Patents

Literature

164results about How to "Aspect ratio height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

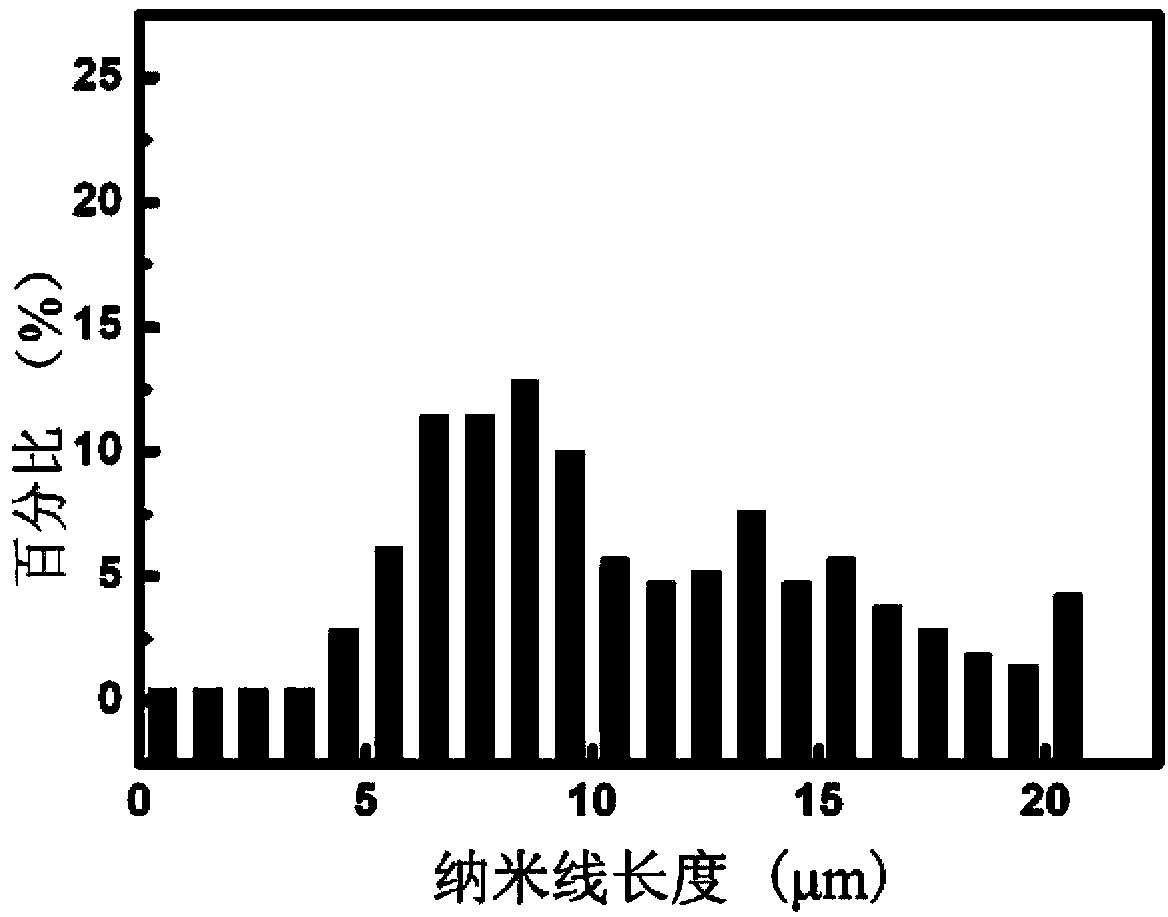

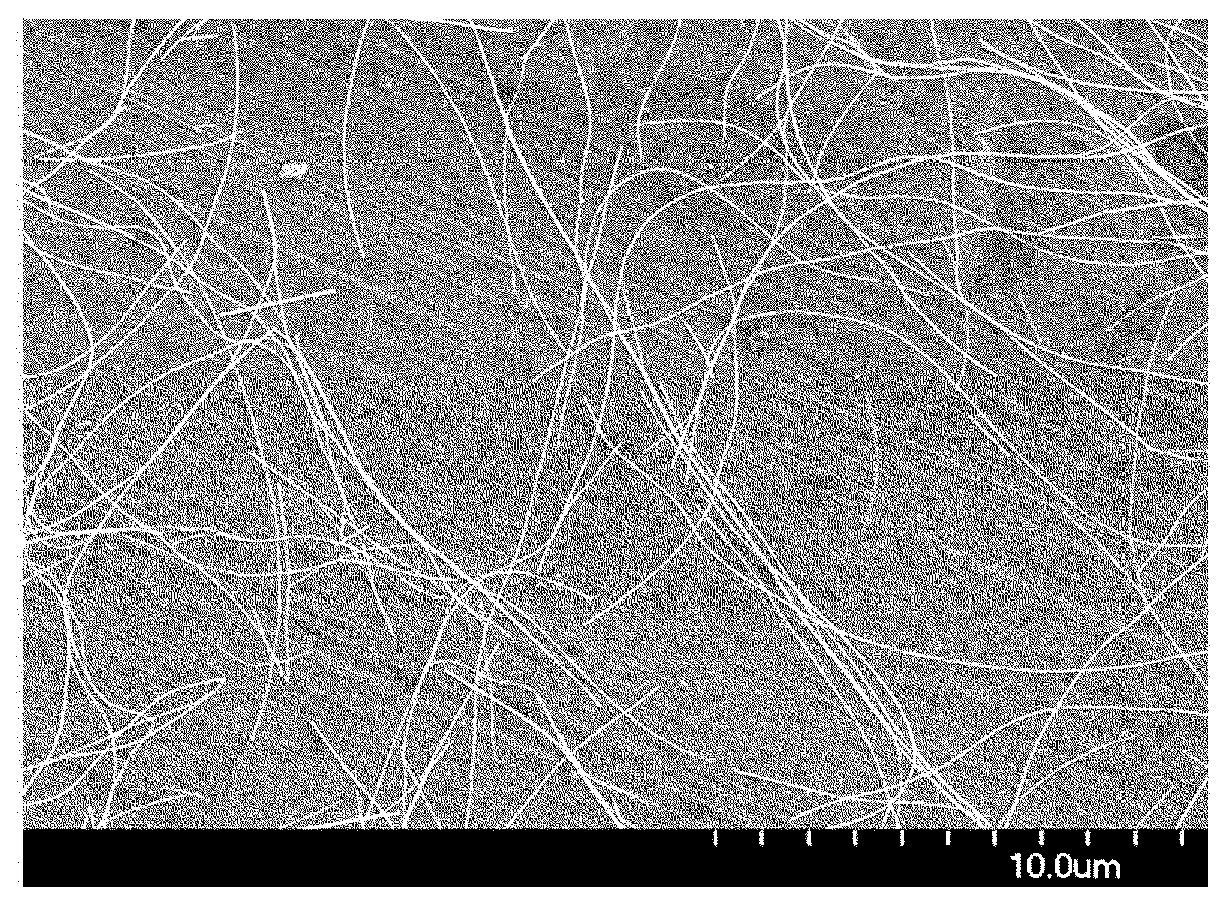

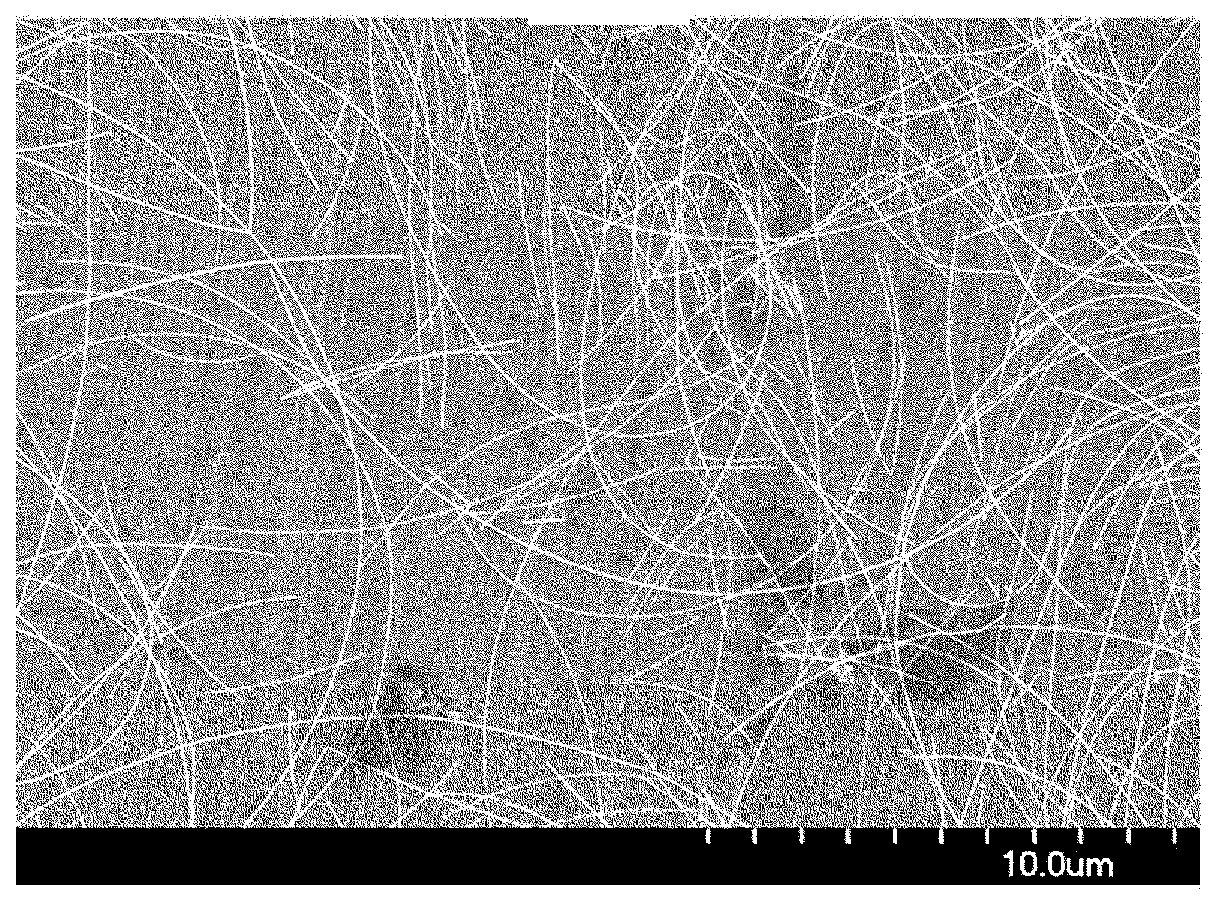

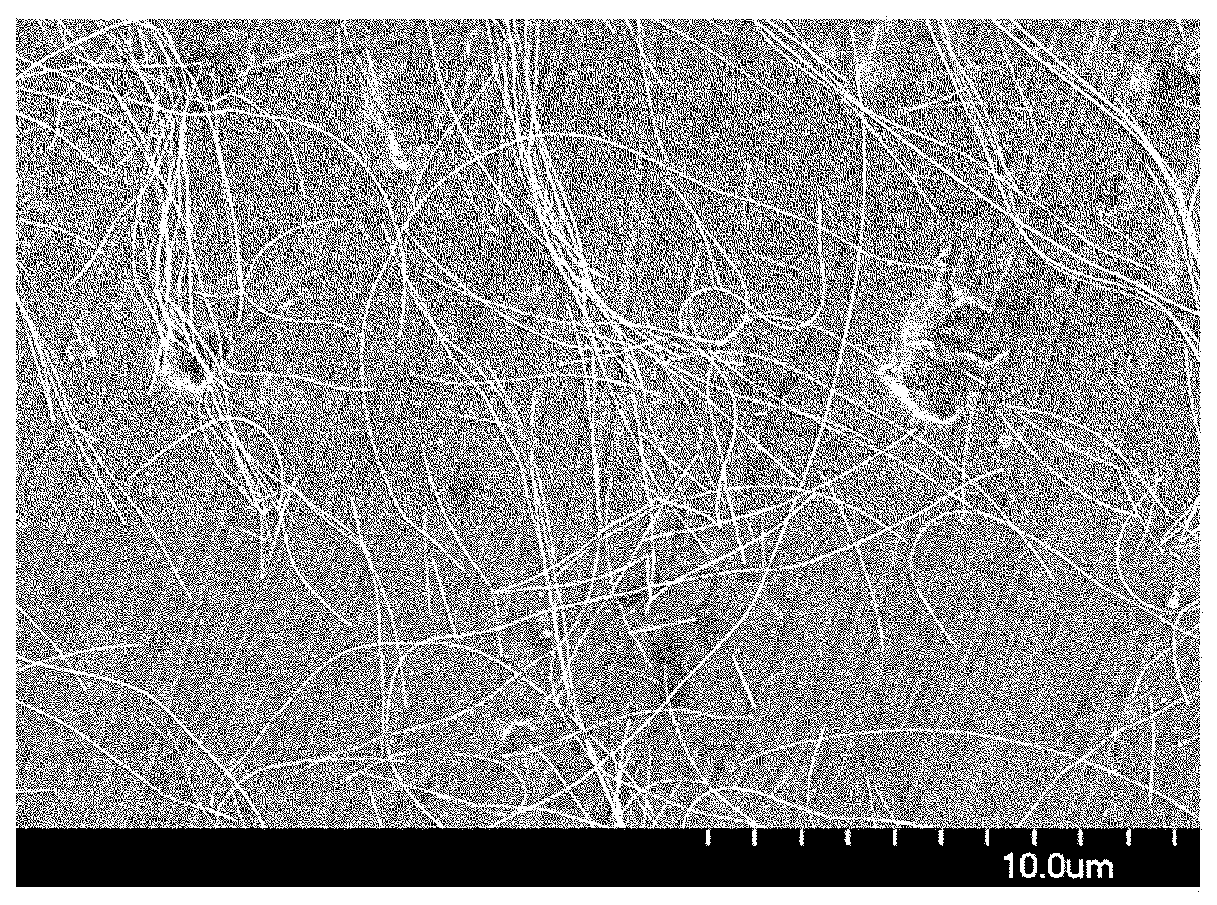

Preparation method and application of silver nanowire with high length-width ratio

ActiveCN103357889AGrowth inhibitionPrompt generation and lengthConductive layers on insulating-supportsMetal/alloy conductorsWidth ratioElectrically conductive

The invention discloses a method for compositing a silver nanowire with a high length-width ratio, that is, through a one-time addition of silver salt to carry out reduction reaction, the silver nanowire with the average length of more than 52 micrometers and the average length-width ratio of more than 400 can be acquired. The method does not need to accurately control the adding velocity of reactant, the composited silver nanowire is good in dispersity and high in uniformity, compared with the traditional polyhydric alcohol method, the average length-width ratio of the silver nanowire is improved by more than 5 times, through the preparation of a flexible transparent conductive film on a transparent flexible plastic substrate, the visible light penetration rate is more than 90 %, and the square resistance is lower than 10 Omega / square. Compared with the traditional polyhydric alcohol method, the method provided by the invention is simple in technology control and high in repeatability, and is in favor of the batch production of the silver nanowire with the high length-width ratio.

Owner:CENT SOUTH UNIV

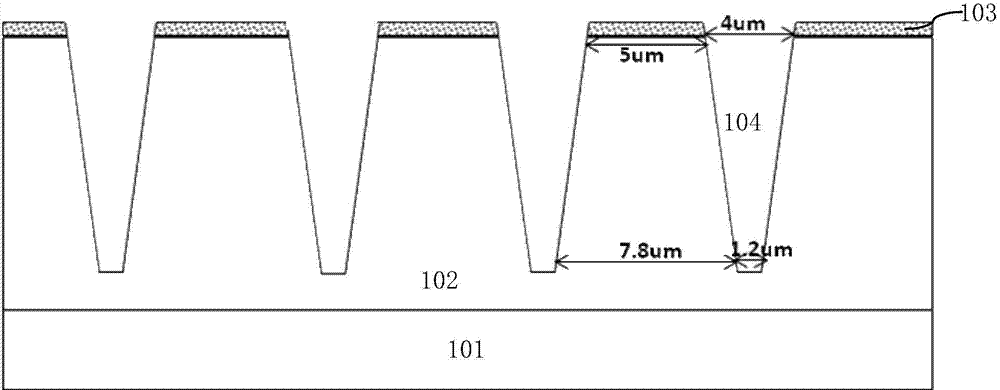

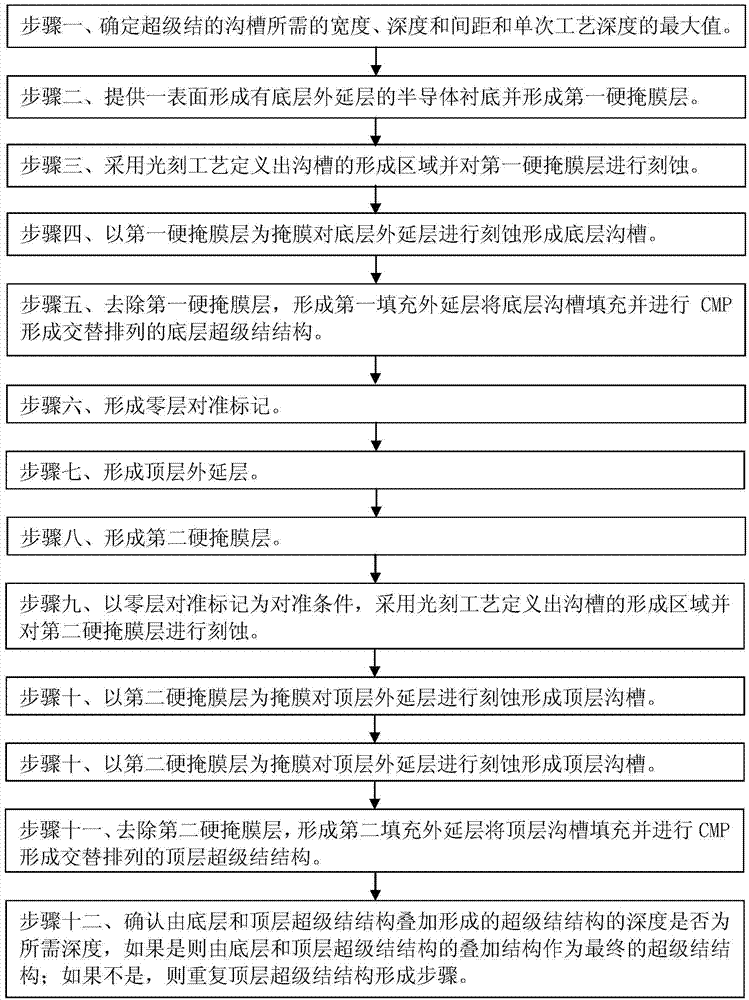

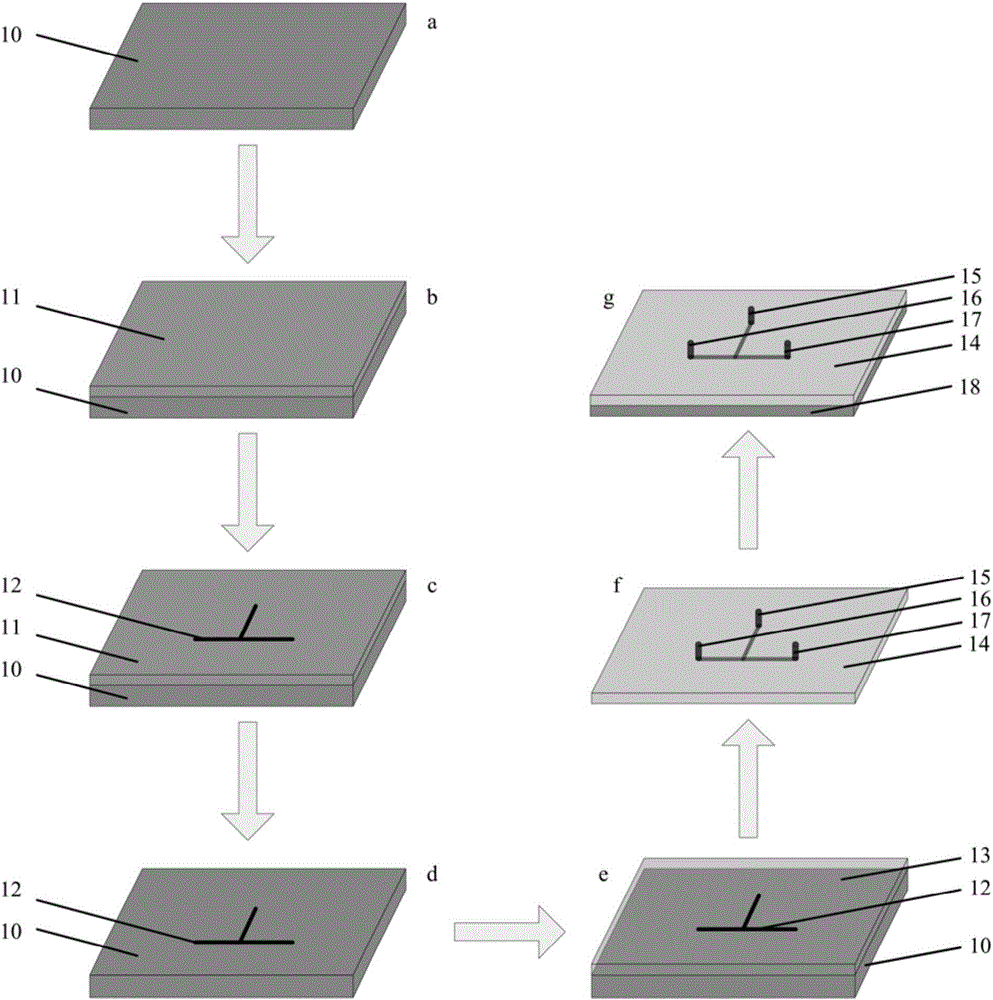

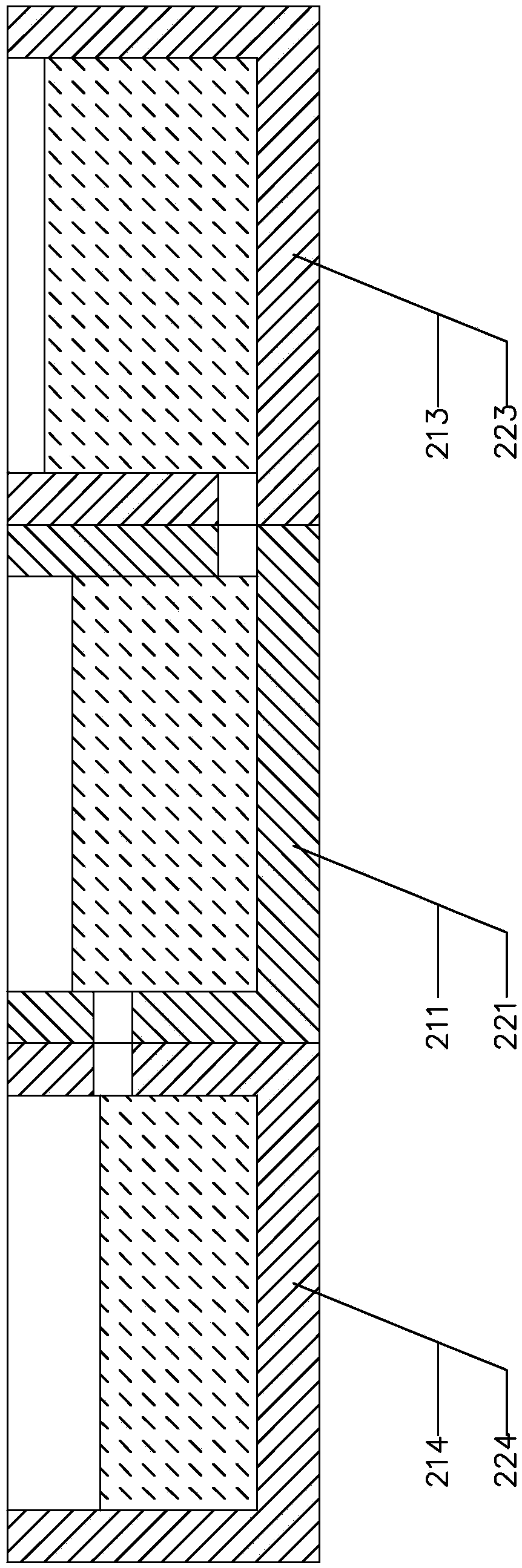

Manufacturing method of groove-type superjunction device

ActiveCN104779293AImprove in-plane uniformityImprove in-plane uniformity and increase trench aspect ratioSemiconductor/solid-state device manufacturingSemiconductor devicesSingle processEngineering

The invention discloses a manufacturing method of a groove-type superjunction device. The manufacturing method comprises the following steps as follows: determining groove size parameters and the maximum value of a single-process depth; providing a substrate, and forming a first hard mask layer; defining a groove forming region; etching a bottom epitaxial layer to form a bottom groove; removing the first hard mask layer, epitaxially filling the bottom groove, and performing CMP; forming a zero layer aligning mark; forming a top epitaxial layer; forming a second hard mask layer; with the zero layer aligning mark as a aligning condition, defining the groove forming region; etching the top epitaxial layer to form a top groove; removing the second hard mask layer, epitaxially filling the top groove, and performing CMP; checking whether the depth of a laminated superjunction structure reaches a required depth, if so, ending the manufacturing method, otherwise, repeating the top superjunction structure forming step. By the manufacturing method, reverse breakdown voltage of a superjunction device can be increased, the conduction resistance can be reduced, the existing equipment and the existing process can be utilized to the maximum extent.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Preparation method of carbon nano-tube array and its application in preparing antenna array

InactiveCN1948142AReduce lossPrecise scale controlAntenna arraysIndividual molecule manipulationFiberOptical frequencies

The present invention relates to a carbon nano tube array, its preparation method and application in preparation of optical frequency dipole antenna array. The invented carbon nano tube optical frequency dipole antenna array is characterized by that the carbon nano tubes are perpendicular to the substrate material and arranged, the length and diameter ratio of carbon nano tube of fibre is greater then 10. The method for making the carbon nano tube array is characterized by that it uses transition metal film catalyst to regulate its thickness, and utilizes plasma chemical gas phase deposition system to regulate plasma energy density and distribution, controls reaction time, gas pressure and gas flow speed ratio so as to implement large-area perpendicular growth of carbon nano tube or fibre array on various substrates at lower temperature and accurately control length and diameter of produced carbon nano tube or fibre.

Owner:王洋

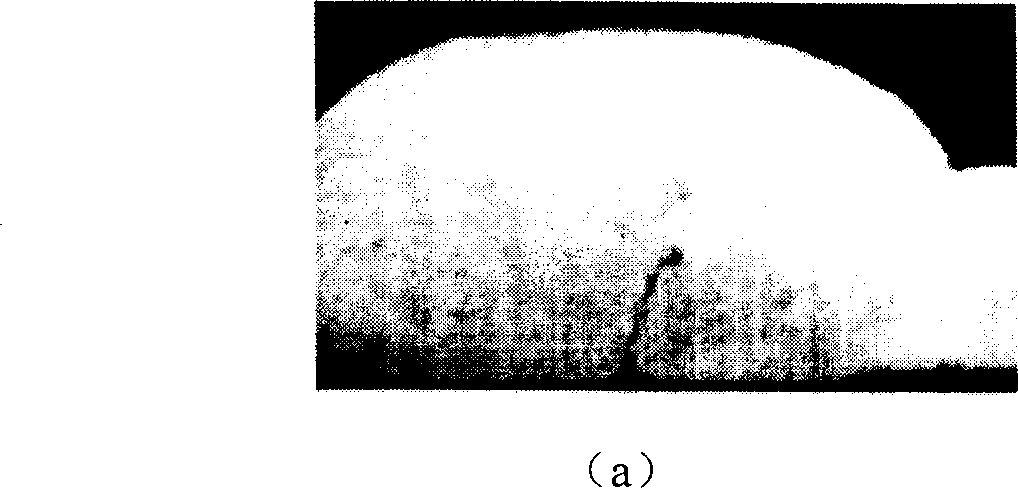

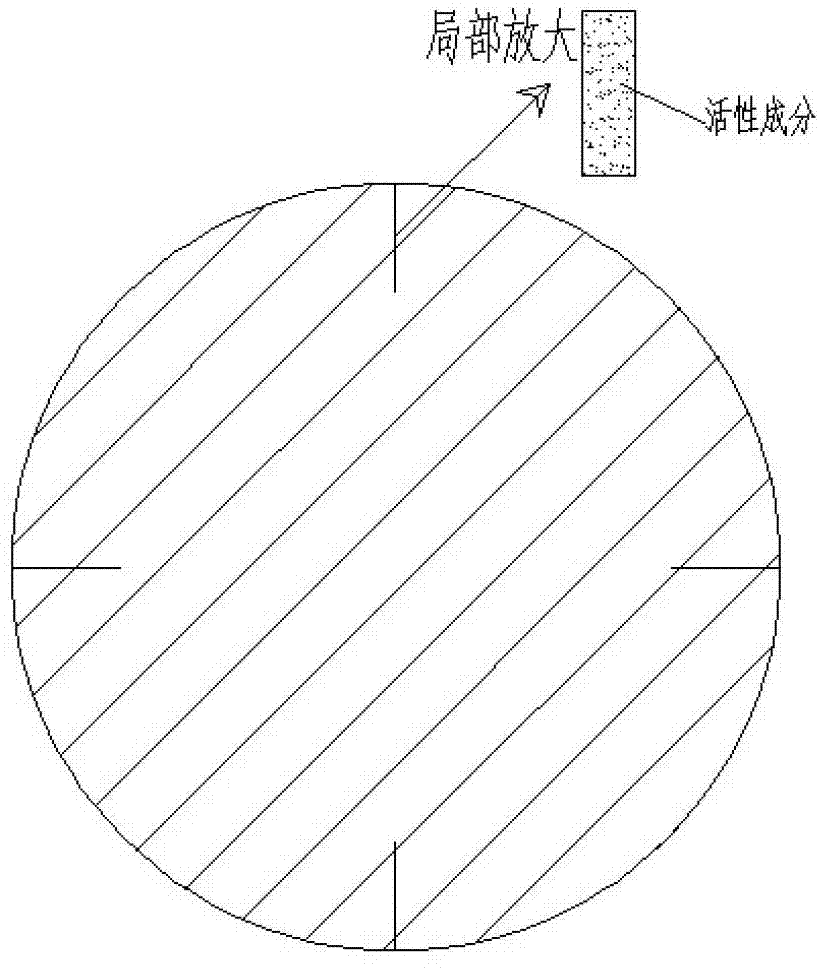

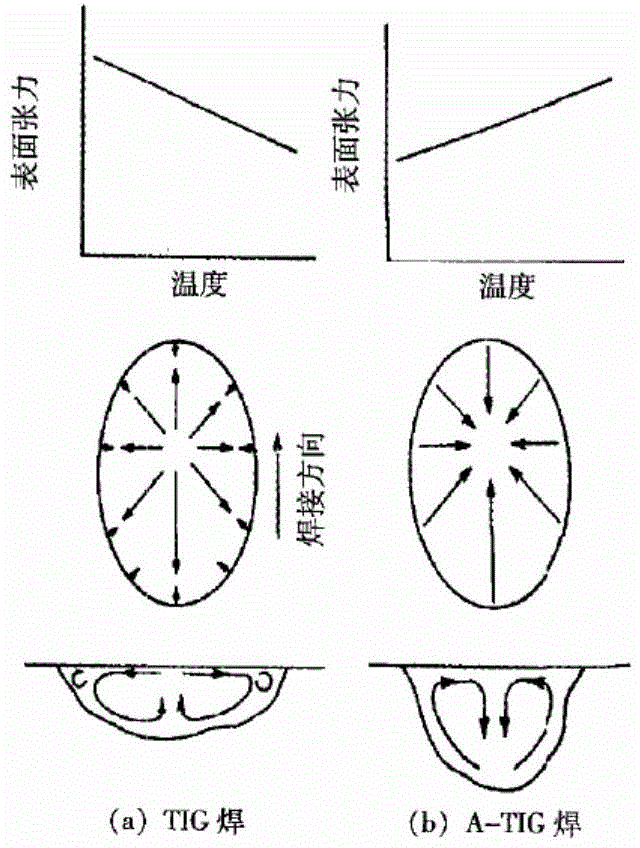

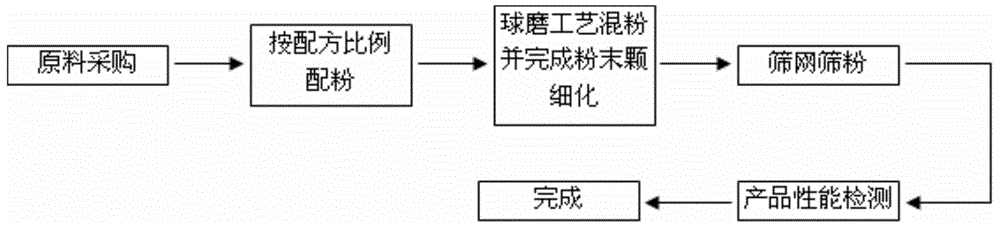

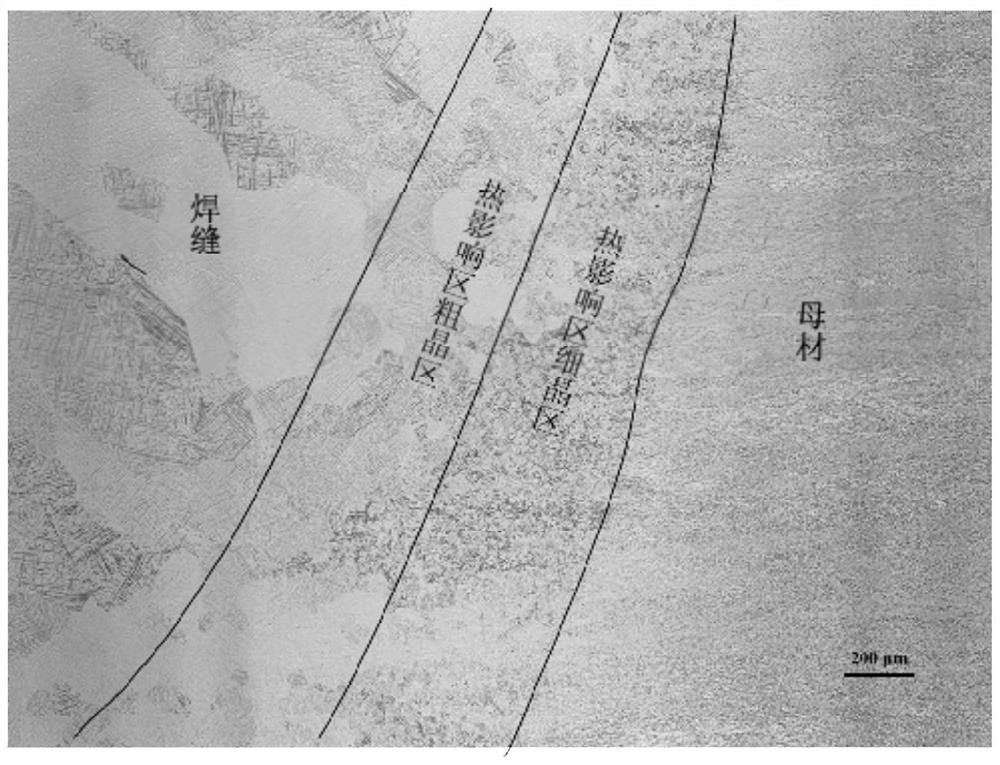

Surfactant for magnesium alloy TIG welding and its prepn process and usage

InactiveCN1974112AAspect ratio heightImprove welding productivityArc welding apparatusWelding/cutting media/materialsMetallic materialsSlurry

The present invention relates to one kind of surfactant for magnesium alloy TIG welding and its preparation process and usage, and belongs to the field of metal material welding technology. The surfactant consists of CdCl2 and / or ZnCl2 40-60 wt%, Cr2O3 15-25 wt%, TiO2 15-25 wt% and SiO2 for the rest. Its preparation process includes mixing the materials and the subsequent ball milling for 2-4 hr. When the surfactant is used, it is first mixed with acetone and / or alcohol to form slurry for easy applying and then spread to the surface of weld pass in the amount of 1-6 mg / sq cm, and after the coating is dried, TIG welding is performed. The surfactant can ensure the welding seam quality, obviously increase fusion depth of the welding seam, simplify the welding process, raise welding efficiency, and lower production efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

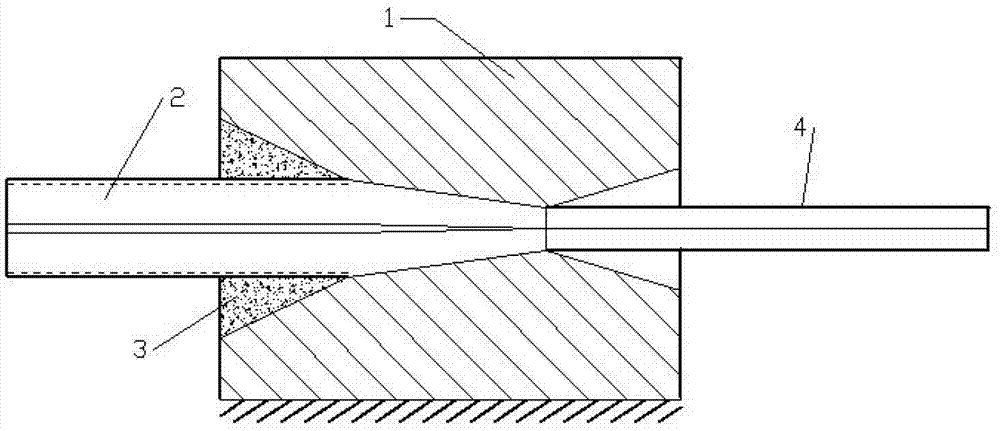

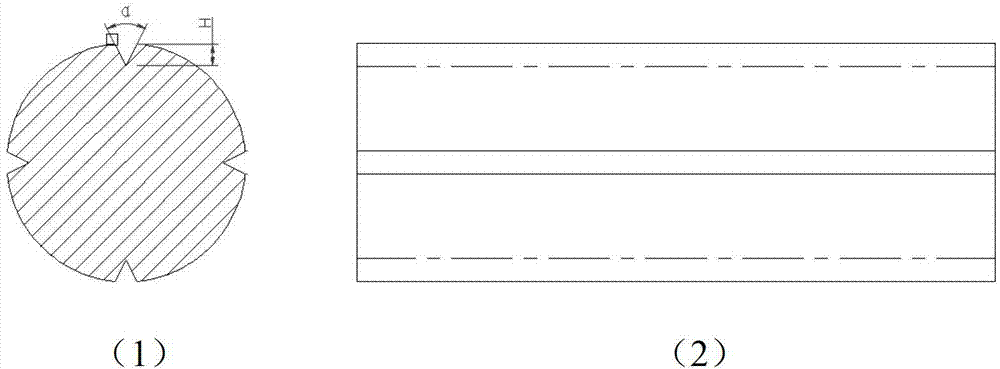

Multi-stage drawing manufacturing method for superfine fluted tube

InactiveCN101898204AIncrease capillary pressureImprove heat transfer performance% diameter reductionKnife holder

The invention discloses a multi-stage drawing manufacturing method for a superfine fluted tube. The method comprises the following steps of: reducing the external diameter of one end of a copper tube with diameter of 6mm to 2.8 to 3mm on a forging hammer type pipe-shrinkage machine; then clamping and fixing a tube reduction die clamp on a horizontal lathe; allowing the diameter reduction section of the copper tube pass through a tube reduction die, clamping and fixing the tube reduction die on a tool rest of the horizontal lathe, starting the horizontal lathe, and drawing the whole copper tube to pass through the tube reduction die, wherein the tube reduction die comprises an induction section and a reforming section, the induction section is a cone-shaped face with cone angle of 20 to 40 DEG C, the reforming section is a round through hole, and under the extrusion of the tube reduction die, the green body of the copper tube performs plastic deformation and the external diameter is reduced; and after first drawing, replacing the tube reduction die by the tube reduction die with smaller through hole of the reforming section, and repeatedly drawing for multiple times until the external diameter of the copper tube is no more than 3mm. The method has the advantages of breaking through the restriction of the conventional manufacturing process for the fluted thermotube, obtaining superfine fluted tubes which have the diameter of no more than 3mm and good superfine fluted tube characteristic in batches, along with simple device and easy processing.

Owner:SOUTH CHINA UNIV OF TECH

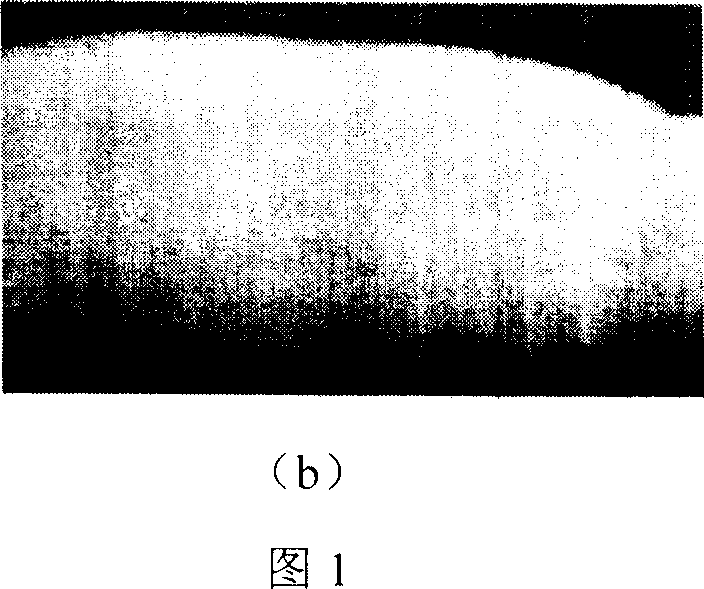

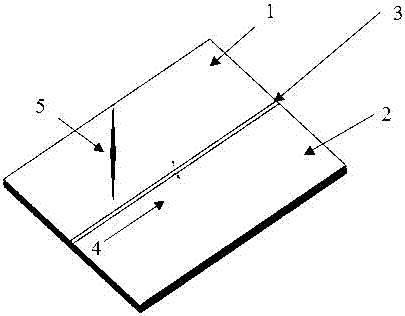

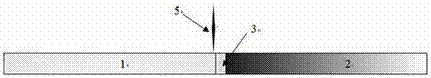

Active coating welding wire for carbon dioxide gas arc welding and preparation method thereof

InactiveCN102962598AStrong penetrating powerMelt width reductionArc welding apparatusWelding/cutting media/materialsWire rodActive agent

The invention discloses an active coating welding wire for carbon dioxide gas arc welding and a preparation method thereof. A wire rod is scored in a horizontal direction and a vertical direction, then the wire rod passes through a wire drawing die added with an active agent, the active agent is compounded with the wire rod, and the wire rod is enable to reaches the corresponding required size through drawing. The active coating welding wire and the preparation method have the advantages that H08A steel is used as the main raw material of the welding wire, so the manufacture cost is low; the production process is simple; and the surface of the welding wire is added with the active agent, so the conductivity and the wire feeding stability are ensured, meanwhile, the forming of weld joints is ensurimproved, the spattering of the welding wire in the welding process is reduced, and the forming effect is good.

Owner:TIANJIN UNIV

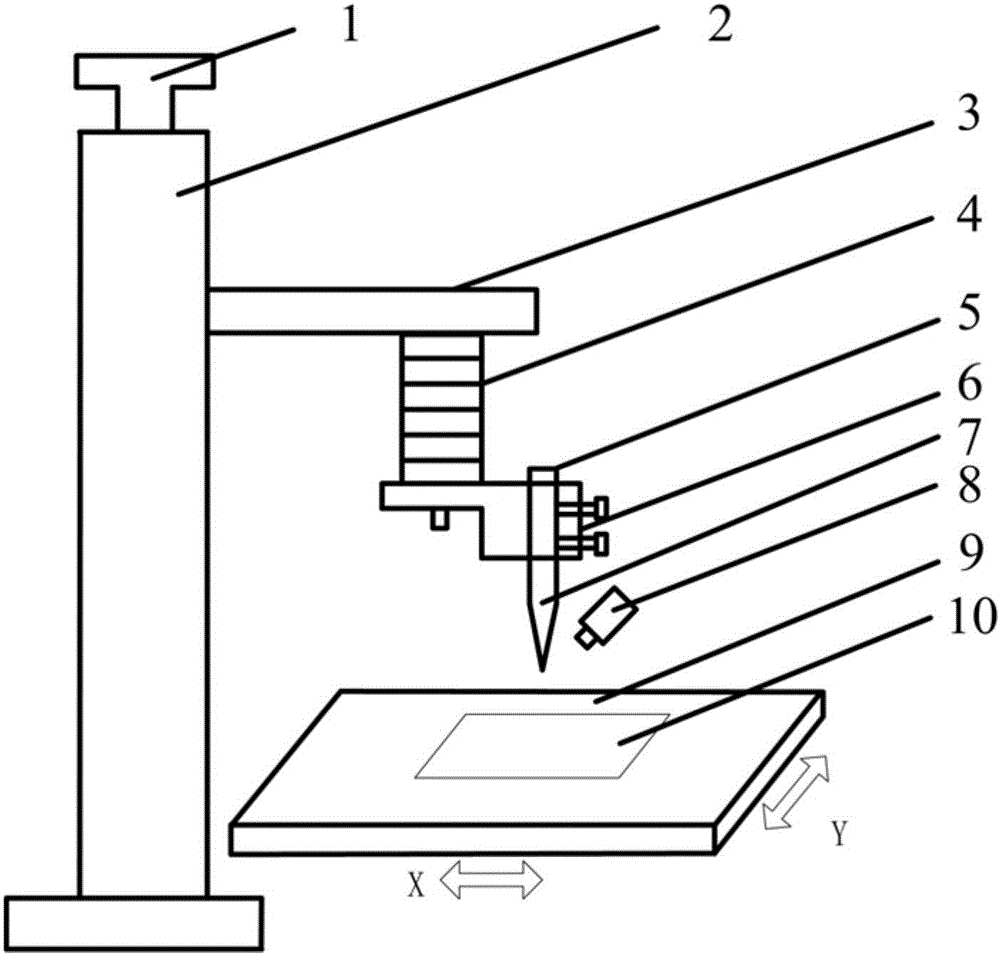

Titanium alloy welding active agent and welding method

ActiveCN104646866AIncrease weld penetrationAspect ratio heightArc welding apparatusWelding/cutting media/materialsActive agentTitanium alloy

The invention provides a titanium alloy welding active agent and a welding method, which is suitable for welding titanium alloy such as TC4. The trademark of the titanium alloy welding active agent is A-TIG-Ti-01, and the titanium alloy welding active agent consists of CaF2, MgF2 and SrF2; the mass content of the CaF2 is 15 to 25 percent; the mass content of the MgF2 is 5 to 15 percent; the mass content of the SrF2 is the residual amount. By adopting the titanium alloy welding active agent, the welding melting depth of the titanium alloy can be increased, the connector performance is excellent, and the titanium alloy welding active agent is suitable for welding a titanium alloy plane structure and a titanium alloy curved structure.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Microfluidic chip shear flow based microcapsule preparation method

The invention discloses a microfluidic chip shear flow based microcapsule preparation method. The method includes the steps of: adopting droplet micro-spray technique to prepare a micro-fluidic chip hydrogel male mould on a glass substrate spin-coated with a sodium alginate coating; then preparing a PDMS micro-fluidic chip negative mould by molding; and bonding the micro-fluidic chip negative mould and the glass substrate together by means of reversible bonding, thus obtaining a micro-fluidic chip; letting a kerosene solution and water of a microcapsule pass through liquid inlets of the micro-fluidic chip respectively through injection pumps, thus obtaining the needed microcapsule at a liquid outlet. According to the invention, the microfluidic chip preparation process is simple, the cost is low, preparation of the hydrogel male mould has no need for specific template, the hydrogel male mould with arbitrary pattern and controllable height can be prepared, and the microfluidic chip has smooth flow channel and large depth-to-width ratio. The prepared microcapsule has the advantages of good consistency and uniform dispersion, uniform and controllable particle size, and good biological activity.

Owner:NANJING UNIV OF SCI & TECH

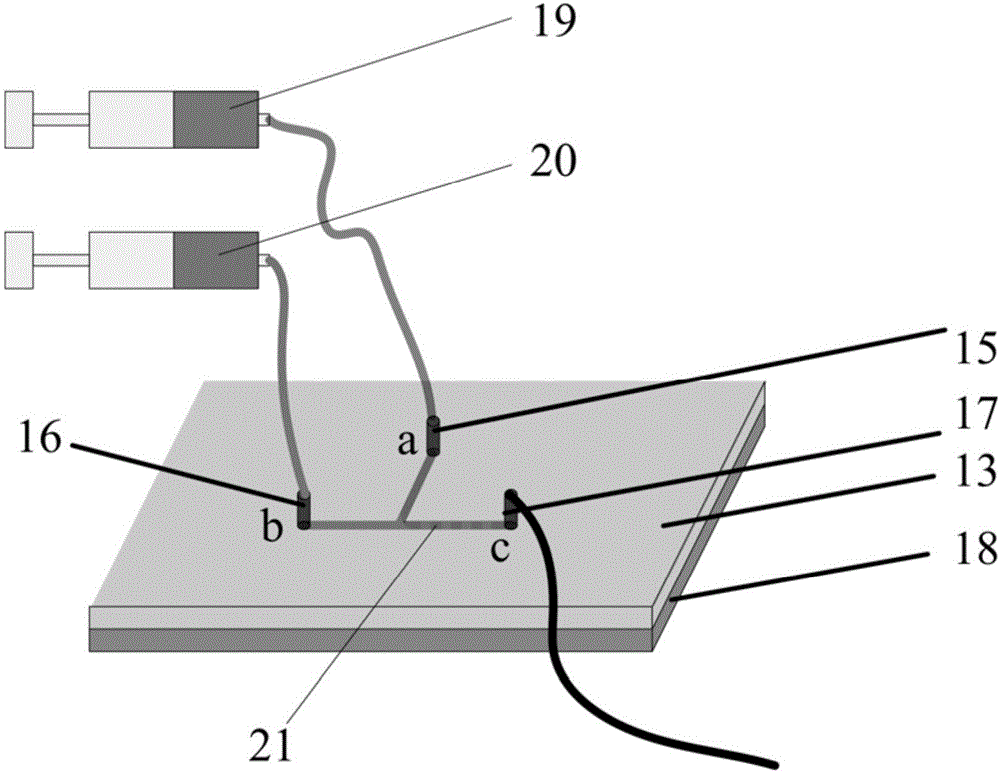

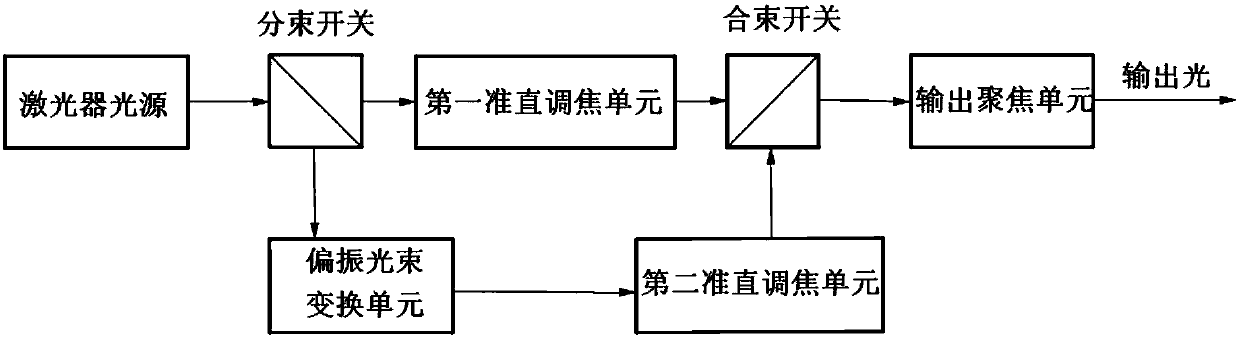

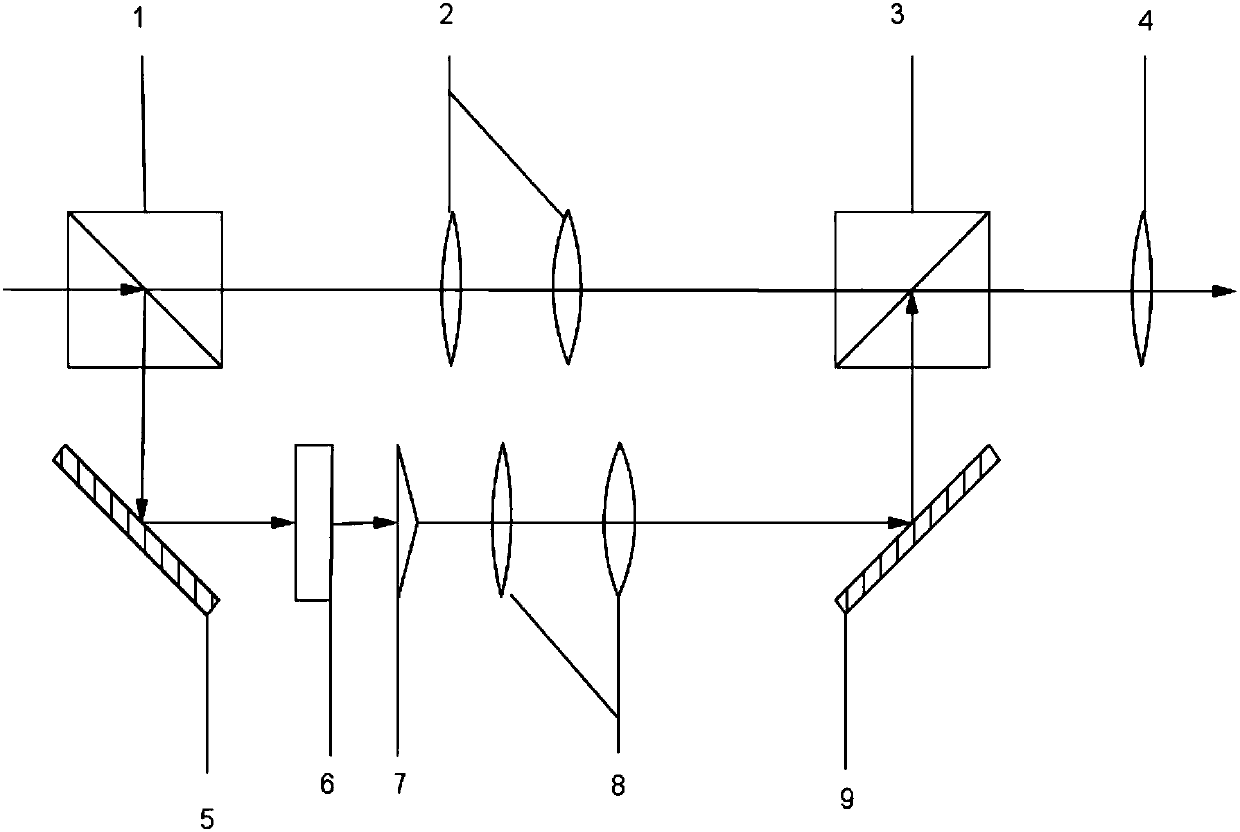

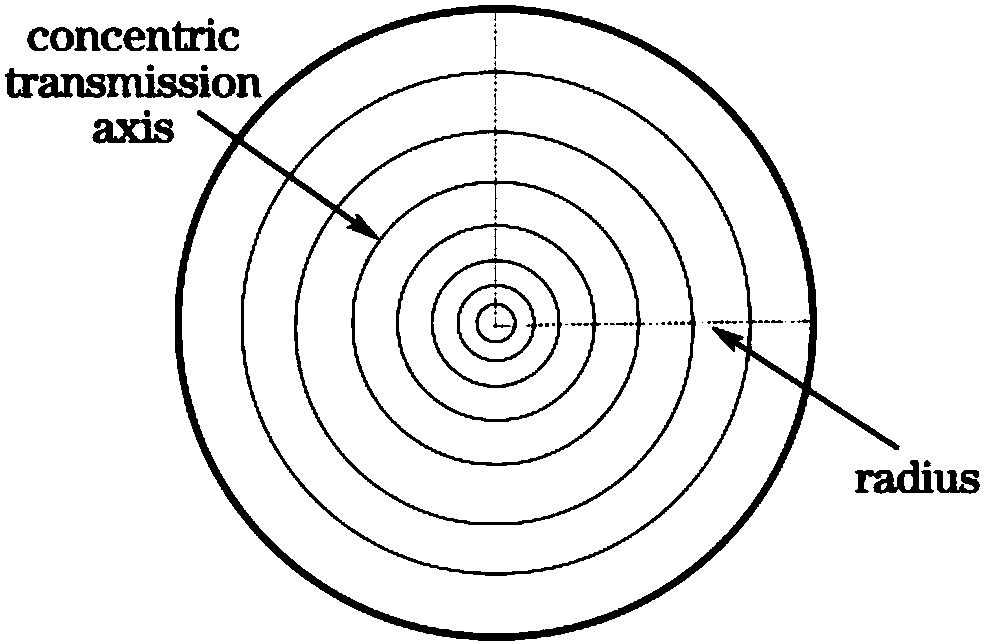

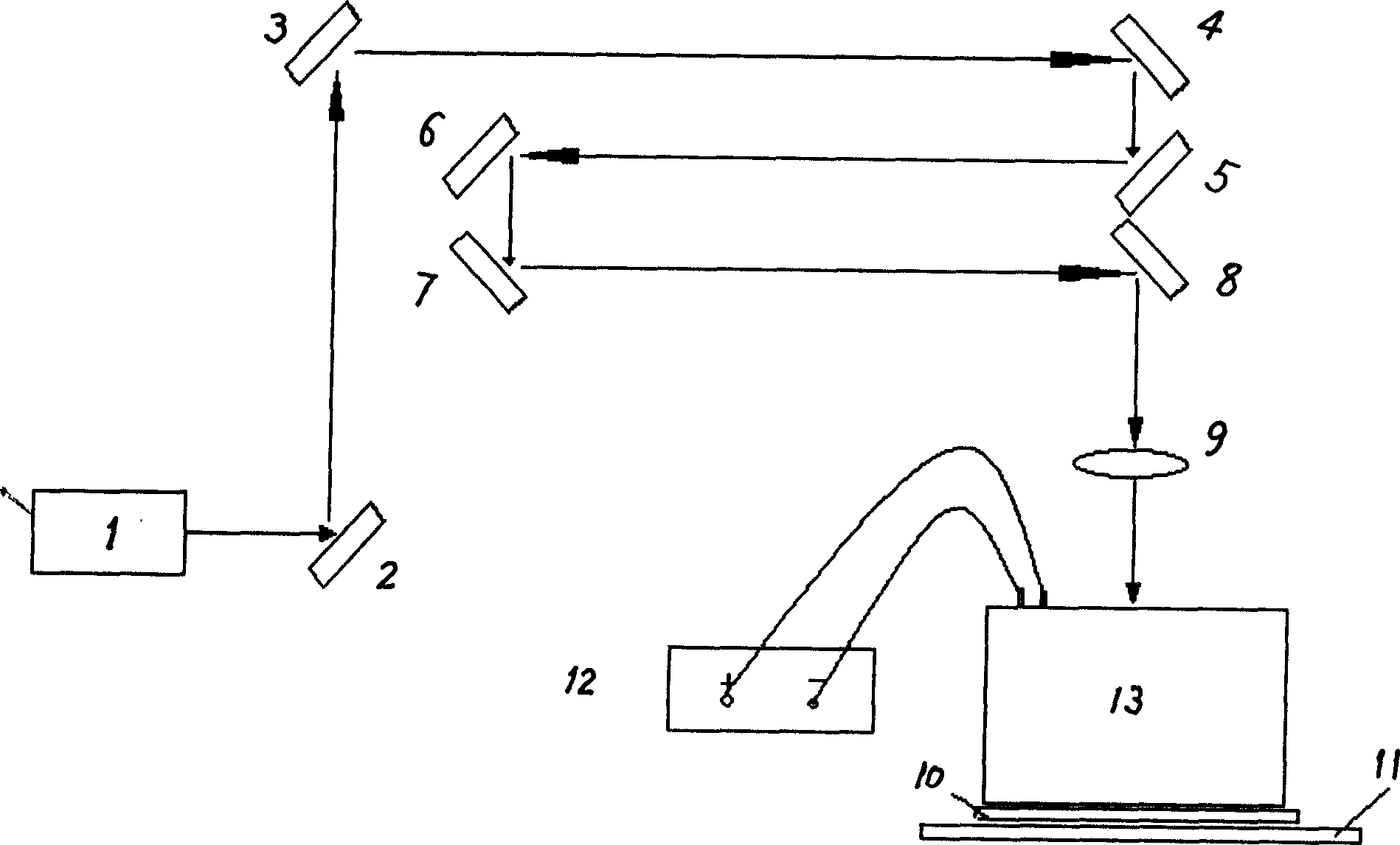

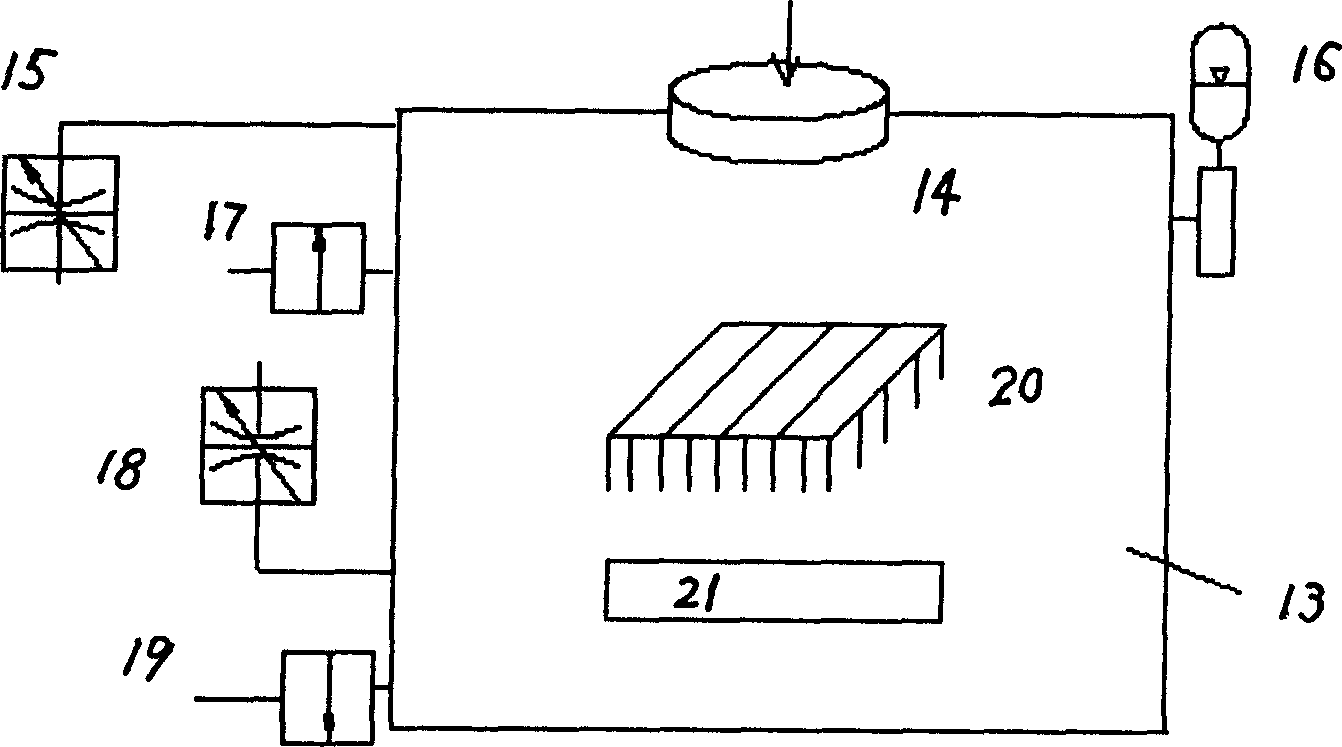

Method and system for laser drilling

PendingCN107824959ANo change in structureEasy to installLaser beam welding apparatusGaussian beamBeam splitting

The invention discloses a method and a system for laser drilling. The system for laser drilling comprises a laser light source, a beam splitting switch and a beam combining switch; a polarized beam conversion unit; the laser light source is used for emitting a fundamental-mode Gaussian beam; the beam splitting switch is used for controlling whether the fundamental-mode Gaussian beam to be deflected or not, when no deflection occurs, and the fundamental-mode Gaussian beam acts on a workpiece to be machined through the beam splitting switch; the polarized beam conversion unit is used for converting the deflected fundamental-mode Gaussian beam into an annular azimuthally polarization type Laguerre-Gaussian beam when the fundamental-mode Gaussian beam is deflected; and the beam combining switch is used for controlling the annular azimuthally polarization type Laguerre-Gaussian beam to be deflected so as to enable the deflected annular azimuthally polarization type Laguerre-Gaussian beam tobe coaxial with the fundamental-mode Gaussian beam emitted by the laser light source so that the annular azimuthally polarization type Laguerre-Gaussian beam can act on the workpiece to be machined.According to the method and the system, an aperture with a larger depth-to-width ratio and a smaller taper can be obtained under the condition of the same energy output.

Owner:HUAZHONG UNIV OF SCI & TECH

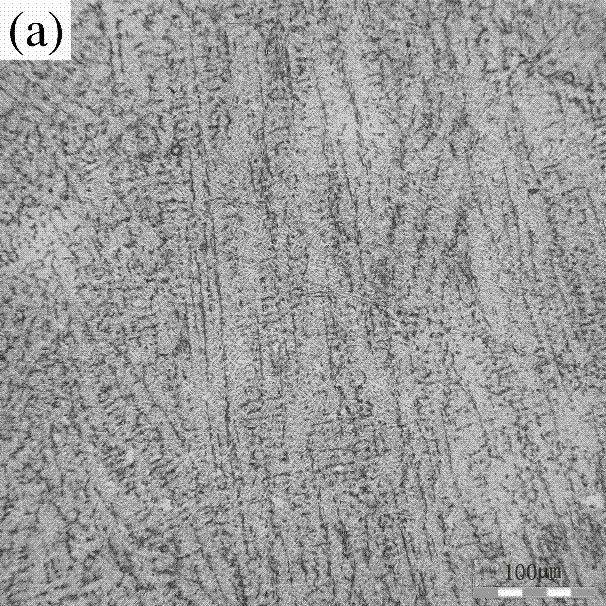

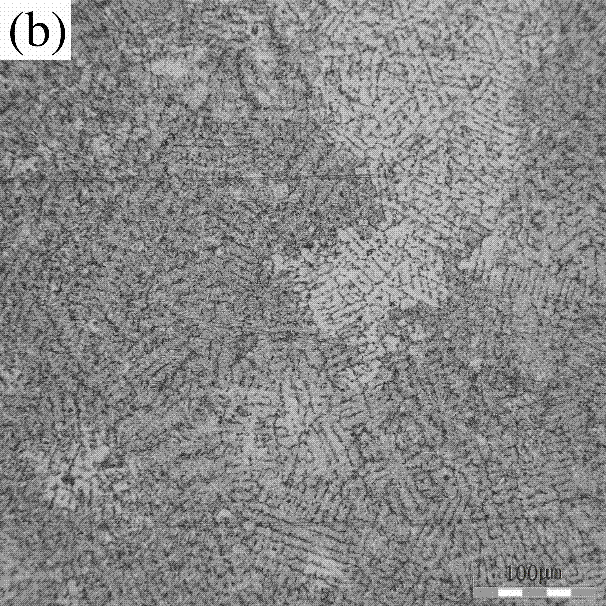

Welding agent-core welding wire for titanium and titanium alloy

ActiveCN107363433AAspect ratio heightEasy to cleanWelding/cutting media/materialsSoldering mediaHydrogenActive agent

The invention provides a welding agent-core welding wire for titanium and titanium alloy. The welding wire is composed of an outer skin and an internal active welding agent core. The outer skin is composed of a titanium belt in which the mass percent of titanium is not less than 98% and the mass percent of hydrogen is not more than 0.015%, and the internal active welding agent core consisting of metal power, Si powder, B powder and an active agent, and comprising the following components in percentage by weight: 16%-34% of Ti, 2%-6% of B, 0.2-0.4% of Co, 0.8-1% of Mn, 0.10%-0.25% of Si, 1%-3% of Ni, 1%-3% of Ni, 1%-3% of Cu, 1%-5% of chloride, 12%-16% of fluoroaluminate, 5%-15% of MgF2, and 20%-60% of SrF2, wherein the chloride, the fluoroaluminate, MgF2 and SrF2 are active agent components in the welding agent core. The welding wire is large in welding depth-to-width ratio and high in melting efficiency, so that the welding technology is simplified in process, and applicable to welding the titanium and titanium alloy.

Owner:HARBIN INST OF TECH AT WEIHAI

Manufacturing method for quartz comb teeth capacitive accelerometer

ActiveCN104133079AIncrease temperatureCTE matchingAcceleration measurementImage resolutionThermal expansion

The invention relates to a manufacturing method for a quartz comb teeth capacitive accelerometer. The accelerometer comprises an upper cover plate, a lower cover plate and sensitive components. The manufacturing method refers to manufacturing of the sensitive components, manufacturing of the upper cover plate and the lower cover plate and bonding between the upper cover plate and the lower cover plate. According to the method, quartz materials are adopted in manufacturing of the teeth capacitive accelerometer for the first time, the manufacturing method aiming at the specific structure of the accelerometer is innovatively designed, and new purposes of the quartz materials are achieved. The whole structure of the capacitive accelerometer is made of the quartz materials, thermal expansion coefficient is matched with the accelerometer, temperature performance of sensors can be improved, great sensing masses and initial capacitance values can be obtained, sensitivity and resolution of the sensors can be obviously improved, and it is ensured that manufactured comb teeth have large depth-to-width ratios.

Owner:BEIJING RES INST OF TELEMETRY +1

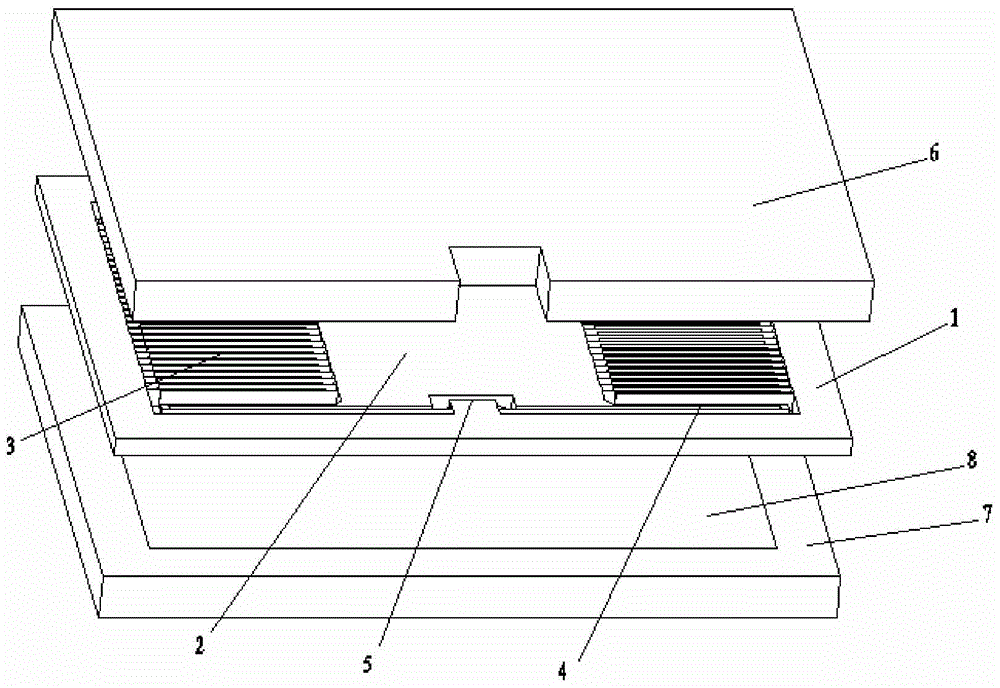

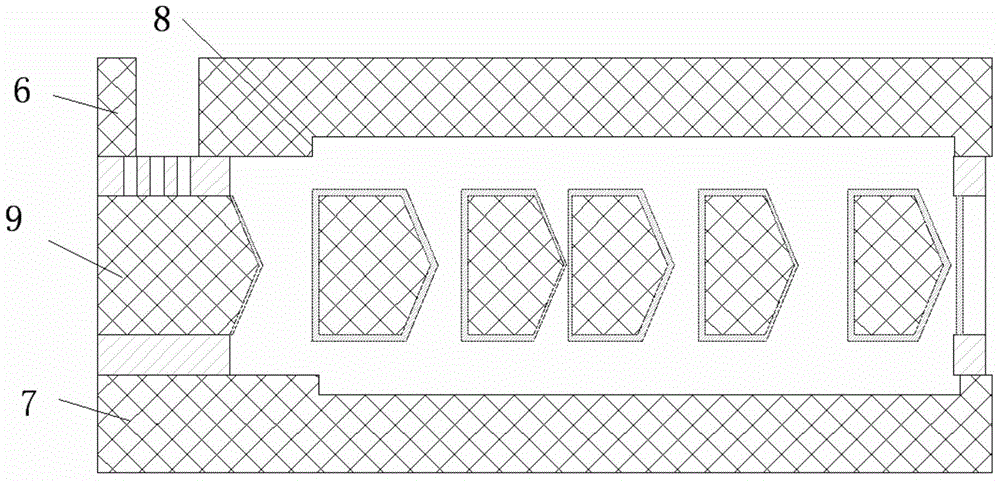

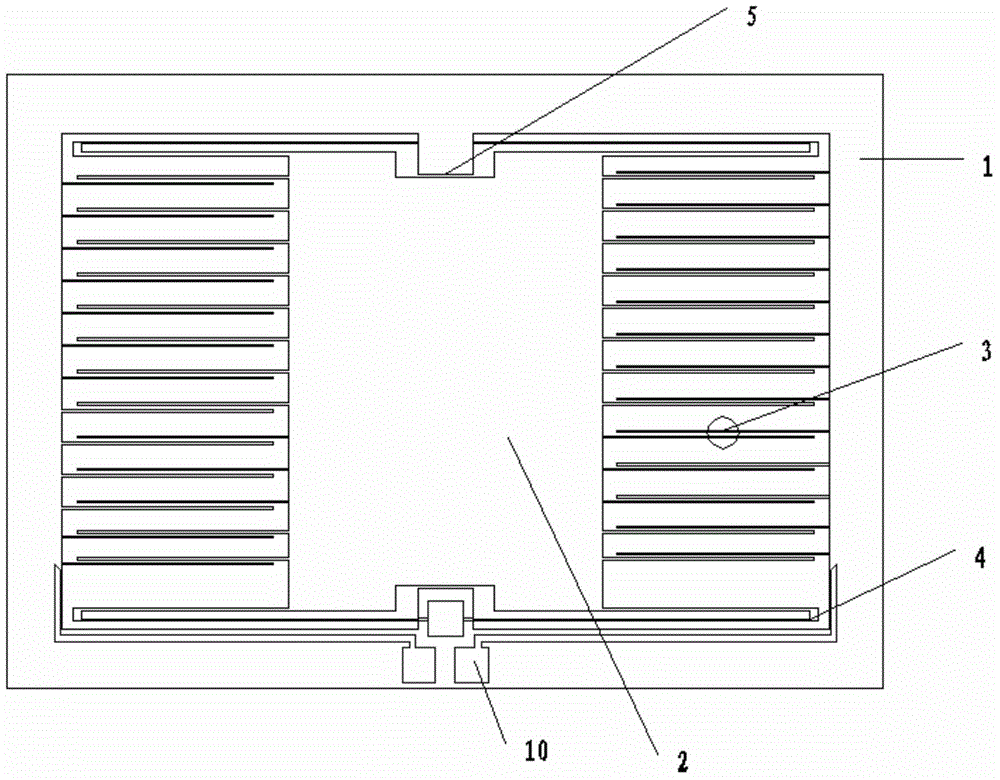

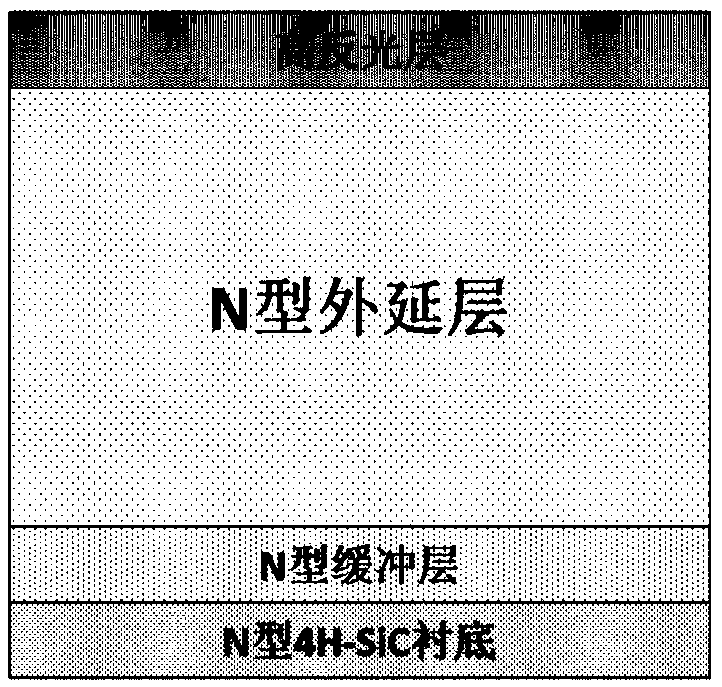

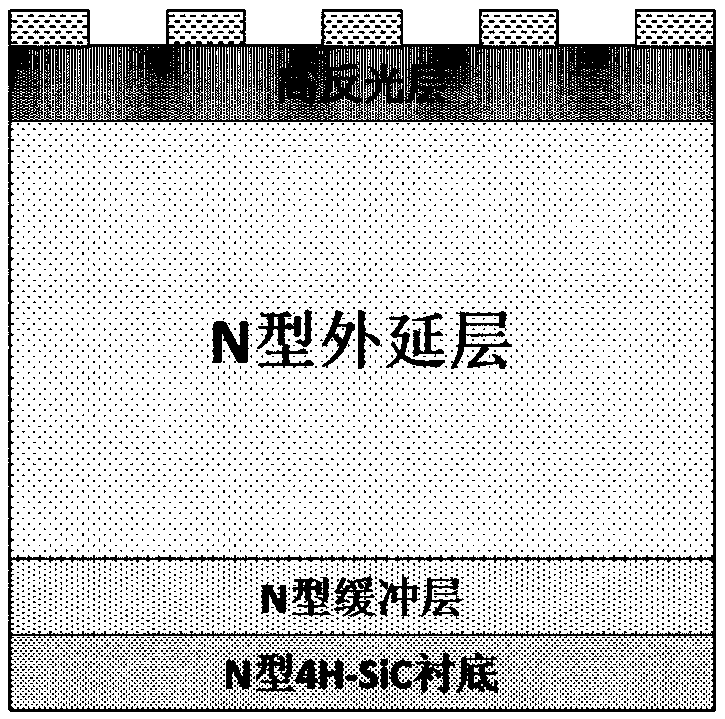

Method for preparing silicon carbide super-junction structure through laser etching

ActiveCN105529246AImprove efficiencyAspect ratio heightSemiconductor/solid-state device manufacturingSemiconductor devicesLaser etchingWidth ratio

The invention provides a method for preparing a silicon carbide super-junction structure. The method comprises the following steps: firstly carrying out graphical etching on silicon carbide epitaxial wafers by adopting laser etching so as to form grooves in the surfaces of the silicon carbide epitaxial wafers; and then carrying out epitaxial growth on silicon carbide in the grooves so as to form the silicon carbide super-junction structure. According to the method, the silicon carbide super-junction structure is prepared through the laser etching, the efficiency of forming the grooves in SiC through etching is obviously increased, the depth-to-width ratio is obviously promoted, and the structure also has the advantages of good uniformity, groove side wall smoothness, simple technology, high operability and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

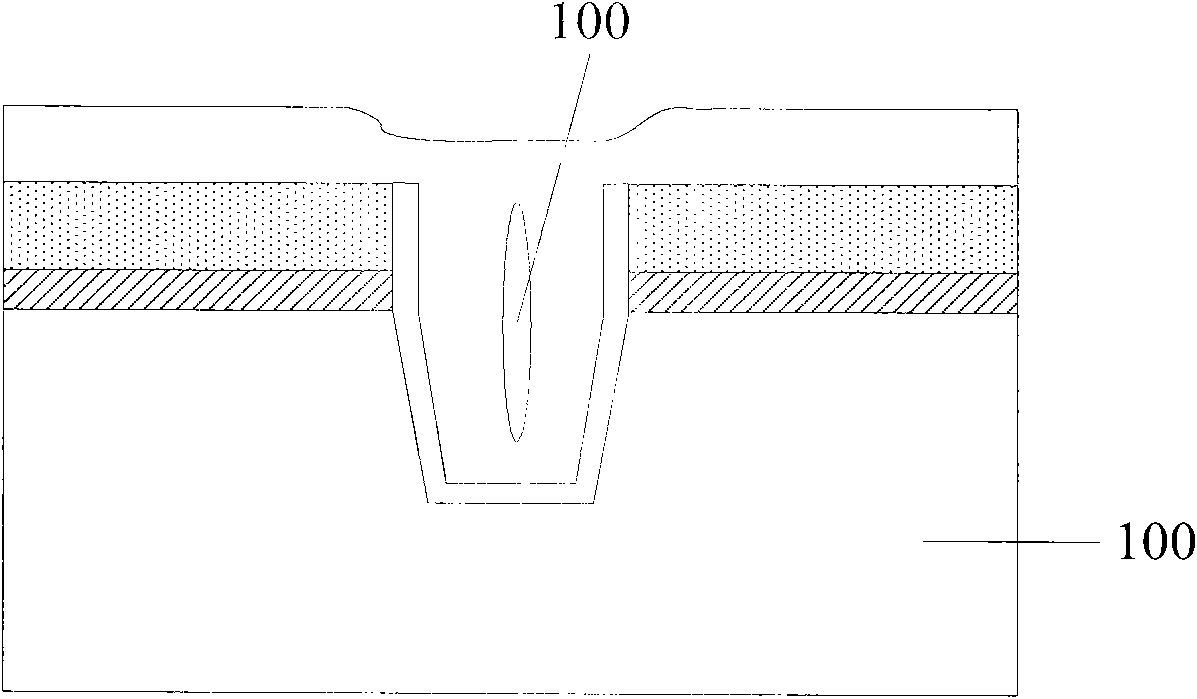

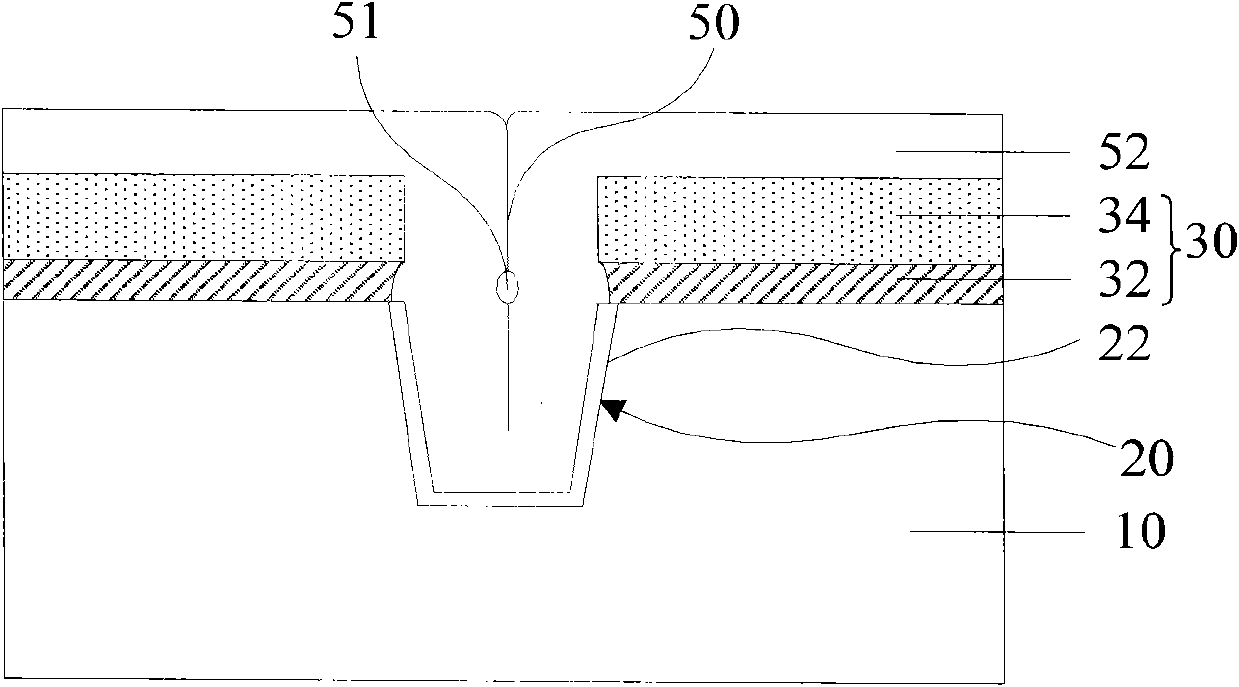

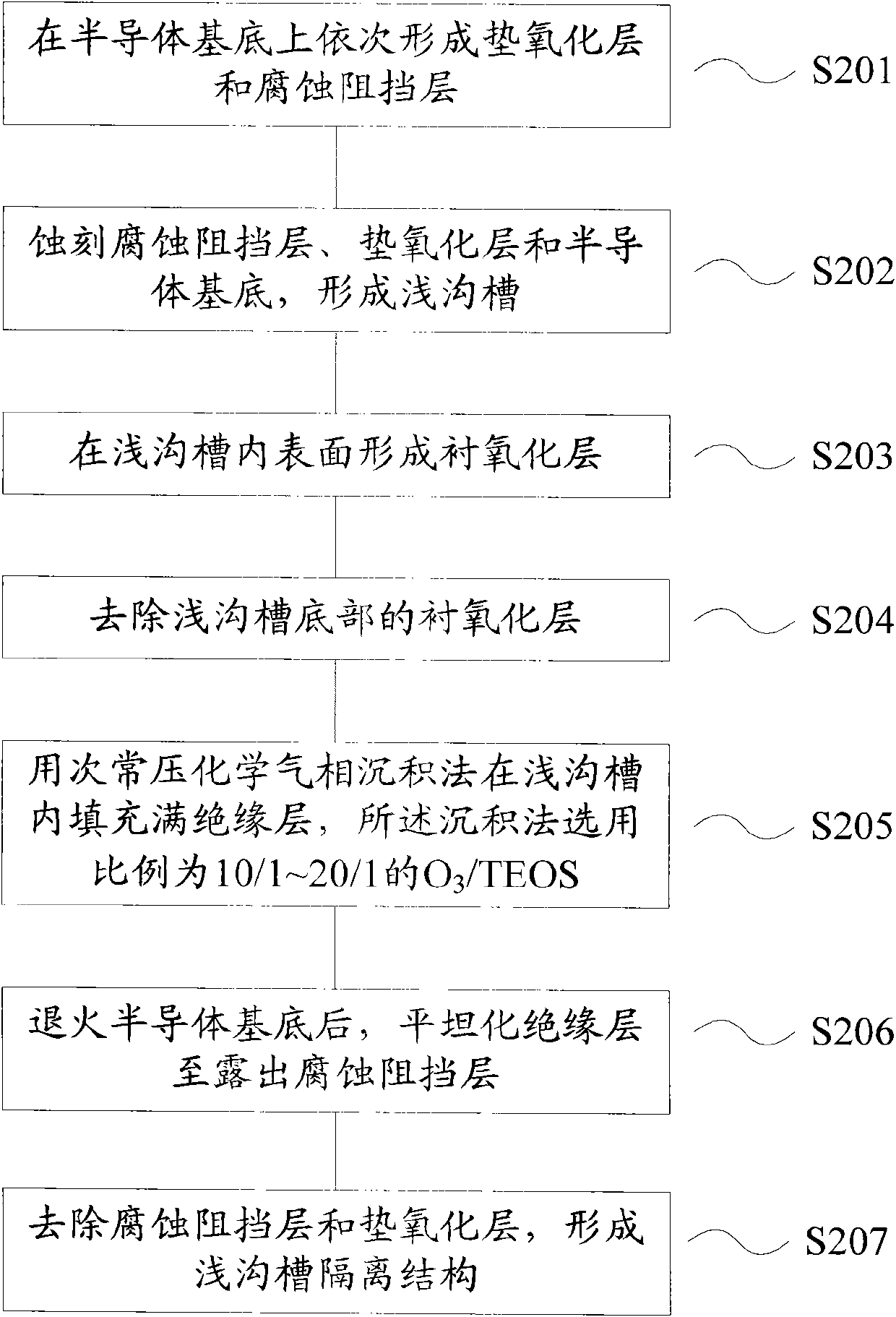

STI (Shallow Trench Isolation) structure and manufacturing method thereof

InactiveCN102201360AAspect ratio heightImprove isolationSemiconductor/solid-state device manufacturingEtchingNitride

The invention discloses a manufacturing method of an STI (Shallow Trench Isolation) structure. The manufacturing method comprises the following steps of: forming a hard mask layer on a semiconductor substrate; etching the hard mask layer and the semiconductor substrate to form a shallow trench; forming an oxide lining layer on the sidewall of the shallow trench and forming nitride lining layers on the oxide lining layer and the hard mask layer; depositing a first insulating layer, filling of the shallow trench and covering the oxide lining layer; carrying out an annealing process and flattening the first insulating layer to expose the nitride layer; removing a part of the first insulating layer in the shallow trench by carrying out a first wet etching process; removing the nitride lining layer on the hard mask layer by carrying out a second wet etching process to enable the height of the nitride lining layer on the sidewall of the shallow trench to be equal to the height of the first insulating layer; depositing a second insulating layer, filling of the shallow trench and covering the hard mask layer; and removing the second insulating layer and the hard mask layer on the semiconductor substrate to form the STI structure. Through the manufacturing method disclosed by the invention, the generation of seams in the shallow trench can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

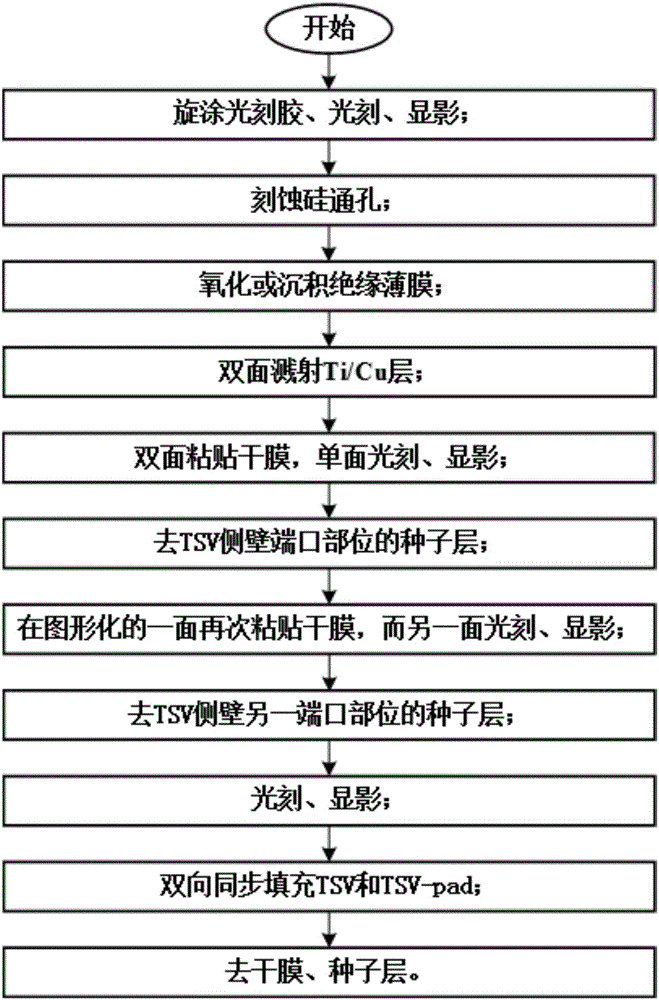

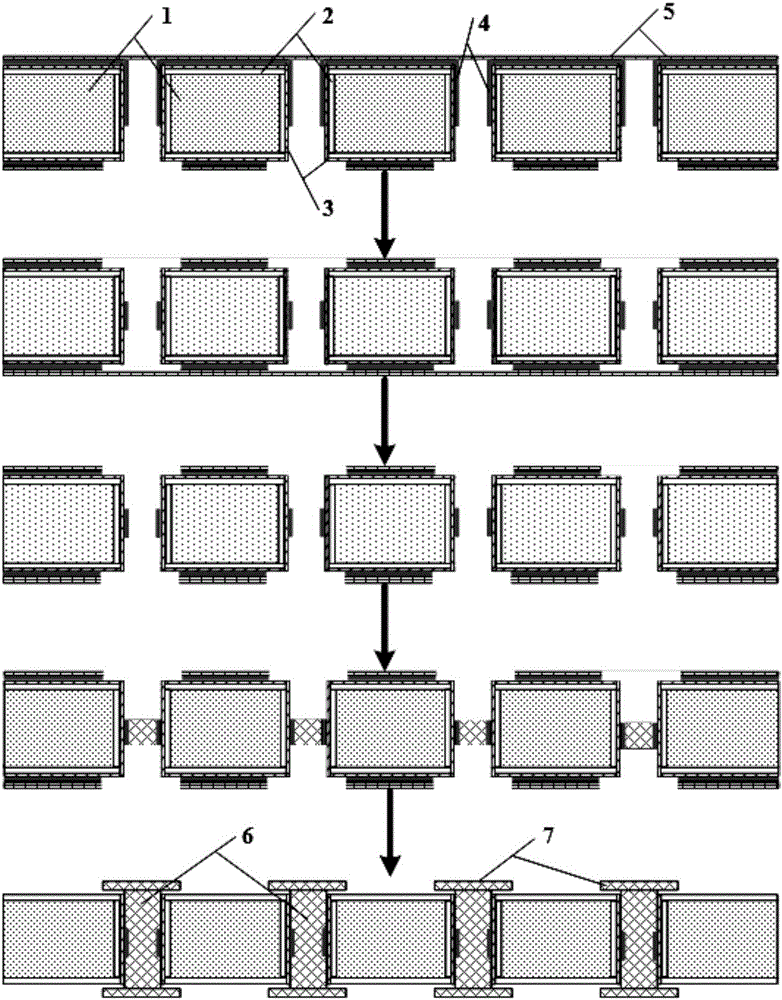

Method for efficiently electroplating and filling silicon-based TSV

ActiveCN105679701AAspect ratio heightIncrease plating rateSemiconductor/solid-state device manufacturingPhotoresistAspect ratio

The invention discloses a method for efficiently electroplating and filling silicon-based TSV. The method specifically comprises the steps of etching and preparing the TSV on a wafer; preparing an insulating layer on the wafer for etching the TSV; preparing a seed layer on the wafer containing the insulating layer; enabling dry films to the adhered to the two surfaces of the wafer, and performing single-surface photoetching and developing; removing the seed layer from the TSV side wall port position; enabling the dry film to be adhered to the patterned surface and developing the other surface; removing the seed layer from the other port position again; then performing photoetching and developing again; next, performing bisynchronous electroplate copper filling to enable TSV-Cu and TSV-pad to be integrally molded without a separating interface; and removing the dry films, the photoresist and the seed layers. According to the method, the TSV through hole electroplating filling process is converted into two blind-hole-like electroplating filling processes, so that the TSV structure can be firmly combined; the process is more flexible and convenient; the high-aspect-ratio TSV through hole electroplating filling difficulty is greatly lowered; and meanwhile, the electroplating efficiency is effectively improved, and the low-cost and efficient TSV preparation can be realized.

Owner:SHANGHAI JIAO TONG UNIV

Method for producing silver nanowires

InactiveCN109890541AAspect ratio heightReduce the amount requiredMaterial nanotechnologyTransportation and packagingAlcoholChloride

To reduce the required amount of a silver-containing solution and improve the yield of long silver nanowires in the production of silver nanowires. The present invention provides a method for producing silver nanowires, the method comprising: adding a silver-containing solution to an alcohol solvent in which a chloride, a bromide, an aluminum salt, an alkali metal hydroxide, and an organic protective agent are dissolved; and reducing and precipitating silver into a wire form in the alcohol solvent, wherein a solution in which a silver compound is dissolved at a silver concentration of 3.5-32.0mol / L is used as the added silver-containing solution. As the silver-containing solution, it is more preferable to use a water-containing solvent having 4.0-100.0% of water in mass%.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

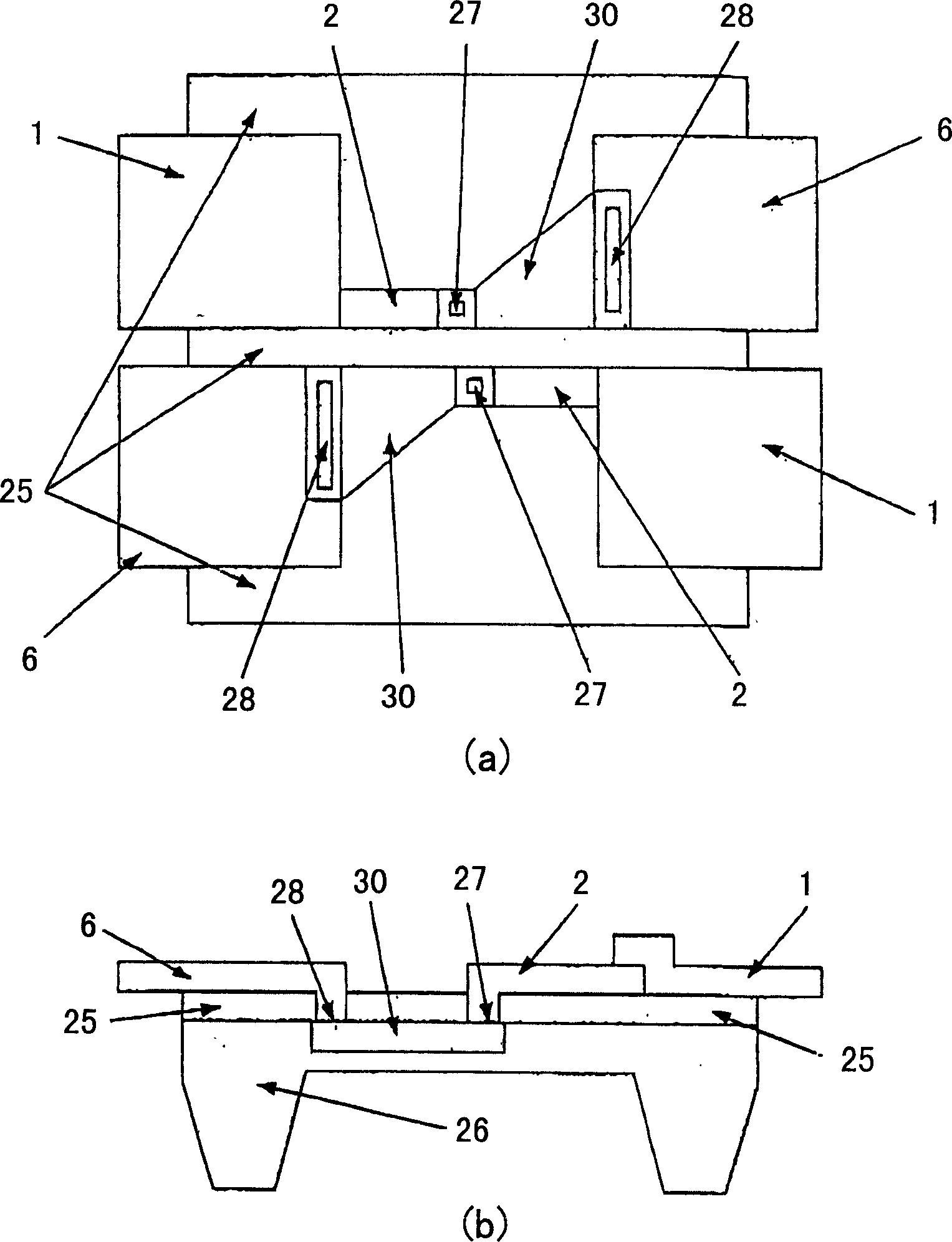

Semiconductor thermocouple microwave power sensor

InactiveCN1510425ASmall heat capacityImprove VSWRPower measurement by thermal methodsElectrical resistance and conductanceInsulation layer

The transducer consists of silicon substrate, N+ silicon under-impedance channel formed by diffusing N+ silicon in the substrate selectively, protective insulation layer prepared on the substrate, microwave absorption resistance set at the protective insulation layer and electrode leads for the first, the second as well as the third metal electrode. The trench which is in punch-through of the substrate and the protective insulation layer is made separately in between leads for the first, the second and the third electrode to form isolated thermocouple channel and isolated micro wave absorption channel in bridge shape.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

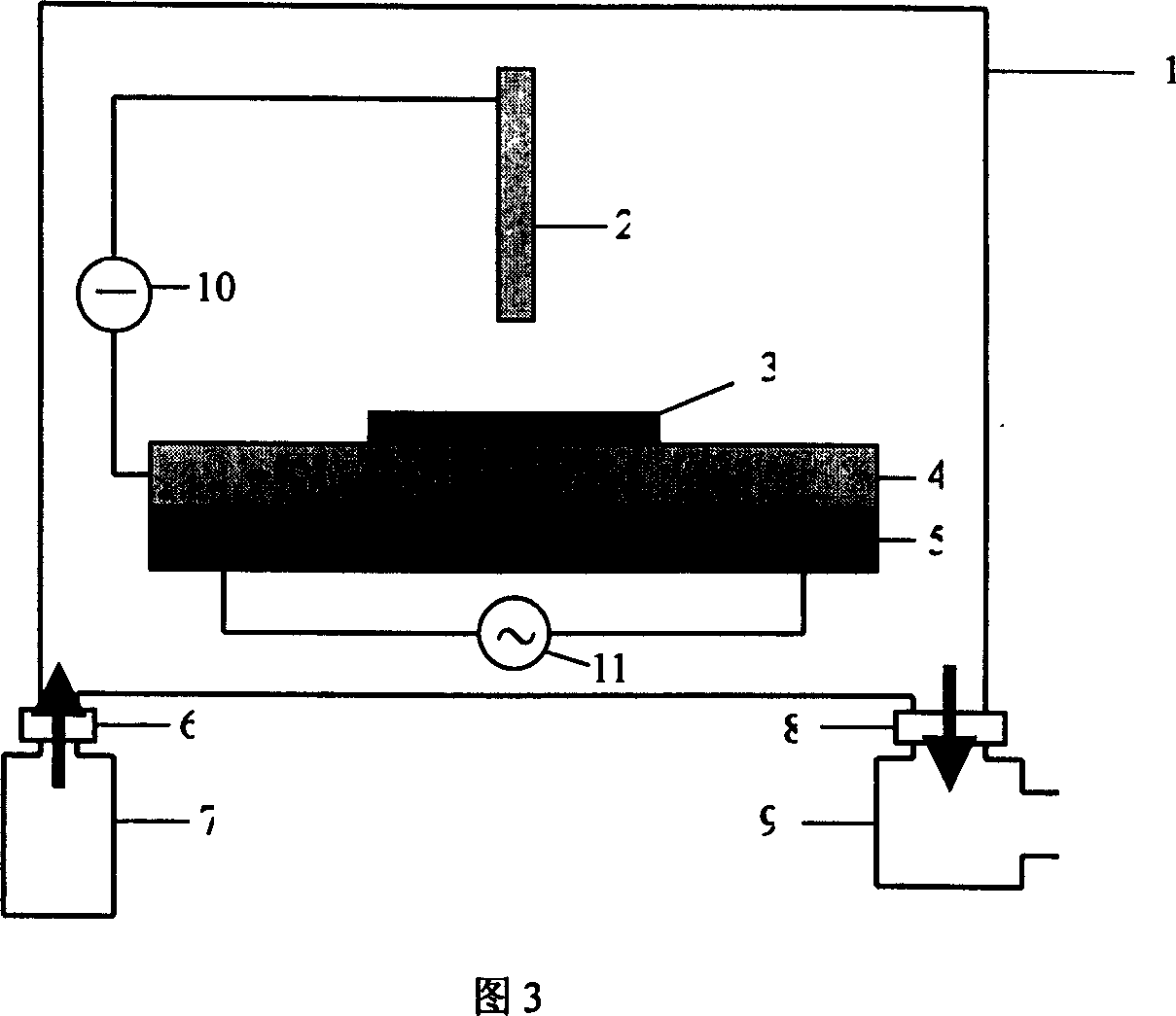

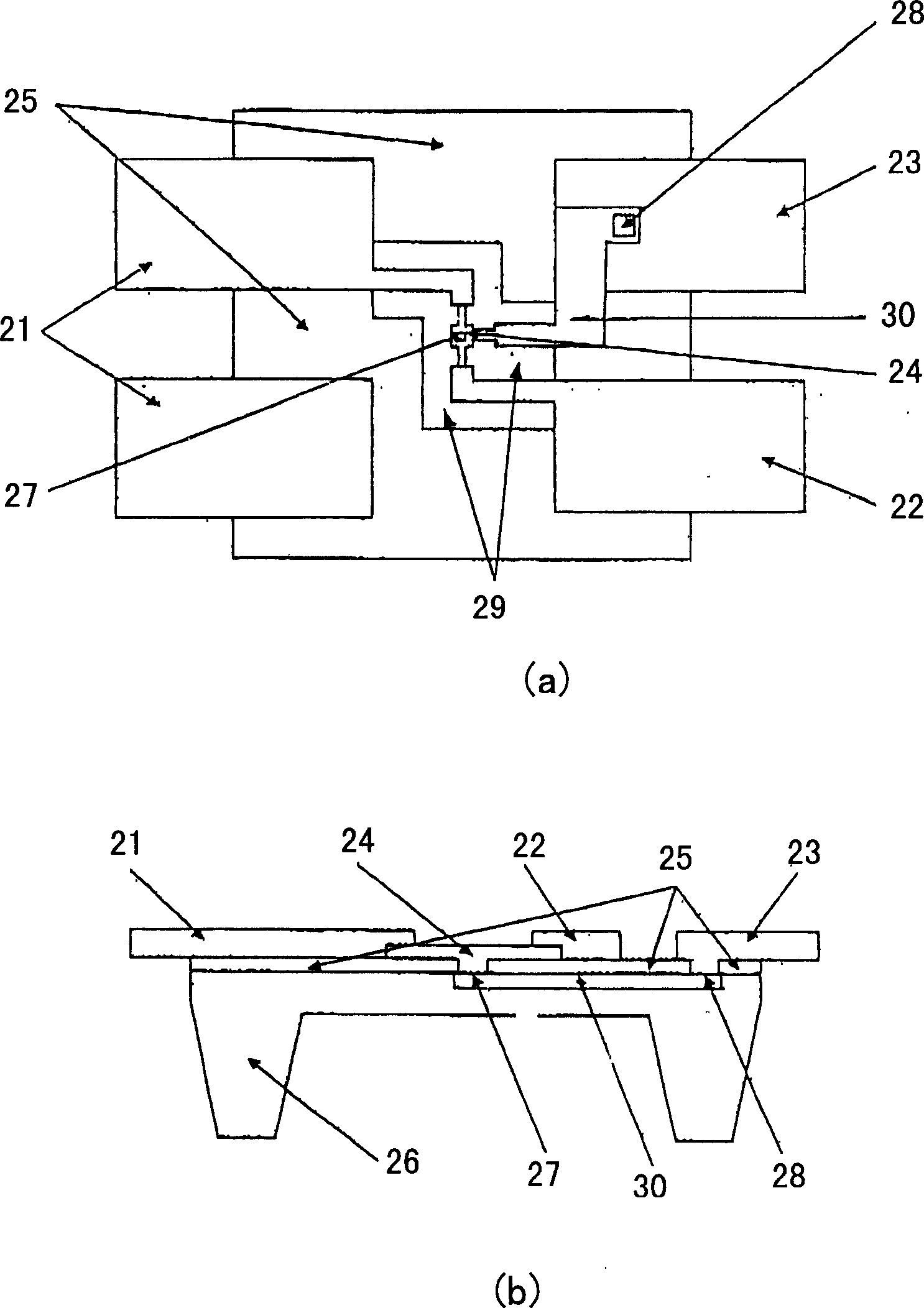

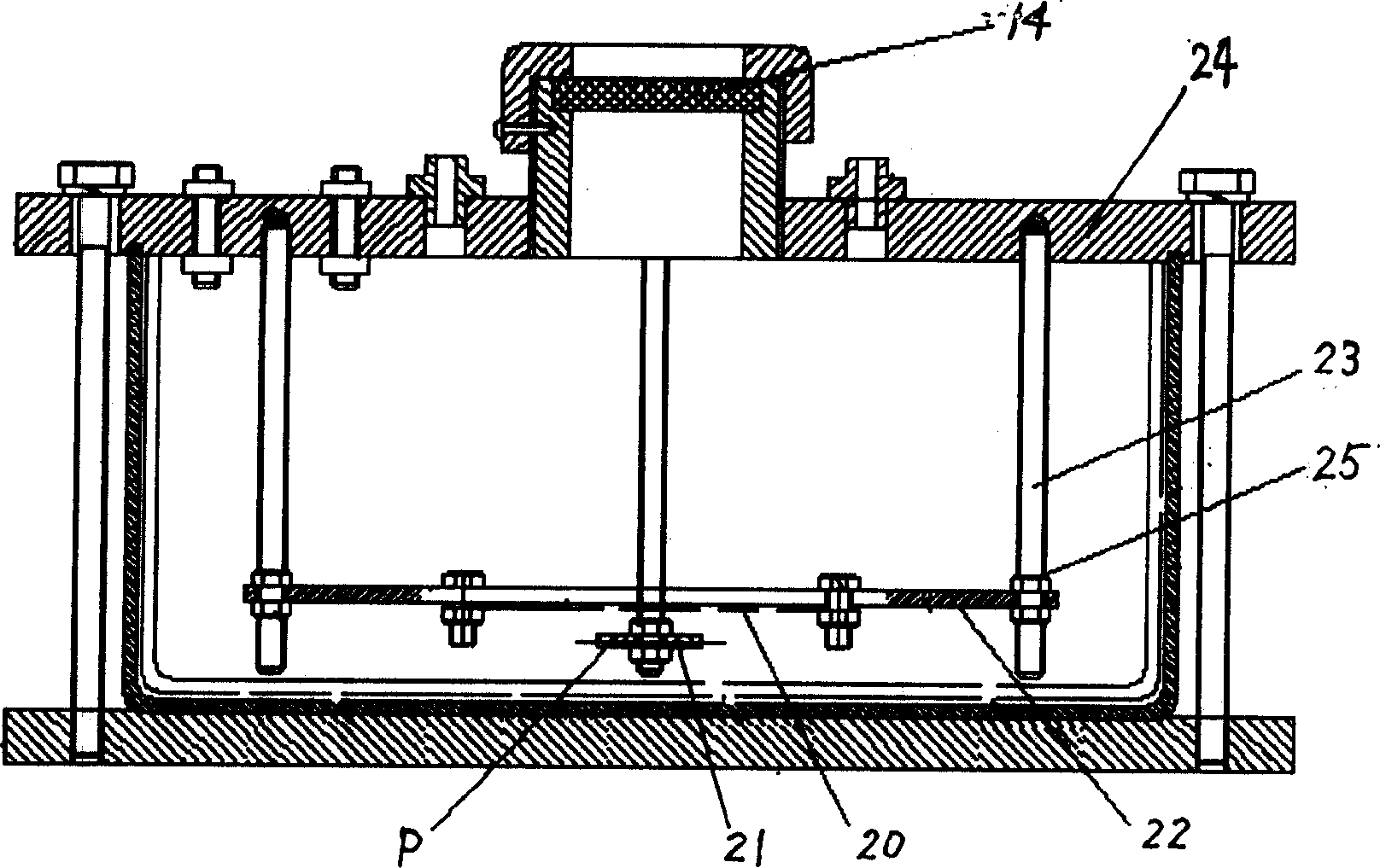

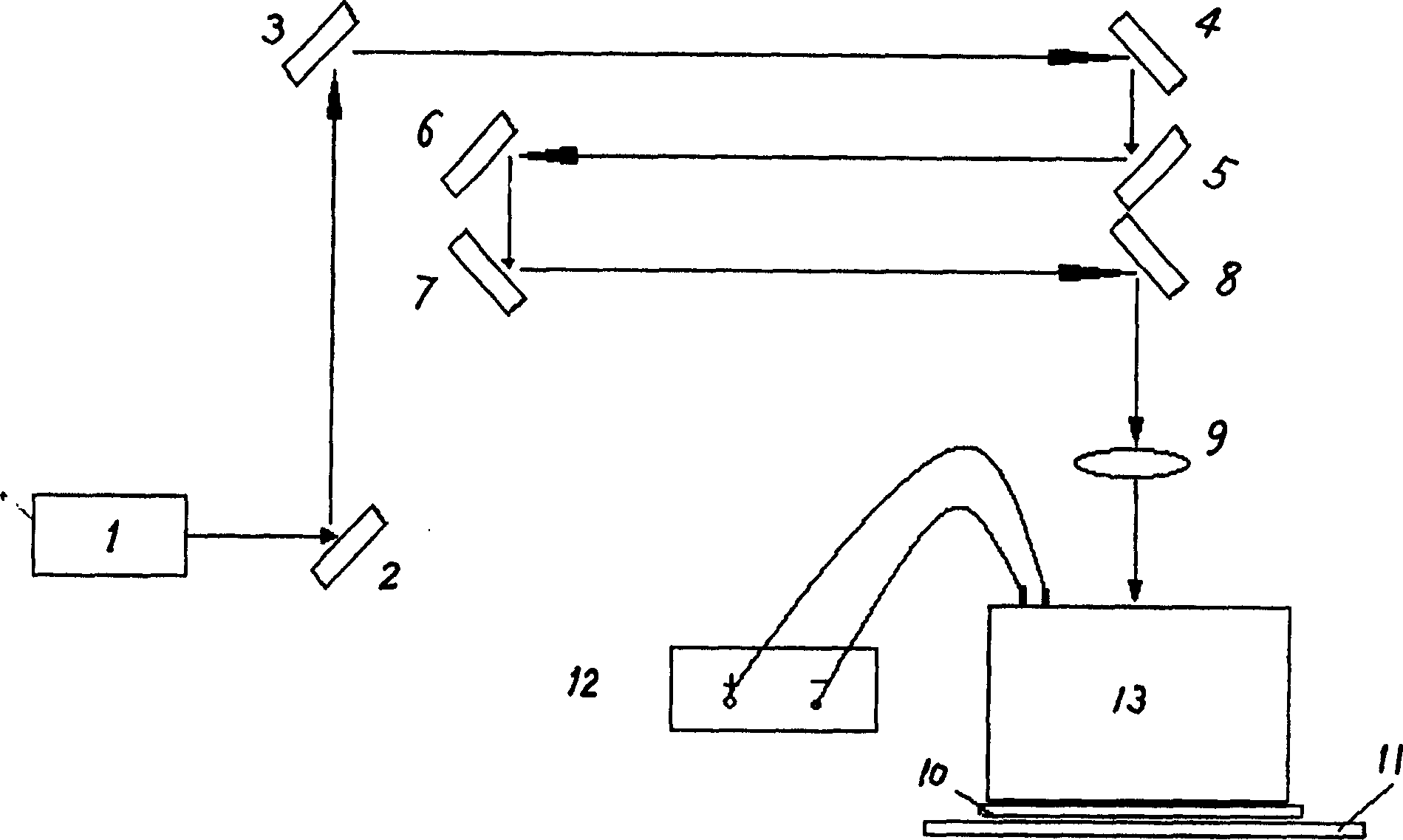

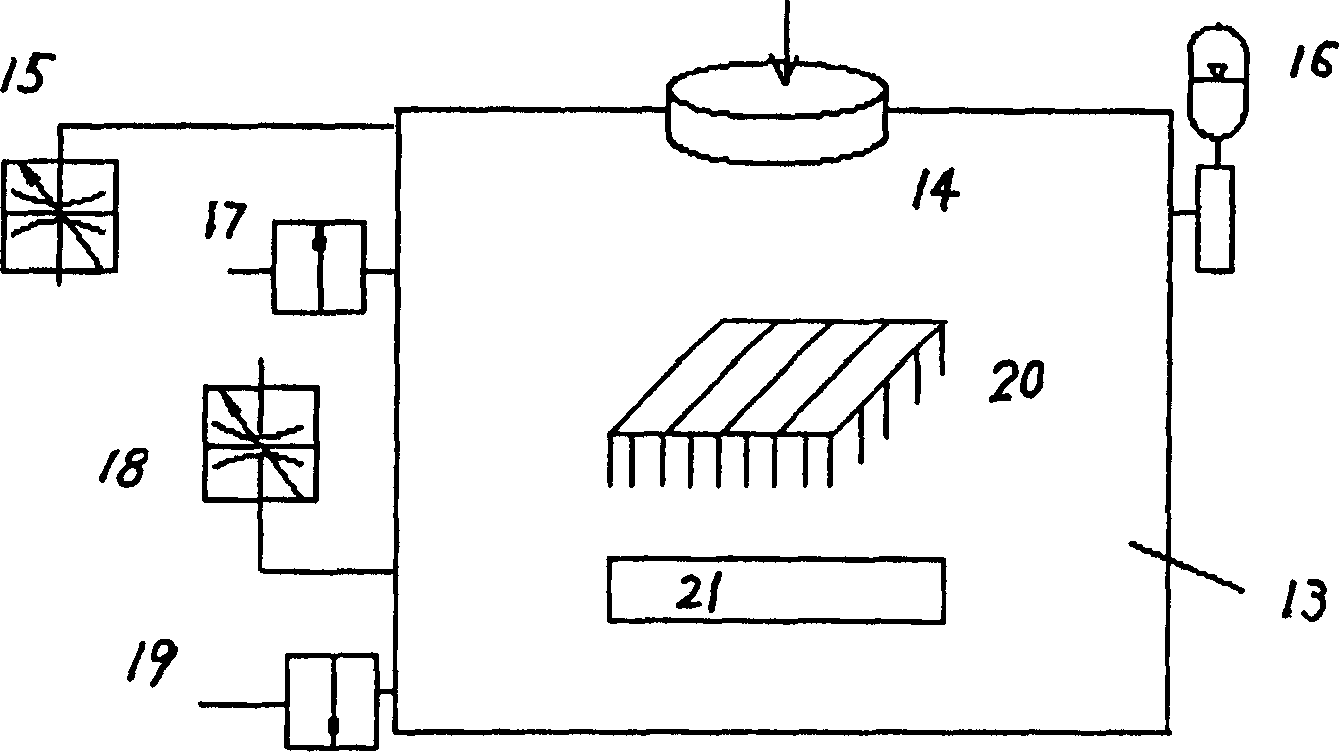

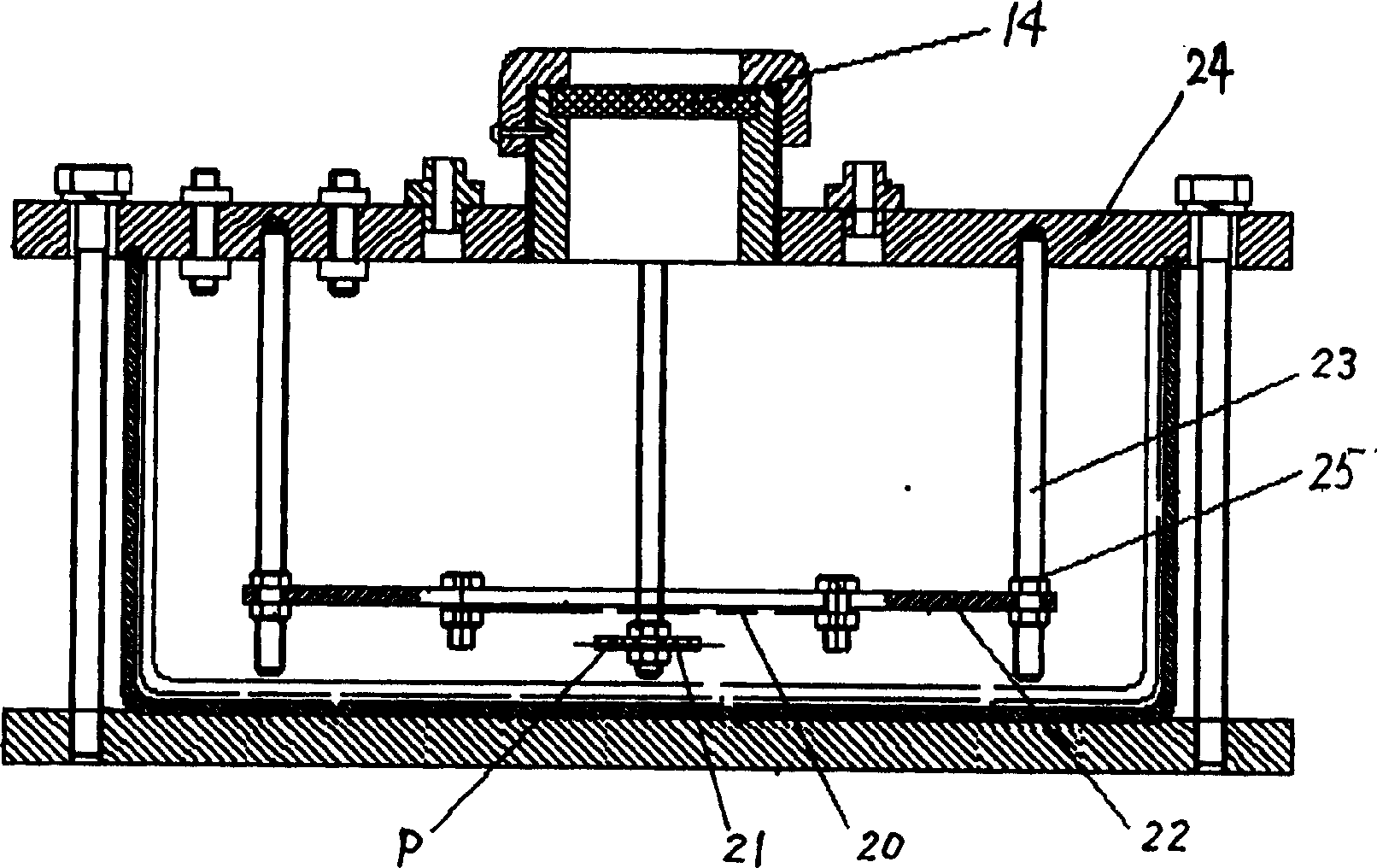

Quasi-molecule laser electrochemical microstructure manufacturing method and equipment

InactiveCN1547079AEliminate damageAspect ratio heightPhotomechanical exposure apparatusMicrolithography exposure apparatusElectrochemical responseShielding gas

The invention belongs to micro manufacturing field, pointing to the deficiency of traditional method, the quasimolecule laser, integrated circuit producing and etching, electric chemical and scanning probe micro technology are integrated together into a new process method. The steps are: (1) produces micro probe array at first; (2) the base is fixed between the plane electrode and the micro probe array, generates the negative voltage, pours in the protection gas; (3) adds in voltage between the two polars after pouring the electrolyte liquid, at the same time, the quasimolecule laser are poured in to control the electrochemical reaction, completes the process. the correspondent device sets an electrochemical reaction room on the laser microprocess machine platform, it includes a laser air moving window, an inlet of protection air, a vacuum pump interface, an electrolyte liquid inlet, a microprobe array, a plane electrode, an assistant electrochemical reaction air inlet and the waste outlet. The invention can acquires microstructure with width-depth ratio 5-50, the character size 1-50 micro meter on the semiconductor base.

Owner:HUAZHONG UNIV OF SCI & TECH

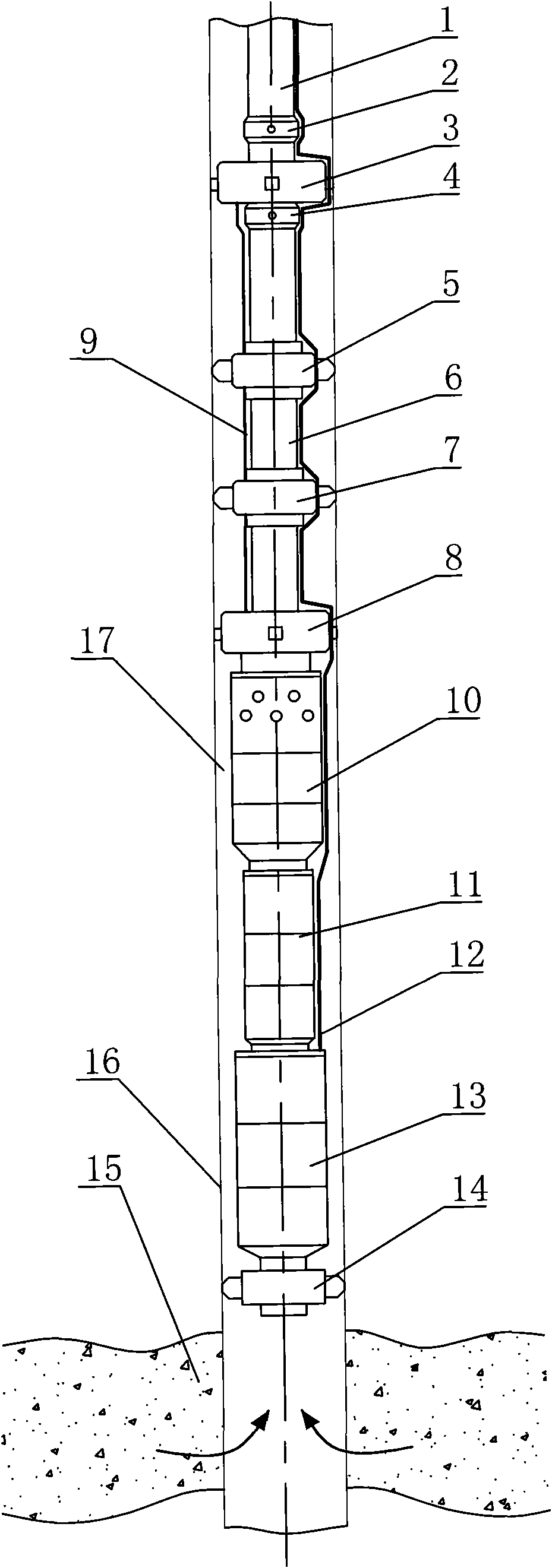

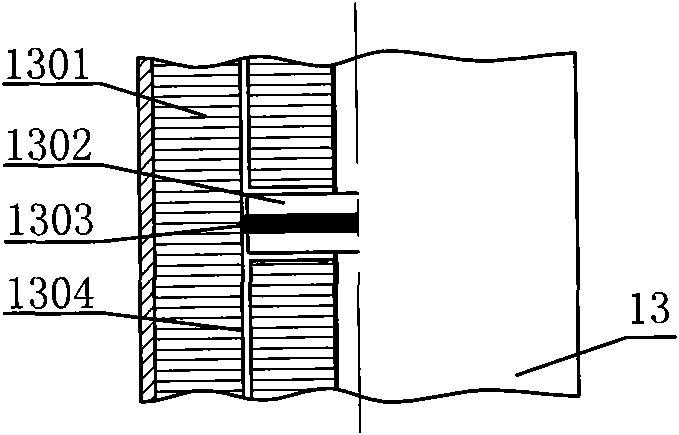

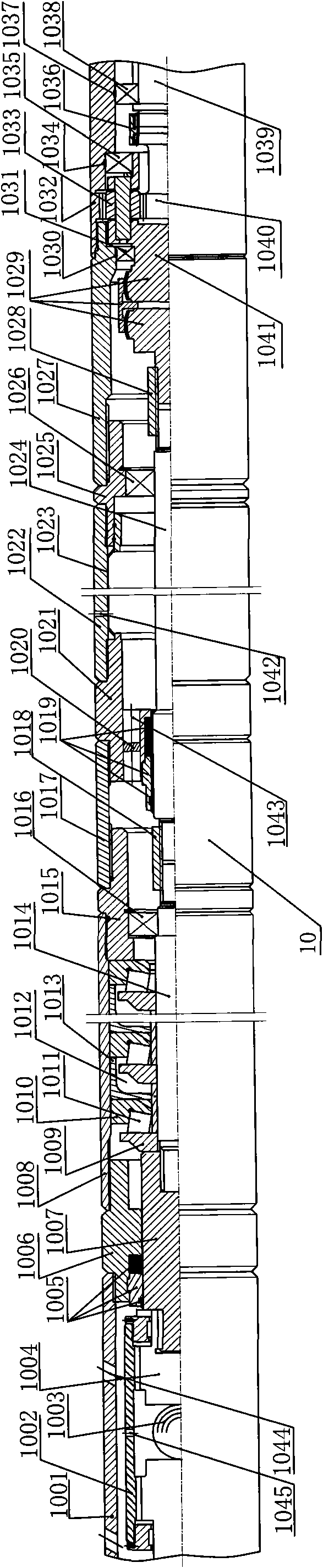

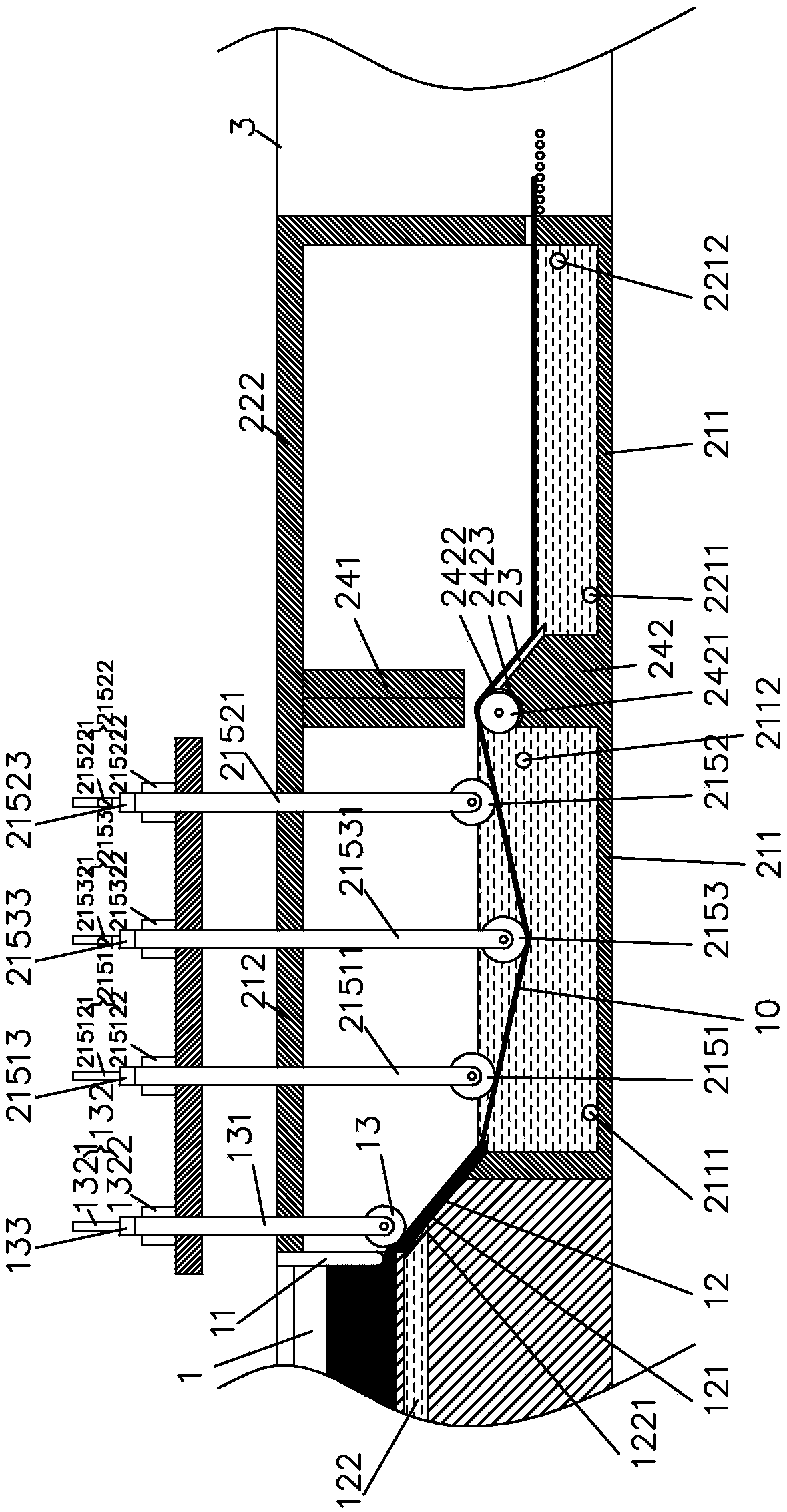

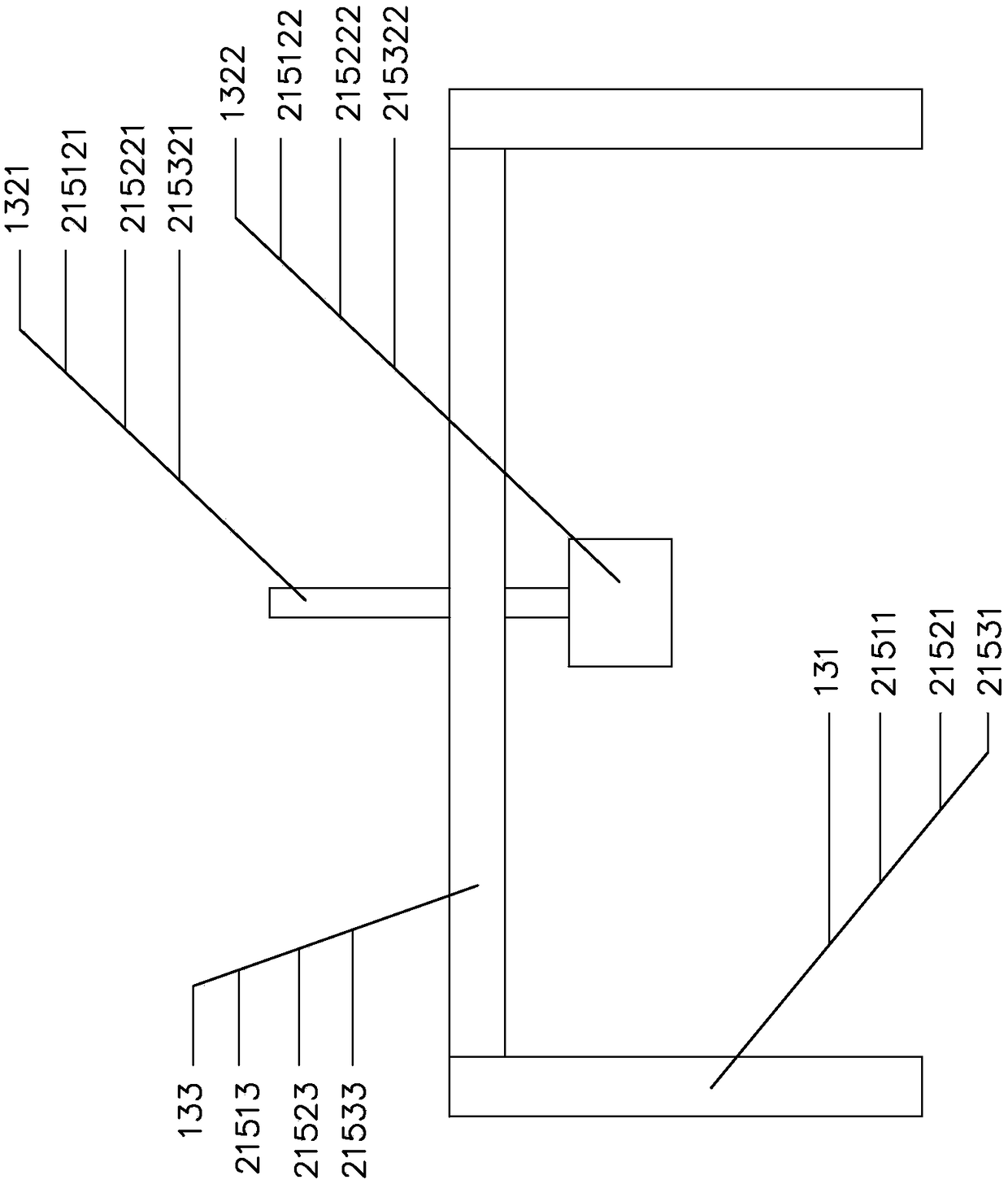

Large-discharge electric submerged screw pump oil extracting equipment

ActiveCN101864932AWith anti-vibration effectAspect ratio heightFluid removalElectric machineCoupling

The invention relates to large-discharge electric submerged screw pump oil extracting equipment. Compared with the traditional electric submerged screw pump oil extracting equipment which belongs to a large-discharge series and also mainly comprises an underground motor, an underground rotating type mechanical drive device, an underground screw pump, and the like, the large-discharge electric submerged screw pump oil extracting equipment has the technical scheme key that the underground screw pump is connected with an underground multistage motor by the underground rotating type mechanical drive device; the screw pump is rigidly fixed on the sleeve pipe wall of an oil well by adopting the underground multistage motor with high torque output and vibration resistance, a drum-gear coupling with high torque output, vibration resistance and an opening type structure, a series combined stopping type bear joint and an underground rotating type mechanical drive device of a compensating type lubricating oil tank through an anchoring device; the problem of oil leakage of an oil pipe of a large-gradient well or a horizontal well is solved by adopting a hydraulic type oil pipe oil drainer; and the large discharge of the electric submerged screw pump is realized by the technical measures, and thus the invention can be used for the oil well with large-discharge (more than 200m<3> / d) on the electric submerged screw pump.

Owner:盘锦三阳石油科技发展有限公司

Connection method for thick plate TiNi alloy and titanium alloy dissimilar materials

ActiveCN107414279AHigh melting pointIncrease energy densityElectron beam welding apparatusWelding/soldering/cutting articlesCrazingThick plate

The invention discloses a connection method for thick plate TiNi alloy and titanium alloy dissimilar materials. The connection method comprises the following steps that a TiNi alloy is subjected to acid pickling to the specified thickness; abrasive paper is used for grinding welded end faces of the dissimilar materials till the welded end faces are level; the position between the butt-joint materials is filled with Nb bars, and a clamp is used for fixing the welding materials; and finally the clamp and the welding materials are fed into an electronic beam equipment vacuum chamber together, electronic beams deviate to one side of a titanium alloy for welding, and a welding joint high in strength and good in comprehensive mechanical performance is obtained. According to the welding method, cracks generated by thick plate TiNi alloy and titanium alloy welding are eliminated; forming of Ti2Ni and other brittle intermetallic compounds is hindered; structure distribution is uniform, and grains are finer; and the strength of extension of the scanning welding joint reaches 551 MPa, the joint toughness is good, good comprehensive performance is achieved, and large engineering significance is achieved.

Owner:NANCHANG HANGKONG UNIVERSITY

Self-shielded flux-cored wire suitable for welding of TC4 titanium alloy

PendingCN111745268AEasy to remove slagFine fish scalesWelding/cutting media/materialsWelding/soldering/cutting articlesCarbon nanotubeTitanium

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

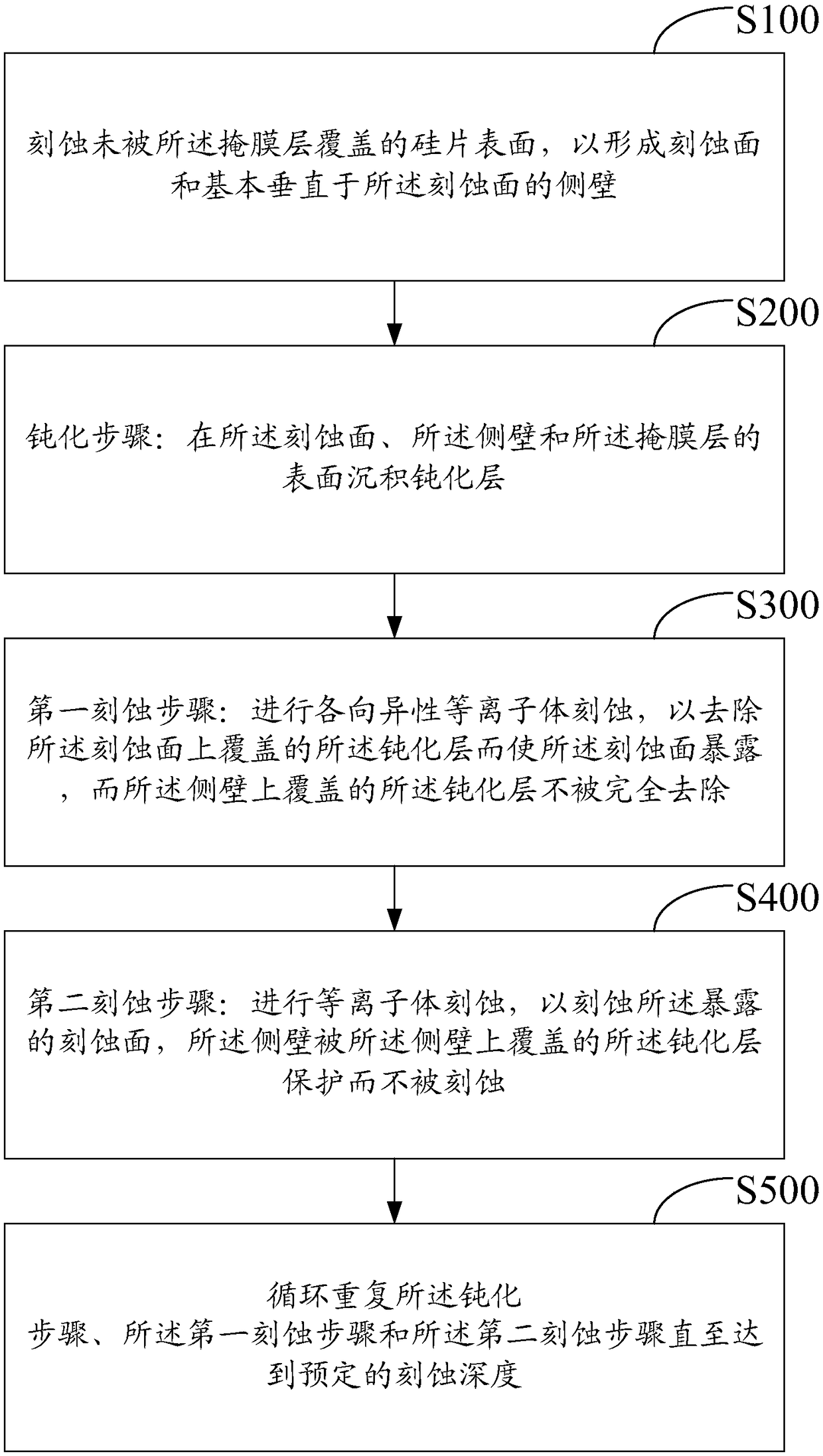

Deep Si etching method

ActiveCN108364867AAdd depthAspect ratio heightDecorative surface effectsSemiconductor/solid-state device manufacturingAtmospheric pressureSilicon

The present invention discloses a deep Si etching method. The method comprises the steps of: providing a silicon wafer coated with a graphical mask layer, and etching the surface of the silicon waferwithout being coated with the mask layer to form an etching surface and a side wall basically perpendicular to the etching surface. The method further comprises repeated and circulated passivation step, first etching step and second etching step until a predetermined etching depth is obtained. With the increasing of the number of times of cycle periods, at least one of conditions (1)-(3) is met that: (1) the deposition time of the passivation step is increased with the increasing of the number of times of the cycle periods, (2) the plate electrode power in the second etching step is increasedwith the increasing of the number of times of the cycle periods, and (3) the air pressure in the second etching step is increased with the increasing of the number of times of the cycle periods.

Owner:TSINGHUA UNIV

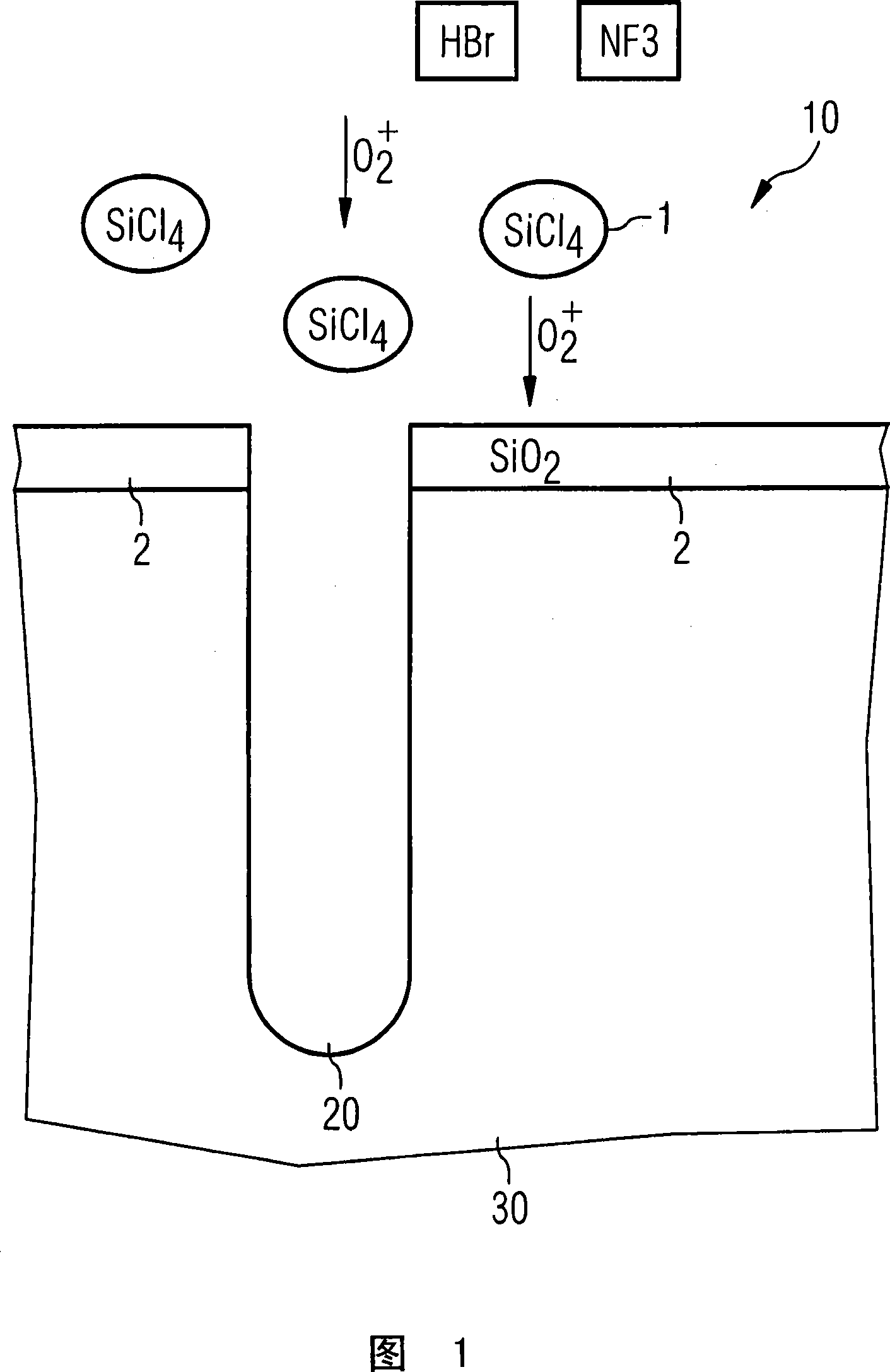

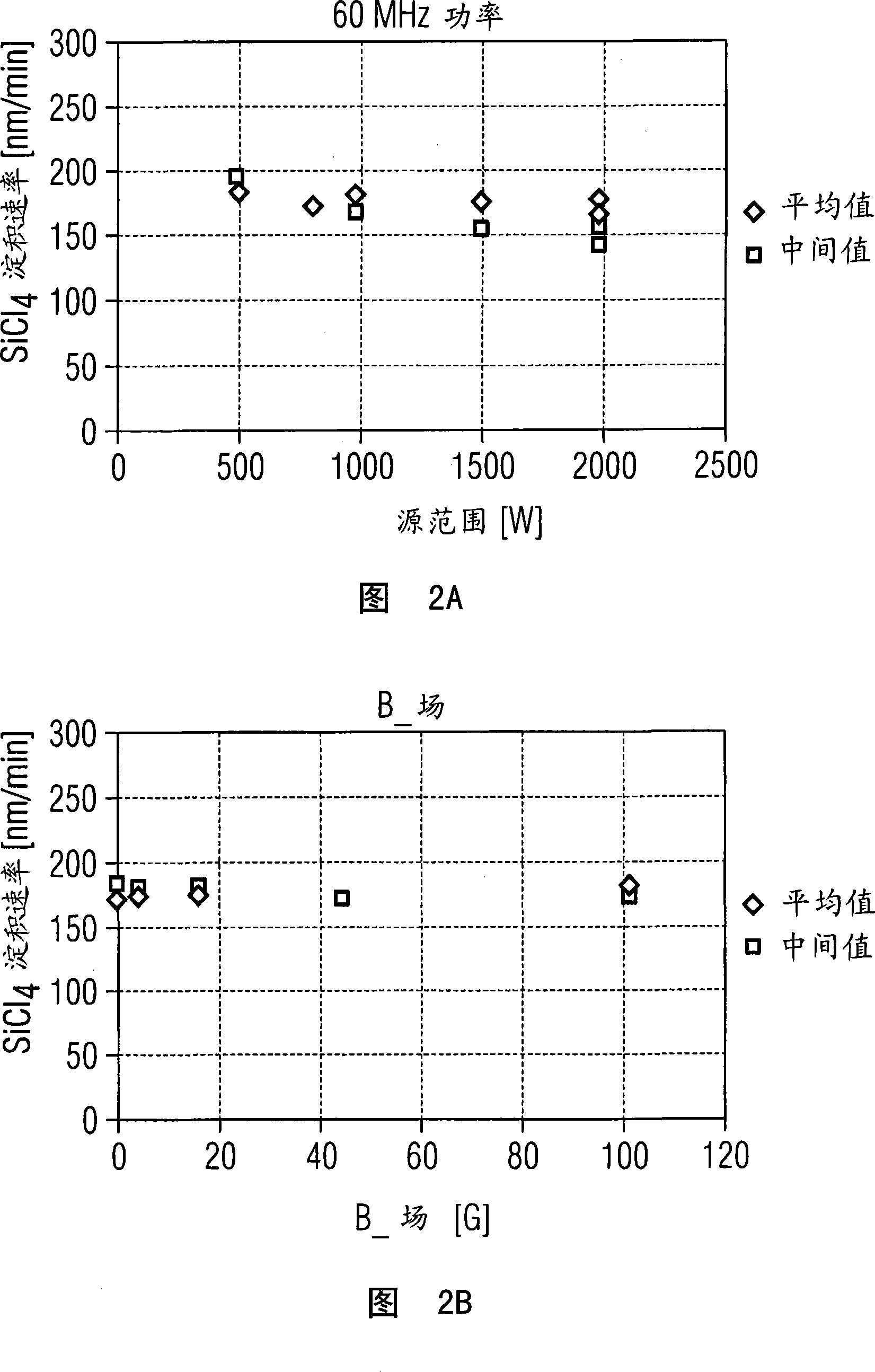

Method and device for depositing a protective layer during an etching procedure

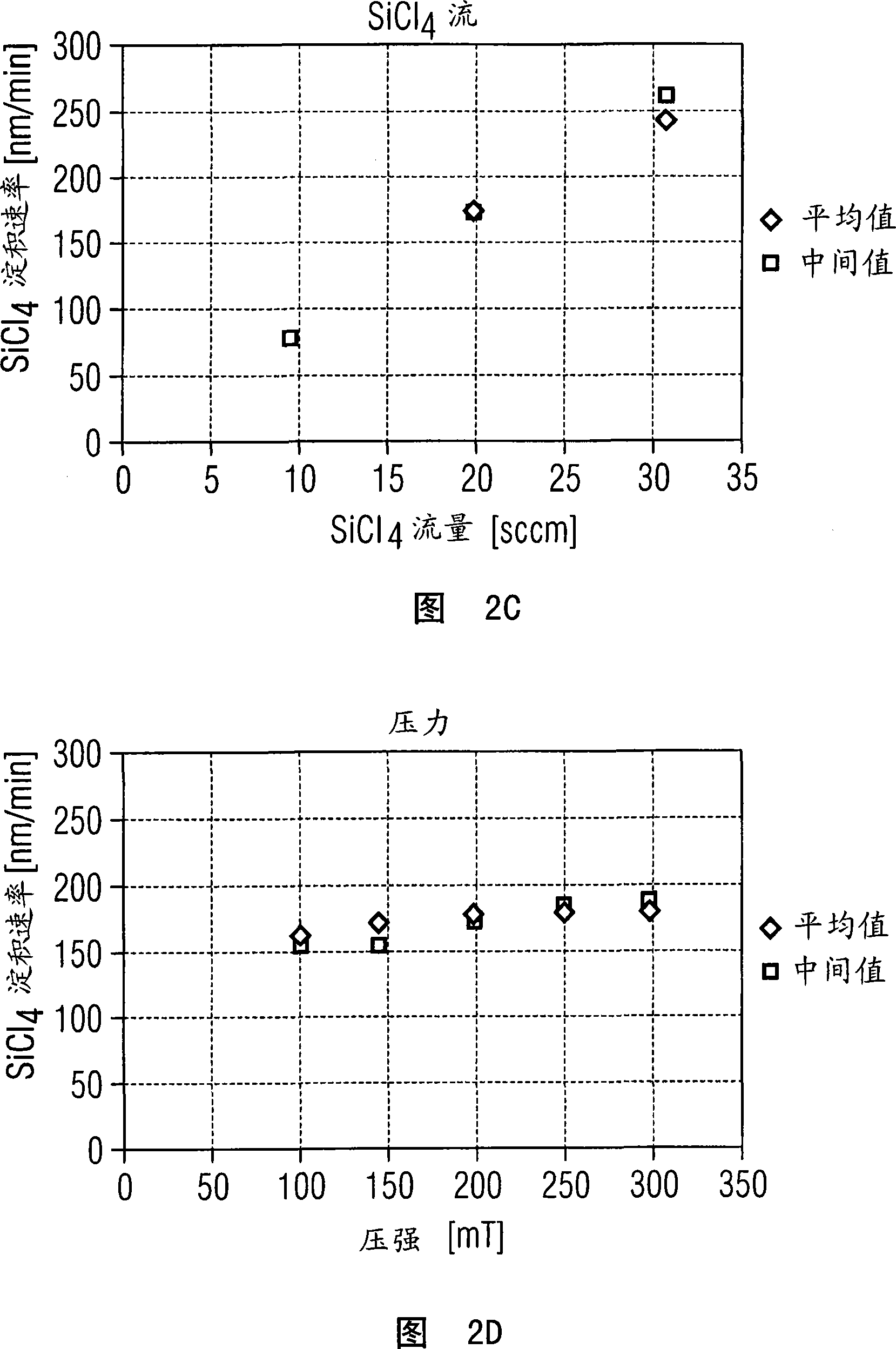

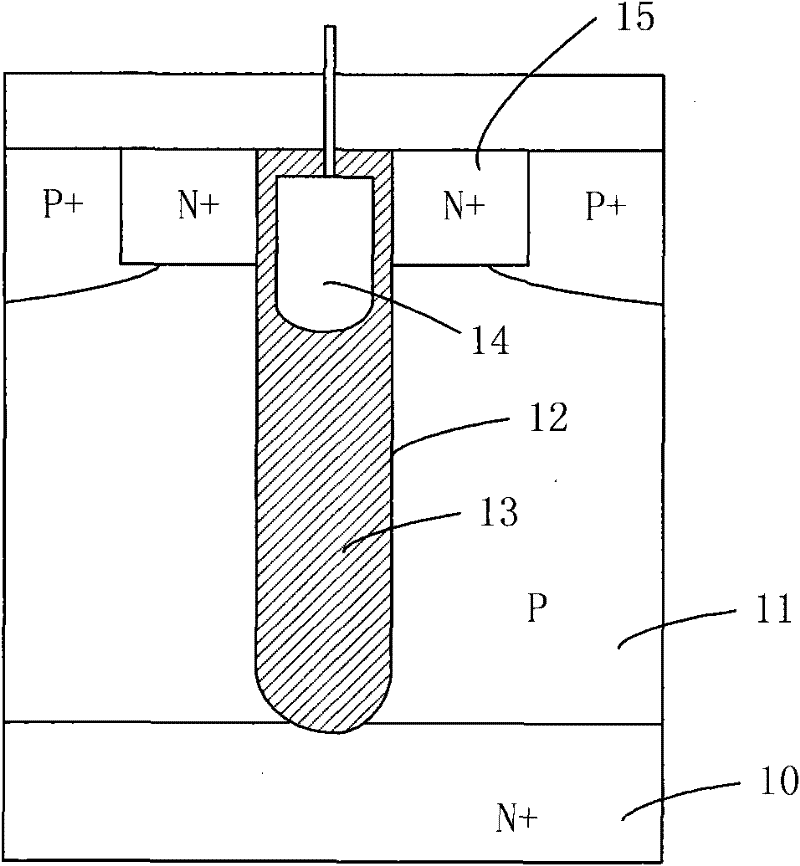

InactiveCN101083207AImprove etch selectivityAspect ratio heightSemiconductor/solid-state device manufacturingDram chipPlasma etching

A device and method for depositing a protective layer on a material during a plasma etching procedure in the course of fabricating semiconductor components, in particular in the course of fabricating DRAM chips, characterized in that the plasma(10) has at least one precursor(1) which, during the plasma etching procedure, together with a constituent of the plasma(10) at least partially forms a protective layer(2) on a planar region of the material(30) and, characterized by a means for feeding the at least one precursor(1) into the plasma(10), in which case, by means of the at least one precursor(1), during the plasma(10) etching procedure, together with a constituent of the plasma, a protective layer(2) can at least partially be deposited on a planar region of the material(30).

Owner:QIMONDA

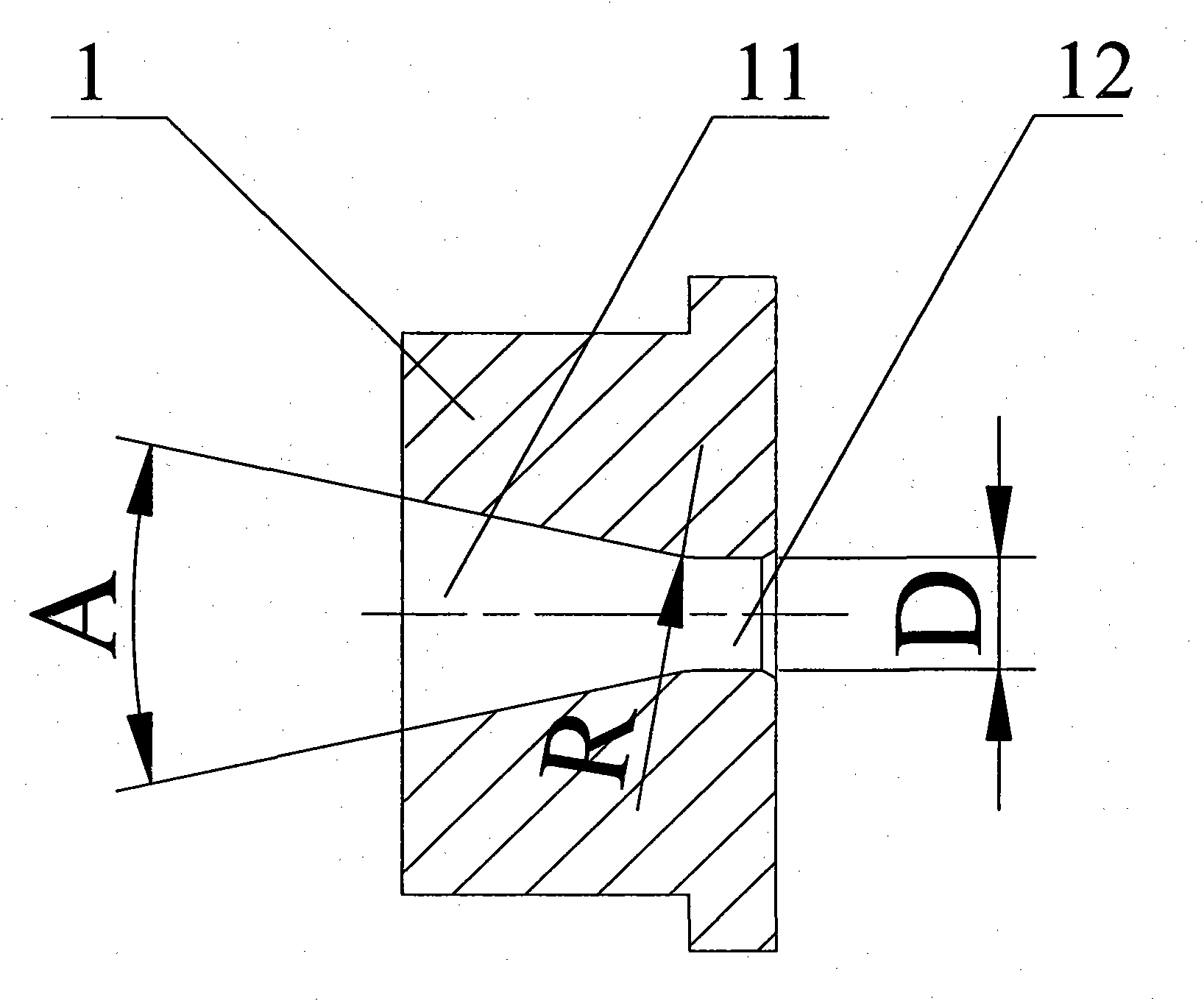

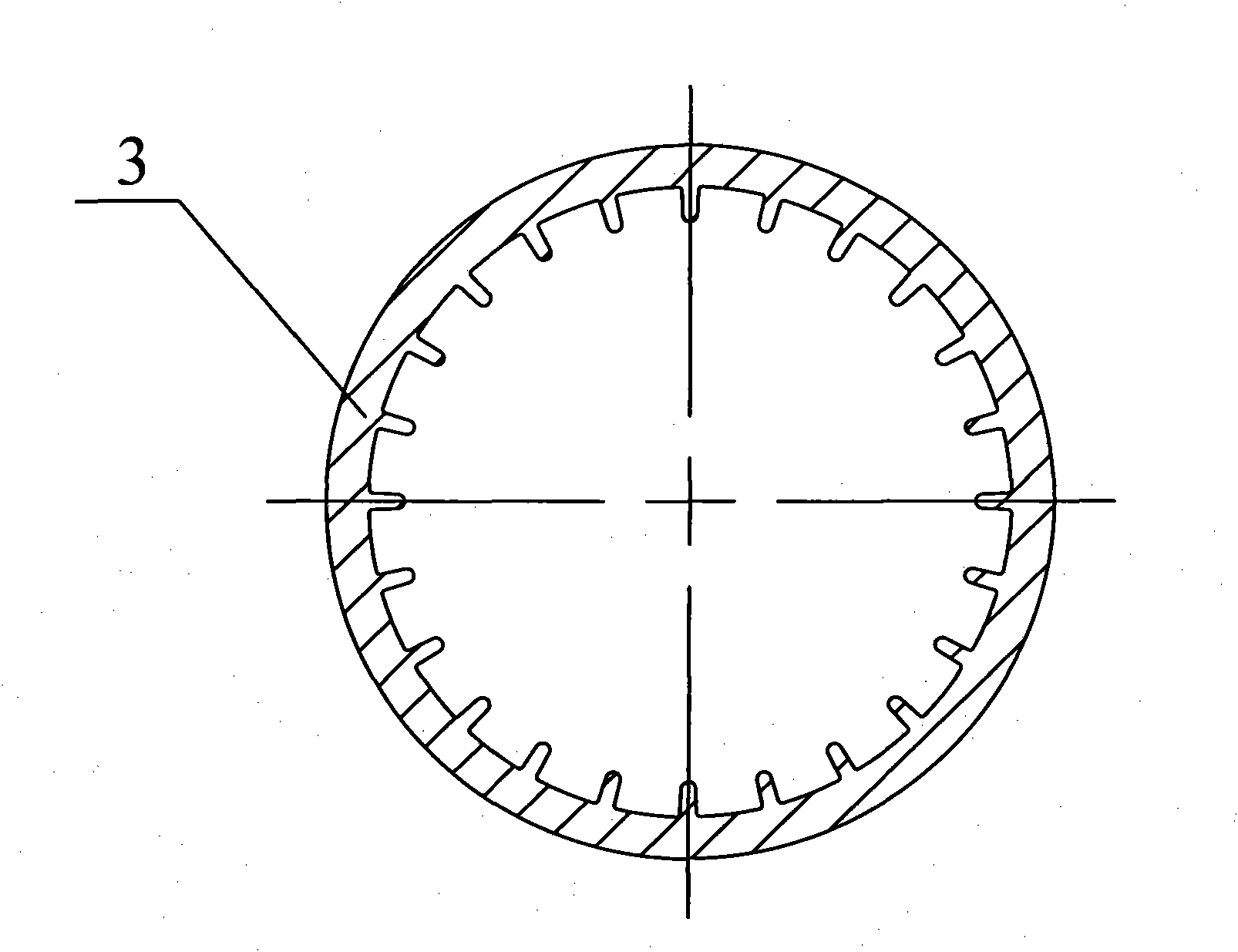

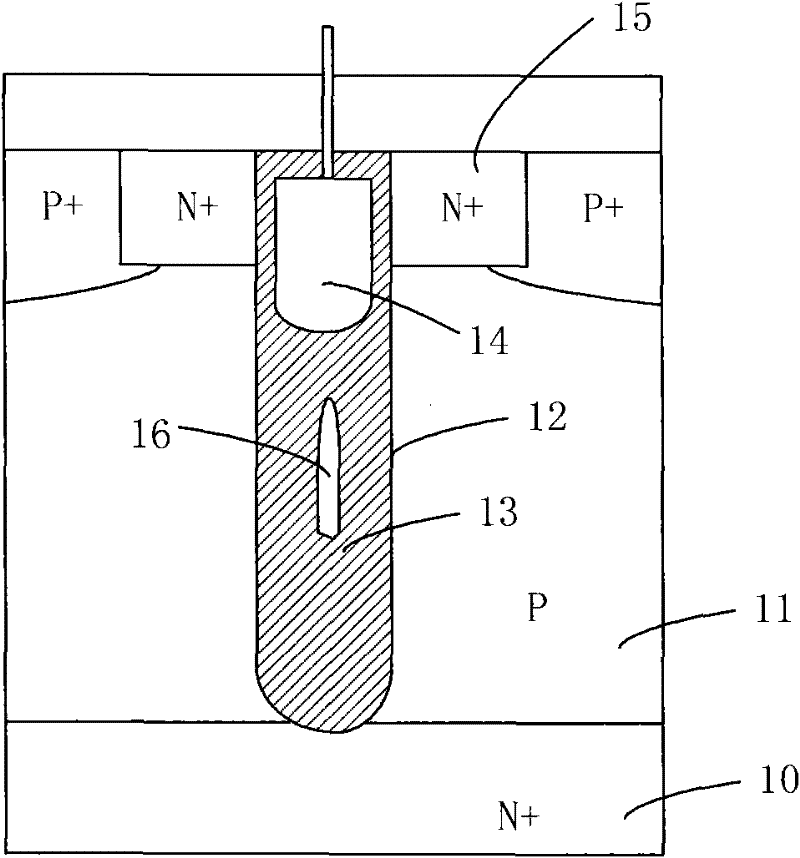

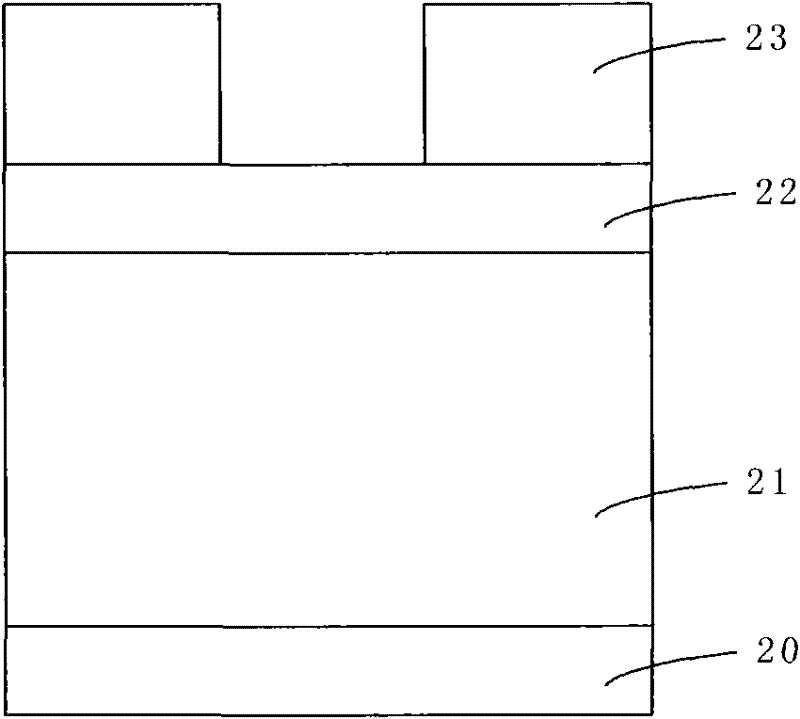

Power field-effect tube and method for manufacturing same

InactiveCN102130161AAspect ratio heightImprove breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesWidth ratioEngineering

The invention relates to a power field-effect tube. The power field-effect tube comprises a substrate, an inverse substrate formed on the substrate, a grid groove formed inside the inverse substrate, a groove oxide deposited inside the grid groove, a polysilicon grid formed inside the grid groove and a source formed inside the inverse substrate and positioned on one side of the grid groove opening, wherein the grid groove consists of a first groove and a second groove which is positioned below and communicated with the first groove; and the width of the second groove is smaller than that of the first groove. By adoption of the grid groove, the deposition of groove oxide inside the grid groove is easier and the pinch-off is avoided; therefore, an engineer can increase the depth-to-width ratio of the grid groove when designing so that the power effect-field tube has greater breakdown voltage and higher switching speed.

Owner:SEMICON MFG INT (SHANGHAI) CORP

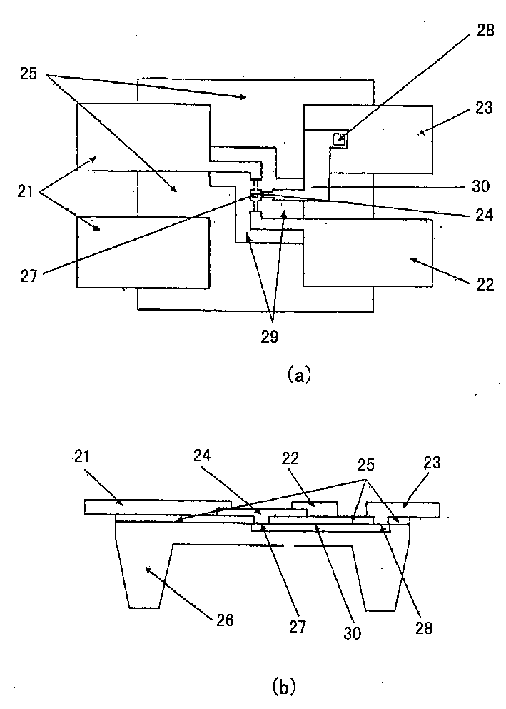

Quasi-molecule laser electrochemical microstructure manufacturing method and equipment

InactiveCN1259598CEliminate damageAspect ratio heightPhotomechanical exposure apparatusMicrolithography exposure apparatusElectrochemical responseShielding gas

The present invention belongs to the field of micro-manufacturing. Aiming at the shortcomings of traditional methods, excimer laser, integrated circuit plate-making lithography, electrochemistry and scanning probe microscopic technology are fused into a new processing method. The steps are: (1) first prepare a microscopic probe Needle array; (2) Fix the substrate between the plate electrode and the microprobe array, generate negative pressure, and inject protective gas; (3) Apply voltage between the electrodes after injecting the electrolyte solution, and at the same time pass through the excimer laser The electrochemical reaction is controlled to complete the machining process. The corresponding device is equipped with an electrochemical reaction chamber on the workbench of the laser microprocessing machine, which includes a laser pneumatic window, a protective gas inlet, a vacuum pump interface, an electrolyte solution inlet, a microprobe array, a flat electrode, an auxiliary electrochemical reaction gas inlet, and a waste outlet. . The invention can obtain a microstructure with an aspect ratio of 5-50 and a characteristic size of 1-50 microns on metal and semiconductor substrates, and has wide applications in the fields of environmental protection, textiles, papermaking, energy, information and national defense.

Owner:HUAZHONG UNIV OF SCI & TECH

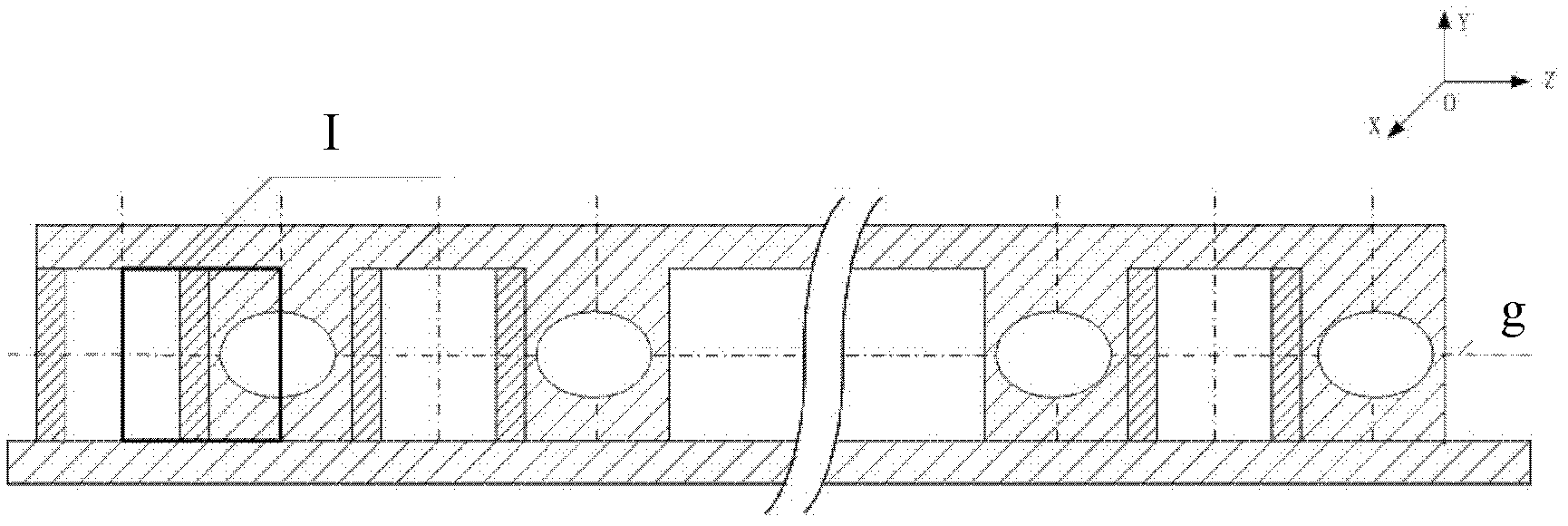

Method for manufacturing metal paraboloid-shaped two-dimensionally-focused X-ray combined refractor

InactiveCN102214493AAspect ratio heightReduce restrictionsHandling using diffraction/refraction/reflectionOptical elementsSoft x rayOptical axis

The invention discloses a method for manufacturing a metal paraboloid-shaped two-dimensionally-focused X-ray combined refractor. The method comprises the following steps of: (1) manufacturing a primary lens of the metal paraboloid-shaped two-dimensionally-focused X-ray combined refractor; (2) manufacturing a secondary lens of the metal paraboloid-shaped two-dimensionally-focused X-ray combined refractor; and (3) assembling the metal paraboloid-shaped two-dimensionally-focused X-ray combined refractor, namely putting the manufactured primary lens and the manufactured secondary lens under a microscope, finding and clamping a clamping arm of the secondary lens, aligning embedded lens bodies of the secondary lens with square holes of the primary lens, making a first parabolic curve and a second parabolic curve orthogonal to each other and making n embedded lens bodies on the secondary lens corresponding to n square holes on the primary lens one to one, embedding, and lightly pressing to obtain the metal paraboloid-shaped two-dimensionally-focused X-ray combined refractor. By the method, the manufacturing process is high in precision; the optical axis of the obtained lens can be self-calibrated at high precision; and the focusing efficiency is high.

Owner:菏泽建数智能科技有限公司

Method for performing phase change memory cell integration by using electrochemical deposition

ActiveCN111081869ADifficult to concentratePrecise control of depositionElectrical apparatusElectrolytic agentPhase-change memory

The invention discloses a method for performing phase change memory cell integration by using electrochemical deposition. The method comprises the following steps of: S1, preparing a conductive substrate; S2, preparing an insulating layer; S3, preparing deep holes; S4, preparing a reaction solution mixed with two different electrolytes; S5, performing electrochemical deposition in the deep holes from bottom to top, and depositing an upper-layer material and a lower-layer material, namely a gating tube and a phase change unit, in each deep hole by adjusting deposition parameters; S6, preparingupper electrodes. The deep holes with nanoscale apertures are etched through a micro-nano machining technology, and then the deep holes are rapidly and effectively filled through the electrochemical deposition method; the nano phase change material can be grown from the bottom of each nano hole; the ultra-large depth-to-width ratio small holes can be filled with a sulfur phase-change material witha multi-layer complex structure; the growth of the materials can be accurately regulated and controlled by regulating and controlling the deposition parameters; graphical growth is realized by designing the shape of electrodes of which the bottom can apply potentials; and preparation of various materials with complex structures is carried out.

Owner:HUAZHONG UNIV OF SCI & TECH

Production process of AG (anti-glare) glass

The invention provides a production process of AG (anti-glare) glass. The process comprises the following steps of smelting glass raw materials by utilizing a smelting furnace so as to form glass fluid; then enabling glass to be molded through a fusion tin chamber by using a float glass process to form an earlier-stage glass pane; then annealing the earlier-stage glass pane by utilizing an annealing chamber to form a finished glass pane; then cutting and edging the finished glass pane to make a glass template; then polishing the glass template; then washing the glass template; then making hardmasking film; then making an ultraviolet curing polymer layer; then making a model; then making a curing layer with the model; then demolding; then etching the glass template by using one of reactiveion etching or inductive coupling plasma etching or using both, wherein the etching speed of the hard masking film is lower than the etching speed of the glass template. Compared with the prior art,the production process of the AG glass can be used for high-efficiency and high-quality production of the AG glass, and the AG glass has excellent performance.

Owner:福建成达玻璃有限公司

Method for preparing large-size silicon pore array

ActiveCN102650069ASmall sizeShallow depthAnodisationDecorative surface effectsMetal particleVolumetric Mass Density

The invention discloses a method for preparing a large-size silicon pore array. The method comprises the steps as follows: firstly, selecting a p-type silicon substrate with low resistance rate, and depositing metal particles; secondly, carrying out anodic oxidation on the silicon substrate with the metal particles deposited on the surface in an oxidant-containing solution; and thirdly, obtaining the large-size silicon pore array of nanometer to micron dimension by controlling current density and corrosion time under constant current.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

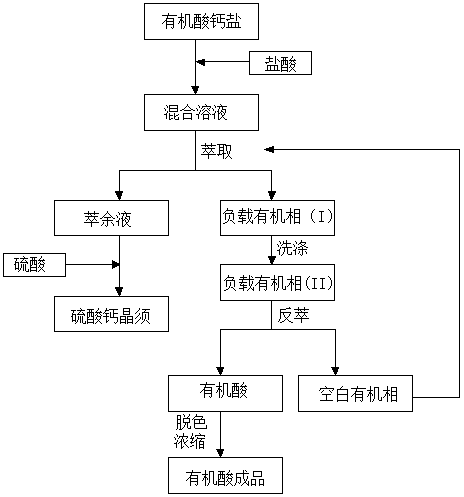

Method for preparing organic acid and calcium sulfate whisker from organic acid calcium salt by hydrochloric acid method

PendingCN110079864AAspect ratio heightSimple methodPreparation from carboxylic acid saltsPolycrystalline material growthRaffinateChemistry

The invention relates to the technical fields of organic acid separation and whisker synthesis, in particular to a method for preparing an organic acid and a calcium sulfate whisker from organic acidcalcium salt by a hydrochloric acid method. The method is characterized by comprising the following steps: (1) taking organic acid calcium salt and hydrochloric acid as raw materials, mixing the organic acid calcium salt with hydrochloric acid to undergo a metathesis reaction to obtain a mixed solution which mainly contains the organic acid, the organic acid calcium salt, calcium chloride and hydrochloric acid; (2) performing solvent extraction on the obtained mixed solution by utilizing an organic solvent to obtain a raffinate and a supported organic phase (I), washing the supported organic phase (I) to obtain a supported organic phase (II), performing RP-extraction on the organic phase (II) to obtain an organic acid washing solution and a blank organic phase; and (3) concentrating or crystallizing the organic acid washing solution obtained in the step (2) to obtain an organic acid product, and reacting the raffinate obtained in the step (2) with sulfuric acid or sulfate to prepare the calcium sulfate whisker. The method has the advantages of zero waste, low cost, high length-diameter ratio of the prepared calcium sulfate whisker and the like.

Owner:HARBIN INST OF TECH AT WEIHAI

Nanoneedle array as well as preparation method and application thereof

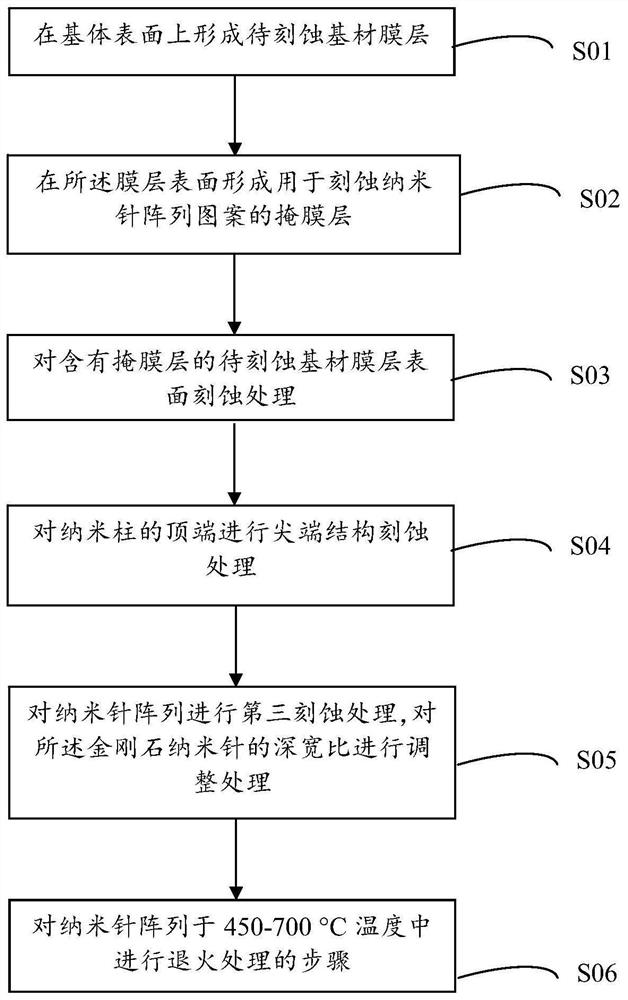

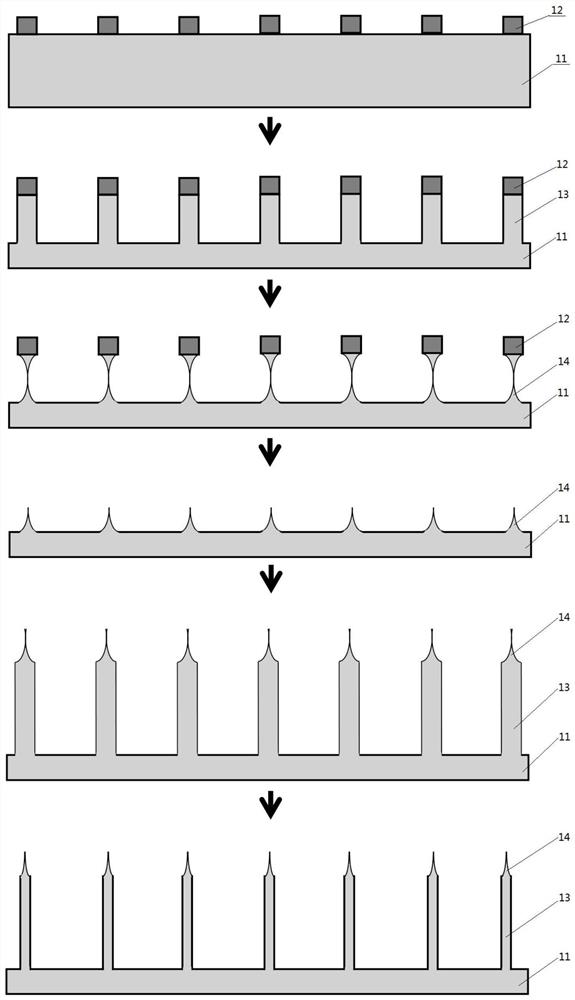

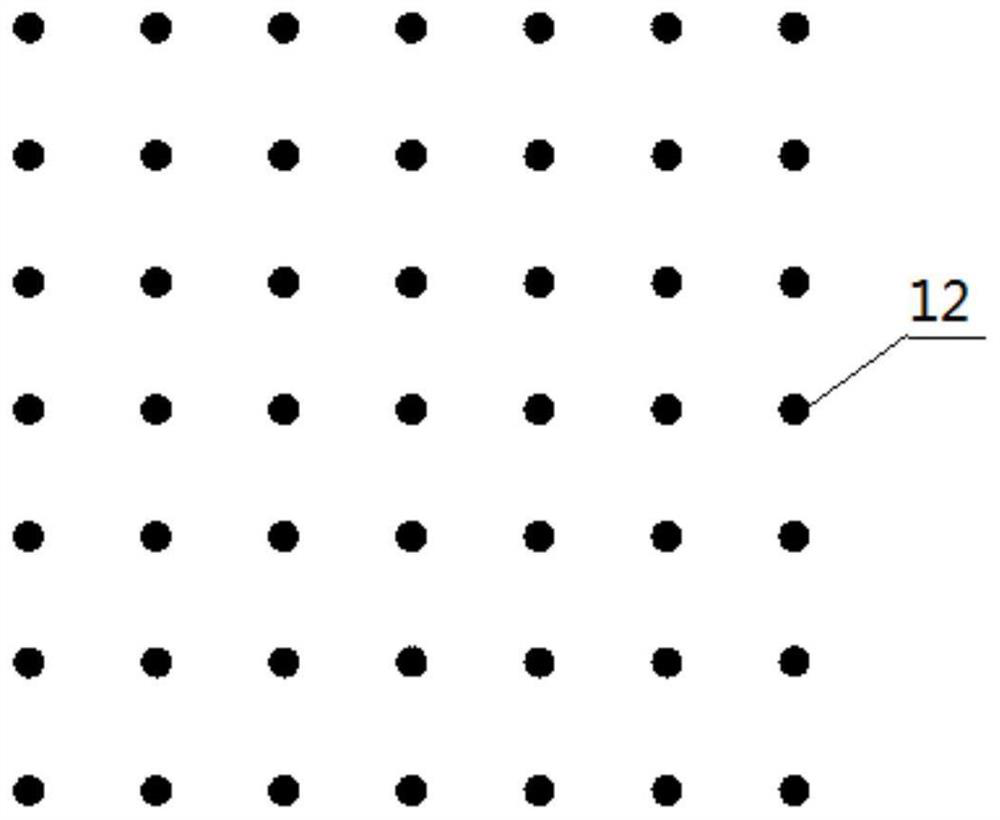

ActiveCN111943130AGood controllability of process conditionsParameter stabilitySemi-permeable membranesFixed microstructural devicesNanopillarMask layer

The invention provides a nanoneedle array as well as a preparation method and application thereof. The preparation method of the nanoneedle array comprises the following steps: forming a to-be-etchedsubstrate film layer on the surface of a substrate; forming a mask layer for etching a nanoneedle array on the surface of the to-be-etched substrate film layer; performing first etching treatment on the surface of the to-be-etched substrate film layer with the mask layer in the direction from the mask layer to the substrate to form a nano-column array; and carrying out second etching treatment onthe top ends of the nanorods in the nanorod array to form a tip structure at the top ends of the nanorods so as to form a nanoneedle array. The nanoneedle contained in the nanoneedle array comprises ananoneedle body, and the head of the nanoneedle body is of a tip structure.

Owner:深圳市安瑞生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com