Wind wheel lengthening ring

A technology for wind rotors and fan blades, which is applied in the field of wind power generation equipment, can solve the problems of blade batching process and shortened development cycle, waste of blade molds and supporting equipment, difficulty in transportation and increased transportation costs, and is conducive to standardization The degree and batch production, reduce the cost of blade development, reduce the difficulty of transportation and the effect of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

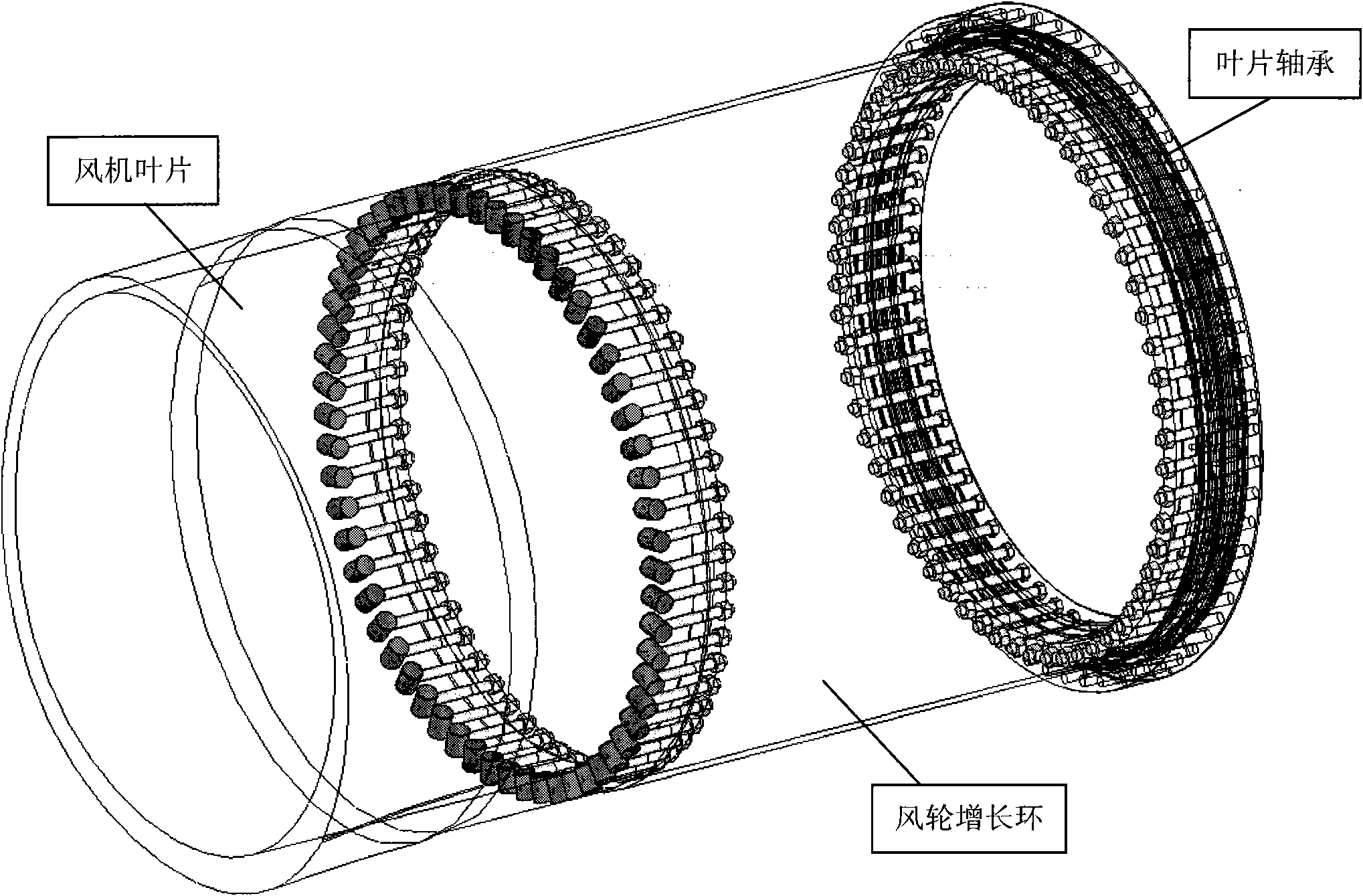

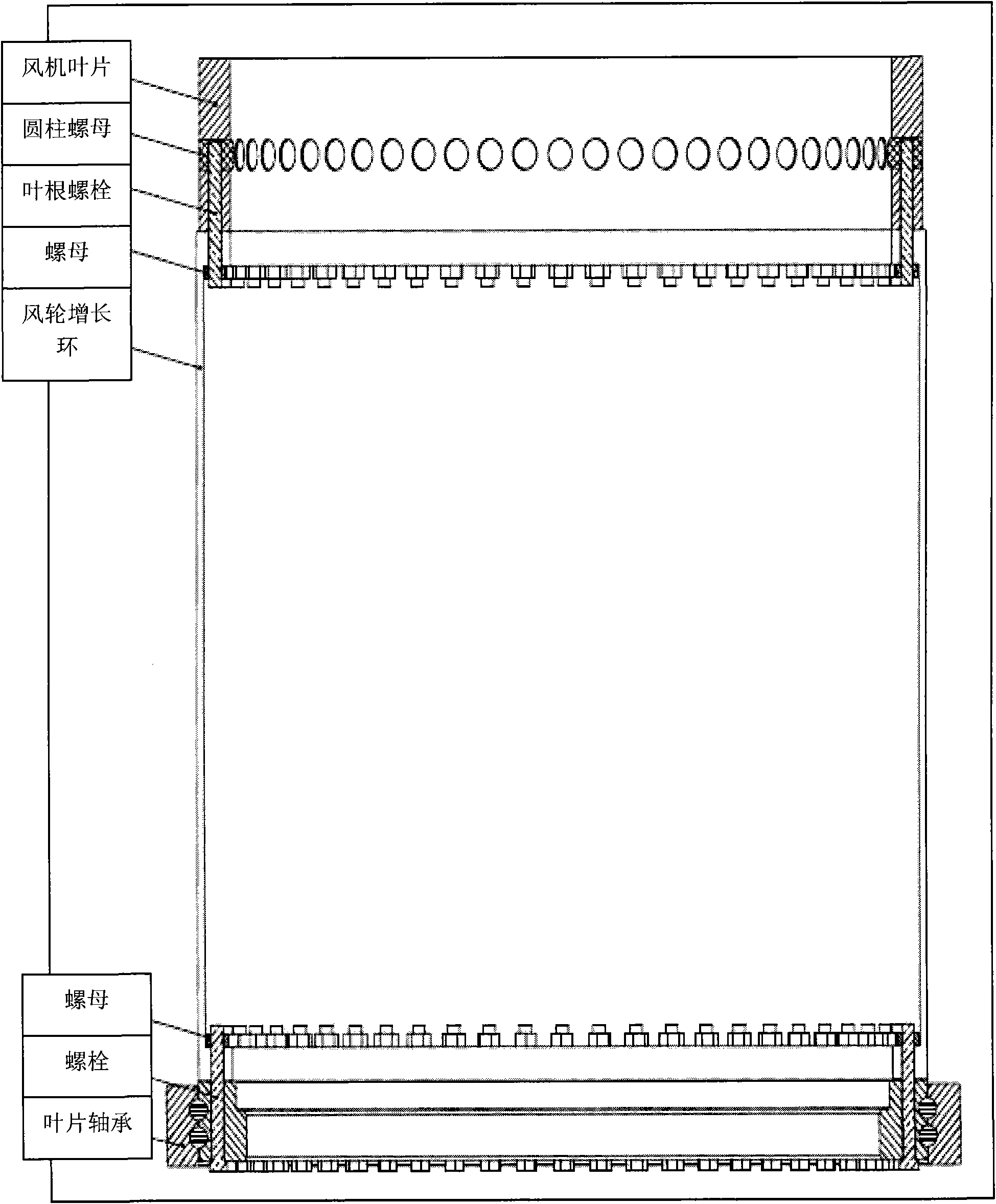

[0015] figure 1 It is a schematic diagram of the connection between the growth ring of the wind rotor and the blades of the fan and the blade bearings. The wind rotor growth ring adopts a cylindrical barrel as the main body, and flanges are welded at both ends of the cylindrical barrel to connect the blades and blade bearings respectively.

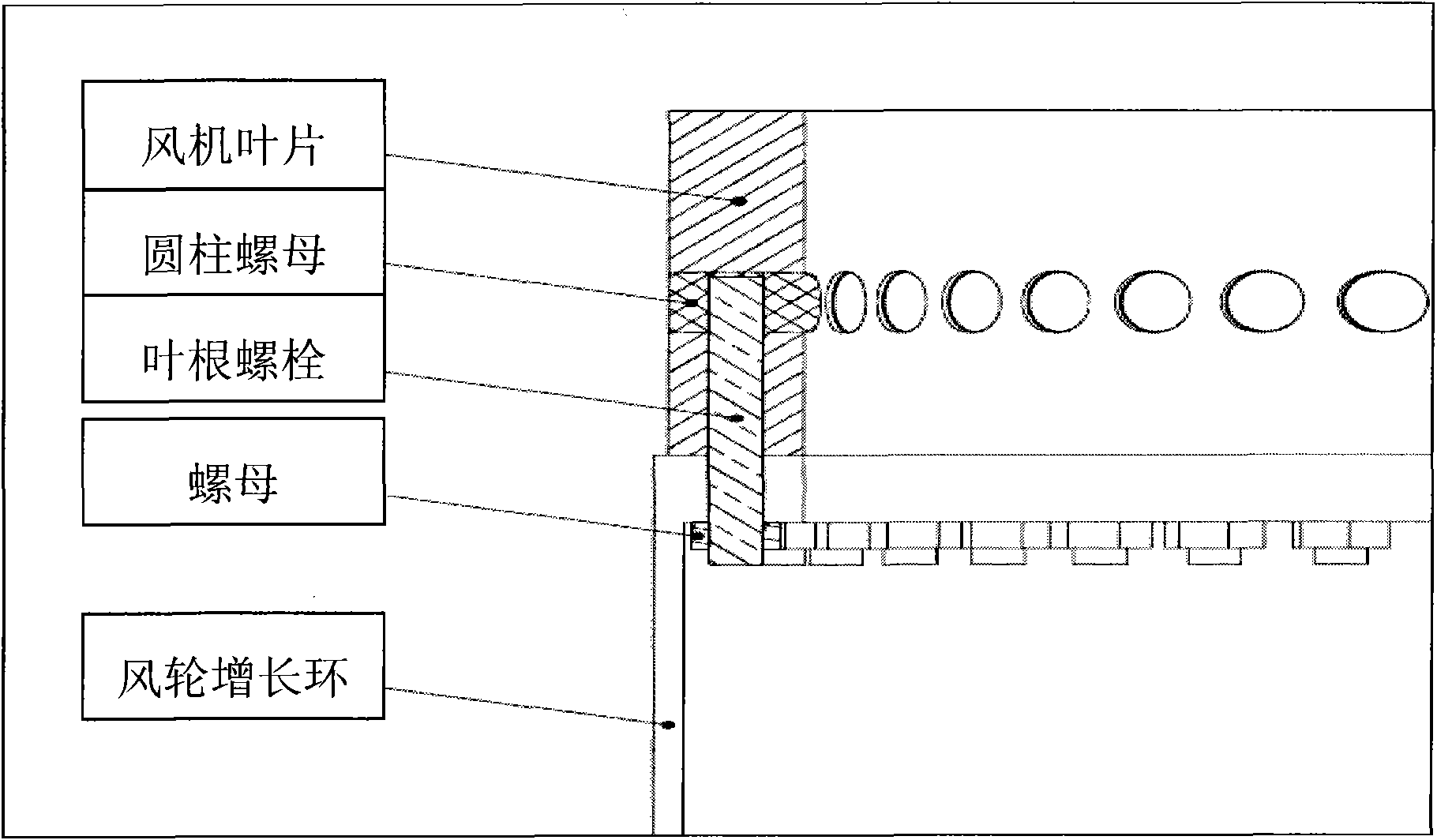

[0016] The wind rotor growth ring is connected to the fan blades through T-shaped bolts. The specific connection method is as follows: image 3 As shown: the wind rotor growth ring is connected to the fan blade through the blade root bolt, the blade root bolt is fixed with a nut at the end of the wind rotor growth ring, and fixed at the blade end with a cylindrical nut installed in the blade, forming a T-bolt structure.

[0017] The wind rotor growth ring is connected to the blade bearing by bolts, and the specific connection method i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com