Method for manufacturing metal paraboloid-shaped two-dimensionally-focused X-ray combined refractor

A technology for combining a refractive lens and a metal material, which is applied in the field of manufacturing a parabolic two-dimensional focusing X-ray combined refractive lens of metal materials, can solve the problems of low focusing efficiency, insufficient manufacturing process accuracy, low lens calibration accuracy, and the like, and achieves calibration. The effect of high precision, small material constraints, and large device aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

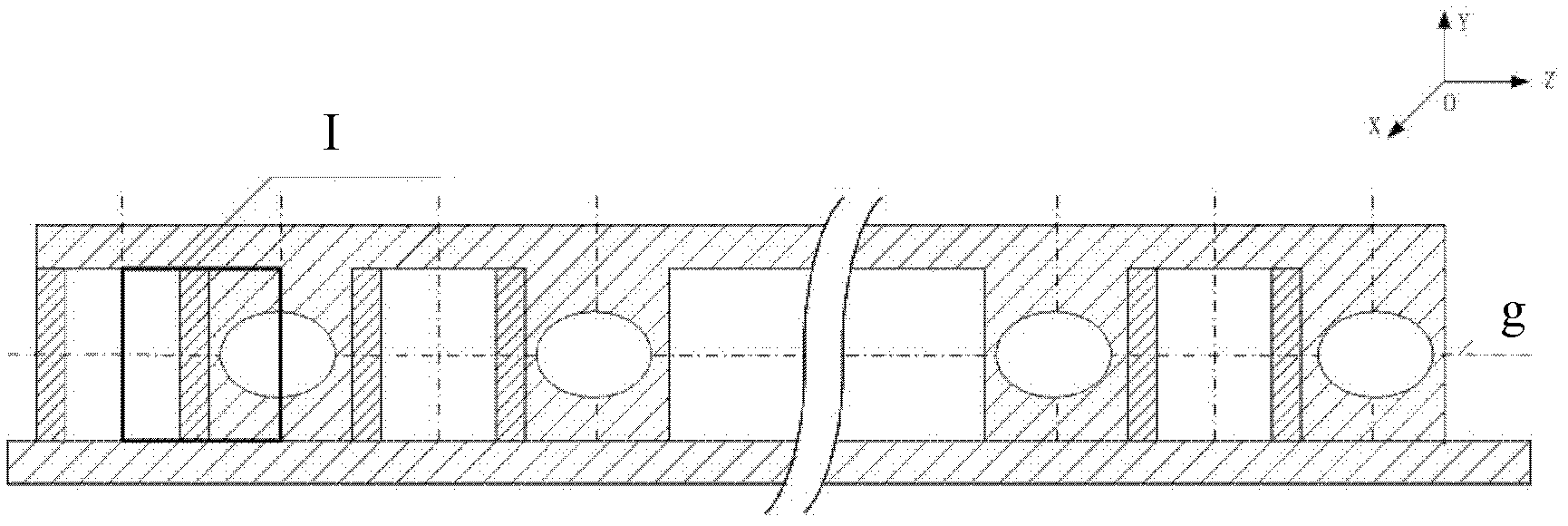

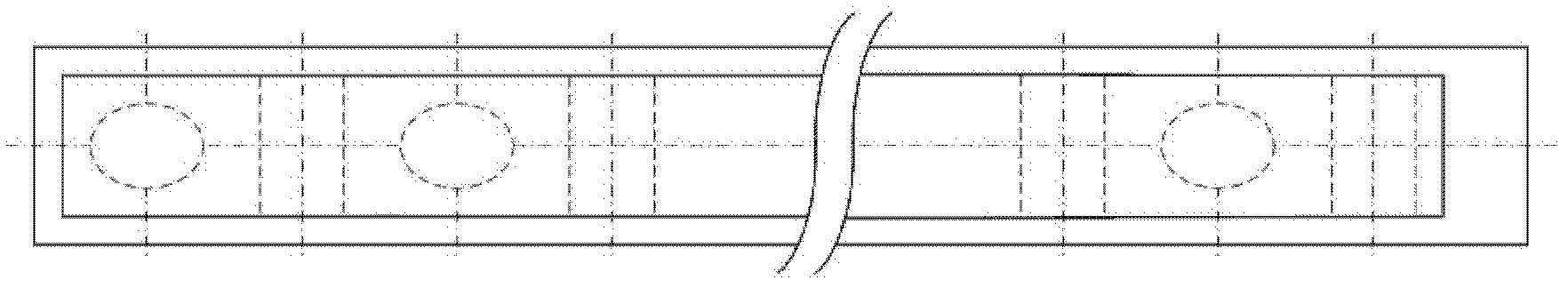

[0050] refer to Figure 1a ~ Figure 2b , a method for manufacturing a metal material parabolic two-dimensional focusing X-ray combined refracting lens, the specific steps are as follows:

[0051] (1) The manufacturing steps of the mother mirror of the metal material parabolic two-dimensional focusing X-ray combined refracting lens:

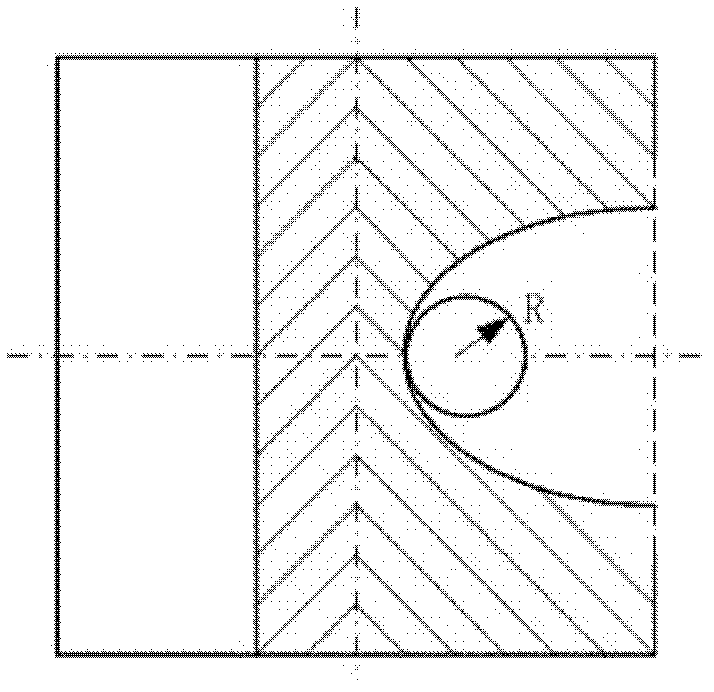

[0052] (A) Make the photolithography mask plate of the mother mirror of glass base metal chromium material with electron beam etching technology, the photolithography mask plate of described mother mirror is arranged as two symmetrical parabolas by the cross-section of a plurality of sequential intervals coaxially Formed first parabolic hole and square hole, the equation of two symmetrical parabolas in the first parabolic hole is expressed as x 2 =2Rz, where R is the radius of curvature at the apex of the parabola, x and z represent the x-axis and the z-axis of the Cartesian coordinate system in Fig. 1 respectively, and the major axis and the min...

Embodiment 2

[0081] refer to Figure 1a ~ Figure 2b , all production steps are the same as in Example 1, except that the major axis is 242 microns, the minor axis is 222 microns, l is 250 microns, δ is 2 microns, n is 100, t is 100 microns, and the electroformed cathode film is aluminum Material, electroforming metal material is nickel.

Embodiment 3

[0083] refer to Figure 1a ~ Figure 2b , all production steps are the same as in Example 1, except that the major axis is 200 microns, the minor axis is 180 microns, l is 210 microns, δ is 1.5 microns, n is 80, t is 80 microns, and the electroformed cathode film is gold Material, the electroforming metal material is iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com