Integral processing type transverse anti-vibration base

A technology of integral processing and anti-vibration machine base, applied in the direction of engine base, mechanical equipment, supporting machine, etc., can solve problems such as damage to the base and support equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

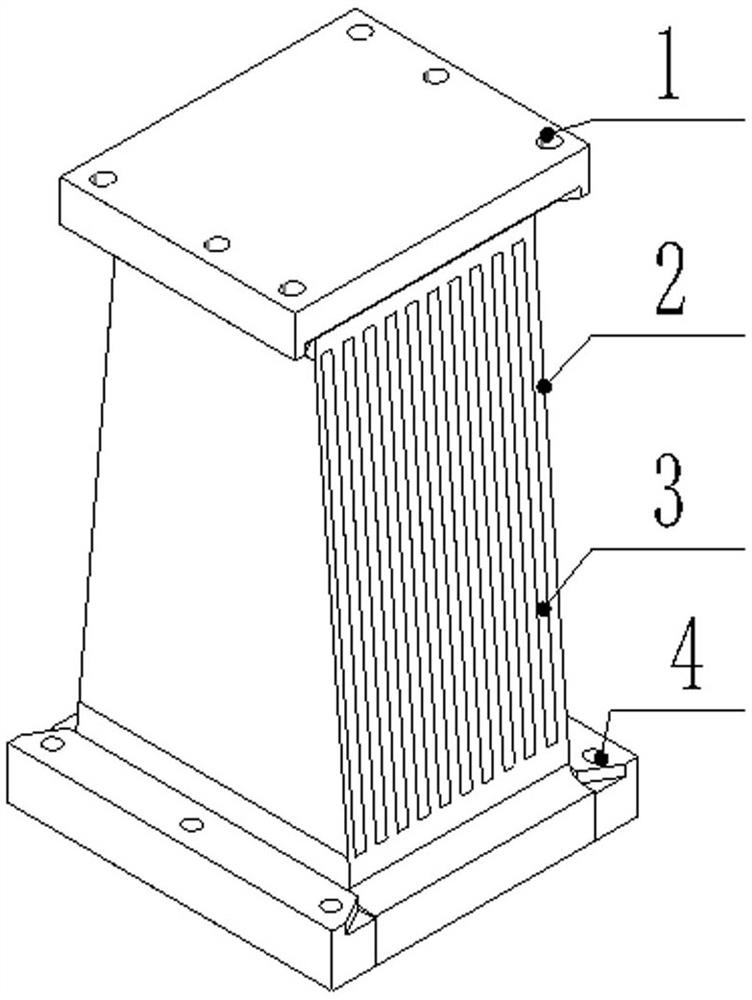

[0020] Such as figure 1 As shown, an integrally processed transverse anti-vibration machine base is integrally processed from a solid forging. The physical properties of the forging are significantly better than that of the casting. Therefore, the mechanical properties of the material of the base of the machine base are significantly improved.

[0021] It consists of top plate 1, web plate 2, through groove 3 and bottom plate 4;

[0022] A web 2 is arranged between the top plate 1 and the bottom plate 4;

[0023] The web 2 is provided with more than two through grooves 3, the width of each through groove 3 is the same, and the thickness of the base material of the web 2 is the same, forming parallel slits and a grid pattern of alternating parallel webs; The machine base has elasticity and flexibility in the lateral direction, which significantly improves the ability of the machine base to withstand lateral deformation. When the supported equipment is subjected to a lateral l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com