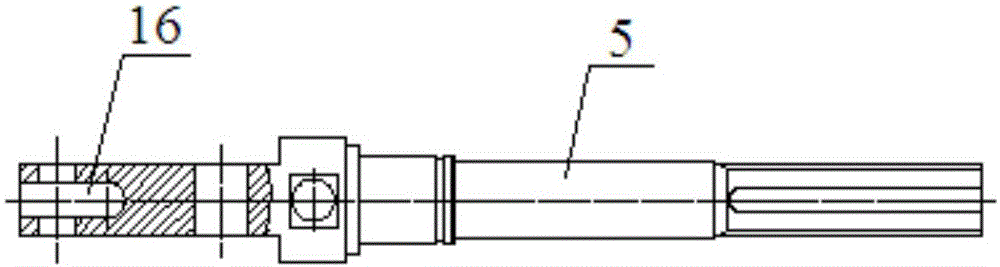

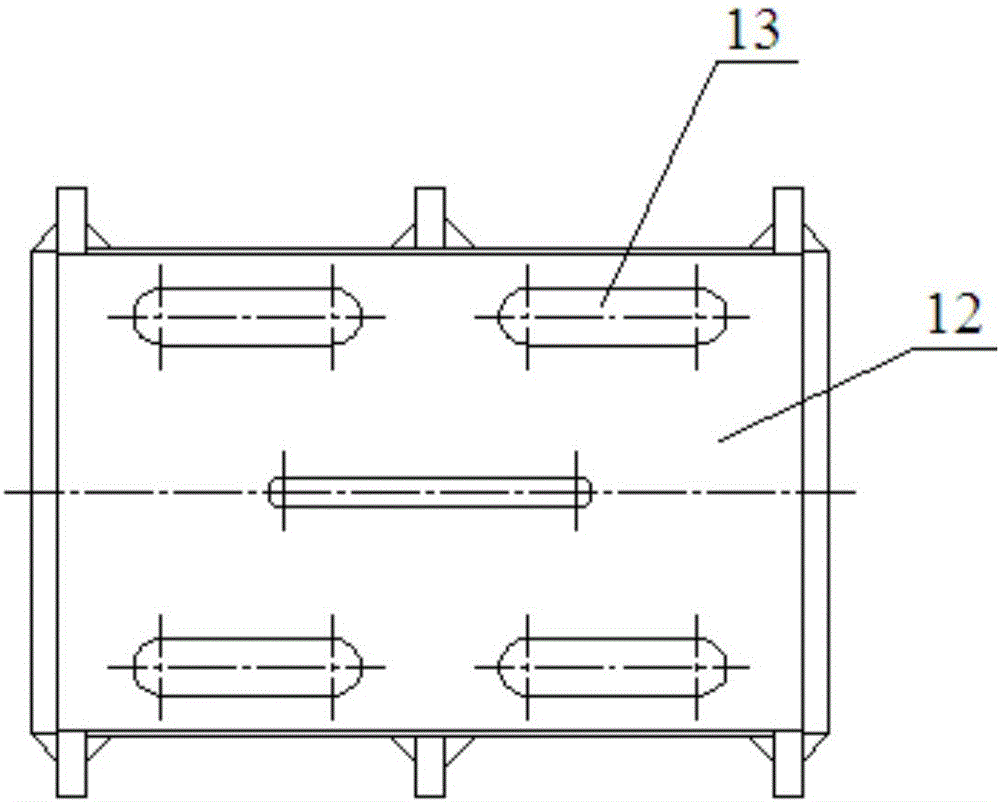

[0022] Refer to the attached drawings, a high-speed wrapping machine includes a wrapping support 1 on which a hollow main shaft 2 arranged horizontally is rotatably installed. The right end of the hollow main shaft 2 is installed with a rotating bracket 3, which surrounds the rotating bracket 3 respectively. A plurality of installation planes 12 are provided, and a plurality of support frames 4 are respectively installed; a plurality of reel shafts 5 arranged in an inclined manner are provided, and a reel 6 is installed in the middle of the plurality of reel shafts 5. The rear part of the shaft 5 is respectively mounted on a plurality of support frames 4 corresponding to rotation, and the plurality of support frames 4 are respectively installed with adjusting screws 7, and the rear ends of the adjusting screws 7 are respectively connected to the rear of the reel shafts rotatably installed on the supporting frame. The left end of the hollow main shaft 2 is equipped with a pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com