Large-discharge electric submerged screw pump oil extracting equipment

A screw pump, high-displacement technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of easy sand card, low output torque capacity of motor and mechanical transmission device, unusable, etc., Achieve the effect of meeting displacement requirements and environmental protection requirements, eliminating smoothbore damage and temperature rise, and increasing maximum torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

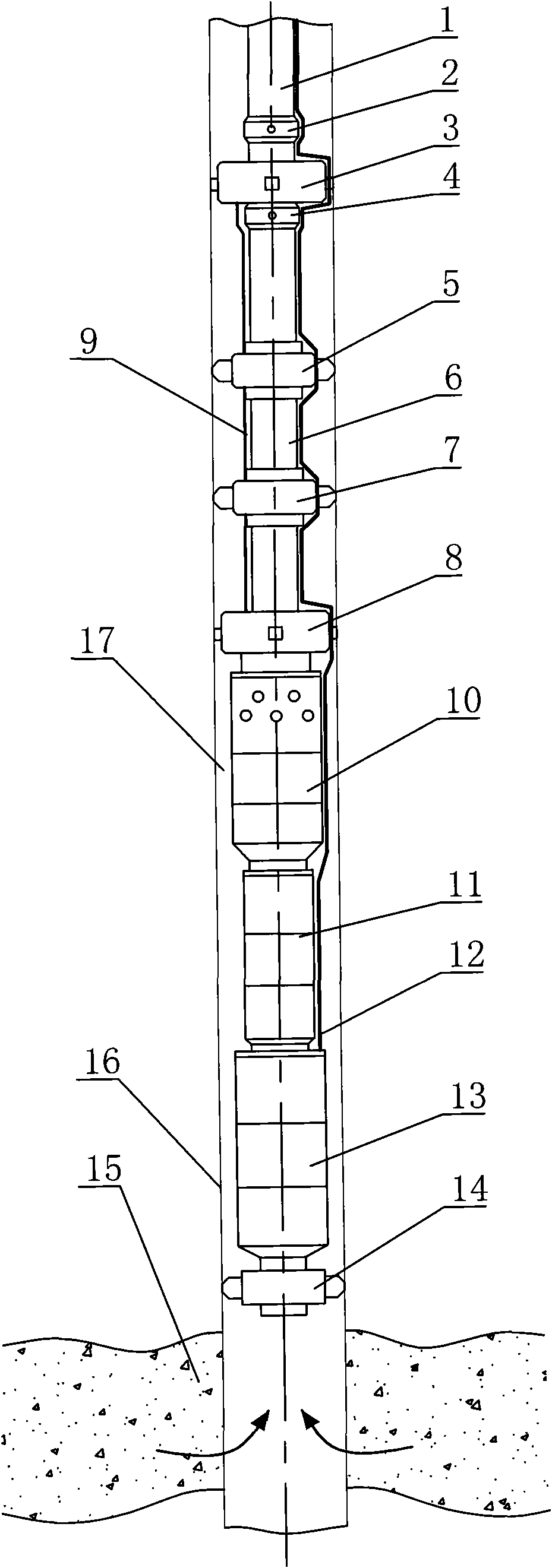

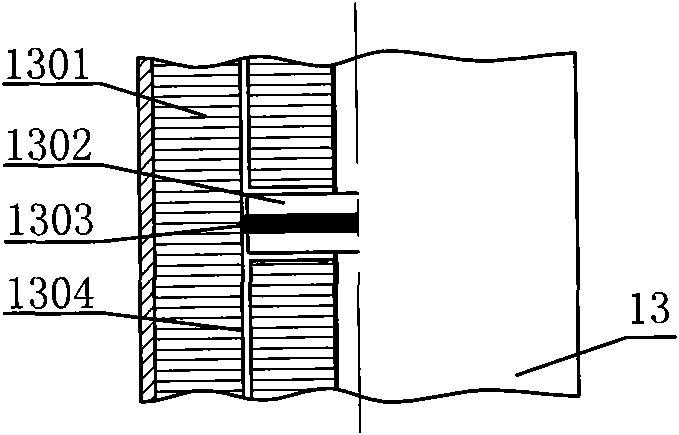

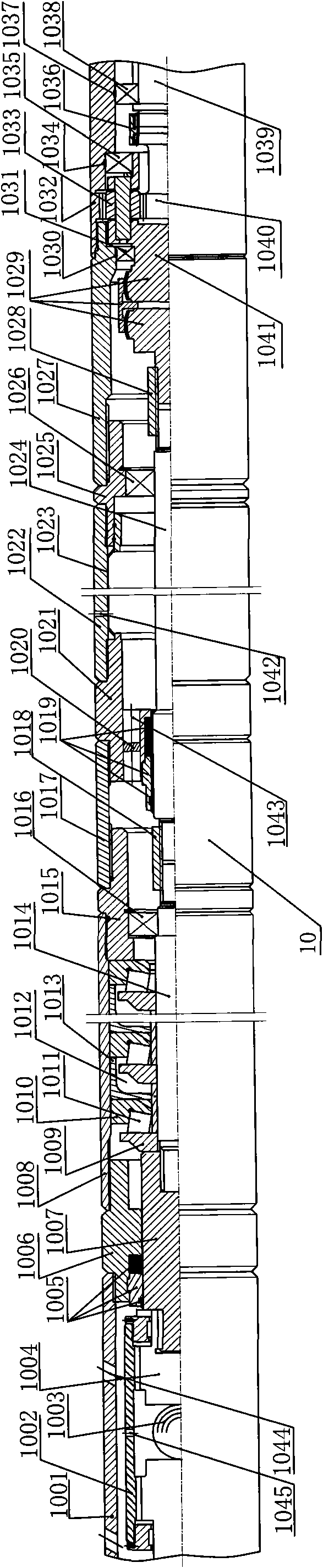

[0047] Depend on Figure 1-6 As shown, 13 in the figure is a downhole motor, 6 is a screw pump, 10 is a downhole rotary mechanical transmission, 12 is a downhole cable, and 16 is an oil well casing; an elastic centralizer 14 is arranged at the tail of the downhole motor 13. The upper part of the downhole motor 13 is connected in series with a downhole motor protector 11, a downhole rotary mechanical transmission device 10, an anchoring device 8, a screw pump 6, and an anchoring device 3; two elastic centralizers 5 and 7. The anchoring device includes: a hydraulic cylinder 3005, a center pipe with a cone 3003, a pin 3004 is connected between the upper part of the cone and the hydraulic cylinder 3005, and a pin 3004 is connected between the bottom of the cone 3003 and the hydraulic cylinder 3005. There is a support block 3002; a layer of copper or lead soft metal 3001 is provided on the outer surface of the support block 3002; in addition, 3006 in the figure is a through hole 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com