Backlight module feeding position correcting mechanism

A backlight module and initial positioning technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of inadequate transportation, uneven placement of backlight modules, and low feeding accuracy. , to achieve the effect of continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

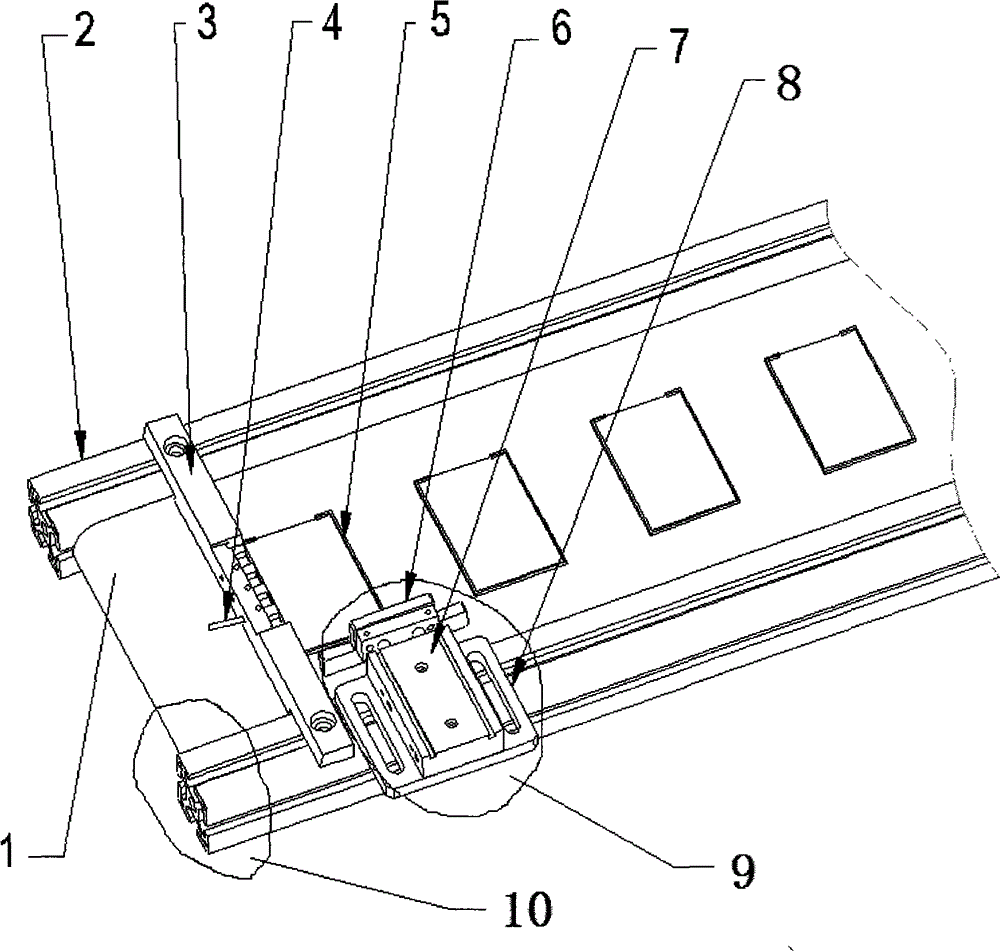

[0009] The feeding position guiding mechanism of the backlight module of the present invention includes a conveyor belt 10 and a baffle 3, the conveyor belt 10 is used for transporting the backlight module 5, and the baffle 3 is used to limit the movement of the backlight module 5 in the X direction (transport direction) The conveyor belt 10 is composed of a load bearing member 1 and a conveyor line 2, and the conveyor line 2 is used to determine the movement of the traction conveyor belt; the baffle plate 3 is connected to an optical fiber sensor 4, and the optical fiber sensor 4 is used to detect the transportation of the BLU 5 information, and the detected information is fed back to the conveying line 2; the baffle plate 3 is vertically connected with a preliminary positioning device 9, and the preliminary positioning device 9 is used to limit the movement of the backlight module 5 in the Y direction (perpendicular to the conveying direction) The movement; the initial positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com