Wind turbine blade wing section group

A technology of wind turbine blades and airfoil families, applied in the field of wind turbine blades, can solve the problems of sensitive leading edge roughness, poor stall characteristics, and low maximum lift coefficient, and achieve improved structural performance, reduced static load, and maximum lift The effect of resistance ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

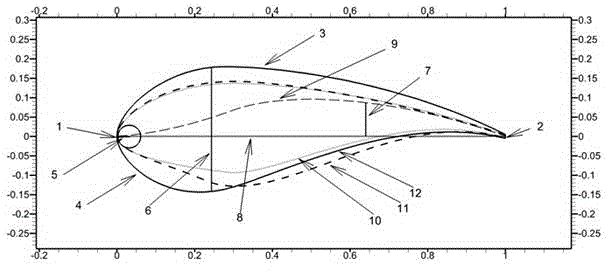

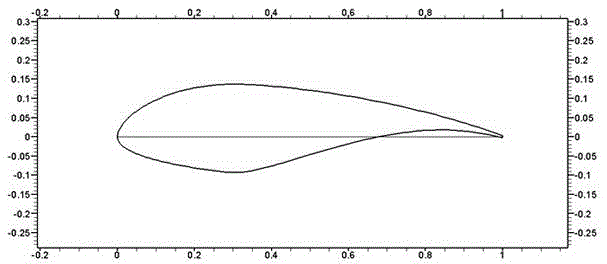

[0027] A wind turbine blade airfoil family of the present invention will be described in detail below in conjunction with the accompanying drawings.

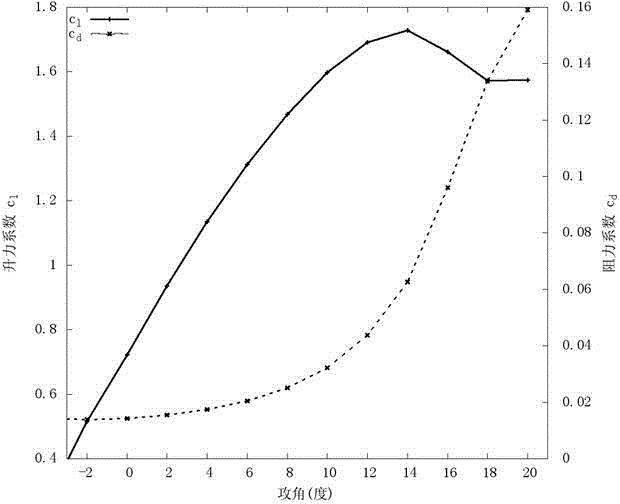

[0028] Design principle: The two most important performance requirements for wind turbine airfoils are insensitivity to leading edge roughness and good stall performance. To reduce the sensitivity to the roughness of the leading edge, the fan airfoil often needs to reduce the thickness of the upper part of the airfoil compared with the aviation airfoil. In order to generate the same lift as the original airfoil, the rear of the pressure surface often presents an S -type implements post-loading methods. In order to obtain the required maximum lift coefficient and good stall performance, bilateral constraints are imposed on the maximum design angle of attack and the lift coefficient at the stall angle of attack. In addition, the location of the separation point of the suction surface is constrained. The separation point should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com