Method for detecting hole location degree by three-coordinate measuring machine

A three-coordinate measuring machine and position degree technology, which is applied in the field of inspection and detection, can solve the problems such as the inability to give quantitative judgment on the normal angle of small holes, the manufacturing problems of comprehensive measuring tools, and the inability to detect the normal hole measurement, so as to improve the accuracy The effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for detecting the position degree of a hole with a three-coordinate measuring machine, comprising the following steps:

[0019] Step 1, the 88 small holes of the tested part 1 are respectively matched as 10 sets of mandrels according to the tolerance of 0.01mm;

[0020] Step 2. Place the part under test 1 stably on the three-coordinate detection workbench, insert the mandrel into the 88 small holes of the part under test, and ensure that the mandrel fits closely with the small holes of the part under test;

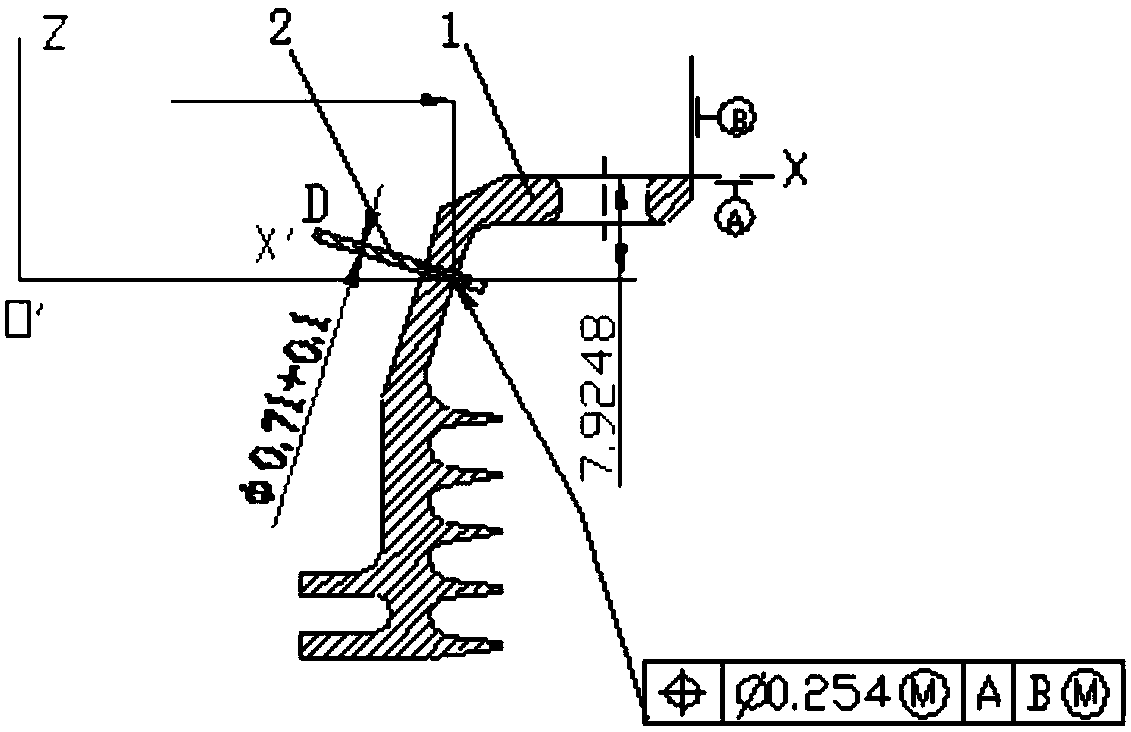

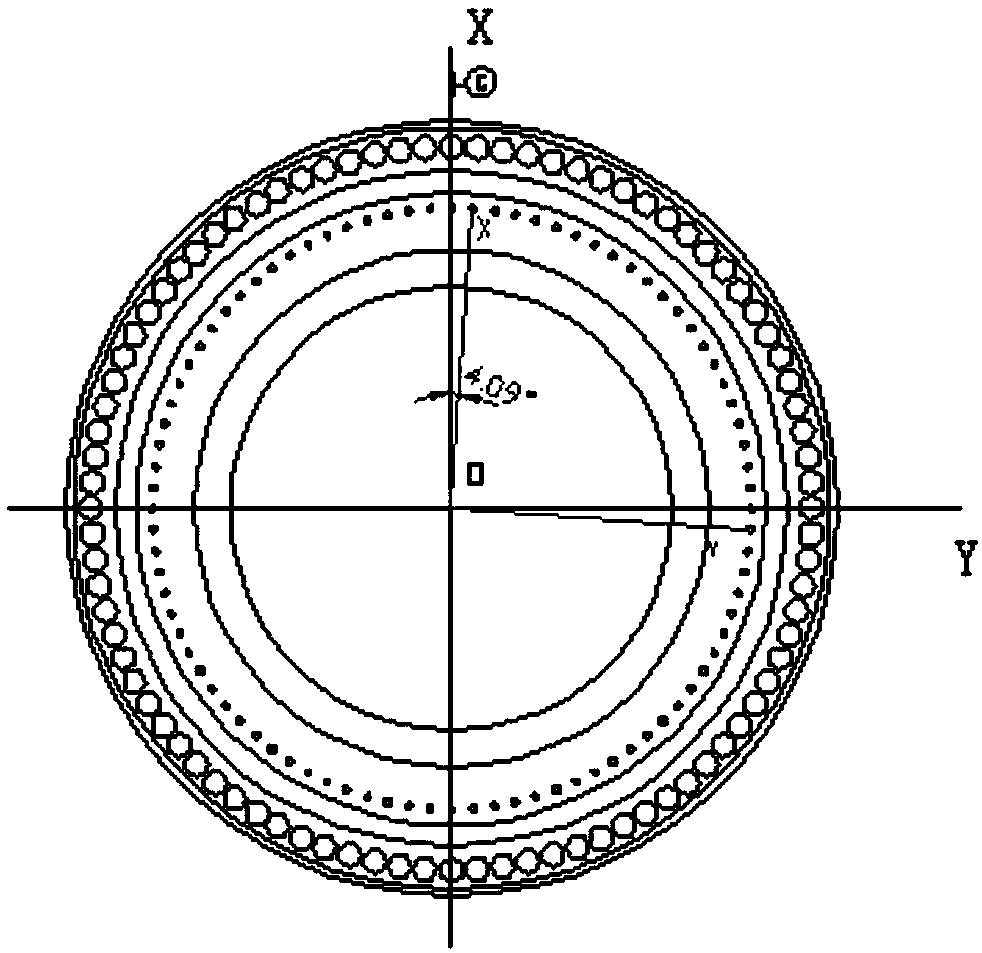

[0021] Step 3, determine the measurement reference element, any one of the 88 small holes in the measured part such as figure 1 shown, combined with figure 2 , the measurement reference elements are the reference plane A, the reference circle B and the mandrel D2 on the angular reference hole C;

[0022] Step 4, establish the basic part coordinate system through the PC-DMIS software on the coordinate measuring machine, and through the "Insert" - "Coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com