Fan blade structure and centrifugal fan with same

A centrifugal fan and fan blade technology, which is applied to components, instruments, and electrical digital data processing of elastic fluid pumping devices, etc. It can solve the problems of burning electronic components, reducing the operation speed of electronic components, and affecting the performance of electronic components. , to achieve the effect of large sweeping area and enhanced heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

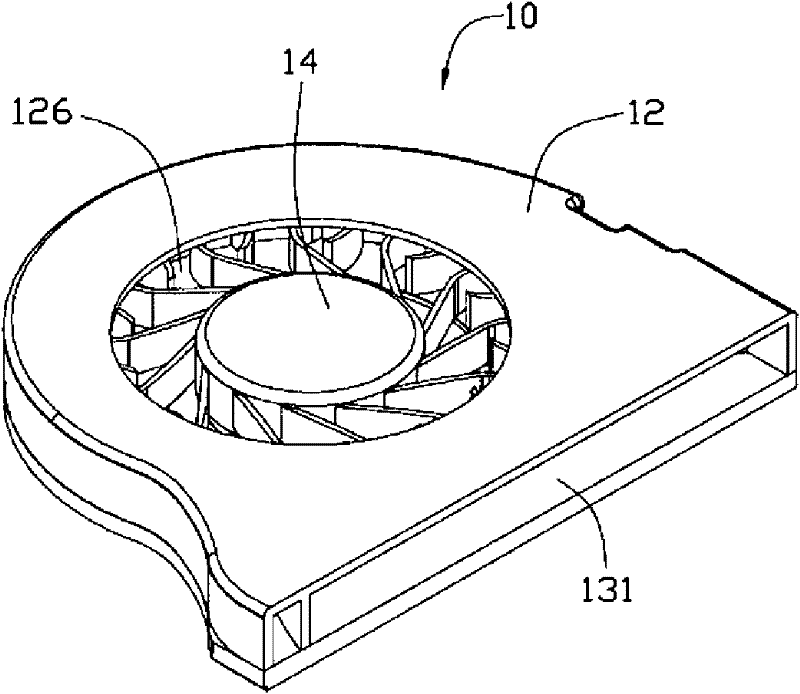

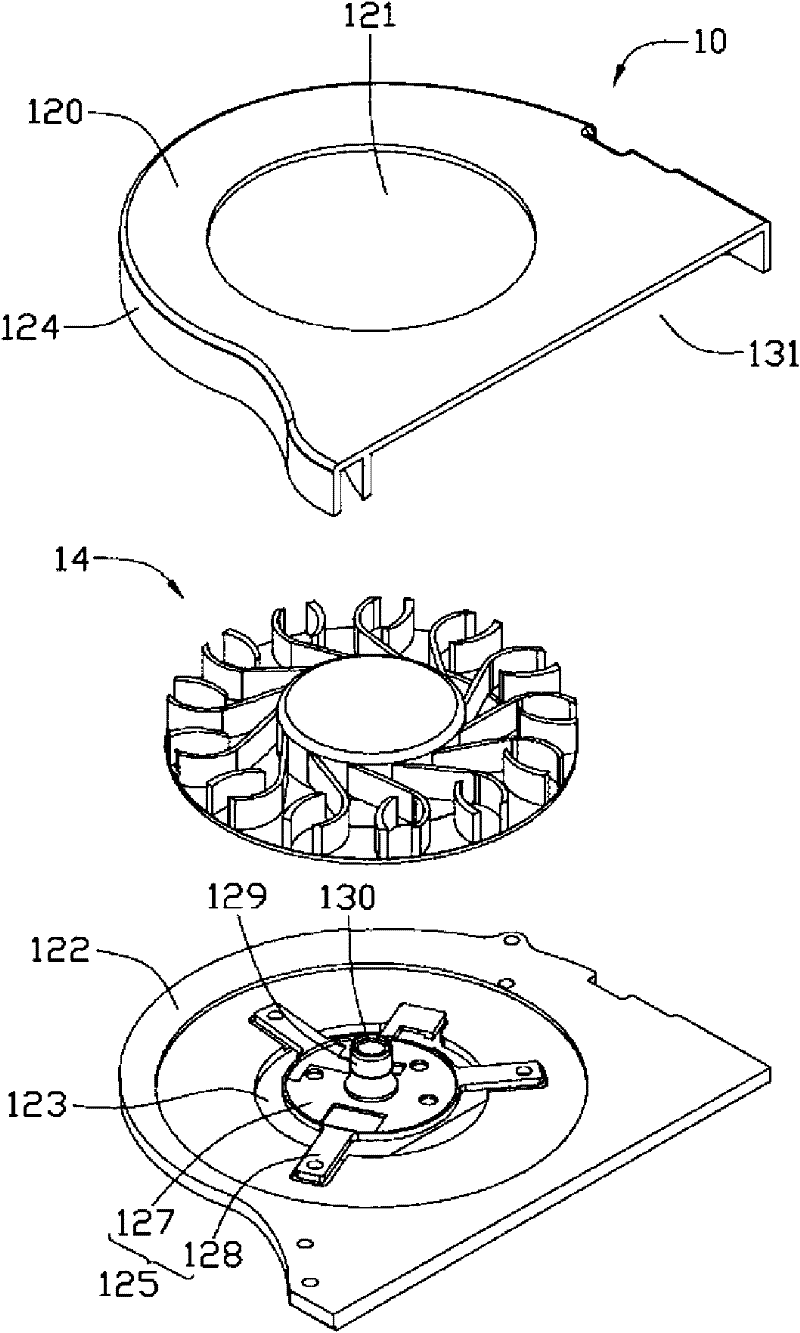

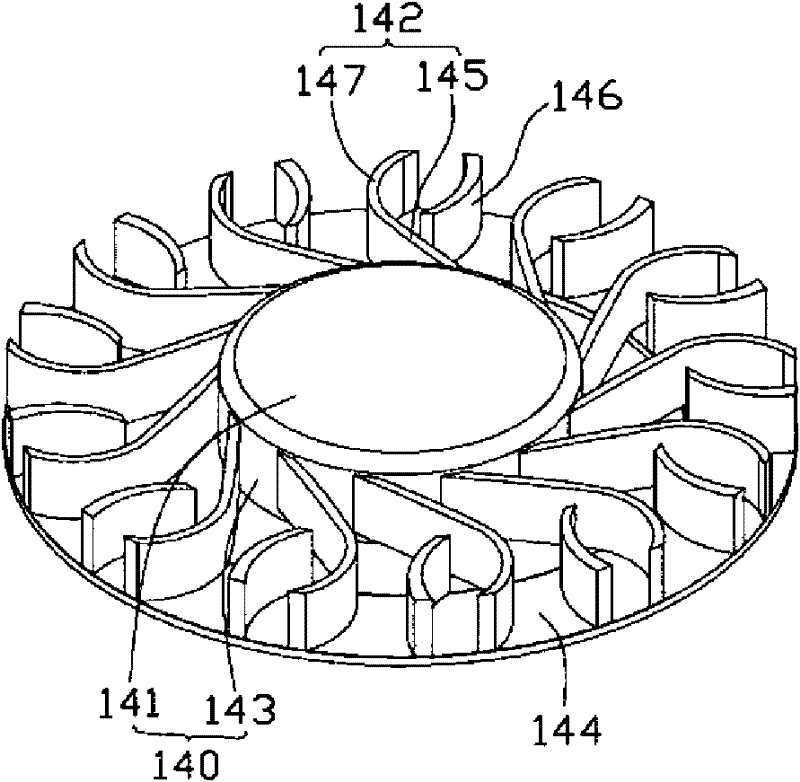

[0014] Such as figure 1 and figure 2 As shown, the centrifugal fan 10 includes a fan frame 12 and a fan blade structure 14 disposed in the fan frame 12 .

[0015] The fan frame 12 includes a top plate 120, a bottom plate 122 and a scroll-shaped side plate 124 connected between the top plate 120 and the bottom plate 122 and integrally formed with the top plate 120. The top plate 120, the bottom plate 122 and the side plate 124 share An accommodating space 126 for accommodating the blade structure 14 is formed. The top plate 120 and the bottom plate 122 are separately arranged on the upper and lower sides of the fan blade structure 14, and the central positions of the top plate 120 and the bottom plate 122, that is, the position of the fan blade structure 14 respectively form a circular upper and lower opening. The air outlets 121 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com